Gasoline steam purifying device with flow returning function

A steam purification and gasoline technology, which is applied to the charging system, adding non-fuel substances to fuel, engine components, etc., can solve the problems of insufficient utilization of oil steam, low negative pressure, and low gasoline volatilization emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

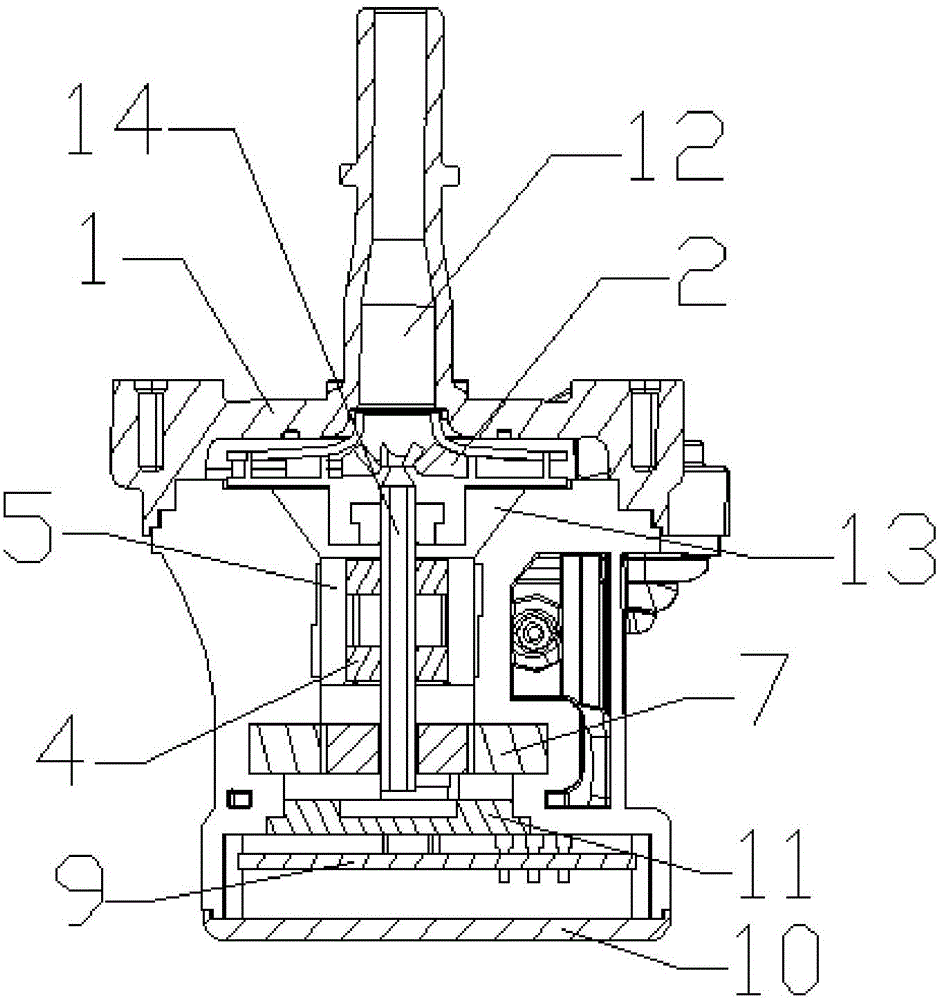

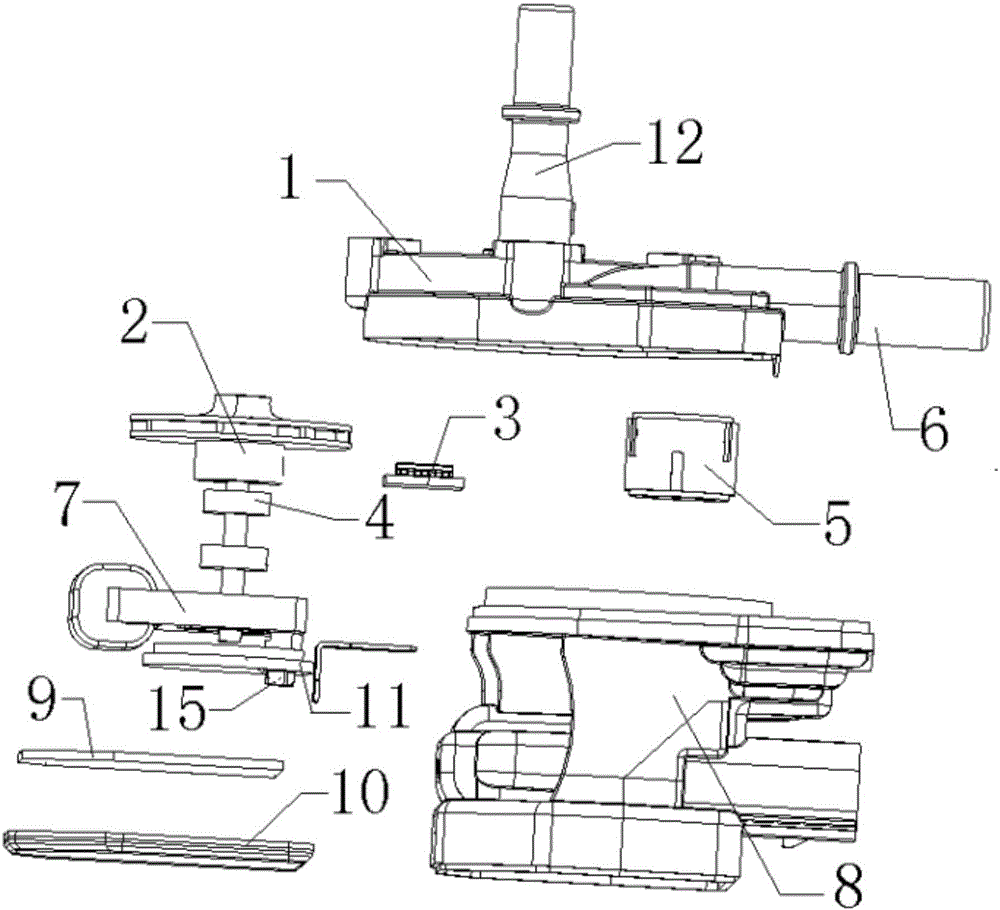

[0023] First connect the air inlet 12 of the device to the carbon tank, and the air outlet 6 to the intake manifold, start the motor 7, and the rotation of the motor 7 drives the impeller 2 to rotate, thereby forming a pressure difference, the pressure of the air inlet 12 and the air outlet 6 The difference is 0.08bar, and the volatilized oil vapor from the fuel tank is sent to the intake manifold to avoid being discharged into the air, so as to achieve the requirement of reducing emissions. The impeller 2 rotates to send the incoming gas to the gas outlet 6, and part of the gas flows to the motor through the gap between the bushing 5 and the base 8, and flows back to the impeller 2 through the through hole 14 on the rotating shaft of the motor 7 to start To a certain cooling effect, the magnetic field sensor 15 is used to detect the rotation speed of the motor 7, and the pressure sensor 3 is used to detect the gas pressure of the gas port 6. The invention has the advantages o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com