Preparation method of high-efficiency nickel-based catalyst for producing hydrogen in methanol-steam reforming

A technology for producing hydrogen from methane steam and reforming, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. The preparation method is simple, the activity is stable, and the conditions are easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Ni / Y 2 Zr 2 o 7 Particle catalyst, the preparation method is as follows:

[0025] (1) Y(NO) with Y:Zr (molar ratio) of 1:1 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

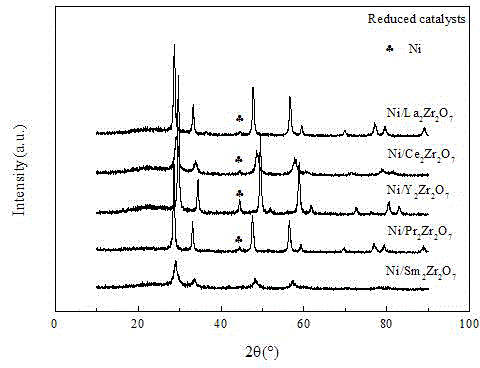

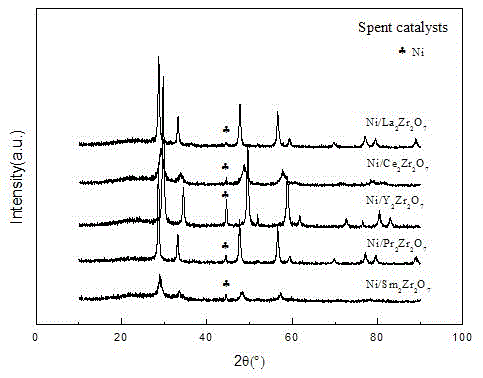

[0026] (2) Dilute industrial ammonia water with a concentration of 25% to 1 time as a precipitant, and slowly add ammonia water dropwise to the above solution (1) to pH = 2-3 under continuous stirring at 40 ° C, and after stirring for 1 hour, at 80 Evaporate in an oven at ℃ to form a gel, rise to the ignition temperature of 200℃ until the combustion reaction occurs; dry the combustion product at 110℃ for 12 hours, and bake in a high-temperature furnace at 800℃ for 4 hours. The furnace temperature setting program is: room temperature at 2℃ / min to the target temperature of 800°C. Produced rare earth Y 2 Zr 2 o 7 Pyrochlore composite oxide support, characterized by XRD, such as figure 1 As shown, the carrier h...

Embodiment 2

[0030] Ni / La 2 Zr 2 o 7 Particle catalyst, the preparation method is as follows:

[0031] (1) La(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

[0032] (2) Dilute industrial ammonia water with a concentration of 25% to 1 time as a precipitant, and slowly add ammonia water dropwise to the above solution (1) to pH = 2-3 under continuous stirring at 40 ° C, and after stirring for 1 hour, at 80 Evaporate in an oven at ℃ to form a gel, rise to the ignition temperature of 300℃ until the combustion reaction occurs; dry the combustion product at 110℃ for 12 hours, and bake in a high-temperature furnace at 800℃ for 4 hours. The furnace temperature setting program is: room temperature at 2℃ / min to reach the target temperature. Rare earth La 2 Zr 2 o 7 Pyrochlore composite oxide support, characterized by XRD, such as figure 1 As shown, the carrier has pyrochlore-type structure characterist...

Embodiment 3

[0036] Ni / Sm 2 Zr 2 o 7 Particle catalyst, the preparation method is as follows:

[0037] (1) Sm(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·5H 2 O is dissolved in metered deionized water to form a solution with a concentration of 0.5mol / L;

[0038] (2) Dilute industrial ammonia water with a concentration of 25% to 1 time as a precipitant, and slowly add ammonia water dropwise to the above solution (1) to pH = 2-3 under continuous stirring at 40 ° C, and after stirring for 1 hour, at 80 Evaporate in an oven at ℃ to form a gel, rise to the ignition temperature of 300℃ until the combustion reaction occurs; dry the combustion product at 110℃ for 12 hours, and bake in a high-temperature furnace at 800℃ for 4 hours. The furnace temperature setting program is: room temperature at 2℃ / min to reach the target temperature. Produced rare earth Y 2 Zr 2 o 7 Pyrochlore composite oxide support, characterized by XRD, such as figure 1 As shown, the carrier has pyrochlore-type structure char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com