CMAS-corrosion-resistant multi-component high-entropy pyrochlore structure thermal barrier coating material and preparation method and application thereof

A pyrochlore structure, thermal barrier coating technology, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve the problems of easy cracking and shedding, limited practical application, low thermal expansion coefficient, etc., to improve corrosion resistance. performance, improving thermal expansion and fracture toughness, reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

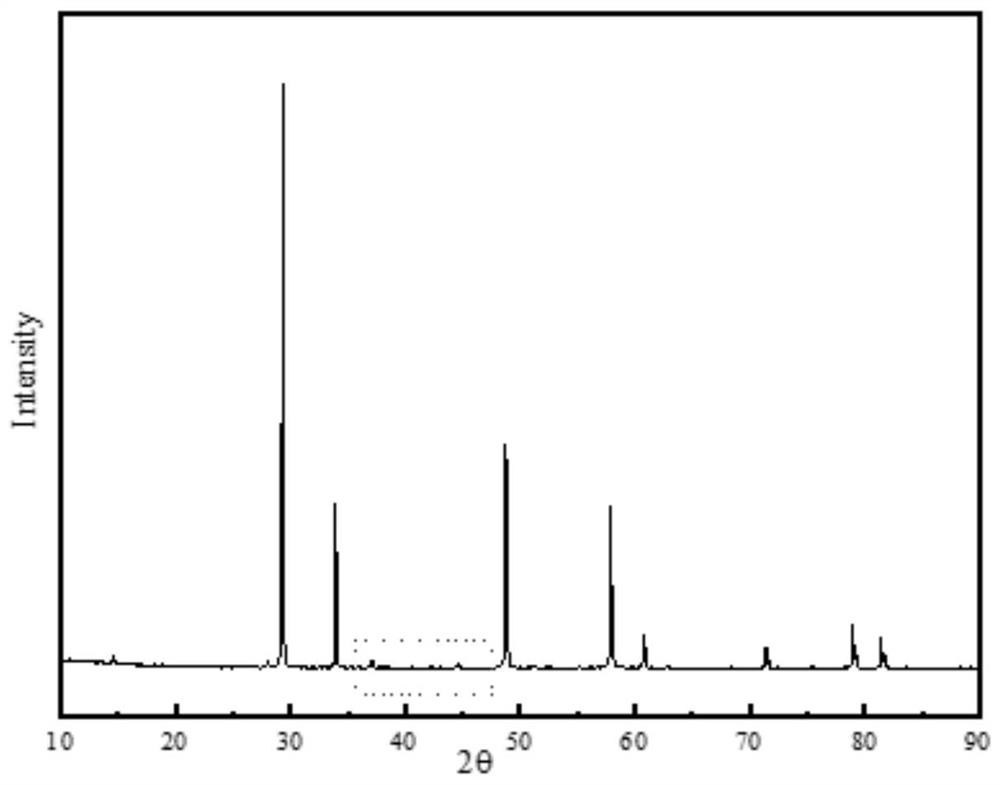

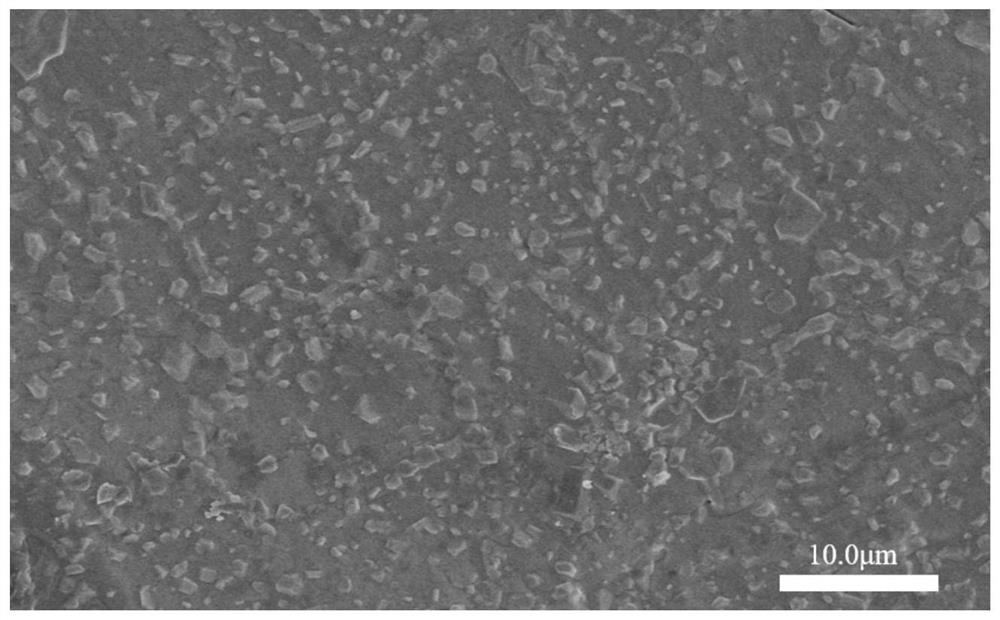

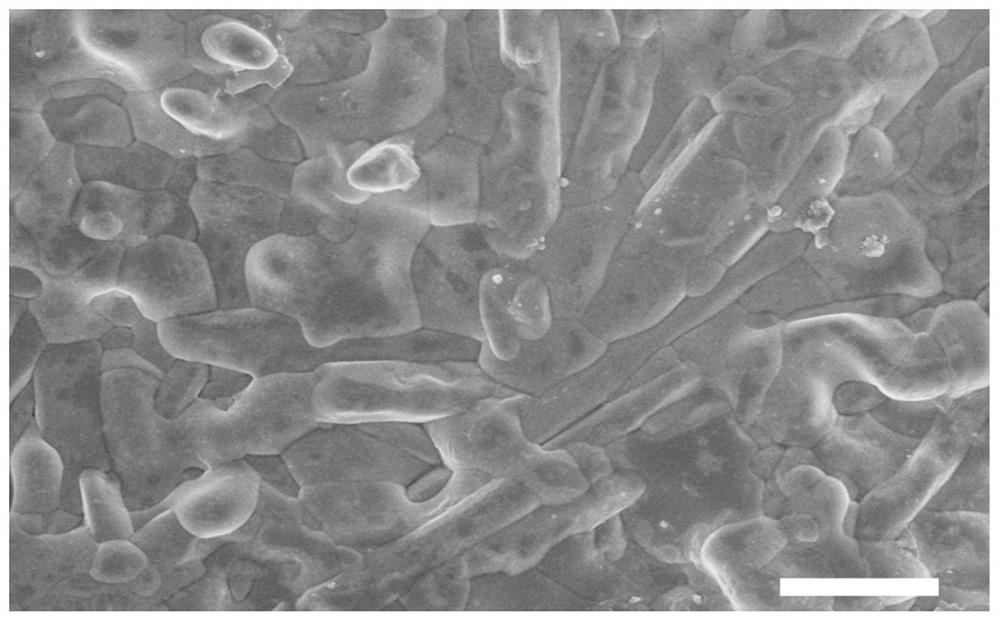

Embodiment 1

[0034] (Yb 0.2 Nd 0.2 SM 0.2 Eu 0.2 Gd 0.2 ) 2 Zr 2 o 7 Preparation of (YHZ): Dissolve ytterbium nitrate, neodymium nitrate, samarium nitrate, europium nitrate and gadolinium nitrate in deionized water to prepare a 0.2mol / L nitrate solution, and dissolve zirconium oxychloride in deionized water to prepare a 0.5 mol / L solution. Mix the solutions in proportion to obtain a mixed solution with a molar ratio of ytterbium ions: neodymium ions: samarium ions: europium ions: gadolinium ions: zirconium ions=1:1:1:1:1:5. The mixed solution was dropped dropwise into excess ammonia solution, and hydroxide precipitate was obtained after stirring and aging, wherein the stirring time was 2 h, and the precipitation aging time was 12 h. The hydroxide precipitate was centrifuged and washed until the silver nitrate solution was added to the supernatant, and no precipitate was formed. After the hydroxide precipitate is dispersed with ethanol, it is dried, ground, sieved with 300 mesh, an...

example 2

[0038] (La 0.2 Nd 0.2 SM 0.2 Eu 0.2 Gd 0.2 ) 2 Zr 2 o 7Preparation of (LHZ): Dissolve lanthanum nitrate, neodymium nitrate, samarium nitrate, europium nitrate and gadolinium nitrate in deionized water to prepare a 0.2mol / L nitrate solution, and dissolve zirconium oxychloride in deionized water to prepare a 0.5 mol / L solution. Mix the solutions in proportion to obtain a mixed solution with a molar ratio of lanthanum ions: neodymium ions: samarium ions: europium ions: gadolinium ions: zirconium ions=1:1:1:1:1:5. The mixed solution was dropped dropwise into excess ammonia solution, and hydroxide precipitate was obtained after stirring and aging, wherein the stirring time was 2 h, and the precipitation aging time was 12 h. The hydroxide precipitate was centrifuged and washed until the silver nitrate solution was added to the supernatant, and no precipitate was formed. After the hydroxide precipitate is dispersed with ethanol, it is dried, ground, sieved with 300 mesh, and...

example 3

[0042] (Y 0.2 La 0.2 Nd 0.2 SM 0.2 Gd 0.2 ) 2 (Zr 0.5 Ti 0.5 ) 2 o 7 Preparation: Dissolve yttrium nitrate, lanthanum nitrate, neodymium nitrate, samarium nitrate and gadolinium nitrate in deionized water to make 0.2mol / L nitrate solution, and dissolve zirconium nitrate in deionized water to make 0.5mol / L For the solution, tetrabutyl titanate was dissolved in ethylene glycol to form a 0.5mol / L solution, and citric acid was mixed with ethylene glycol at a ratio of total metal ions: citric acid = 1:1.2, and stirred until a transparent solution was formed. Mix the solutions in proportion to obtain a mixed solution with a molar ratio of yttrium ion: lanthanum ion: neodymium ion: samarium ion: gadolinium ion: zirconium ion: titanium ion = 2:2:2:2:2:5:5, adjusted with ammonia water The pH of the solution is neutral, heated at 80°C until gel is formed, the gel is calcined at 500°C for 2 hours, the obtained powder is ground to 300 mesh and sieved, and calcined at 1300°C for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com