Preparation method of gadolinium zirconate-based material, gadolinium zirconate-based ceramic pelletizing powder for ionic spraying and preparation method of gadolinium zirconate-based ceramic pelletizing powder

A gadolinium zirconate-based and ceramic material technology, which is applied in metal material coating process, coating, fusion spraying, etc., can solve the problems of high power consumption, etc., and achieve the effect of improving densification, reducing production cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The invention provides a preparation method of gadolinium zirconate-based ceramic material, comprising the following steps:

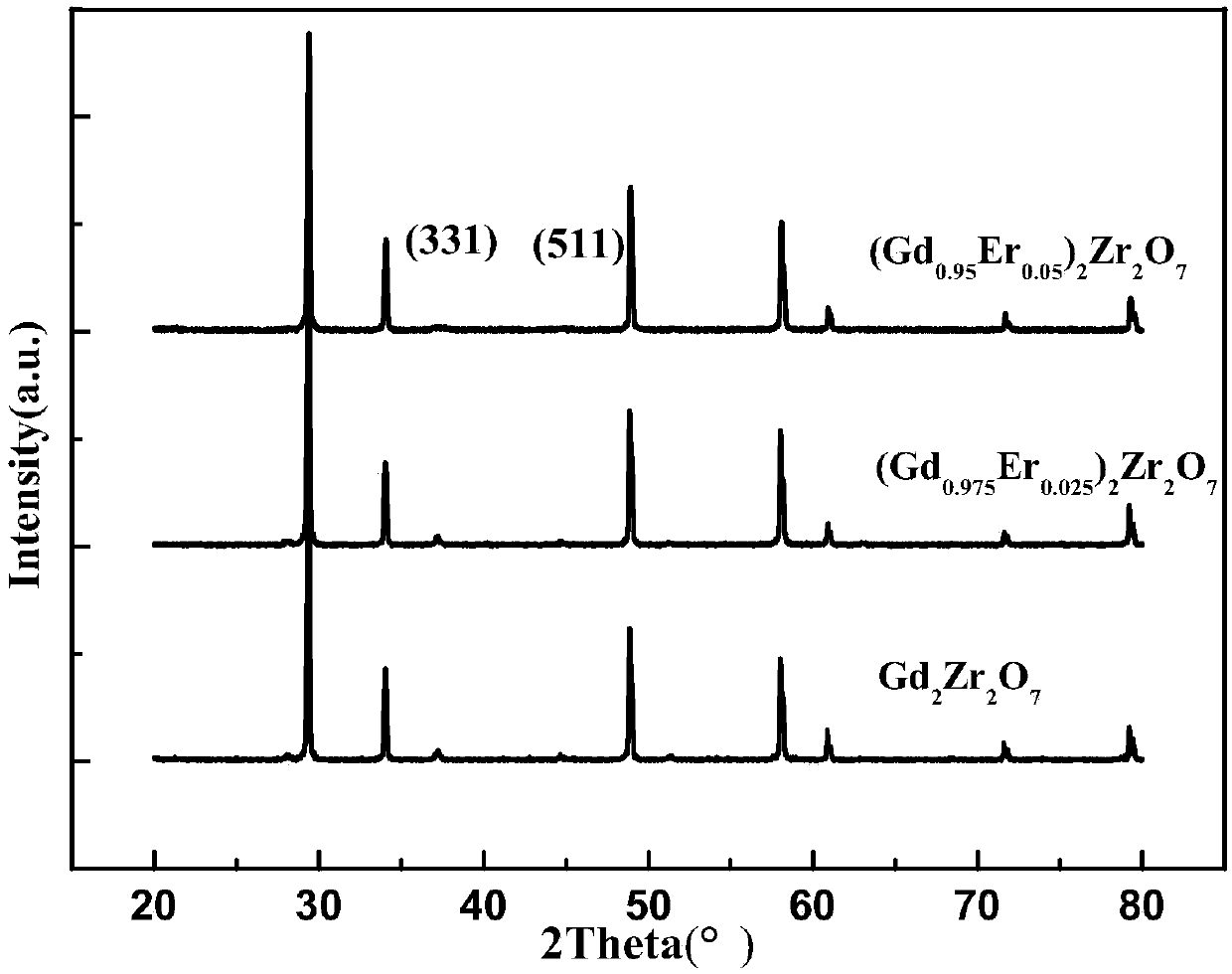

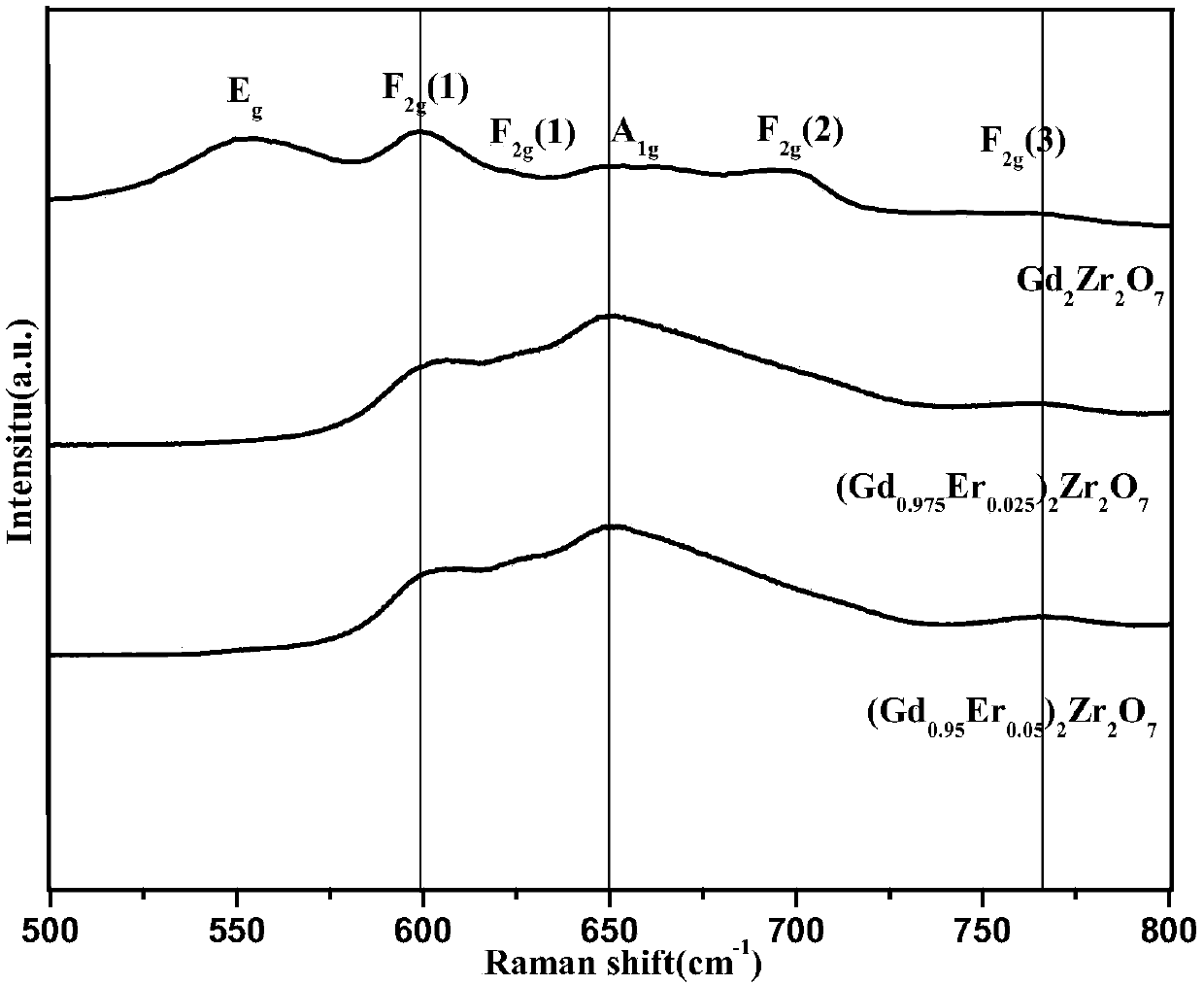

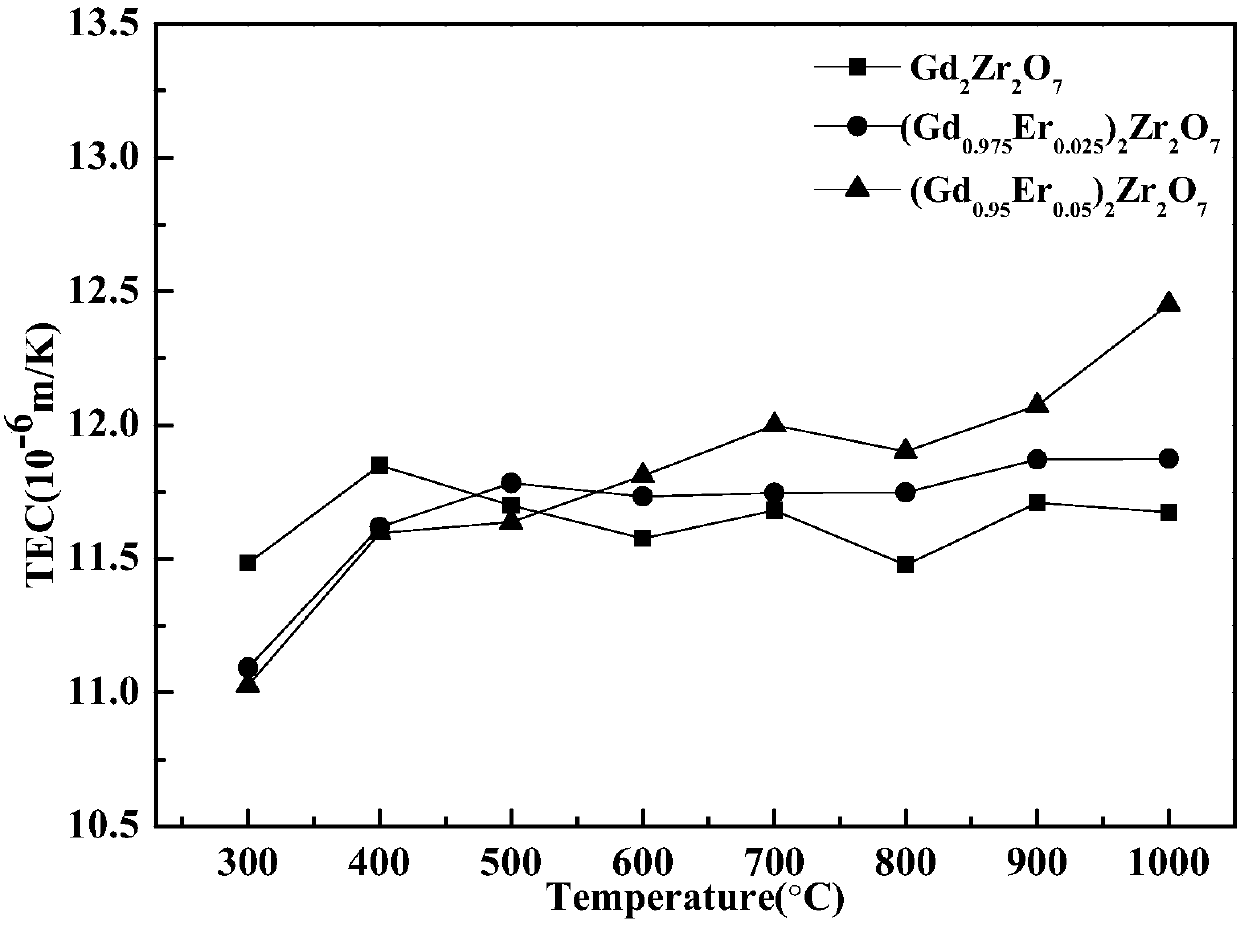

[0044] (1) A mixture comprising zirconia and gadolinium oxide is provided; the particle size of the mixture is below 100nm; the mixture also includes erbium oxide, and the amount of substance of the erbium oxide is the total substance of gadolinium oxide and erbium oxide [0,0.04%] of the amount;

[0045] (2) Carrying out wet sanding to the mixture according to the order of the sanding speed from low to high, to obtain sanding slurry;

[0046] (3) drying the sanding slurry obtained in the step (2) to obtain a sanding powder;

[0047] (4) Carry out atmospheric pressure sintering to the sand-milled powder that described step (3) obtains, obtain the gadolinium zirconate-based ceramic material of bulk;

[0048] Or press the sand mill powder obtained in the step (3) and carry out normal pressure sintering to obtain powdery gadolinium zirconate-based ...

Embodiment 1

[0102] (1) According to the stoichiometric ratio, Gd with a chemical purity ≥ 99.99% 2 o 3 and ZrO 2 The powder is placed in a polyurethane ball mill tank with a molar ratio of 1:2, and ball milled at a speed of 140r / min for 1 hour to meet the feed particle size requirements of the sand mill and prevent coarse particles from clogging the pipeline. Both the inner lining of the stirring ball mill and the jacket of the stirring rod are made of polyurethane, 8-10mm zirconia balls are used for the grinding body, and deionized water is used for the dispersion medium. Material passes through 80 mesh sieves.

[0103] (2) Use a sand mill to further grind the powder. The ball milling medium is deionized water, and the grinding body with a particle size of 0.3mm is zirconia beads. The mass ratio of material: balls: deionized water is 1:1.3 : 2, the amount of dispersant polymethacrylic acid amine is 0.7wt% of the raw material powder, and the speed of the sand mill is 2200r / min, 2400r / m...

Embodiment 2

[0107] (1) According to the stoichiometric ratio, Gd with a chemical purity ≥ 99.99% 2 o 3 、Er 2 o 3 and ZrO 2 The powder was placed in a polyurethane ball mill tank at a molar ratio of 0.975:0.025:2, and ball milled at a speed of 140r / min for 2 hours to meet the feed particle size requirements of the sand mill and prevent coarse particles from clogging the pipeline. Both the lining of the stirring ball mill and the jacket of the stirring rod are made of polyurethane, the grinding body uses 8-10mm zirconia balls, the dispersion medium uses deionized water, the mass ratio of material to ball is 1:2, and the mass ratio of material to water is 1:1. Material passes through 80 mesh sieves.

[0108] (2) Use a sand mill to further grind the powder. The ball milling medium is deionized water, and the grinding body with a particle size of 0.3mm is zirconia beads. The mass ratio of material: balls: deionized water is 1:1.5 : 2, the amount of dispersant polymethacrylic acid amine is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com