Active optoceramics with cubic crystal structure, method of production of the optoceramics, and uses thereof

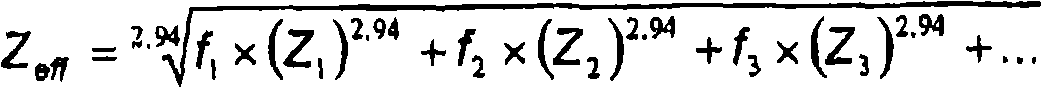

A technology of electro-optic ceramics and cubic structure, which is applied in chemical instruments and methods, luminescent materials, radiation measurement, etc., and can solve problems such as opacity, difficulty in preparation, and low effective atomic number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] working example

[0092] 1. By uniaxial pressing (with reactive sintering) from Ce:Gd 2 f 2 o 7 and Ce:Lu 2 f 2 o 7 The embodiment that prepares transparent ceramic

[0093] In proportion to target composition, weighed from CeO 2 、Gd 2 o 3 or Lu 2 o 3 and HfO 2 A powder having primary particles with a diameter 2 The batch was ball mixed for 12 hours.

[0094] The milled suspension was dried on a hot plate.

[0095] The powder was subsequently uniaxially pressed into sheets. The pressure condition is about 20 MPa, and the pressing time is several seconds. The preformed compact (Pressling) is repressed with cooling isostatic pressure, wherein the pressing force is about 180 MPa. The pressure transmission medium is water.

[0096] The binder is then burned off in a first heating step. The tempering time was 2.5 hours and the temperature was 700°C. The fired green body is then fired in a vacuum sintering furnace (negative pressure: 10 -5 mbar) for sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com