Alkali reductive water diaphragm-free electrolysis device

An electrolysis device without a diaphragm technology, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of inability to obtain a wide range of alkalinity and long time for electrolysis of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

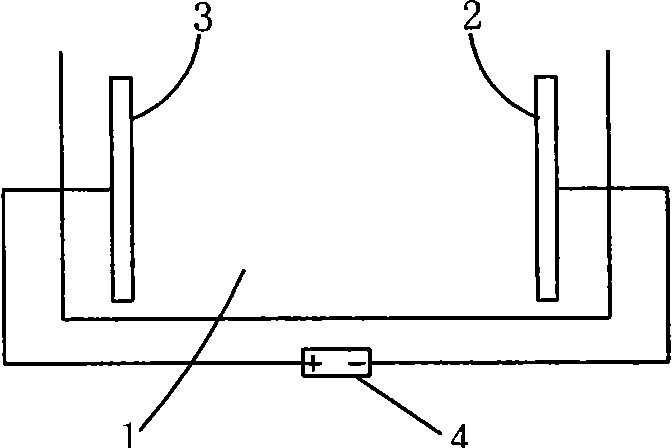

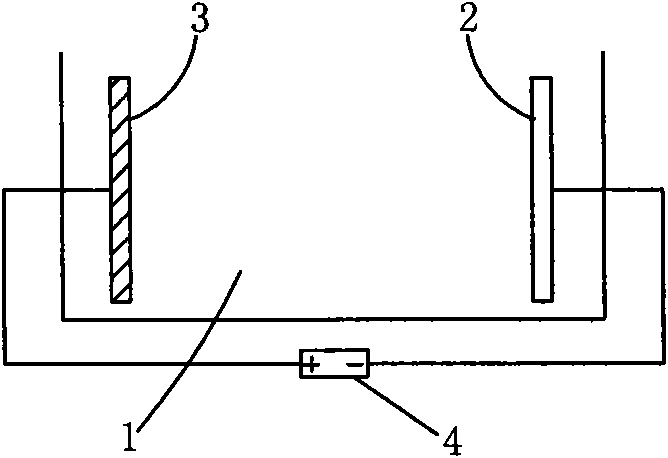

[0047] The alkaline reduced water electrolysis device without diaphragm of the present embodiment is as figure 2 As shown, it includes a water container 1, a pair of negative and positive electrodes 2, 3 placed in the water container 1, and a DC power supply 4 electrically connected to the negative and positive electrodes 2, 3. The positive electrode 3 is a plate-shaped activated carbon electrode made of activated carbon. The activated carbon is specifically made of high-quality coconut shell granular activated carbon and carbon black is added, and an appropriate amount of polytetrafluoroethylene emulsion adhesive is added. It is then dried at 220°C and finally cut. The negative electrode 2 is a plate-shaped metal electrode made of a titanium plate coated with an inert metal layer (platinum layer). The cathode and anode electrodes 2 and 3 have the same geometric shape but different thicknesses, both are 120mm×80mm, and the thickness is 0.3mm. The cathode electrode 2 has a th...

Embodiment 2

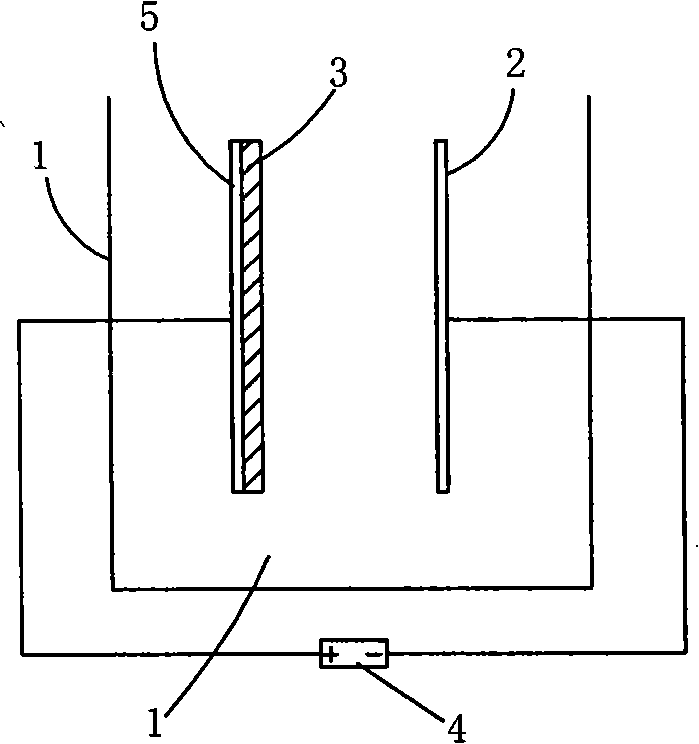

[0056] The alkaline reduced water electrolysis device without diaphragm of the present embodiment is as image 3 As shown, its structural composition is basically the same as that of Embodiment 1, and the difference is: 1) the anode plate 3 also contains an auxiliary metal electrode 5 made of metal, and the auxiliary metal electrode 5 is attached to a part (one side) of the activated carbon electrode surface And form a composite electrode with the activated carbon electrode, the other part (the other side) of the surface of the activated carbon electrode faces the cathode plate 2, and the auxiliary metal electrode 5 adopts the same titanium-based surface as the cathode plate 2 to coat platinum; 2) DC power supply is the output DC stabilized power supply with a voltage of 30V and a current of 2A; 3) Activated carbon is made of high-quality bamboo carbon with carbon black added and shaped by nano-activation treatment, sintered at a temperature of 750°C, and finally cut. The spec...

Embodiment 3

[0064] The alkaline reduced water electrolysis device without diaphragm of the present embodiment is as Figure 4 As shown, its structural composition is basically the same as that of Example 2, the difference is: 1) the auxiliary metal electrode 5 is made of titanium metal mesh 120mm × 80mm × 15mm expanded mesh, activated carbon is wrapped in the expanded mesh; 2) negative, The position where the anode electrodes 2 and 3 are placed in the water container 1 is exactly rotated by 90 degrees compared with the position in Example 2; 3) The activated carbon is sintered at a temperature of 900°C, and the specific surface area of the activated carbon electrode is 950m 2 / g, its resistivity is 2.6 / Ω·cm -1 ; 4) The DC power supply is formed by 220 volt mains electricity after transformer isolation and full-wave rectification, with an output voltage of 18V and a current of 1A.

[0065] The present inventor combined the alkaline reduced water electrolysis device without diaphragm of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com