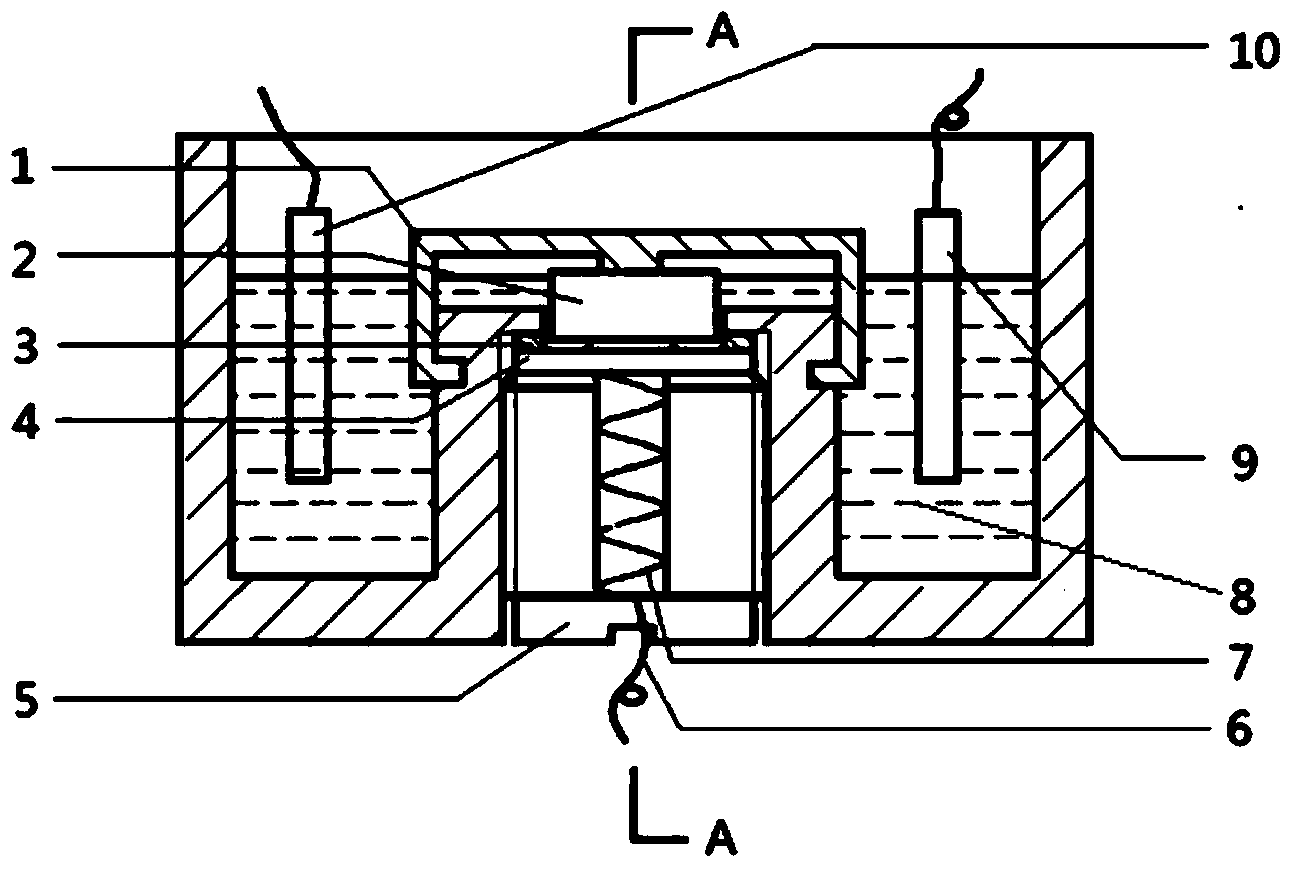

Electrochemical performance testing device for crevice corrosion

A technology of crevice corrosion and test equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve problems such as large differences in corrosion rates, inability to evaluate material crevice corrosion performance, and uncontrollable gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Prepare the required test sample, the size of the sample is required to be larger than the size of the sample through hole 13 in the middle of the solution tank, and smaller than the nominal diameter of the thread of the PVC bolt 5, and the sample is weighed before the experiment. Place the O-ring 3 on the test surface of the sample 4 facing up, and the test surface of the sample 4 faces up, and place the two on the upper end of the threaded through hole 11 in the solution tank, and the threaded through hole 11 is installed at the center of the bottom of the solution tank, Tighten the PVC bolt 5 with the spring 7 in the middle of the threaded through hole 11, and press it on the top of the threaded through hole 11 for sealing to prevent the test solution from leaking out. The wire 6 is connected to the spring 7 and is drawn out from the wire through hole 14 at the top of the PVC bolt. Place a PPET indenter 2 with micron-scale small cylindrical protrusions on the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com