Catalyst based on modified molecular sieve and hydrotalcite derived oxides and applied to diesel engine, preparation and application

A molecular sieve and catalyst technology, applied in the field of adsorption-reduction catalyst and its preparation, can solve the problems of poor adsorption effect, poor stability of catalytic coating, difficulty in improving the adsorption performance of LNT catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

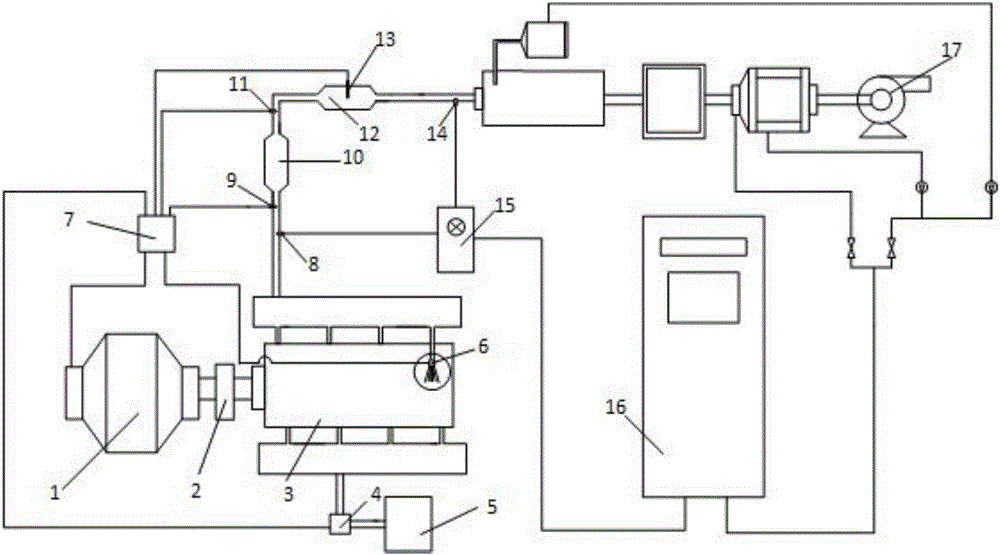

Image

Examples

preparation example Construction

[0044] The preparation method of the catalyst for diesel engine based on modified molecular sieve and hydrotalcite derivative oxide, its concrete process comprises following 5 steps:

[0045] (1) Determination of the catalyst raw material consumption;

[0046] (2) Preparation of Co-modified ZSM-5 molecular sieve main catalyst

[0047] (3) Preparation of multiple metal modified hydrotalcite derived composite oxides;

[0048] (4) Preparation of coating slurry;

[0049] (5) Coating of coating slurry.

[0050] Preparation method of catalyst for diesel engine based on modified molecular sieve and hydrotalcite-derived oxide, including multiple metal modified hydrotalcite-derived composite oxide, Co modified ZSM-5 molecular sieve, CeO 2 -ZrO 2 Solid solution, γ-Al 2 o 3 And 400 mesh cordierite honeycomb ceramics, etc.

[0051] The main catalyst of the catalyst of the present invention is composed of Co modified ZSM-5 molecular sieves, wherein the Co element is represented by C...

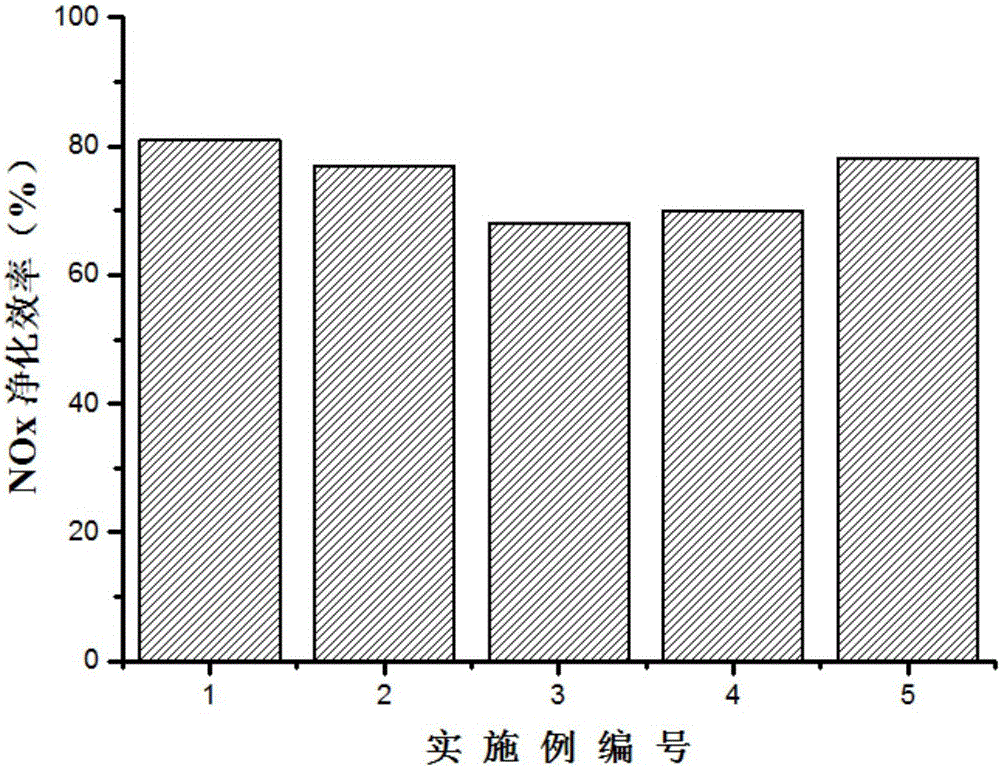

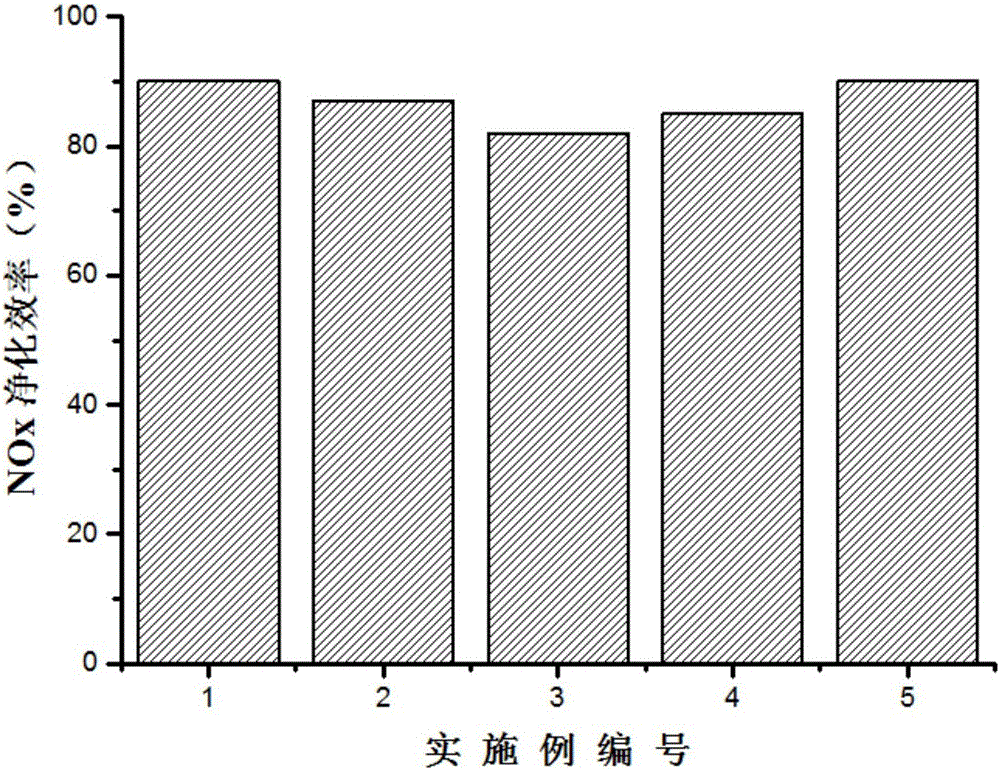

Embodiment 1

[0060] (1) Determination of the amount of catalyst raw material used

[0061] Co in the main catalyst of the catalyst prepared in Design Example 1 3 o 4 The mass ratio of the ZSM-5 molecular sieve is: 5%:95%; the mass ratio of the main catalyst, co-catalyst and coating base material is: 8%:20%:72%; CeO in the co-catalyst 2 and ZrO 2 The mass ratio is: 60%:40%; multi-element metal modified hydrotalcite derived composite oxide and γ-Al in the coating base material 2 o 3 The mass ratio of MgO and CuO is: 11%:89%, Al 2 o 3 and Fe 2 o 3 The mass ratio is: 0%:100%; pure γ-Al in the coating base material 2 o 3 Convert with aluminum sol to generate γ-Al 2 o 3 The mass ratio is: 40%:60%; every 100g of catalytic coating requires 15g of polyethylene glycol with an average molecular weight of 20,000 and 50g of nitric acid; the preparation of every 100g of Co modified ZSM-5 molecular sieve requires 200ml of n-hexane. According to the conversion ratio, calculate the required raw...

Embodiment 2

[0072] (1) Determination of the amount of catalyst raw material used

[0073] Co in the main catalyst of the catalyst prepared in Design Example 2 3 o 4 The mass ratio of the ZSM-5 molecular sieve is: 15%: 85%; the mass ratio of the main catalyst, co-catalyst and coating base material is: 4%: 10%: 86%; CeO in the co-catalyst 2 , ZrO 2 The mass ratio is: 80%:20%; multi-element metal modified hydrotalcite derived composite oxide and γ-Al in the coating base material 2 o 3 The mass ratio of MgO and CuO is: 34%: 66%, Al 2 o 3 and Fe 2 o 3 The mass ratio is: 39%:61%; pure γ-Al in the coating base material 2 o 3 Convert with aluminum sol to generate γ-Al 2 o 3 The mass ratio is: 0%:100%; every 100g coating requires 15g of polyethylene glycol with an average molecular weight of 20,000 and 25g of nitric acid; the preparation of every 100g of Co modified ZSM-5 molecular sieve requires 300ml of n-hexane. According to the conversion ratio, calculate the required raw material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com