Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "High oxygen storage performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile exhaust purifying catalyst and preparation method thereof

ActiveCN101601999AGood low temperature ignition activityGood aging resistanceDispersed particle separationCatalyst activation/preparationLayered structureChemistry

The invention provides an automobile exhaust purifying catalyst and a preparation method thereof. Honeycomb ceramics are used as a carrier, activated aluminum oxide and an oxygen storage material are used as a coating, noble metals of palladium and rhodium are used as activated components of the catalyst; the coating is of a double-layered structure, wherein a first-layer load is loaded on the carrier, and contains the activated aluminum oxide and the oxygen storage material; a second-layer load is loaded on the first coating and contains the activated aluminum oxide along with or without the oxygen storage material; the activated components of the noble metals of palladium and rhodium are respectively loaded on different materials; a metal and / or oxide load of rhodium is loaded on the first-layer oxygen storage material, and a metal and / or oxide load of palladium is loaded on the second-layer activated aluminum oxide. The automobile exhaust purifying catalyst has the advantages of good low-temperature combustion activity and good anti-aging performance and can satisfy the requirement for low emission.

Owner:常熟华虞环境科技有限公司

Hydrogen-storing material with low-cerium and production thereof

ActiveCN1817447AHigh oxygen storage performanceIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsHydrogenCerium

An O2-bearing low-Ce RE material with high performance and multiple purposes is a composite oxide consisting of cerium oxide, zirconium oxide and assistant chosen from lanthanum oxide, strontium oxide and yttrium oxide. It is prepared through codeposition and calcining at 500-600 deg.C. It can be used as the carrier and assistant of the catalyst for cleaning the tail gas of car.

Owner:SINOCAT ENVIRONMENTAL TECH

Pd/Ce0.8Zr0.2O2/cordierite honeycomb ceramic monolithic catalyst, preparation method and application thereof

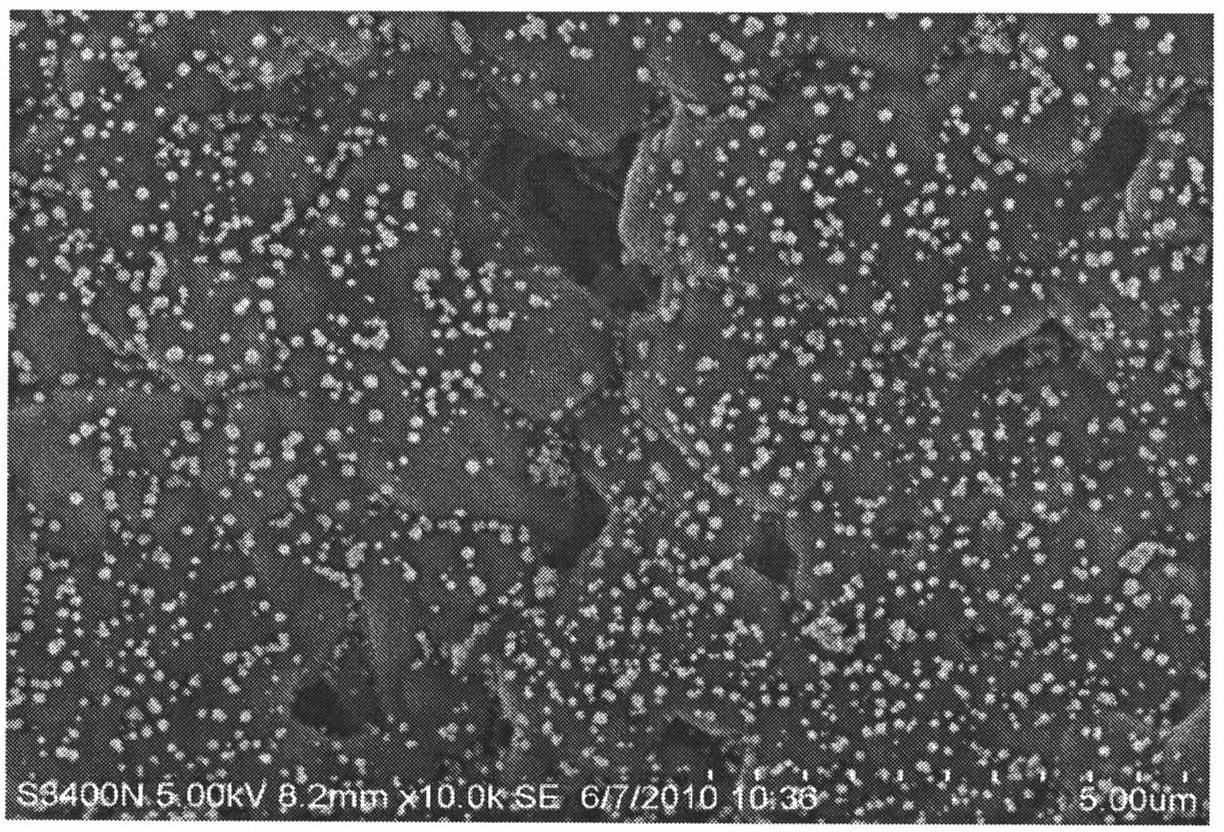

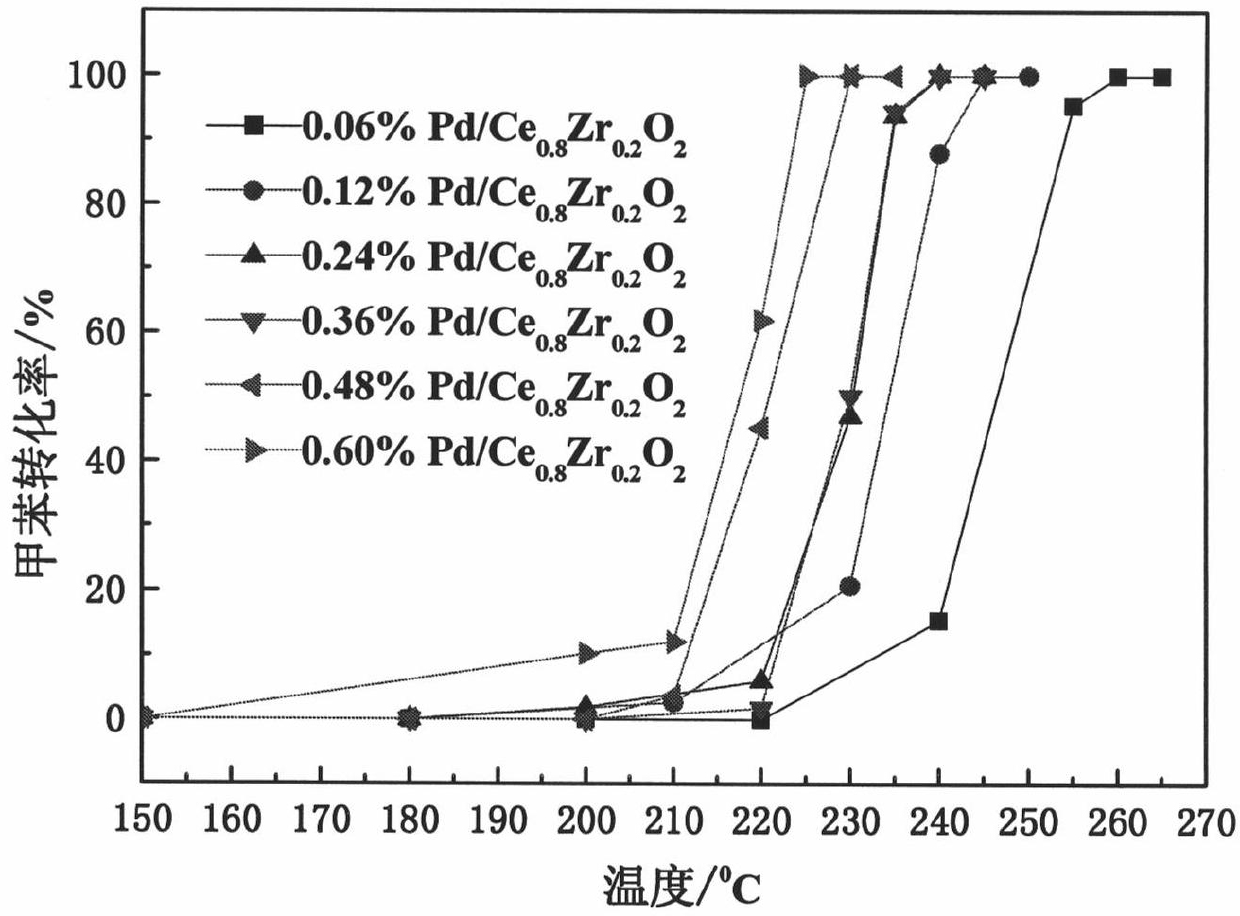

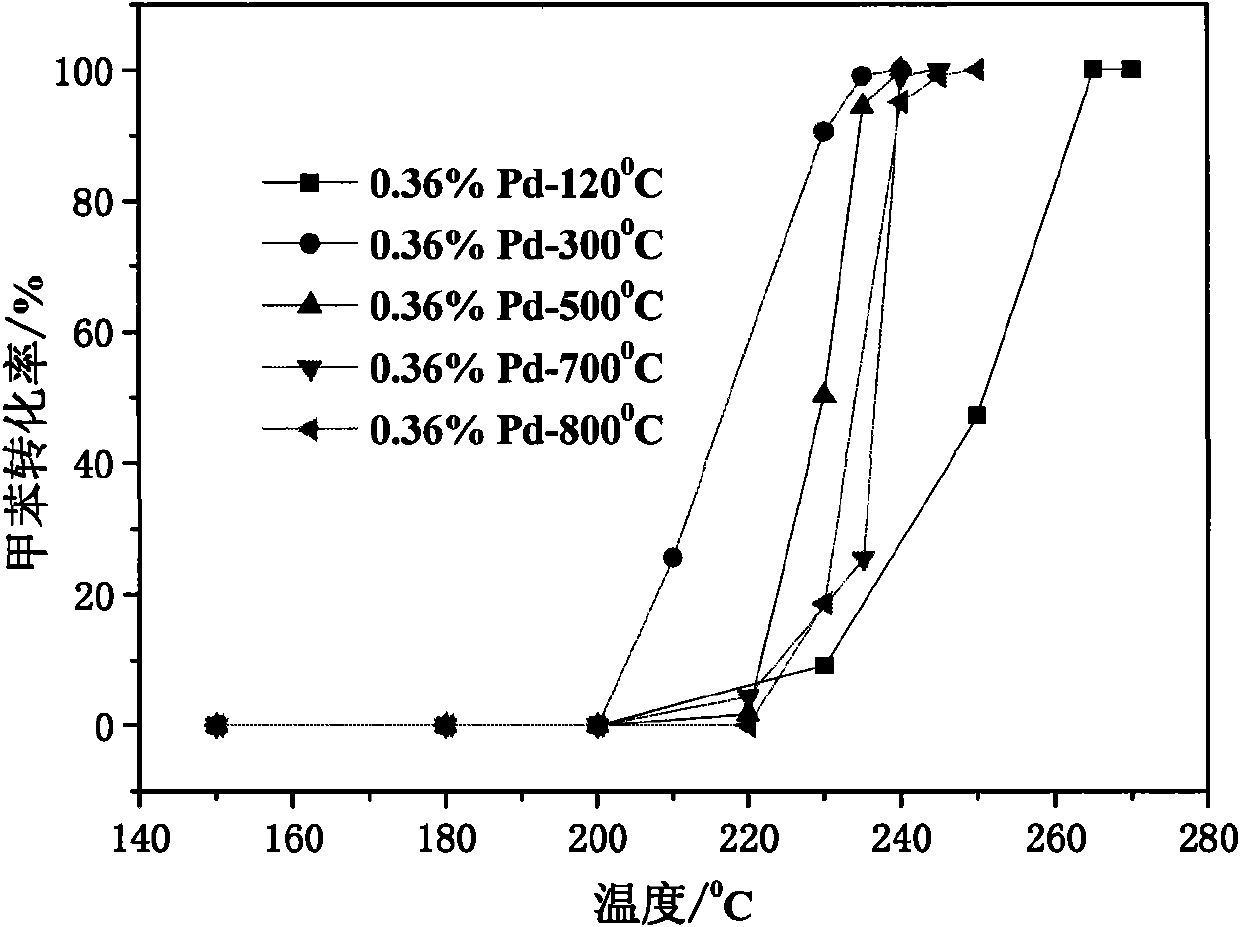

InactiveCN102000570AHigh catalytic activityImprove high temperature resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSodium phosphates

The invention discloses a Pd / Ce0.8Zr0.2O2 / cordierite honeycomb ceramic monolithic catalyst, a preparation method and application thereof. The catalyst is prepared by taking cordierite honeycomb ceramic which is eroded by hydrochloric acid as a first carrier, a cerium-zirconium composite oxide as a second carrier, and a precious metal, namely palladium (Pd) as an active ingredient; preparing a cerium-zirconium composite coating on the cordierite carrier by an immersion method; immersing the carrier into plating solution; and directly reducing palladium onto the cordierite honeycomb ceramic coated with the cerium-zirconium composite coating by the redox reaction of palladium chloride and sodium hypophosphite and the self-catalysis of the palladium. The preparation method improves the oxygen storage performance of the catalyst, improves high-temperature resistance, and realizes uniform load of nano-palladium particles on the carriers without embedding active sites; moreover, the using amount of the palladium is small, the utilization rate of the palladium is improved, the process is simple, the preparation period is short, and the production cost is low. The monolithic catalyst prepared by the method has high activity and high stability; and the methylbenzene can be oxidized into harmless carbon dioxide (CO2) and water (H2O) in the presence of the catalyst at the temperature of 220 to 300 DEG C.

Owner:GUANGDONG UNIV OF TECH

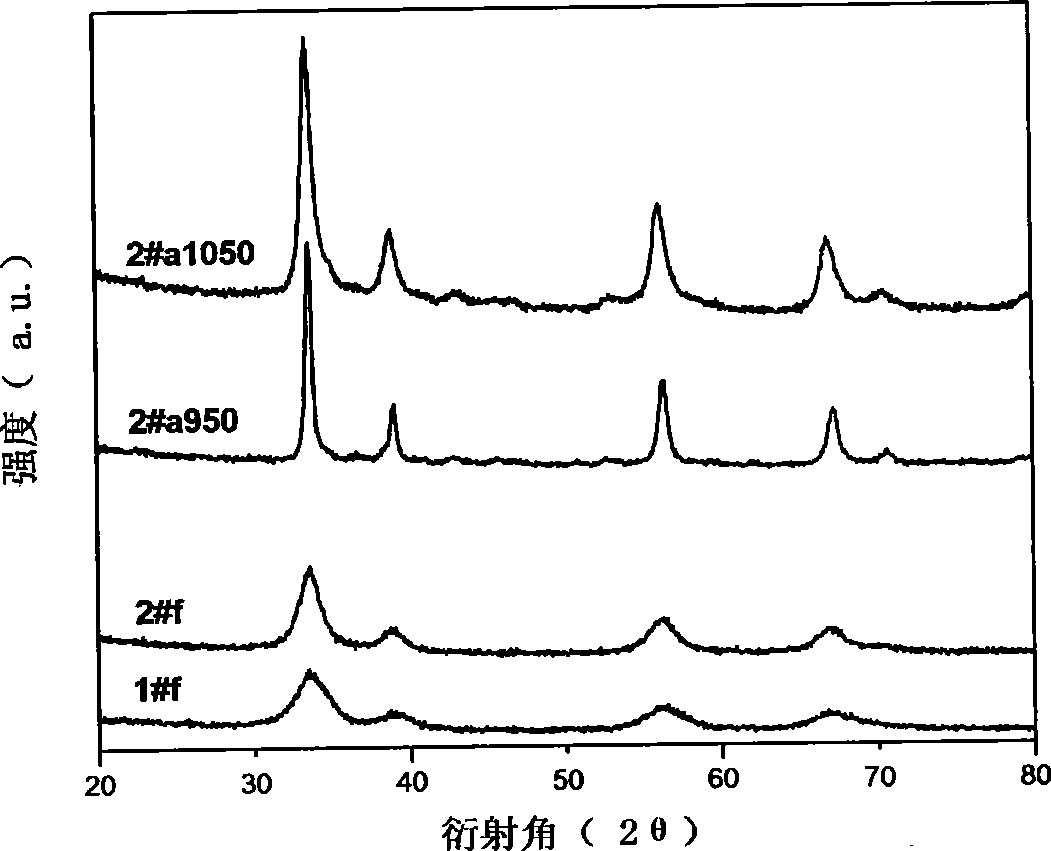

Ceria-zirconia base composite oxide, method for producing the same, and catalyst for purification of exhaust gas using the ceria-zirconia base composite oxide

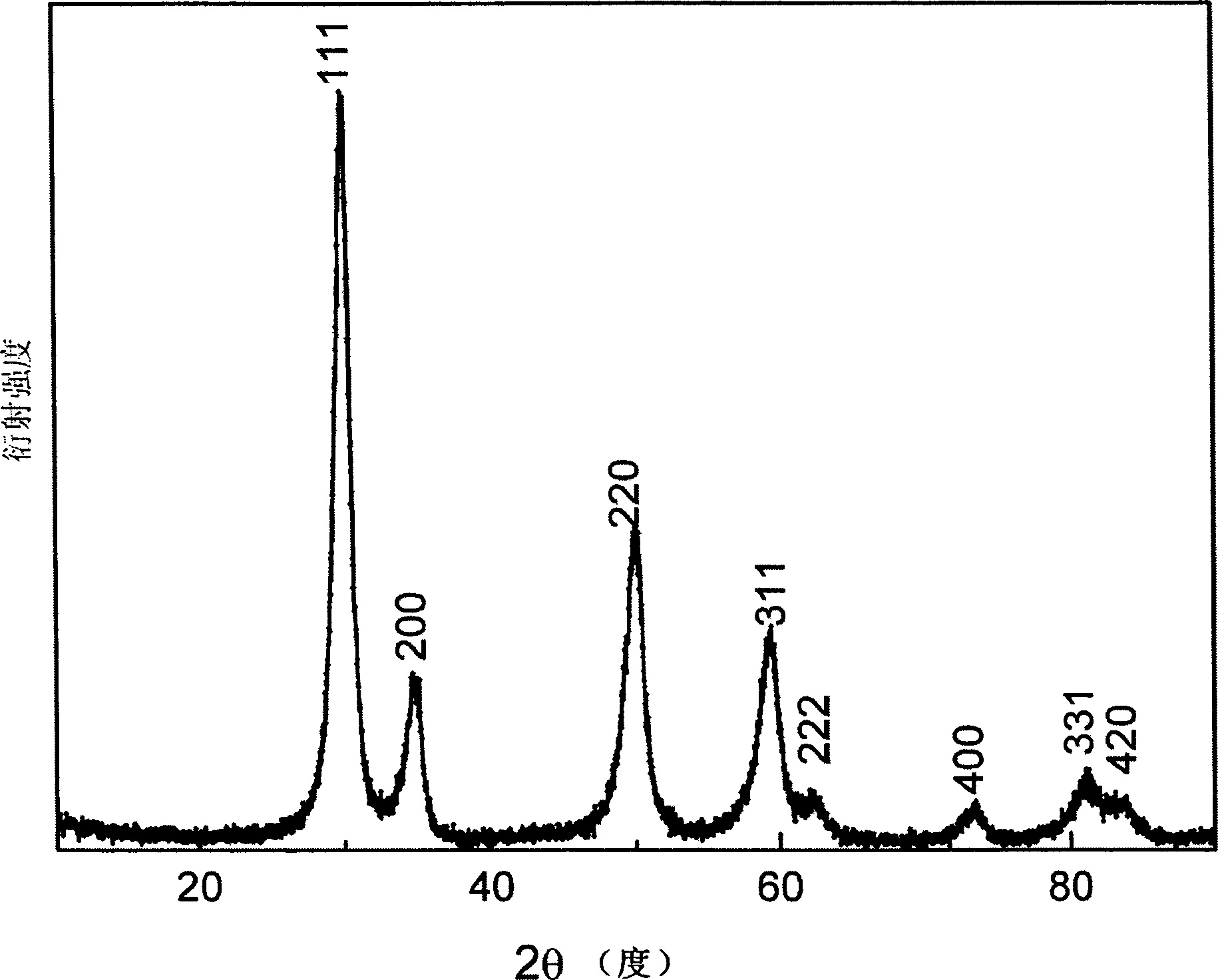

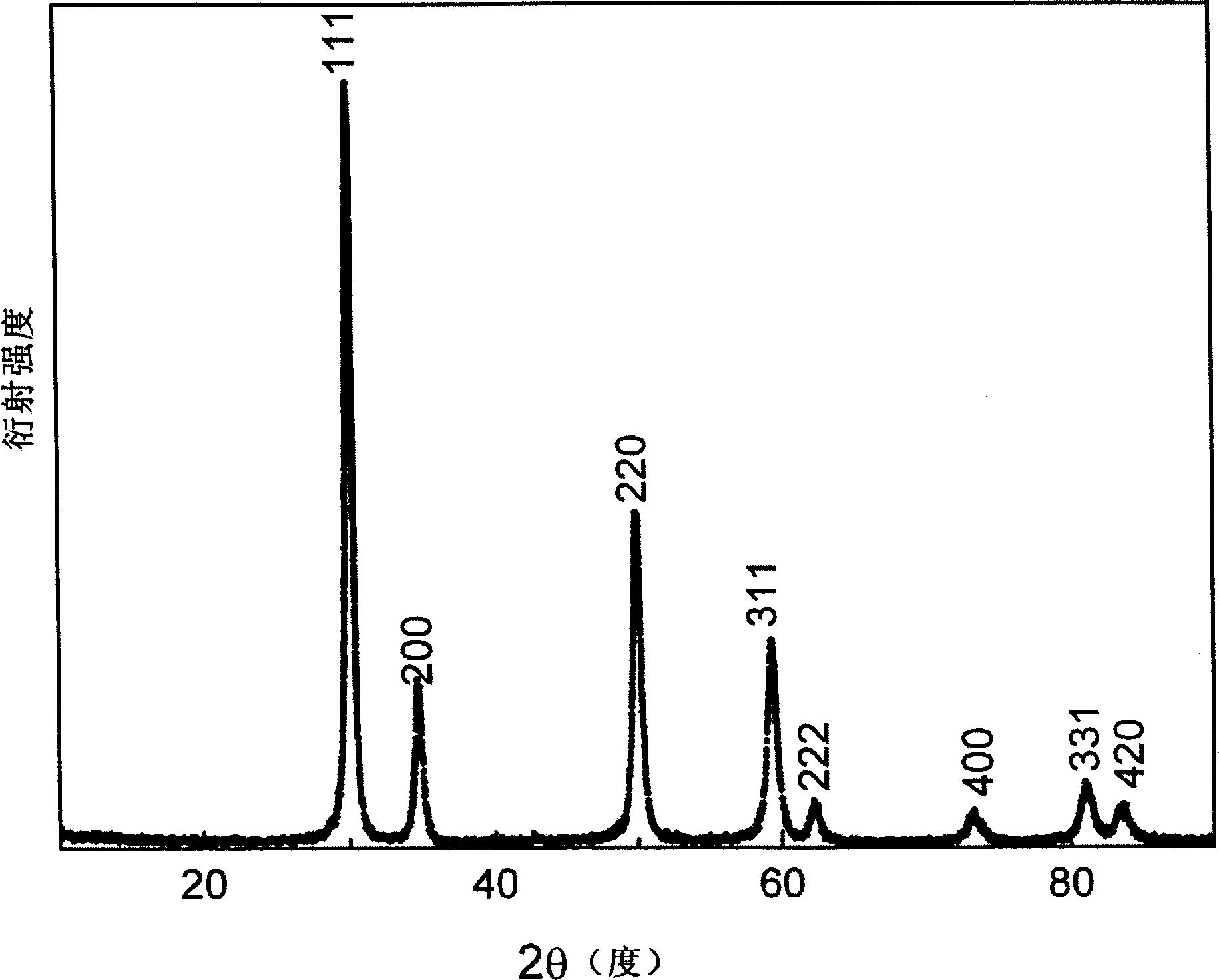

ActiveUS20130029840A1High oxygen storage performanceImprove heat resistanceZirconium compoundsMetal/metal-oxides/metal-hydroxide catalystsCerium(IV) oxideX-ray

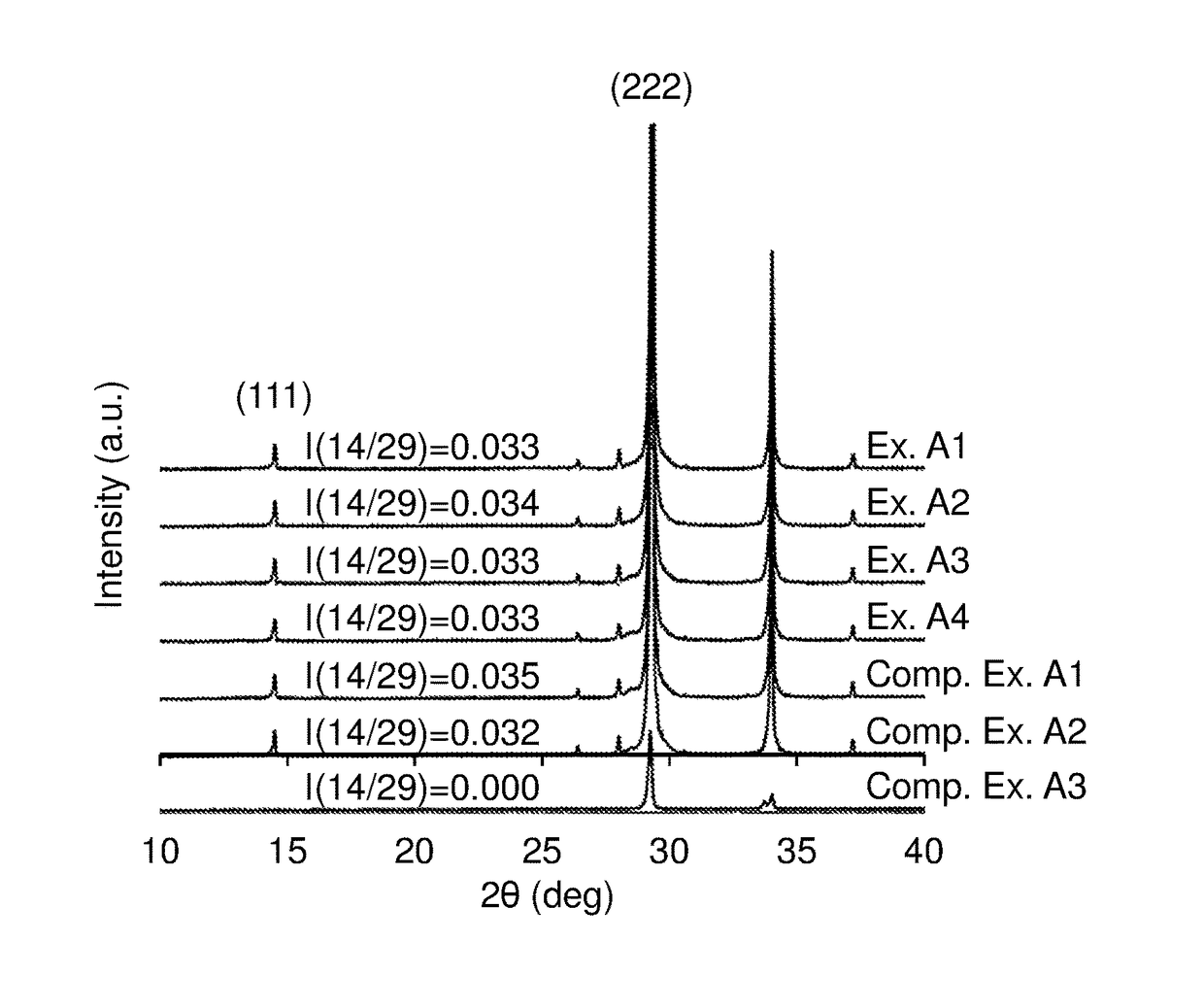

A ceria-zirconia base composite oxide contains a composite oxide of ceria and zirconia. In the ceria-zirconia base composite oxide, a content ratio between cerium and zirconium in the composite oxide is in a range from 43:57 to 48:52 in terms of molar ratio ([cerium]: [zirconium]). An intensity ratio of a diffraction line at 2θ=14.5° to a diffraction line at 2θ=29° {I(14 / 29) value} and an intensity ratio of a diffraction line at 2θ=28.5° to the diffraction line at 2θ=29° {I(28 / 29) value}, which are calculated from an X-ray diffraction pattern obtained by an X-ray diffraction measurement using CuKa after heating under a temperature condition of 1100° C. in air for 5 hours, respectively satisfy the following conditions:I(14 / 29)value≧0.015, and I(28 / 29)value≦0.08.

Owner:CATALER CORP +2

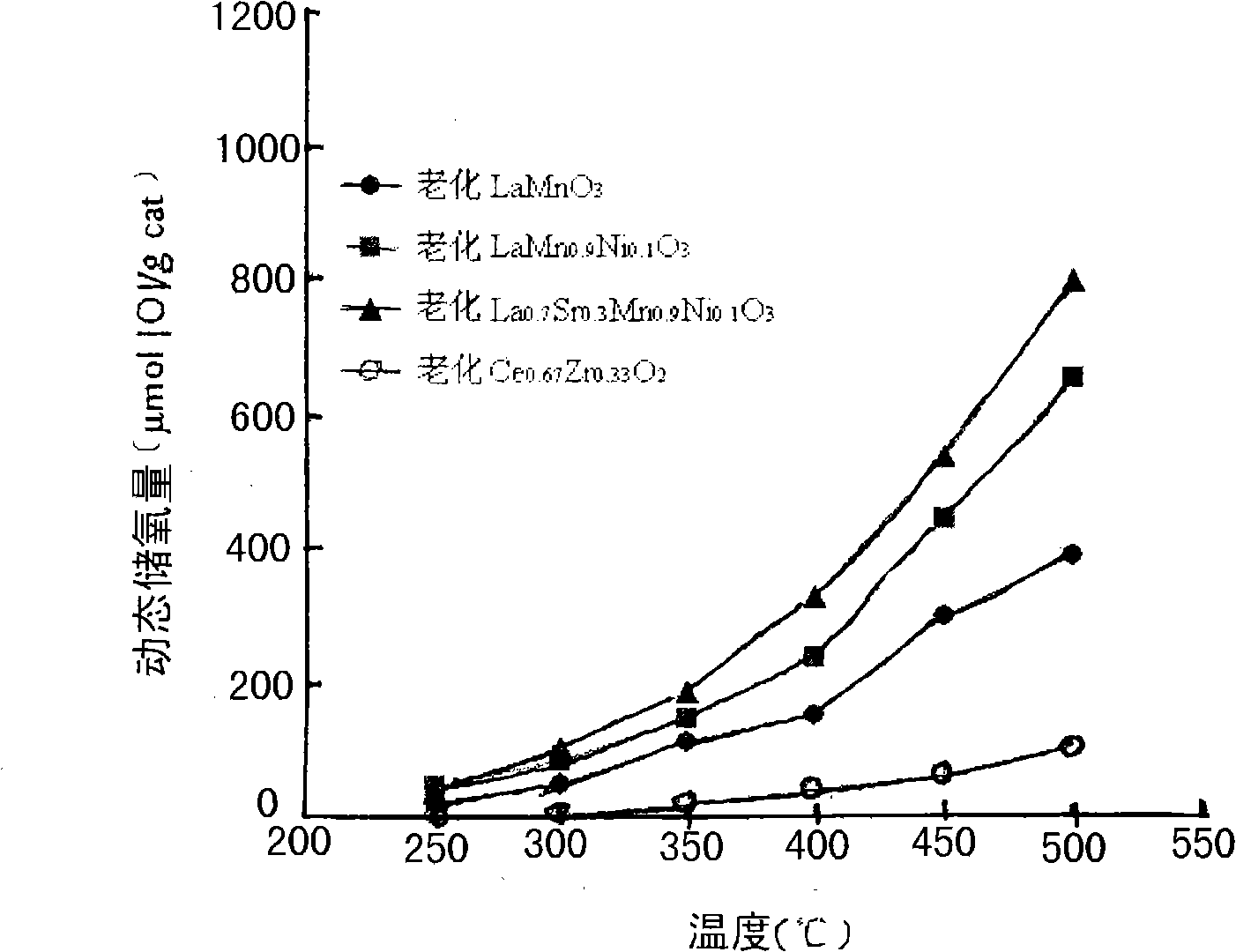

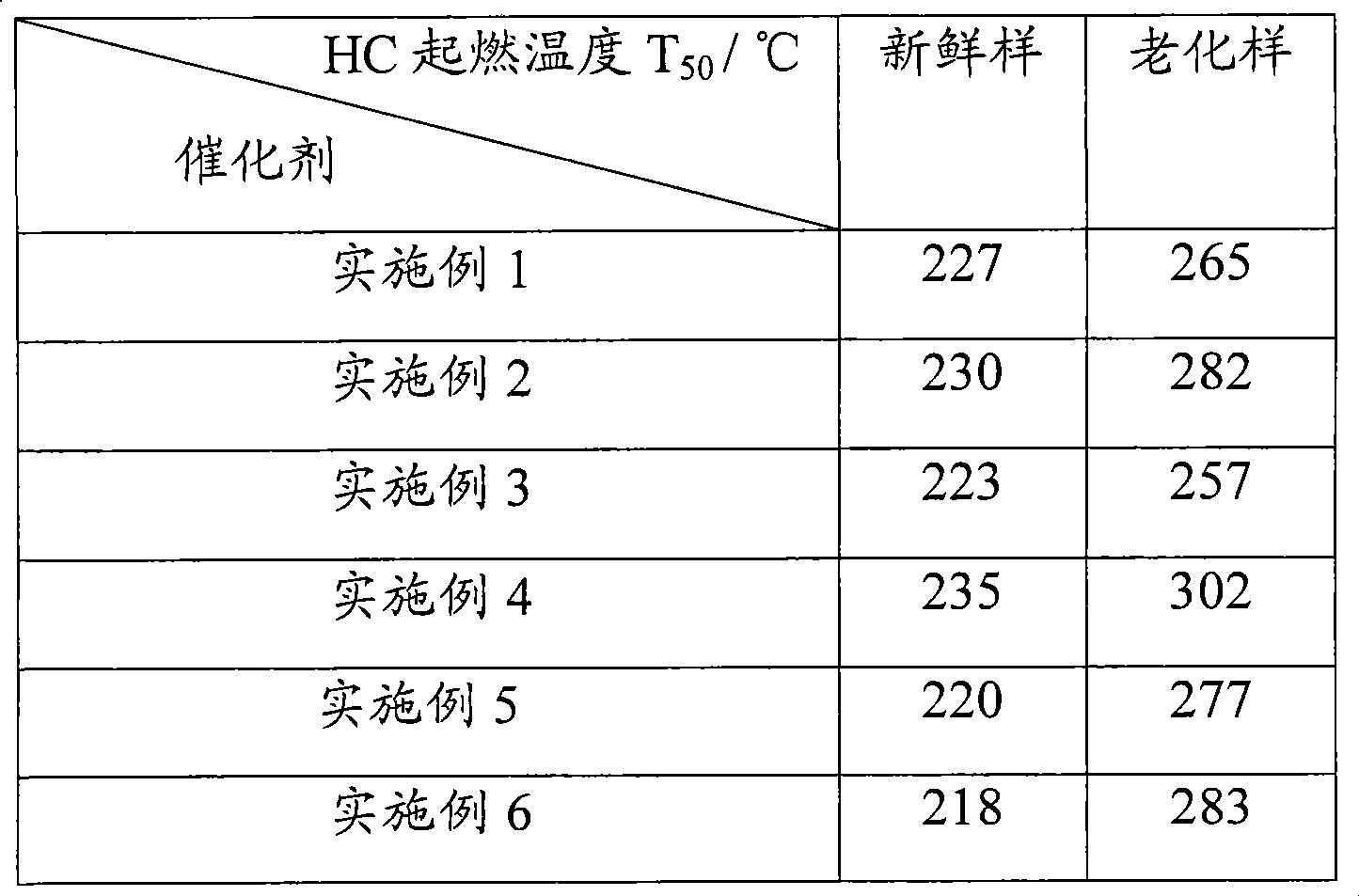

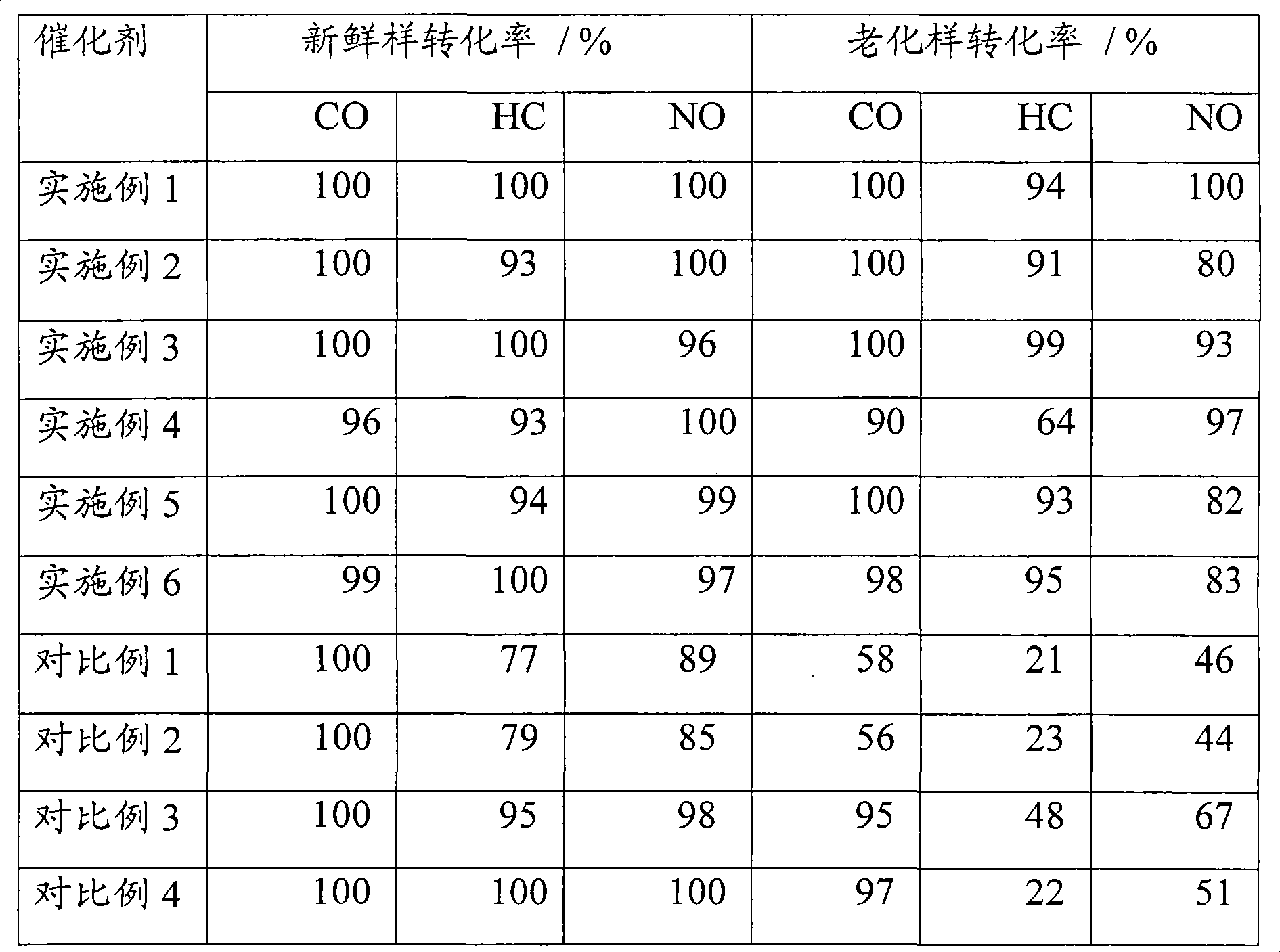

Rare earth perovskite type oxygen storage material for purifying vehicle tail gas

ActiveCN101274215AExcellent medium and low temperature oxygen storage performance and high temperature thermal stabilityGood oxygen storage performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsExhaust gasChemistry

The invention discloses a rare earth perovskite typed oxygen storage material used for the purification of automobile tail gas, belonging to the field of automobile tail gas catalyst technique. The general formula of the oxygen storage material is La1-xAxMn1-yByO3; wherein, A is one of Sr, Y, Ce, Pr or Nd; B is one of Ni, Fe, Cu or Co; x and y are mol values. The oxygen storage material provided by the invention has outstanding middle and low temperature oxygen storage performance and high temperature heat stability, can keep excellent oxygen storage performance after high temperature aging, has the testing performance which is far higher than that of ceria-zirconia oxygen storage material which is widely applied at present, meets the requirements of current automobile tail gas disposal technique on the low temperature performance and practical service life of the oxygen storage material, can replace the ceria-zirconia oxygen storage material to be applied in purification of automobile tail gas so as to widen the operation window of the purification catalyst of the automobile tail gas, and has strong generalized values. The process adopted by the rare earth perovskite typed oxygen storage material is simple, has good repeatability and is easy to realize the industrialization production.

Owner:TSINGHUA UNIV

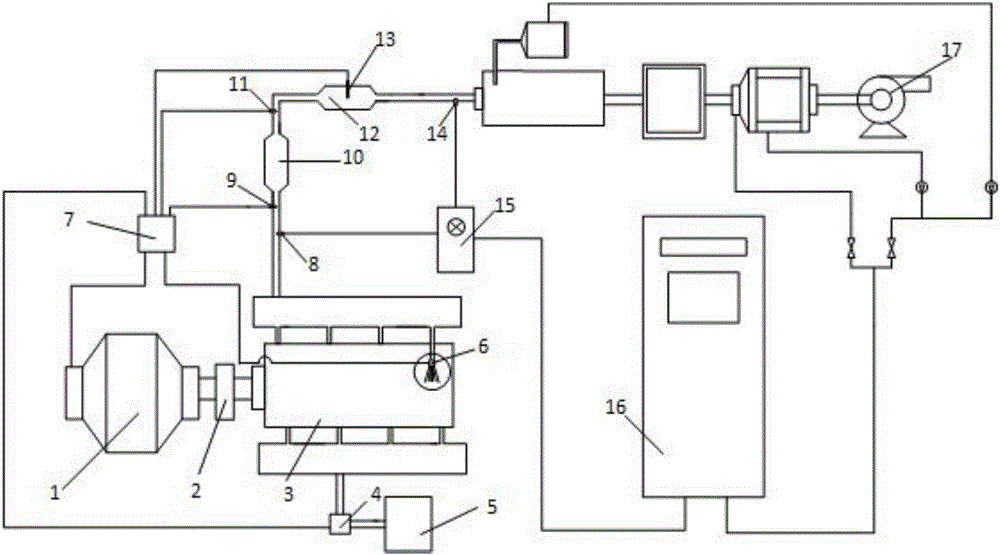

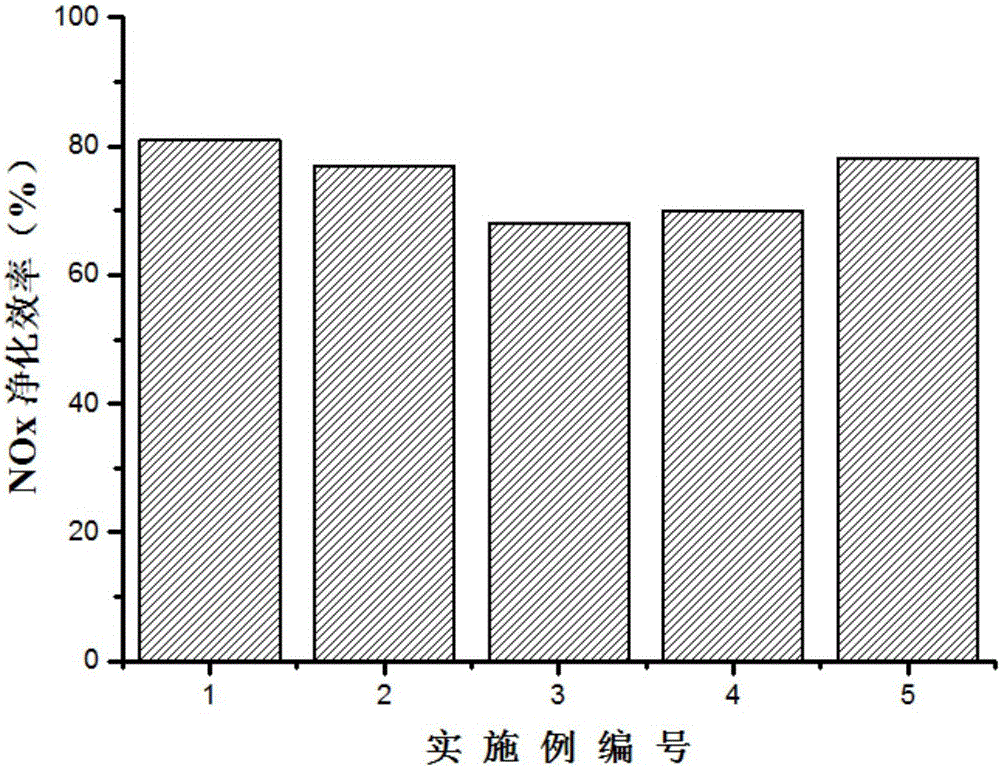

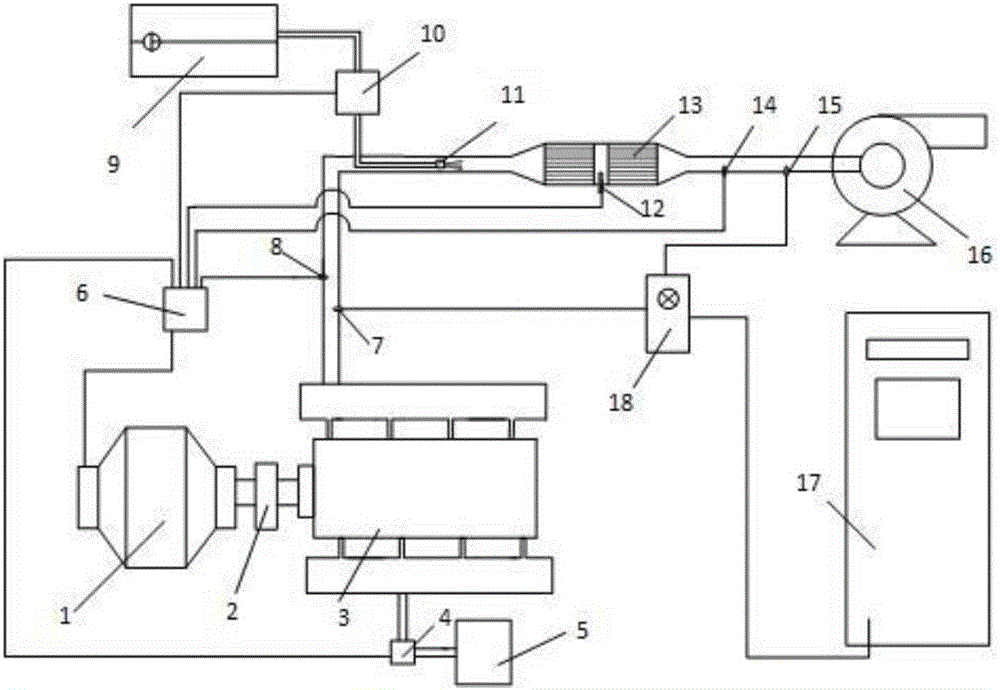

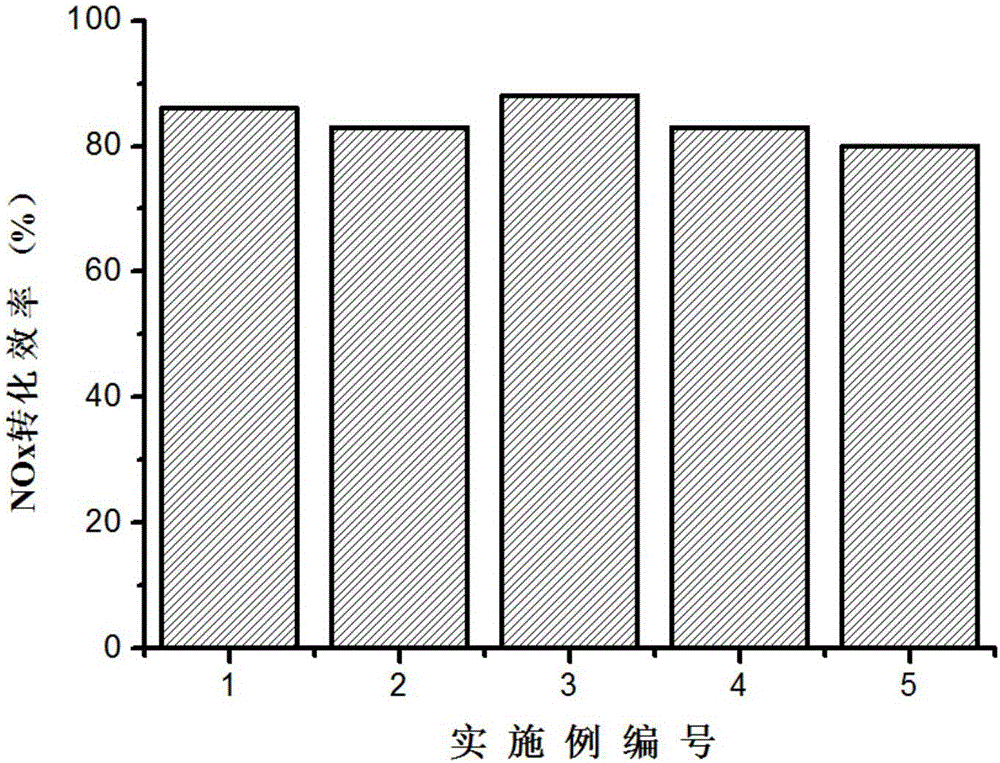

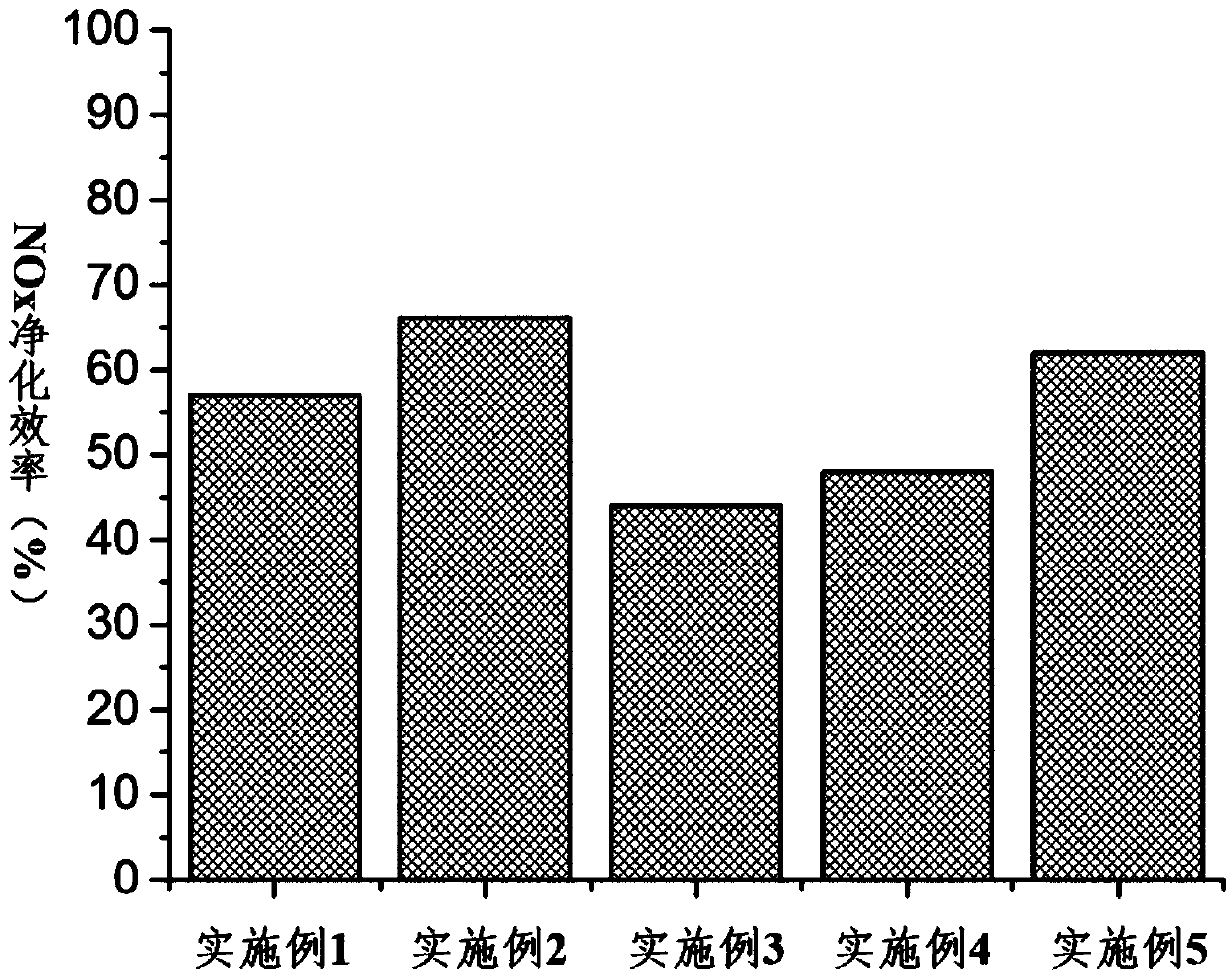

Catalyst based on modified molecular sieve and hydrotalcite derived oxides and applied to diesel engine, preparation and application

ActiveCN106582794ASimple manufacturing processHigh oxygen storage performanceNitrous oxide captureGas treatmentHeat stabilityCordierite

The invention discloses a catalyst based on a modified molecular sieve and hydrotalcite derived oxides and applied to a diesel engine. The catalyst adopts the Co modified ZSM-5 molecular sieve as a main catalyst, a CeO2-ZrO2 solid solution as a cocatalyst, adopts multi-metal modified hydrotalcite derived composite oxides and gamma-Al2O3 as coating base materials and adopts cordierite honeycomb ceramic as a catalyst support. A preparation technology comprises steps as follows: determination of the use quantity of the raw materials of the catalyst; preparation of the Co modified ZSM-5 molecular sieve and the multi-metal modified hydrotalcite derived composite oxides; preparation and coating of coating slurry. The catalyst can efficiently catalyze adsorption-reductive purification reaction of NOx in exhaust gas. By means of the synergistic effect of four metallic oxides, NOx adsorption performance and heat stability of the hydrotalcite derived oxides are improved. Meanwhile, a precious metal main catalyst is replaced with the Co modified ZSM-5 molecular sieve, so that the cost of the raw materials is reduced, and sulfur resistance and heat stability of the catalyst are improved.

Owner:TIANJIN UNIV

Preparation of homogeneous mischcrystal cerium-zirconium-aluminum coating material by coprecipitation method and technique thereof

InactiveCN101433831AImprove high temperature resistanceReduce specific surface area lossInternal combustion piston enginesDispersed particle separationCeriumCoating materials

The invention relates to preparation of a uniform solid solution Ce-Zr-Al based coating material by a coprecipitation method and a process method thereof. A mixed solution of soluble salts of Ce and Zr is coprecipitated by an alkaline solution, a soluble salt solution of Al is separately precipitated by the alkaline solution, the interaction degree of Ce-Zr and Al is regulated and controlled by controlling the aging time, and suspensions are evenly mixed after the aging and then are dried and baked. The method can obtain a Ce-Zr-Al three-phase solid solution with a uniform cubic phase structure. The method has a simple production technology and lower production energy consumption, and greatly improves performances of the Ce-Zr-Al based coating material such as specific surface area, thermal stability, oxygen storage performance and so on. The method ensures that a catalyst containing the Ce-Zr-Al based coating material becomes an excellent and high-performance three-effect catalyst for the purification of automobile tail gas.

Owner:TIANJIN UNIV

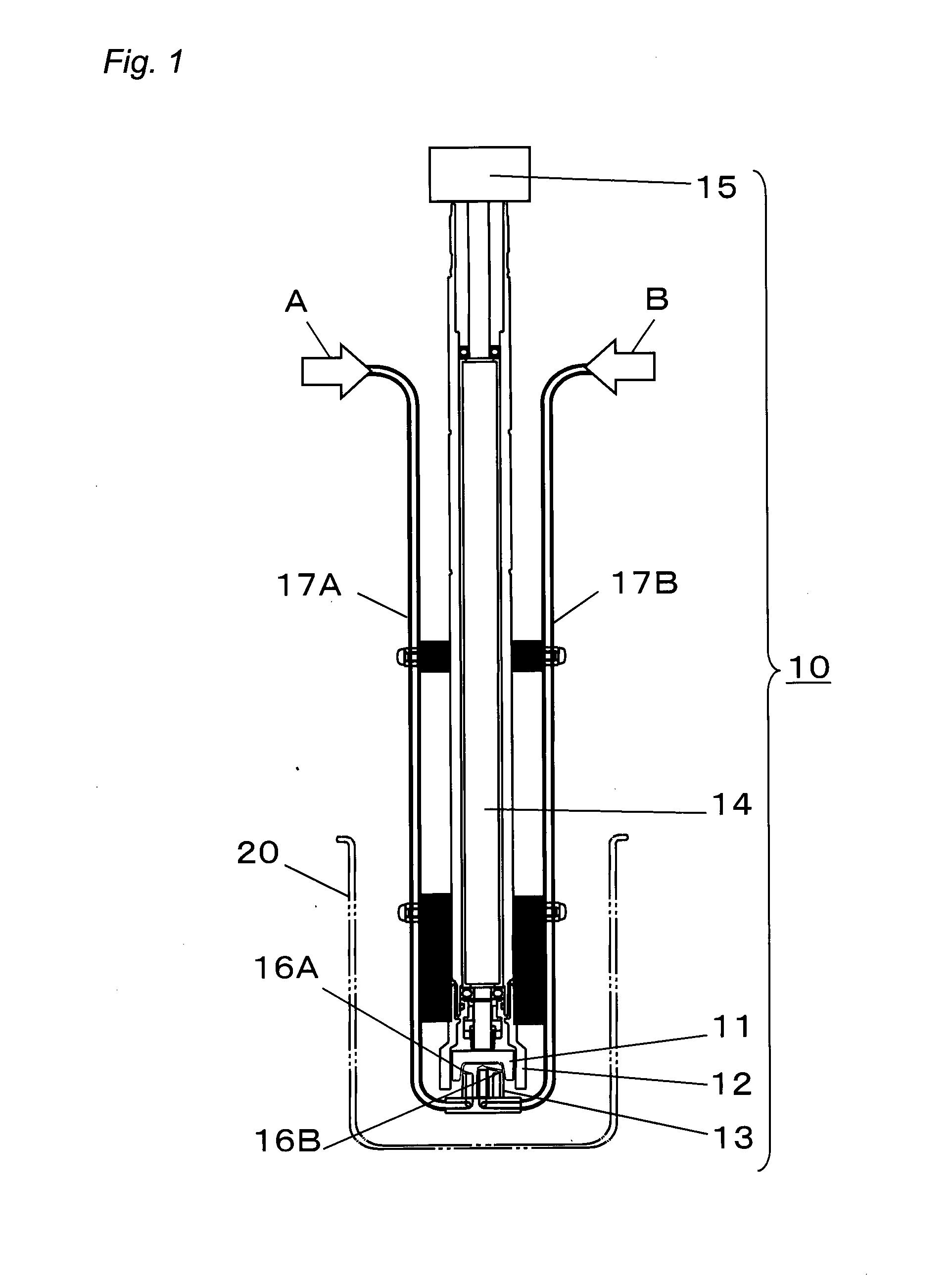

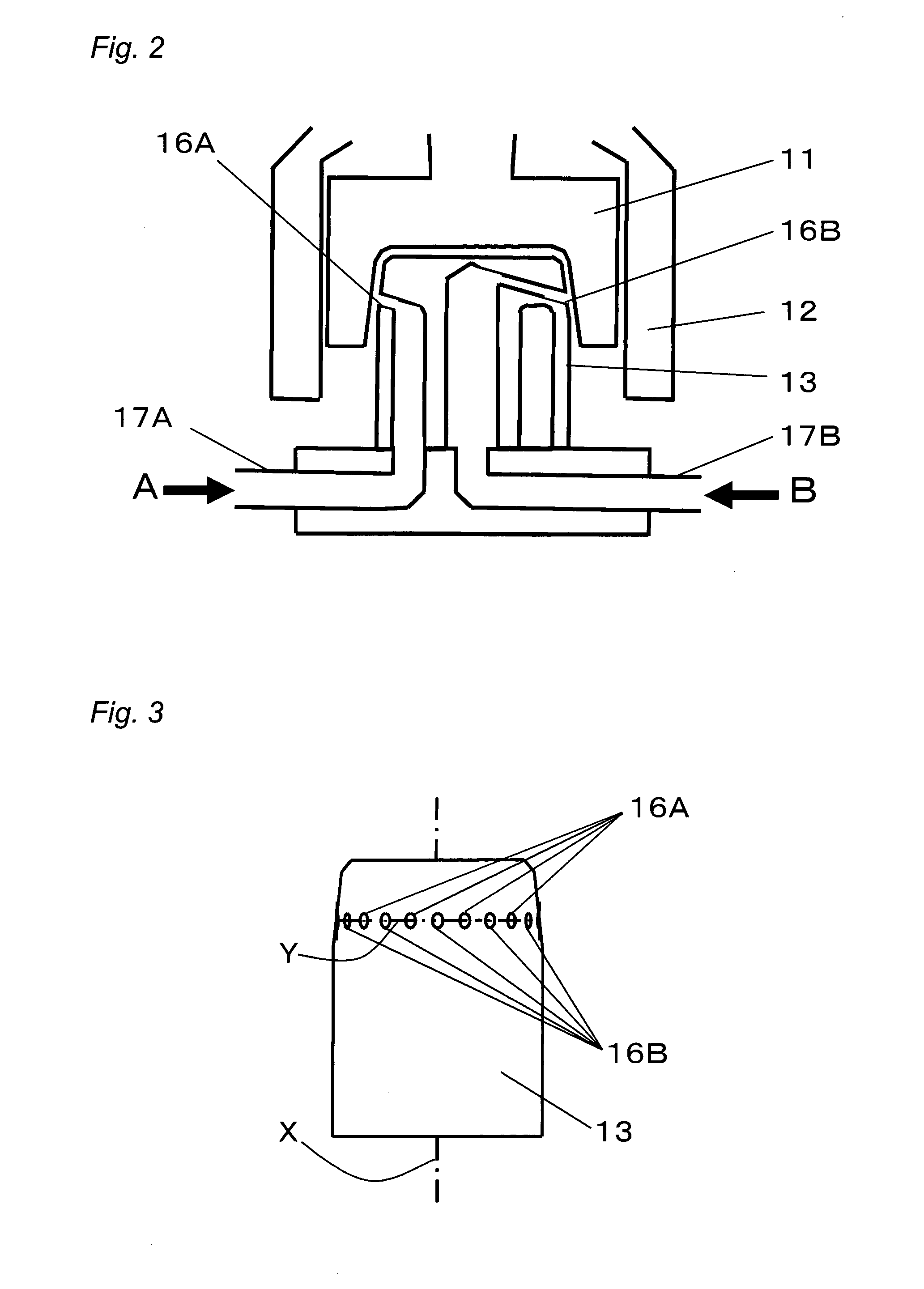

Catalyst support for purification of exhaust gas, catalyst for purification of exhaust gas using same, and method for producing catalyst support for purification of exhaust gas

ActiveCN104602809AHigh oxygen storage performanceHigh catalytic activityInternal combustion piston enginesHeterogenous catalyst chemical elementsCerium(IV) oxideCalcination

A catalyst support for purification of exhaust gas comprises a porous composite metal oxide, the porous composite metal oxide containing alumina, ceria, and zirconia and having an alumina content ratio of from 5 to 80% by mass, wherein after calcination in the air at 1100 DEG C for 5 hours, the porous composite metal oxide satisfies a condition such that standard deviations of content ratios (as at% unit) of aluminum, cerium and zirconium elements are each 19 or less with respect to 100 minute areas (with one minute area being 300 nm in length x 330 nm in width) of the porous composite metal oxide, the standard deviation being determined by energy dispersive X-ray spectroscopy using a scanning transmission electron microscope equipped with a spherical aberration corrector.

Owner:TOYOTA JIDOSHA KK

Catalyst for purification of waste incineration flue gas and preparation method of catalyst

ActiveCN109126773AHigh catalytic activityImprove adsorption capacityGas treatmentDispersed particle separationCarbon nanotubePlatinum oxide

The invention discloses a catalyst for purification of waste incineration flue gas. The catalyst takes vanadium oxide, platinum oxide and tungsten oxide as active components, gamma-alumina, titanium oxide and carbon nanotubes as carriers and one or more of manganese oxide, iron oxide, copper oxide, tin oxide and cerium oxide as active aids. The catalyst has the functions of decomposing dioxin andchlorobenzene compounds and functions of denitration and sulfur resistance and still has excellent removal capacity for dioxin and NOx at lower temperature. The invention also discloses a preparationmethod of the catalyst for purification of waste incineration flue gas. The preparation method has the advantages of being simple to operate, convenient, controllable and suitable for mass industrialproduction.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

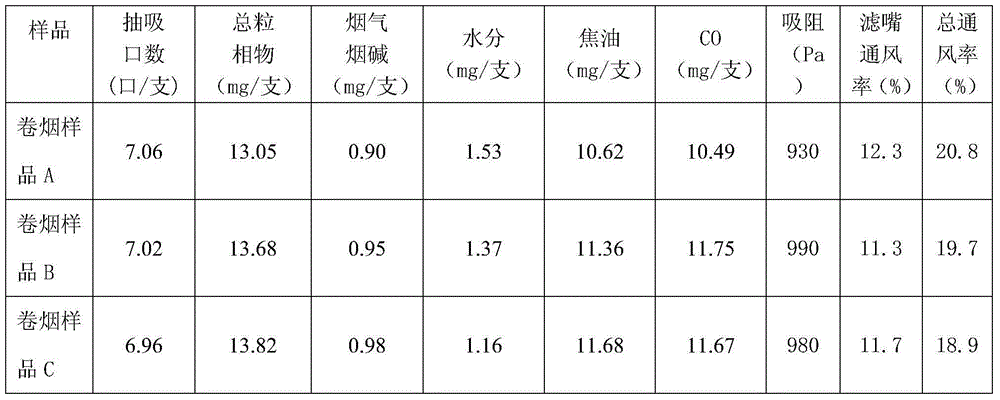

Functional low-gram-weight cigarette paper and preparation method thereof

ActiveCN104790264AGood technical effectImprove sensory qualityFlexible coversCoatings with pigmentsFiberAdditive ingredient

The invention relates to functional low-gram-weight cigarette paper, wherein the body phase thereof contains cut tobacco fibres or a first tobacco powder, a second tobacco powder is attached to the outer surface of at least one side of the body phase, and the first tobacco powder is the same as or different from the second tobacco powder. The invention further relates to a preparation method of the functional low-gram-weight cigarette paper. The preparation method comprises the following steps: (1) preparing paper pulp; (2) preparing special suspension stabilizing fluid for cigarette paper coating; and (3) making paper by a paper machine. The functional low-gram-weight cigarette paper disclosed by the invention is uniform in colouring and capable of improving the non-transparency of the cigarette paper; moreover, the functional low-gram-weight cigarette paper is good in stiffness and beneficial to roll; meanwhile, the functional low-gram-weight cigarette paper is good in ash wrapping force and capable of improving the smoking feeling of cigarettes. The functional low-gram-weight cigarette paper disclosed by the invention is also capable of effectively improving the sensory quality of the rolled cigarette produced during a smoking process and reducing harmful ingredients in the smoke of the cigarettes. Therefore, the functional low-gram-weight cigarette paper disclosed by the invention has a wide application prospect.

Owner:CHINA TOBACCO YUNNAN IND

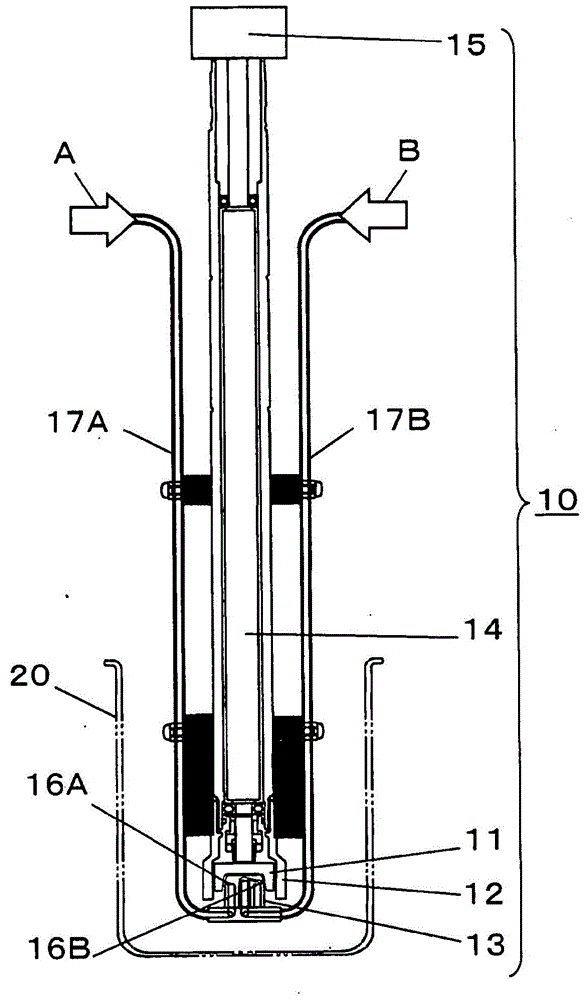

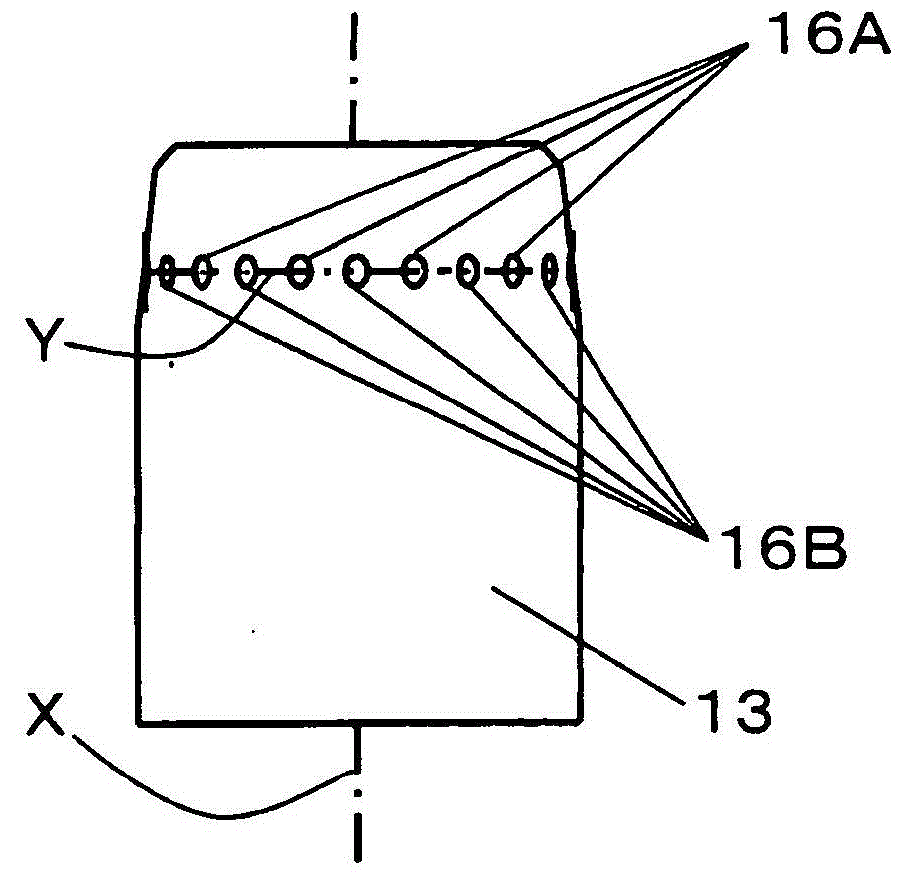

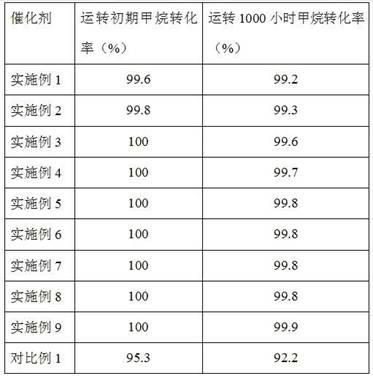

Monolithic catalyst for coal mine low-concentration ventilation air methane (VAM) combustion and preparation method thereof

InactiveCN102500393AHigh activityReduce dosageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsTransformation ratioCoal

The invention provides a monolithic catalyst for coal mine low-concentration ventilation air methane (VAM) combustion and a preparation method thereof. The catalyst is composed of a honeycomb ceramic support with a coating and a noble metal active component Pd on the support, wherein the honeycomb ceramic coating is prepared from the following components in percentage by weight: 20-80% of activated Al2O3 and 20-80% of hexaaluminate; and a H2PdCl4 water solution which is the active Pd component impregnates and is supported on the surface of the honeycomb ceramic support coating, and the active Pd component accounts for 0.3-1 wt% of the catalyst. When the catalyst is filled in a catalytic reflux reactor in a self-made laboratory, the inspection on the catalytic combustion reaction using simulated VAM containing 1% of methane indicates that the methane conversion rate is up to more than 99% within the 1000-hour running period.

Owner:HUNAN UNIV OF SCI & TECH

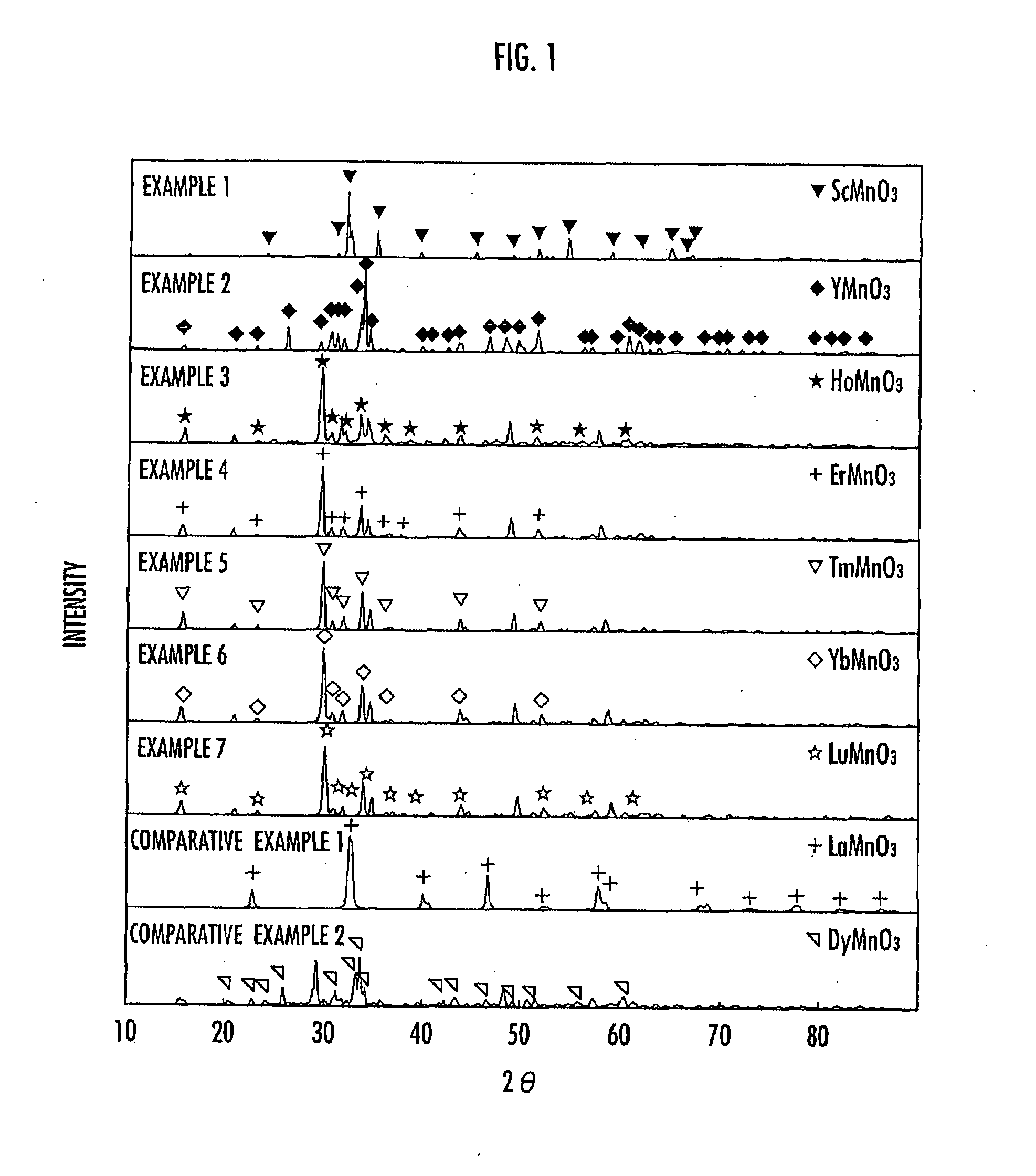

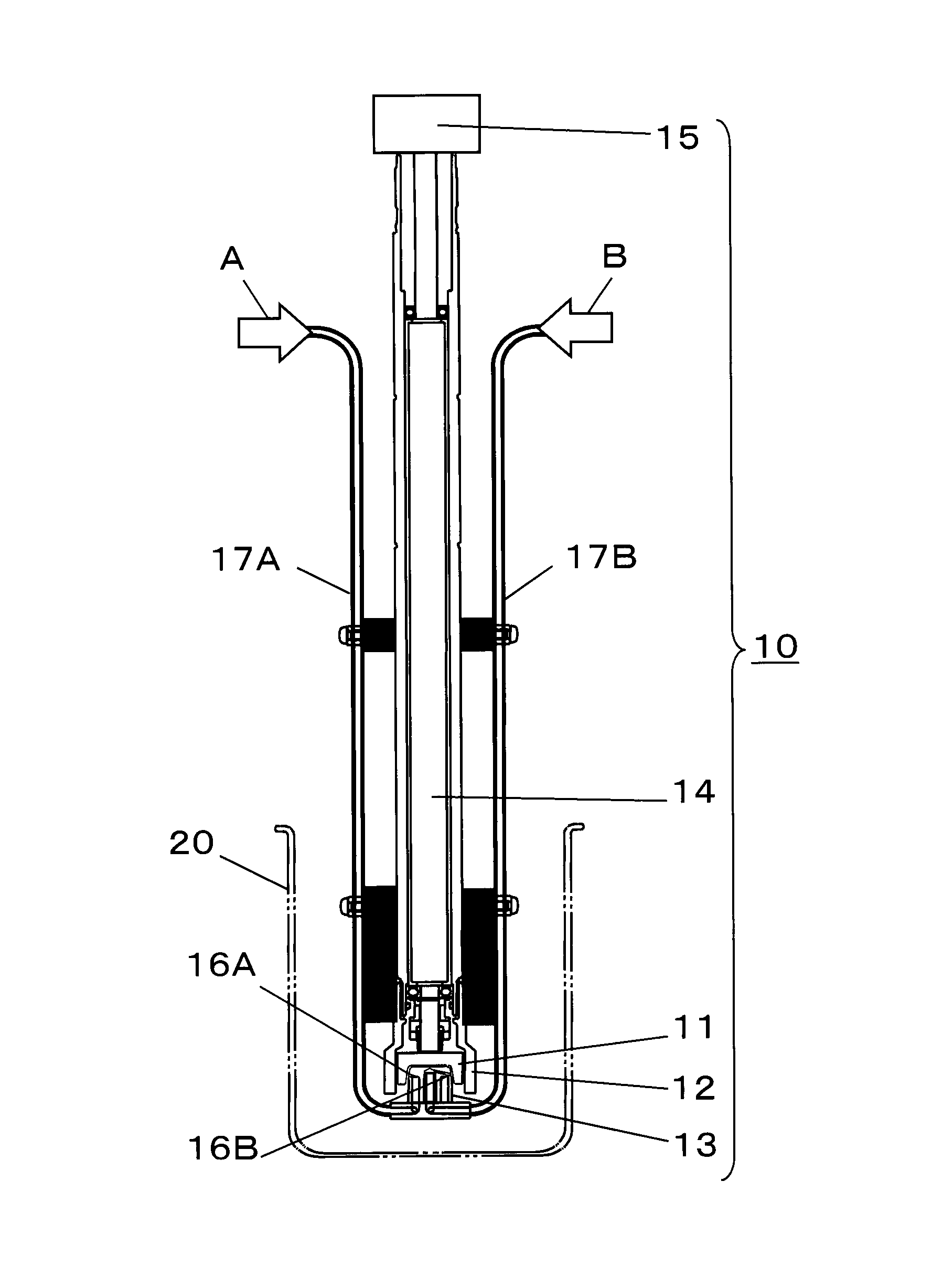

Method of producing oxidation catalyst for cleaning exhaust gas

InactiveUS20090202412A1Excellent in function of oxidizing high boiling point materialHigh oxygen storage performanceInternal combustion piston enginesHeterogenous catalyst chemical elementsParticulatesInternal combustion engine

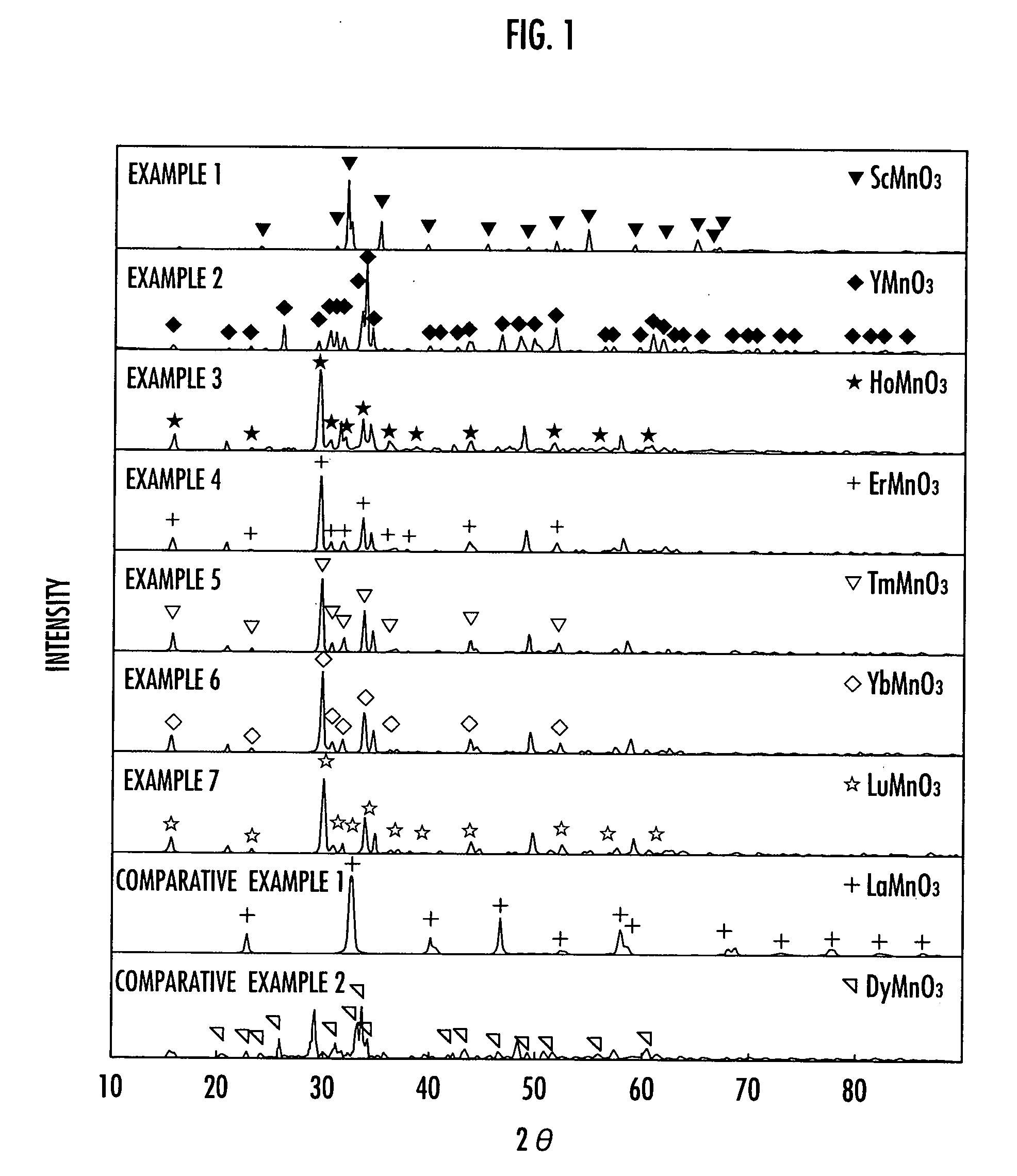

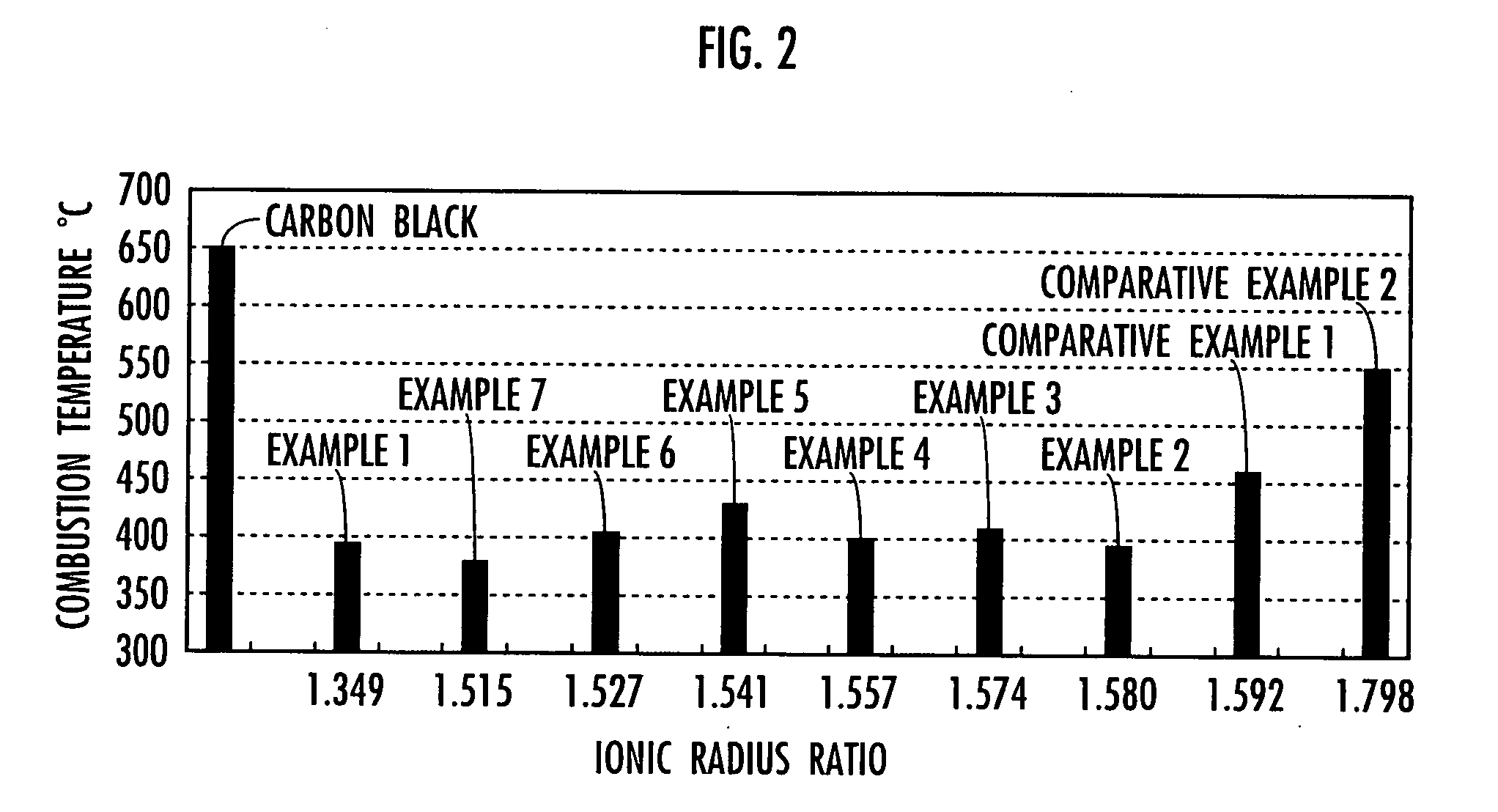

A method of producing an oxidation catalyst for cleaning exhaust gas, excellent in the function of oxidizing high boiling point materials such as particulates and polycyclic aromatic hydrocarbons contained in the exhaust gas of internal-combustion engines is provided. Metal elements A and B are selected so that the value of the ionic radius of metal element A / the ionic radius of metal element B is in the range of from 1.349 to 1.580. After reacting the grind mixed material of the first metal element A, the second metal element B, and urea, the reactant material is grind mixed, and thereafter subjected to firing at 600 to 1200° C. for 1 to 5 hours. By doing so, an oxidation catalyst for cleaning exhaust gas comprising a composite oxide represented by the general formula ABO3 is obtained.

Owner:HONDA MOTOR CO LTD

Ceria-zirconia base composite oxide, method for producing the same, and catalyst for purification of exhaust gas using the ceria-zirconia base composite oxide

ActiveUS9376327B2High oxygen storage performanceImprove heat resistanceMolecular sieve catalystsZirconium compoundsCrystallographyX-ray

A ceria-zirconia base composite oxide contains a composite oxide of ceria and zirconia. In the ceria-zirconia base composite oxide, a content ratio between cerium and zirconium in the composite oxide is in a range from 43:57 to 48:52 in terms of molar ratio ([cerium]:[zirconium]). An intensity ratio of a diffraction line at 2θ=14.5° to a diffraction line at 2θ=29° {I(14 / 29) value} and an intensity ratio of a diffraction line at 2θ=28.5° to the diffraction line at 2θ=29° {I(28 / 29) value}, which are calculated from an X-ray diffraction pattern obtained by an X-ray diffraction measurement using CuKa after heating under a temperature condition of 1100° C. in air for 5 hours, respectively satisfy the following conditions: I(14 / 29) value≧0.015, and I(28 / 29) value≦0.08.

Owner:CATALER CORP +2

Catalyst support for purification of exhaust gas, catalyst for purification of exhaust gas using the same, and method for producing the catalyst support for purification of exhaust gas

ActiveUS9409152B2High oxygen storage performanceHigh catalytic activityInternal combustion piston enginesOther chemical processesCerium(IV) oxideCalcination

A catalyst support for purification of exhaust gas includes a porous composite metal oxide, the porous composite metal oxide containing alumina, ceria, and zirconia and having an alumina content ratio of from 5 to 80% by mass, wherein after calcination in the air at 1100° C. for 5 hours, the porous composite metal oxide satisfies a condition such that standard deviations of content ratios (as at % unit) of aluminum, cerium and zirconium elements are each 19 or less with respect to 100 minute areas (with one minute area being 300 nm in length×330 nm in width) of the porous composite metal oxide, the standard deviation being determined by energy dispersive X-ray spectroscopy using a scanning transmission electron microscope equipped with a spherical aberration corrector.

Owner:TOYOTA CENT RES & DEV LAB INC +1

Automobile tail gas cleaning catalyst and its preparation method

ActiveCN101362091AImprove anti-poisoning performanceLow costDispersed particle separationCatalyst activation/preparationPt elementStorage material

The invention provides a catalyst used for purifying motor vehicle exhaust, and a preparation method thereof. The catalyst comprises a carrier with one coating or a plurality of coatings; each coating contains alumina carrying silver and an oxygen storage material carrying platinum or / and palladium, wherein, the silver is impregnated to be carried on the active alumina by a mixed solution of soluble silver salt and citric acid, and the platinum and the palladium are respectively impregnated to be carried on the oxygen storage material by the salt solutions thereof, wherein, the platinum and the palladium are not carried on the same oxygen storage material. The preparation method comprises the following steps: (1) the active alumina is impregnated by using the mixed solution of the soluble silver salt and the citric acid to prepare the alumina carrying silver; the oxygen storage material carrying the platinum and the oxygen storage material carrying the palladium are prepared; (2) a coating sizing material is prepared; (3) the coating sizing material is coated on the catalyst carrier to prepare the catalyst. The catalyst provided by the invention for purifying the motor vehicle exhaust has low cost, good combustion activity and good resistance to aging.

Owner:BYD CO LTD

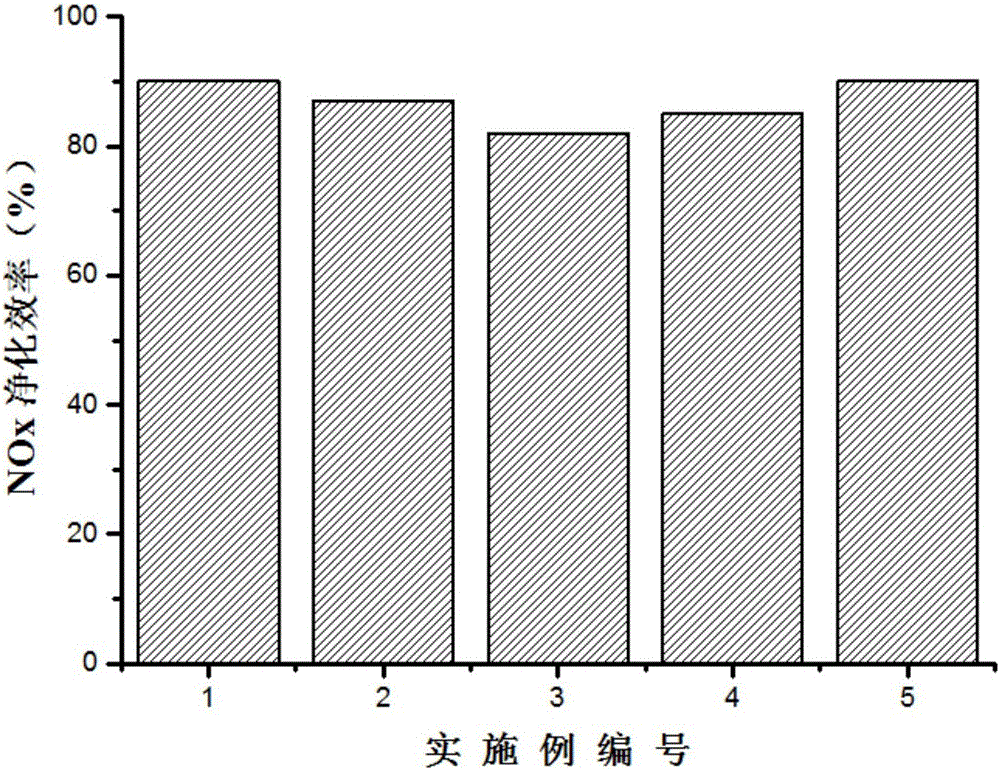

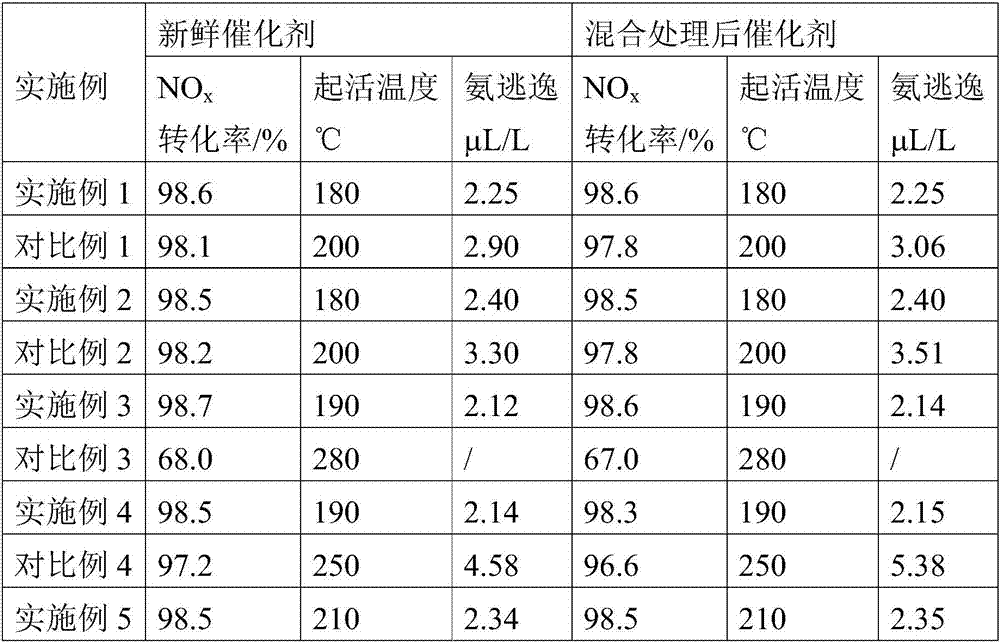

Ferrous modified molecular sieve type diesel engine selective catalytic reduction catalyst

ActiveCN106622348AImprove the catalytic activity of low temperature SCR reactionSuppress generationGas treatmentMolecular sieve catalystsCordieriteSlurry

The invention discloses a ferrous modified molecular sieve type diesel engine selective catalytic reduction catalyst. The catalyst is composed of a main catalyst, an auxiliary catalyst, a coating base material and a catalyst carrier, wherein a ferrous-La bimetallic modified ZSM-5 molecular sieve serves as the main catalyst; a CeO2-ZrO2 solid solution serves as the auxiliary catalyst; the coating base material is composed of SiO2, TiO2 and gamma-Al2O3; and a 400-mesh cordierite honeycomb ceramic serves as the catalyst carrier. A preparation process comprises the following steps: preparing and confirming the dosage of the supported catalyst raw materials; preparing the main catalyst, namely, the ferrous-La bimetallic modified ZSM-5 molecular sieve; and preparing the coating slurry and coating. The catalyst is packaged in a diesel engine SCR catalytic converter and is used for catalyzing the SCR reaction of the reducing agent and NOx, so as to realize the purification of NOx pollutants in the exhaust gas of the diesel engine. According to the invention, the environmental harm of the traditional catalyst is reduced, the generation of the secondary pollutants, such as SO3 derivatives, is restrained, and the low-temperature SCR reaction catalytic activity of the catalyst is obviously improved.

Owner:TIANJIN UNIV

Catalyst support for purification of exhaust gas, catalyst for purification of exhaust gas using the same, and method for producing the catalyst support for purification of exhaust gas

ActiveUS20150266004A1High oxygen storage performanceHigh catalytic activityAluminium compoundsInternal combustion piston enginesCeriumCalcination

A catalyst support for purification of exhaust gas includes a porous composite metal oxide, the porous composite metal oxide containing alumina, ceria, and zirconia and having an alumina content ratio of from 5 to 80% by mass, wherein after calcination in the air at 1100° C. for 5 hours, the porous composite metal oxide satisfies a condition such that standard deviations of content ratios (as at % unit) of aluminum, cerium and zirconium elements are each 19 or less with respect to 100 minute areas (with one minute area being 300 nm in length×330 nm in width) of the porous composite metal oxide, the standard deviation being determined by energy dispersive X-ray spectroscopy using a scanning transmission electron microscope equipped with a spherical aberration corrector.

Owner:TOYOTA CENT RES & DEV LAB INC +1

Selective catalytic reduction catalyst based on copper-vanadium bimetallic modified molecular sieve and preparation method thereof

InactiveCN107930678AGood low temperatureIncrease temperatureMolecular sieve catalystsDispersed particle separationDispersitySlurry

The invention discloses a selective catalytic reduction catalyst based on a copper-vanadium bimetallic modified molecular sieve and a preparation method thereof. In the catalyst, a copper-vanadium bimetallic modified molecular sieve is taken as a main active component, CeO2 and ZrO2 are taken as auxiliary active ingredients, gamma-Al2O3 and SiO2 construct a coating auxiliary material, and 400-meshcordierite honeycomb ceramics is taken as a catalyst carrier. A preparation process comprises: determination of the using amounts of raw materials, preparation of the copper-vanadium bimetallic modified molecular sieve and preparation and coating of coating slurry. The advantages of high catalysis activity and high dispersity of a copper modified molecular sieve catalyst in a low-temperature SCR(Selective Catalytic Reduction) reaction and the advantage of high catalysis activity of V2O5 in a high-temperature SCR reaction can be brought into play at the same time; meanwhile, the using amountof the V2O5 is reduced, and the toxicity of the catalyst is lowered; the coating auxiliary material consisting of the gamma-Al2O3 and the SiO2 can improve the thermal stability and mechanical strengthof a catalytic coating, and the dispersion uniformity of the active components; through addition of the CeO2 serving as the auxiliary active component, the catalysis activity of the catalyst in the low-temperature SCR reaction is enhanced.

Owner:HEFEI SHENZHOU CATALSIS PURIFIER CO LTD

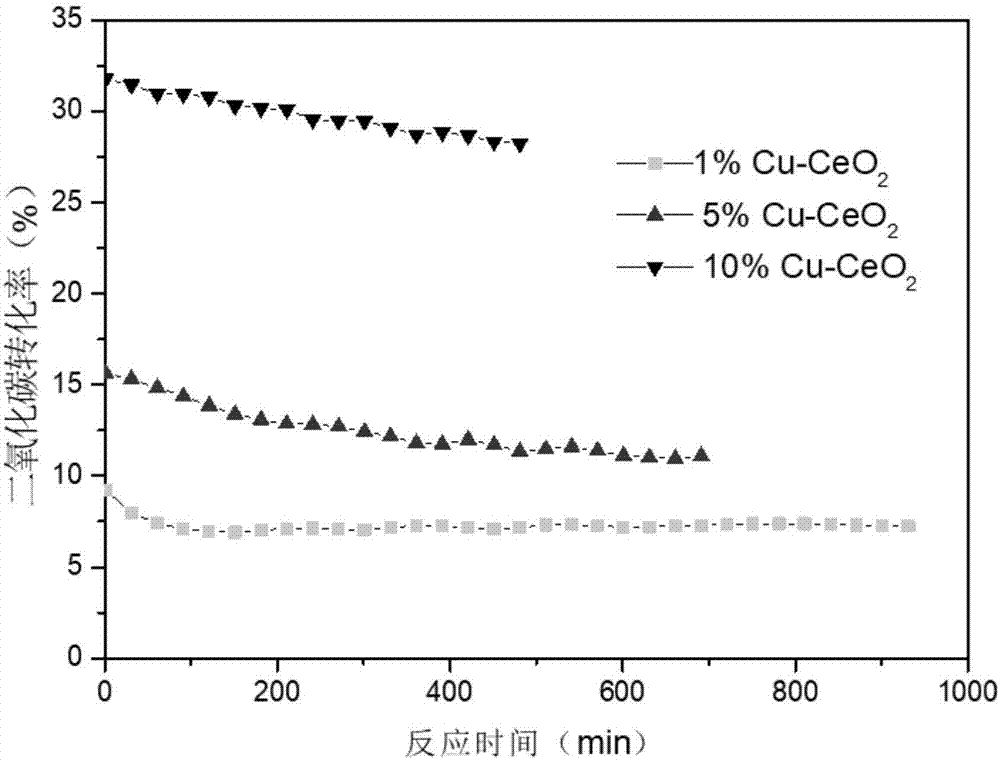

Copper-based catalyst for reverse water-gas shift reaction and preparation method therefor

ActiveCN107497439AReduce loadImprove hydrogenation activityCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsWater-gas shift reactionCopper

The invention relates to the field of catalysts and discloses a copper-based catalyst for a reverse water-gas shift reaction and a preparation method therefor. The catalyst is prepared from the following raw materials: 0.3wt% to 5.4wt% of Cu(NO3)2.3H2O, 14wt% to 24wt% of Ce(NO3)3.6H2O, 4wt% to 7wt% of glycine, 53wt% to 71wt% of deionized water and 7wt% to 12wt% of neutral silica sol, wherein the content of Cu in the obtained Cu-CeO2 catalyst is 1wt% to 20wt%. According to the copper-based catalyst for the reverse water-gas shift reaction and the preparation method therefor, the mesoporous Cu-CeO2 catalyst is prepared by using a silica sol method and has good thermal stability due to a mesoporous structure, and the disadvantage of the traditional copper-based catalysts that the thermal stability is poor is overcome. In a reaction process, the production of a byproduct, i.e., methane is not discovered, the catalyst selectivity is high, and the copper-based catalyst for reverse water-gas shift has high activity and good stability and has an extremely high industrial application value.

Owner:ZHEJIANG OCEAN UNIV

Cellular denitrification catalyst and preparation method thereof

InactiveCN107126950AHigh activityPenetration deepGas treatmentHeterogenous catalyst chemical elementsGlass fiberFiltration

The invention discloses a cellular denitrification catalyst and a preparation method thereof. The catalyst preparation method comprises the following steps: dissolving a titanium source precursor in an acid to form a solution; respectively dissolving a molybdenum source precursor and a rare earth precursor to form solutions; uniformly mixing the above solutions, regulating the pH value to 7-12, and performing precipitation and filtration; then adding deionized water to form a pulp through blending; adding a vanadium source precursor solution, performing uniform mixing, and then directly performing drying, roasting and powder grinding; then adding an extrusion aid, the molybdenum source precursor solution and a pore forming agent into the powder, adding water with stirring to form a paste through blending, and regulating the pH value to alkaline; then adding nano silicon dioxide, glass fibers and an adhesive, and performing uniform mixing; and conducting extruding through an extruder to obtain a cellular blank, and performing drying and roasting to obtain the finished product. The cellular denitrification catalyst prepared by the preparation method disclosed by the invention can overcome the defects of the denitrification catalyst in the prior art, such as active center imbalance and unstable activity in flue gas.

Owner:PETROCHINA CO LTD

Prepositioned SCO intensified flue gas denitration and demercuration system of coal-fired power plant

ActiveCN105561774AGood sulfur resistanceHigh oxygen storage performanceGas treatmentDispersed particle separationCobalt oxideManganese oxide

The invention relates to a prepositioned SCO intensified flue gas denitration and demercuration technology of a coal-fired power plant. NO and Hg<0> in flue gas are oxidized into NO2 and Hg<2+> in advance and then the NO2 and the Hg<2+> are subjected to an SCR (Selective Catalytic Reduction), so that the aim of efficient denitration and demercuration is realized. A catalyst used by an SCO unit is a Co-Mn-Ti-Ce series catalyst, an active component is one or two of cobalt oxide or manganese oxide, an auxiliary agent component is W and a catalyst carrier is Ce doped TiO2. The Hg<0> can be efficiently oxidized and removed under the condition that previous facilities of the coal-fired power plant do not need to be excessively modified; the oxidization efficiency of the Hg<0> is not influenced in an ammonification process. Meanwhile, dependence on HCl is avoided when O2 and NO are used as an oxidant of the Hg<0>; the given mercury oxidization removing efficiency can be realized without adding additional components in the flue gas; a prepositioned SCO process is used for converting 50 percent of NO at an inlet of an SCR unit into the NO2, so that the reaction efficiency of the SCR process can be remarkably improved. The technology provided by the invention has the advantages that raw materials of the catalyst are easy to obtain, the technological process is easy to implement and industrial application is facilitated.

Owner:WUHAN UNIV

Denitration catalyst with low sulfur dioxide oxidation rate and preparation method thereof

ActiveCN103240077AGuaranteed denitrification rateReduce outputDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateRare earth

The invention discloses a denitration catalyst with a low sulfur dioxide oxidation rate and a preparation method thereof. The denitration catalyst mainly comprises the following components in parts by mass: 70-92 parts of titanium dioxide, 0.3-1.5 parts of vanadium pentoxide, 2-10 parts of tungsten trioxide, 1-5 parts of niobium oxide, 2-5 parts of rare earth oxide and 2-14 parts of silica-alumina mixed oxide. The preparation method comprises the following steps: 1) preparing the silica-alumina mixed oxide; 2) fully mixing and stirring a formula amount of silica-alumina mixed oxide, titanium dioxide, ammonium metavanadate, ammonium paratungstate, niobium nitrate, rare earth oxide, auxiliary shaping materials, deionized water and oxalic acid; and 3) performing extrusion molding on the shaping colloid obtained in the step 2) through a thin-walled die, drying and roasting. The activity of the denitration catalyst is equivalent to that of a common SCR (selective catalytic reduction) denitration catalyst under the high-temperature high-sulfur conditions, and the sulfur dioxide oxidation rate is only 60-80 percent of that of the SCR denitration catalyst.

Owner:CHONGQING YUANDA CATALYST MFG

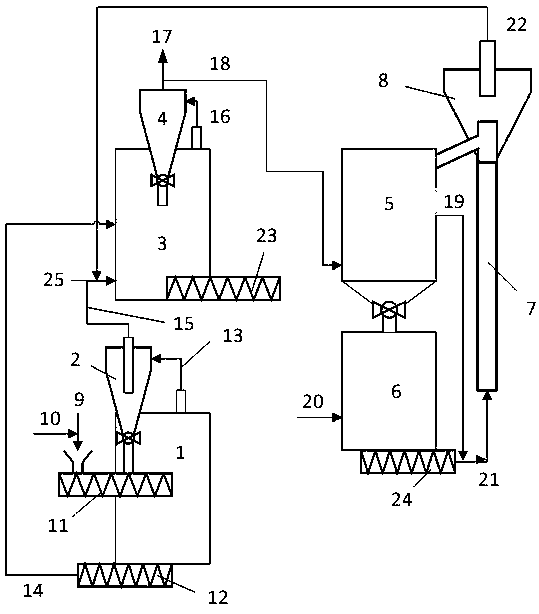

Biomass microwave gasification utilization method and system

ActiveCN111378511AReduce tar contentExtended Cycle ReliabilityGasification processes detailsCombustible gas productionMicrowave pyrolysisProcess engineering

The invention discloses biomass microwave gasification utilization method and system, wherein the method comprises the steps: enabling a biomass raw material to enter a microwave pyrolysis reactor fora pyrolysis reaction to obtain a pyrolysis volatile component and a pyrolysis solid-phase material after the reaction, and performing gas-solid separation on the pyrolysis volatile component for obtaining a first gas-phase material and a solid-phase material; feeding the first gas-phase material and the pyrolysis solid-phase material to a microwave gasification reactor, and carrying out gas-solidseparation on a gas-phase product to obtain synthesis gas; feeding the synthesis gas to an oxygen carrier reduction reactor to react with an oxygen carrier in the reactor to obtain a reduction-stateoxygen carrier and a second gas-phase material; feeding the obtained reduction-state oxygen carrier to an oxygen carrier regenerator to be in contact with water vapor for reaction, so that hydrogen and an oxidation-state oxygen carrier are obtained after the reaction. The synthesis gas obtained by the method disclosed by the invention can meet the requirements of synthesis of liquid fuel, and theproblem of poor quality of the synthesis gas and hydrogen in a process for preparing the synthesis gas and the hydrogen by taking biomass as a raw material in the prior art is solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Methane catalytic oxidation catalyst for natural gas vehicle and preparation method of methane catalytic oxidation catalyst

ActiveCN104549213AHigh content of active ingredientsPromote oxidation reactionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationRare earth

The invention relates to a methane catalytic oxidation catalyst for natural gas vehicle exhaust aftertreatment and a preparation method of the methane catalytic oxidation catalyst. The methane catalytic oxidation catalyst is a stannum-zirconium composite oxide solid solution catalyst, wherein the stannum / zirconium atomic ratio is at least 1.1, the general equation is Sn(1-x)ZrxM0.10O2, M is at least one of rare earth and transition metal, and x is a coefficient; the methane catalytic oxidation catalyst is prepared from the following components in percentage by weight: 50-70% of a stannic oxide (SnO2) precursor, 15-40% of a zirconium dioxide (ZrO2) precursor and the balance being a stabilizer oxide precursor. The preparation method sequentially comprises the following steps: (1) preparing mixed salt; (2) adding a precipitant-urea; (3) carrying out homogeneous precipitation reaction; and (4) roasting to obtain a finished product. The methane catalytic oxidation catalyst has the high active component content and can completely oxidize methane at about 500 DEG C, and the catalytic oxidation ability of a stannum-zirconium composite oxide solid solution on the methane, propane and carbon monoxide can be remarkably improved; and besides, the preparation method is simple, can be operated easily and is low in cost.

Owner:韩霜

Method and device for decomposing dioxin in incineration flue gas by low-temperature plasma coupling catalysis

ActiveCN110935299AEasy to handleEasy to removeGas treatmentDispersed particle separationPtru catalystFlue gas

The invention relates to a method and a device for decomposing dioxin in incineration flue gas by low-temperature plasma coupling catalysis. According to the method, a low-temperature plasma reactionunit and a catalytic reaction unit are connected in series, so that waste incineration flue gas firstly passes through the low-temperature plasma reaction unit, and dioxin in the flue gas is partiallyoxidized by strong oxidizing particles such as ozone generated by high-voltage discharge; and the dioxin enters the catalytic reaction unit, and on the surface of the catalyst, the dioxin can be thoroughly catalyzed and oxidized into small molecular substances such as carbon dioxide, water and hydrogen chloride under the condition of lower smoke temperature by virtue of strong oxidizing particlesgenerated in the low-temperature plasma reaction unit. The advantages of the low-temperature plasma and the catalyst are synergistically utilized, the treatment effect is good, secondary pollution ofozone is avoided, and industrial popularization can be carried out.

Owner:HEBEI UNIV OF TECH

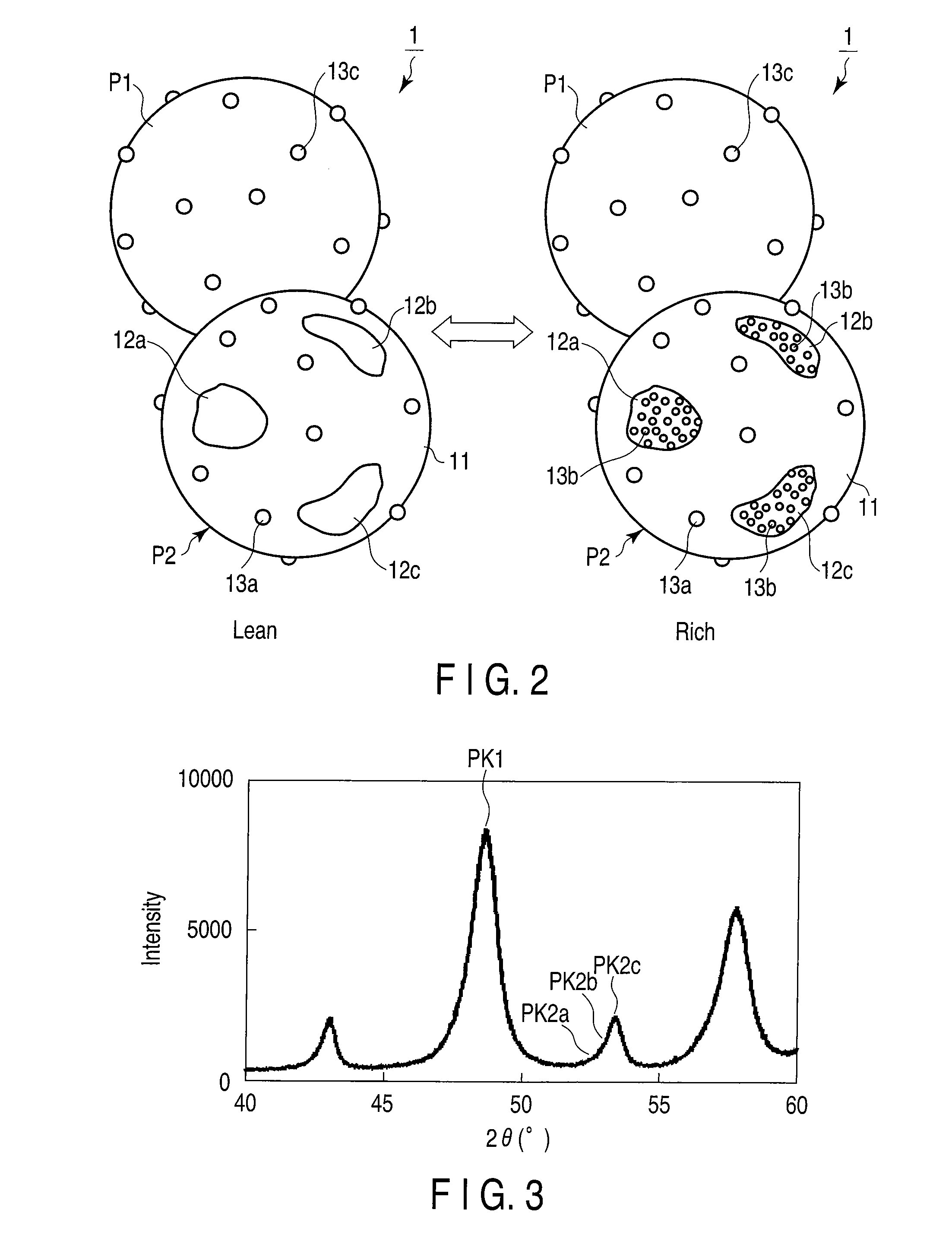

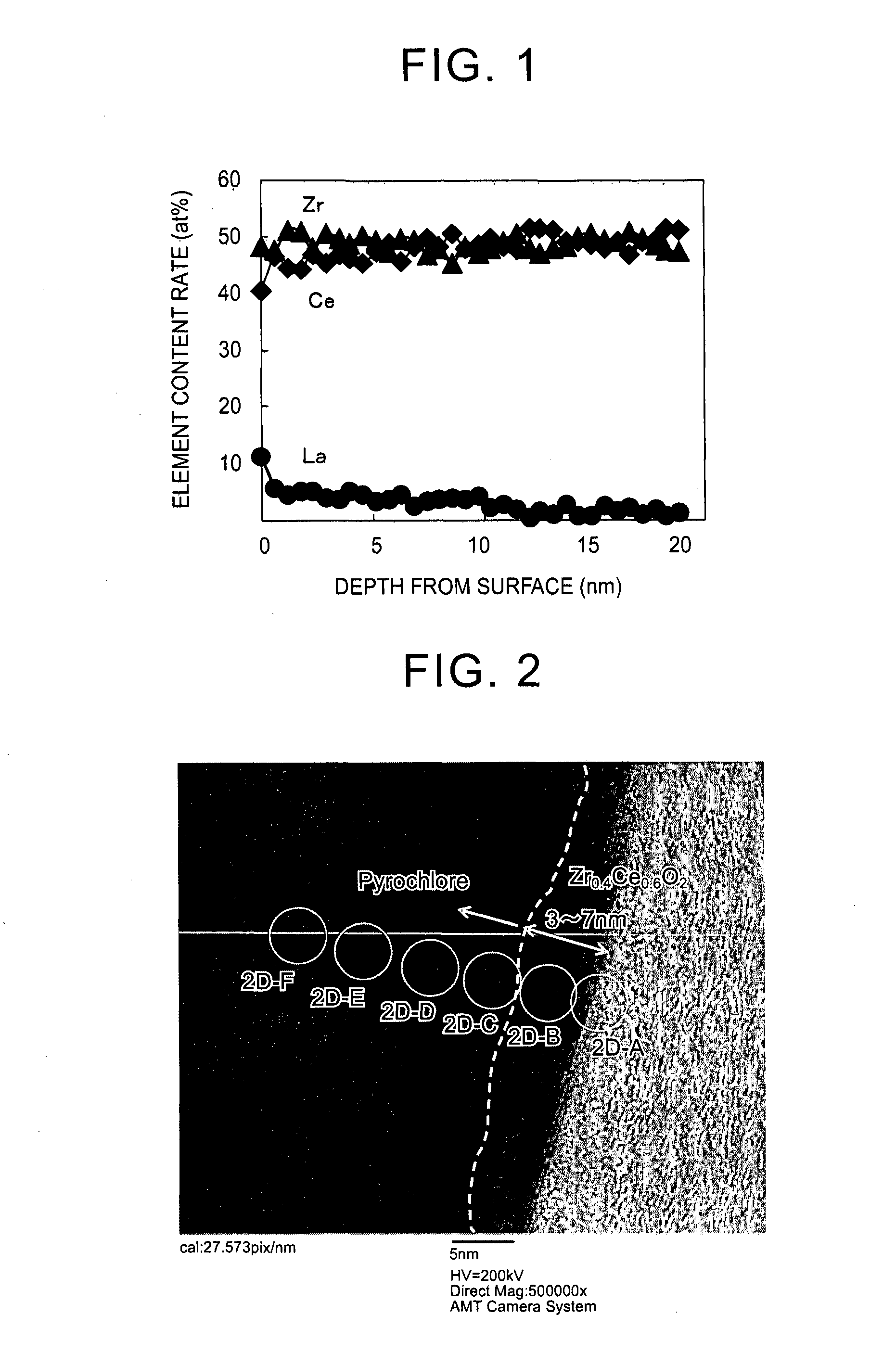

Core-shell oxide material, method for producing the same, and catalyst and method for purification of exhaust gas using the core-shell oxide material

ActiveUS9868087B2Increase capacityShorten the purification processHeterogenous catalyst chemical elementsDispersed particle separationSolid solutionCore shell

Owner:TOYOTA JIDOSHA KK

Oxygen storage material

InactiveUS20100004123A1High oxygen storage performanceGas treatmentHeterogenous catalyst chemical elementsRare-earth elementAlkaline earth metal

An excellent oxygen storage capacity is achieved even in the case used for a long period of time under high temperature conditions. An oxygen storage material contains a first particle made of a composite oxide of cerium and zirconium or a composite oxide of cerium, a rare-earth element other than cerium and zirconium, a second particle including a composite oxide of a rare-earth element, an alkaline-earth element and zirconium, and a precious metal. A part of the precious metal forms a solid solution with the composite oxide included in the second particle.

Owner:CATALER CORP +1

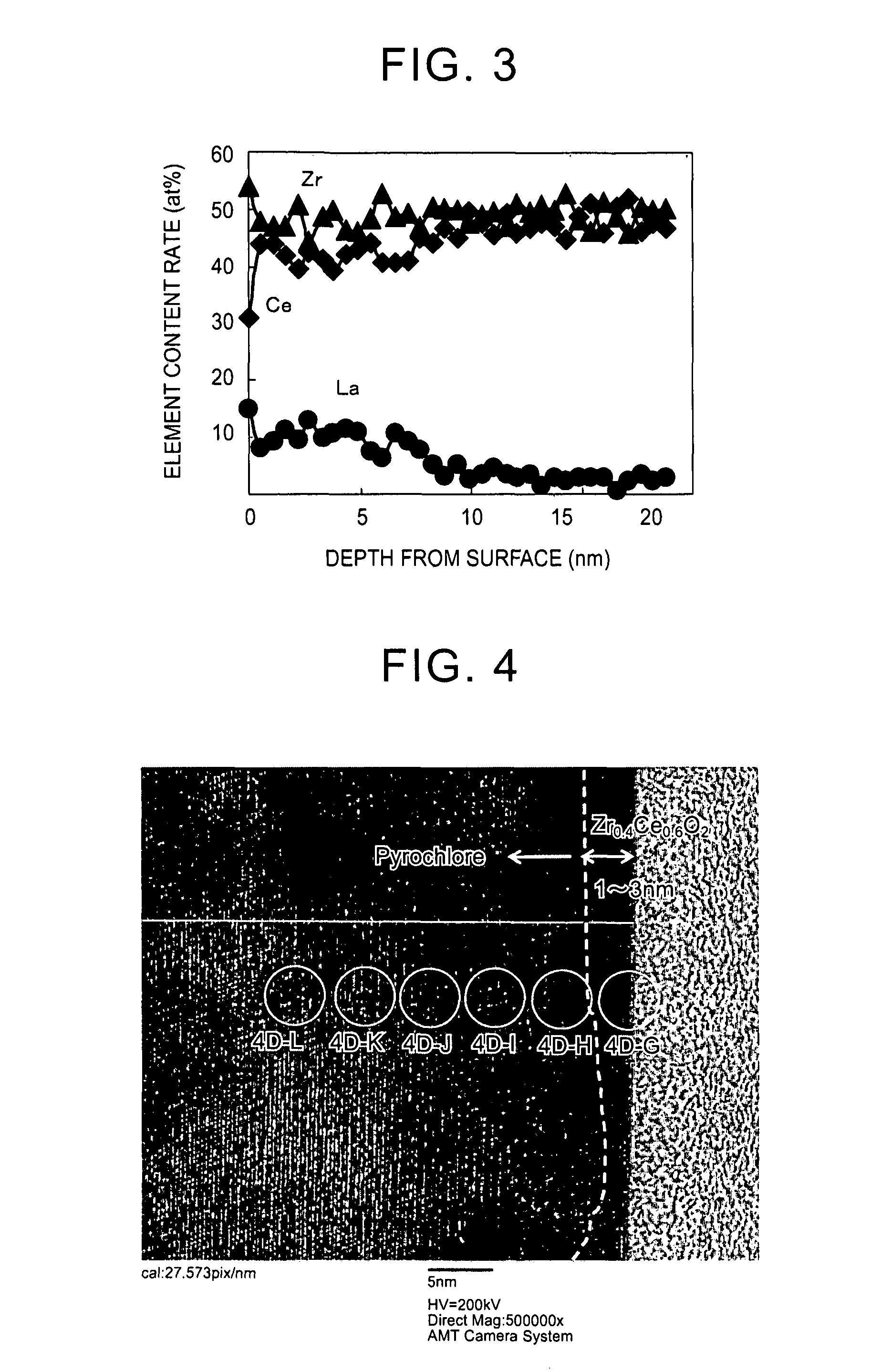

Ceria-zirconia composite oxide, method for producing the same, and catalyst for purifying exhaust gas using the ceria-zirconia composite oxide

ActiveUS20160250620A1Improve heat resistanceOxygen storage capacity deterioratesInternal combustion piston enginesZirconium compoundsRare-earth elementCerium

A ceria-zirconia composite oxide includes at least one of lanthanum, yttrium, and praseodymium. A rate of a total content of the at least one rare earth element to a total content of cerium and zirconium is 0.1 at % to 4.0 at %. A content of the rare earth element present in near-surface regions, which are at a distance of less than 50 nm from surfaces of primary particles of the ceria-zirconia composite oxide, accounts for 90 at % or more of the total content of the rare earth element. An average particle size of the primary particles of the ceria-zirconia composite oxide is 2.2 μm to 4.5 μm. After a predetermined durability test, the intensity ratio I(14 / 29) of a diffraction line at 2θ=14.5° to a diffraction line at 2θ=29° and the intensity ratio I(28 / 29) of a diffraction line at 2θ=28.5° to the diffraction line at 2θ=29° respectively satisfy the following conditions:I(14 / 29)≧0.02, andI(28 / 29)≦0.08.

Owner:TOYOTA JIDOSHA KK +1

Oxidation catalyst for cleaning exhaust gas

InactiveUS20070191218A1Excellent in function of oxidizing high boiling point materialHigh oxygen storage performanceInternal combustion piston enginesHeterogenous catalyst chemical elementsParticulatesPolycyclic aromatic hydrocarbon

An oxidation catalyst for cleaning exhaust gas, excellent in the function of oxidizing high boiling point materials such as particulates and polycyclic aromatic hydrocarbons contained in the exhaust gas of internal-combustion engines is provided. The catalyst is a composite oxide containing two kinds of metal elements, wherein, when the two kinds of metal elements are defined as A and B, the value of the ionic radius of metal element A / the ionic radius of metal element B is in the range of from 1.349 to 1.580. The metal element A is selected from the group consisting of Sc, Y, Ho, Er, Tm, Yb, and Lu, and the metal element B is Mn. The composite oxide has a hexagonal structure.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com