Anode material for lithium ion power battery and preparation method thereof

A technology of power battery and negative electrode material, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems affecting the development process of lithium-ion power batteries, poor liquid absorption performance of battery negative pole pieces, and affecting the performance of lithium-ion power batteries, etc. Achieve the effect of superior liquid absorption, easy control and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the negative electrode material that lithium ion battery of the present invention is used comprises the following steps:

[0021] 1. Use the GS-300 high-speed mixer of Wuxi Xinguang Powder Processing Technology Co., Ltd. to mix graphite and the precursor of non-graphite carbon materials with a mass of graphite of 1 to 10.0% with the solvent at a speed of 600 to 2100r / min. The phases are mixed for 10-180 minutes to obtain a suspension liquid mixture with a solid content of 10-70 wt%.

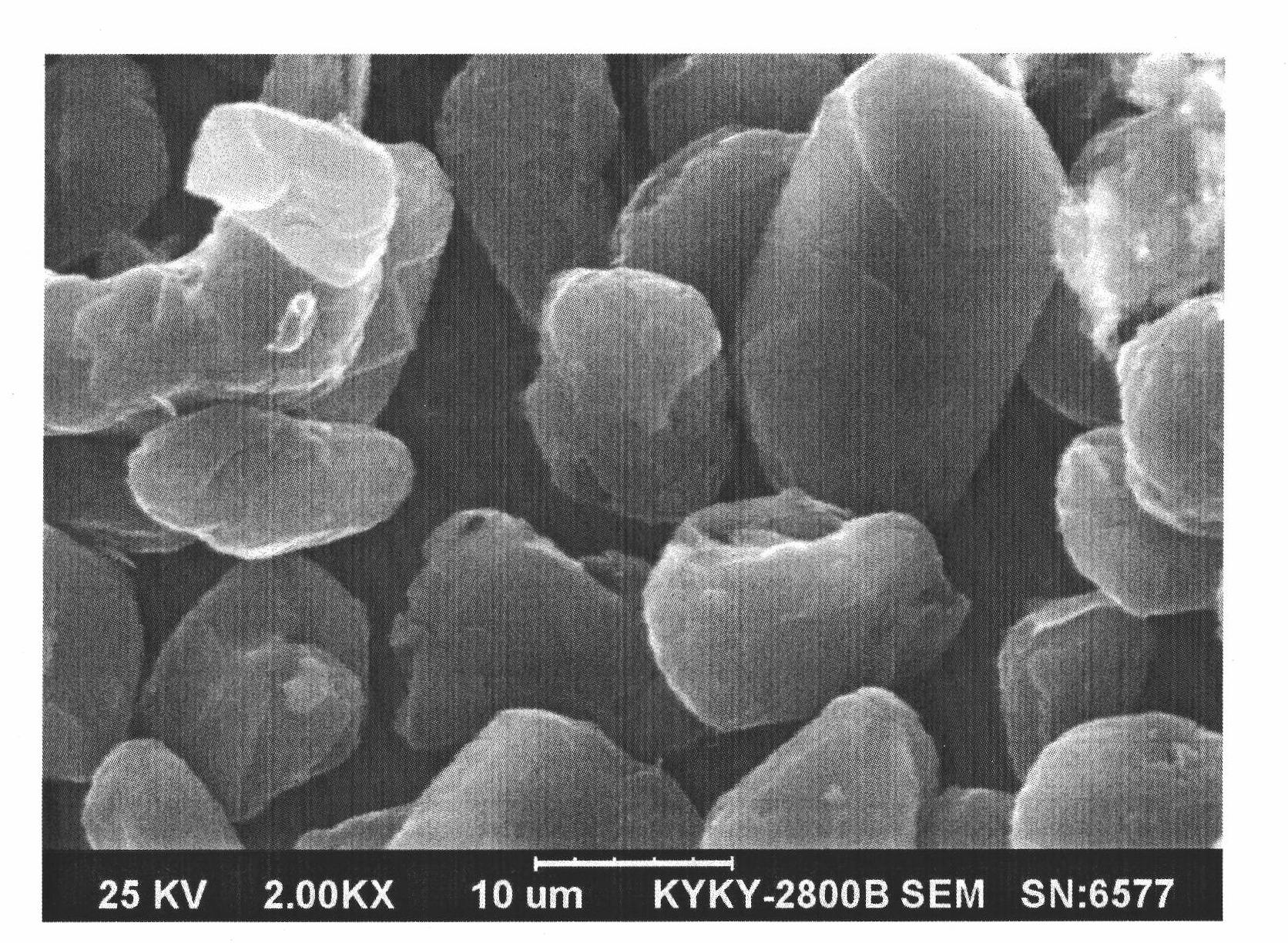

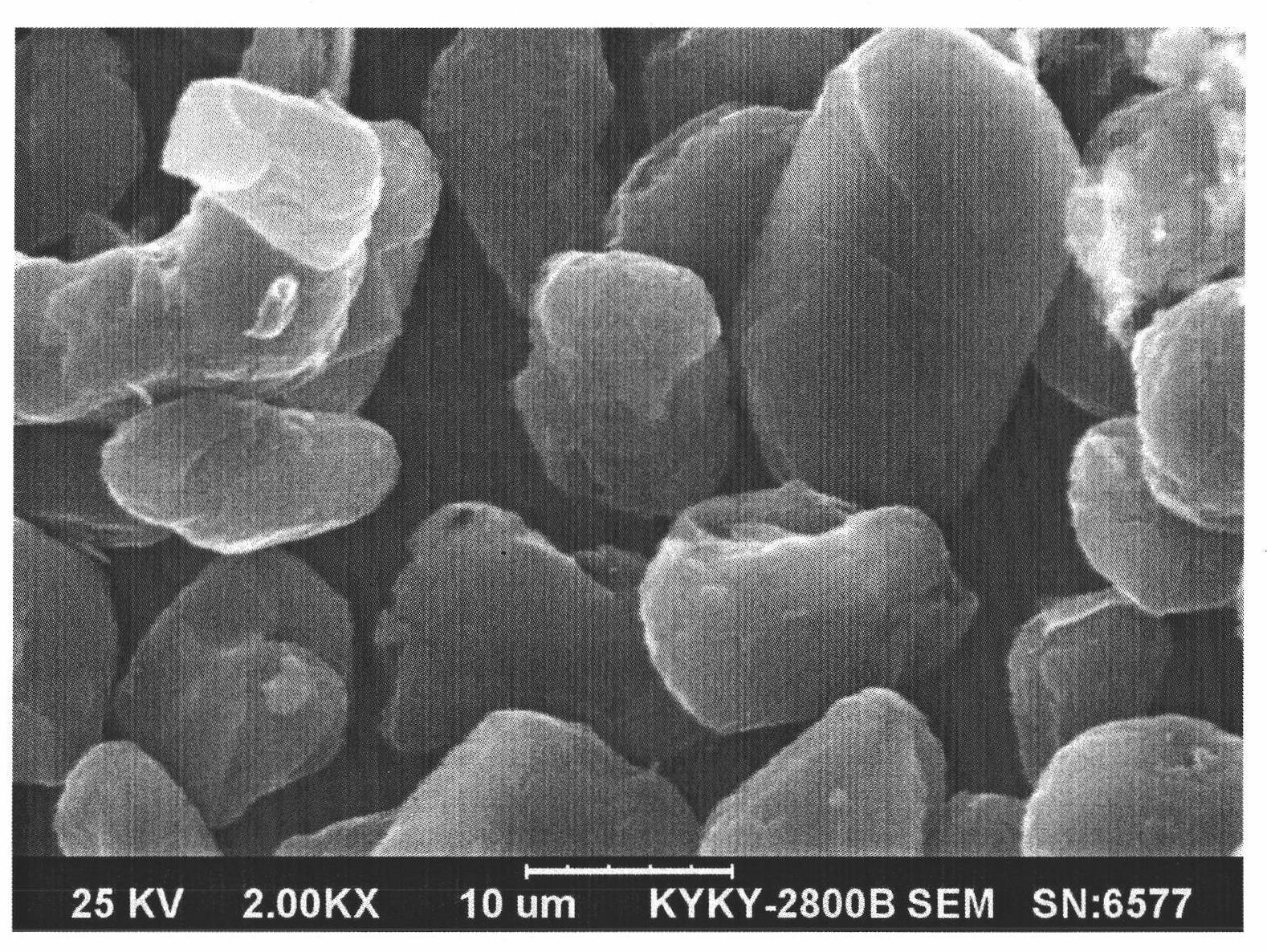

[0022] Graphite is natural graphite powder with a carbon content of 90-99%, and an average particle size of 3.0-39.0 μm.

[0023] The precursors of non-graphite carbon materials are pitch and resin. The pitch is more than one of coal pitch, petroleum pitch, coal tar and emulsified pitch. The resin is furan resin, urea-formaldehyde resin, pyrimidine resin, phenolic resin, epoxy resin, One or more of polymethyl methacrylate resin and acrylic resin.

[0024] The so...

Embodiment 1

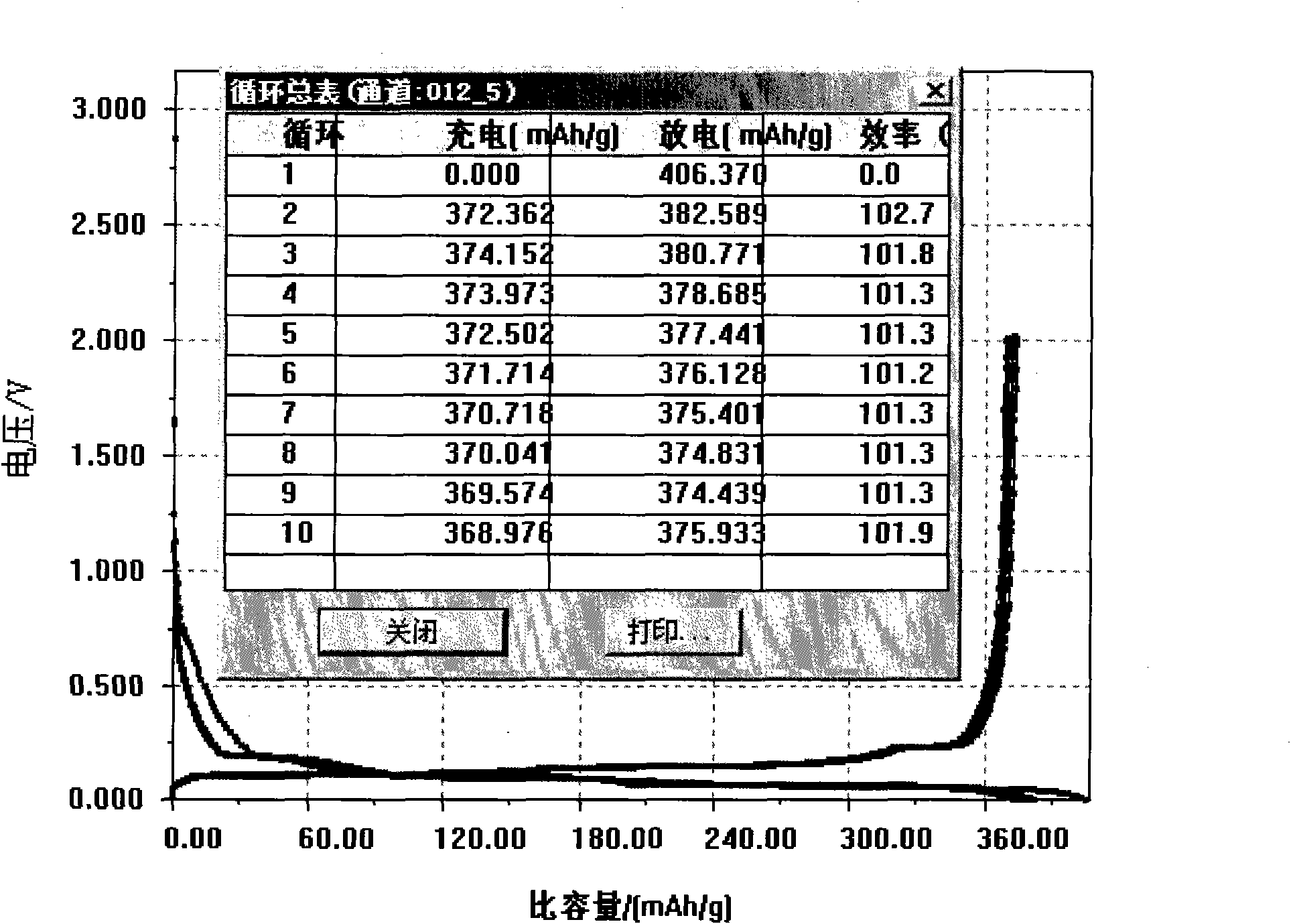

[0037] Embodiment 1, adopt spherical natural graphite as raw material, its carbon content is 99%, and 10% asphalt of graphite quality is mixed through liquid phase and rotating speed is 1300r / min, stirs 50min, and solid content is 60%, then through VC mixer, above-mentioned The mixture was coated with a rotating speed of 500r / min for 30 minutes, and then carbonized at 1100°C for 16 hours at a heating rate of 11°C / min, the protective gas was nitrogen, the flow rate was 80L / h, and the temperature was lowered at a cooling rate of 6°C / min. Sift the pack.

Embodiment 2

[0038] Embodiment 2, adopt spherical natural graphite as raw material, its carbon content is 92%, mix with graphite quality 3% asphalt through liquid phase, rotating speed is 2100r / min, stir 10min, solid content is 20%, then through VC mixer The above mixture is coated with a rotation speed of 300r / min, stirred for 15min, and then carbonized at 1800°C for 4 hours at a heating rate of 20°C / min. The protective gas is argon, the flow rate is 10L / h, and the temperature is lowered at a cooling rate of 13°C / min. , sieved packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com