Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

260 results about "Pyrochlore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

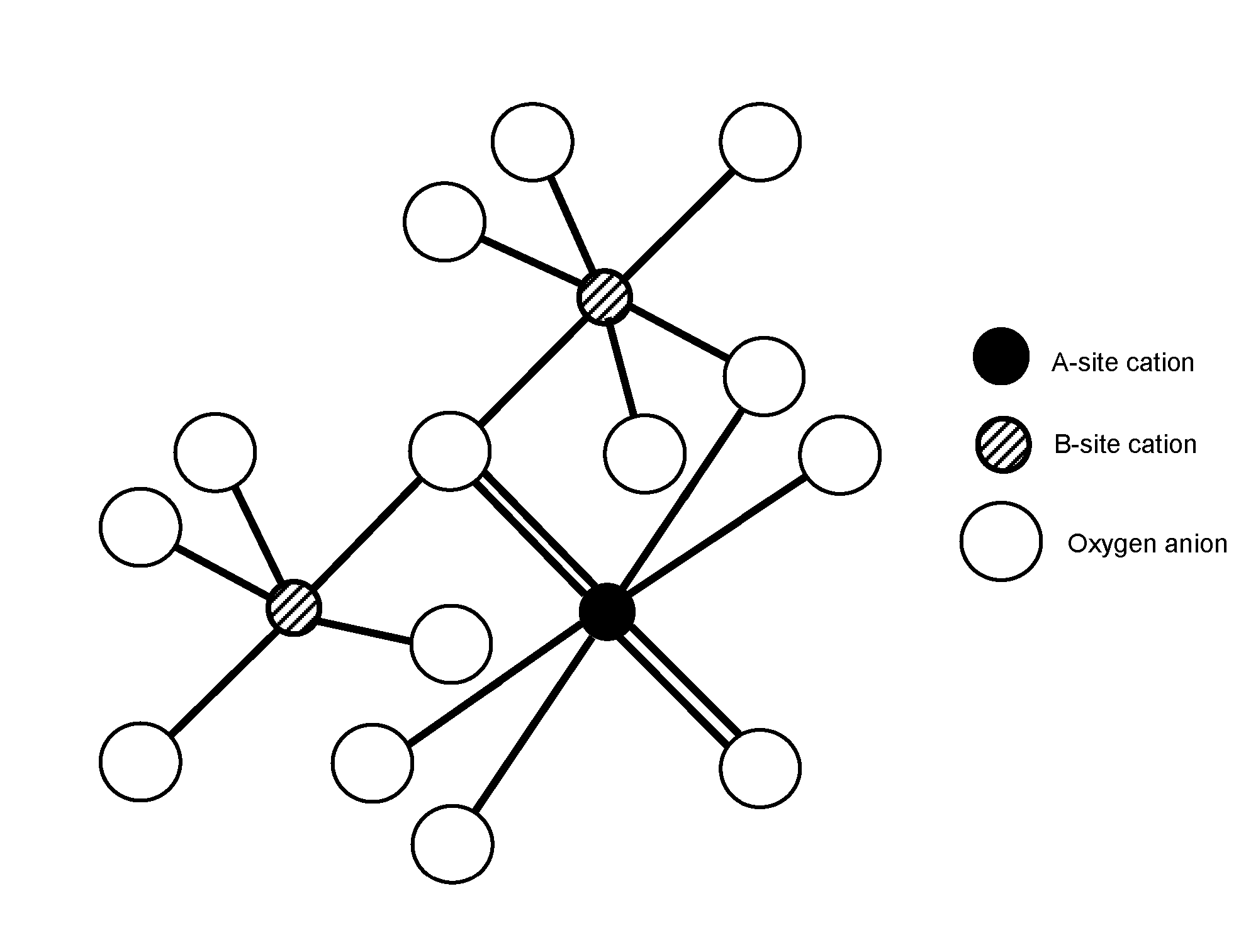

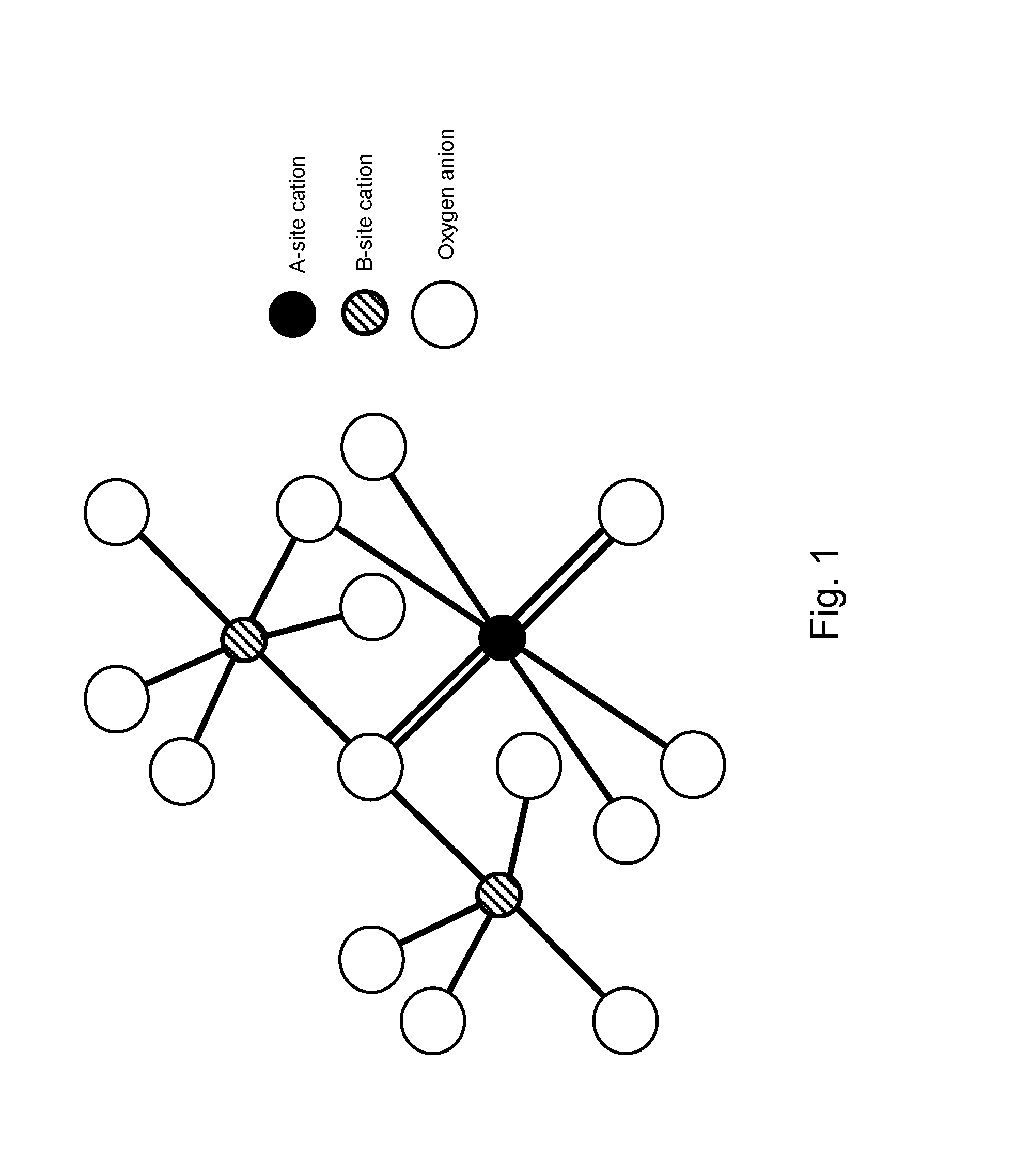

Pyrochlore (Na,Ca)₂Nb₂O₆(OH,F) is a mineral group of the niobium end member of the pyrochlore supergroup. The general formula, A₂B₂O₇ (A and B are metals), represent a family of phases isostructural to the mineral pyrochlore. Pyrochlores are important class of materials from the point of view of diverse technological applications like in luminescence, ionic conductivity, nuclear waste immobilization, high temperature thermal barrier coatings, automobile exhaust gas control, catalysts, solid oxide fuel cell, ionic/electric conductors etc.

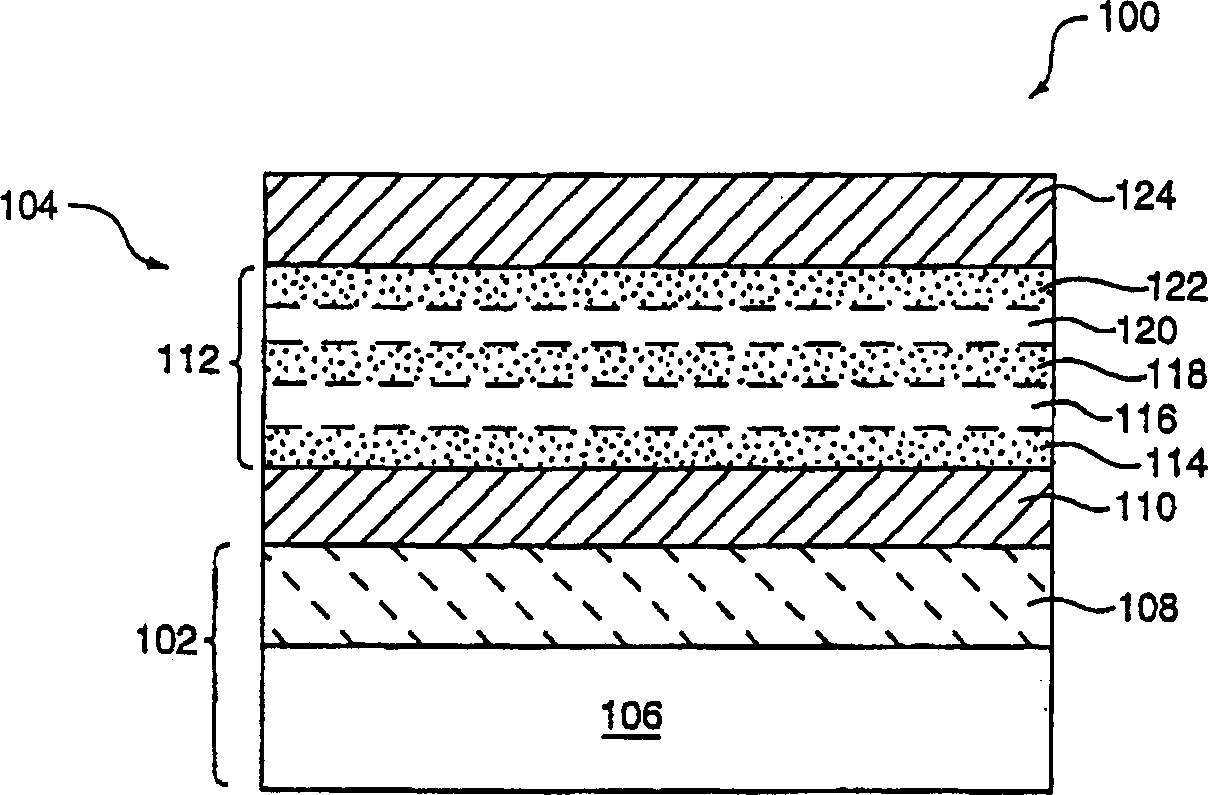

Perovskite-based thin film structures on miscut semiconductor substrates

InactiveUS20060288928A1Quality improvementGood metallic behaviorPolycrystalline material growthFrom chemically reactive gasesCrystal structureCrystal plane

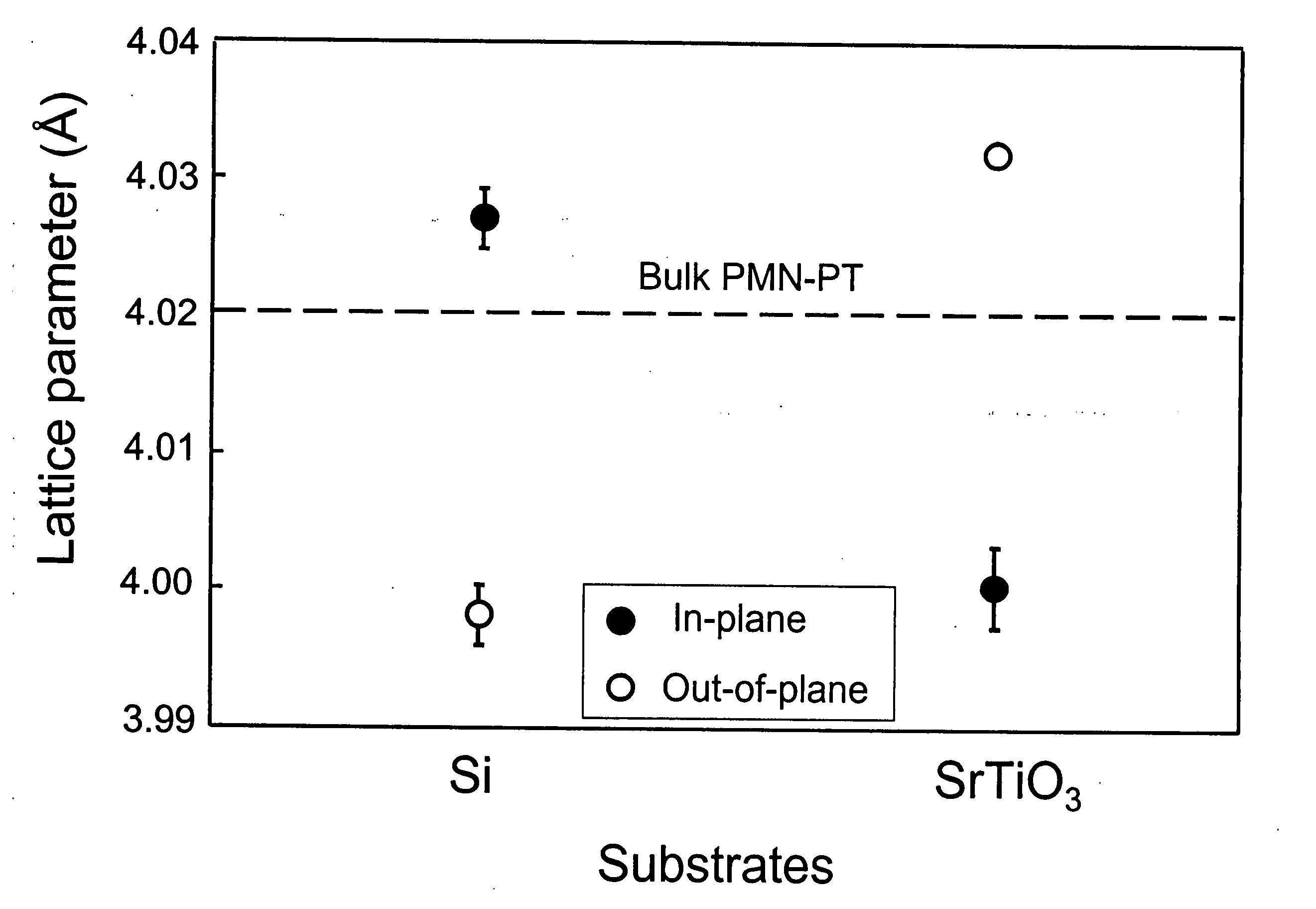

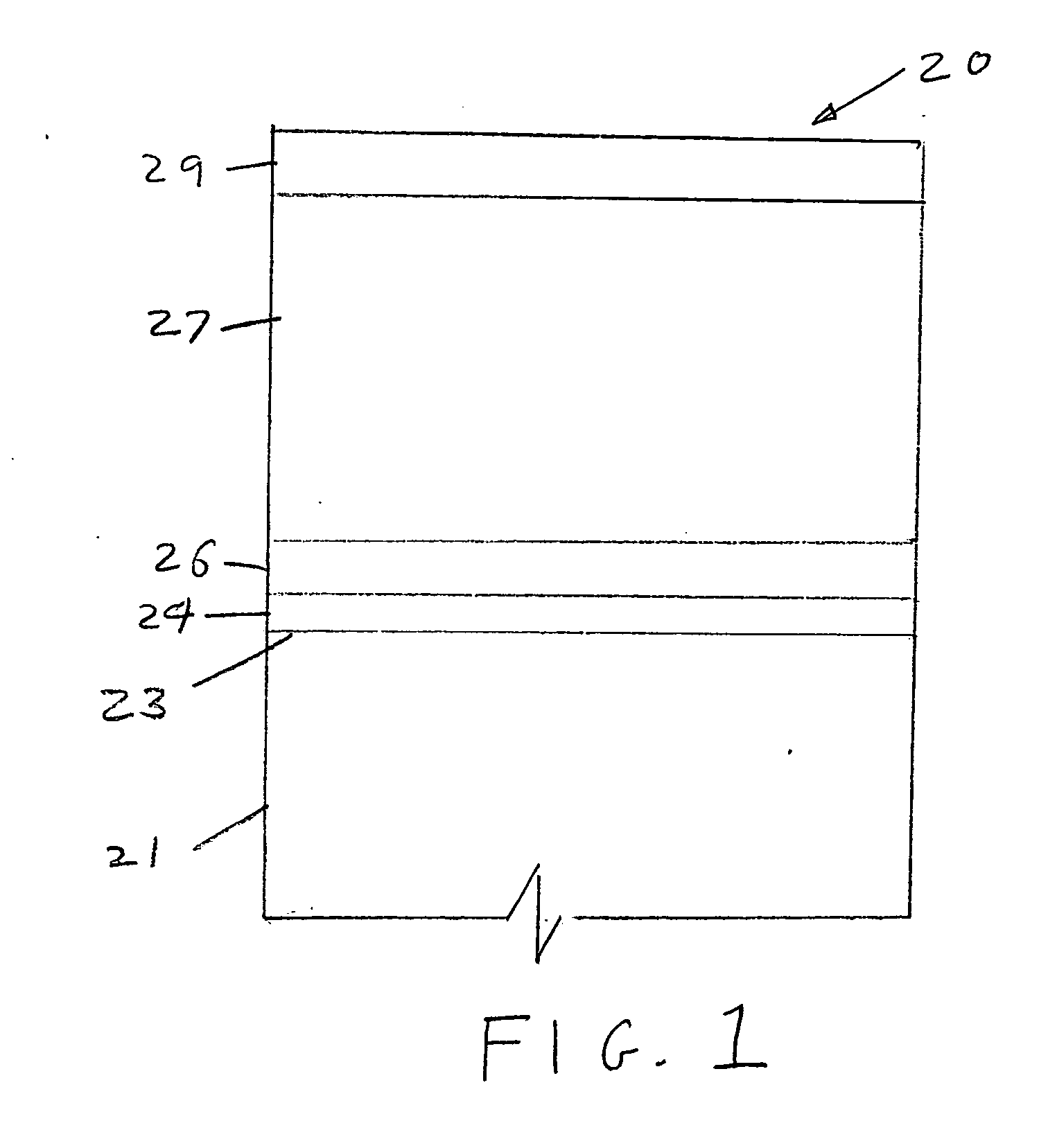

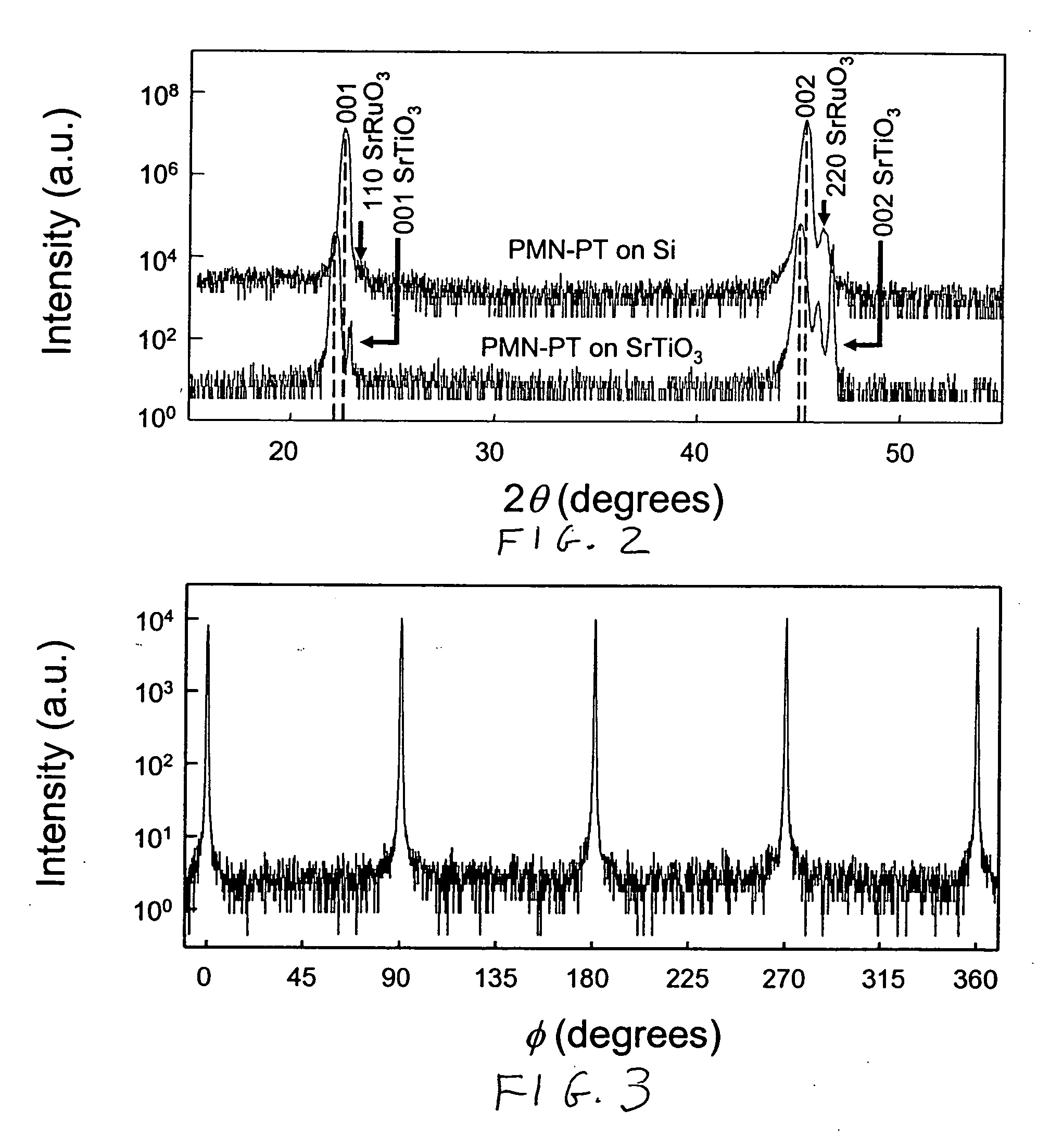

A perovskite-based thin film structure includes a semiconductor substrate layer, such as a crystalline silicon layer, having a top surface cut at an angle to the (001) crystal plane of the crystalline silicon. A perovskite seed layer is epitaxially grown on the top surface of the substrate layer. An overlayer of perovskite material is epitaxially grown above the seed layer. In some embodiments the perovskite overlayer is a piezoelectric layer grown to a thickness of at least 0.5 μm and having a substantially pure perovskite crystal structure, preferably substantially free of pyrochlore phase, resulting in large improvements in piezoelectric characteristics as compared to conventional thin film piezoelectric materials.

Owner:PENN STATE RES FOUND +1

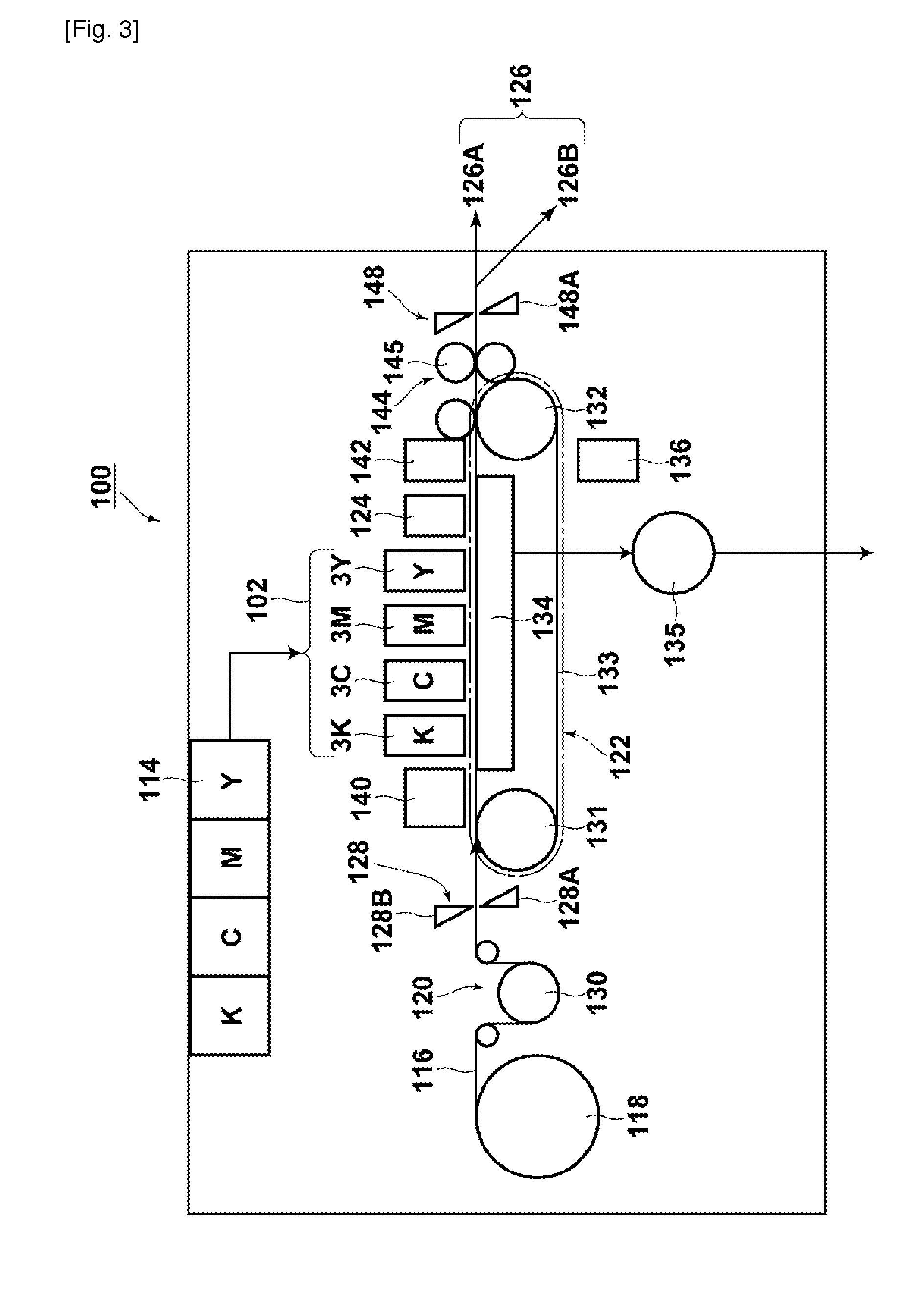

Catalyst system to be used in automobile exhaust gas purification apparatus, exhaust gas purification apparatus using the same and exhaust gas purification method

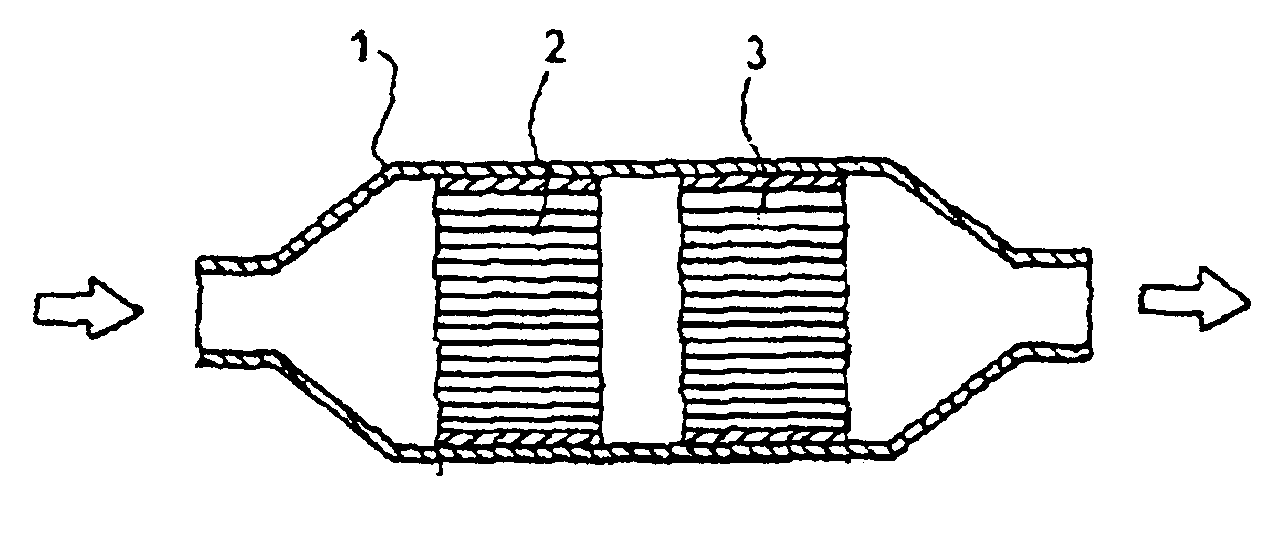

ActiveUS20100061903A1Improve purification effectEfficient purificationCombination devicesNitrogen compoundsPtru catalystNitrogen oxides

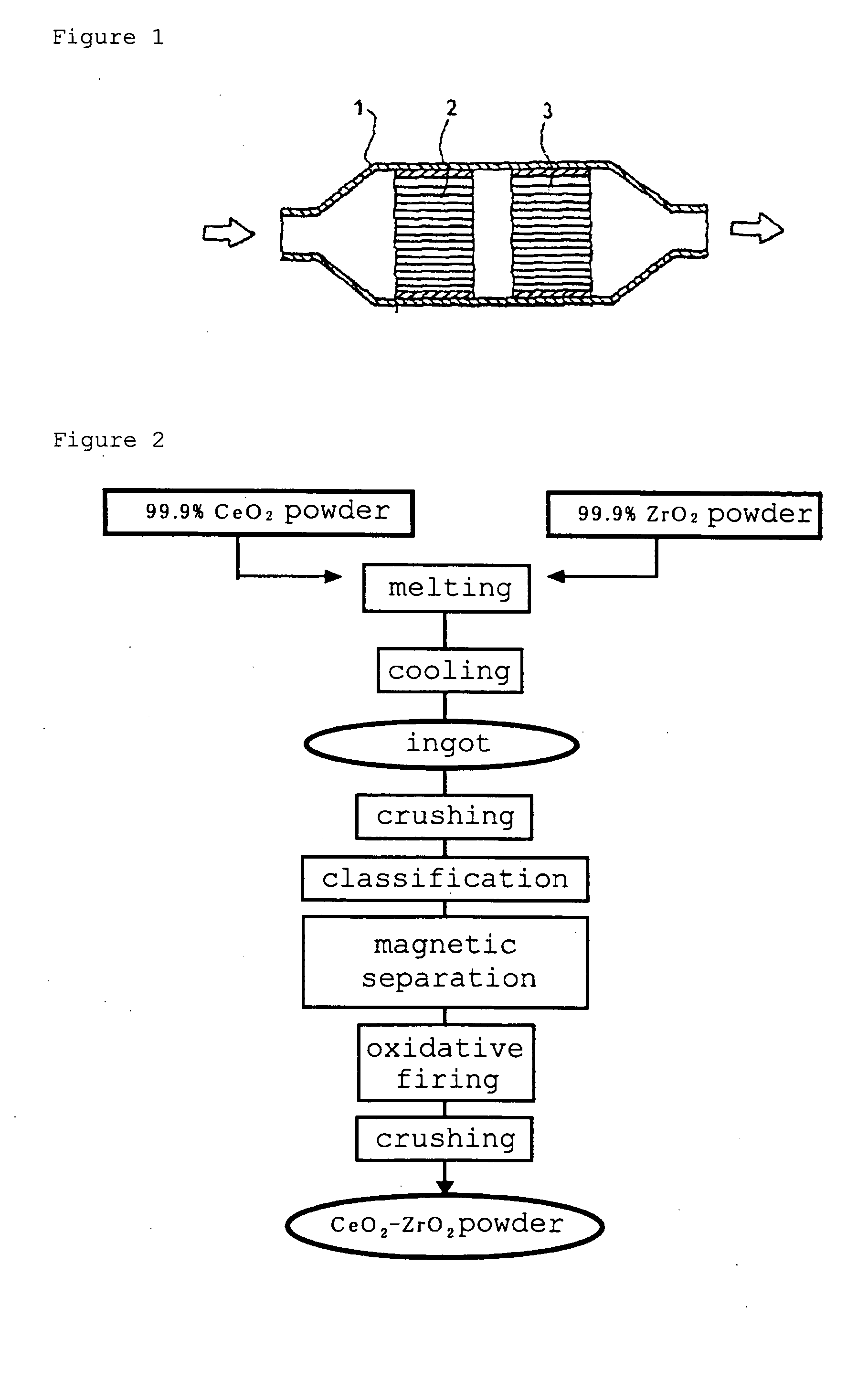

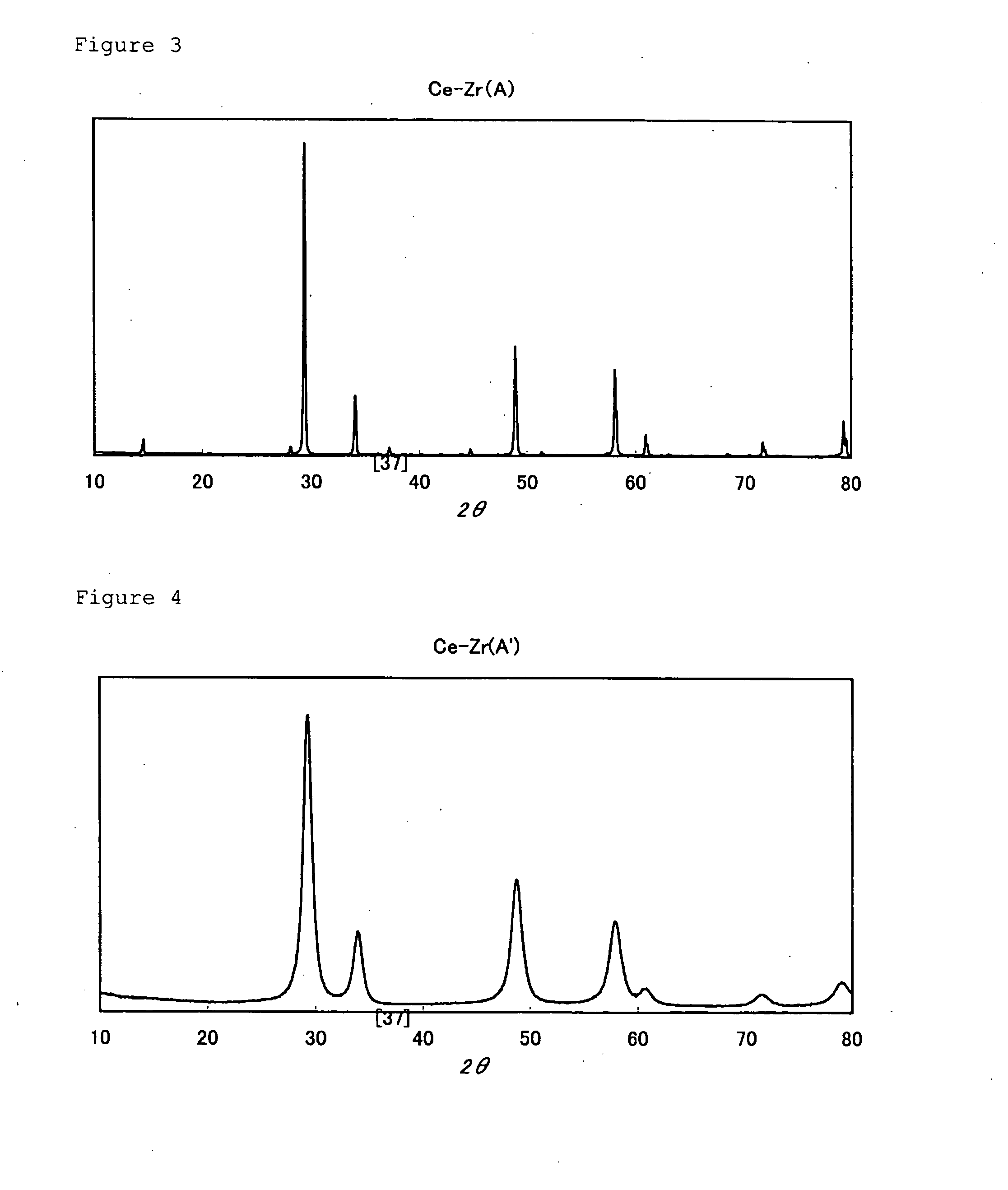

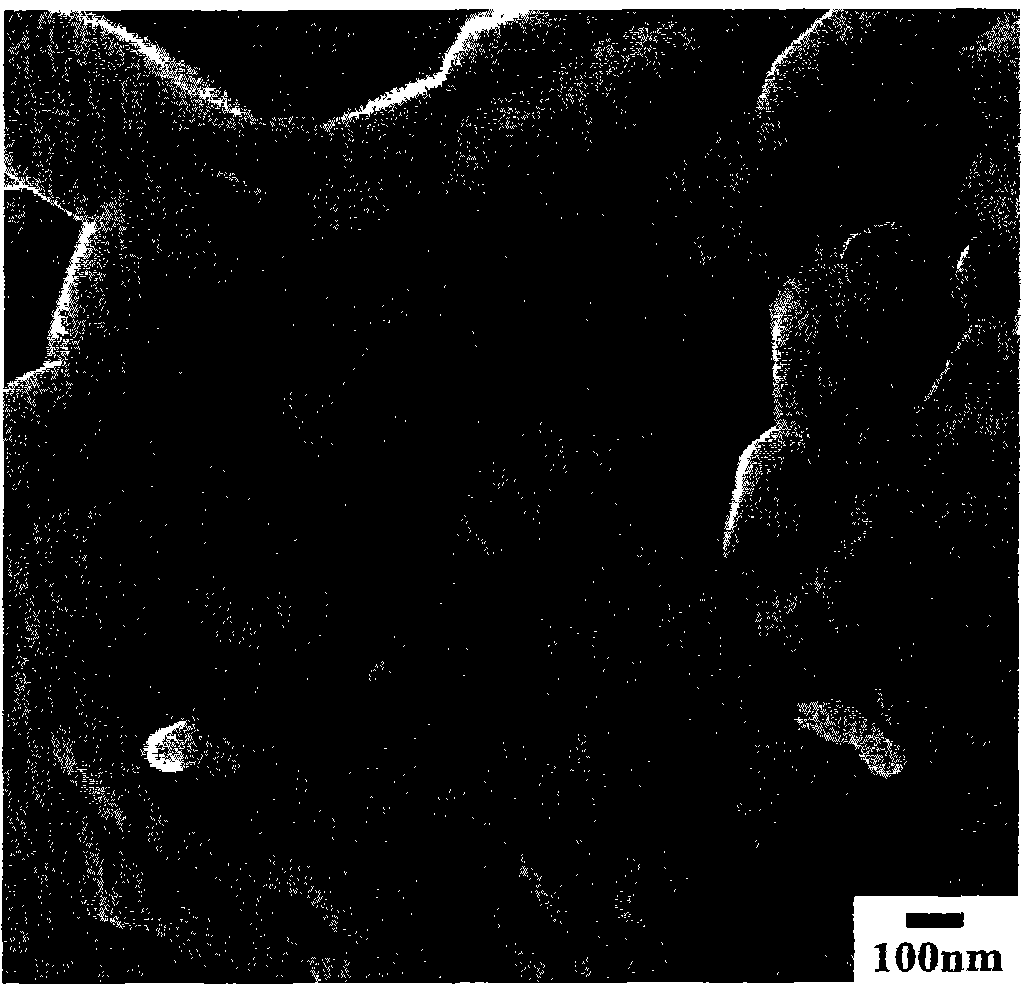

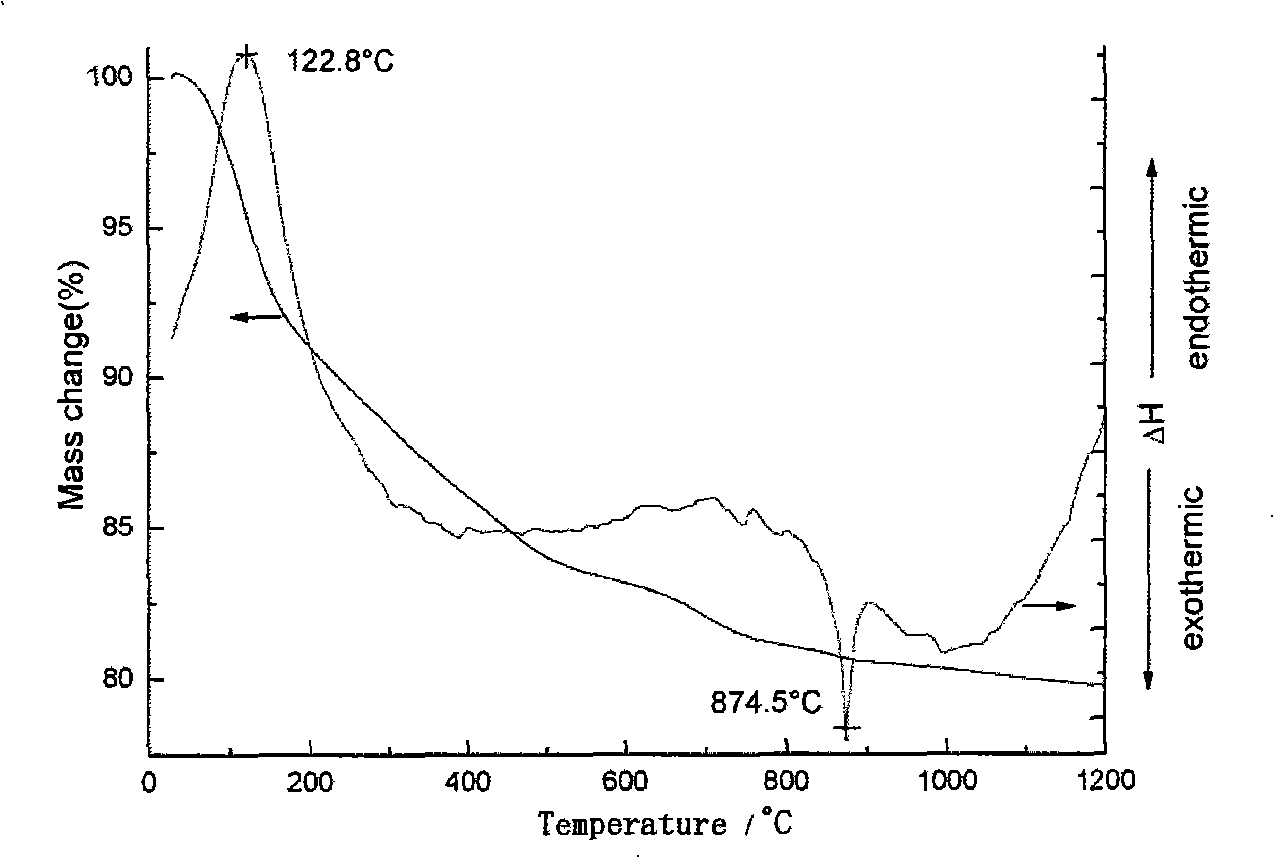

A catalyst system to be used in an automobile exhaust gas purification apparatus which exerts excellent purification capability to a nitrogen oxide, even when hydrocarbon concentration varies, by subjecting exhaust gas discharged from an automotive internal engine to contacting with a catalyst, an exhaust gas purification apparatus using the same, and an exhaust gas purification method.A catalyst system etc. to be used in an automobile exhaust gas purification apparatus, composed by using two or more exhaust gas purification catalysts, containing a first catalyst supported on an inorganic structural carrier and a second catalyst other than this, characterized by having the first catalyst supported on apart of the inorganic structural carrier positioned at the upstream side, when arranged in an exhaust gas passage; on the other hand having the second catalyst supported on a part of the inorganic structural carrier, positioned at the downstream side, when arranged in an exhaust gas passage; and containing a cerium-zirconium-type composite oxide (A) having a pyrochlore phase in the crystal structure.

Owner:DAIICHI KIGENSO KAGAKU KOGYO CO LTD +1

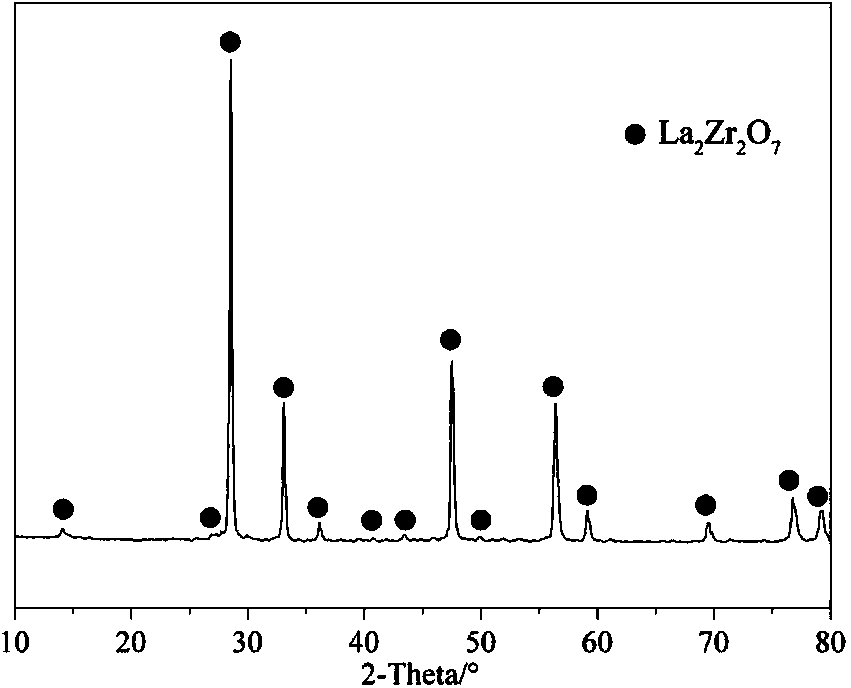

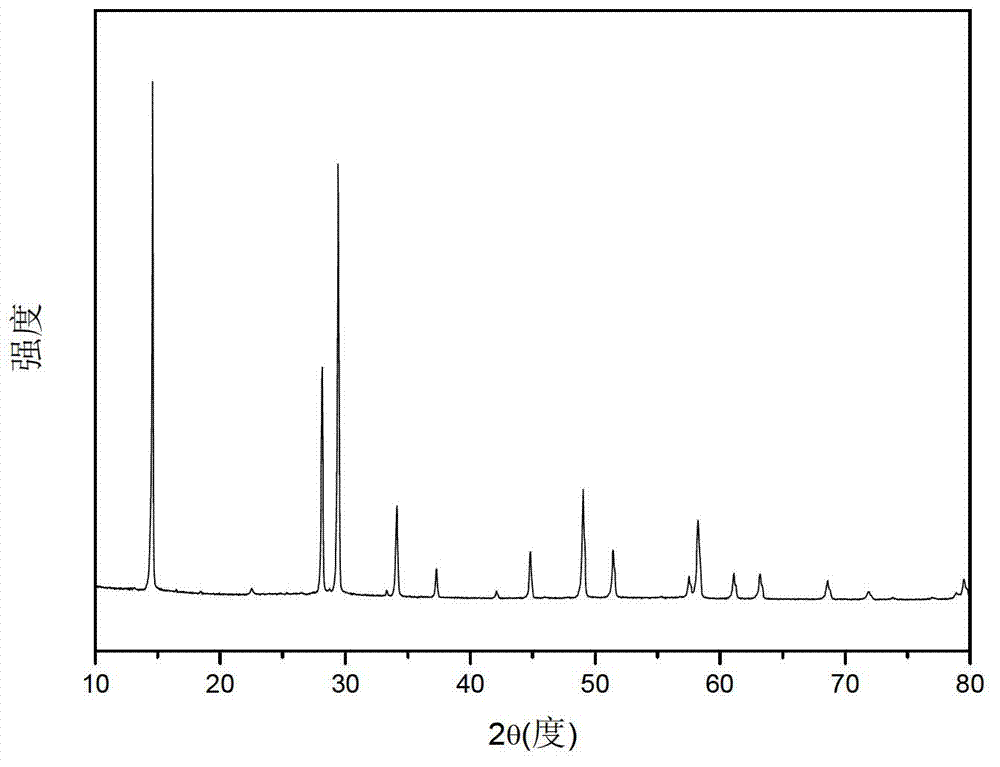

Method for preparing lanthanum zirconate powder

InactiveCN101407336ALow thermal conductivityGood heat insulationZirconium compoundsRare earth metal compoundsSolid reactionPyrochlore

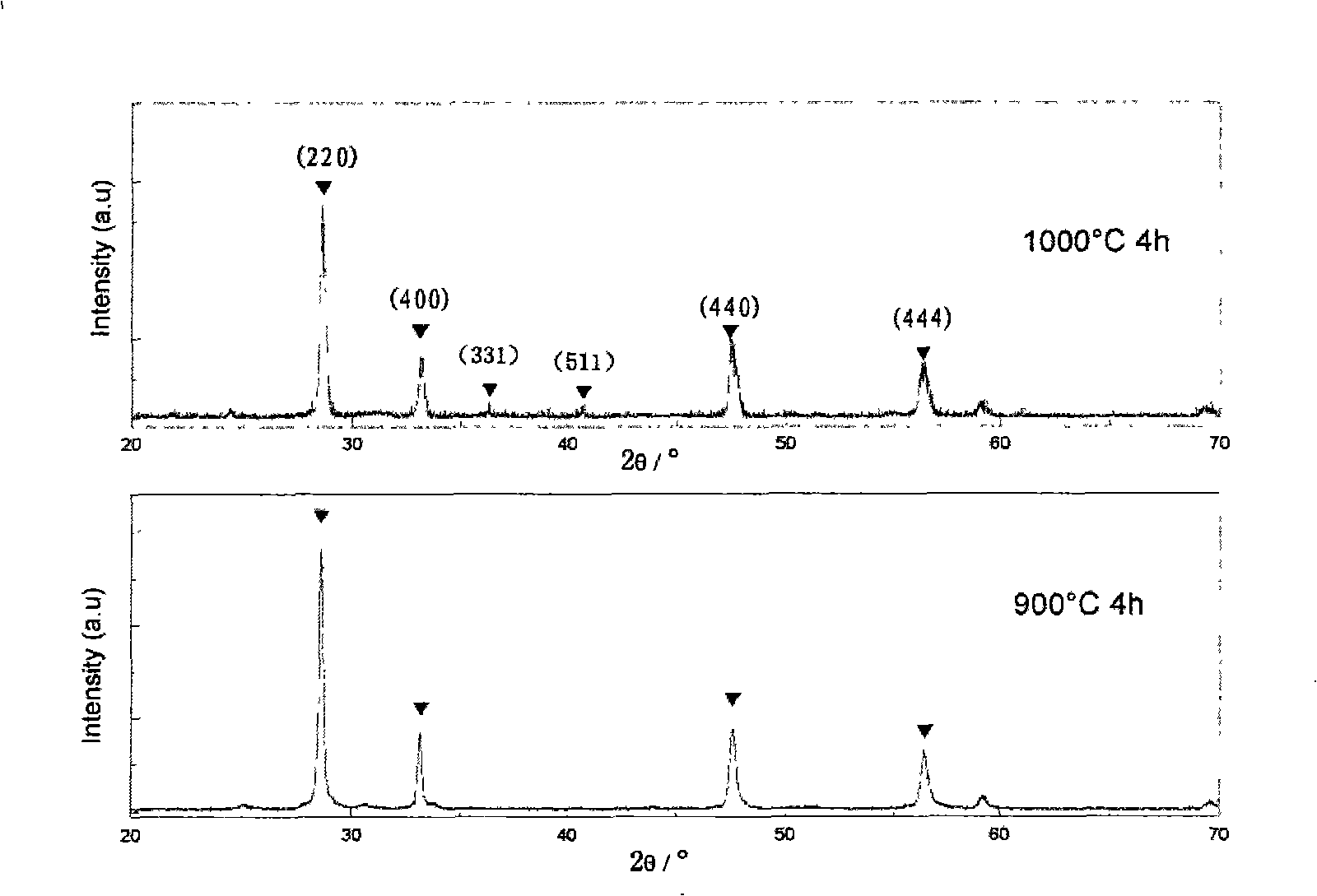

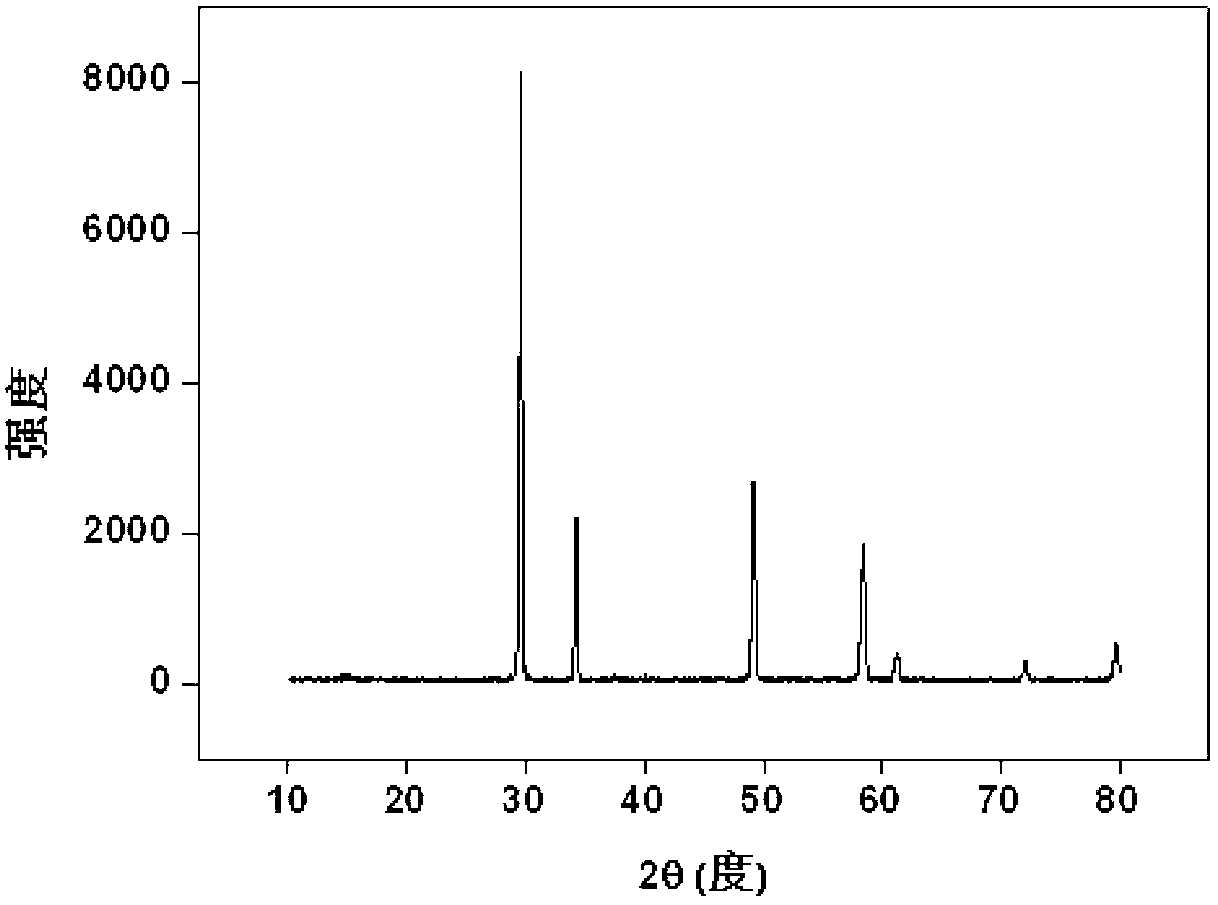

The invention relates to a method for preparing a lanthanum zirconic acid powder, which belongs to the preparation field of ceramic powder used for high temperature heat barrier. The method uses lanthanum oxide or lanthanum soluble salt and zircon salt for respectively preparing the solutions containing La<3+> and Zr<4+>; the two solutions are mixed and dropped into a precipitator (or the precipitator is dropped into the mixing solutions) under continual stirring to obtain precipitate; and the precipitate are washed with a plurality of times, then dried, ground and finally calcined at certain temperature to obtain La2Zr2O7 of defect fluorite structure or pyrochlore constitution. Compared with the existing universal solid reaction process, the method lowers the synthesis temperature by 500-700 DEG C. The heat-insulating property (heat diffusivity) of the obtained power is reduced by about 50 percent compared with YSZ, and reduced by about 40 percent compared with the lanthanum zirconic acid powder obtained by the solid reaction process. The method solves the problems of overhigh heat diffusivity, severe sinter and phase change inefficiency in the existing ceramic materials used for the coating of high temperature heat barrier.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

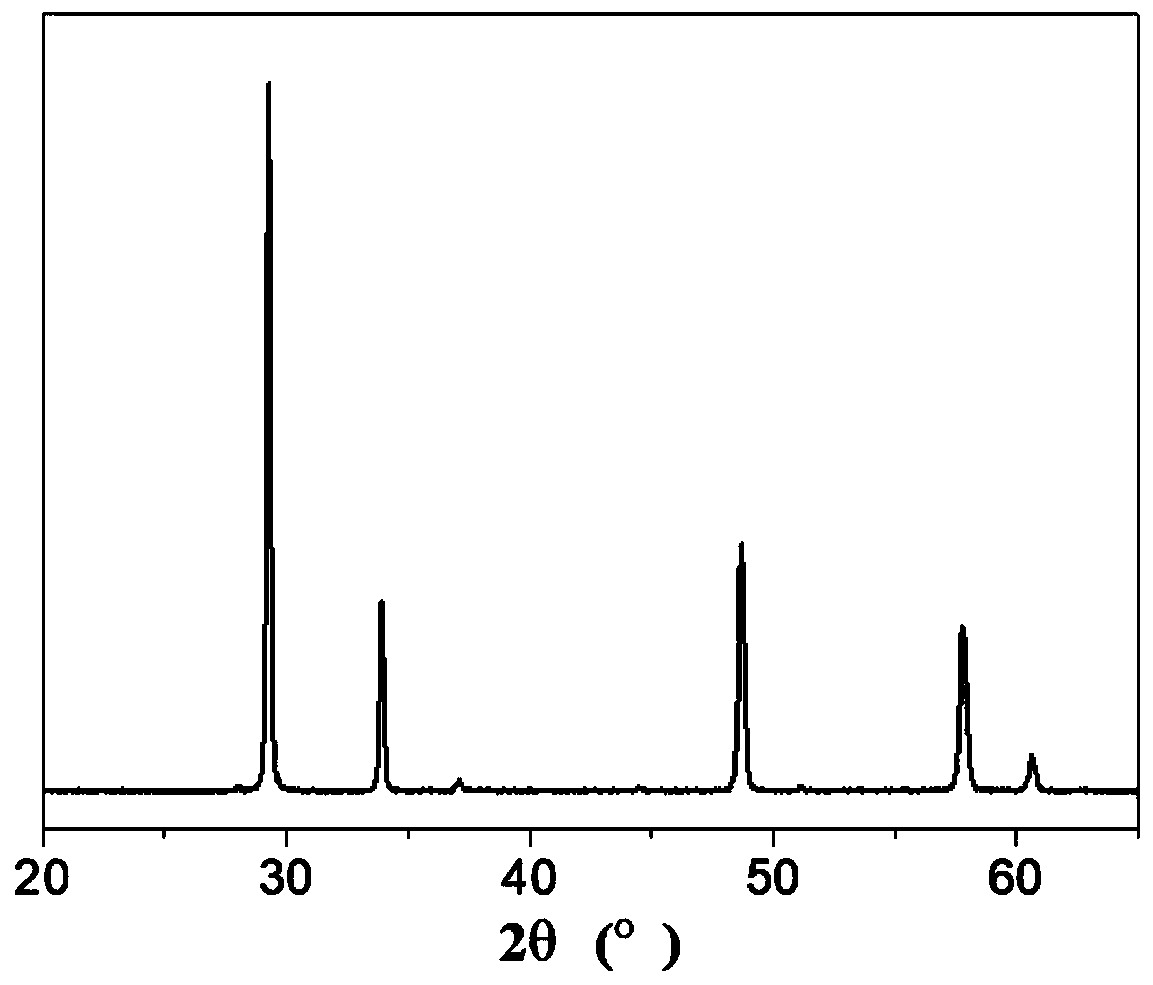

High-entropy ceramic powder used for thermal barrier coating and preparation method of ceramic powder

ActiveCN110272278ALow thermal conductivityImprove lattice distortionAir atmosphereRare-earth element

The invention discloses high-entropy ceramic powder used for a thermal barrier coating. The ceramic powder is characterized by having a pyrochlore structure and a chemical formula of RE2Zr2O7, wherein RE is any 3-7 different metal elements selected from rare earth elements including Y, La, Pr, Nd, Sm, Eu and Gd, and the percentage of one mole number of each RE element to the total mole number of all RE elements is 5%-35%. The preparation method comprises the following steps: mixing RE2O3 powder and ZrO2 powder, and heating the mixed powder under the heating condition of 1000-1700 DEG C for 1-10 h in an air atmosphere to obtain the high-entropy ceramic powder. According to the method provided by the invention, the high-entropy ceramic powder prepared by the method enriches a system of a thermal barrier coating material, has the advantages of low costs, simple and easy operation, a wide application range and the like, and is expected to be used in the field of thermal barrier coatings.

Owner:DONGHUA UNIV

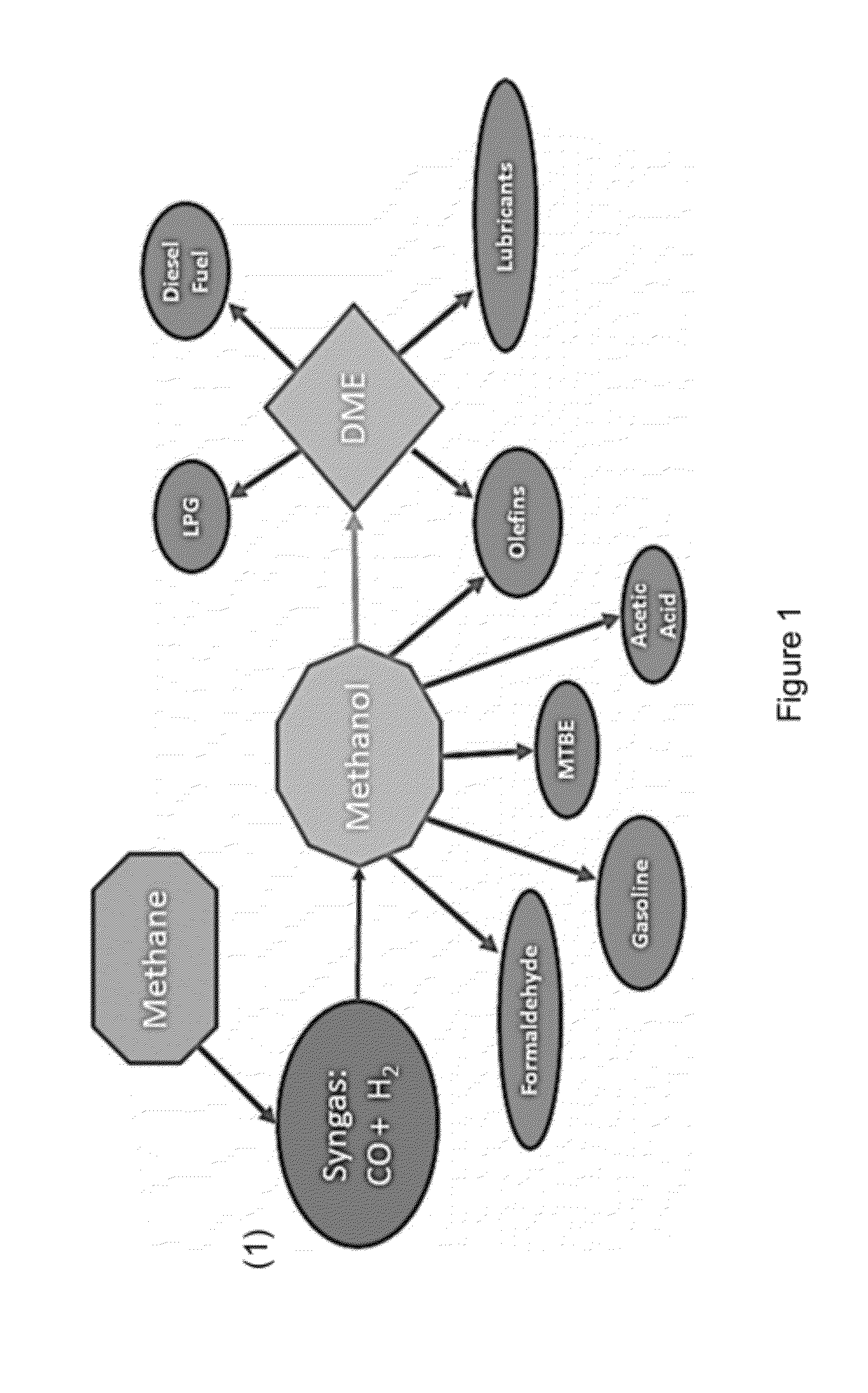

Pyrochlore-type catalysts for the reforming of hydrocarbon fuels

ActiveUS8133463B1Reducing metal sinteringReduce catalyst deactivationHydrogenHydrocarbon from carbon oxidesCatalytic reformingFuel cells

A method of catalytically reforming a reactant gas mixture using a pyrochlore catalyst material comprised of one or more pyrochlores having the composition A2-w-xA′wA″xB2-y-zB′yB″zO7-Δ. Distribution of catalytically active metals throughout the structure at the B site creates an active and well dispersed metal locked into place in the crystal structure. This greatly reduces the metal sintering that typically occurs on supported catalysts used in reforming reactions, and reduces deactivation by sulfur and carbon. Further, oxygen mobility may also be enhanced by elemental exchange of promoters at sites in the pyrochlore. The pyrochlore catalyst material may be utilized in catalytic reforming reactions for the conversion of hydrocarbon fuels into synthesis gas (H2+CO) for fuel cells, among other uses.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

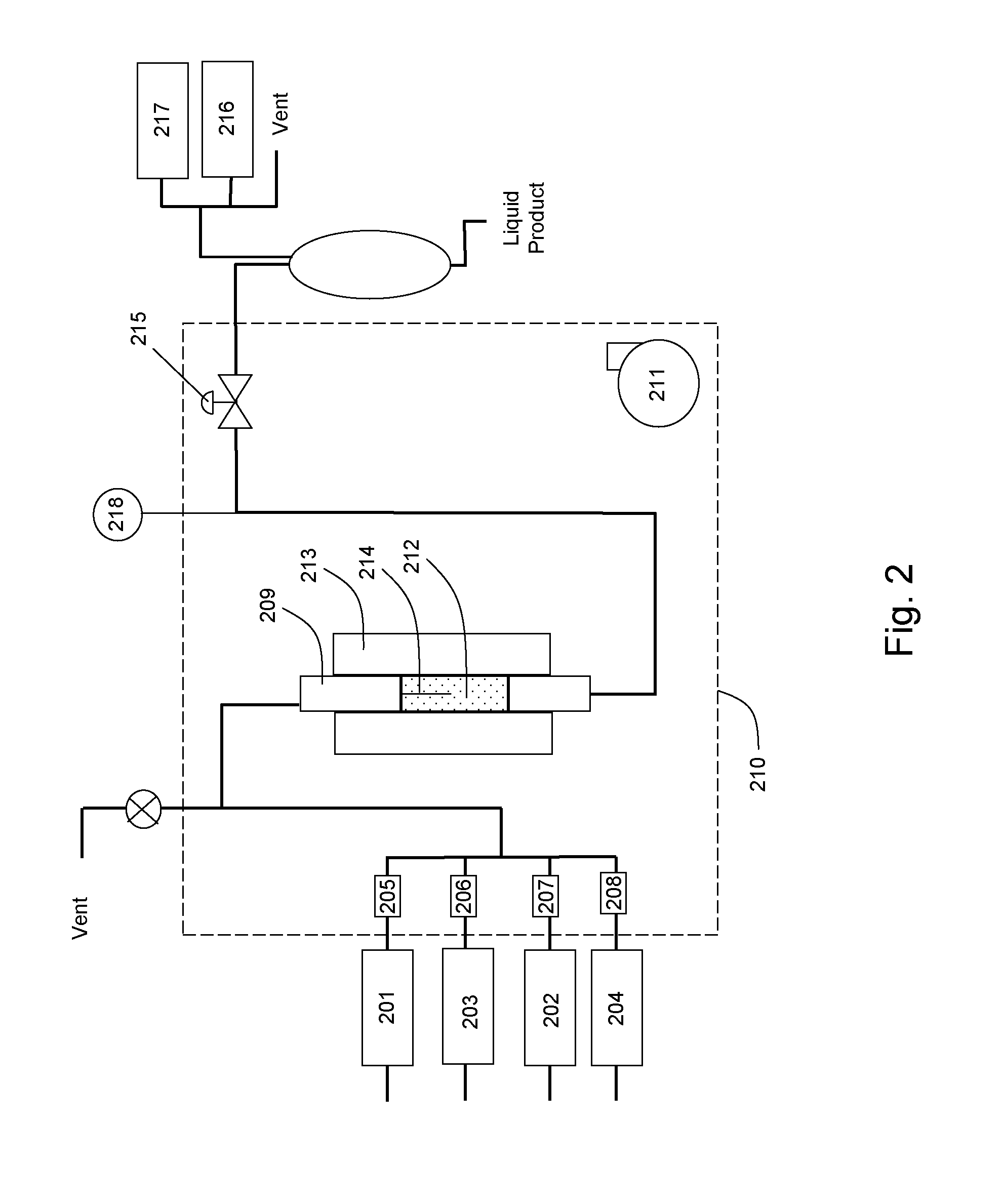

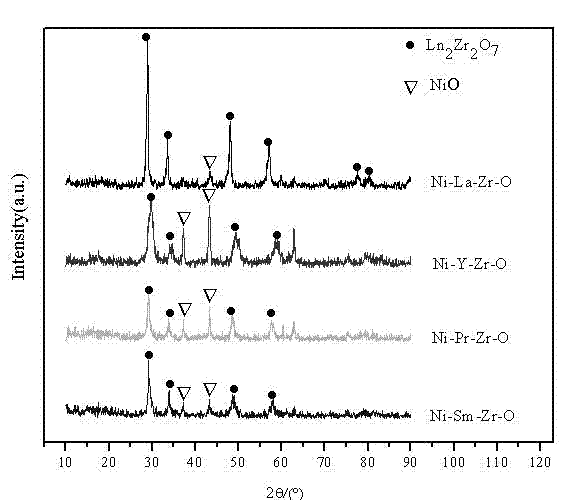

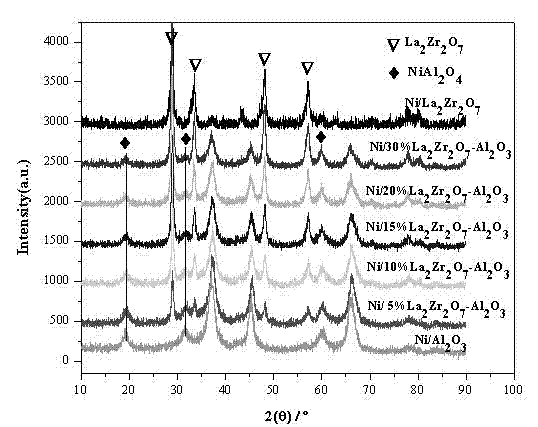

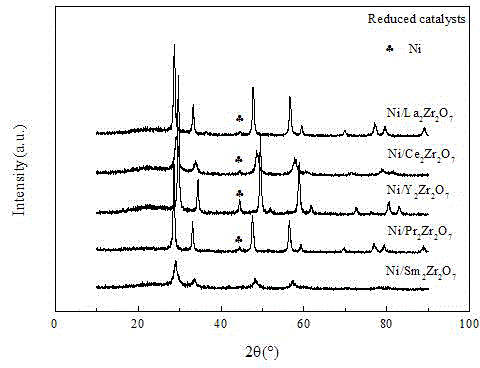

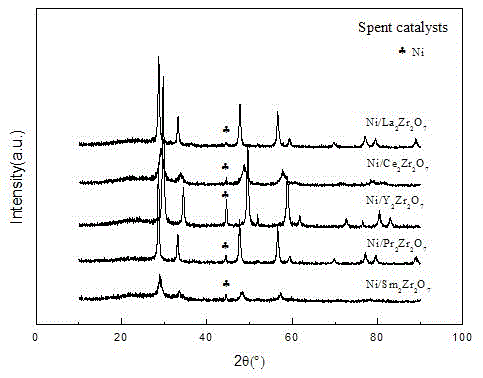

Anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and preparation method thereof

ActiveCN103752319AMeet activityMeet service life requirementsHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

The invention relates to an anti-carbon-deposition Ni-based catalyst for hydrogen production by methane steam reforming and a preparation method thereof. By taking lanthanum nitrate, praseodymium nitrate, samarium nitrate, yttrium nitrate, zirconium nitrate, zirconium carbonate, zirconium oxychloride, and the like as precursors and taking ammonia as a precipitant, a pyrochlore composite oxide is prepared through using a coprecipitation method; and then the pyrochlore composite oxide is mixed with alumina by using a mechanical mixing method so as to obtain a pyrochlore alumina composite carrier. Nickel nitrate, nickel chloride, nickel sulfate, nickel oxalate and the like serving as nickel sources are loaded on the pyrochlore alumina composite carrier through direct immersion. The loading capacity of nickel in the catalyst accounts for 5-30% of the weight of the catalyst, the pyrochlore content of the catalyst is 5-50%, and the alumina content of the catalyst is 20-90%. By taking the pyrochlore alumina composite oxide as a carrier, the reaction activity and anti-carbon-deposition performance of the catalyst can be greatly increased; the preparation method of the catalyst is simple; and the catalyst has excellent catalytic activity and stability to methane steam reforming in a stationary bed.

Owner:NANCHANG UNIV +1

Bismuth-based dielectric material for microwave tuning and preparation thereof

The invention relates to a bismuth-based dielectric material for a microwave tuning component. Through the research on the dielectric tuning mechanism of a bismuth zinc niobate material with a structure of bismuth-based pyrochlore and based on the in-depth understanding of the dielectric tuning mechanism of materials with a bismuth-based pyrochlore structure, the invention provides an assumption and an executive plan to strengthen the dielectric tunable characteristics of the materials with the bismuth-based pyrochlore structure, and discloses a dielectric material for microwave tuning and a method for preparing the same. The chemical composition of the bismuth-based dielectric material for the microwave tuning is Bi1.5MNb1.5O7, wherein M is a bivalent metal cation, the ion radius of the M is smaller than that of Zn; particularly, the M ion is Mg ion, and the chemical formula of the dielectric material is Bi1.5MgNb1.5O7. The invention also discloses a method for preparing the bismuth-based dielectric material for the microwave tuning. The dielectric material of the invention is an excellent dielectric material applied to a voltage-controlled microwave frequency component.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

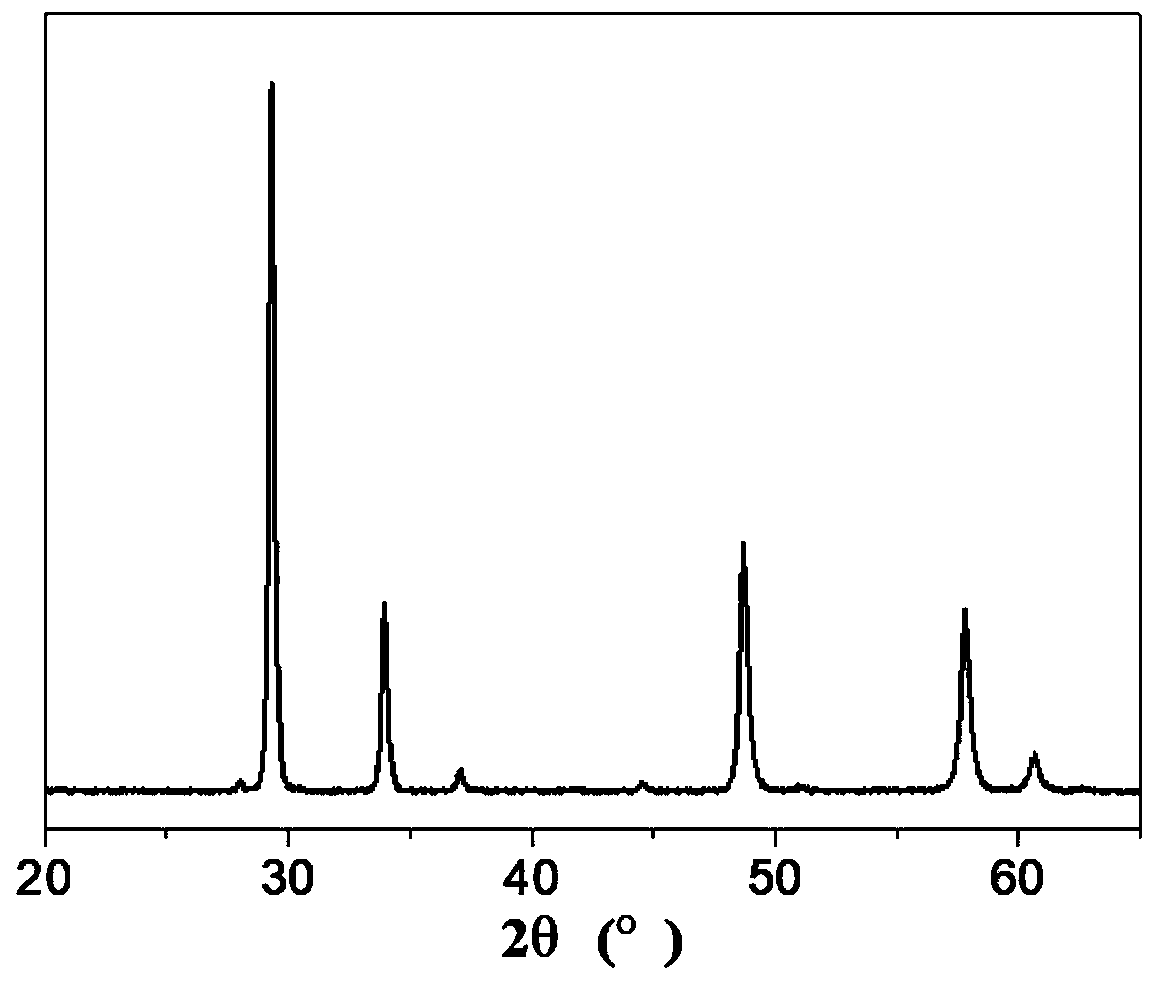

Pyrochlore type high-entropy oxide solidified body and preparation method thereof

ActiveCN111533557AHigh selectivityPromote solid solutionRare-earth elementDeep geological repository

The invention relates to a pyrochlore type high-entropy oxide solidified body and a preparation method thereof. The high-entropy oxide solidified body has a pyrochlore structure, and the chemical formula is RE2M2O7, wherein RE is a rare earth element, and M is a transition metal element. The pyrochlore-type high-entropy oxide solidified body of the invention has excellent chemical stability. Radioactive nuclides of different valence states and types can be solidified in crystal lattices of a high-entropy oxide base material, deep geological disposal is facilitated, , and the system of solidification treatment of base materials for radioactive nuclear waste is enriched. The method is low-cost, is simple and feasible and has a wide application range. The process is high in efficiency and good in safety, and is expected to be applied to the technical field of radioactive nuclear waste treatment.

Owner:DONGHUA UNIV

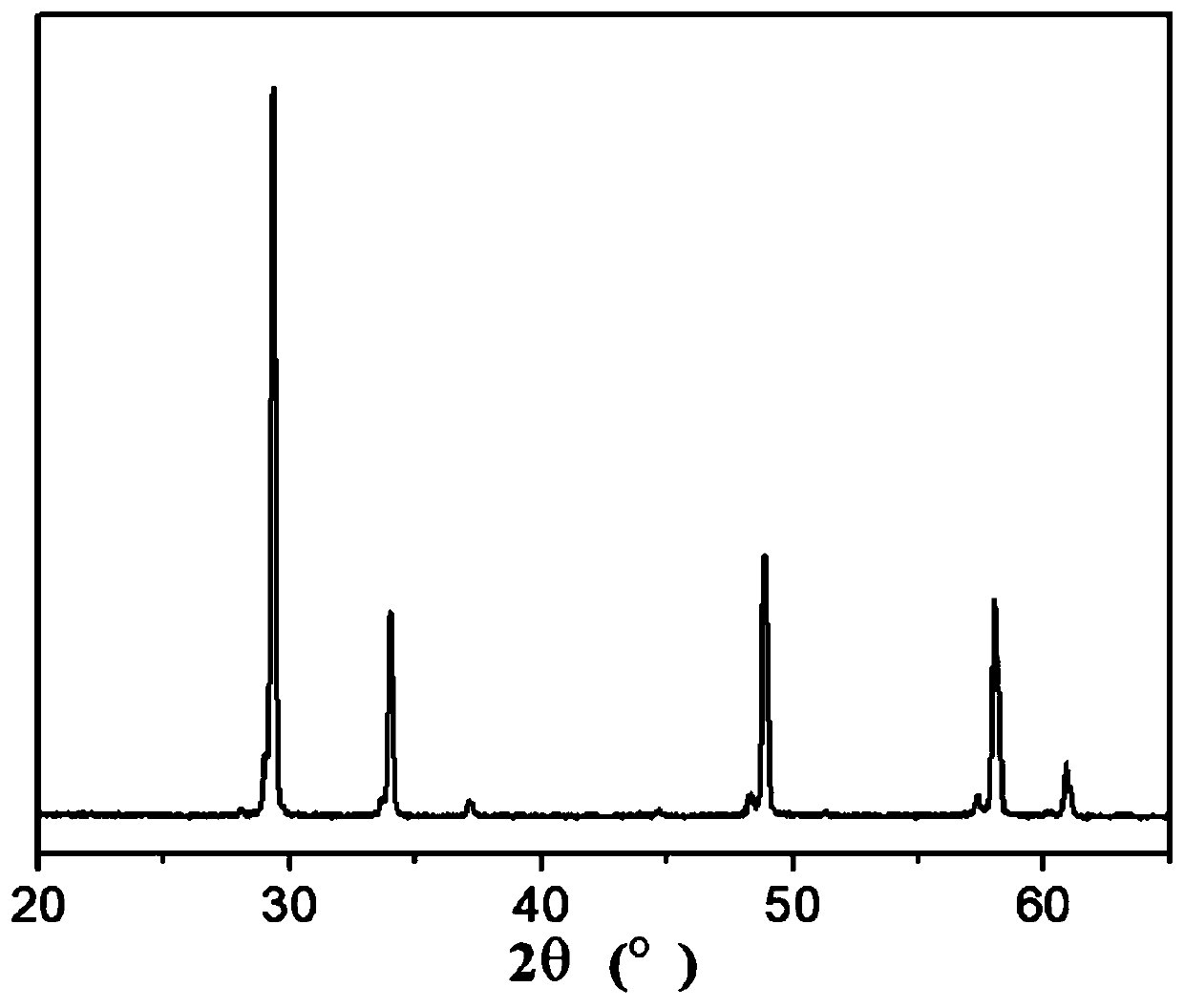

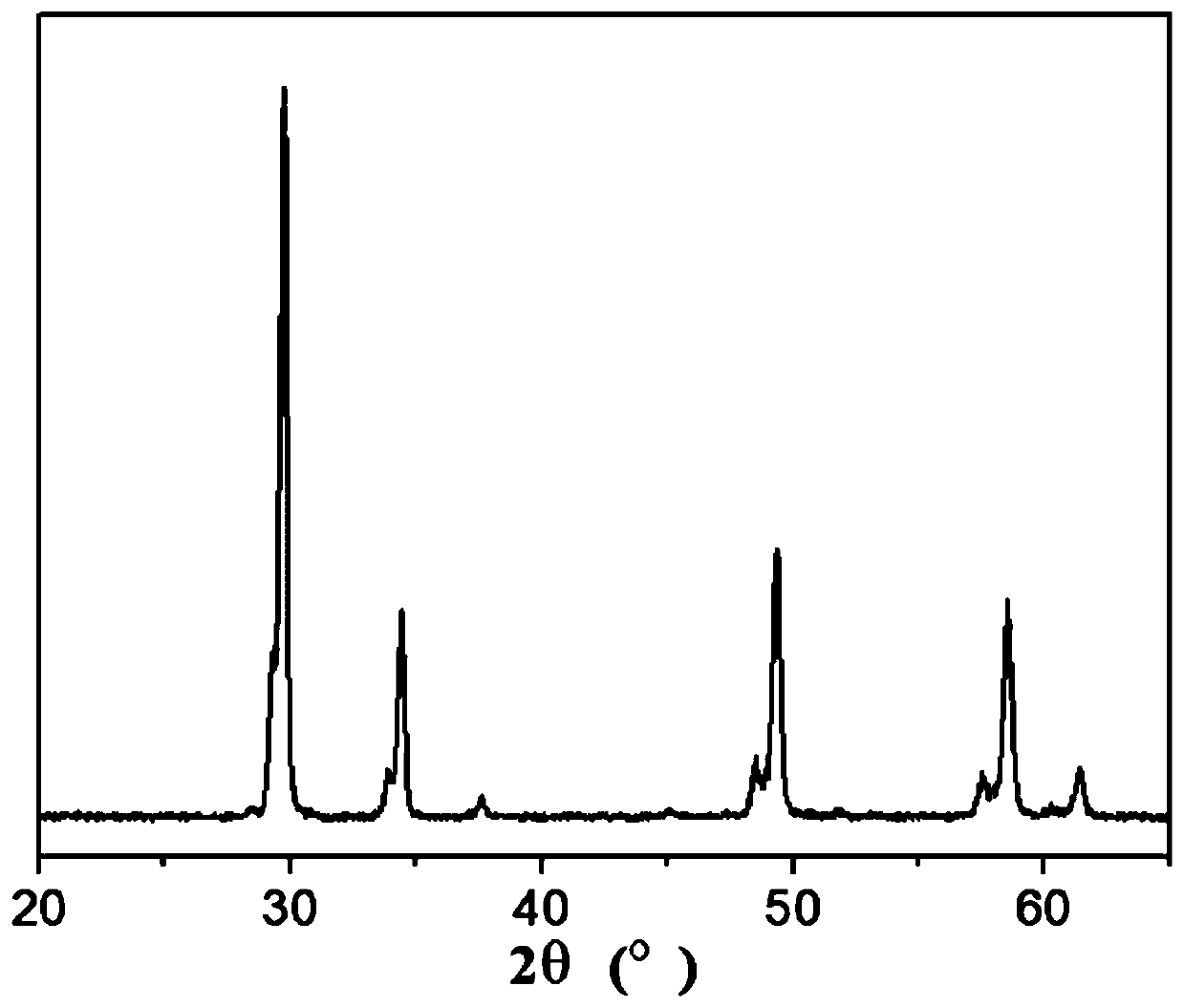

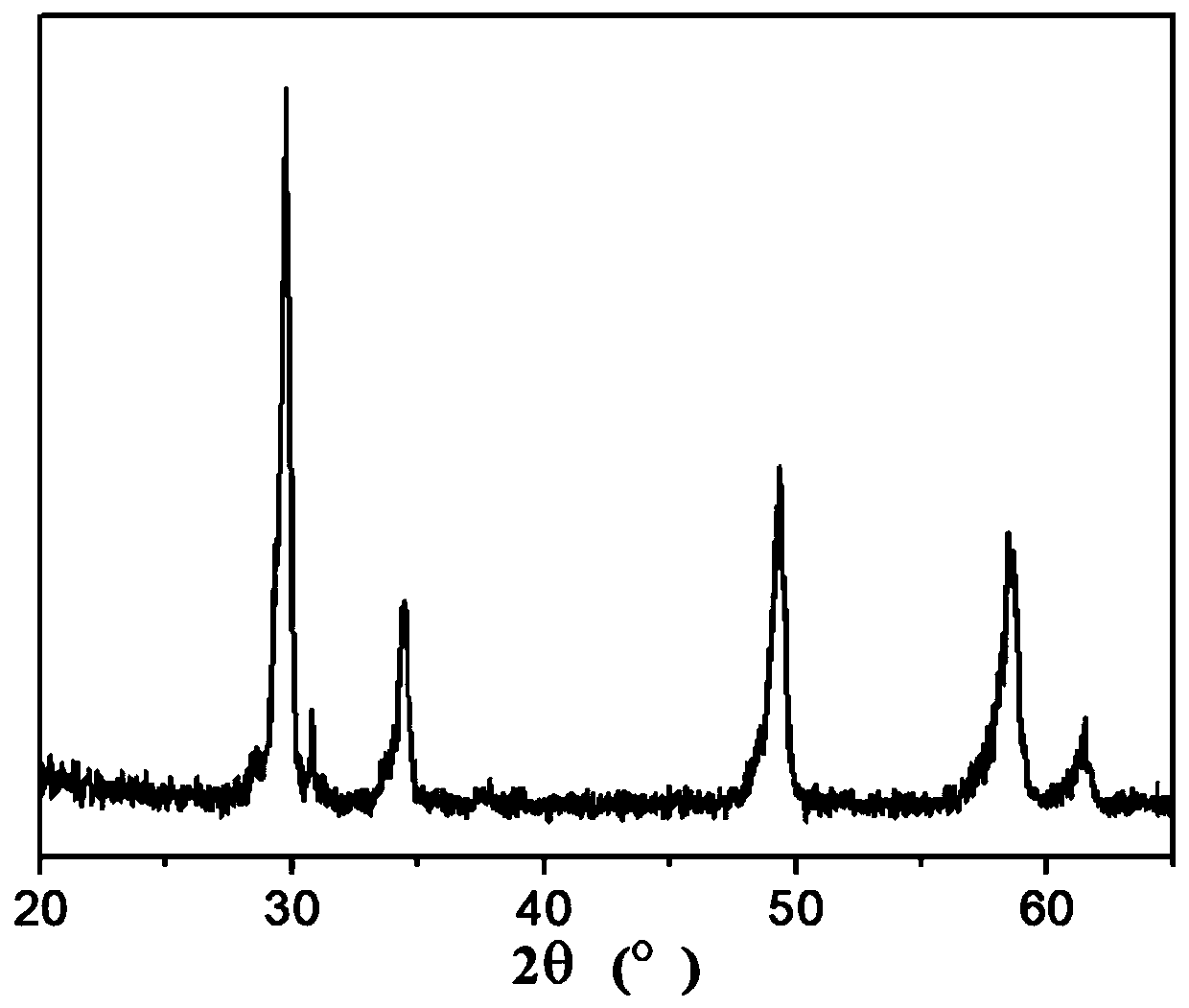

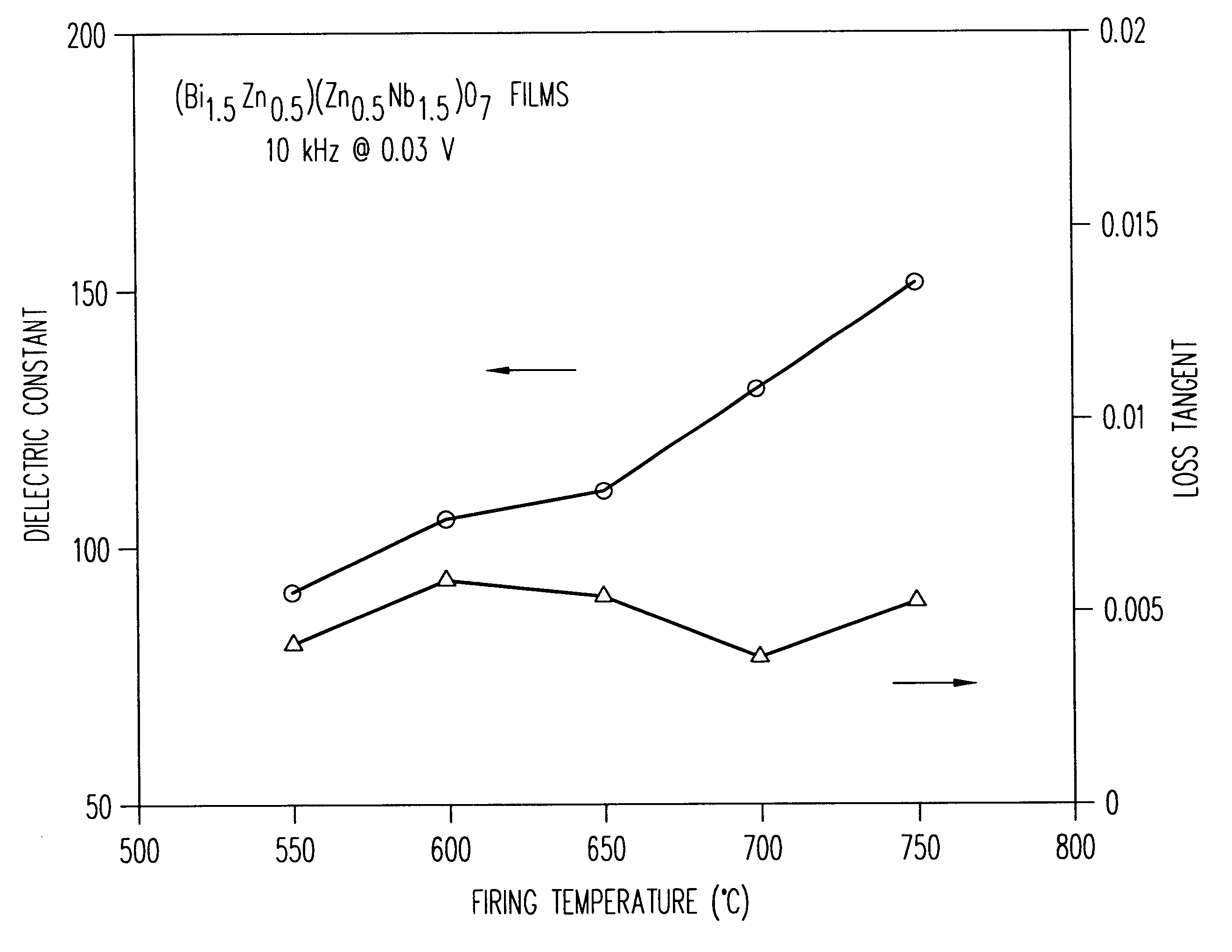

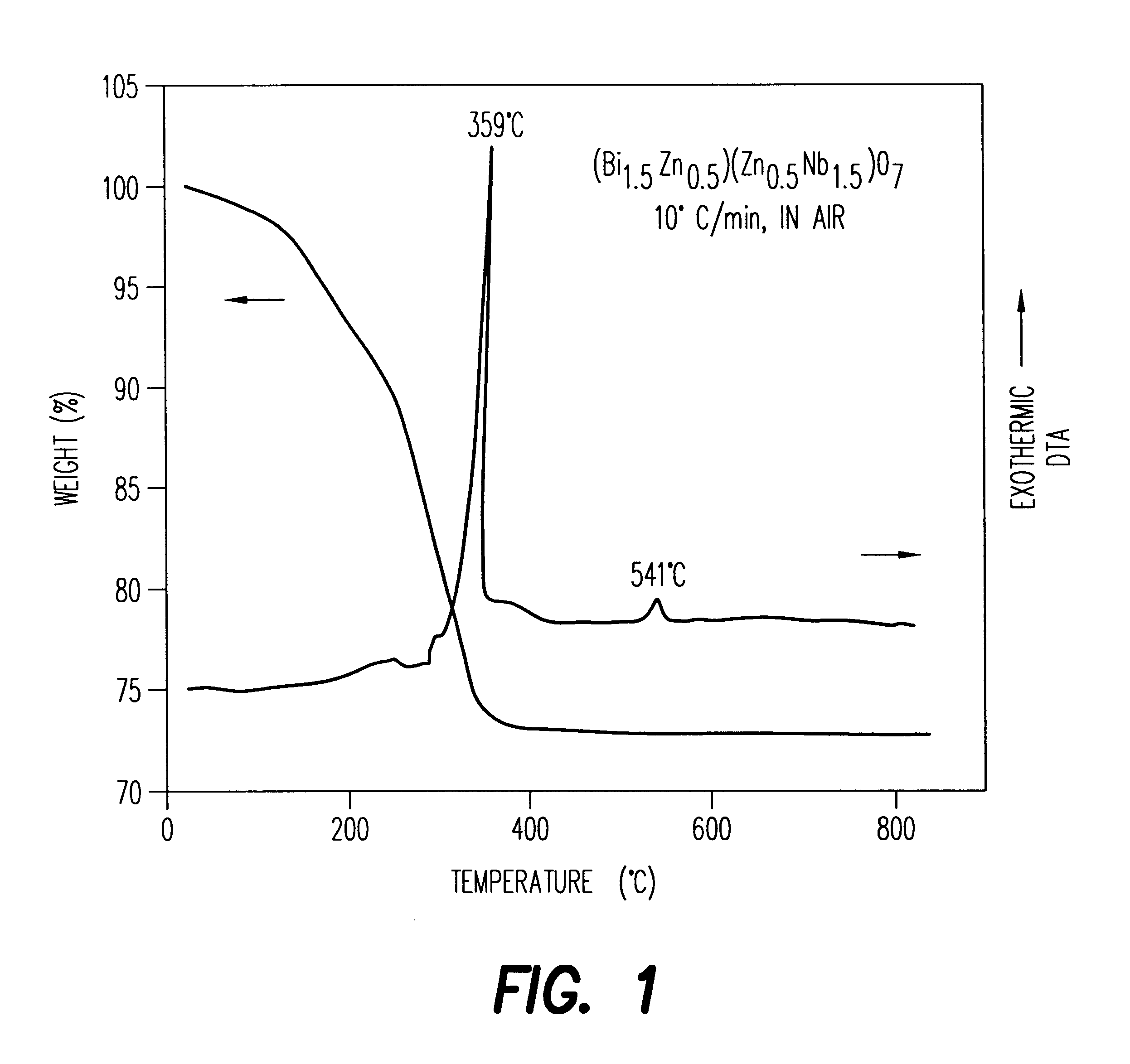

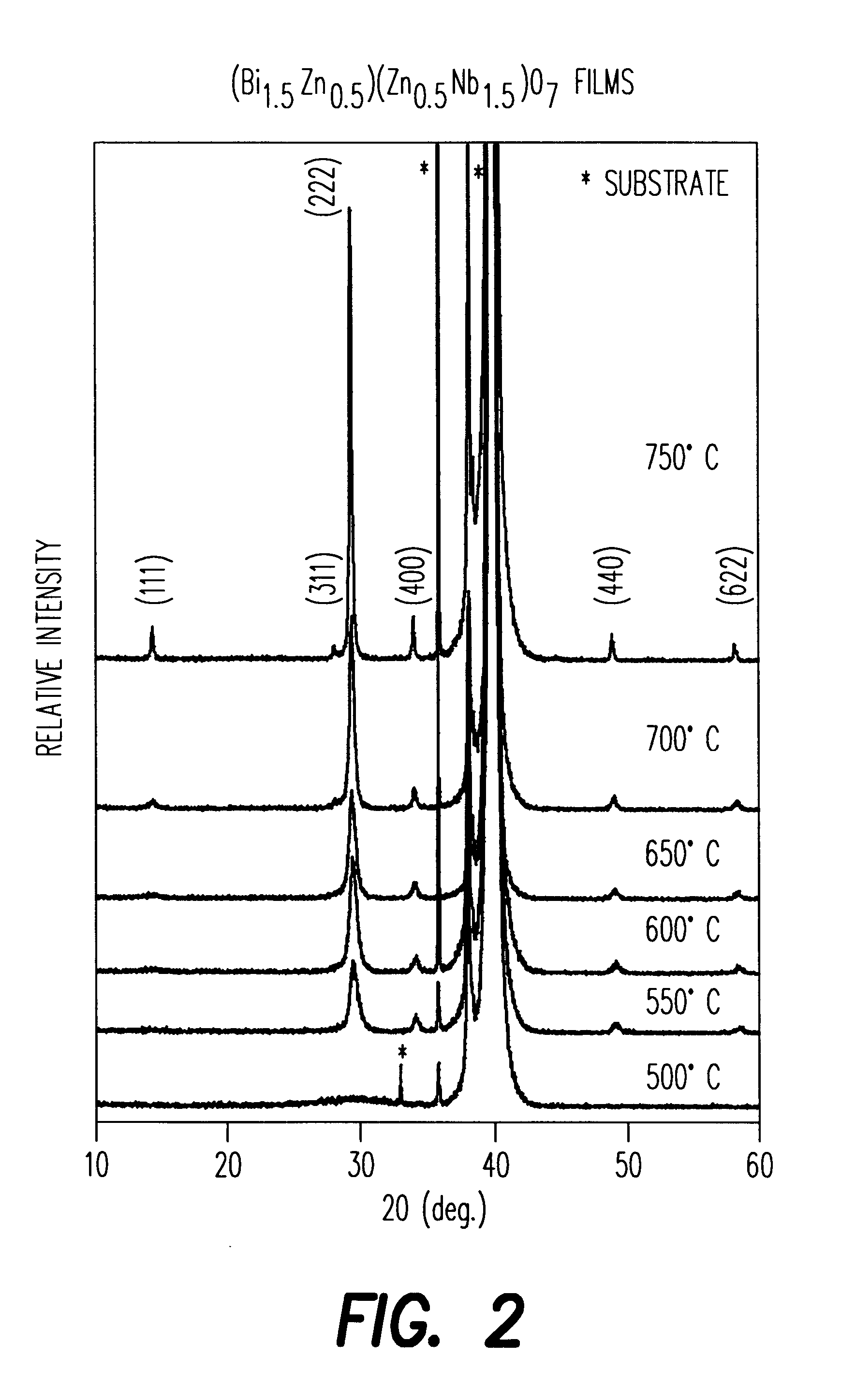

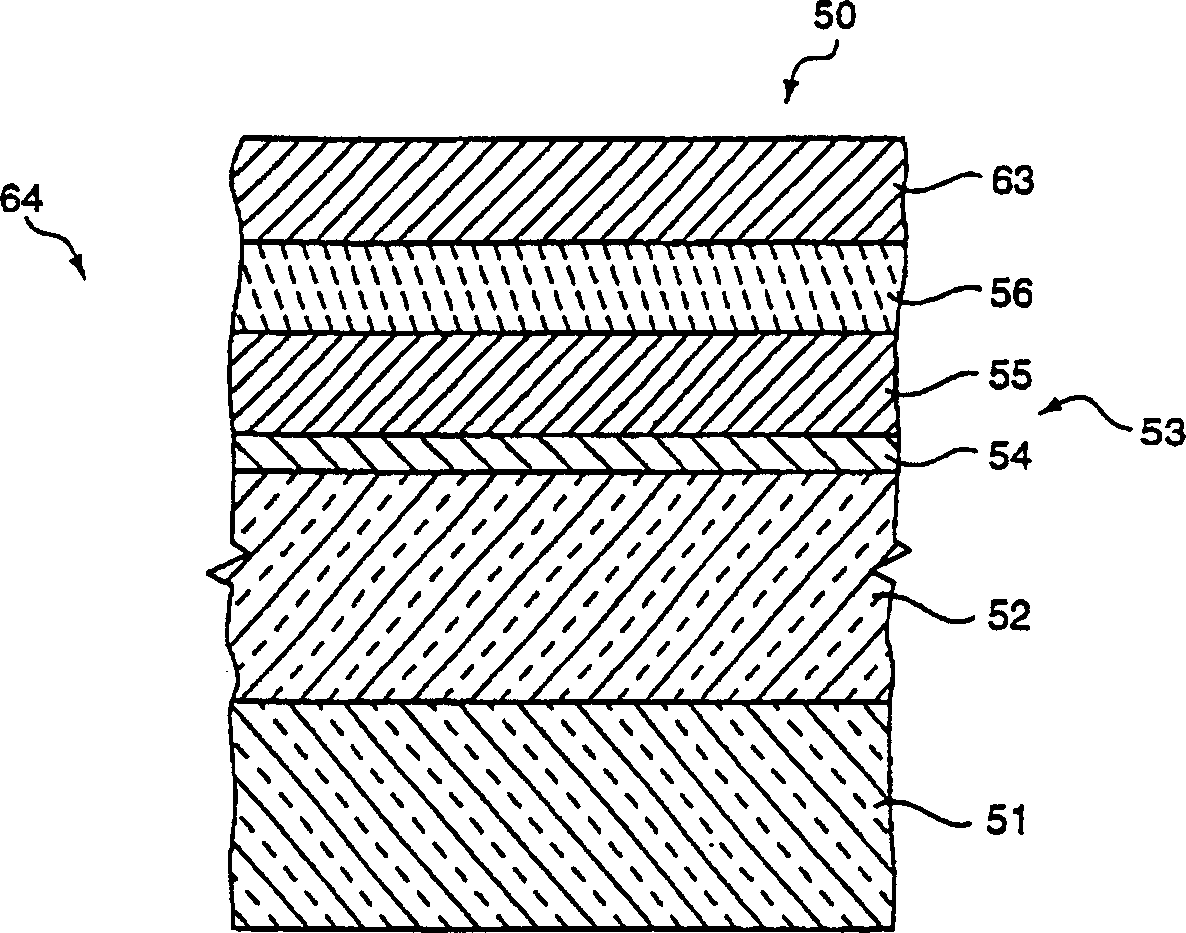

Pyrochlore thin films and process for making

A thin film comprising a pyrochlore represented by the formula:wherein x is from about 0.45 to about 0.73 and an article comprising a substrate and, coated on the substrate, a thin film of the pyrochlore are provided. Also provided is a process for depositing on a substrate the above pyrochlore thin film. The process includes the steps of coating the substrate with a composition comprising bismuth carboxylate, zinc carboxylate, niobium alkoxide, an organic solvent, an organic acid and an organic base, heating to remove organic components and annealing at a temperature and for a length of time sufficient to produce the pyrochlore thin film on the substrate.

Owner:PENN STATE RES FOUND

Composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of diesel vehicle and preparation method thereof

InactiveCN101879445AHigh selectivityThe synthesis process is simpleDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare earthPyrochlore

The invention provides a composite rear earth pyrochlore-type oxide catalyst for catalyzing burning for removing soot of a diesel vehicle and a preparation method thereof, belonging to the technical field of a tail gas cleaning catalyst of the diesel vehicle. The expression formula of the composite metal oxide is A2B2-xMxO7, wherein A is La, B is Sn, M is Mn, Fe, Co, Ni or Cu. The invention adopts a coprecipitation method to prepare the catalyst, the preparation process is simple, and the cost is low. The preparation method comprises the following steps: mixing metal nitrate and tin tetrachloride solution; adjusting the pH value by ammonia solution; drying the obtained deposit; and roasting the deposit at the high temperature to obtain the composite rear earth pyrochlore-type oxide catalyst. Under the effect of the catalyst, a simulation diesel vehicle exhausts, the burning temperature of the soot particles is lowered to the exhaust range of the diesel vehicle, and the speed of the soot oxidation rate is improved. The catalyst is a useful catalyst for removing the pollution of soot particles of the diesel vehicle.

Owner:UNIV OF JINAN

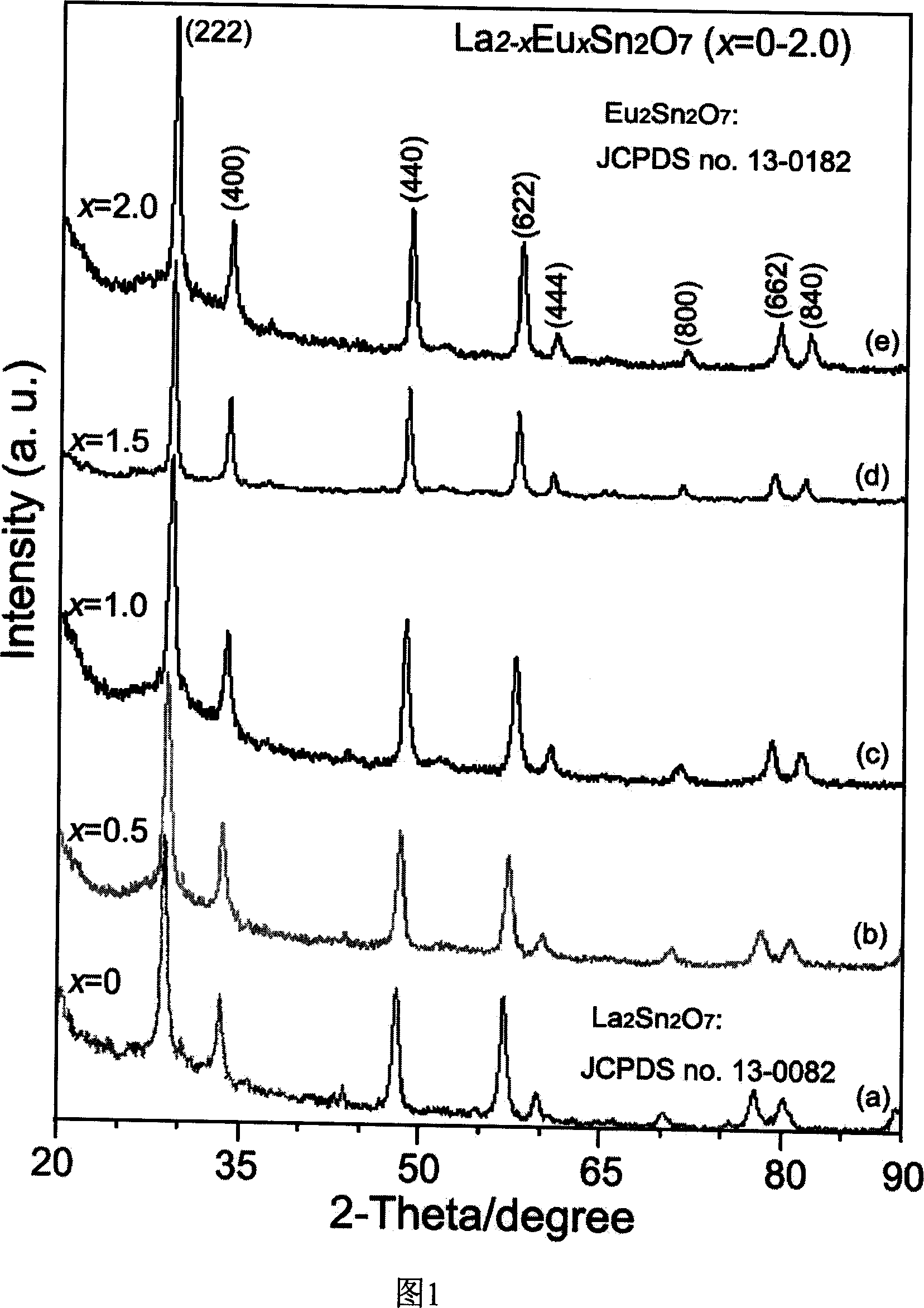

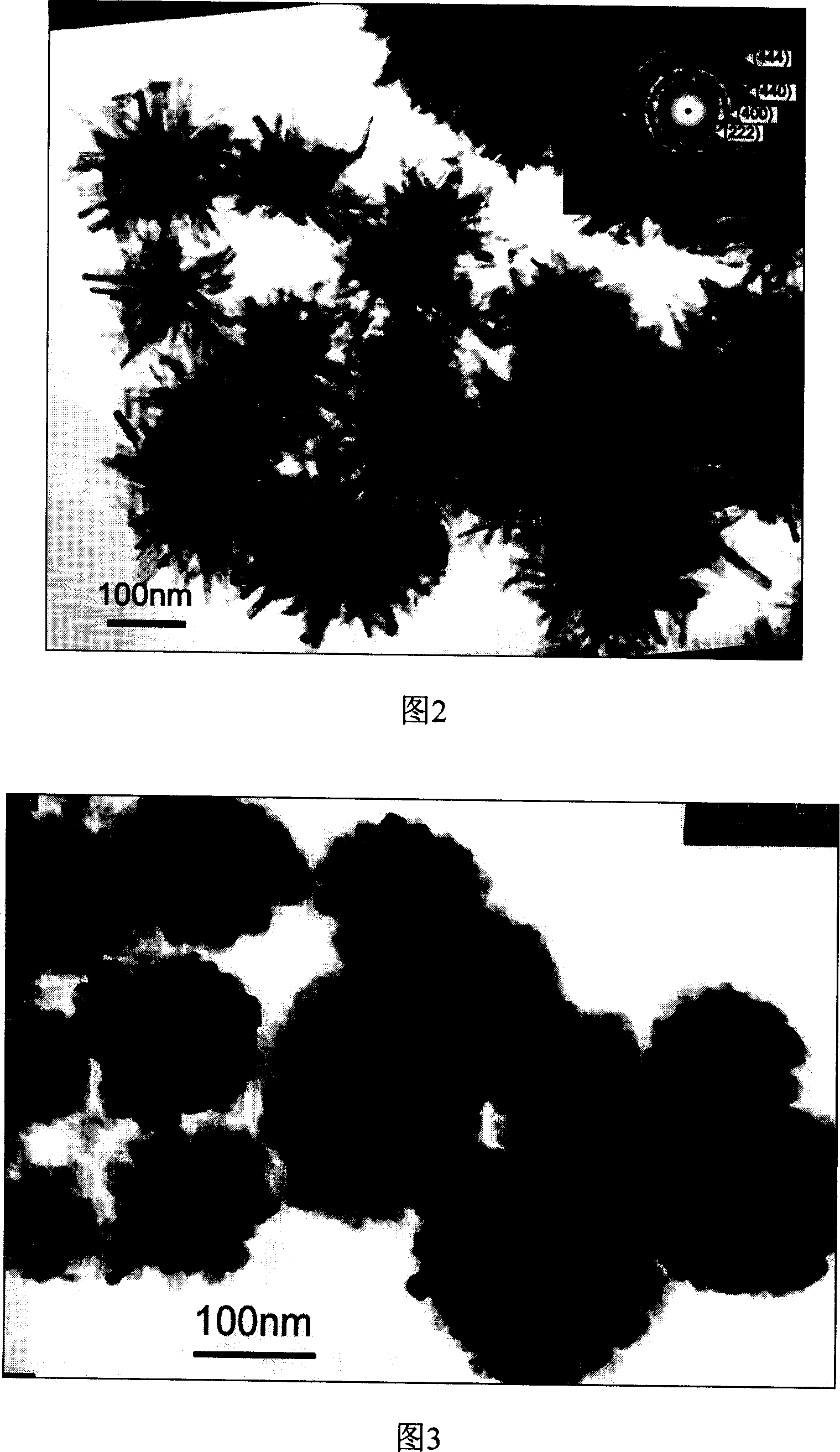

Lanthanum stannate, europium stannate and its composite stannate nanopowder synthesis method

InactiveCN1951822AAchieve synthesisThe ratio can be adjusted arbitrarilyTin compoundsRare earth metal compoundsRare earthPotassium

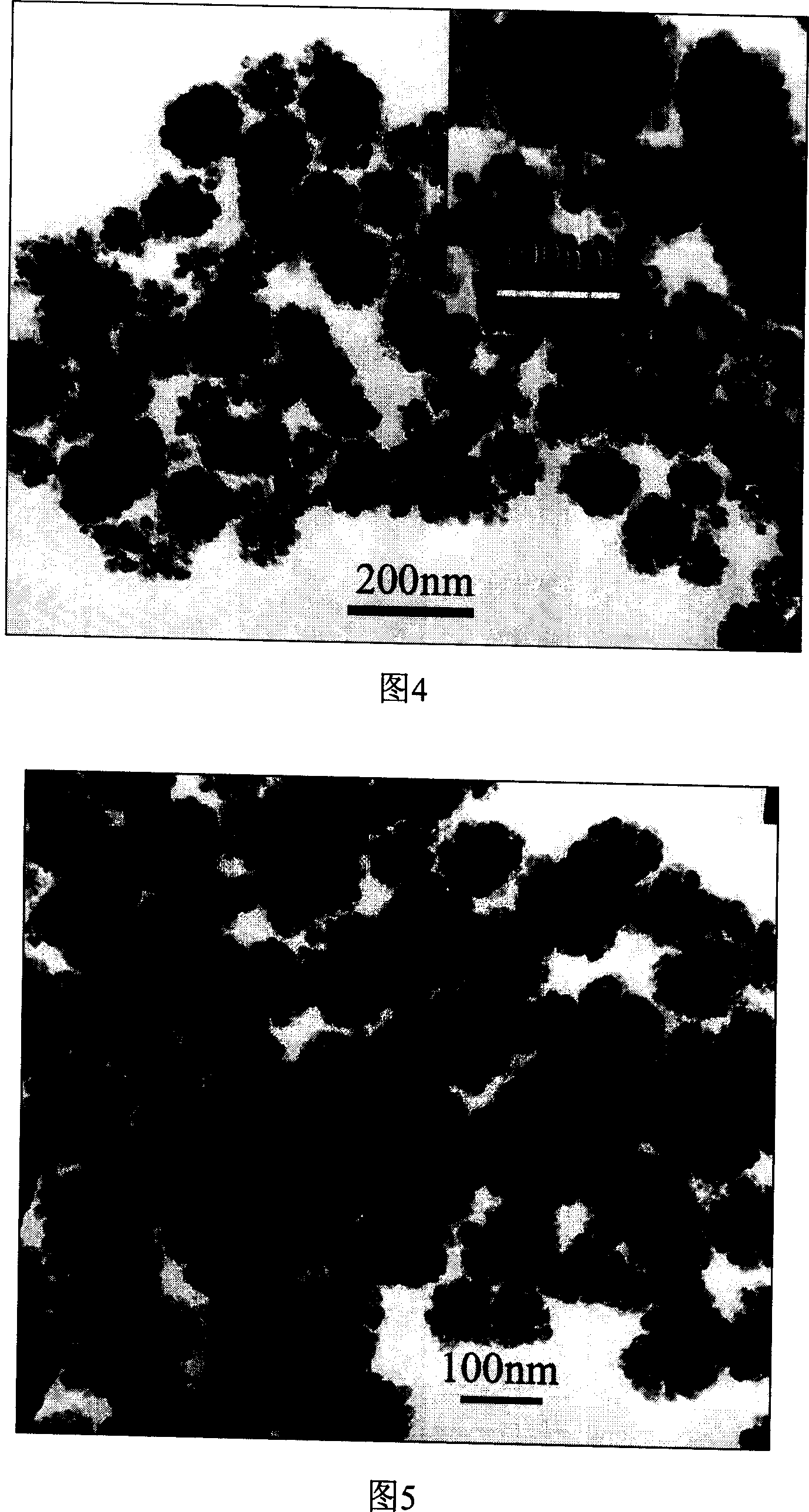

The invention discloses a synthesizing method of lanthanum stannate, europium stannate and composite stannate nanometer powder, which comprises the following steps: dissolving lanthanum stannate and europium stannate with different molar rates or lanthanum stannate or europium stannate in the deionized water; stirring; adding sodium stannate or potassium stannate with the molar weight as the sum of lanthanum stannate and europium stannate in the solution; stirring; putting terminal solution into high-pressure autoclave; setting the filling density at 80-90%; disposing for 4-30h within 180-250 deg.c through hot water; centrifuging the disposed solution; cleaning; drying the product; obtaining the product with diameter at 15-35nm. The molecular formula of the product is La2-xEuxSn2O7 (x=02), which produces single and one-phase product.

Owner:ZHEJIANG SCI-TECH UNIV

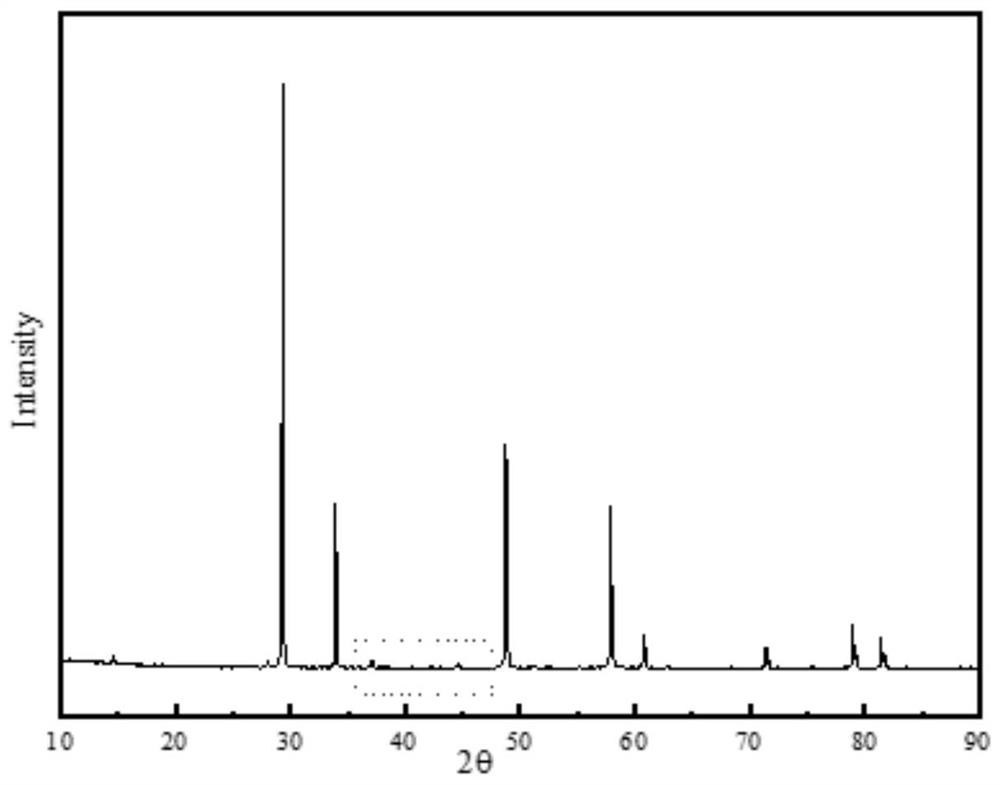

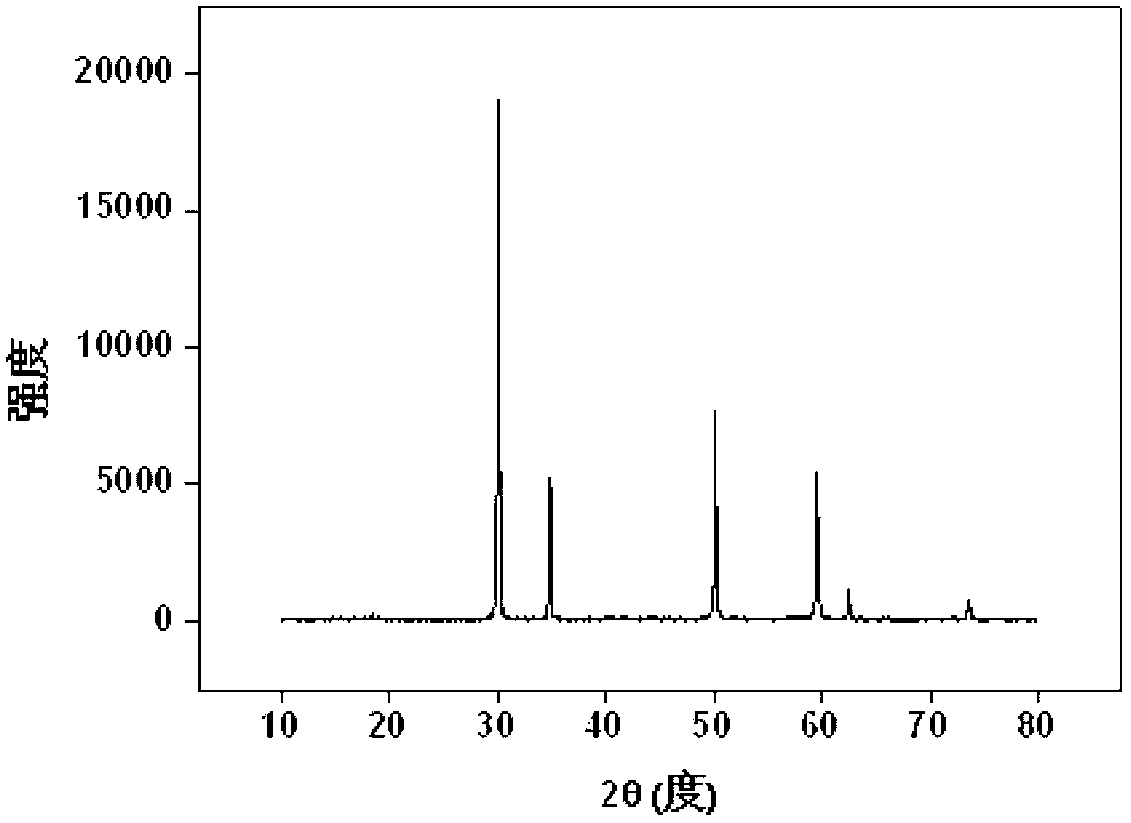

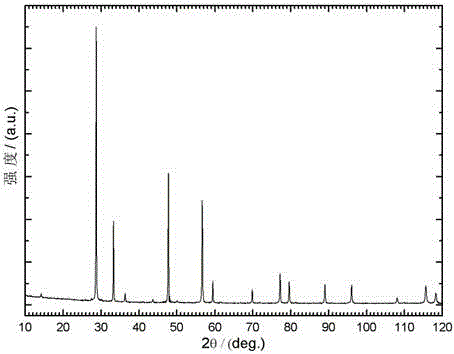

High-temperature and high-pressure rapid synthesis method of Gd2Zr2O7 pyrochlore ceramic

The invention discloses a high-temperature and high-pressure rapid synthesis method of Gd2Zr2O7 pyrochlore ceramic, which comprises the five steps of: batching, grinding, drying, dry pressing and high-temperature and high-pressure synthesis. The high-temperature and high-pressure rapid synthesis method has the beneficial effects that within the wide pressure and temperature scope, a multi-component oxide mixture is taken as a raw material, the synthesis of a Gd2-xAxZr2-yByO7 (x is more than or equal to 0 but less than or equal to 2, and y is more than or equal to 0 but less than or equal to 2) compound with a pyrochlore structure and the dense sintering of the ceramic is realized at the same time, and the time required is only 15-30 minutes, so that the preparation time of the pyrochlore ceramic is greatly shortened; and compared with the prior art, the time used is shortened by 100 times at least, the efficiency is improved, and the practicability is strong.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Metal oxie thin films for high dielectric constant applications

A high dielectric constant insulator including a thin film of a metal oxide selected from the group consisting of tungsten-bronze-type oxides, pyrochlore-type oxides, and combinations of Bi2O3 with an oxide selected from the group consisting of perovskites and pyrochlore-type oxides. An embodiment contains metal oxides represented by the general stoichiometric formulae AB2O6, A2B2O7 and A2Bi2B2O10, wherein A represents A-site atoms selected from the group of metals consisting of Ba, Bi, Sr, Pb, Ca, K, Na and La; and B represents B-site atoms selected from the group of metals consisting of Ti, Zr, Ta, Hf, Mo, W and Nb. Preferably, the metal oxides are (BaxSr1-x)(TayNb1-y)2O6,where 0< / =x< / =1.0 and 0< / =y< / =1.0; (BaxSr1-x)2(TayNb1-y)2O7, where 0< / =x< / =1.0 and 0< / =y< / =1.0; and(BaxSr1-x)2Bi2(TayNb1-y)2O10, where 0< / =x< / =1.0 and 0< / =y< / =1.0. Thin films according to the invention have a relative dielectric constant > / =40, and preferably about 100. The value of Vcc in the metal oxides of the invention is close to zero. The value of Tcc is <1000ppm, preferably <100.

Owner:SYMETRIX +1

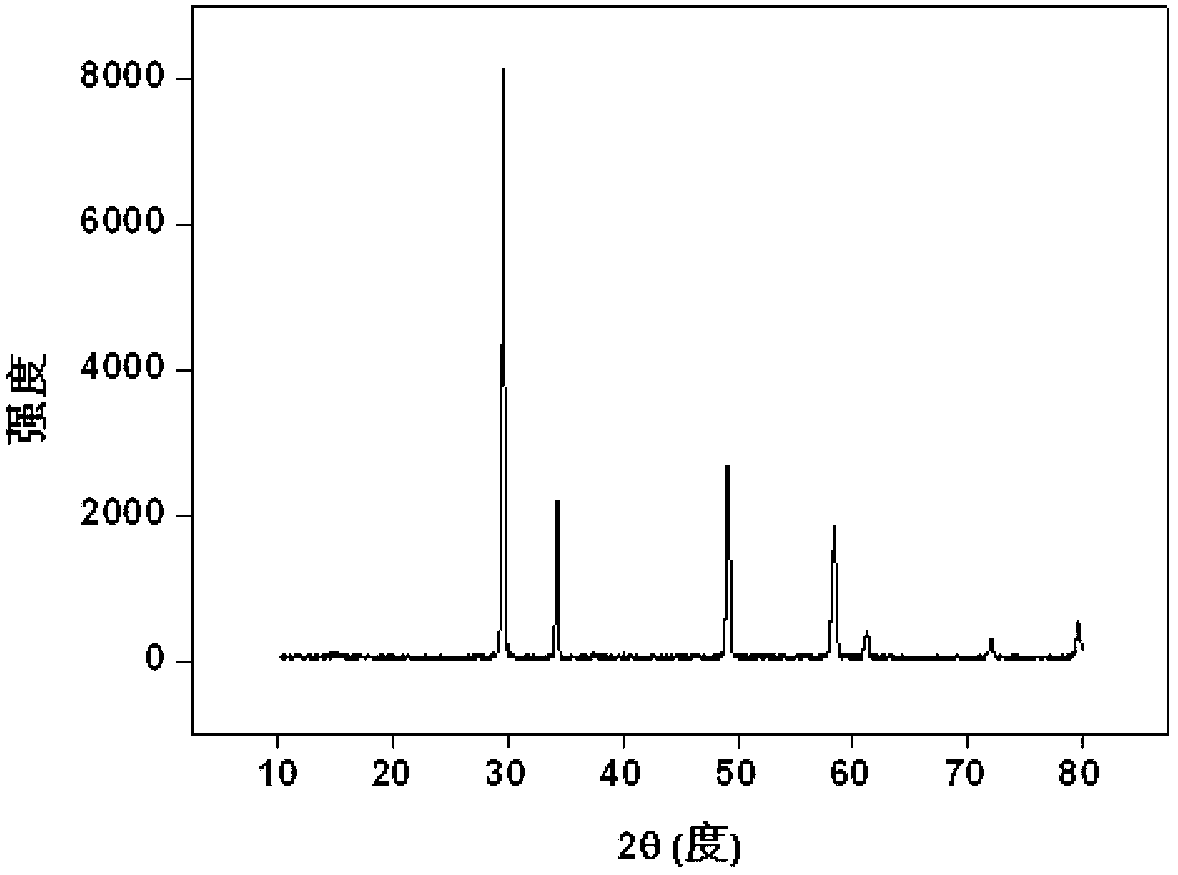

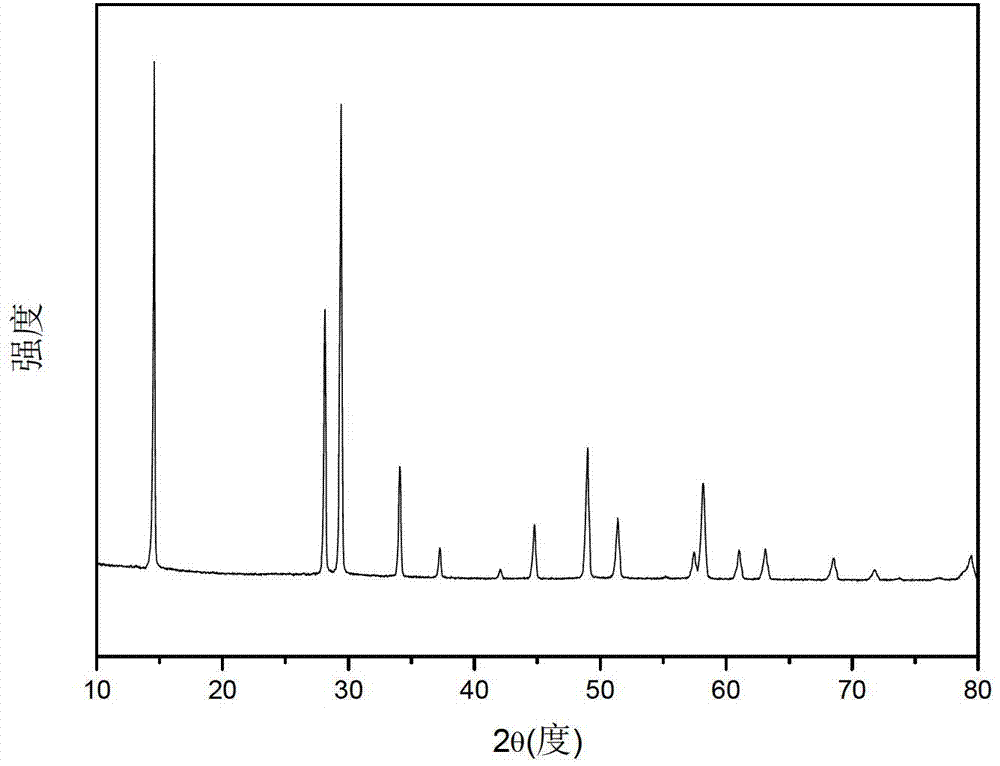

Preparation method of single-phase pyrochlore-type La2Zr2O7 nano-powder

The invention relates to a preparation method of single-phase pyrochlore-type La2Zr2O7 nano-powder. The preparation method is characterized in that the La2Zr2O7 nano-powder is obtained by ageing, drying and high-temperature roasting by using Zr<4+> and La<3+> hydration inorganic salt as a precursor, citric acid as a complexing agent, an amide organic matter as a gel accelerant and polyethylene glycol as a dispersing agent. The single-phase pyrochlore-type La2Zr2O7 nano-powder has the advantages that the particle size of the obtained La2Zr2O7 nano-powder is 20-100nm, the molar ratio of Zr to La is approximate to 1:1, the crystal structure of the La2Zr2O7 nano-powder is single-phase pyrochlore-type, and the La2Zr2O7 nano-powder has high degree of crystallinity and excellent performances such as low heat conduction, sintering resistance, good high-temperature stability and the like and is applied to the field of thermal barrier coatings of aviation turbine engines and protective coatings in high-temperature wet-oxygen environments.

Owner:NAT UNIV OF DEFENSE TECH

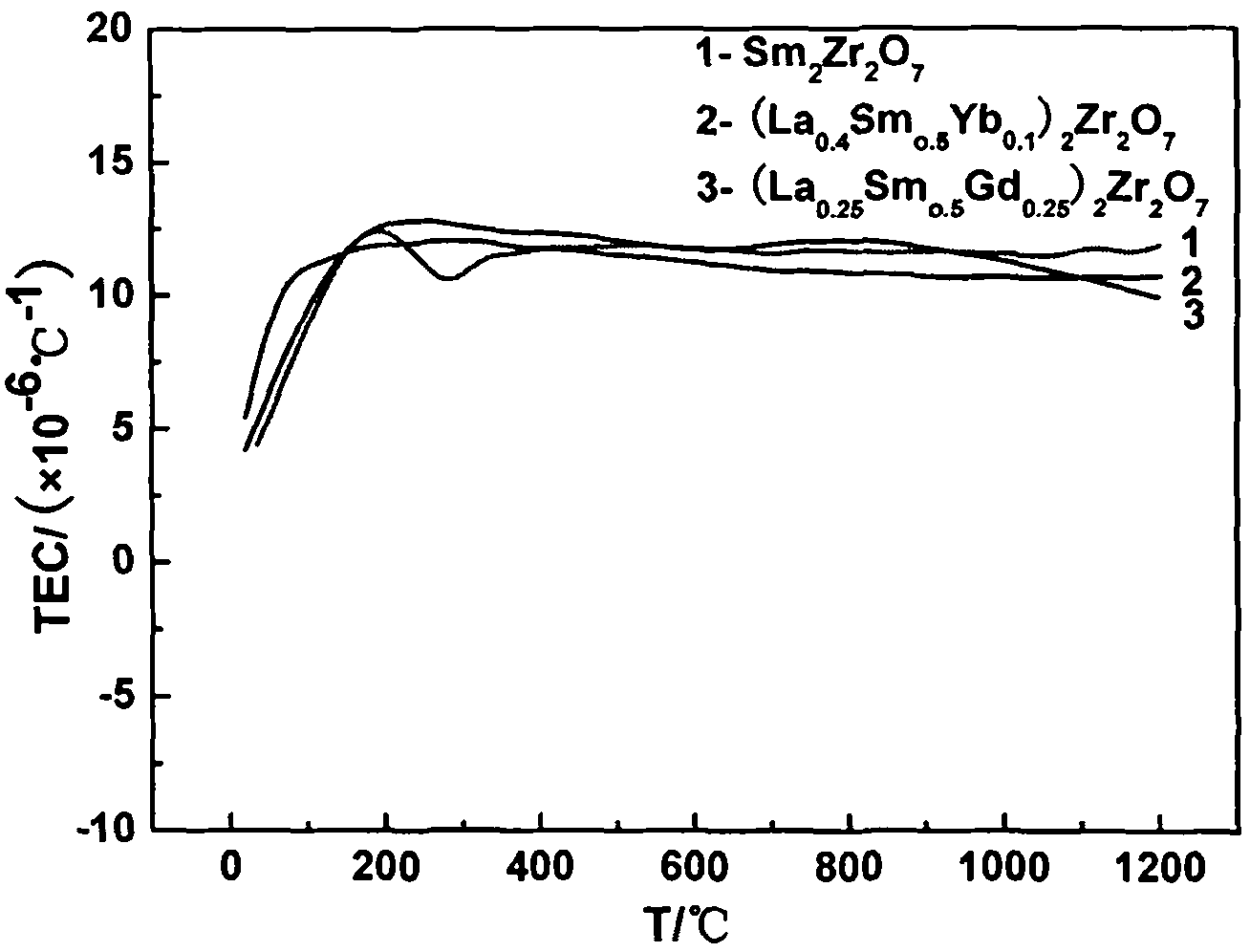

Pyrochlore structural rare-earth zirconate material and preparation method and application thereof

ActiveCN102070335AImprove wild swingsLow thermal conductivityMolten spray coatingRare-earth elementZirconate

The invention discloses a pyrochlore structural rare-earth zirconate material system capable of being used for a heat barrier coating. The chemical composition of the material is (0.5-x)R'2O3-0.5Sm2O3-xR''2O3-2ZrO2, wherein x is more than 0 and less than or equal to 0.25; the R' is rare-earth elements or composition thereof, the ion radius of which is greater than that of Sm; and R'' is rare-earth elements or composition thereof, the ion radius of which is smaller than that of Sm. The material provided by the invention has low thermal conductivity, high thermal stability and high-temperature sintering resistance; the thermal expansion performance of the material is stable compared with a single pyrochlore structural material; and the material is favorable for reducing thermal stress generated by mismatching of thermal expansion coefficients in the thermal cycle process, and can prolong the thermal cycle life of the coating. Because of good high-temperature phase stability, the pyrochlore structural rare-earth zirconate material can be used for designing and preparing a novel high-temperature heat barrier coating material, the use temperature of which is below 1,550 DEG C.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

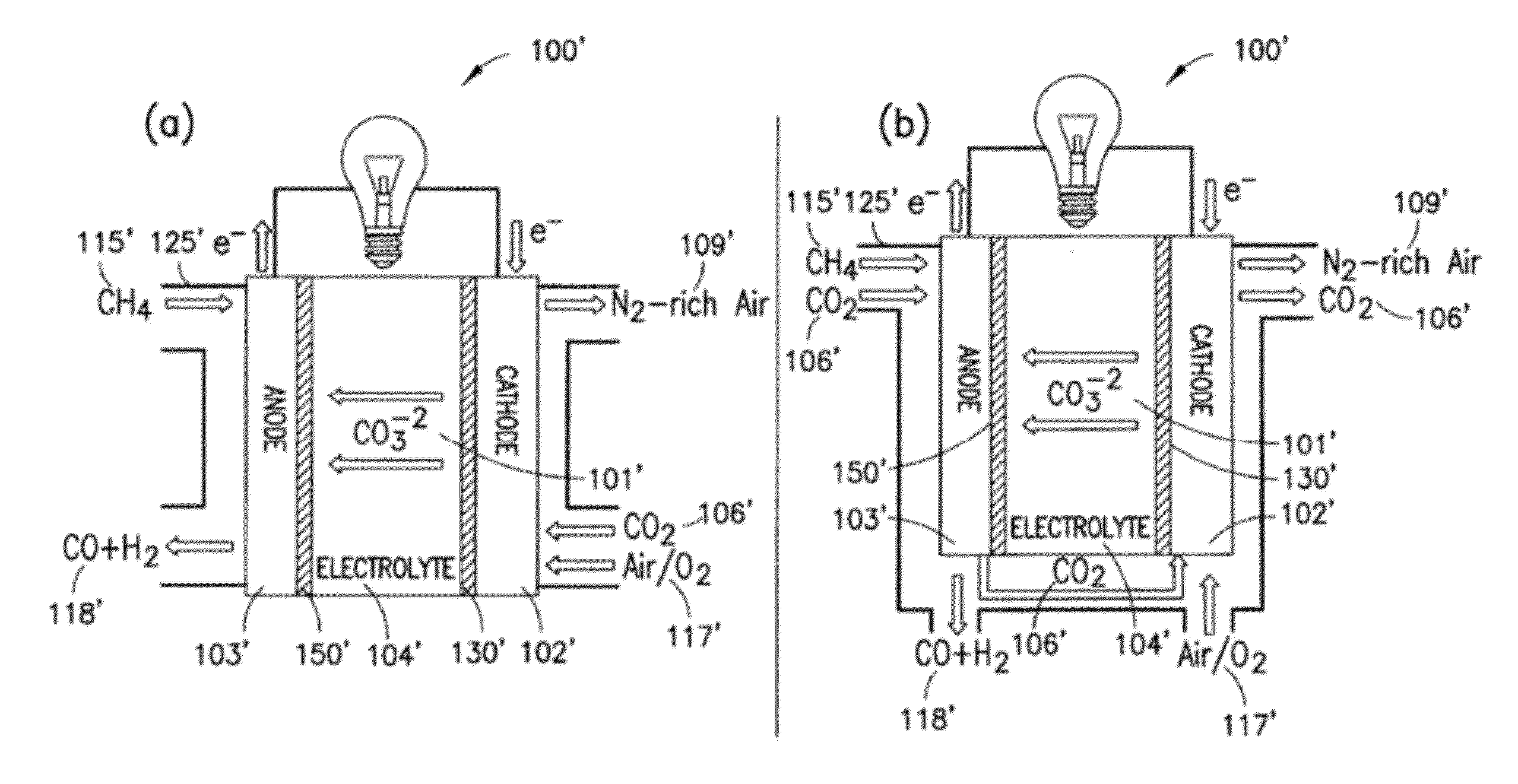

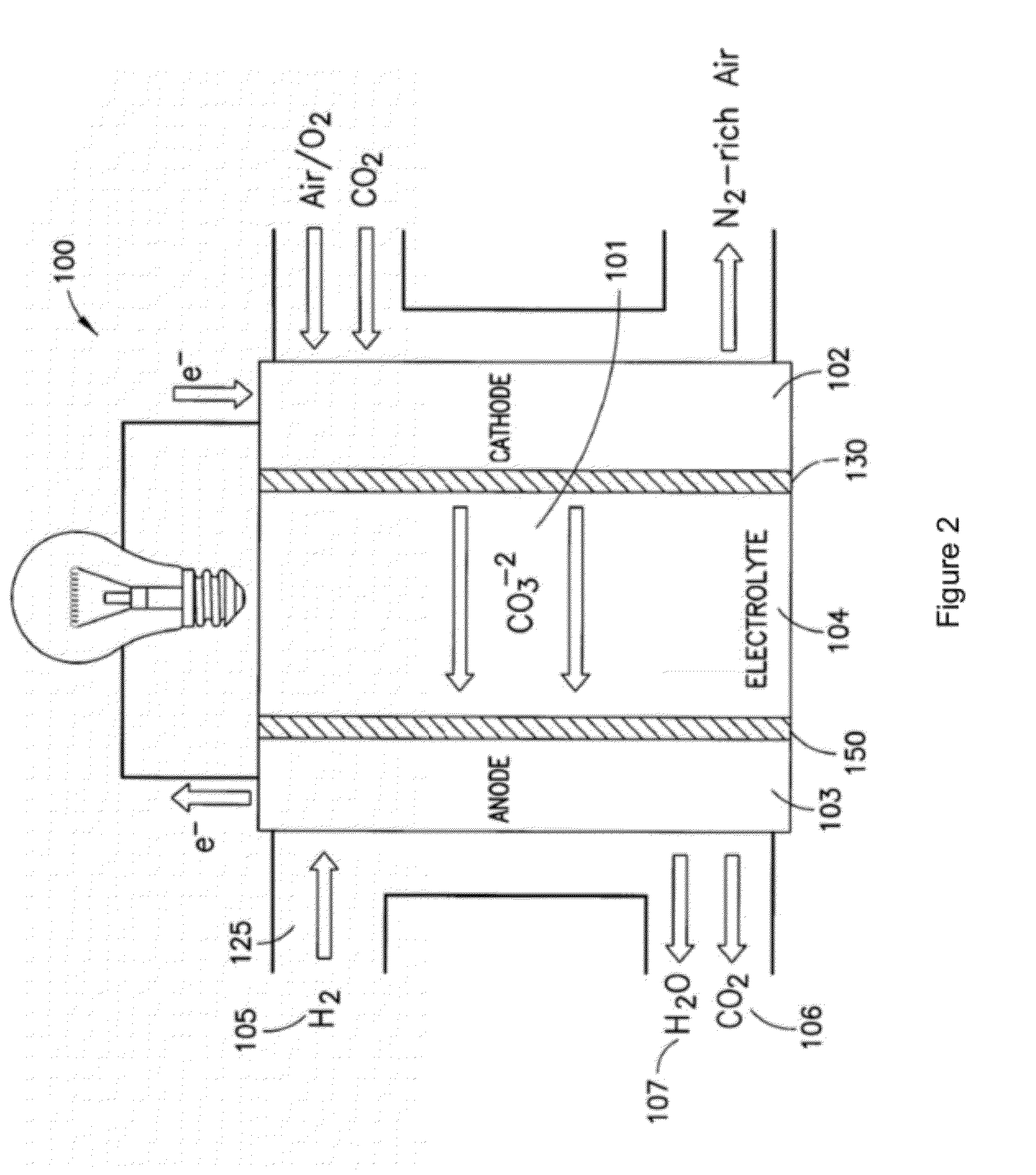

Electrochemical Reactor for CO2 Conversion Utilization and Associated Carbonate Electrocatalyst

InactiveUS20120193222A1Improve stabilityReduce degradationCellsCell electrodesElectrochemical responseFuel cells

Electrochemical reactors are provided that operate on the carbonate cycle at extremely low temperatures (e.g., less than 50° C.), thereby allowing operation in as many as three (3) modes, namely as: (i) a room temperature carbonate fuel cell; (ii) an electrochemically assisted CO2 membrane separator; and (iii) a CO2 conversion device. Electrocatalysts are also provided that have the ability to selectively form carbonate anions over hydroxide anions under fully humidified conditions. Exemplary electrocatalysts according to the present disclosure include pyrochlores.

Owner:UNIV OF CONNECTICUT

Ceramic material based on bismuth niobate substituted with zinc

The invention relates to ceramic materials based on bismuth niobate substituted with zinc and can be used for producing multilayer high frequency thermostable ceramic condensers provided with electrodes based on an alloy which comprises Ag and Pd, and also for producing multilayer microwave films. The aim of the invention is to develop a ceramic material having a low sintering temperature sufficient for using silver-palladium electrodes having a silver content of up to 90%. Said material has an optimum dielectric permittivity and thermostability which are sufficient for producing a wide range of items based on said material. Zinc niobate ZnNb2O6 having a structure of columbite with a quantity ranging from 7.0 to 99.0, expressed in mass %, is added into a ceramic material based on the bismuth niobate substituted with zinc having a crystal-chemical formula (Bi⅔[ ]⅓)2(Zn<2+>⅓Nd⅔)2O6[ ]1,[ ] being a vacancy with a pyrochlore structure. Glass having the following component ratio, in mass %, can be added into the material: PbO ranging from 26 to 33, Bi2 ranging from 14 to 24, B2O3 ranging from 4 to 10, TiO2 ranging from 15 to 21, ZnO ranging from 21 to 28.

Owner:NENASHEVA ELIZAVETA ARKADIEVNA +1

CMAS-corrosion-resistant multi-component high-entropy pyrochlore structure thermal barrier coating material and preparation method and application thereof

InactiveCN113772723AImprove performanceLow thermal conductivityZirconium compoundsRare-earth elementThermal dilatation

The invention discloses a CMAS-corrosion-resistant multi-component high-entropy pyrochlore-structured thermal barrier coating material as well as a preparation method and an application thereof. The chemical formula of the thermal barrier coating material is A2B2O7, A comprises at least five elements of rare earth elements, Al and Ba, and B is one or more of Zr, Ti, Hf, Nb and Ce. The invention provides the CMAS corrosion resistant multi-component high-entropy pyrochlore structure thermal barrier coating material prepared through more than five multi-principal component designs. The low heat conductivity and the improved thermal expansion and fracture toughness are obtained through the high-entropy effect, meanwhile, the corrosion resistance of the thermal barrier coating material can be further improved by introducing anti-corrosion elements such as Al, Ba, Ti and Hf, and therefore the thermal barrier coating material with the excellent comprehensive performance is obtained, and the thermal barrier coating material has the wide application prospect in the field of next-generation engine thermal barrier coatings with the high thrust-weight ratio.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Method for solidifying actinium series nuclide by pyrochlore type rare earth zirconate

ActiveCN102779561AEasy disposalImprove efficiencyRadioactive decontaminationWaste processingDeep geological repository

The invention discloses a method for solidifying actinium series nuclide by pyrochlore type rare earth zirconate and belongs to the technical field of radioactive nuclear waste processing. The method includes adopting rare earth nitrate, zirconium nitrate or zirconium oxynitrate, actinium series nuclide raw materials and a little fluxing agent as raw materials, grinding and mixing the raw materials and directly placing the raw materials in a sintering furnace to conduct sintering under certain temperature to obtain a pyrochlore type rare earth zirconate solidified body containing actinium series nuclide. Therefore, radioactive nuclide can be solidified in lattices of the rare earth zirconate to facilitate deep geology processing. The whole solidification process does not require complex high-energy-consumption dangerous steps of repeated grinding, piece pressing, long-time high-temperature sintering, sol gel preprocessing, piece pressing, long-time high-temperature sintering and the like. The method is energy-saving, high in efficiency and good in safety and reduces consumption.

Owner:TSINGHUA UNIV

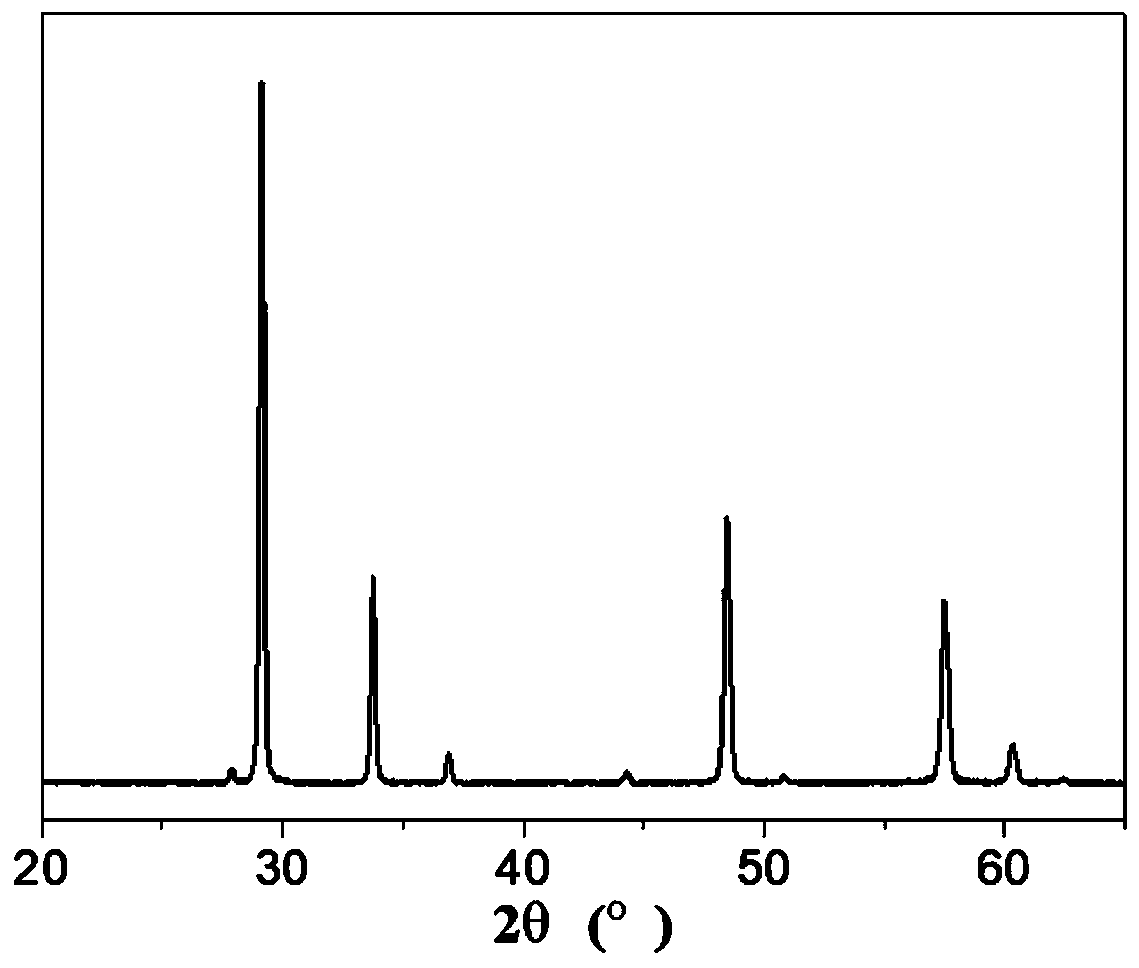

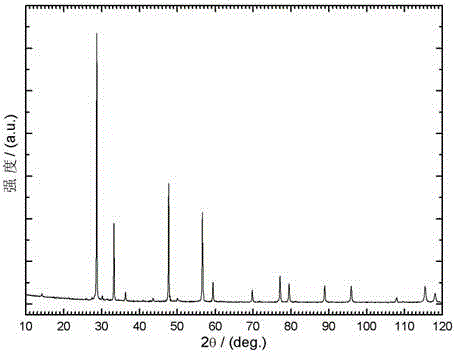

Cerium-doped lanthanum zirconate nano powder and preparation method thereof

InactiveCN102718485AExcellent anti-sinteringSmall granularityNanotechnologyChemical industryPyrochlore

The invention relates to cerium-doped lanthanum zirconate nano powder and a preparation method thereof. The cerium-doped lanthanum zirconate nano powder is characterized in that the cerium-doped lanthanum zirconate nano powder is of a single-phase pyrochlore structure, has the particle size of 30 to 250nm, is uniformly distributed, is of a sphere shape, is prepared by carrying out doping on the Zr position by Ce and has the chemical formula of La2Zr2-xCexO7, wherein x is less than or equal to 0.5 and more than or equal to 0.1. The cerium-doped lanthanum zirconate nano powder is of the single-phase pyrochlore structure, has excellent anti-sintering performance, has small particle size, is uniformly distributed, has regular morphology and has stable structure at high temperature; the thermal expansion coefficient of the powder from the room temperature to the temperature of 1,400 DEG C can reach 12*10<-6<K<-1>; and the cerium-doped lanthanum zirconate nano powder has the thermal conductivity of lower than 1.5W.m<-1>.K<-1>, is particularly suitable for preparation of various high temperature resistance thermal barrier coating or high temperature resistance abrasion-resistant anticorrosion coating materials, and is applied to the industries of aerospace, gas turbines, ships, vehicles, machinery, chemical industry and the like.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

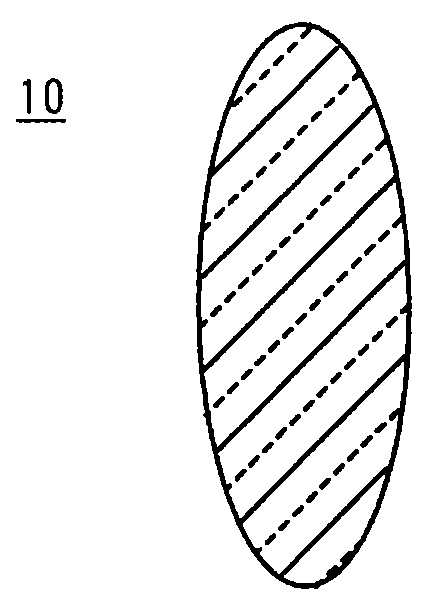

Translucent ceramic, method for producing the same, optical component, and optical device

ActiveUS20080233406A1High anomalous dispersionHigh refractive indexOxygen/ozone/oxide/hydroxideAlkali metal oxidesOptical pickupCubic crystal system

A translucent ceramic having a high linear transmittance and a high refractive index, substantially not causing double refraction, and exhibiting a high anomalous dispersion has a pyrochlore compound represented by the general formula AxByOw (wherein 1.00≦x / y≦1.10 and w represents a positive number maintaining electroneutrality) as a main component. The main component has a cubic crystal system. Preferably, the A site comprises a trivalent metallic element, and the B site comprises a tetravalent metallic element. More preferably, A is at least one of La, Y, Gd, Yb, and Lu, and B is of at least one of Ti, Sn, Zr, and Hf. The translucent ceramic is useful as a material of, for example, an objective lens used in an optical pickup.

Owner:MURATA MFG CO LTD

Active optoceramics with cubic crystal structure, method of production of the optoceramics, and uses thereof

InactiveCN101811868AShort decay timeX/gamma/cosmic radiation measurmentLuminescent compositionsHigh energyPyrochlore

The present invention refers to active optoceramics with a cubic crystal structure, a method of producing the same and its use, particularly to the optoceramics having high transmissions, high densities and high effective atomic numbers. The optoceramics are doped with activator elements. The materials are suitable to absorb high-energy radiation and transform it to photons of visible light. Thus the materials suit as scintillator media for e.g. medical imaging (CT, PET, SPECT or combined PET / CT systems), security (X-ray detectors) or can serve in object tracing or investigation (exploration, prospecting for resources). The crystallite grains, forming the materials of the present invention, have cubic crystal structures (point and space groups as well as atom layers isotypic to those of the pyrochlore or fluorite minerals) or are clearly derivable from both mentioned minerals in terms of crystal structure. and have the following formula: A2+xByDzE7, wherein 0<=x<=1.1, 0<=y<=3, 0<=z<=1.6, and 3x+4y+5z=8, and wherein A is at least one trivalent rare earth cation, B is at least one tetravalent cation, D is at least one pentavalent cation, and E is at least one divalent anion.

Owner:SCHOTT AG

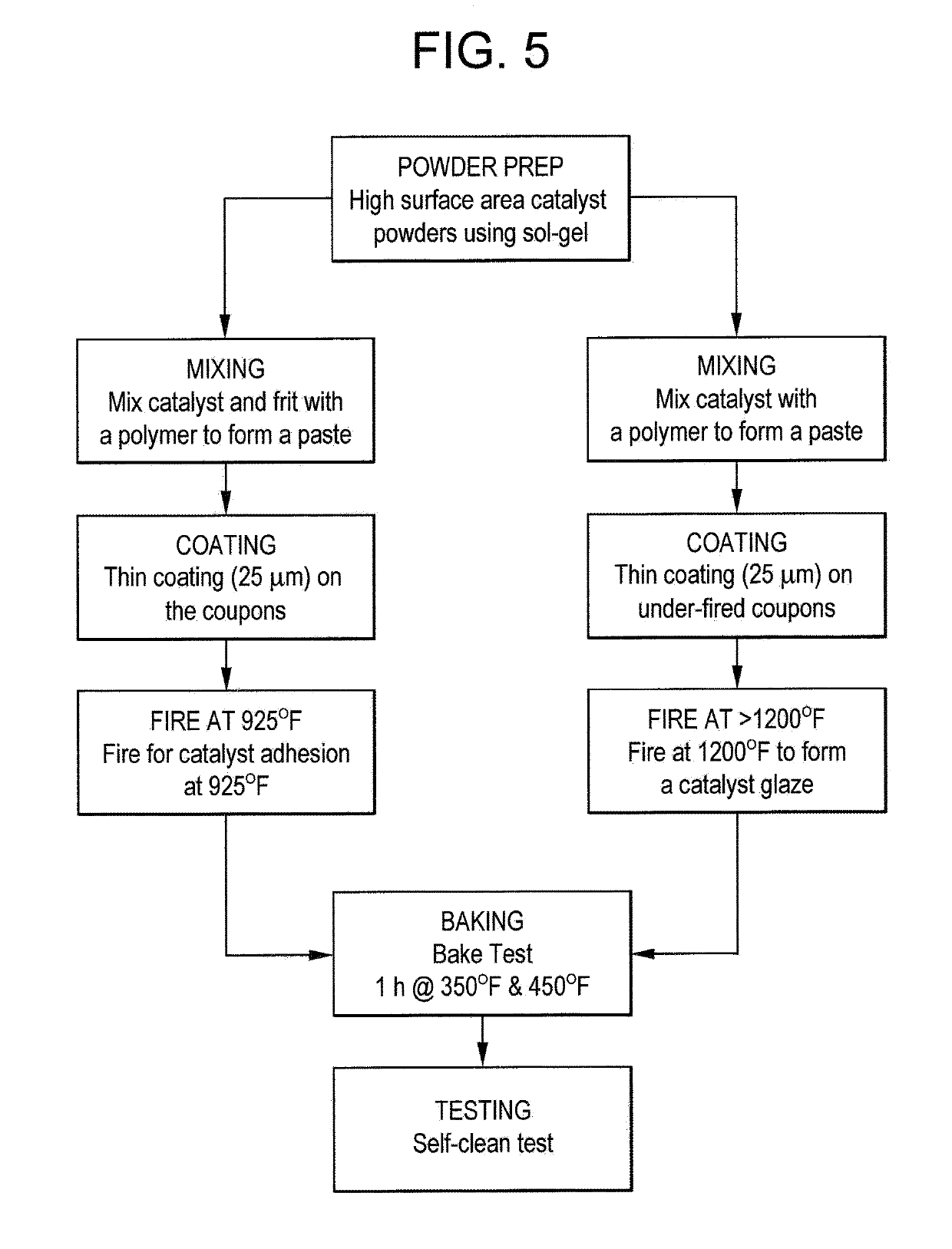

Pyrocatalytic coatings for heating devices

ActiveUS20090325782A1Combustion temperature can be reducedReduce the temperatureDomestic stoves or rangesBaking ovenSelf-cleaning ovenCrystalline materials

Heating devices such as self-cleaning ovens include at least one surface comprising metal oxide crystalline catalytic material disposed thereon. The metal oxide crystalline material includes perovskite and perovskite-like materials, pyrochlores, rare earth metal oxides, spinels, and combinations of the foregoing. Also disclosed herein are processes for process for forming a pyrocatalytic coating on a substrate.

Owner:HAIER US APPLIANCE SOLUTIONS INC

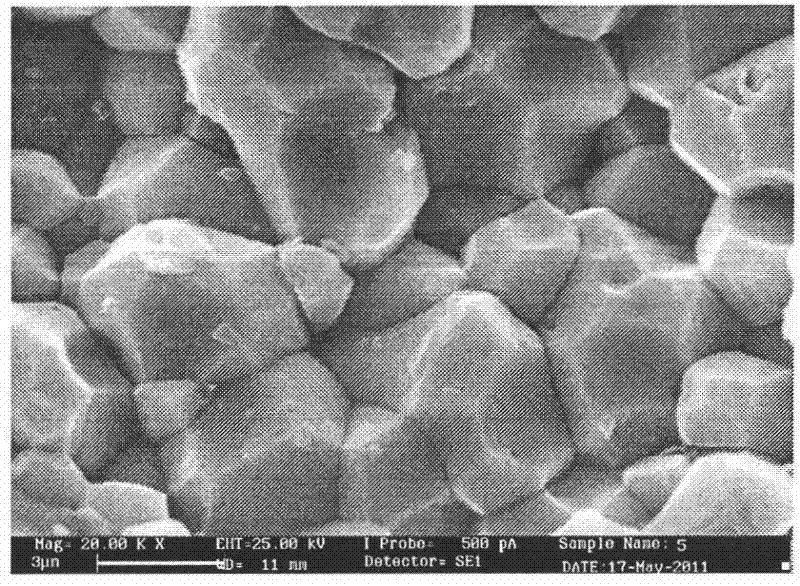

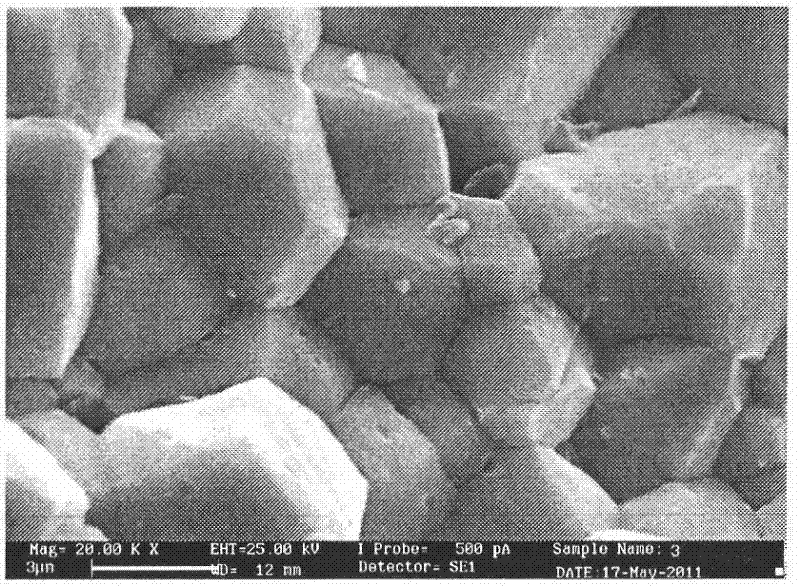

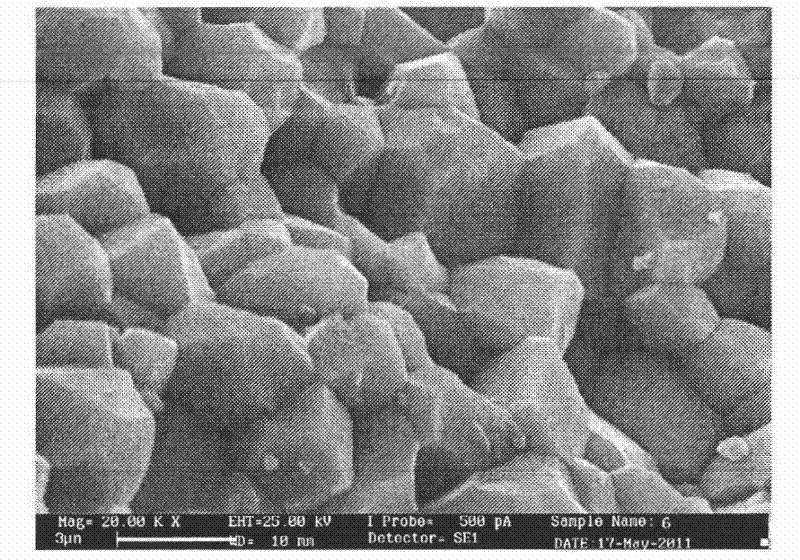

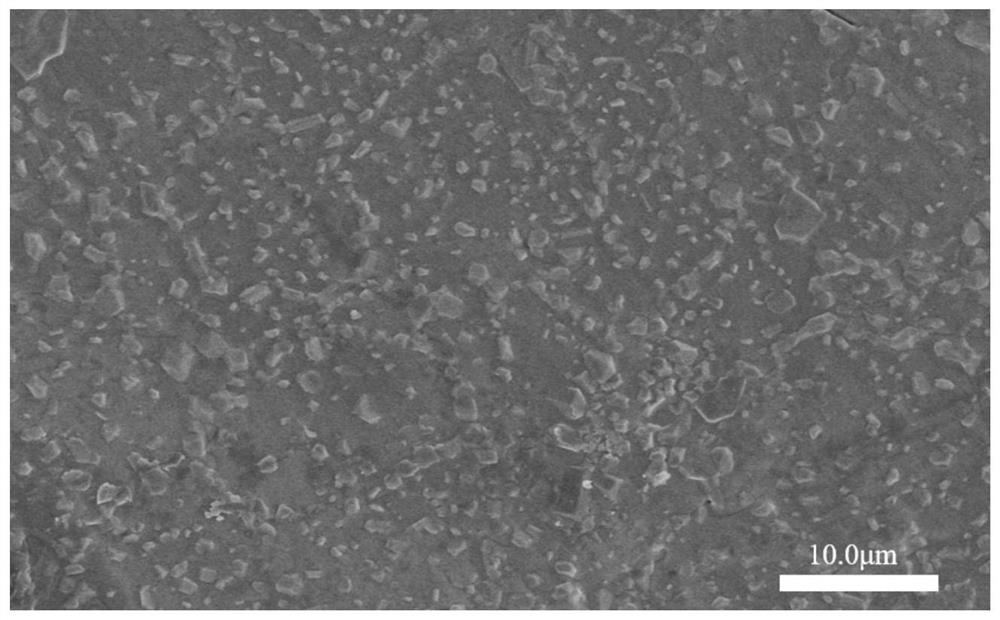

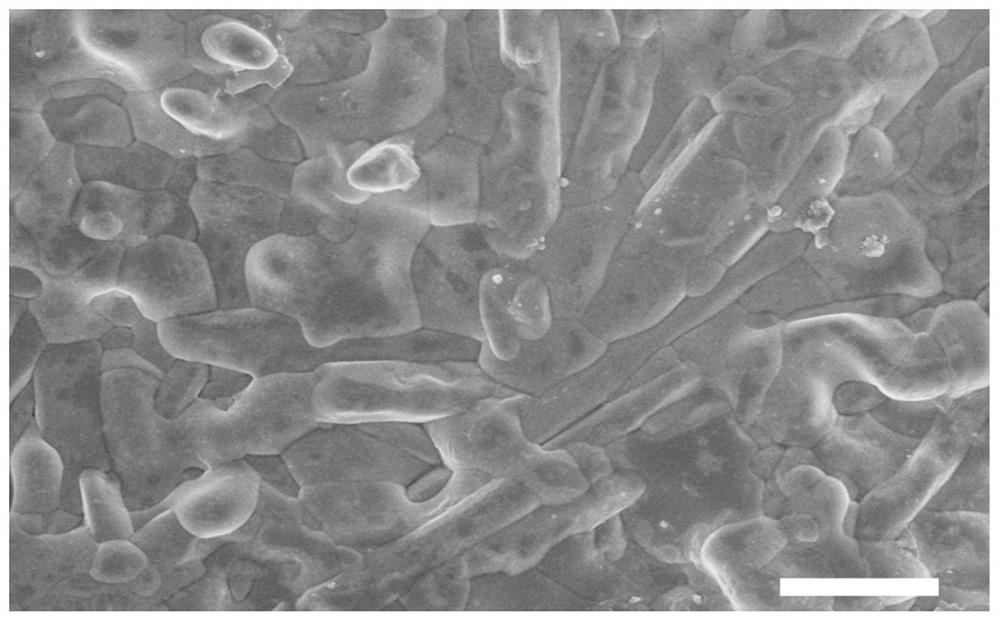

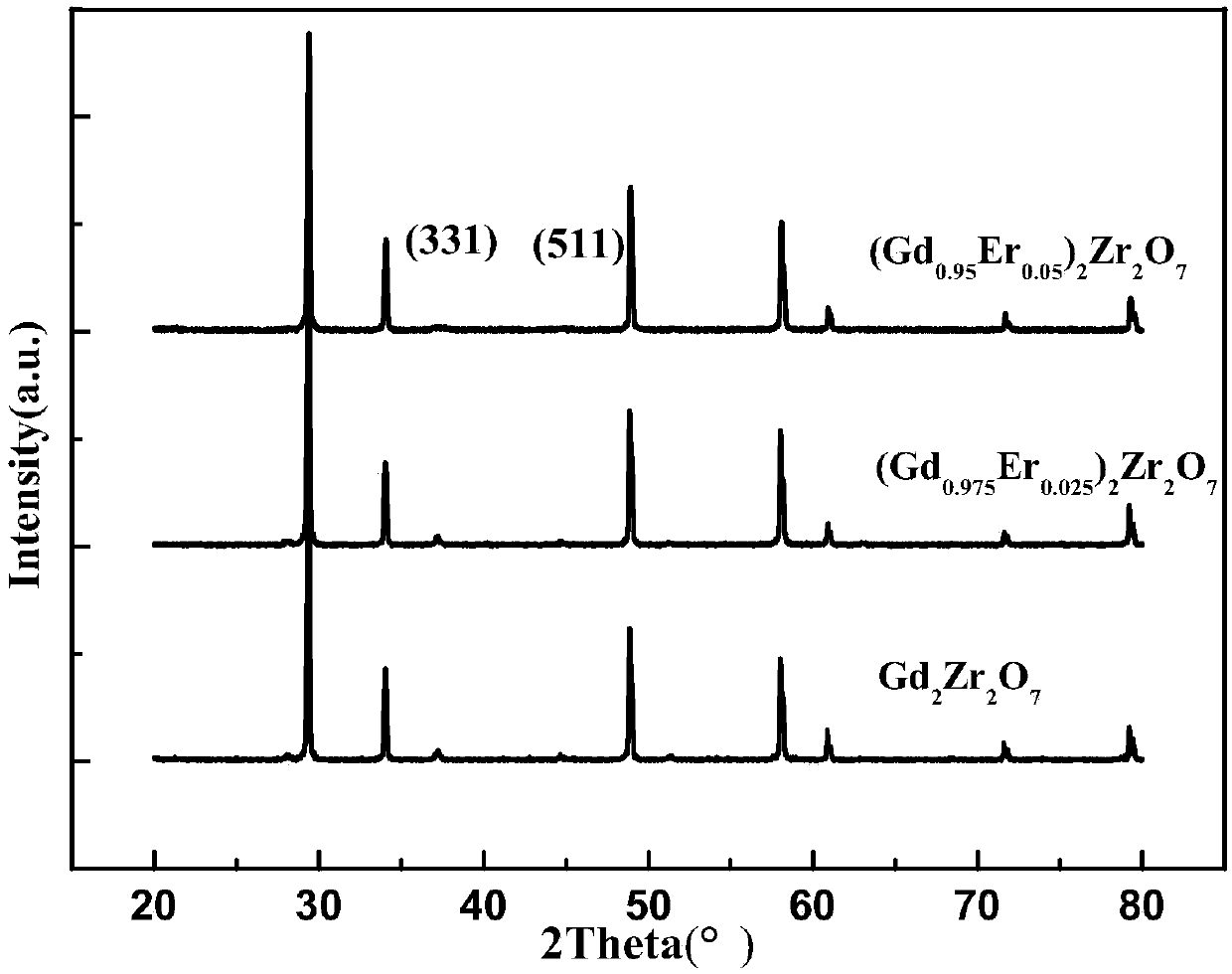

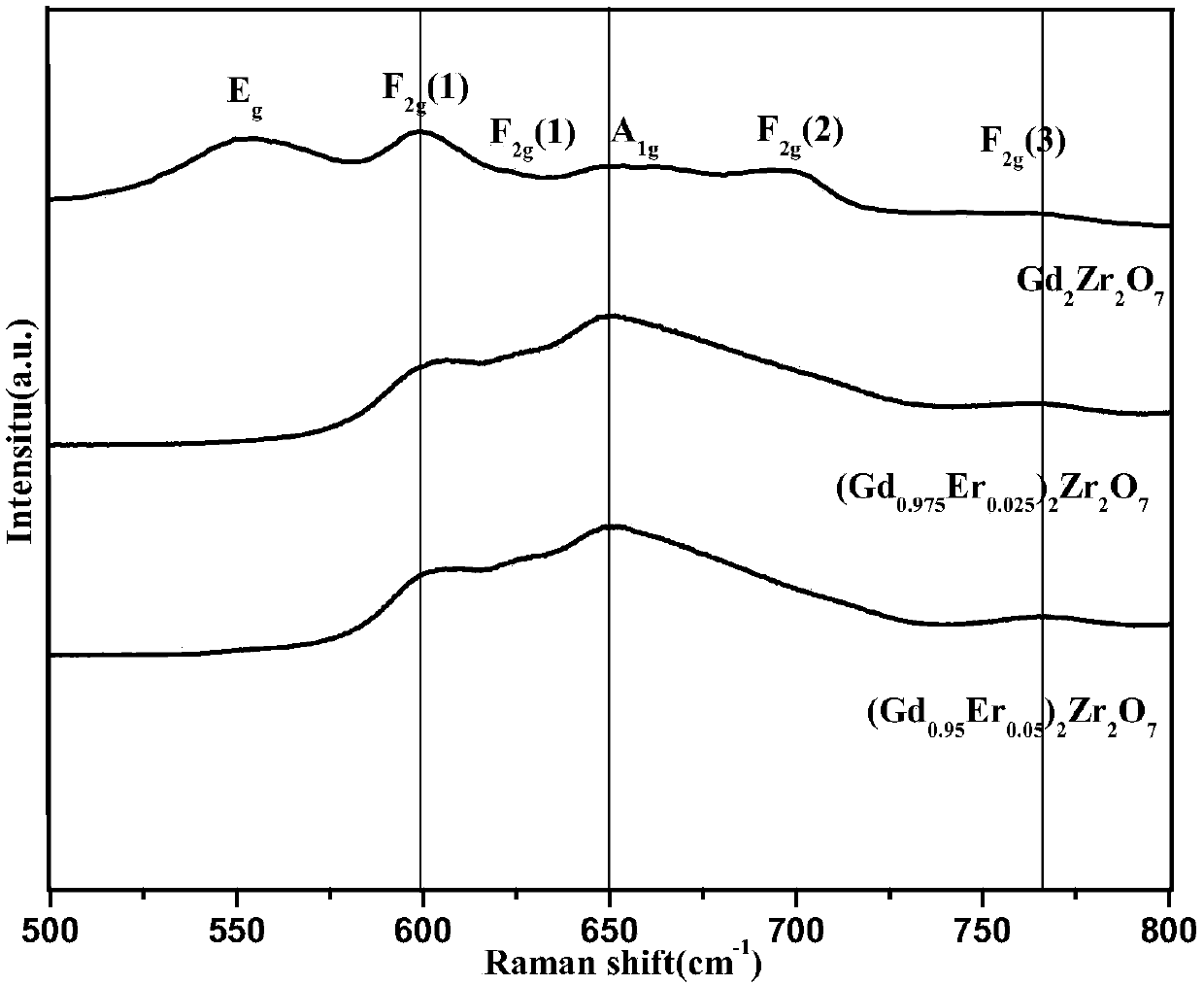

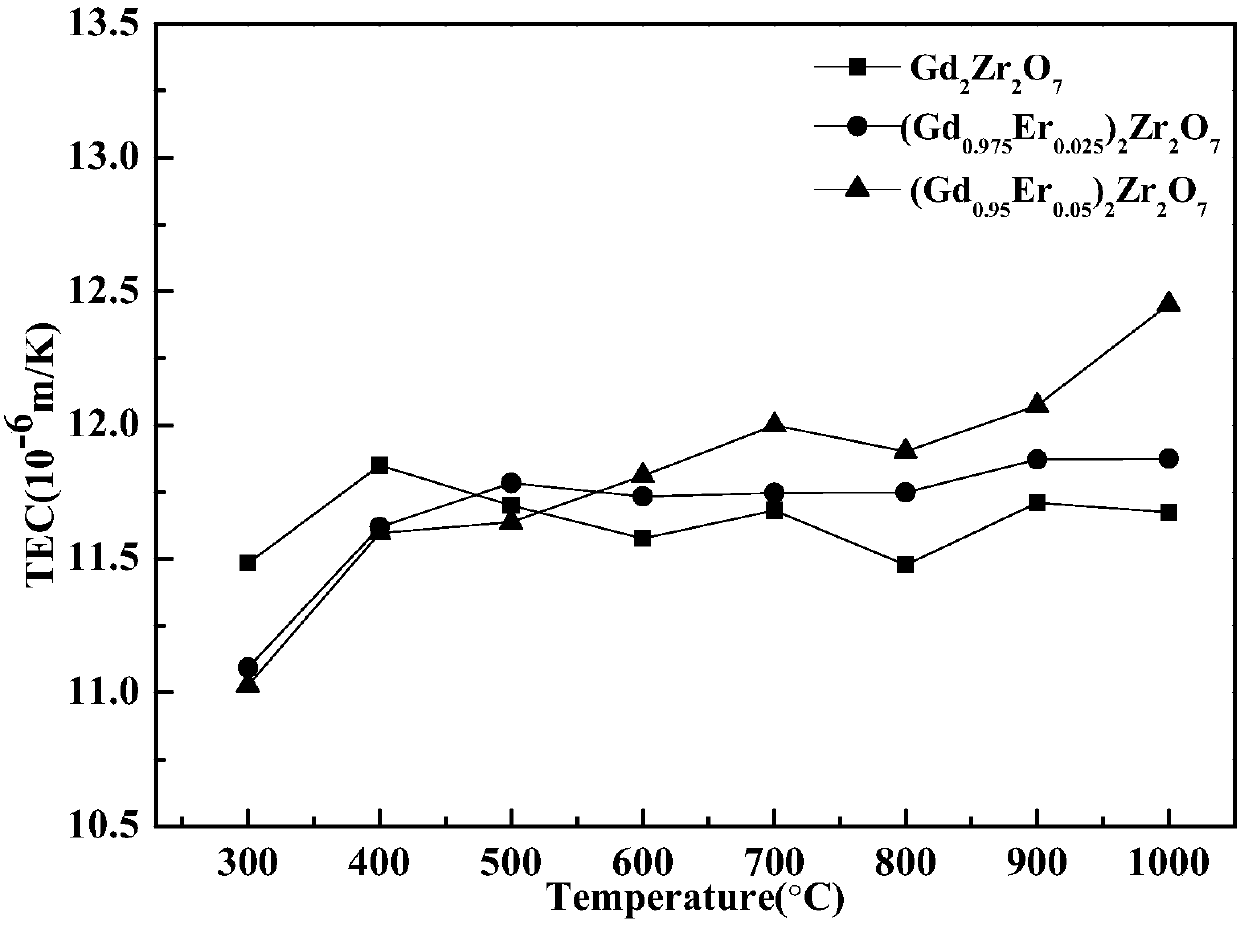

Preparation method of gadolinium zirconate-based material, gadolinium zirconate-based ceramic pelletizing powder for ionic spraying and preparation method of gadolinium zirconate-based ceramic pelletizing powder

ActiveCN108033788AParticle distance is smallLarge specific surface areaMolten spray coatingZirconateMixed materials

The invention provides a preparation method of a gadolinium zirconate-based material, gadolinium zirconate-based ceramic pelletizing powder for ionic spraying and a preparation method of the gadolinium zirconate-based ceramic pelletizing powder. According to the preparation method, oxides are mixed and grinded at a rotation speed which is increased gradually, then large micro-grade granules of rawmaterials are gradually crushed into nano-grade powder, the powder of which the particle size is relatively uniform is made, the powder has a relatively high specific surface area, solid-phase reactions in later sintering process are carried out smoothly, or the mixed material of the powder is further pressed into blocks, then distances among mass points of the powder granules are further reduced, the pore content is reduced, the density is improved, mixed oxide blocks are prepared, the solid-phase reactions in later sintering process are carried out smoothly, the solid-phase reactions can bestill ensured without high-pressure sintering, and a stable pyrochlore structure can be prepared.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

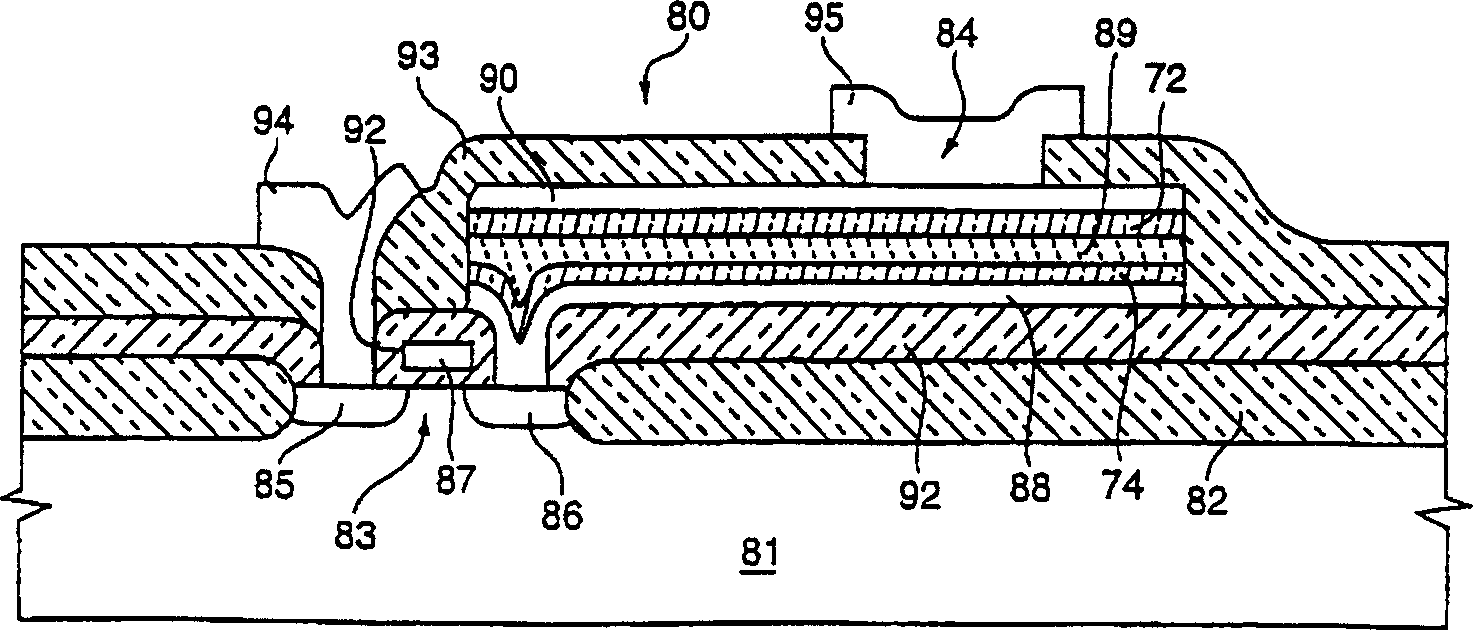

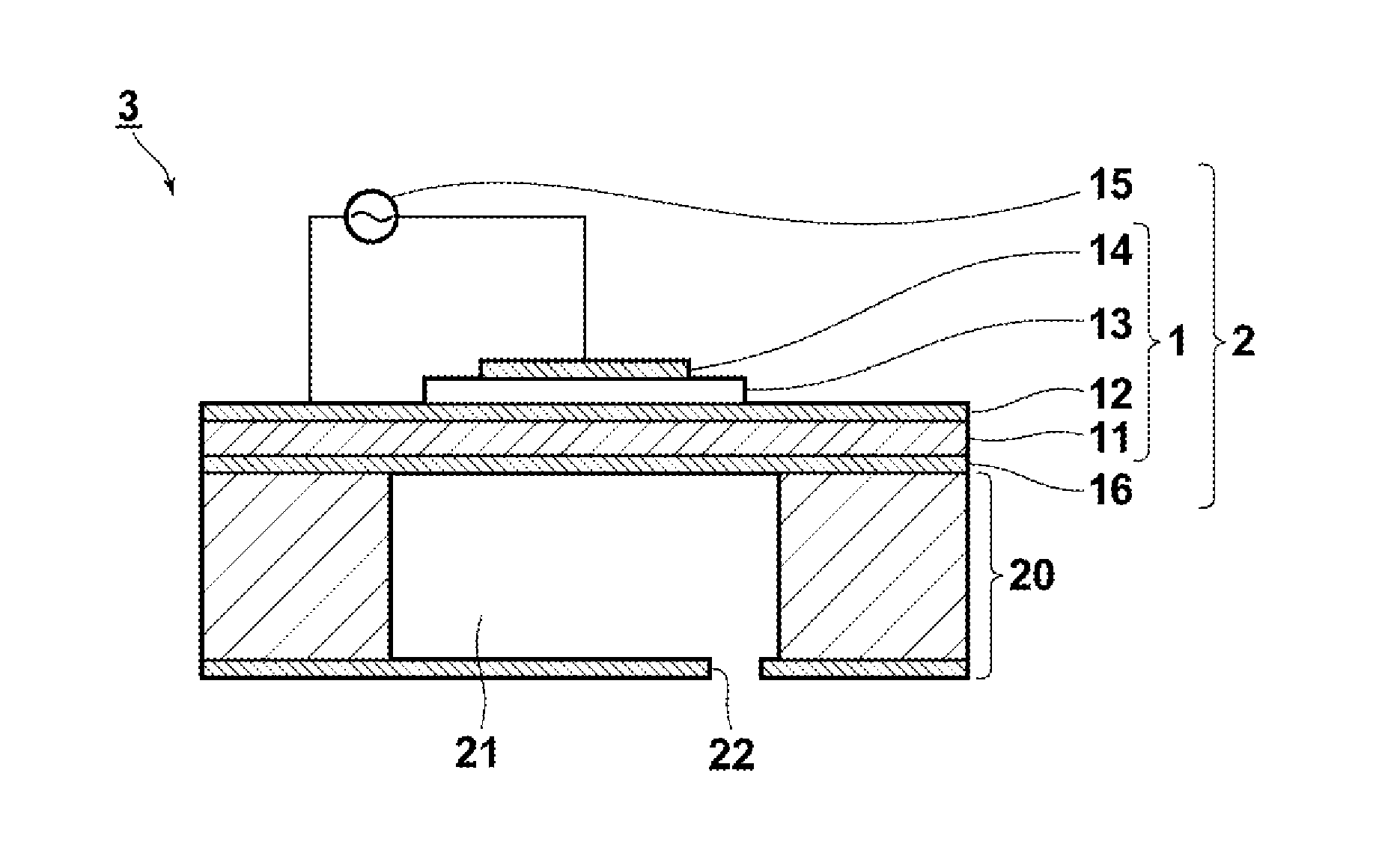

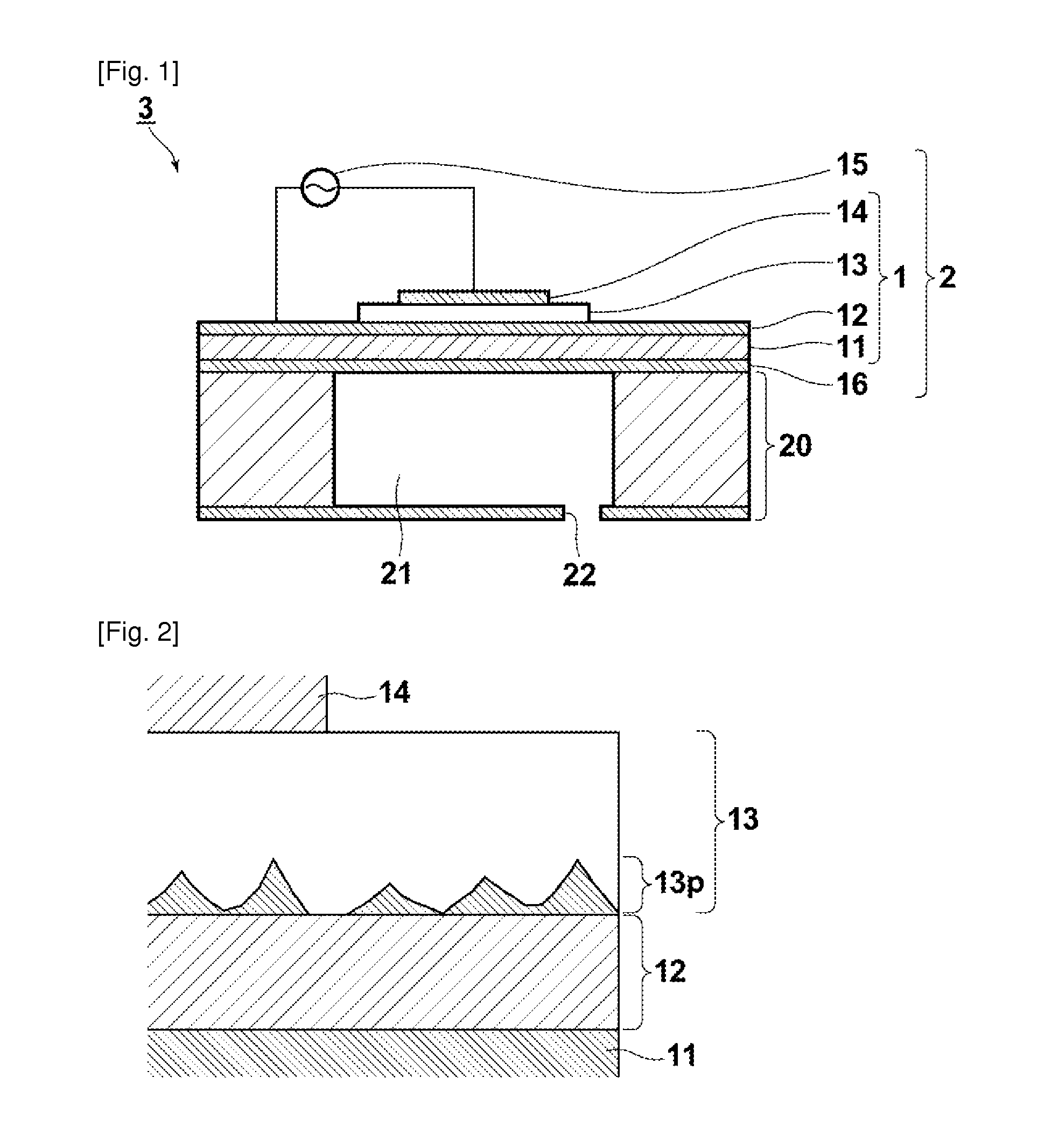

Piezoelectric device, piezoelectric device manufacturing method, and liquid discharge apparatus

ActiveUS20110121096A1Improve moisture resistanceIncreased durabilityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPyrochloreOxygen

A piezoelectric device, including the following on a substrate in the order listed below: a lower electrode, a piezoelectric film which contains a Pb containing perovskite oxide represented by a general expression (P) below, and an upper electrode, in which the piezoelectric film has a layer of pyrochlore oxide on the surface facing the lower electrode, and the average layer thickness of the pyrochlore oxide layer is not greater than 20 nm.AaBbO3 (P)where, A: at least one type of A-site element containing Pb as a major component, B: at least one type of B-site element selected from the group consisting of Ti, Zr, V, Nb, Ta, Cr, Mo, W, Mn, Sc, Co, Cu, In, Sn, Ga, Zn, Cd, Fe, and Ni, and O: an oxygen element.

Owner:FUJIFILM CORP

Preparation method of high-efficiency nickel-based catalyst for producing hydrogen in methanol-steam reforming

ActiveCN104971727AHigh activityHigh specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingWater vapor

The invention discloses a preparation method of a high-efficiency nickel-based catalyst for producing hydrogen in methanol-steam reforming. According to the preparation method, a pyrochlore compounding oxide is prepared through a glycine-nitrate combustion method; metal nitrate or perchlorate is adopted as an oxidizing agent; an organic matter is used as fuel; self-propagating combustion is generated through an oxidation-reduction reaction between reaction mixtures; a pyrochlore-type composite oxide carrier is synthesized by utilizing the heat generated during combustion. Nickel nitrate, nickel sulfate, nickel oxalate, and the like are used as nickel sources, and the nickel sources are loaded on the pyrochlore-type composite oxide carrier by a direct immersion method. The loading quantity of nickel in the catalyst is 5-20 wt% of the catalyst, and the content of pyrochlore is 80-95% of the catalyst. The composite oxide, namely pyrochlore alumina, is utilized as a carrier, so that the reaction activity and the carbon-deposition resisting performance of the catalyst can be greatly improved; besides, the preparation method of the catalyst is simple, and the catalyst has high catalytic activity and stability for methanol-steam reforming in a stationary bed.

Owner:NANCHANG UNIV

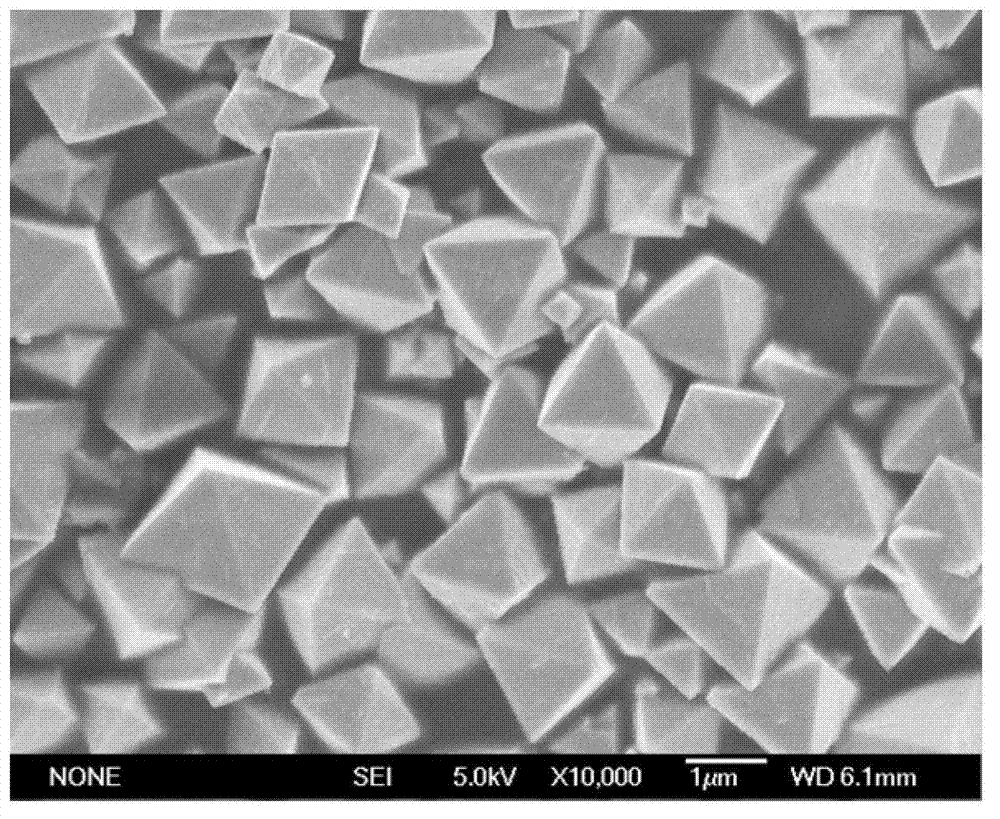

Method for preparing KNbWO6.H2O

The invention relates to a method for preparing KNbWO6.H2O, belonging to the technical field of inorganic material preparation technology. The provided method comprises the following steps of: firstly processing Nb2O5 and KOH under hydrothermal condition to get [Nb6O19]8- solution; then adding a certain amount of octanol and H2WO4 in the [Nb6O19]8- solution, regulating the pH value of the reaction liquid by diluted hydrochloric acid, and then obtaining KNbWO6.H2O with a pyrochlore structure under the solvothermal condition. The method is simple, convenient, easy to carry out and low in cost, and overcomes the tedious steps of the conventional high temperature solid phase method, such as repeated high temperature firing and grinding; and the obtained KNbWO6.H2O is a monodispersed octahedron in appearance.

Owner:JILIN UNIV

Preparation method of pyrochlore-type A2B2O7 transparent ceramics

The invention discloses a preparation method of pyrochlore-type A2B2O7 transparent ceramics, relating to A2B2O7-series nano powder preparation by a sol-gel process and belonging to the field of ceramic material preparation. The preparation method comprises the following steps: at room temperature, weighing RE2O3 and ZrOCl2.8H2O or TiCl4 according to the stoichiometric proportion, dissolving the rare earth oxide in nitric acid, adding the ZrOCl2.8H2O or TiCl4 to be dissolved, adding a mixed solution containing a dispersing agent (NH4)2SO4 and PAA (polyacrylic acid), slowly and dropwisely adding into an ammonium bicarbonate solution to obtain a precursor, and drying; adding a certain amount of sintering assistant ethyl orthosilicate or silicon dioxide sol into the precursor, carrying out ball milling, drying, screening and calcining to obtain nano powder; and carrying out compression molding, isostatic cool pressing, vacuum sintering, annealing and polishing treatment to finally obtain the transparent A2B2O7-series ceramics. By adopting the self-made high-activity nano powder to prepare the transparent A2B2O7-series ceramics at low temperature, the technique is simple and feasible.

Owner:FUJIAN CASTECH CRYSTALS

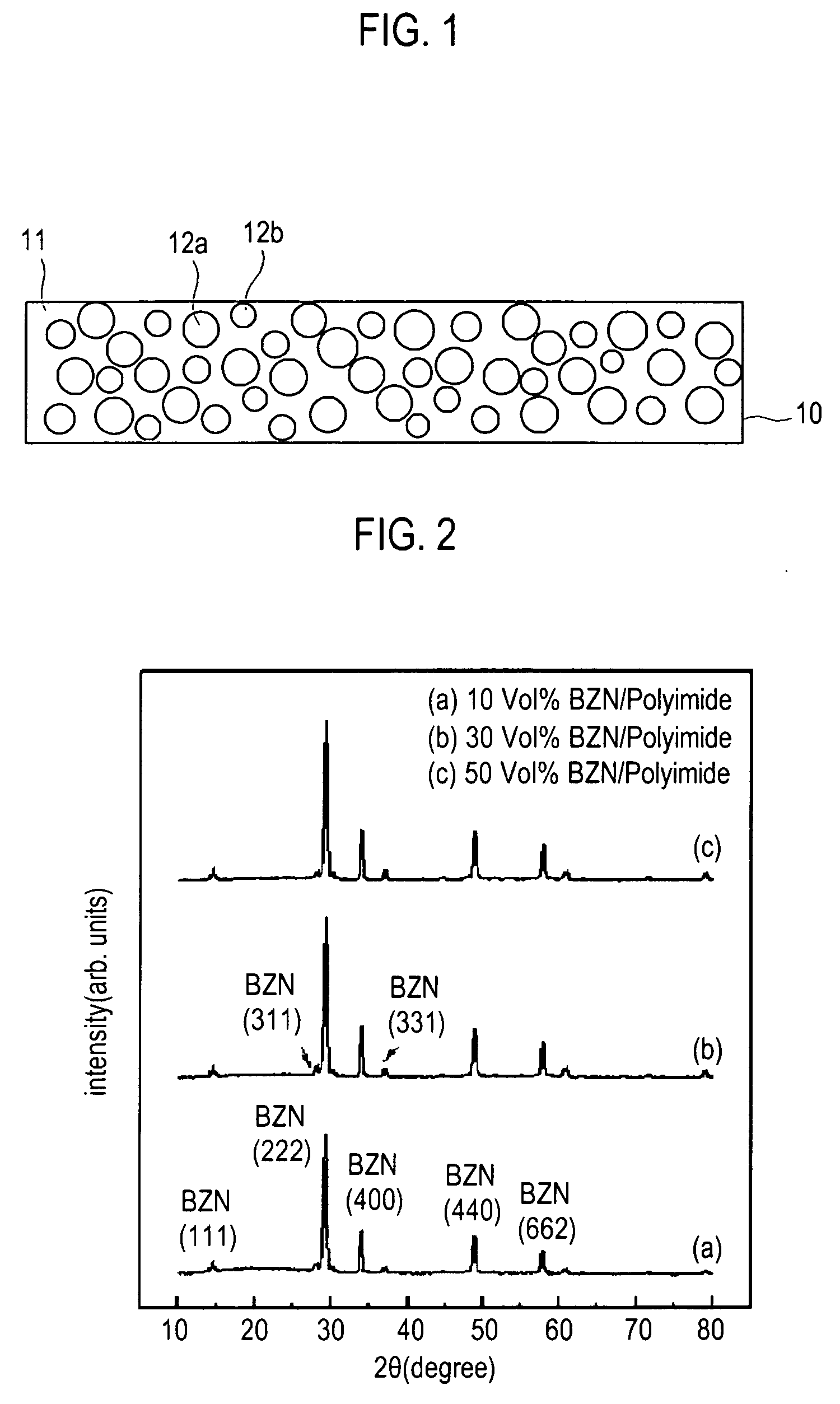

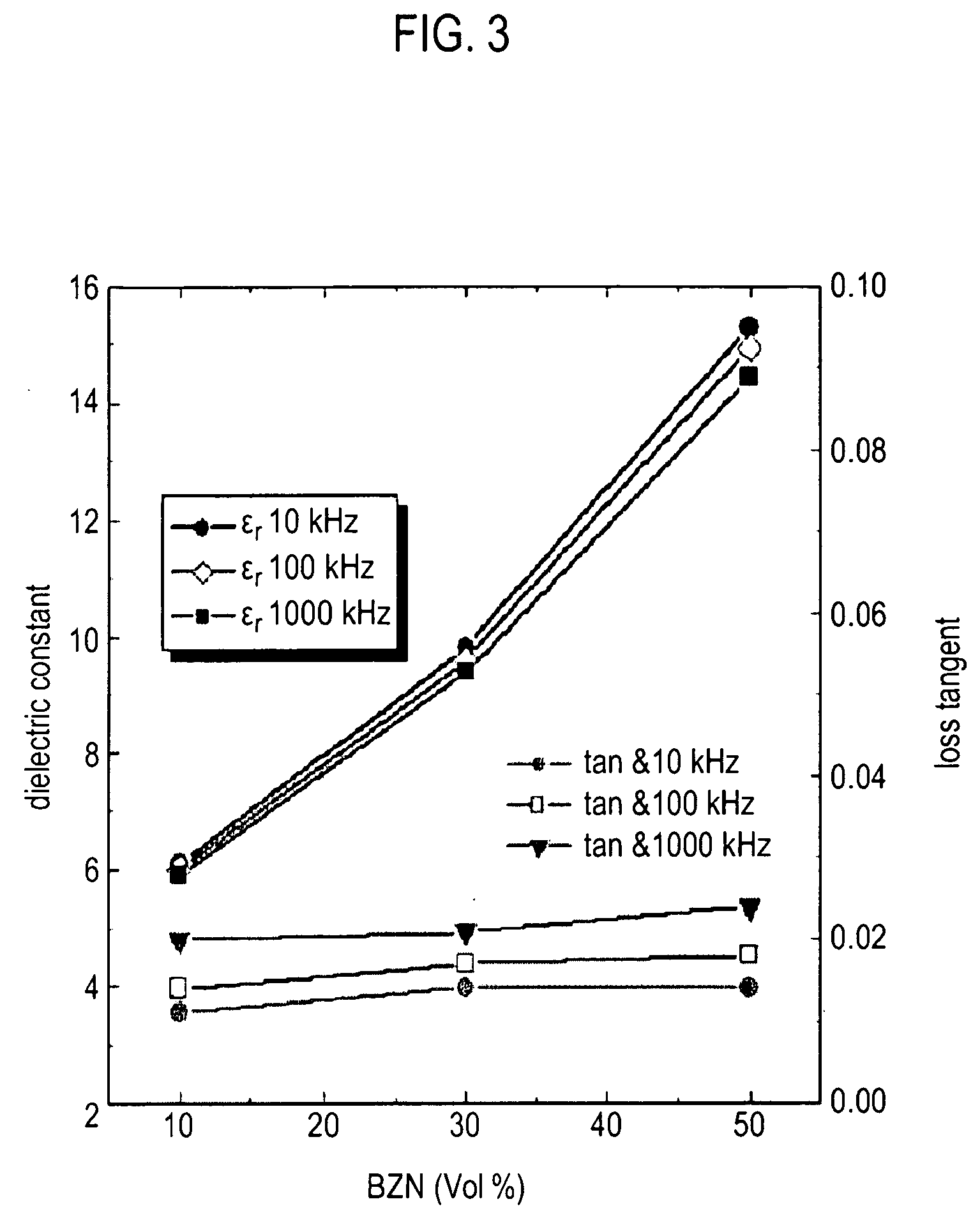

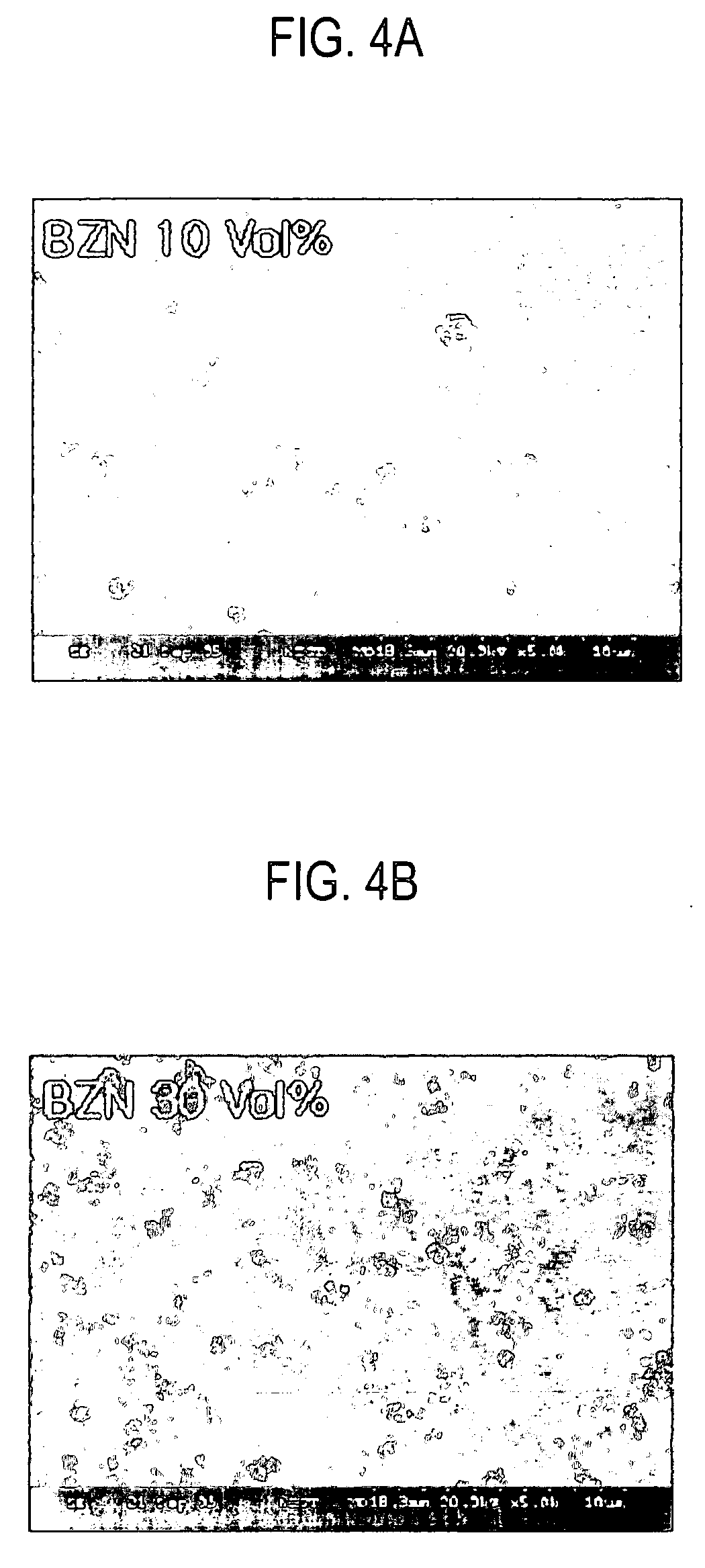

Composite dielectric film including polymer and pyrochlore ceramic and method of forming the same

The present invention provides a composite dielectric film including a polymer and a ceramic with pyrochlore structure and a method of fabricating the same. The composite dielectric film includes a polymer matrix and a ceramic of a pyrochlore structure filled in such polymer matrix.

Owner:KOREA INST OF SCI & TECH

Tantalum containing glasses and glass ceramics

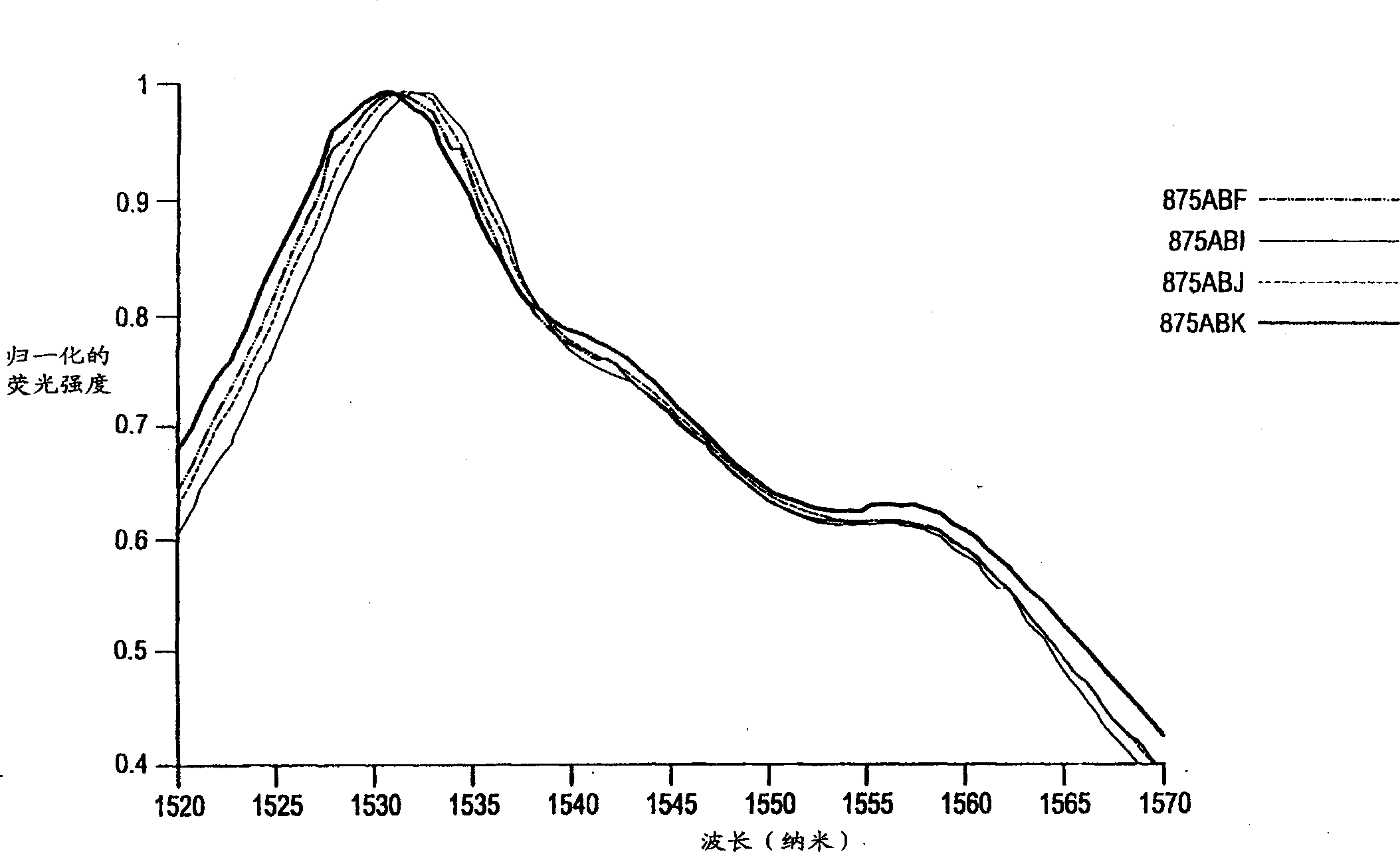

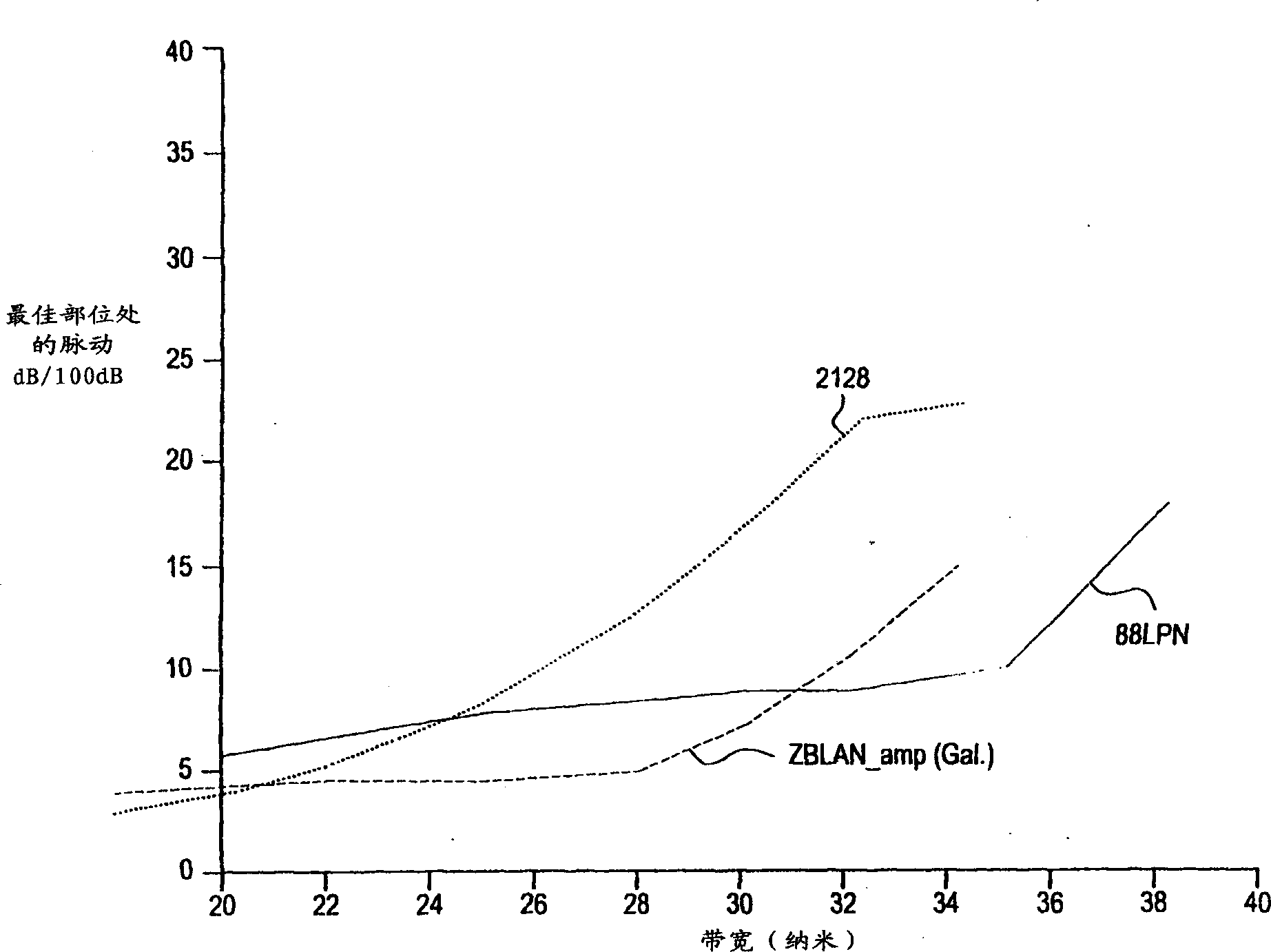

InactiveCN1308591AMaintain stabilityIncrease widthActive medium materialOptical light guidesRare-earth elementPolymer science

The present invention relates to a glass matrix which includes 4-70 wt.% SiO2, 0.5-20 wt.% Al2O3, 0-20 wt.% R2O, 0-30 wt.% R'O, 8-85 wt.% Ta2O5, 0-40 wt.% Nb2O5, and 0.01-1.0 wt.% R''2O3, where R2O + R'O is between about 2-35 wt.%, Ta2O5 + Nb2O5 is between about 8-85 wt.%, R is selected from a group consisting of Li, Na, K, and combinations thereof, R' is selected from a group consisting of Ba, Sr, Ca, Mg, Zn, Pb, and combinations thereof, and R'' is a rare earth element. The present invention also relates to use of the glass matrix in forming optic waveguides such as optic amplifiers. The present invention further relates to a transparent glass ceramic that contains pyrochlore, perovskite, or a combination thereof as its major crystal phase, and includes 4-40 wt.% SiO2, 1-15 wt.% Al2O3, 0-20 wt.% K2O, 0-12 wt.% Na2O, 0-5 wt.% Li2O, 8-85 wt.% Ta2O5, and 0-45 wt.% Nb2O5, wherein Ta2O5 + Nb2O5 is at least about 20 wt.% and (K2O + Li2O + Na2O) is between about 5-20 wt.%. Also disclosed is a method of making the glass ceramic and use of the glass ceramic as a ferro-electric component in electro-optical devices or as a filtering core in an optical filtering device.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com