Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Low emission requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

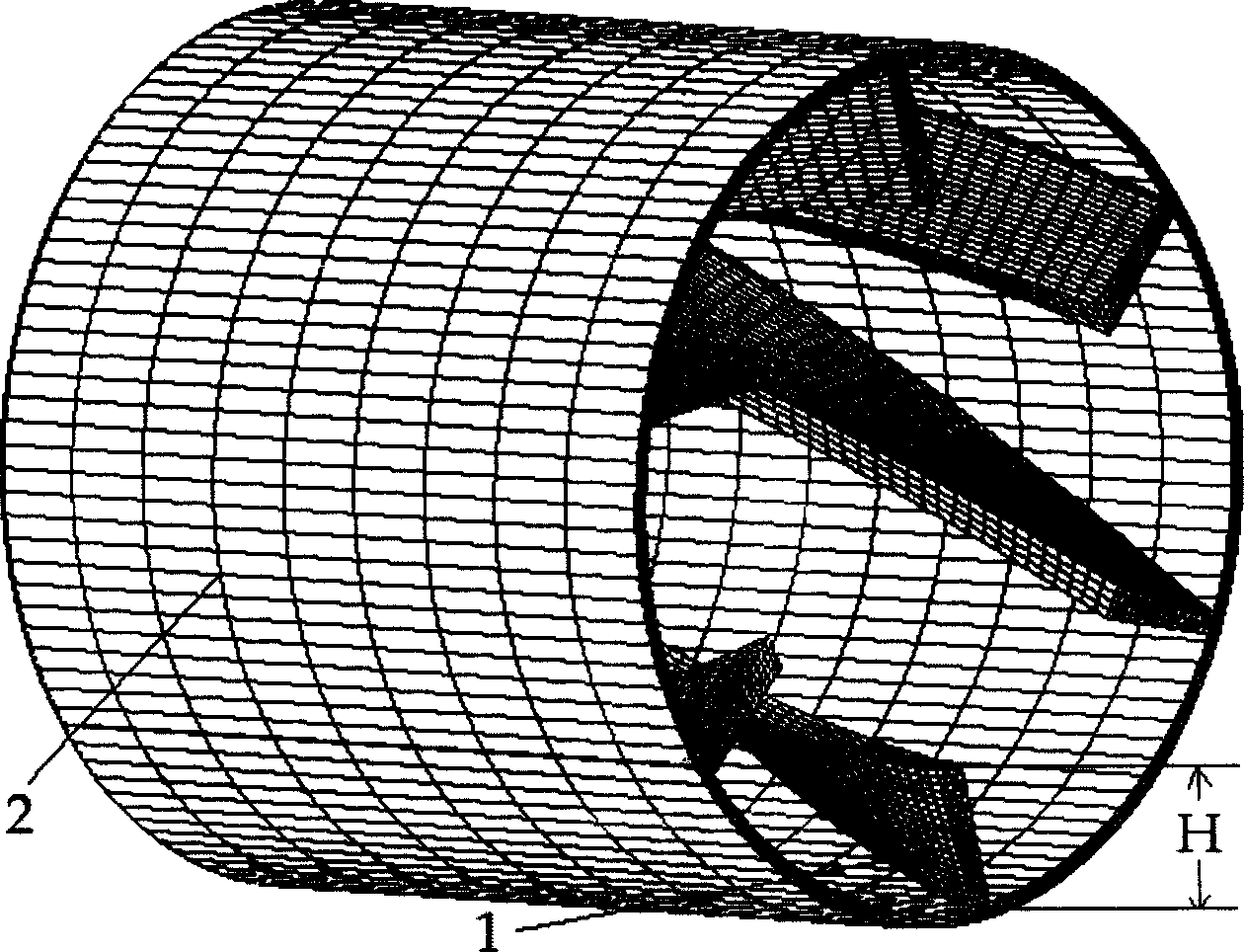

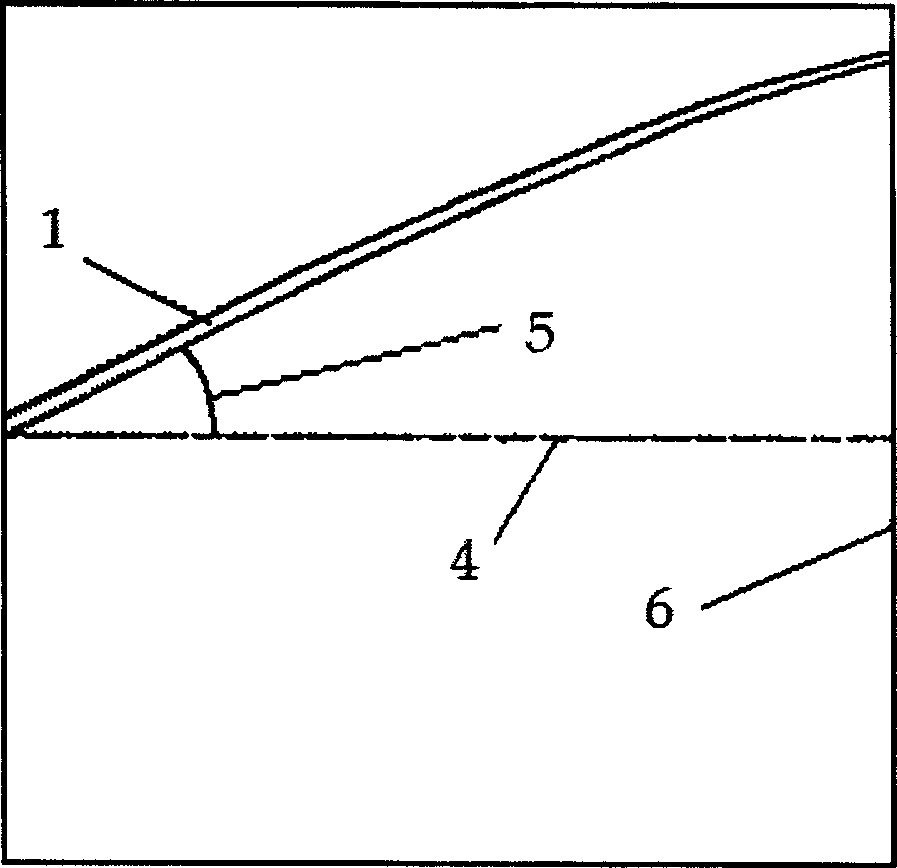

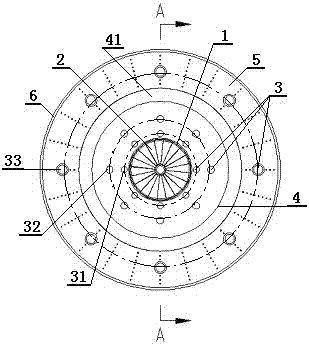

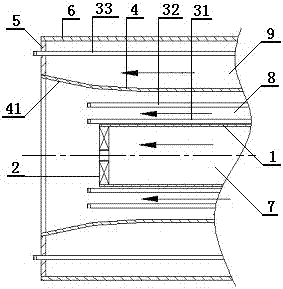

Multi-medium multi-channel discrete low-NOx pulverized coal burner for rotary cement kiln

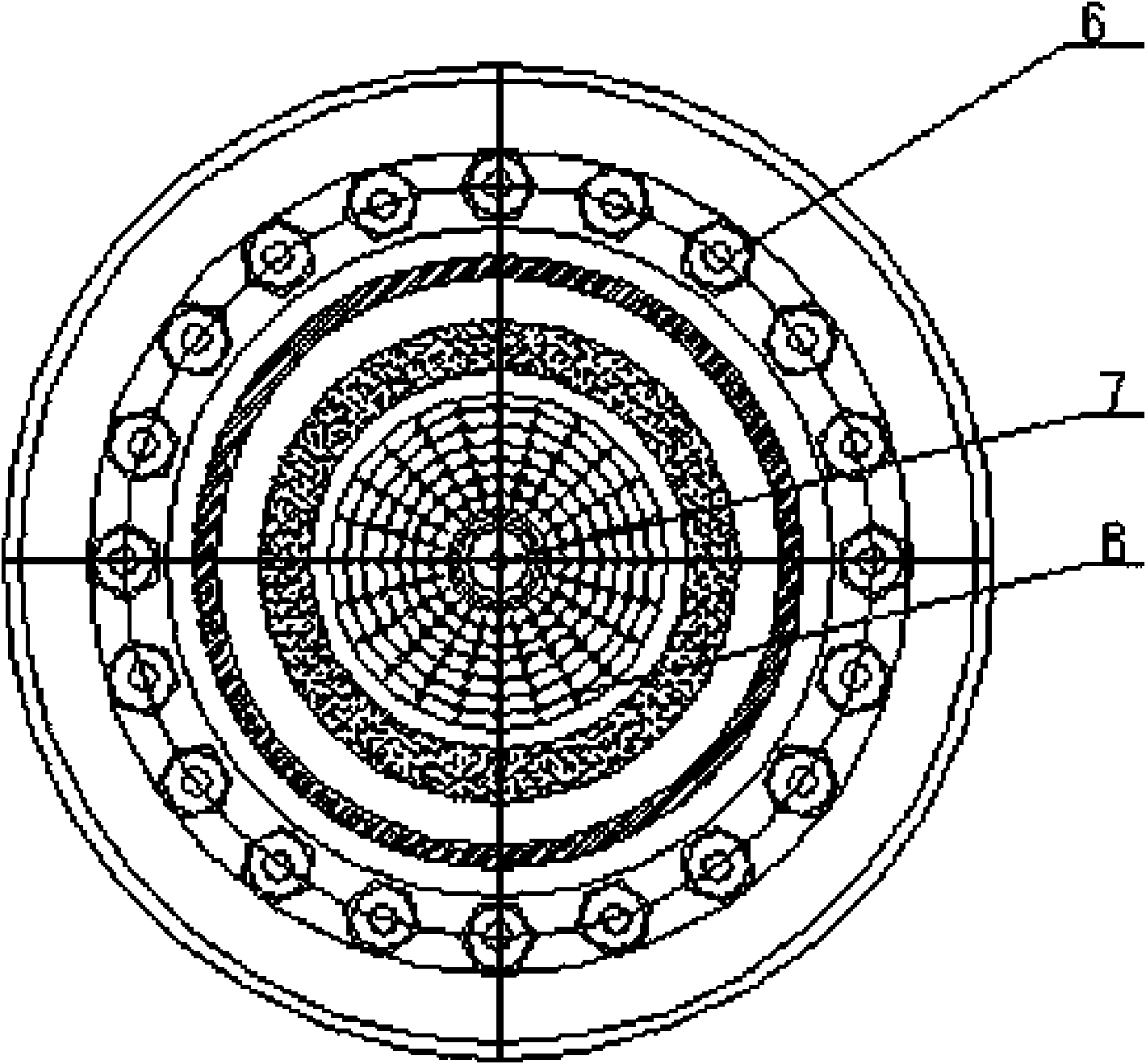

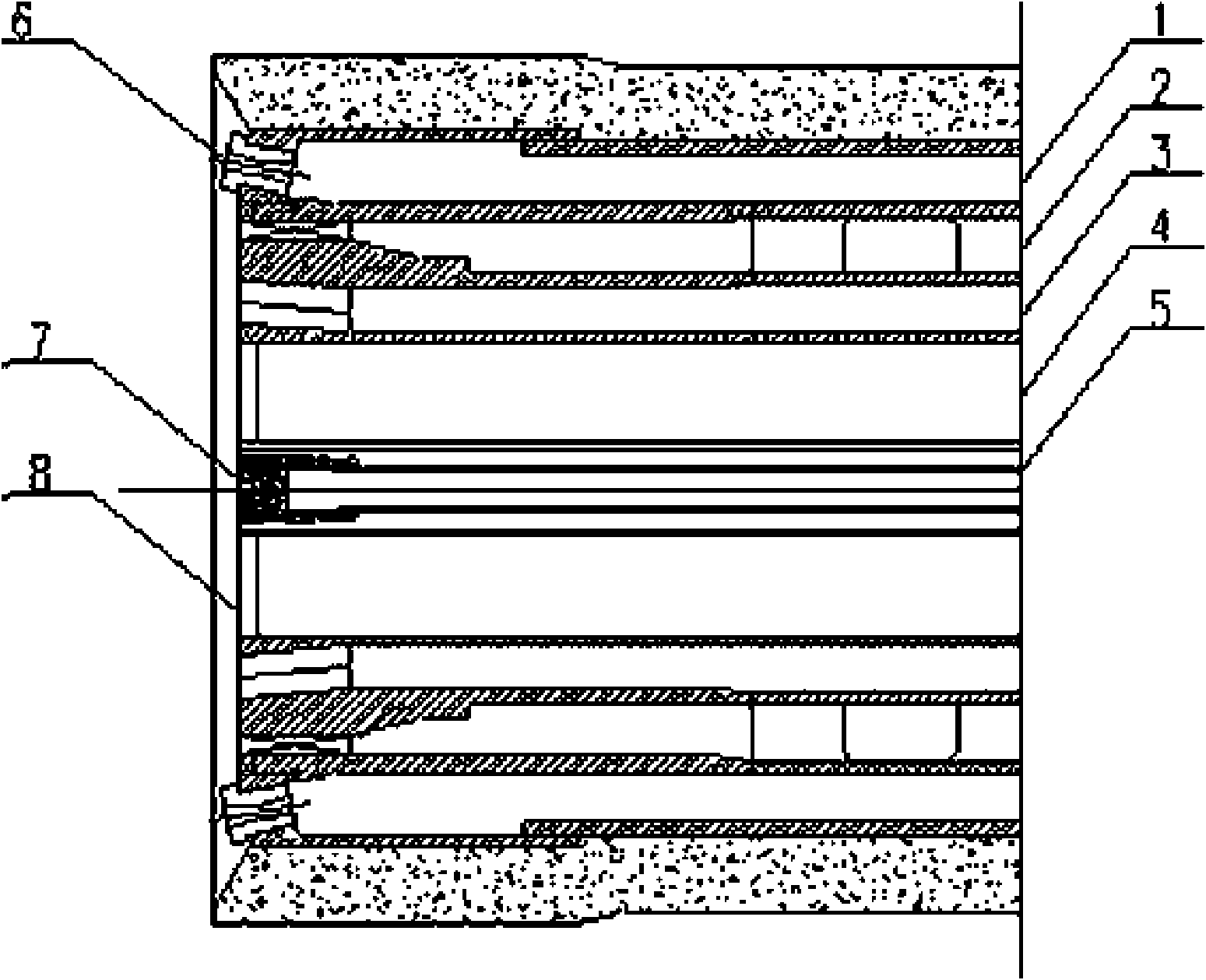

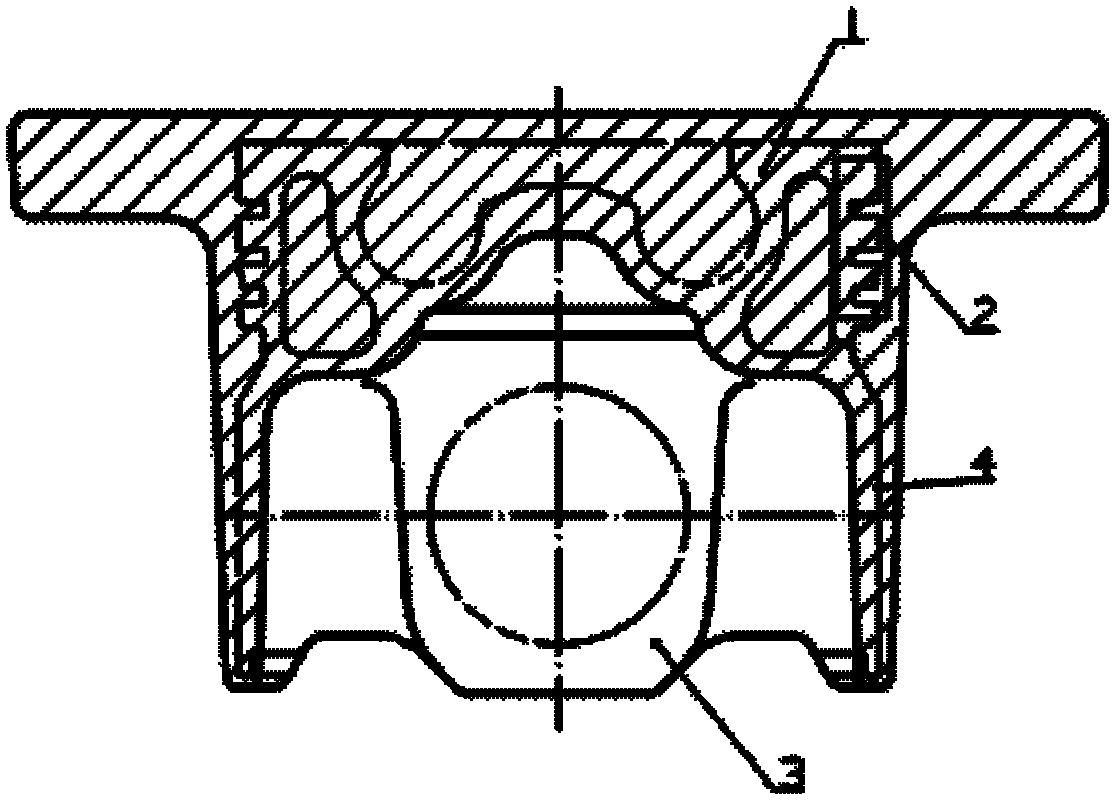

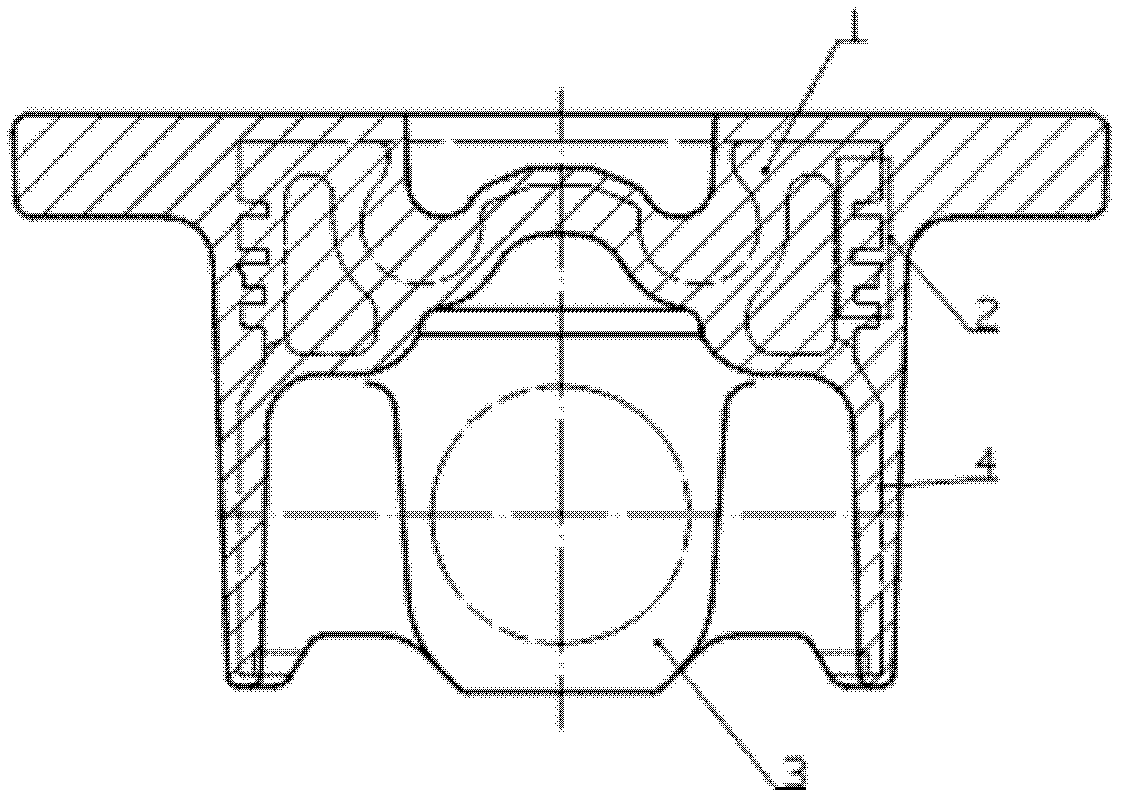

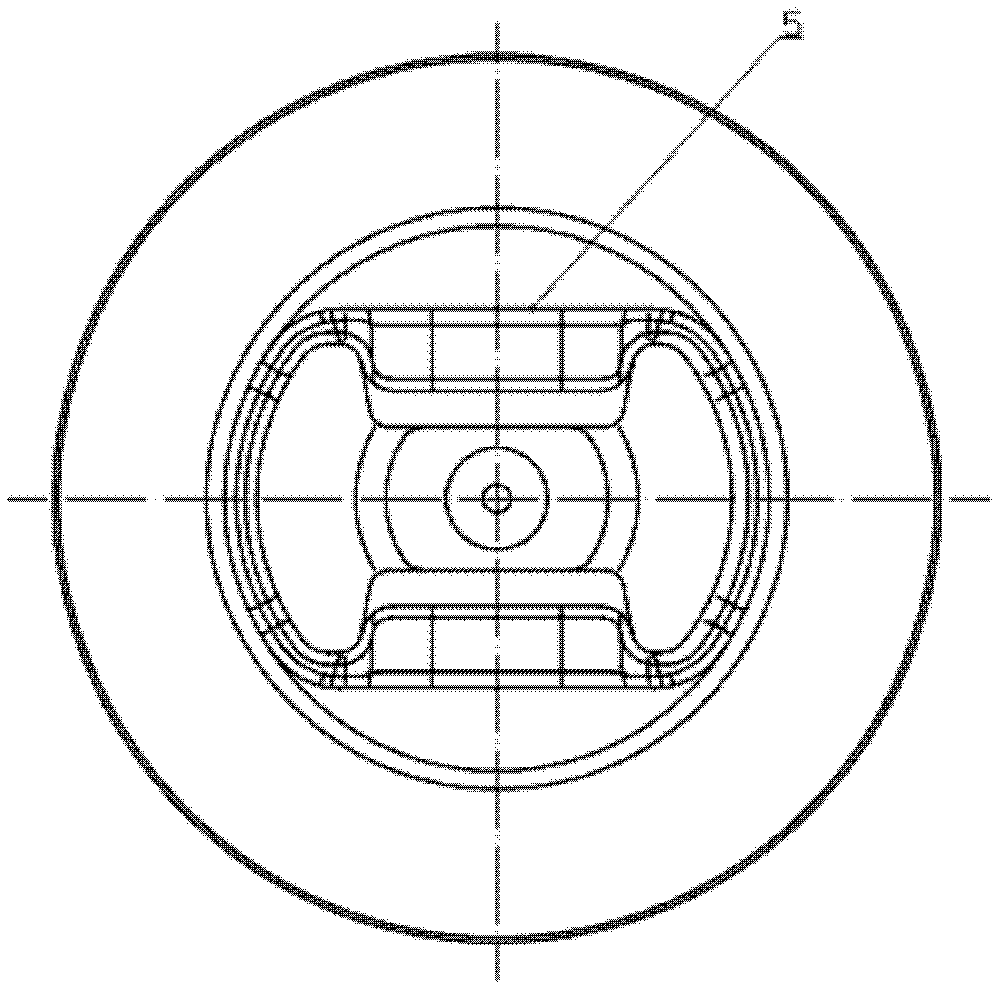

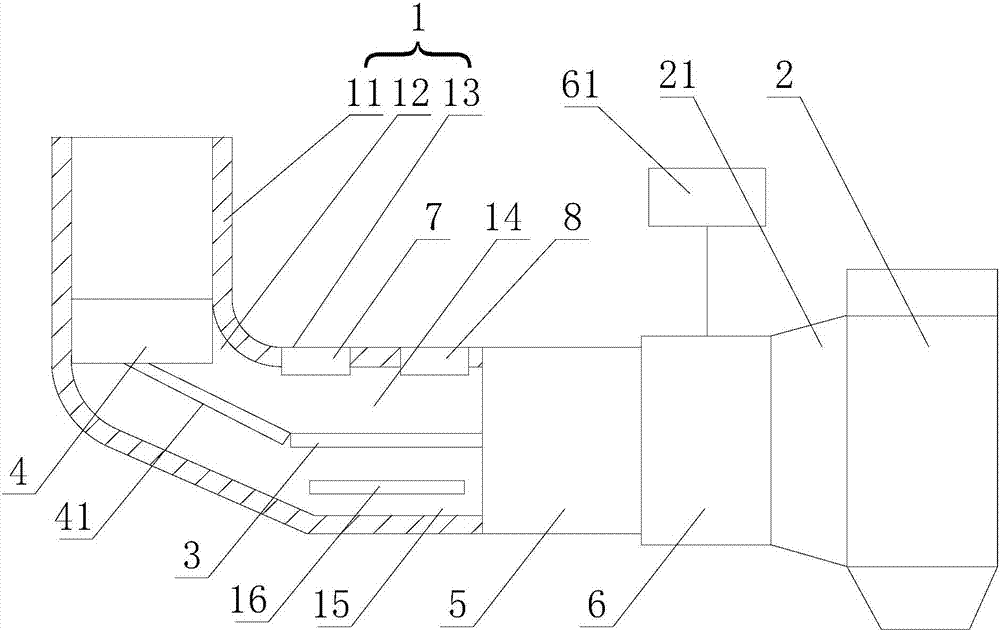

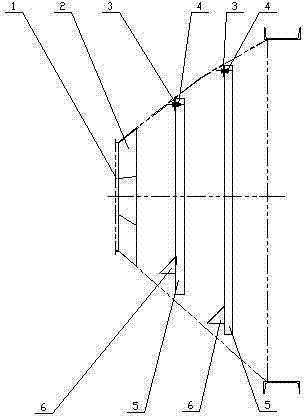

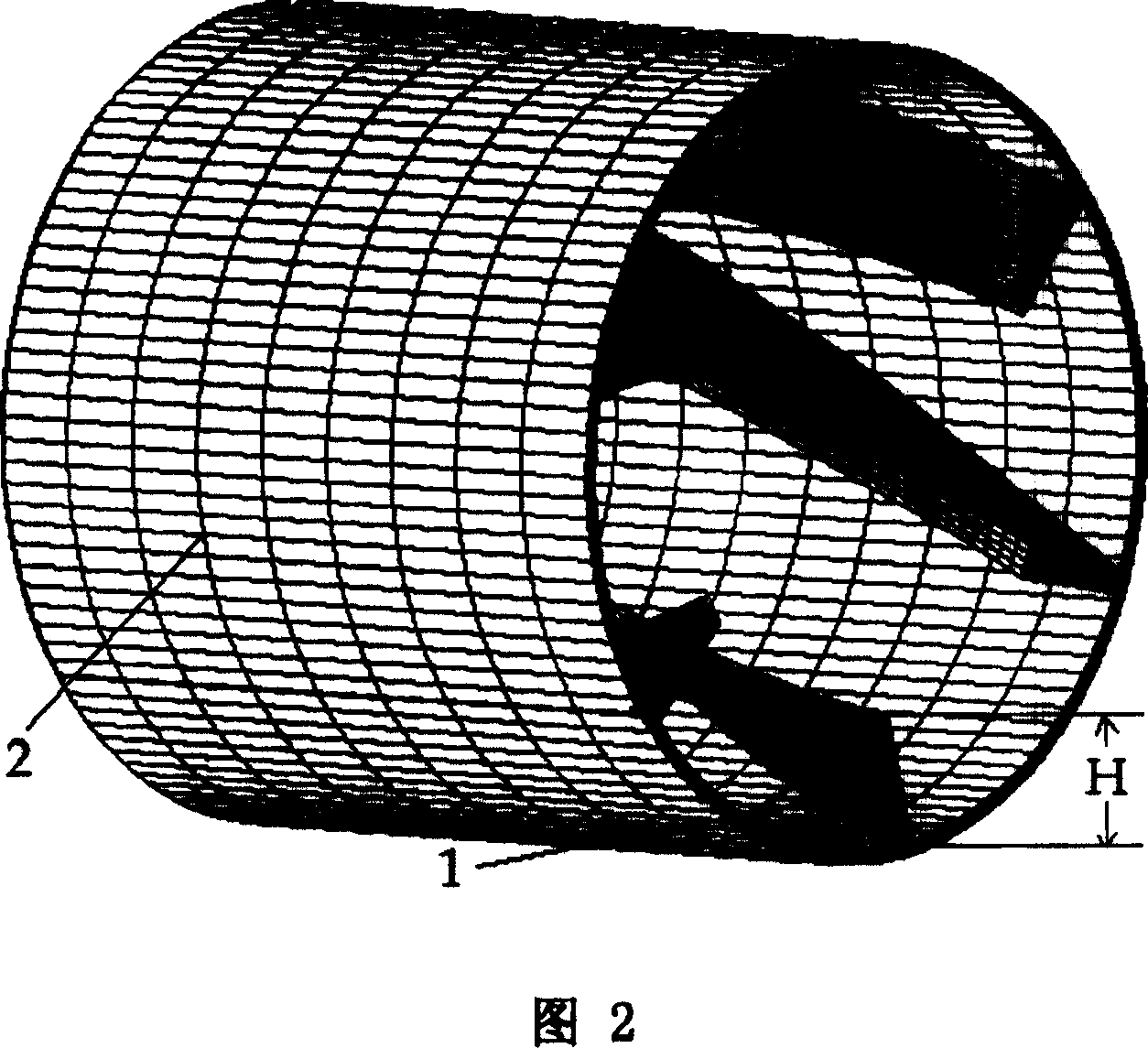

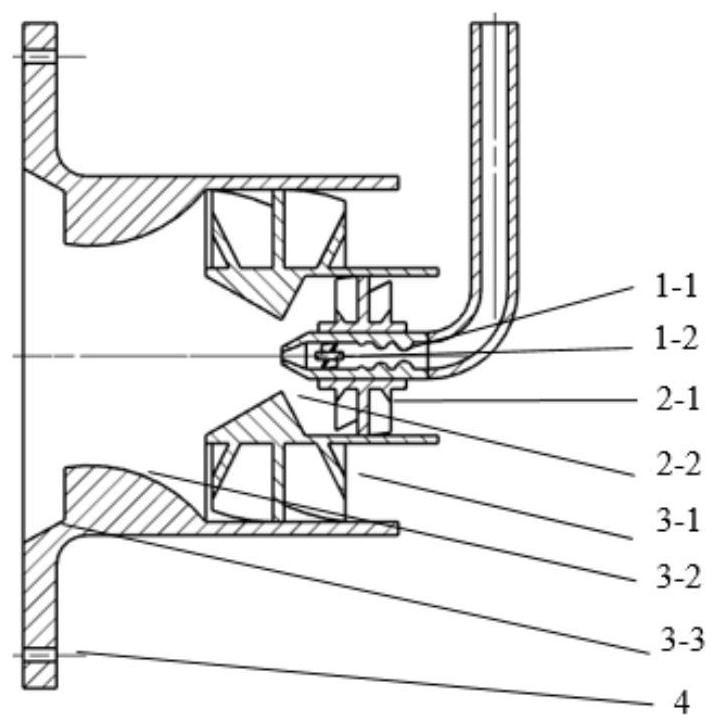

The invention provides a low-NOx pulverized coal burner for a rotary cement kiln, which is characterized by effectively controllable NOx emission, low primary air volume, reasonable flame shape, flexible and convenient operation, wide regulation scope, strong coal quality adaptability, etc. The pulverized coal burner consists of four ring-shaped channels, namely an axial flow air channel (1), a rotational flow air channel (2), a coal air channel (3) and a central air channel (4) from outside to inside; the center of the burner is provided with a water-coal-slurry pipeline (5) and the outlet of the water-coal-slurry pipeline (5) is provided with a water-coal-slurry burner nozzle (7).

Owner:SINOMA INT ENG

Air-storage engine, pressurizing system and method thereof, and emission reducing system and method thereof

ActiveCN101660454ALow emission requirementsMeet the power performance requirementsInternal combustion piston enginesExhaust apparatusHigh pressurePower performance

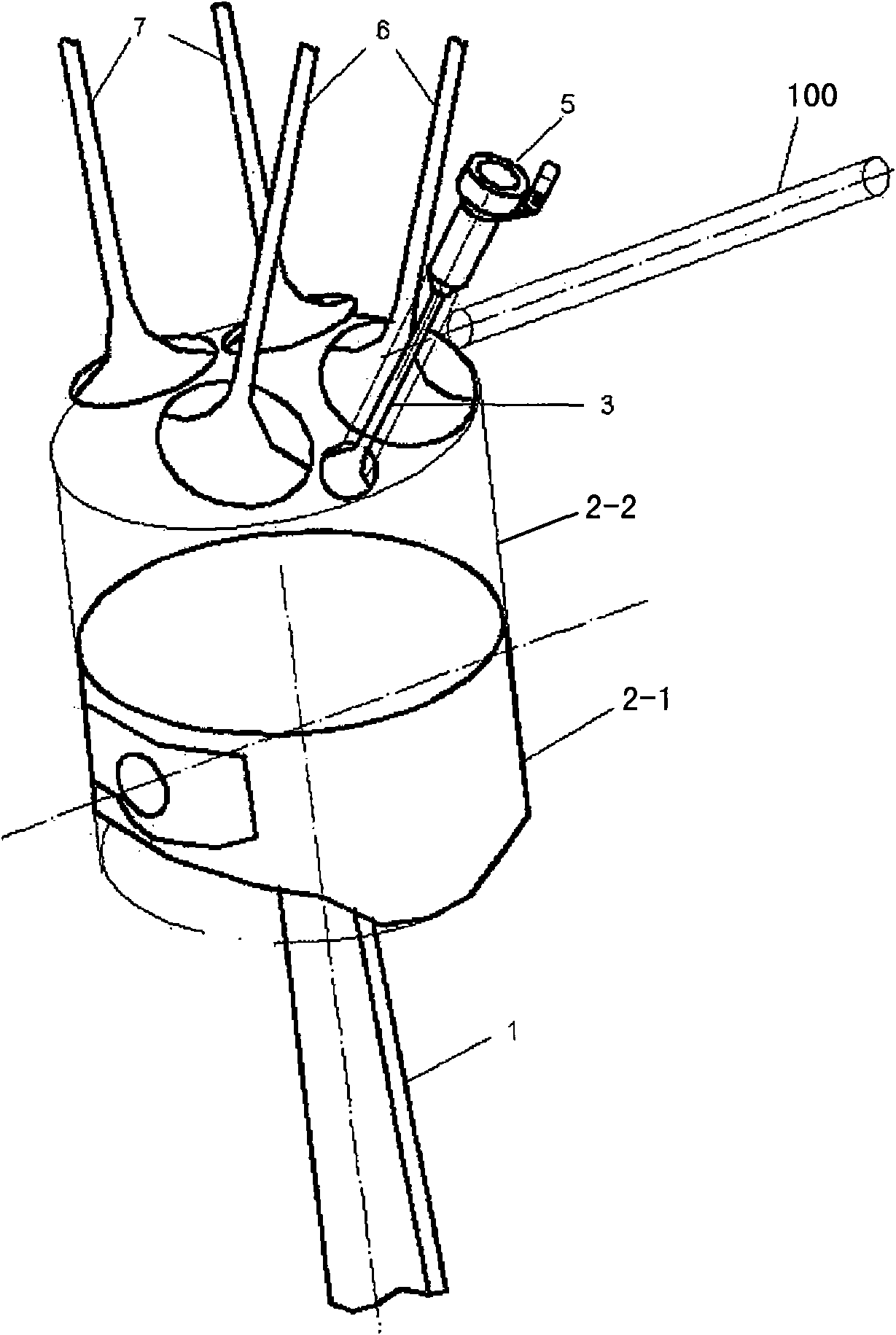

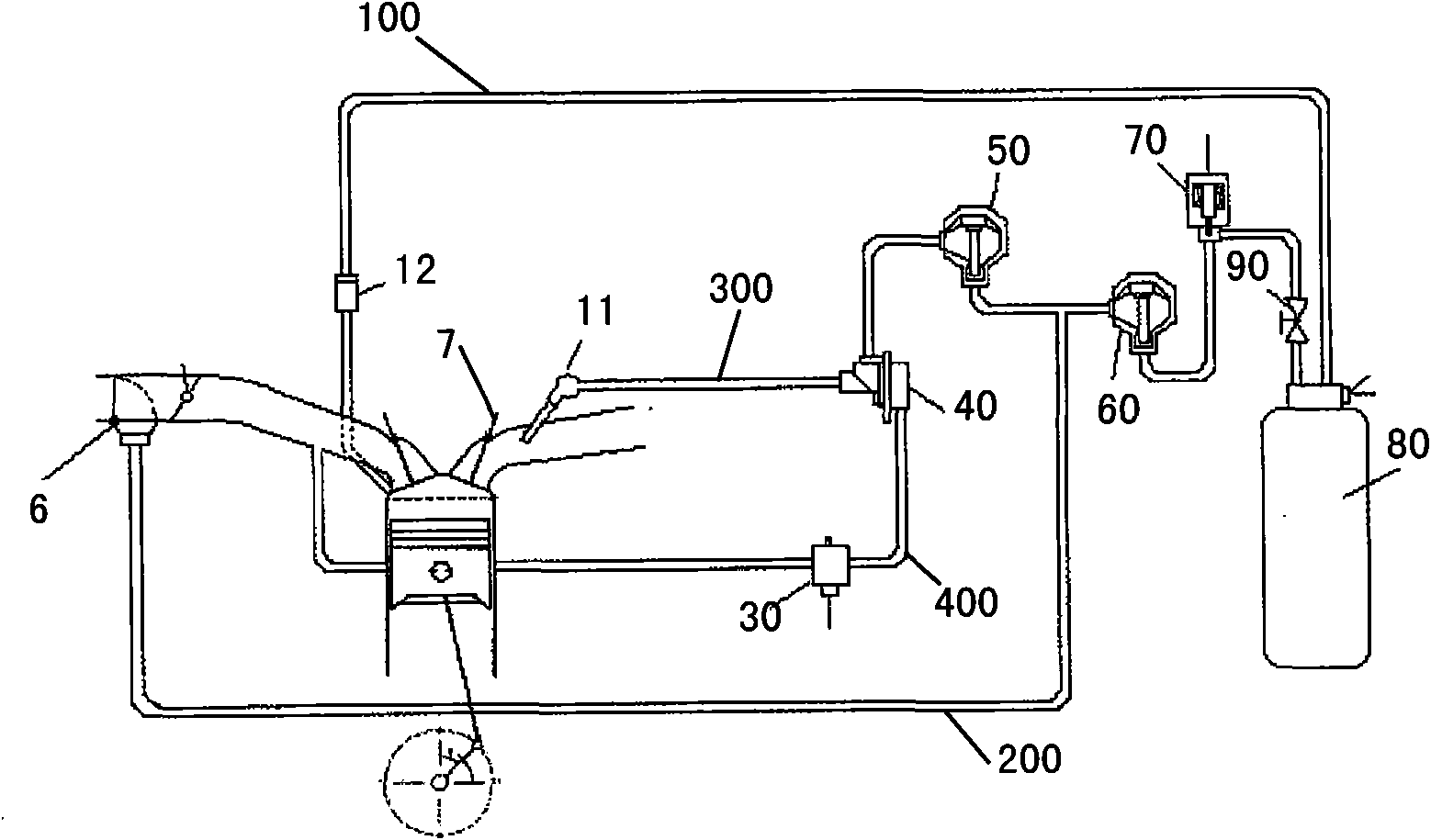

The invention relates to an air-storage engine, a pressurizing system and a method thereof, and an emission reducing system and a method thereof. The compressed air of the engine in the vehicle braking stage is recycled and stored in an air storage device; when the engine is cold-started, a secondary air source is provided by the air storage device to meet the requirement of low emission of vehicles; and when the vehicle works in the full throttle state, the air storage device is used for providing a high-pressure air source into the intake pipe of the engine to realize the transient pressurization and meet the power performance requirement of the vehicles. The emission reducing technique and the pressurizing technique realize a virtuous cycle of recycle, emission reduction, pressurizationand the like.

Owner:SAIC MOTOR

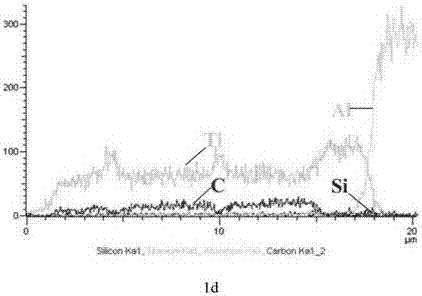

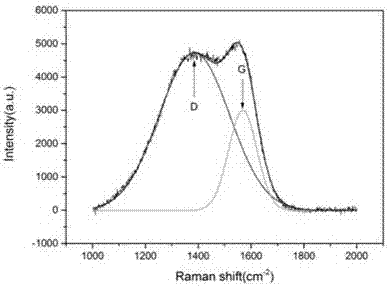

Piston with Ti-doping diamond multi-layer thick heat-insulating film on top face and preparation method and application of piston

ActiveCN106978593AEffective stress reliefImprove bindingVacuum evaporation coatingSputtering coatingTi dopingThermal impact

The invention relates to a piston with a Ti-doping diamond multi-layer thick heat-insulating film on the top face and a preparation method and application of the piston. The piston comprises a piston substrate, a transitional layer, n layers of TiC / DLC film layers and m buffer layers, wherein the outermost layer of the top face of the piston is the last TiC / DLC film layer. According to the preparation method of the piston, the transitional layer is prepared on the top face of the piston substrate; then the first TiC / DLC film layer is prepared; one buffer layer is formed on the first TiC / DLC film layer; the TiC / DLC film layers and the buffer layers are formed alternately, so that a middle layer is obtained, and then the last TiC / DLC film layer is prepared. According to the piston with the Ti-doping diamond multi-layer thick heat-insulating film on the top face has excellent abrasion resistance and thermal impact resistance and can meet the requirement of modern engines for high efficiency and low emission.

Owner:XIANGTAN UNIV

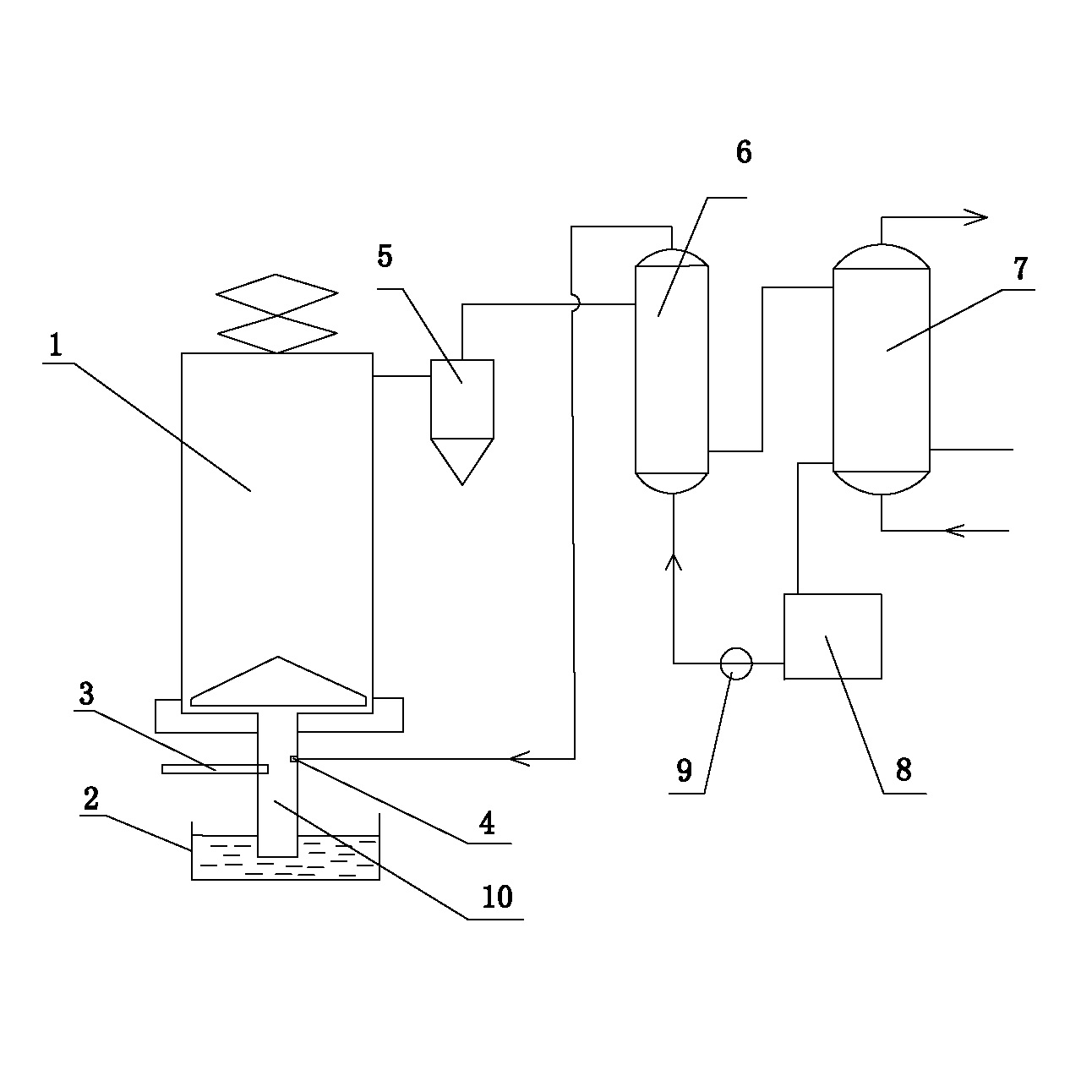

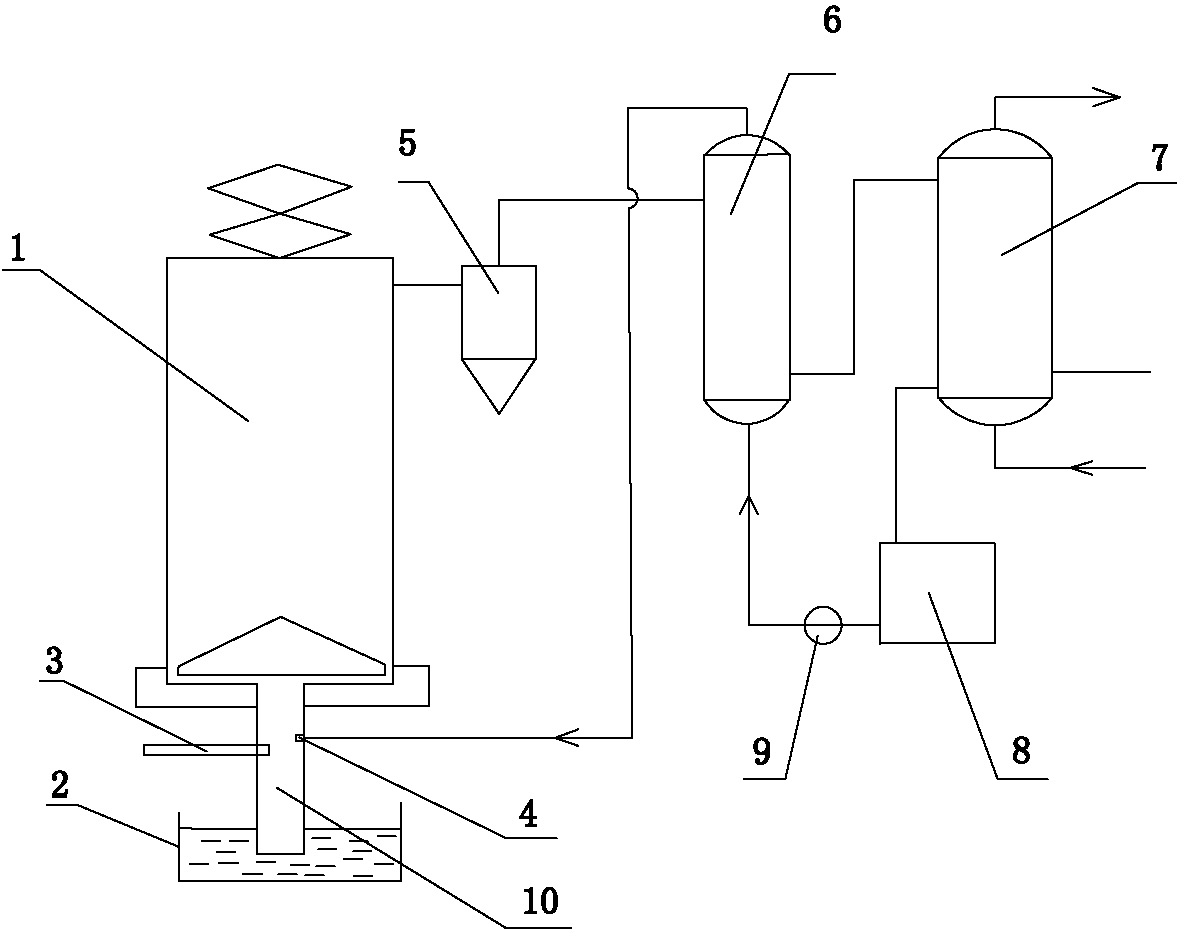

Novel coal gas phenol water treatment device

InactiveCN102485849AReduce processing costsLow emission requirementsEnergy inputWater/sewage treatment by heatingWater dischargeSpray nozzle

The invention discloses a novel coal gas phenol water treatment device, which comprises a coal gas producer, the coal gas outlet of which is in connection with the inlet of a dust collector. A dust collector outlet is connected to a phenol water evaporator, the outlet of which is in connection with the inlet of a coal gas cooler. The outlet of the coal gas cooler is connected to an oil-water separator, the phenol water outlet of which is in connection with the phenol water evaporator. The treatment device is characterized in that the lower end of the coal gas producer is provided with a water seal pipe, the lower end of which is positioned in a water seal tank, and the side wall of the water seal pipe is provided with an air inlet pipe. The phenol water outlet of the oil-water separator is connected to the phenol water evaporator and is then connected to a spraying nozzle on the side wall of the water seal pipe. Characterized by simple and practical structure, and low cost, the coal gas phenol water treatment device of the invention reutilizes the phenol water in coal gas production so as to meet the demand of reducing phenol water discharge and improve the discharge environmental protection standards of enterprises, thus both being in line with the environmental protection requirements of production and reducing the sewage treatment cost of enterprises.

Owner:JIANGSU JINSHAN ENVIRONMENTAL PROTECTION TECH

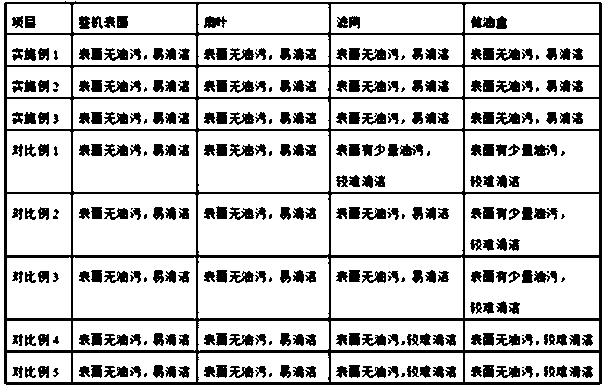

Kitchen heavy oil stain cleaning agent and preparation method thereof

InactiveCN111349526APromote degradationEfficient degradationOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsOLEAMIDOPROPYL BETAINECocamidopropyl betaine

The invention belongs to the field of daily chemicals. The invention discloses a kitchen heavy oil stain cleaning agent comprising the following components in percentage by weight: 1 to 10 percent ofsodium cocoyl isethionate, 1 to 20 percent of fatty alcohol-polyoxyethylene ether-9, 1 to 5 percent of cocamidopropyl betaine, 0.5 to 2 percent of a preservative, 0.05 to 0.2 percent of an antioxidant, 0.1 to 1 percent of a solubilizer, 0.1 to 1 percent of an essence, 0.05 to 0.2 percent of a chelating agent and the balance being water. The cleaning agent disclosed by the invention is mild, low inirritation, environment-friendly, good in permeability and strong in dirt-removing power, and can be used for rapidly and efficiently removing heavy oil stains in kitchens.

Owner:HUIZHOU ZHAOTING COSMETIC

Technology for manufacturing hotly-spun pressed forged steel single-piece piston with inner cooling oil cavity

The invention discloses a technology for manufacturing a hotly-spun pressed forged steel single-piece piston with an inner cooling oil cavity, which comprises the following steps of: forging piston blanks; mechanically processing the piston blanks to obtain the piston as a semi-finished product with an inside part of the inner cooling oil cavity and a covering part for blocking the inner cooling oil cavity, heating the covering part and downwardly spinning the covering part of the inner cooling oil cavity in the piston by the hot spinning technology to contact the inside part of the inner cooling oil cavity to form a complete inner cooling oil cavity; and not processing gaps of the inside part and the covering part of the inner cooling oil cavity, remaining the gaps or simply sealing by the general welding technology, such as argon arc welding and the like, and precisely processing into the piston as a finished product. The hotly-spun pressed forged steel single-piece piston with the inner cooling oil cavity manufactured by the technology disclosed by the invention is simple in structure, relatively easy and convenient to manufacture, high in production efficiency and low in manufacturing cost, and can meet the requirements of an engine on high power, high strength, and low emission, and the like.

Owner:BINZHOU BOHAI PISTON CO LTD

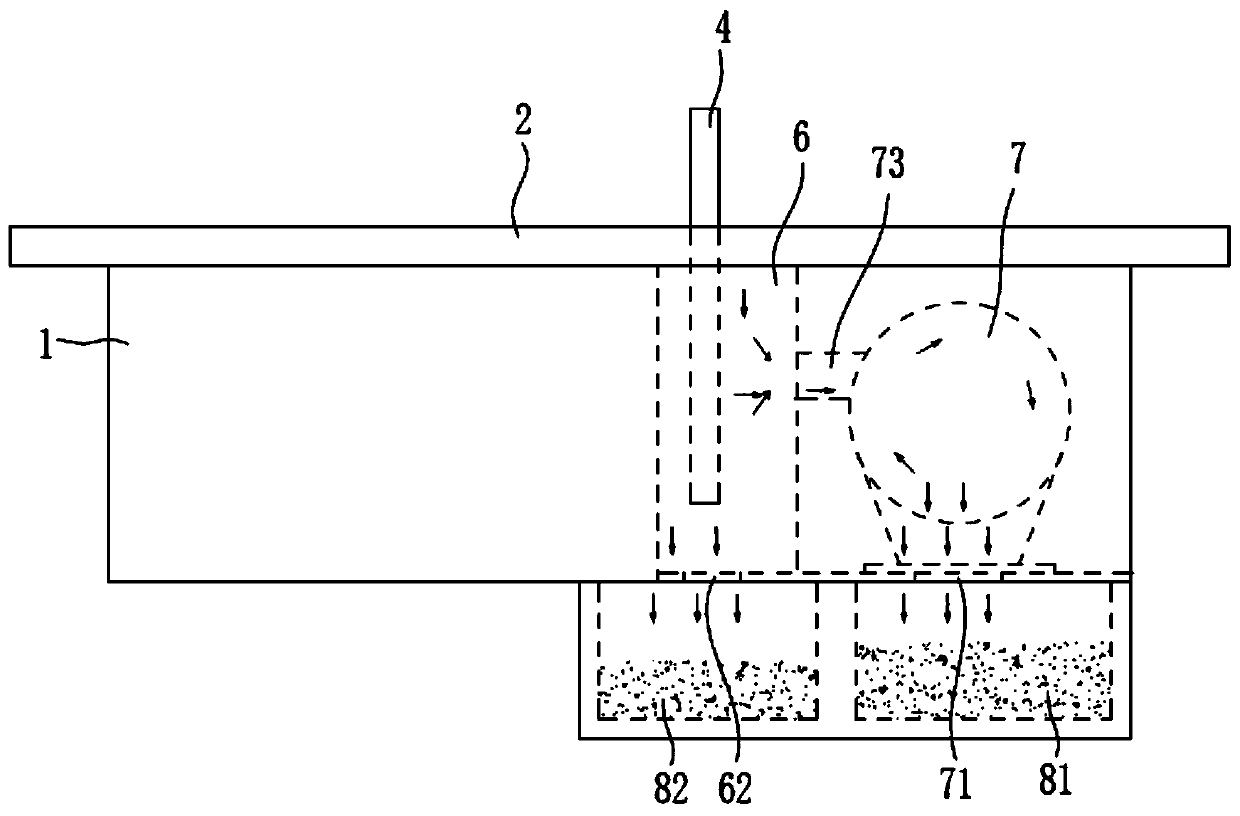

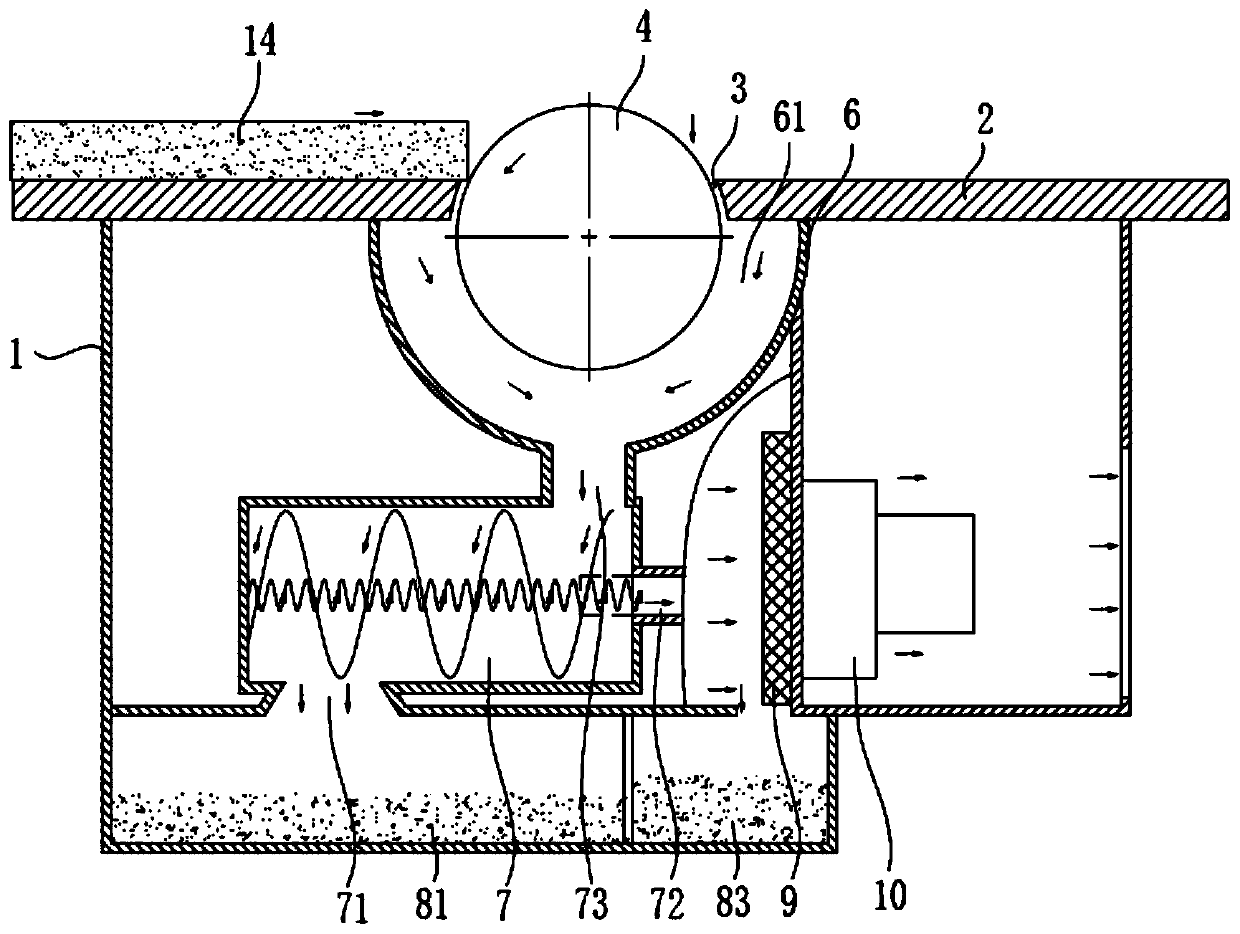

PM 2.5 agglomerating device

ActiveCN107081215AImprove the reunion effectGood separation effectElectrostatic separationDispersed particle separationVertical segmentInertia force

The invention relates to a PM 2.5 agglomerating device. The PM 2.5 agglomerating device comprises a smoke channel and an electric dust remover. The smoke channel comprises a vertical segment, an elbow segment and a horizontal segment. The horizontal segment is divided into a first treating cavity and a second treating cavity. The elbow segment is provided with a separator. Coarse dust particles and fine dust particles in the smoke channel are automatically separated through inertia force. The other end of the horizontal segment is provided with a mixing device, and the horizontal segment is connected with a turbulent mixing agglomerating device which is connected with the electric dust remover. The PM 2.5 agglomerating device has the beneficial effects that under the action of coulomb force and adhesive power, the fine dust particles are agglomerated the first time in the first treating cavity, the primary agglomerated fine dust particles and the coarse dust particles with positive charges enter the mixing device to be agglomerated the second time, agglomerated particles are formed and enter the turbulent mixing agglomerating device to be subjected to turbulent mixing, SO3 in the smoke is effectively condensed and adsorbed, and the particle agglomeration effect is further improved.

Owner:浙江菲达环保科技股份有限公司

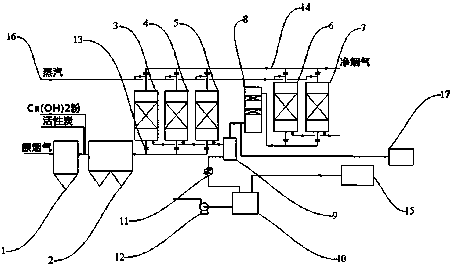

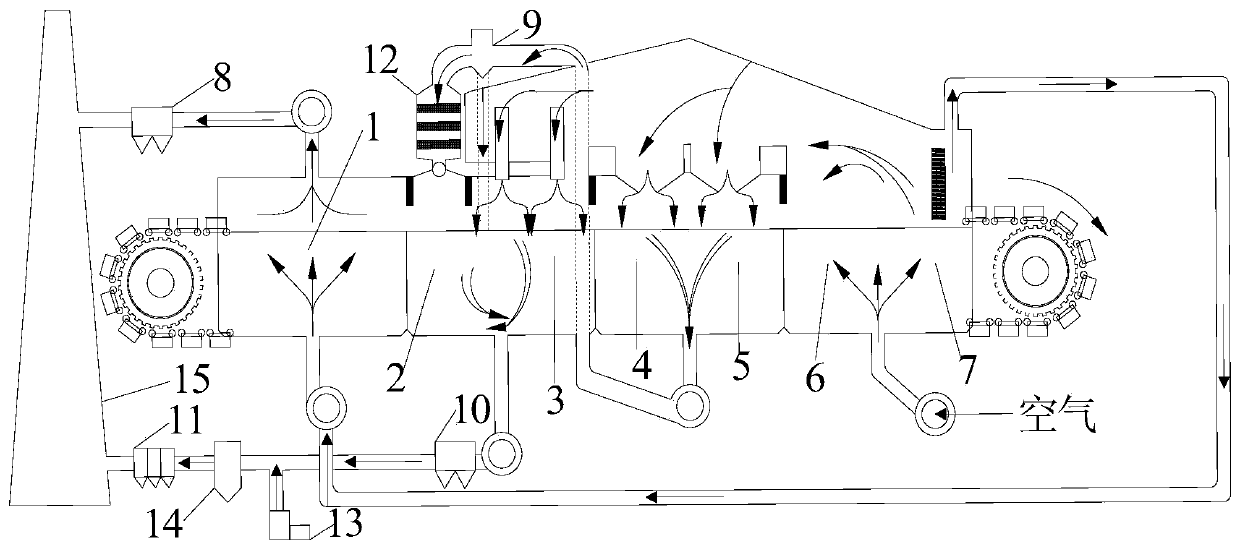

Low emission technology and complete set of equipment for pollutant in flue gas from garbage power generating boiler

PendingCN107638801ADesign scienceCompact layoutDispersed particle separationDecompositionEmission standard

The invention discloses an ultra-low emission technology and a complete set of equipment for pollutants in flue gas from a garbage power generating boiler. An SDA reactor, a bag-type dust collector, afirst adsorption tank, a regeneration tank and a gas-liquid separator are sequentially connected, the gas-liquid separator is connected with a neutralization tank and an oxidation decomposition towercorrespondingly, the oxidation decomposition tower is connected with a second adsorption tank, flue gas enters the SDA reactor, dry injection is conducted, the bag-type dust collector absorbs a largeamount of acid and adsorbs dust in the flue gas, and obtained gas enters into the first adsorption tank, the regeneration tank continues to absorb heavy metals, dioxins and oxidized NOx in the flue gas, and adsorption and regeneration are alternately performed. Regenerated gas enters the gas-liquid separator to separate gas and liquid, and the obtained liquid flows into the neutralization tank and reacts with sodium alkali or ammonia water in the neutralization tank, the gas enters the oxidation decomposition tower and enters the second adsorption tank after oxidation, purified smoke obtainedby two-stage adsorption is emitted, regenerated gas after the second stage adsorption also returns to the gas-liquid separator for secondary oxidation and absorption until emission standards and ultra-low emission requirements are met.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

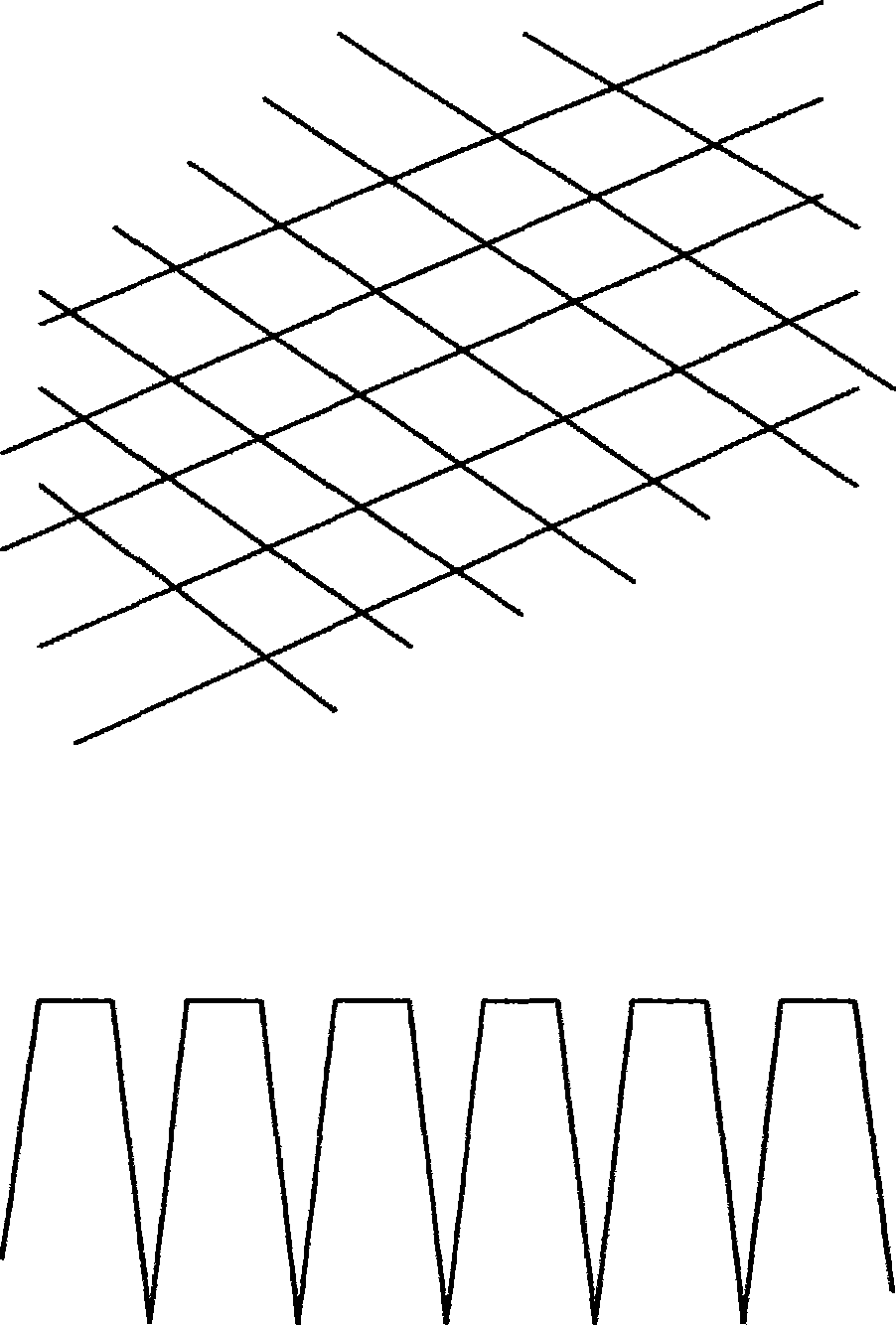

Air flow uniform distribution device for electric dust remover

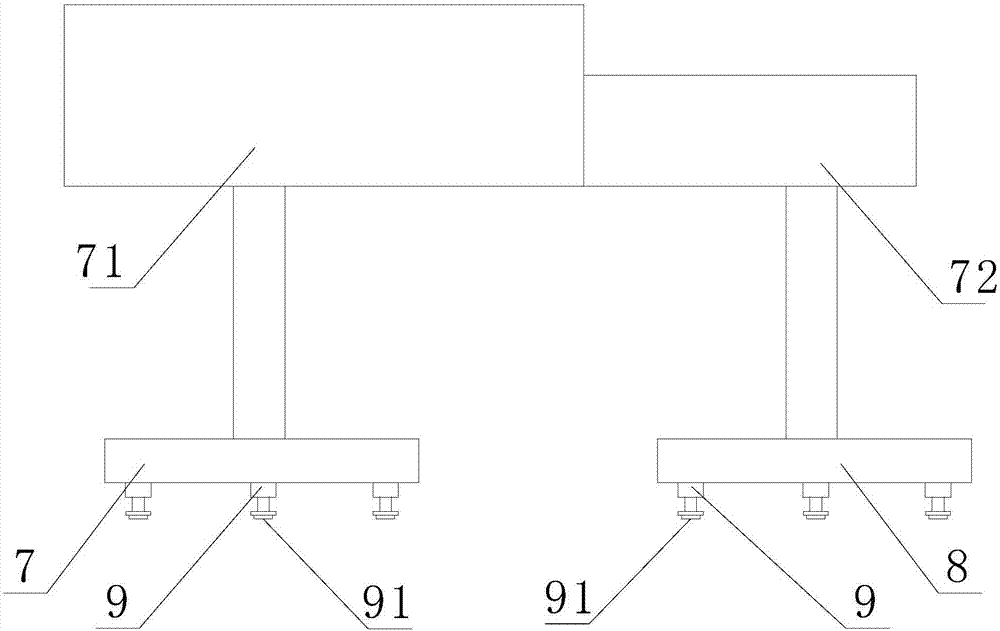

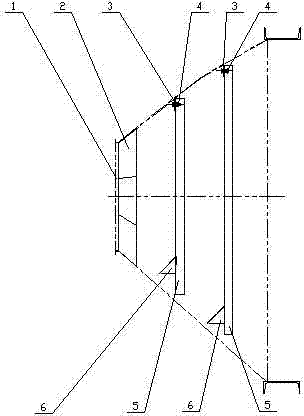

The invention provides an air flow uniform distribution device for an electric dust remover. The device comprises a flow guide grating, hanging plates, bolt components, flow equalizing plates and triangular flow guide plates, wherein the periphery of the flow guide grating is welded on an inlet smoke box and fixed; the hanging plates are welded on an upper sealing plate of the inlet smoke box and fixed; the flow equalizing plates are fixed on the hanging plates through bolts and nuts; two sides of each flow equalizing plate are welded and fixed with side sealing plates of the inlet smoke box; the triangular flow guide plates are hung in holes of the flow equalizing plates; the hanging plates are welded and fixed with the flow equalizing plates after being bent; and after flue gas enters the inlet smoke box, air flow is uniformly divided by the flow guide grating, the flue gas enters the first layer of flow equalizing plate and the second layer of flow equalizing plate to be diffused and uniformly distributed, the flow in an area with high flue gas flow velocity is locally choked by the triangular flow guide plates, and the part of flue gas is choked and distributed, so that an ideal uniform distribution effect of the flue gas entering an electric field is achieved. By the device, resistance caused by a plurality of layers of flow choking plates previously is reduced, the operating cost of the electric dust remover is reduced, the whole steel consumption is reduced, and investment cost is saved.

Owner:JIANGSU KEHANG ENVIRONMENT ENG TECH

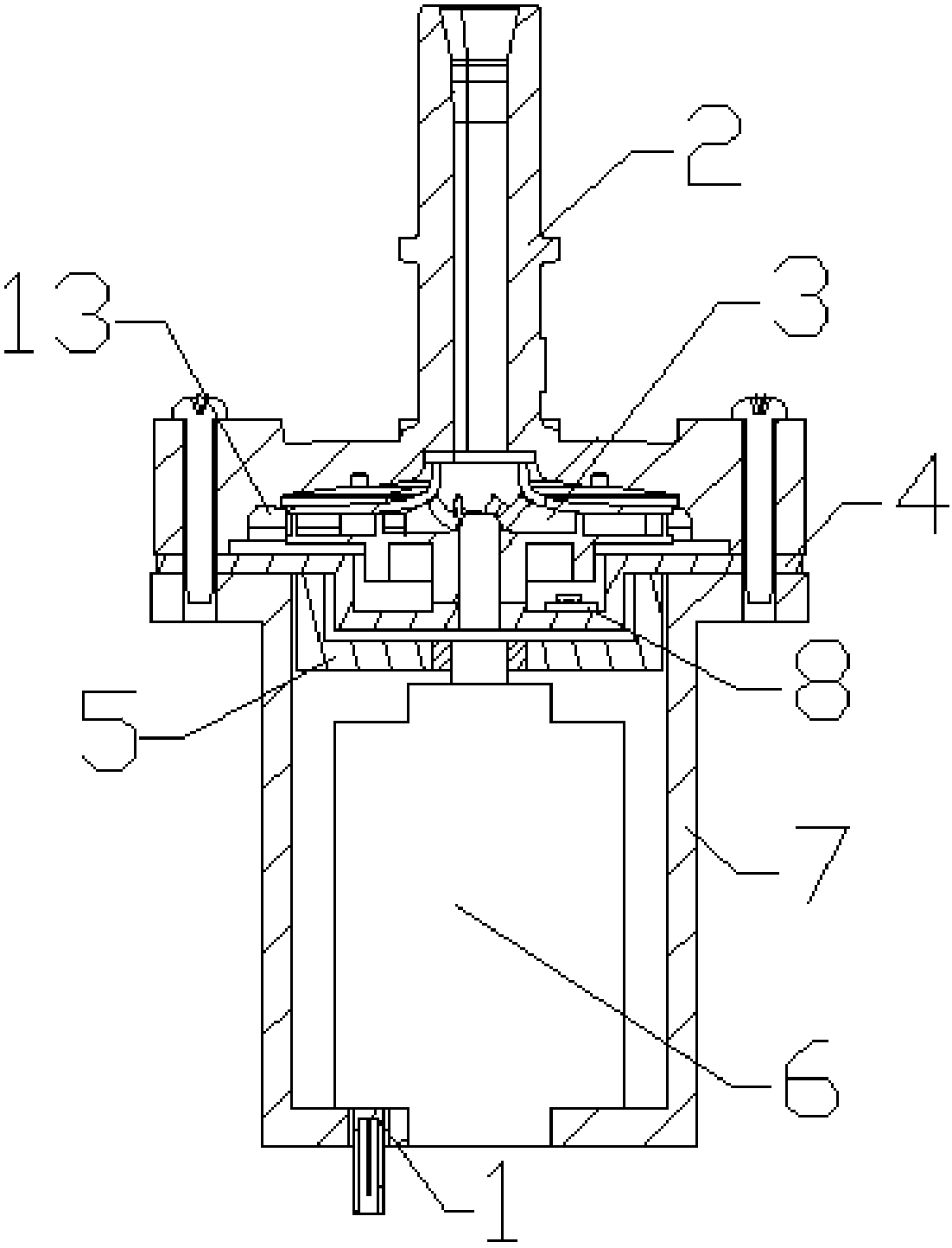

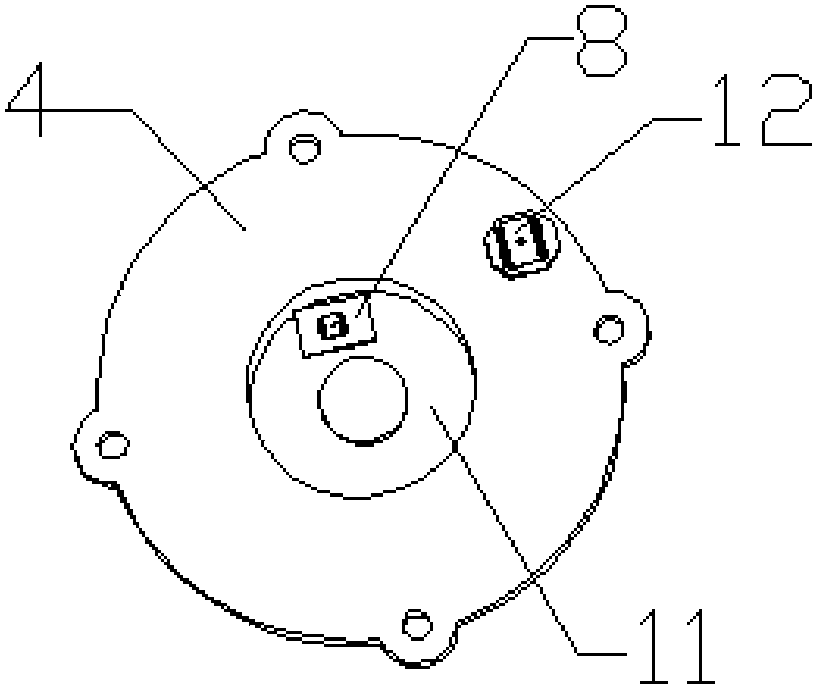

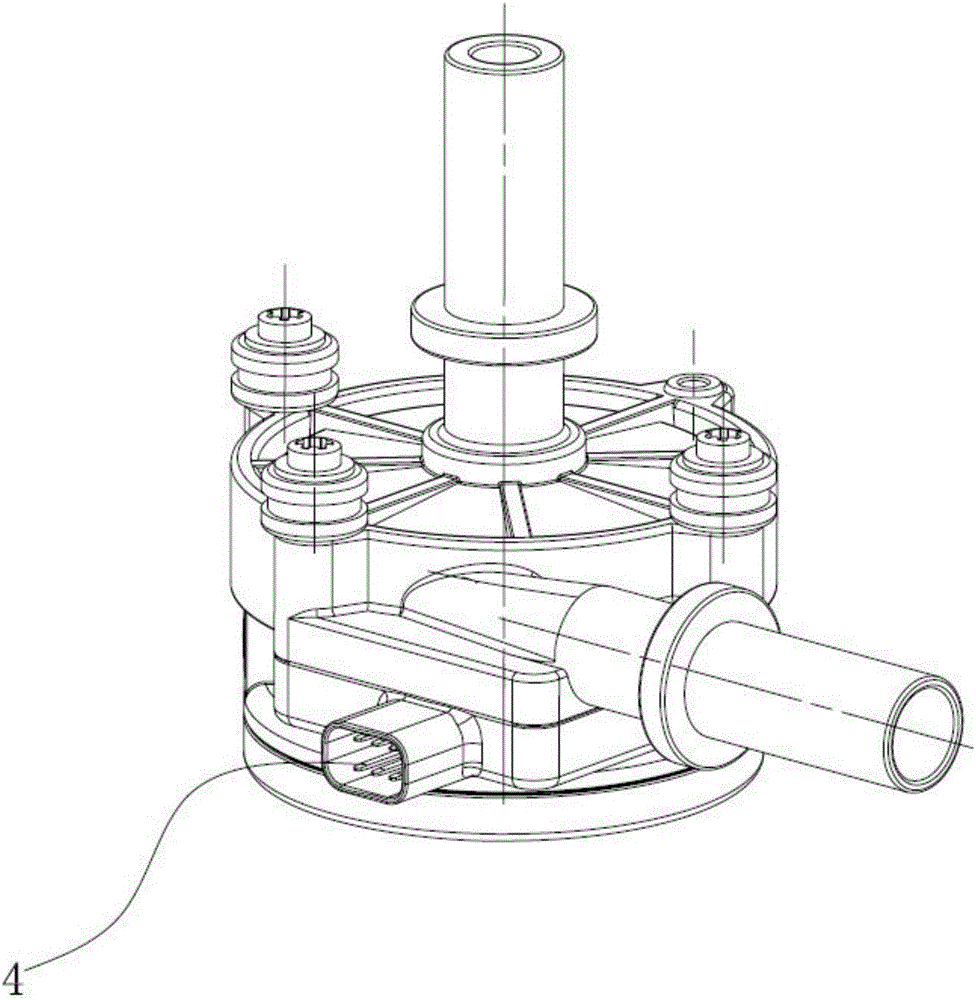

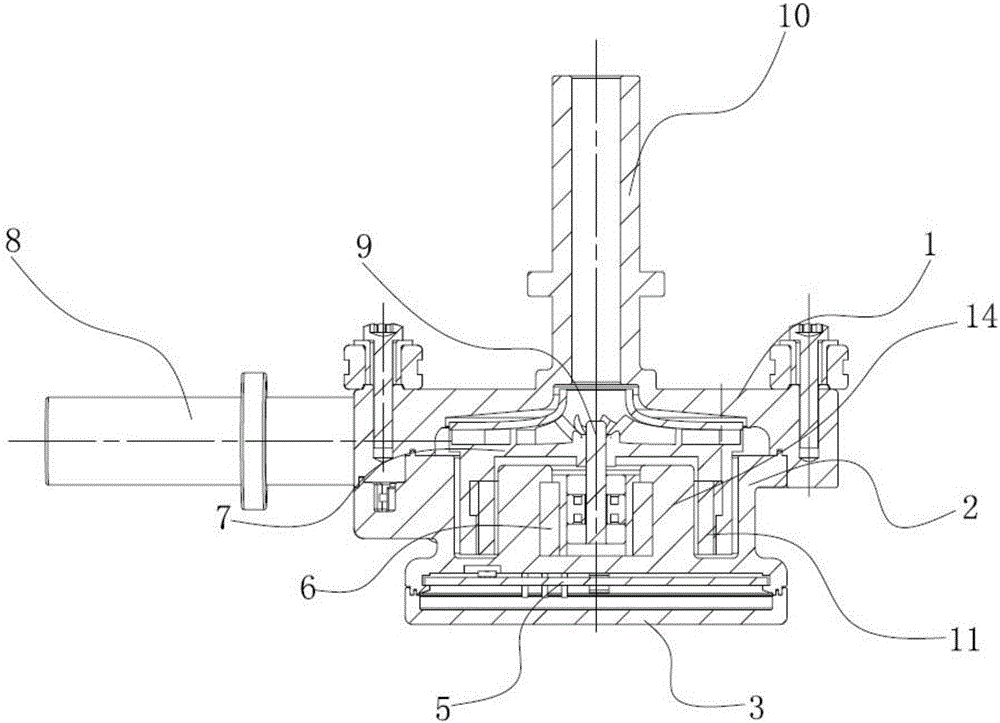

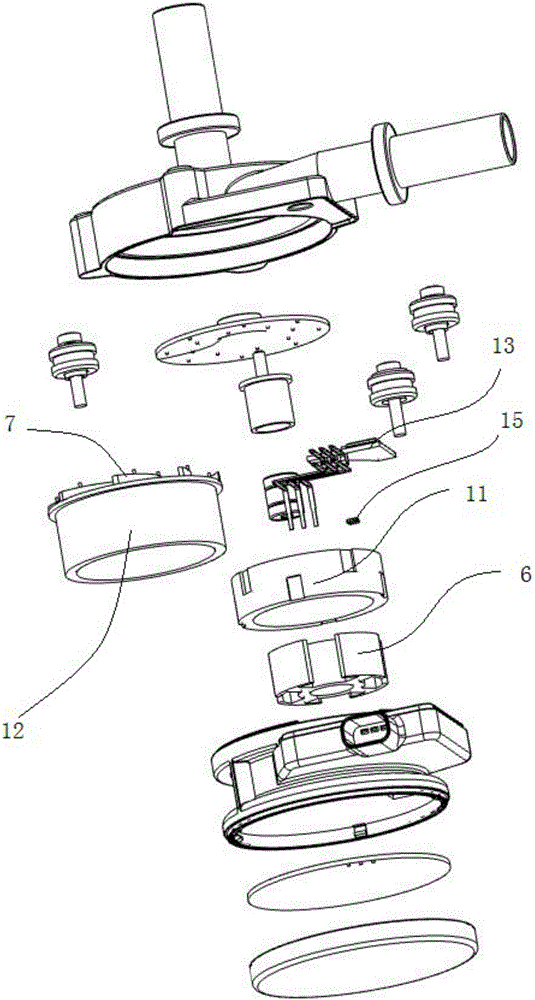

Gasoline steam purifying device with flow returning function

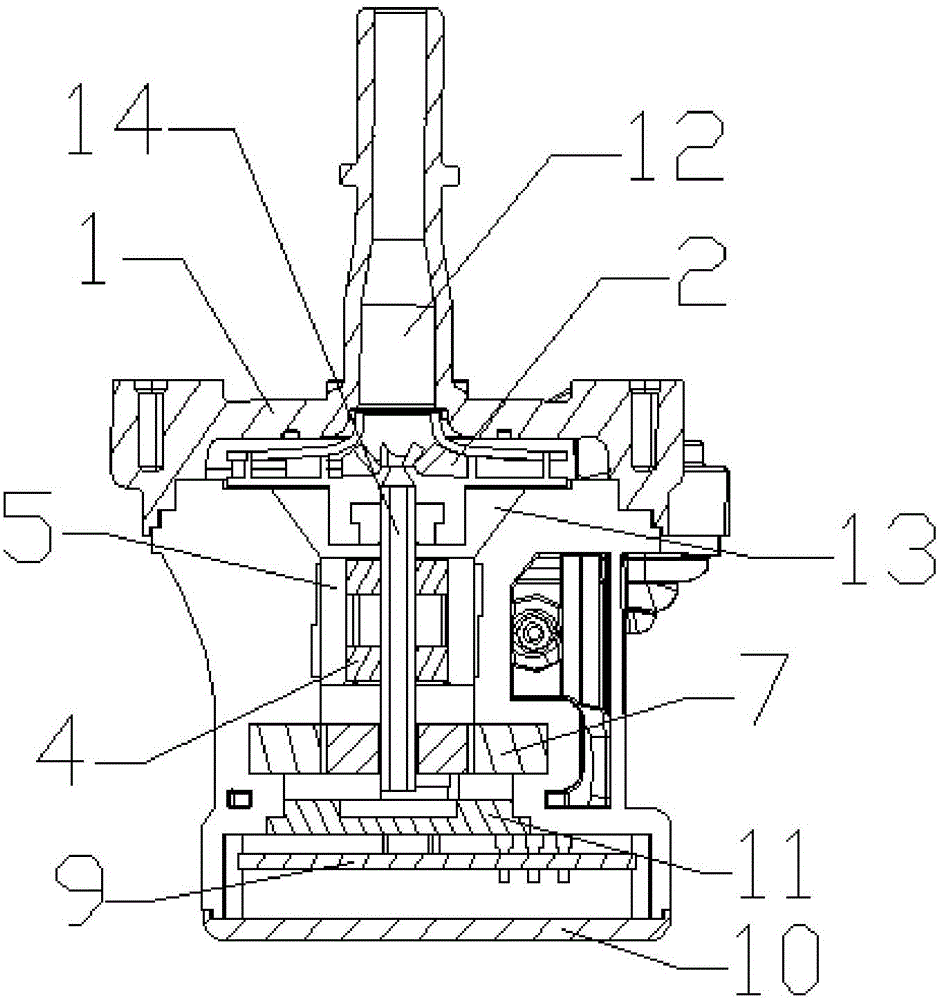

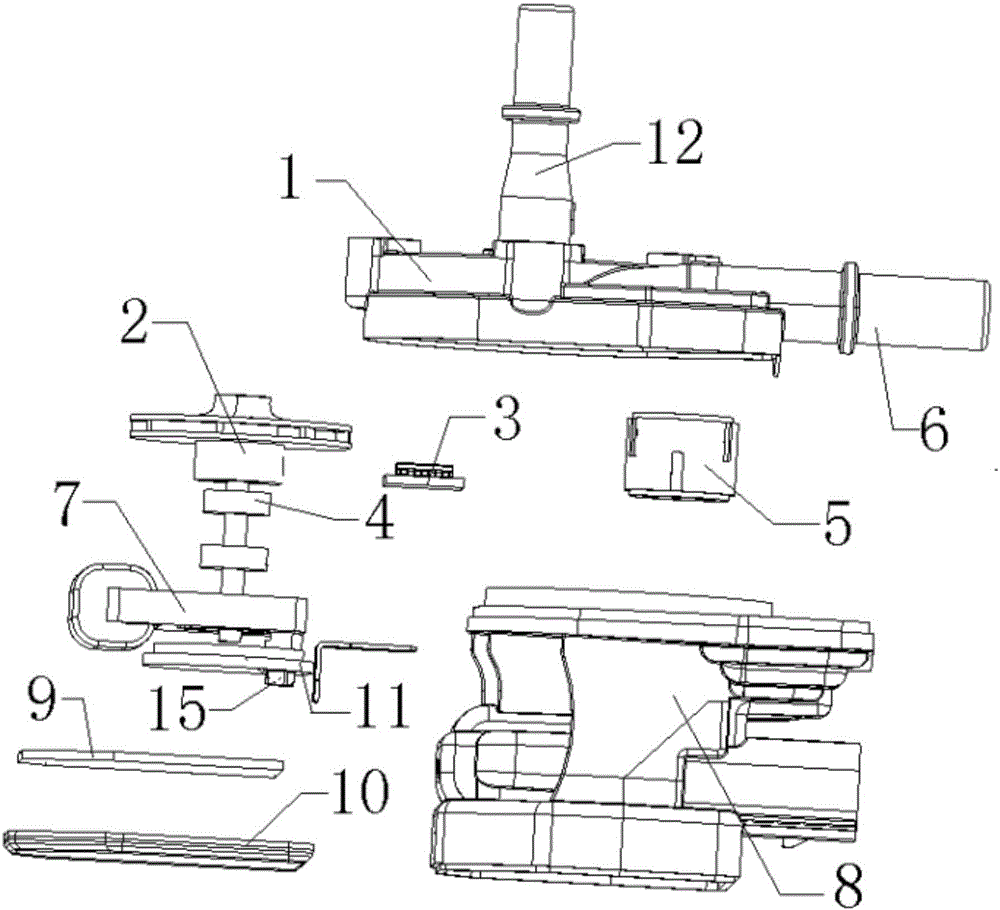

ActiveCN105888889ALow emission requirementsPlay a cooling roleNon-fuel substance addition to fuelMachines/enginesImpellerReturn function

The invention relates to a gasoline steam purifying device with a flow returning function. The gasoline steam purifying device with the flow returning function comprises an upper cover, an impeller and a base body, wherein the upper cover is mounted at the upper end of the base body; a cavity is formed between the upper cover and the base body; a motor is mounted in the middle of the base body; a rotating shaft of the motor vertically extends into the cavity and is connected with the impeller; a through hole is vertically formed in the rotating shaft of the motor; the upper end of the through hole communicates with the impeller; a part, which is positioned below the motor, of the base body is sealed by a sealing cover; the lower end of the through hole communicates with a gap between the motor and the sealing cover; an air inlet is vertically formed in the cavity and corresponds to a position above the center of the impeller; and an air outlet which is arranged in the tangential direction of the impeller is formed in a side wall of the cavity. Rotation of the motor is controlled so as to drive the impeller to rotate, and therefore, pressure difference is formed. Oil steam is delivered into a manifold inlet and is prevented from being discharged in air, and the requirement of emission reduction is met.

Owner:NINGBO TUOPU INTELLIGENT BRAKE SYST

Main burner equipment with outer rotational flow and inner direct flow

ActiveCN1687640AIncrease entrainmentIncreased turbulence intensityPulverulent fuel combustion burnersCoalAirflow

The invention is the outer cyclone inner direct flow main combustor device and belongs to the combustor device of boiler. The purpose of the invention is to produce the backflow area and the stable combustion. One device of the invention is to evenly arrange the delivery blades between the primary air diverting tube and the delivery tube, and the inside diameter of the delivery tube is as 0.5-0.7 times as the diameter of the primary air diverting tube. The other device is to evenly arrange the delivery blades in the inner chamber of the primary air diverting tube, and the axial height of the delivery blades is as 0.1-0.5 time as the semi-diameter of the primary air diverting tube. The invention through changing the opposite angles, the number, the length and the height of the delivery blades and the lengths and the section of the delivery tube to change the intensity and the size of the cyclone amount to adapt the characteristics of different fuels and ensure the stability and economy of the boiler combustion. The invention has simple structure and convenient equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

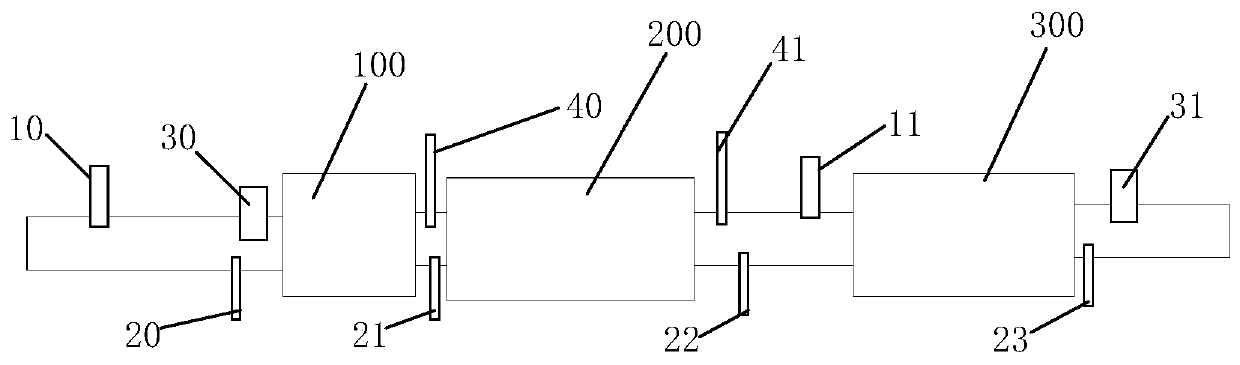

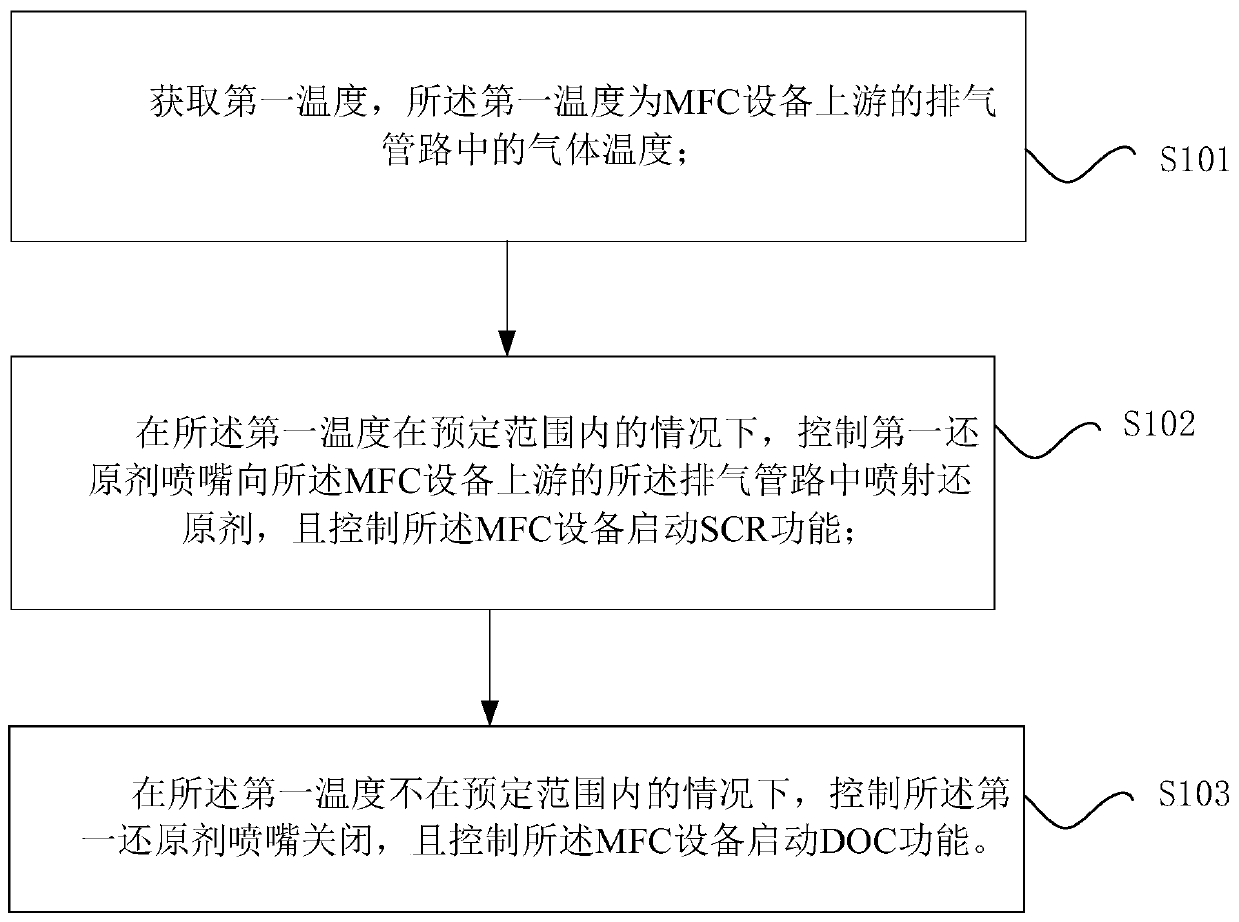

Exhaust gas treatment device, control method and control device thereof and storage medium

InactiveCN111396177AImprove conversion efficiencyLow emission requirementsInternal combustion piston enginesExhaust apparatusSpray nozzleProcess engineering

The invention provides an exhaust gas treatment device, a control method and control device thereof, a storage medium, a treater, an exhaust gas treatment system and a mobile carrier. The treatment device comprises MFC equipment, DPF equipment and SCR equipment which are arranged on an exhaust pipe in sequence. A first reducing agent spray nozzle is arranged on the part, on the upstream of the MFCequipment, of the exhaust pipe. A second reducing agent spray nozzle is arranged on the part, between the DPF equipment and the SCR equipment, of the exhaust pipe. The MFC equipment belongs to a multifunctional catalytic device and has the DOC function and the SCR function. The exhaust pipe belongs to an exhaust line of an engine. According to the treatment device, the DOC and SCR dual functionsare integrated in the MFC equipment, the structure of the exhaust gas after-treatment device is simplified, and the SCR conversion efficiency is improved; the exhaust gas treatment device achieves theDOC ignition function and can also reduce emissions of NOx by replacing DOC with MFC; and accordingly, the whole after-treatment device is simplified in arrangement and saves space.

Owner:WEICHAI POWER CO LTD

Environment-cleaning dust-free table type cutting machine

PendingCN111113593ANot easy to blockExtended cleaning and replacement intervalsCombination devicesMetal sawing accessoriesEngineeringWorkbench

The invention belongs to the technical field of cutting equipment, and particularly relates to an environment-cleaning dust-free table type cutting machine. The environment-cleaning dust-free table type cutting machine comprises a shell and a cutting workbench arranged on the shell, wherein a saw opening is formed in the cutting workbench; an air suction bin is arranged below the cutting workbench; the saw opening serves as an air inlet of the air suction bin; an air outlet of the air suction bin is formed in the air suction bin; a horizontal centrifugal separator is installed at the air outlet of the air suction bin; a separator ash falling port is formed in the rear end of the horizontal centrifugal separator; a first ash collecting box is arranged at the separator ash falling port; a separator air outlet is formed in the front end of the horizontal centrifugal separator; a filter cylinder is arranged at the separator air outlet; and a negative pressure fan is installed at an air outlet of the filter cylinder. According to the environment-cleaning dust-free table type cutting machine, the dust-gas pre-separation of dust-containing airflow can be realized, not only can the dust-free cutting be realized, but also the long-term stable operation of the cutting machine can be guaranteed, and the environment-cleaning dust-free table type cutting machine is small in size and convenient to carry and use.

Owner:NANJING VORTEK MASCH CO LTD

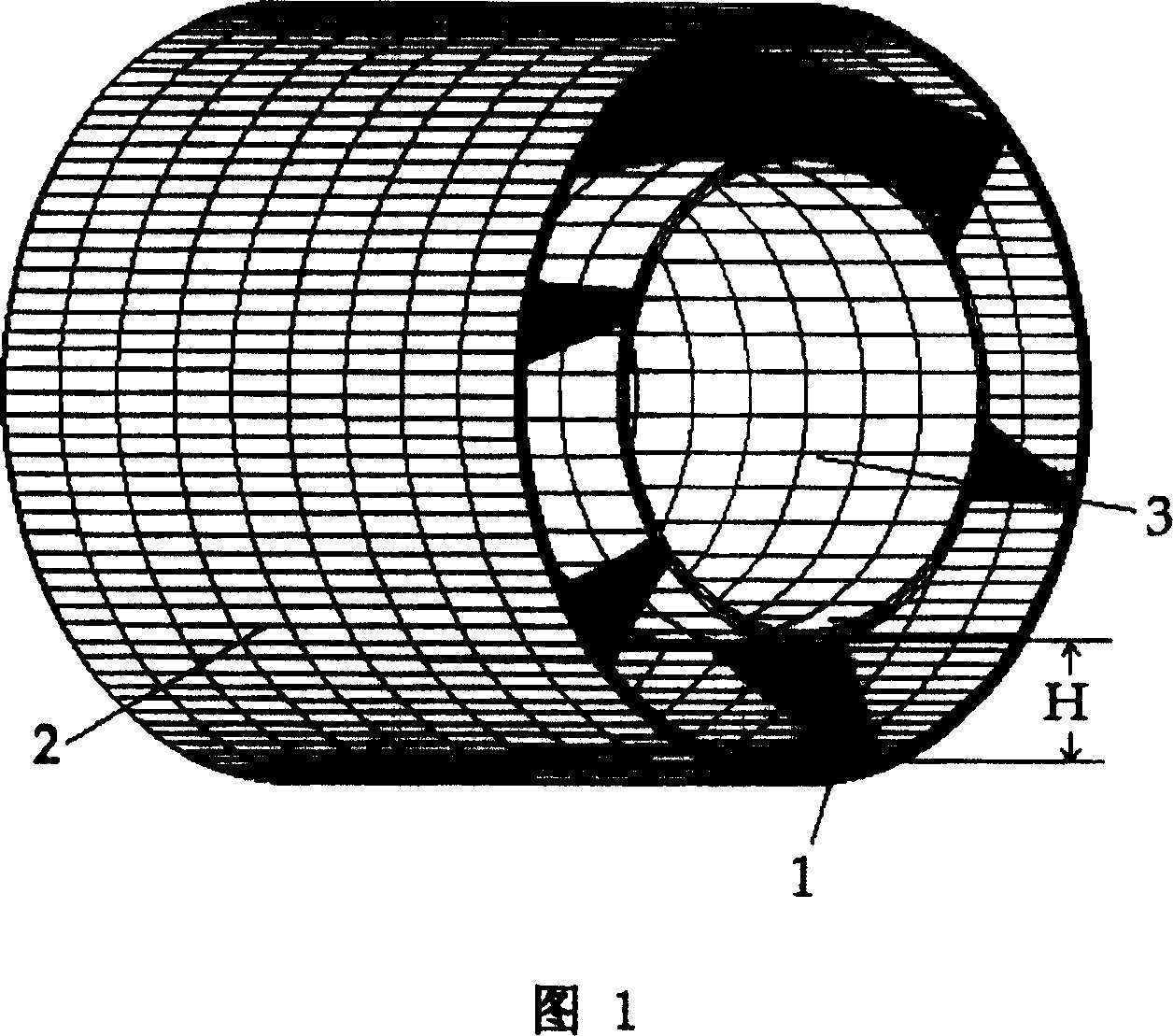

Use of laser honing technique in ocean engine cylinder liner

InactiveCN101386151AUniform widthEven consistencyHoning machinesLaser beam welding apparatusMarine engineeringPiston ring

The invention provides an application of a laser honing technology in a cylinder liner of an ocean engine, which combines laser and the honing technology and causes the final processing of the surface of the cylinder liner to comprise three procedures, namely, rough honing, laser forming and fine honing; a platform reticulate pattern after laser honing has even deep grooves and uniform width and interval, thus building an oil lamella on the surface of a platform and having good lubricating effect; the deep grooves have the function of storing engine oil and releases the engine oil for lubricating friction timely; meanwhile, the platform supports the motion of a piston ring and meets the requirements of high abrasive resistance and low emission.

Owner:韦加伟

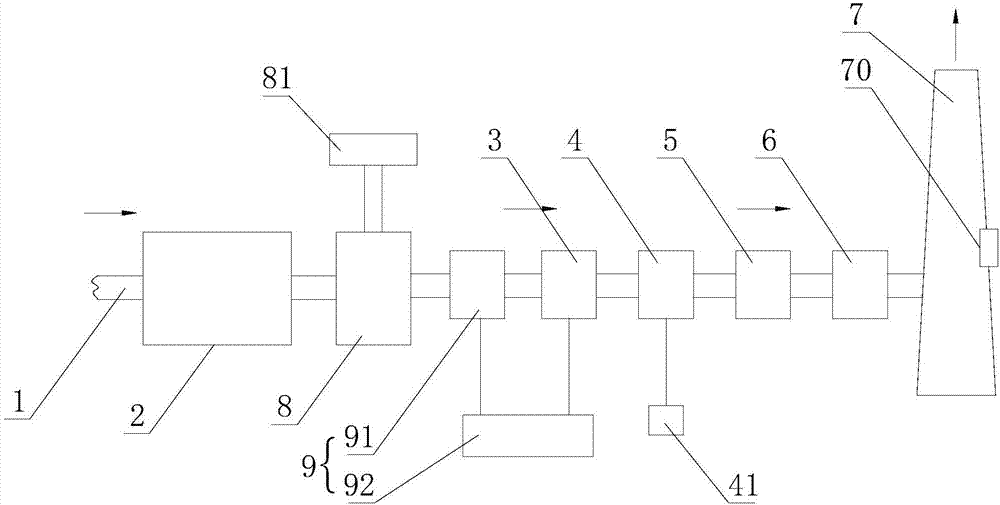

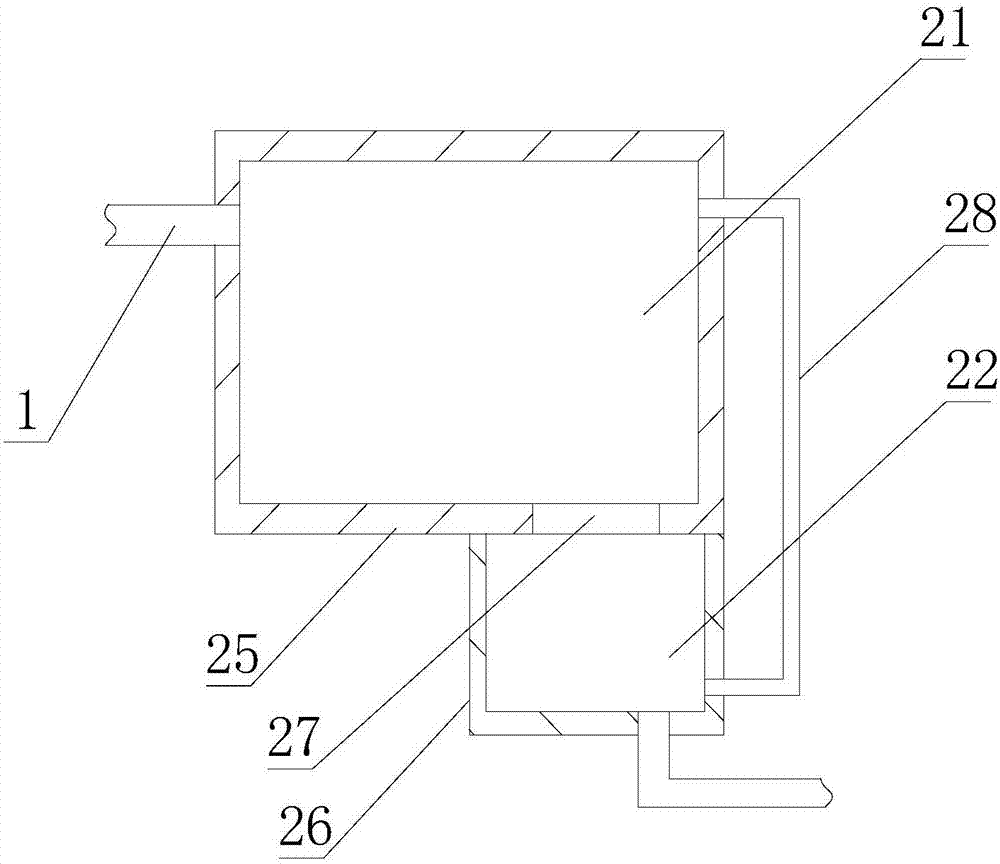

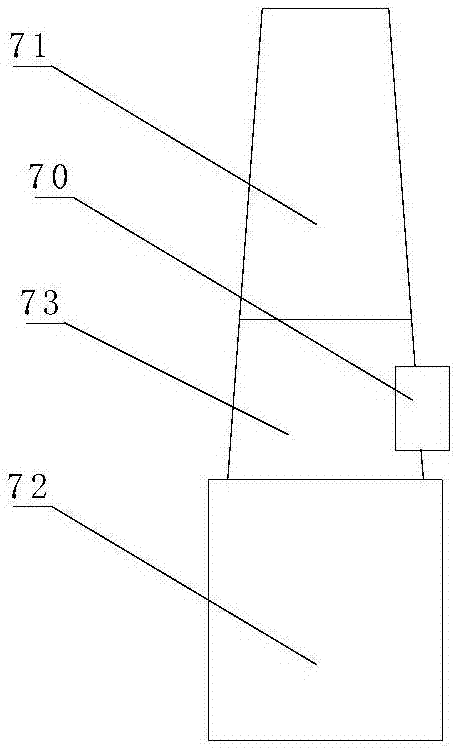

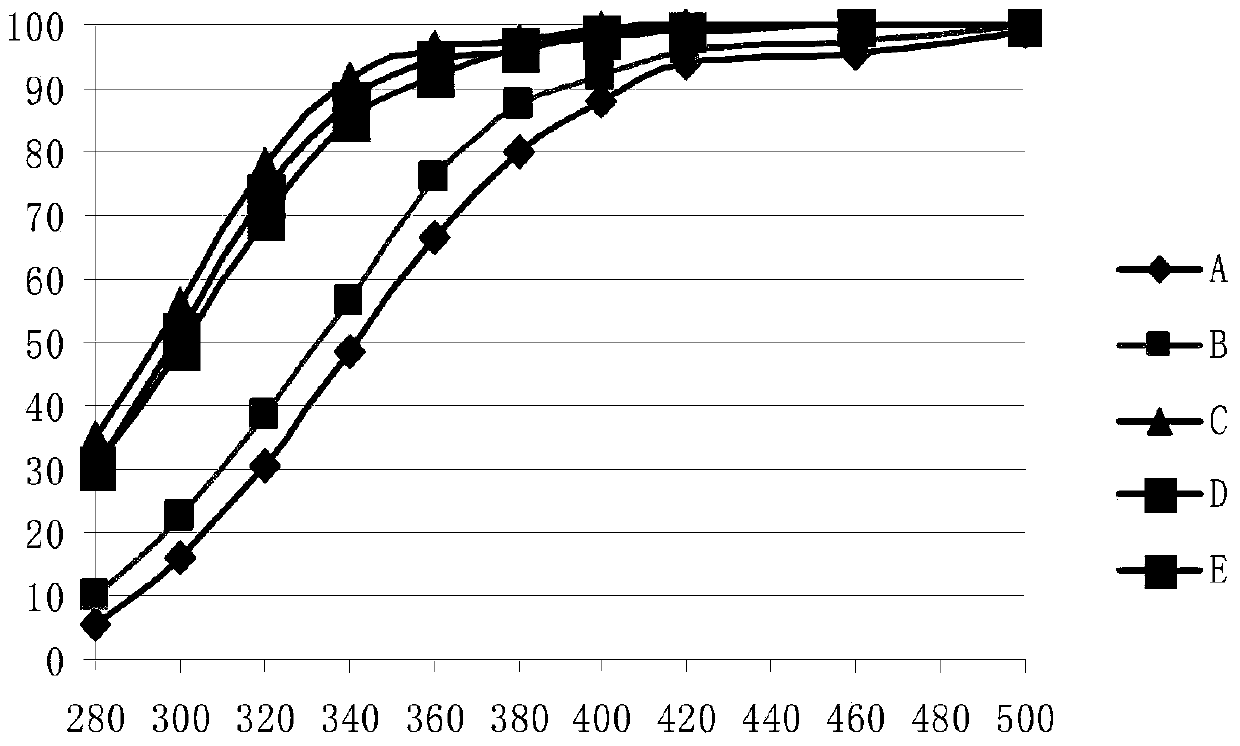

Belt type pellet roasting flue gas desulfurization and denitrification system and method

InactiveCN111298620AEfficient use ofLow costGas treatmentDispersed particle separationParticulatesDust control

The invention provides a belt type pellet roasting flue gas desulfurization and denitrification system and method, the system is reasonably provided with a gas flow channel, nitrogen oxide, sulfur oxide and particles in flue gas are treated according to the characteristics of each section of flue gas, and flue gas waste heat is effectively utilized. According to the system, a gas flow channel is reasonably arranged, coke oven gas serves as fuel, the purpose of roasting pellets is achieved, and the fuel cost is reduced. The system can remarkably reduce the concentration of NOx and the concentration of sulfur oxide in exhausted flue gas, the dust removal efficiency is high, iron-containing dust is recycled, and flue gas pollutants can meet the requirement for ultralow emission.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A Gasoline Vapor Purification Device Using Magnetic Induction Drive

ActiveCN105840352BLow emission requirementsNon-fuel substance addition to fuelMachines/enginesImpellerElectric machine

Owner:NINGBO TUOPU INTELLIGENT BRAKE SYST

an ultra-low no x gas burner

The invention relates to an ultra-low NO X The gas burner includes a central cylinder, a swirler, a gas gun group, a throat, a front panel and a casing. Composed of an inner gas gun, a middle gas gun and an outer gas gun, the front panel is provided with a cross-flow hole and an extension hole for the nozzle of the outer gas gun, the central cylinder cavity is the central combustion air channel, and the ring cavity between the central cylinder and the throat It is a direct-current combustion-supporting air channel, and the annular cavity between the periphery of the throat and the shell is a cooling air channel. The inner gas gun and the middle gas gun are arranged in the direct-current combustion-supporting air channel, and the outer gas gun is arranged in the cooling air channel. When working, due to the gas sprayed by the middle gas gun as the excessive gas segmented configuration and staged combustion, the gas is fully burned in a dispersed state, effectively dilutes the oxygen content in the furnace, and reduces NO X The emissions are below 10ppm, and no CO is produced.

Owner:SHANGHAI WISEBOND TECH

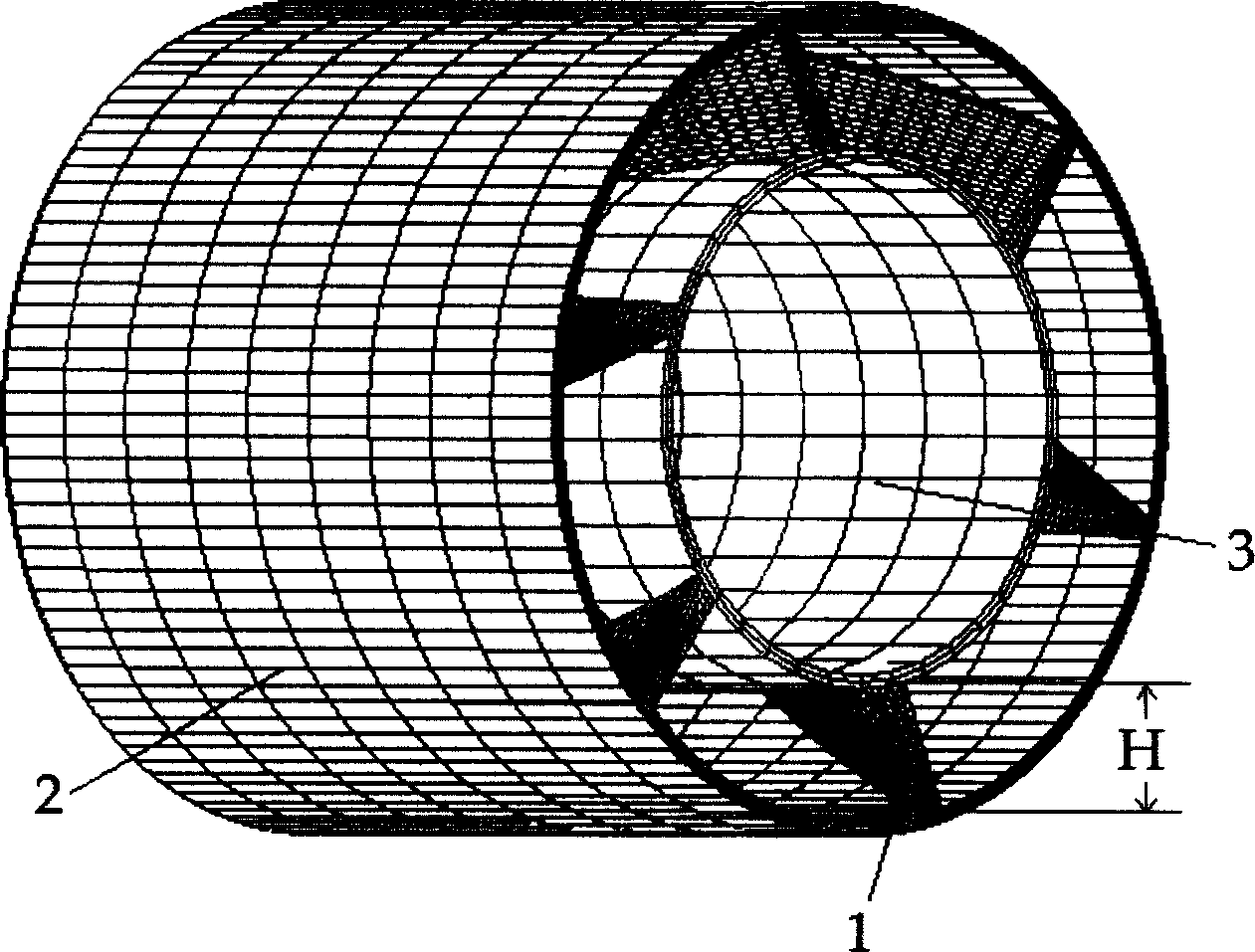

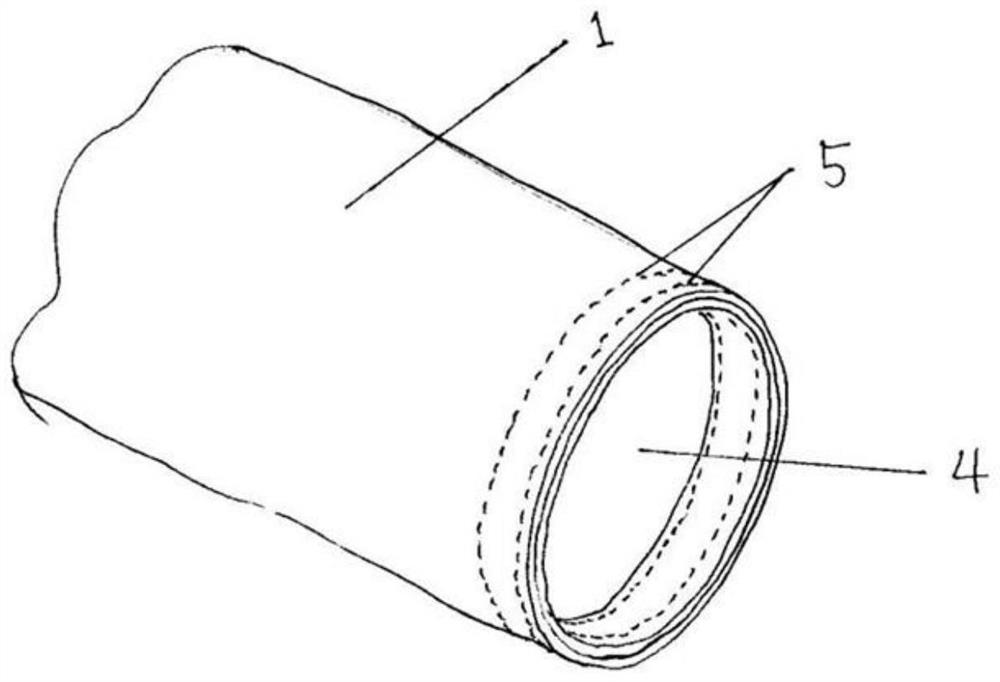

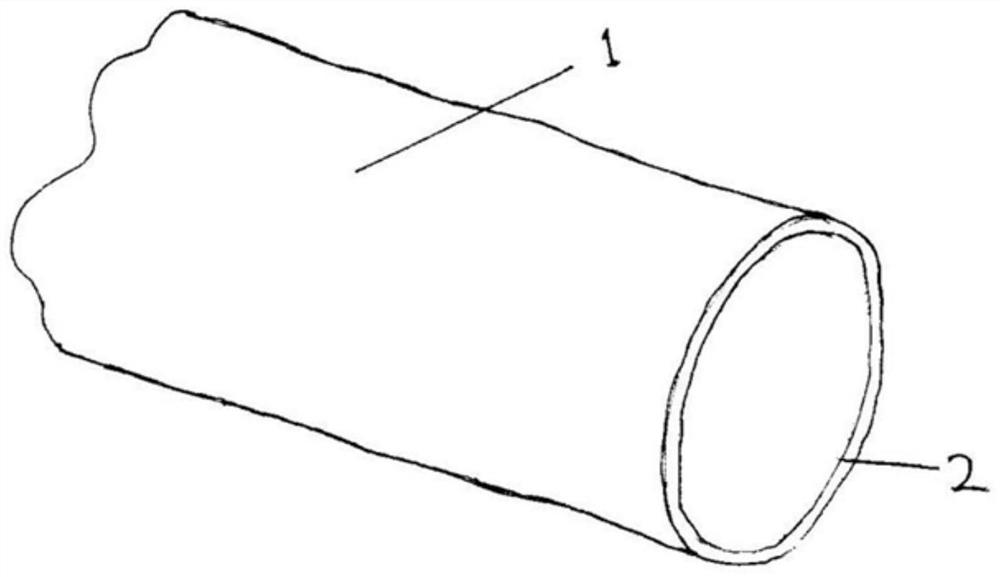

A method and special equipment and filter bag for making the bottom of a dust filter bag

ActiveCN111465441BGuaranteed to stay togetherEliminate Dust Exhaust Channel ProblemsDispersed particle filtrationGravity filtersDust controlEngineering

A method for making the bottom of a dust-removing filter bag. The filter material at the port at the end of the cylindrical bag body (1) to be made into the bag bottom, including the cylindrical filter material connected and extended to the filter material of the bag body, is tightly Gather into a pinch to form an airtight bag bottom. At the same time, it provides the corresponding special equipment for making the bottom of the bag, as well as the corresponding buckle and seal the bottom of the bag.

Owner:SHANDONG MICROGRAM ENVIRONMENTAL PROTECTION TECH CO LTD

A gasoline vapor purification device with backflow function

ActiveCN105888889BLow emission requirementsPlay a cooling roleNon-fuel substance addition to fuelMachines/enginesRefluxImpeller

The invention relates to a gasoline steam purifying device with a flow returning function. The gasoline steam purifying device with the flow returning function comprises an upper cover, an impeller and a base body, wherein the upper cover is mounted at the upper end of the base body; a cavity is formed between the upper cover and the base body; a motor is mounted in the middle of the base body; a rotating shaft of the motor vertically extends into the cavity and is connected with the impeller; a through hole is vertically formed in the rotating shaft of the motor; the upper end of the through hole communicates with the impeller; a part, which is positioned below the motor, of the base body is sealed by a sealing cover; the lower end of the through hole communicates with a gap between the motor and the sealing cover; an air inlet is vertically formed in the cavity and corresponds to a position above the center of the impeller; and an air outlet which is arranged in the tangential direction of the impeller is formed in a side wall of the cavity. Rotation of the motor is controlled so as to drive the impeller to rotate, and therefore, pressure difference is formed. Oil steam is delivered into a manifold inlet and is prevented from being discharged in air, and the requirement of emission reduction is met.

Owner:NINGBO TUOPU INTELLIGENT BRAKE SYST

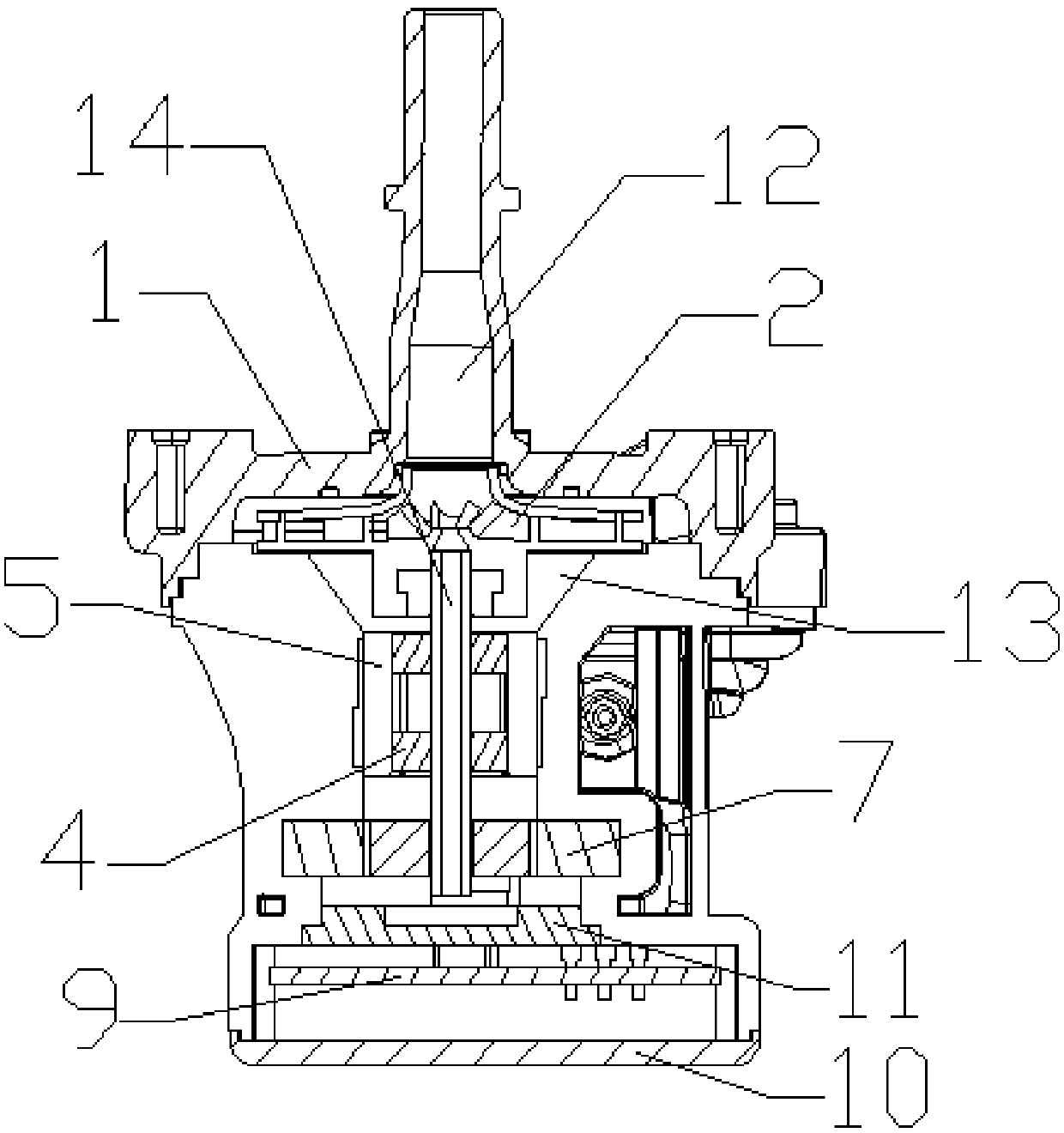

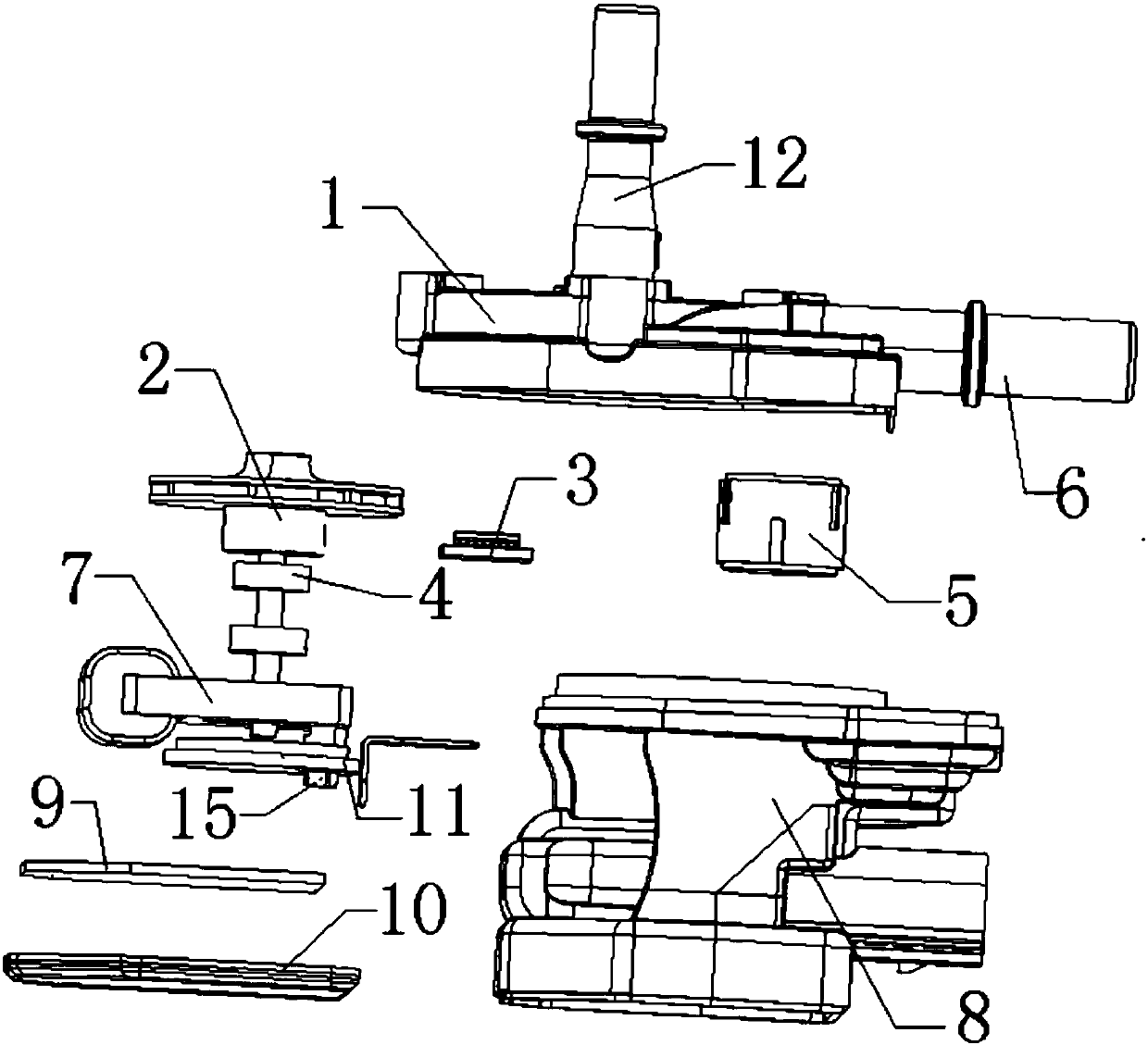

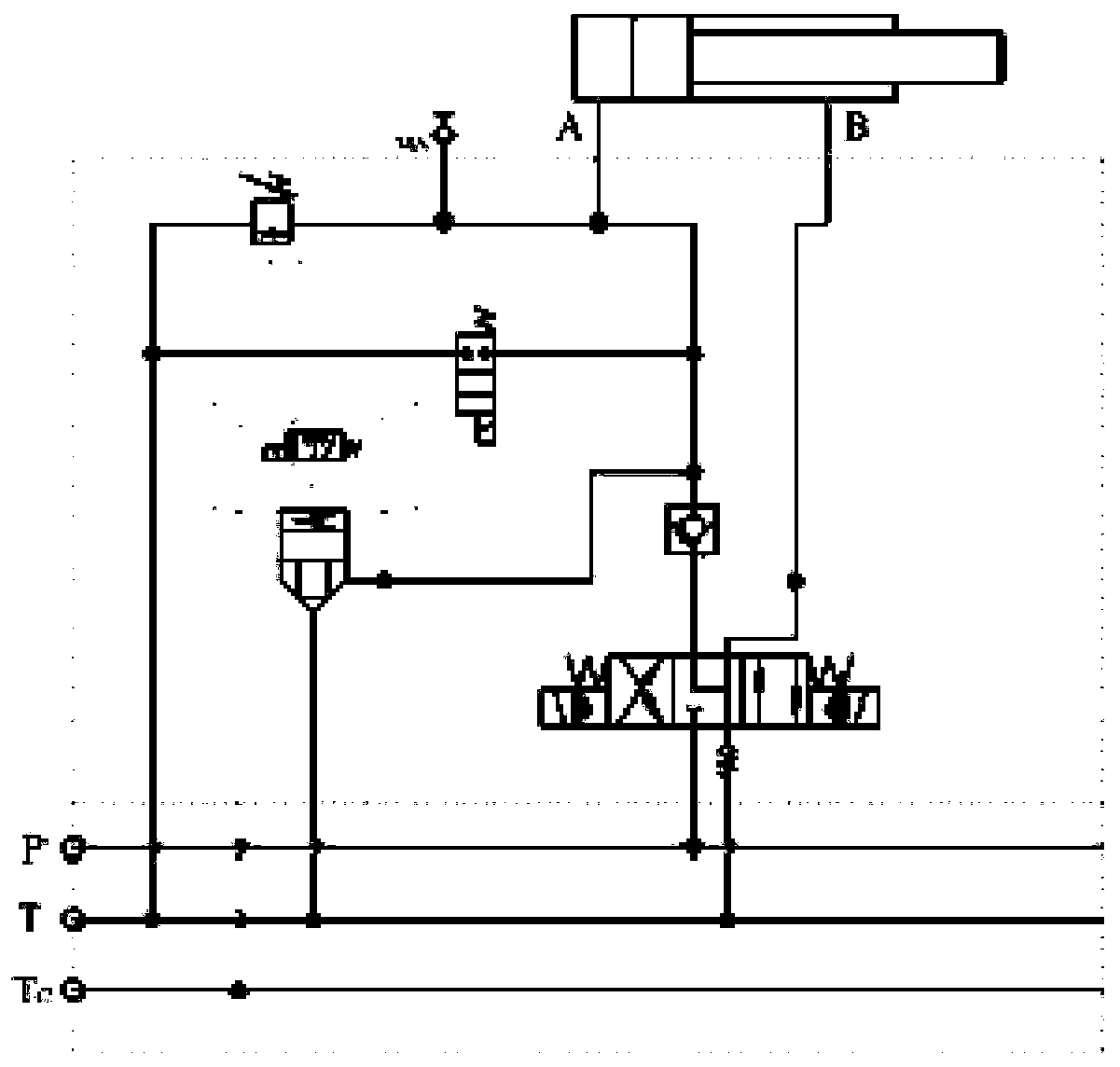

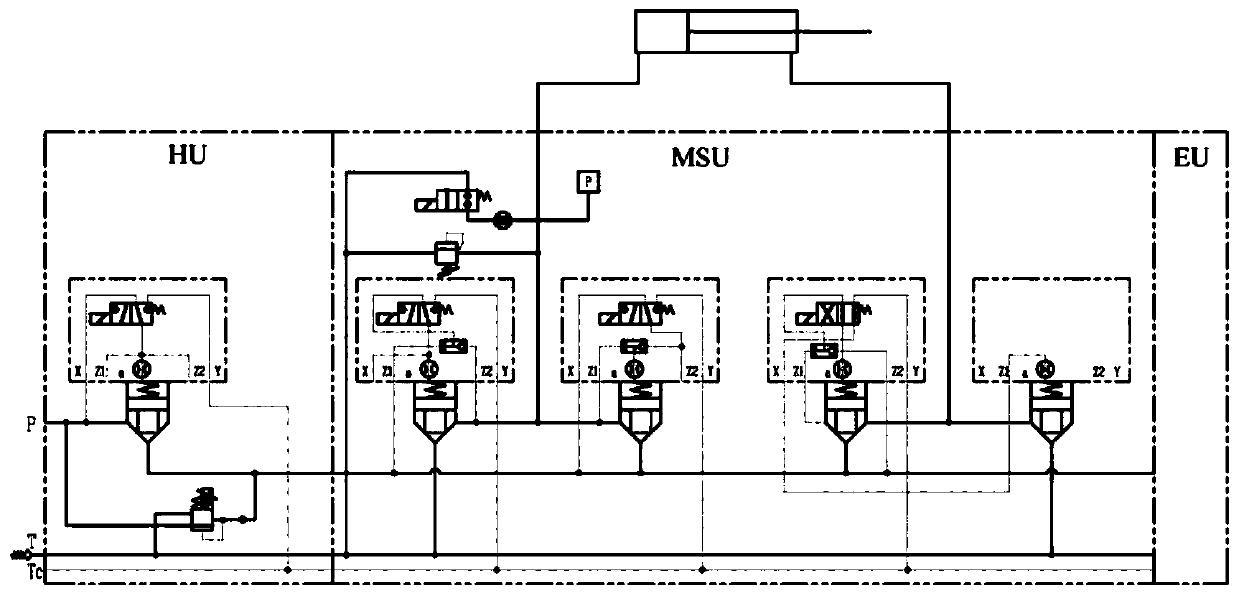

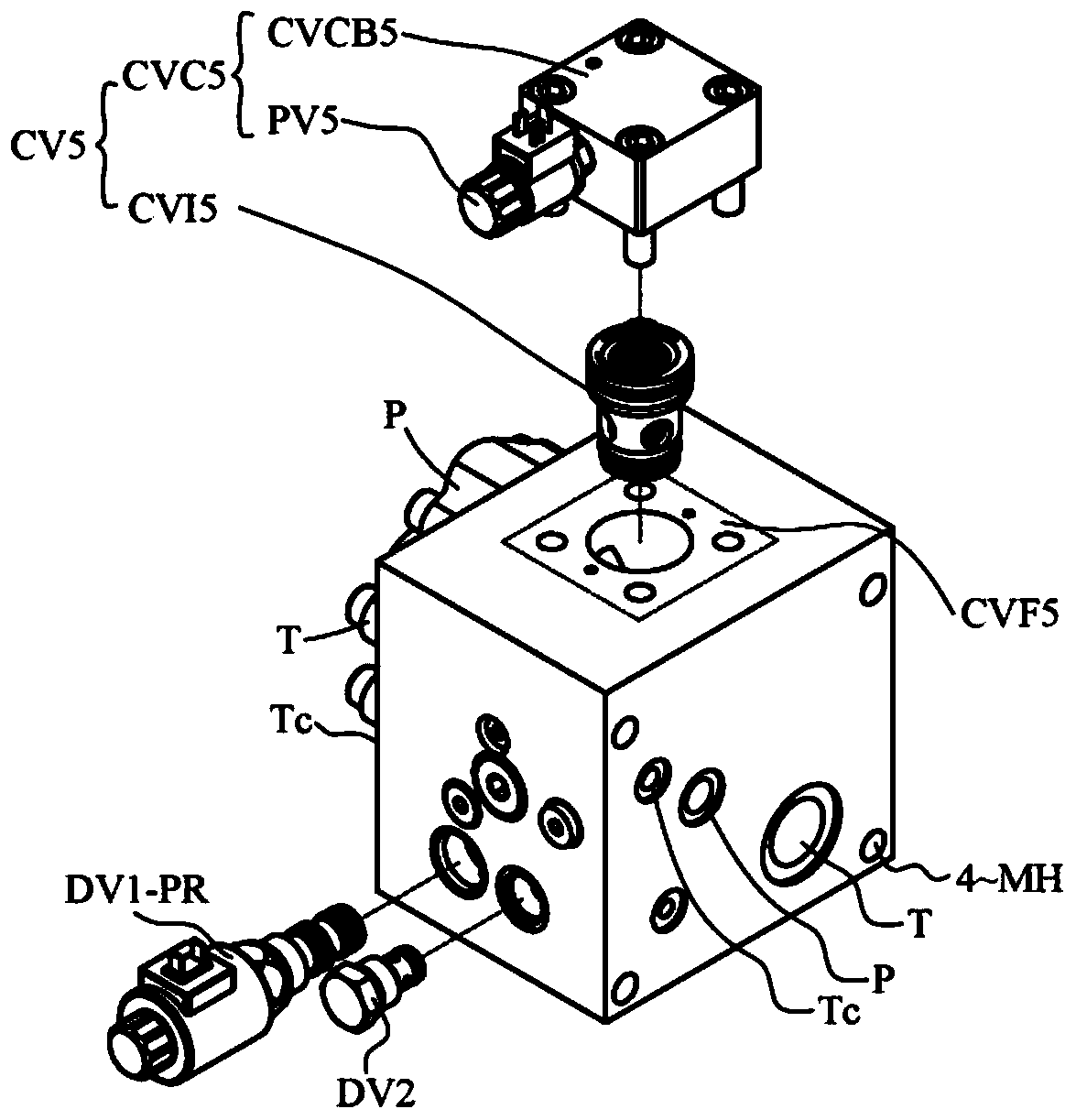

Tunnel boring machine propulsion valve group adopting full cartridge valve control

PendingCN111442010AIn line with the development trendReduce weightServomotor componentsTunnelsMarine engineeringTunnel boring machine

The invention relates to a tunnel boring machine propulsion valve group adopting full cartridge valve control. A base joint group body comprises an oil feeding joint unit, a plurality of working jointunits, a tail joint unit and connecting, detecting and communicating accessories; the plurality of working joint units are connected between the oil feeding joint unit and the tail joint unit in series; the oil feeding joint unit is provided with a compact two-way cartridge valve; the compact two-way cartridge valve is connected with a combined flange control cover plate provided with a threadedpilot control valve; the combined flange control cover plate provided with the threaded pilot control valve controls the opening or closing of the compact two-way cartridge valve; each working joint unit is provided with two groups of compact two-way cartridge valves, and each group of compact two-way cartridge valves consists of two compact two-way cartridge valves; and the two groups of compacttwo-way cartridge valves are respectively connected with a rodless cavity and a rod cavity of a propulsion oil cylinder of a tunnel boring machine through combined flange control cover plates providedwith pilot control valves. The propulsion valve group of the tunnel boring machine controlled by the full cartridge valves has good manufacturability, assemblability and maintainability, and the configuration scheme of the propulsion valve group makes the tunnel boring machine to be more efficient and energy-saving and meet lower emission requirements.

Owner:SHANGHAI HAIYUE HYDRAULIC ELECTROMECHANICAL ENG COOP

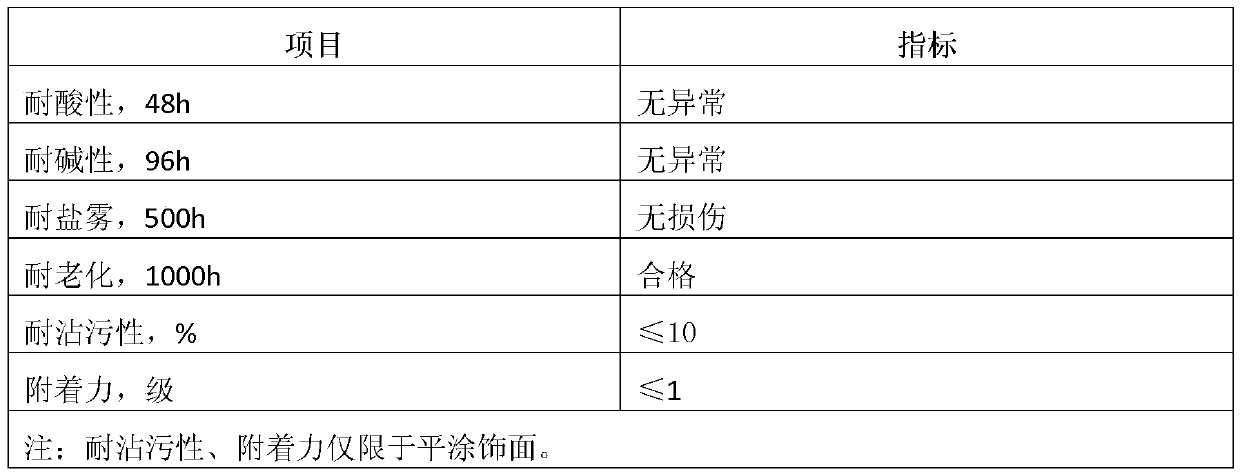

Environment-friendly paint for thermal-insulation decorative boards and preparation method thereof

InactiveCN105505061AEmission reductionEmissions meetAnti-corrosive paintsWater dispersibleThermal insulation

The invention discloses an environment-friendly paint for thermal-insulation decorative boards and a preparation method thereof. The environment-friendly paint is prepared by mixing 5-6 parts by weight of first component and 1 part by weight of water-dispersible isocyanate. The first component is prepared by mixing 0.2 part of wetting agent, 0.3 part of anti-settling agent, 0.3 part of leveling agent, 1-2.3 parts of dispersing agent, 0.3 part of defoaming agent, 20-30 parts of rutile titanium white, 12 parts of heavy calcium carbonate powder, 0.1 part of pH regulator, 45-55 parts of water-dispersible hydroxyacrylic acid, 0.3-0.5 part of alkali-swellable thickener, 0.2-0.4 part of associated thickener and 9-12 parts of water. The environment-friendly paint has the advantages of high weather resistance, high hardness, high scratch resistance, high chemical resistance and the like, can satisfy the performance requirements for the decorative topcoat layer of the thermal-insulation decorative board, comprehensively lowers the VOC (volatile organic compound) emission amount, and can satisfy the requirements of the National Environmental Protection Department for VOC emissions.

Owner:FIRST NEW MATERIAL TECH DEV

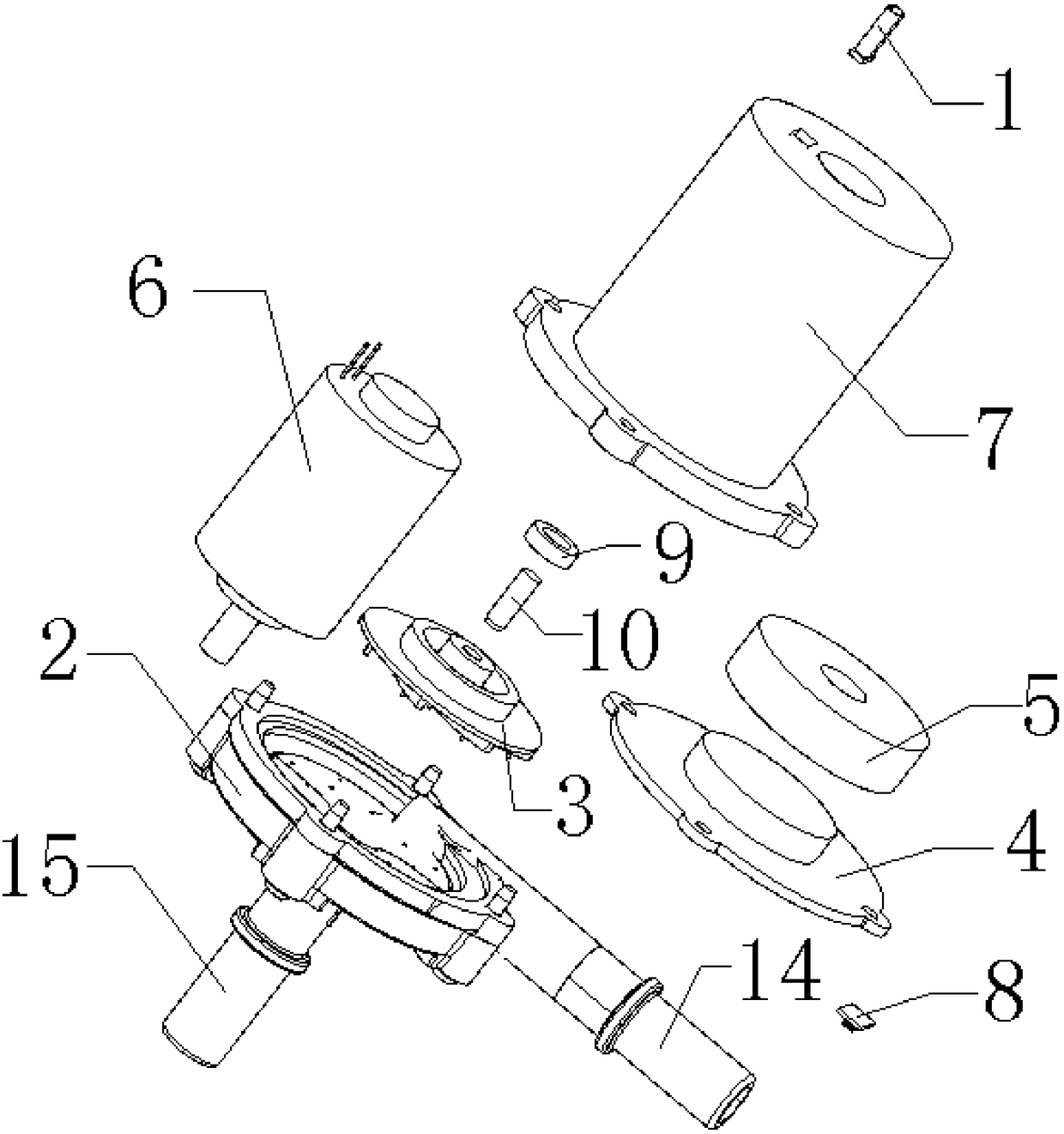

Gasoline steam purification device utilizing electric magnetism-generating transmission principle

ActiveCN105863891AAvoid row toLow emission requirementsNon-fuel substance addition to fuelMachines/enginesImpellerGasoline

The invention relates to a gasoline steam purification device utilizing an electric magnetism-generating transmission principle. The gasoline steam purification device utilizing the electric magnetism-generating transmission principle comprises a volute, an impeller and a shell. The upper end of the shell is connected with the volute. A cylindrical partition plate is arranged in the middle of the inner bottom of the shell. A stator is installed inside the cylindrical partition plate. The magnetic impeller arranged coaxially with the stator is installed in the position, above the cylindrical partition plate, of the volute in a rotating mode. An air intake pipe is vertically arranged in the position, corresponding to the center of the magnetic impeller, of the upper end of the volute. An air exhaust pipe is arranged on the side wall of the volute in the tangent direction of the magnetic impeller. A bottom cover is installed at the bottom of the shell. A PCB is installed between the bottom cover and the shell. A magnetic field is generated inside the gasoline steam purification device through the electric magnetism-generating principle, the magnetic impeller is driven to rotate by the magnetic field, and accordingly pressure difference is formed; and oil steam collected by a carbon tank is fed into an air intake manifold and prevented from being exhausted into air, and the requirement for emission reduction is met accordingly.

Owner:NINGBO TUOPU INTELLIGENT BRAKE SYST

Main burner equipment with outer rotational flow and inner direct flow

ActiveCN1308617CIncrease swirl intensityEnhanced entrainmentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The invention is the outer cyclone inner direct flow main combustor device and belongs to the combustor device of boiler. The purpose of the invention is to produce the backflow area and the stable combustion. One device of the invention is to evenly arrange the delivery blades between the primary air diverting tube and the delivery tube, and the inside diameter of the delivery tube is as 0.5-0.7 times as the diameter of the primary air diverting tube. The other device is to evenly arrange the delivery blades in the inner chamber of the primary air diverting tube, and the axial height of the delivery blades is as 0.1-0.5 time as the semi-diameter of the primary air diverting tube. The invention through changing the opposite angles, the number, the length and the height of the delivery blades and the lengths and the section of the delivery tube to change the intensity and the size of the cyclone amount to adapt the characteristics of different fuels and ensure the stability and economy of the boiler combustion. The invention has simple structure and convenient equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

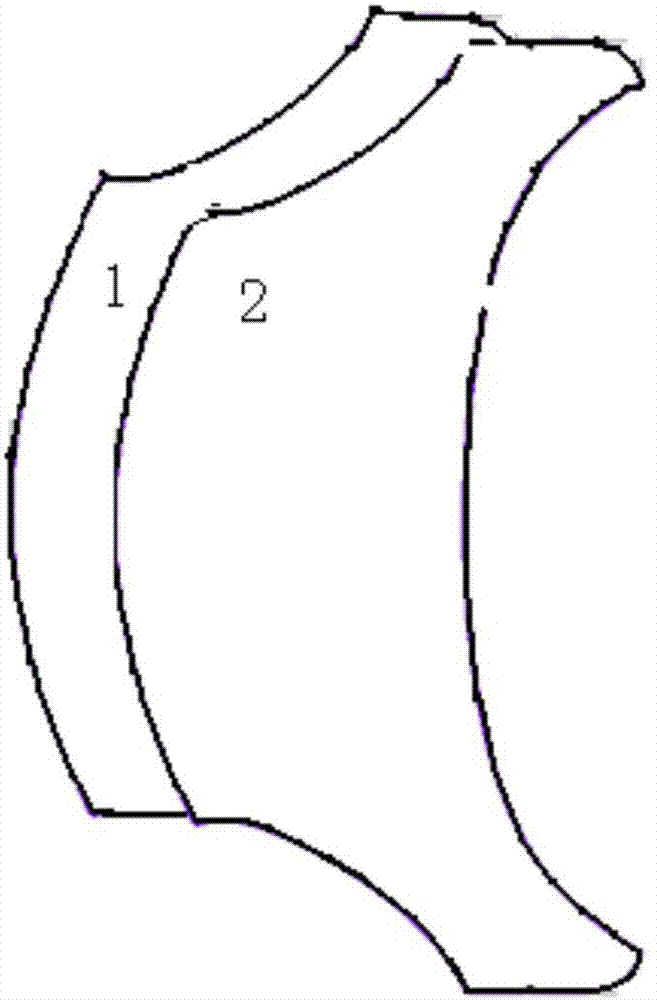

Engine hood made from composite material

InactiveCN107323024AReduce weightLow emission requirementsSuperstructure subunitsGlass/slag layered productsGlass fiberPollutant emissions

The invention discloses an engine hood made from a composite material. The engine hood is equipped with an engine hood main body, wherein an outer layer 1 of the engine hood main body is made from a carbon fiber composite material; an inner layer 2 is made from a glass fiber material; the inner layer 2 is connected with the outer layer 1. The engine hood made from the composite material can meet the requirements of reducing the weight of the engine hood, reducing the fuel consumption and reducing pollutant emission and meanwhile can guarantee crash safety and controllable cost.

Owner:CHERY AUTOMOBILE CO LTD

Welded high-strength wheel

InactiveCN109421430AReduce fuel consumptionSmall unsprung massRimsWheel manufactureEngineeringHigh intensity

Owner:林继奎

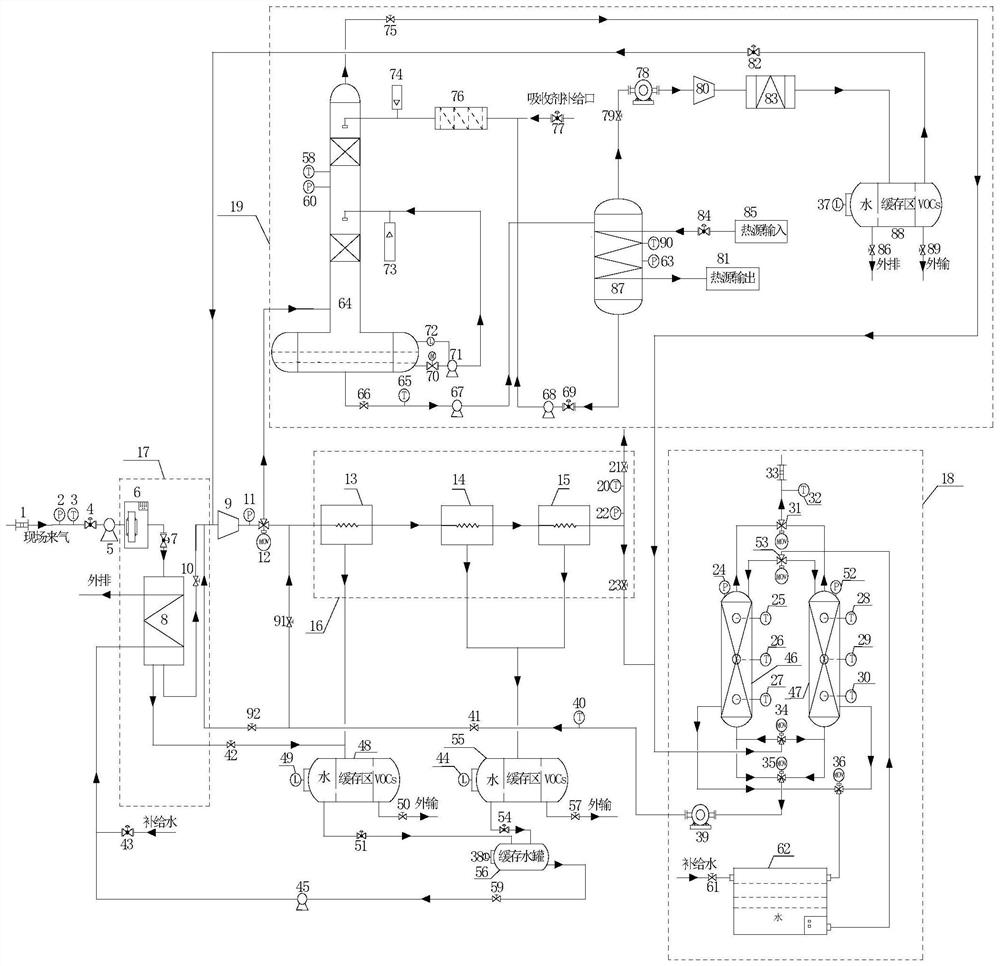

Pressurized multi-stage absorption, condensation and adsorption module combined organic waste gas recovery method

PendingCN113908663AHigh recovery rateAvoid disadvantagesGas treatmentDispersed particle separationExhaust fumesPumping vacuum

The invention discloses a pressurized multi-stage absorption, condensation and adsorption module combined type organic waste gas recovery method, which is characterized in that organic waste gas passes through a pretreatment module, enters an absorption / desorption module or a condensation module, and finally enters the adsorption / desorption module for up-to-standard emission. An adsorbent is desorbed and regenerated through vacuum pumping after adsorption penetration, and desorbed gas and pretreated gas are mixed and returned to the absorption / desorption module or the condensation module. According to the pressurized multi-stage absorption, condensation and adsorption module combined type organic waste gas recovery method provided by the invention, respective advantages of absorption, condensation and adsorption are fully utilized, an optimal recovery process can be selected according to engineering requirements, module combined type multifunctional recovery is realized, the application range is wide, and the goals of efficient recovery, operation cost reduction and ultralow-concentration emission are achieved.

Owner:CHANGZHOU UNIV

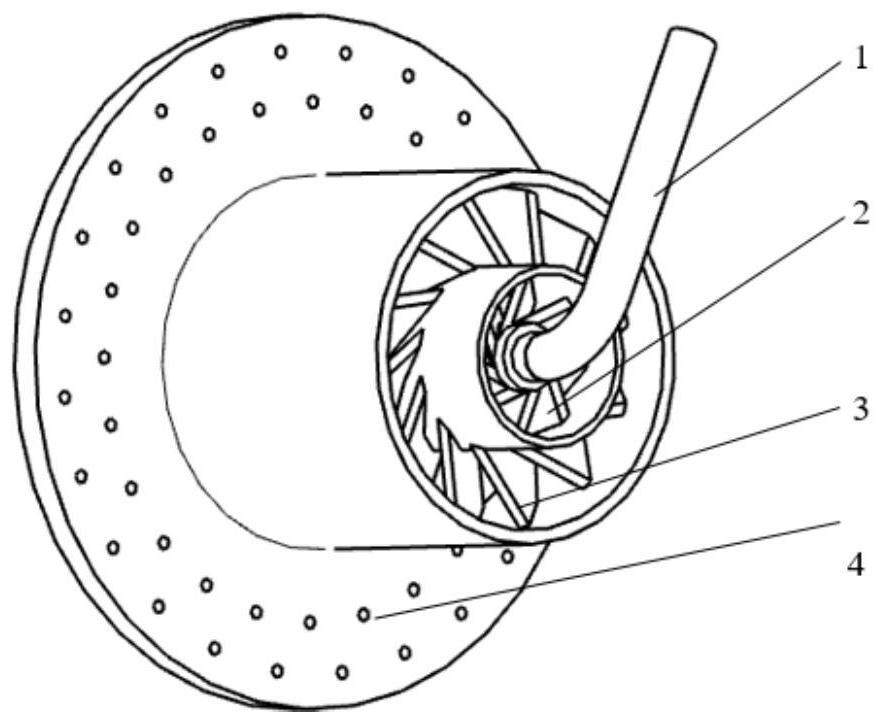

An anti-backfire fuel flash swirl integrated nozzle

ActiveCN111006243BEliminate high temperature zonesReduce generationContinuous combustion chamberPollutant emissionsEngineering

The invention provides an anti-backfire fuel oil flash evaporation and swirling integrated nozzle, which comprises a pressure swirl nozzle, a first-stage swirler and a second-stage swirler from insideto outside, wherein the second-stage swirler comprises an outer wall, a second-stage hub and second-stage axial swirl blades arranged between the inner surface of the outer wall and the outer surfaceof the second-stage hub; a rear step is arranged at the end of the inner surface of the outer wall; the first-stage swirler comprises a first-stage hub and first-stage axial swirl blades arranged between the outer surface of the first-stage hub and the inner surface of the second-stage hub; a contraction section and an expansion section are arranged on the inner surface of the second-stage hub toform a contraction-expansion Venturi tube; the pressure swirl nozzle is connected with the inner wall of the first-stage hub; and the outlet position of the pressure swirl nozzle corresponds to the throat portion of the contraction-expansion Venturi tube. The nozzle not only can avoid backfire, but also can improve the oil-gas mixing level and reduce the pollutant emission.

Owner:HARBIN ENG UNIV

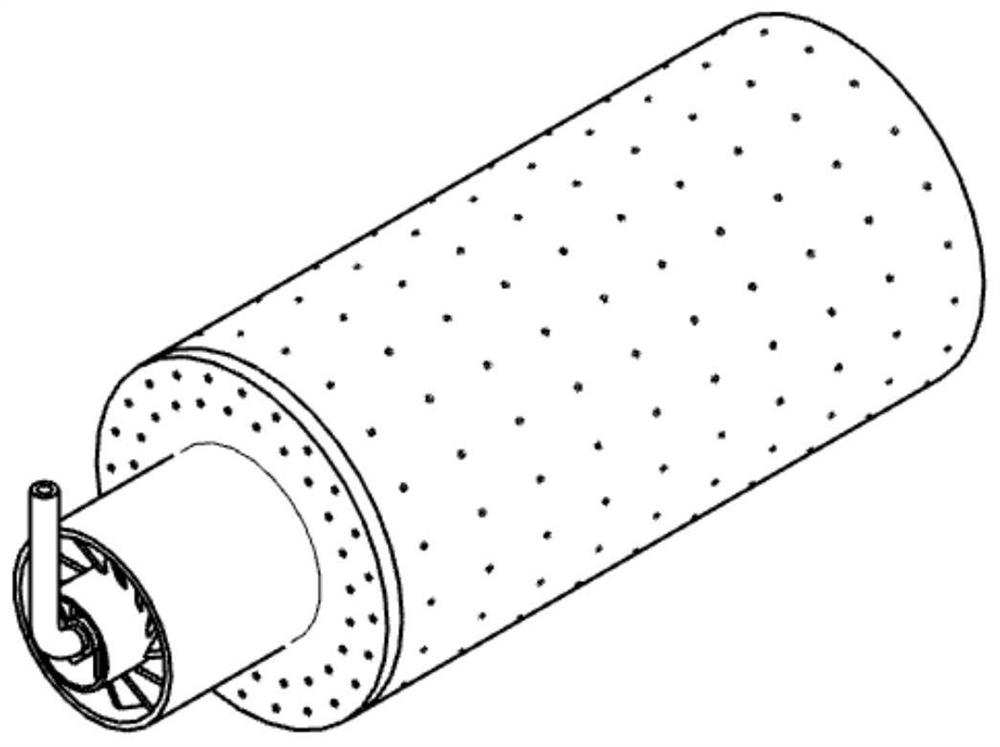

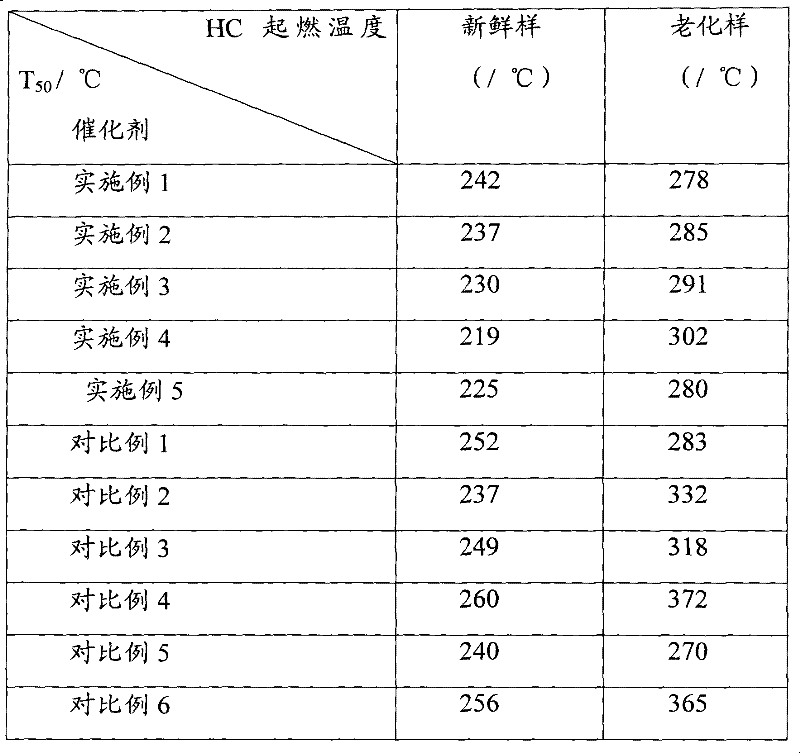

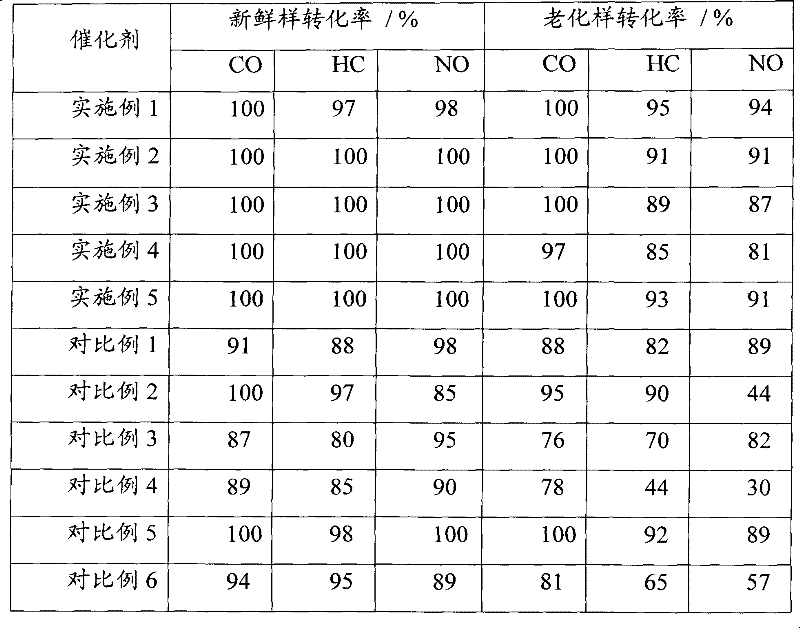

Automobile exhaust purifying catalyst and preparation method thereof

ActiveCN101601999BDecreased oxygen storage performanceHigh oxygen storage performanceDispersed particle separationCatalyst activation/preparationStorage materialLayered structure

Owner:常熟华虞环境科技有限公司

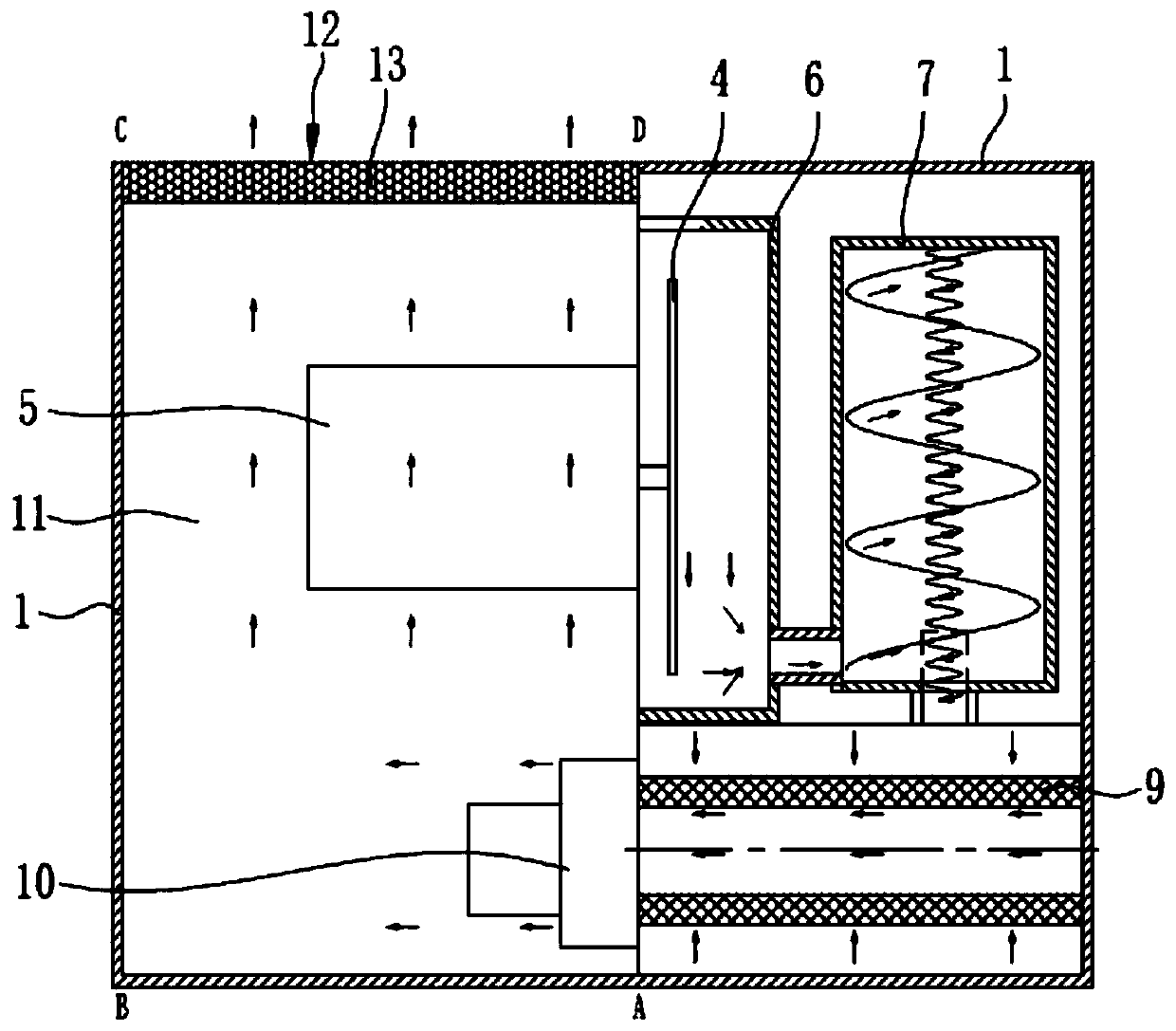

Smoke near-zero-emission system of coal-fired power plant

ActiveCN107081049AEmission reductionAchieve near-zero emissionsCombination devicesGas treatmentPollutionReducing agent

The invention relates to a smoke near-zero-emission system of a coal-fired power plant. The smoke near-zero-release emission system comprises a discharging pipe, wherein the discharging pipe is successively provided with a denitration apparatus, an electric dust collector, a wet-method desulphurization apparatus, a wet-type electric dust collector, a smoke reheating apparatus and a chimney; the denitration apparatus is provided with a first treatment cavity and a second treatment cavity, the first treatment cavity is internally provided with a reducing agent, and the second treatment cavity is internally provided with an oxidized catalyst with Hg; and the discharging pipe between the denitration apparatus and the electric dust collector is provided with a cooling apparatus for lowering the temperature of smoke. The smoke near-zero-emission system has the advantages that the smoke is successively treated by virtue of the denitration apparatus, the electric dust collector, the wet-method desulphurization apparatus and the wet-type electric dust collector, main pollutants in the smoke can be gradually removed, and the smoke is then heated by virtue of the smoke reheating apparatus, so that the visual pollution is eliminated; and finally the smoke is discharged by virtue of the chimney, and the near-zero emission of the smoke is realized, so that the content of pollutants in the smoke is greatly reduced, the smoke pollution is reduced, and the living quality is improved.

Owner:浙江菲达环保科技股份有限公司

A kind of automobile exhaust gas purification catalyst and preparation method thereof

ActiveCN105435834BGood low temperature ignition activityEasy to prepareMolecular sieve catalystsDispersed particle separationHigh concentrationMolecular sieve

The invention discloses an automobile tail gas purification catalyst and a preparation method thereof. The catalyst is composed of a carrier and a catalyst coating coated on the carrier; the catalyst of the present invention is a double-coated catalyst, wherein the first layer is made of alumina and molecular sieve; the second coating is a precious metal coating, and the method of impregnation is used to Precious metals are fixed on the material, reducing the impact of uneven dispersion of precious metals caused by the later migration of precious metals. The first coating of the catalyst of the present invention is a non-precious metal coating, the cost is lower than that of the noble metal coating, and the molecular sieve and alumina have a strong adsorption effect, especially at low temperature, a large amount of methane is adsorbed, thereby promoting a small amount of methane to react with the active material of the second layer , to achieve the effect of rapid ignition; the second coating is a noble metal coating, and the concentration of noble metal in the coating is high, which can play the role of low-temperature ignition.

Owner:SINOCAT ENVIRONMENTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com