High-temperature and high-pressure rapid synthesis method of Gd2Zr2O7 pyrochlore ceramic

A gd2zr2o7, high temperature and high pressure technology is applied in the field of high temperature and high pressure rapid synthesis, which can solve the problems of inaccessibility to the actual needs of engineering, low efficiency and high cost, and achieve the effects of shortening preparation time, improving efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

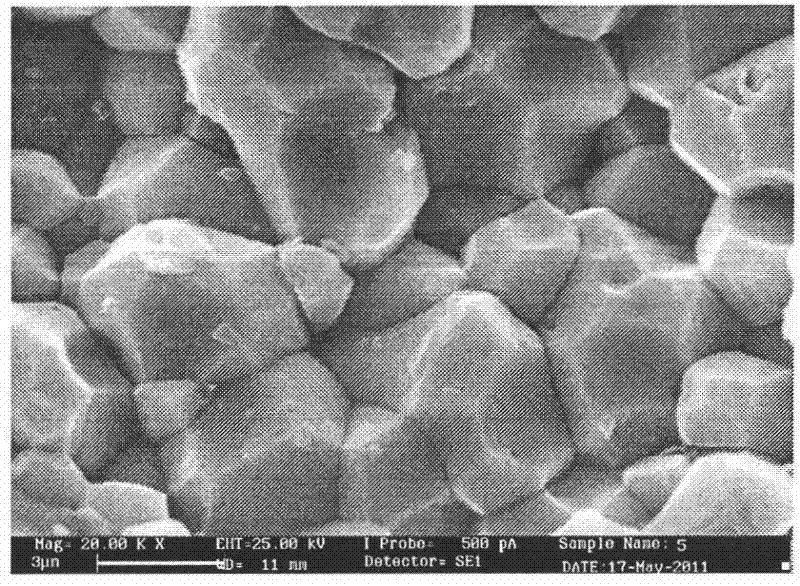

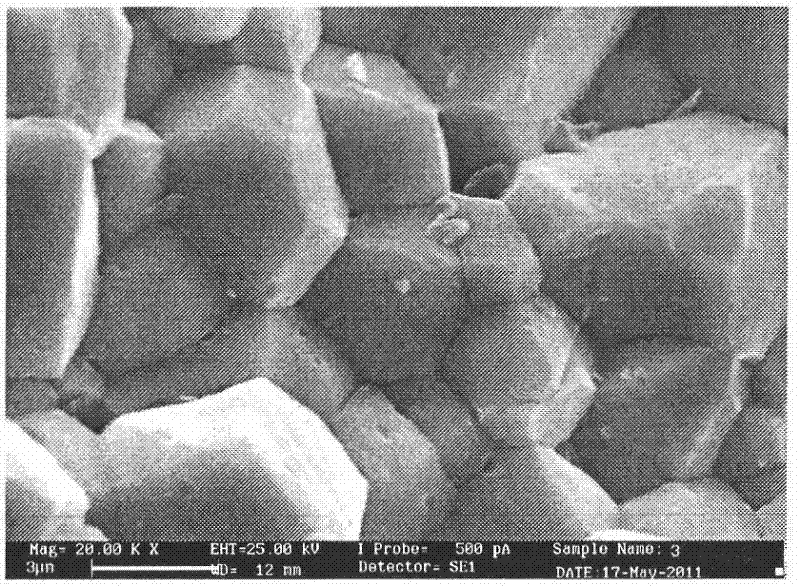

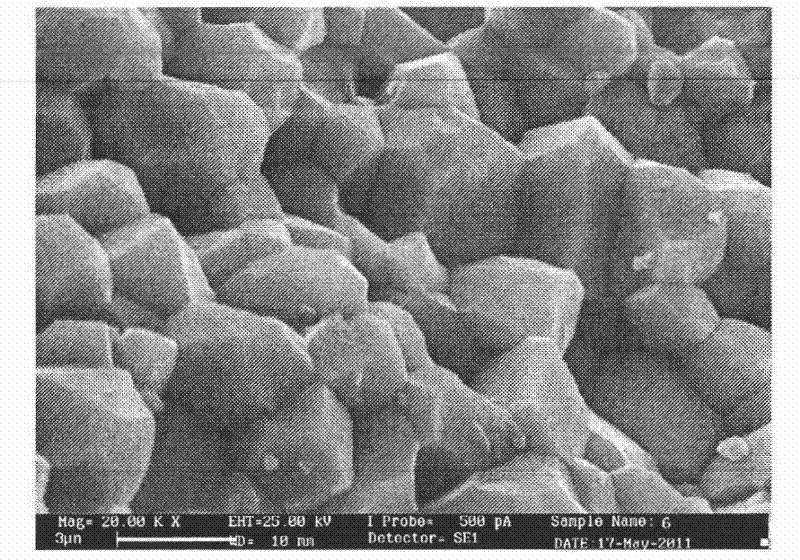

[0037] Embodiment 1-10 of the present invention: a high temperature and high pressure solid phase reaction synthesis method of pyrochlore, including five steps of batching, grinding, drying, dry pressing and high temperature and high pressure synthesis.

[0038] Described batching step presses stoichiometric formula Gd 2-x A x Zr 2 o 7 Take Gd 2 o 3 , ZrO 2 and trivalent element oxide A 2 o 3 Three kinds of raw materials, the trivalent element oxide uses Nd 2 o 3 , then the formula for calculating the mass percentage of Nd is

[0039] W 1 = M Nd M 0 = 144.24 x 144.24 x + 16 × 7 + ( 2 - ...

Embodiment 19-29

[0067] Examples 19-29 of the present invention: a high-temperature, high-pressure solid-phase reaction synthesis method for pyrochlore, including five steps of batching, grinding, drying, dry pressing and sintering at high temperature and high pressure.

[0068] Described batching step presses molecular formula Gd 2-x A x Zr 2-y B y o 7 The ratio of the stoichiometric numbers in is taken as Gd 2 o 3 , ZrO 2 , Trivalent element oxide A 2 o 3 and tetravalent element oxide BO 2 Four raw materials, wherein the trivalent element oxide A 2o 3 and tetravalent element oxide BO 2 Nd 2 o 3 and CeO 2 , then the mass percentage of Nd W 3 and the mass percentage of Ce W 4 respectively

[0069] W 3 = M Nd M 0 = 144.24 x 257.25 ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com