A kind of composite fabric electrode for flexible supercapacitor and its preparation and application

A fabric electrode and ternary composite technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low specific capacity and insufficient stability of flexible electrode materials, and achieve low performance requirements and high stability of equipment Sexuality, maintaining flexibility and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Synthesis of organic ligands:

[0040] 1mmol 3,4,9,10-perylenetetracarboxylic dianhydride and 2mmol 2-aminobenzimidazole were ultrasonically dispersed in 40mL N,N-dimethylformamide, heated in an oil bath at 150°C for 10 days, centrifuged, washed with ethanol, get organic ligands;

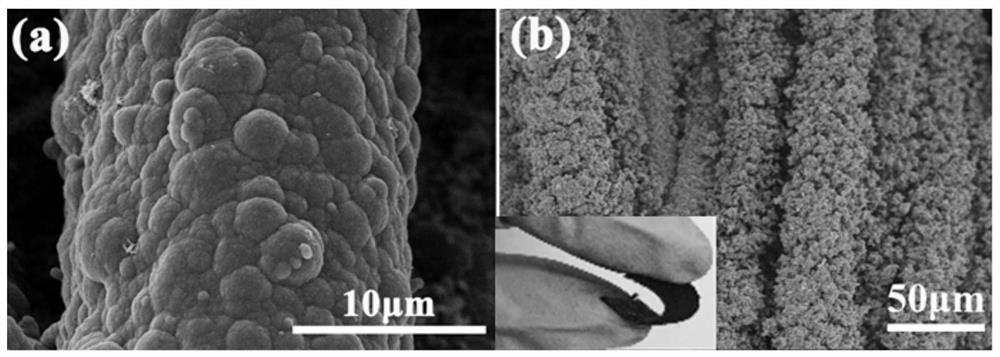

[0041] (2) Preparation of MOFs / carbon material composite nanoparticles and metal oxide / carbon material composite nanomaterials:

[0042] Ultrasonic preparation of 3g / L carbon nanotube dispersion; disperse the organic ligand in (1) in 20mL N, N-dimethylformamide, and then add it to the carbon nanotube dispersion to obtain a mixed solution, organic ligand and metal The molar ratio of salt is 1:5; CoCl with a total ion concentration of 0.005mol / L 2 ·6H 2 O and NiCl 2 ·6H 2 Add O into the mixture, the molar ratio of the two is 2:1, ultrasonically disperse for 50min, react at 100°C for 24h, after the reaction, filter with suction, and dry at 80-100°C to obtain Ni / Co-MOFs / carbon nanotube c...

Embodiment 2

[0048] (1) Synthesis of organic ligands:

[0049] 1mmol 3,4,9,10-perylenetetracarboxylic dianhydride and 6mmol 5-aminobenzimidazole were ultrasonically dispersed in 40mL N,N-dimethylformamide, heated in an oil bath at 140°C for 3 days, centrifuged, washed with ethanol, get organic ligands;

[0050] (2) Preparation of MOFs / carbon material composite nanoparticles and metal oxide / carbon material composite nanomaterials:

[0051] Ultrasonic preparation of 5g / L carbon nanotube dispersion; disperse the organic ligand in (1) in 20mL methanol, and then add it to the carbon nanotube dispersion to obtain a mixed solution, the molar ratio of organic ligand and metal salt is 1:3 ; CoCl with a total ion concentration of 0.01mol / L 2 ·6H 2 O and NiCl 2 ·6H 2 Add O into the mixture, the molar ratio of the two is 2:1, ultrasonically disperse for 50min, react at 100°C for 24h, after the reaction, filter with suction, and dry at 80-100°C to obtain Ni / Co-MOFs / carbon nanotube composite Nanop...

Embodiment 3

[0057] (1) Synthesis of organic ligands:

[0058] 1mmol 3,4,9,10-perylenetetracarboxylic dianhydride and 2mmol 2-aminoimidazole were ultrasonically dispersed in 40mL N,N-dimethylformamide, heated in an oil bath at 150°C for 10 days, centrifuged, washed with ethanol, and organic Ligand;

[0059] (2) Preparation of MOFs / carbon material composite nanoparticles and metal oxide / carbon material composite nanomaterials:

[0060] Ultrasonic preparation of 10g / L carbon nanotube dispersion; disperse the organic ligand in (1) in 20mL methanol, and then add it to the carbon nanotube dispersion to obtain a mixed solution, the molar ratio of organic ligand and metal salt is 2:1 ; MnCl with a total ion concentration of 0.01mol / L 2 4H 2 O and NiCl 2 ·6H 2 Add O into the mixture, the molar ratio of the two is 1:1, ultrasonically disperse for 50min, react at 100°C for 36h, after the reaction, filter with suction, and dry at 80-100°C to obtain Ni / Mn-MOFs / carbon nanotube composite Nanoparti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com