Selective catalytic reduction catalyst based on copper-vanadium bimetallic modified molecular sieve and preparation method thereof

A molecular sieve and bimetallic technology, applied in the field of selective catalytic reduction catalyst and preparation based on copper-vanadium bimetallic modified molecular sieve, can solve the problem that the catalytic activity of copper or iron modified molecular sieve type catalyst is not improved at high temperature and low temperature activity It can improve the catalytic activity of low-temperature SCR reaction, reduce the harm to the environment and human health, and enhance the oxygen storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

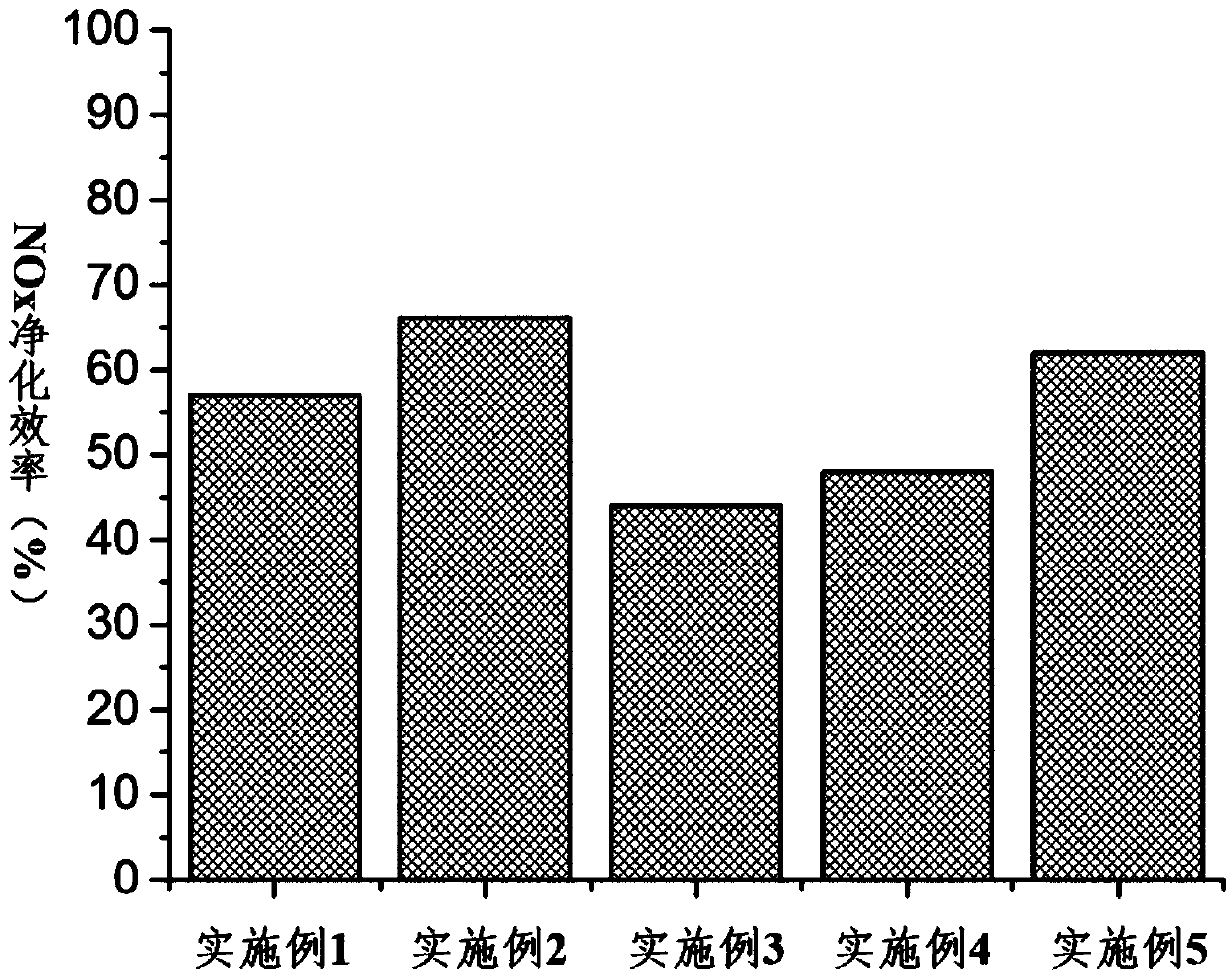

Examples

Embodiment 1

[0043] A method for preparing a selective catalytic reduction catalyst based on copper-vanadium bimetallic modified molecular sieves, prepared through the following steps:

[0044] (1) Determination of the amount of raw materials

[0045] The mass percentages of main active ingredients, auxiliary active ingredients and coating auxiliary materials are: 20%: 15%: 65%;

[0046] Among them, CuO, V 2 o 5 And the mass percent of ZSM-5 type molecular sieve is 5%: 5%: 90%;

[0047] Co-active ingredient CeO 2 and ZrO 2 The mass percentage is 90%:10%;

[0048] Among coating auxiliary materials, γ-Al 2 o 3 with SiO 2 The mass percentage is 60%: 40%;

[0049] Pure γ-Al in Coating Auxiliary Materials 2 o 3 Convert with aluminum sol to generate γ-Al 2 o 3 The mass percentage is 75%: 25%;

[0050] Every mole of ammonium metavanadate needs 2 moles of oxalic acid; every 100g of catalytic coating needs 10g of polyethylene glycol with an average molecular weight of 20000 and 50g of...

Embodiment 2

[0065] (1) Determination of the amount of raw materials

[0066] The mass percentages of main active ingredients, auxiliary active ingredients and coating auxiliary materials are: 25%: 15%: 60%;

[0067] Among them, CuO, V 2 o 5 And the mass percent of ZSM-5 type molecular sieve is 16%: 4%: 80%;

[0068] Co-active ingredient CeO 2 and ZrO 2 The mass percentage is 60%: 40%;

[0069] Among coating auxiliary materials, γ-Al 2 o 3 with SiO 2 The mass percentage is 80%:20%;

[0070] Pure γ-Al in Coating Auxiliary Materials 2 o 3 Convert with aluminum sol to generate γ-Al 2 o 3 The mass percentage is 60%: 40%;

[0071] Every mole of ammonium metavanadate needs 3 moles of oxalic acid; every 100g of catalytic coating needs 5g of polyethylene glycol with an average molecular weight of 20000 and 25g of nitric acid; every 100g of copper-vanadium bimetallic modified molecular sieve needs 200ml of n-hexane; 2000g The amount of raw materials required for catalytic coating is: ...

Embodiment 3

[0086] (1) Determination of the amount of raw materials

[0087] The mass percentages of main active ingredients, auxiliary active ingredients and coating auxiliary materials are: 10%:10%:80%;

[0088] Among them, CuO, V 2 o 5 And the mass percent of ZSM-5 type molecular sieve is 10%: 10%: 80%;

[0089] Co-active ingredient CeO 2 and ZrO 2 The mass percentage is 80%:20%;

[0090] Among coating auxiliary materials, γ-Al 2 o 3 with SiO 2 The mass percentage is 75%: 25%;

[0091] Pure γ-Al in Coating Auxiliary Materials 2 o 3 Convert with aluminum sol to generate γ-Al 2 o 3 The mass percentage is 60%: 40%;

[0092] Every mole of ammonium metavanadate needs 2 moles of oxalic acid; every 100g of catalytic coating needs 8g of polyethylene glycol with an average molecular weight of 20,000 and 40g of nitric acid; every 100g of copper-vanadium bimetallic modified molecular sieve needs 300ml of n-hexane; 2000g The amount of raw materials required for catalytic coating is: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com