A kind of automobile exhaust gas purification catalyst and preparation method thereof

A technology for purifying catalysts and automobile exhaust, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of reduced effective utilization of precious metals, migration of active components, etc., and achieves easy control of preparation process conditions, strong Adsorption, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

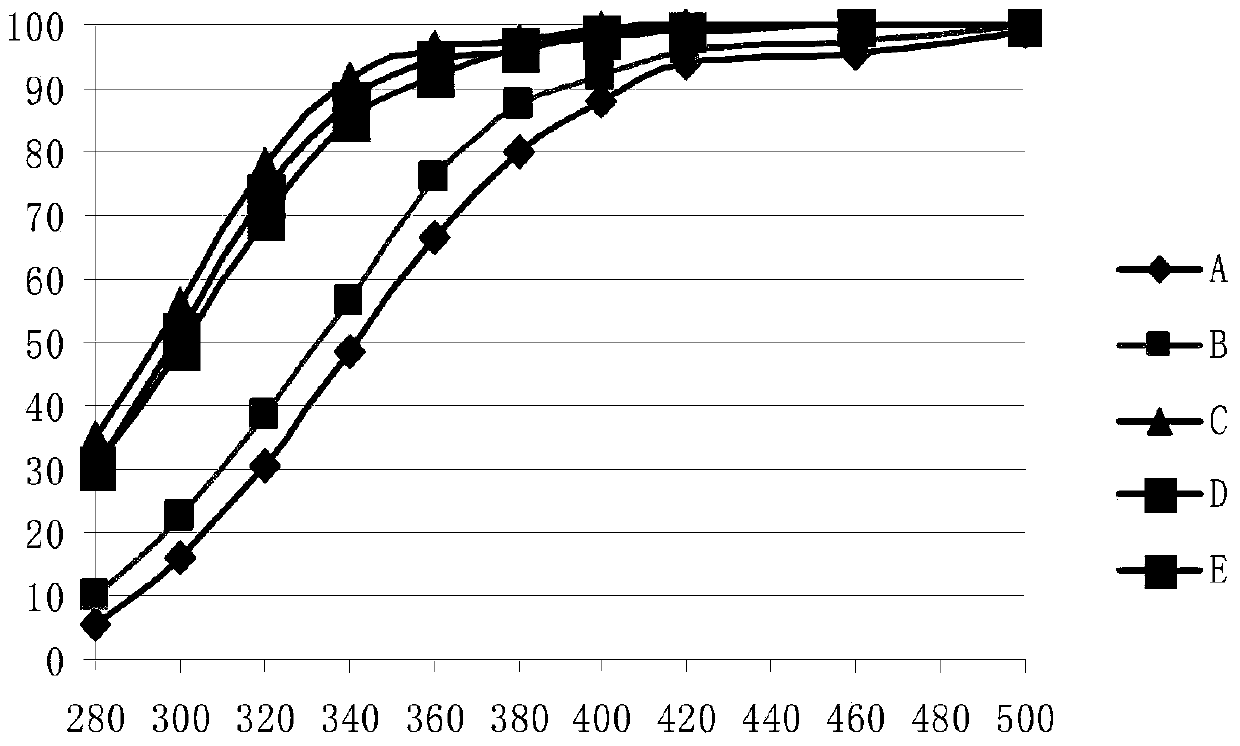

Image

Examples

Embodiment 1

[0035] Add a binder to 49g of γ-Al2O3 and 441g of molecular sieve, add a certain amount of deionized water, and ball mill to make a slurry. The obtained slurry is uniformly coated on a hole number of 400cell / in 2 , on a cordierite honeycomb ceramic carrier with a volume of 13.16ml, the coating amount was 0.658g, vacuum-dried at 80°C, and calcined at 500°C for 1h to obtain catalyst 1. Weigh platinum nitrate and palladium nitrate salt solutions (containing Pt6.98g and Pd27.92g) respectively, add deionized water, add 965g gamma-Al2O3 powder into it, stir quickly and evenly, let stand for more than 30min, and then vacuum dry at 90°C to Constant weight, and then roasted at 500°C for 2 hours to obtain precious metal powder. Mix the precious metal-containing powder with a binder, add a certain amount of deionized water, and ball mill to make a slurry, which is evenly coated on catalyst 1 with a coating amount of 1.1186g, dried and calcined to obtain the target catalyst.

Embodiment 2

[0037] Add binder to 122.5g gamma-Al2O3 and 367.5g molecular sieve, add a certain amount of deionized water, and ball mill to make slurry. The obtained slurry is uniformly coated on a hole number of 400cell / in 2 , on a cordierite honeycomb ceramic carrier with a volume of 13.16ml, the coating amount was 0.658g, vacuum-dried at 80°C, and calcined at 500°C for 1h to obtain catalyst 1. Weigh platinum nitrate and palladium nitrate salt solutions (containing Pt6.98g and Pd27.92g) respectively, add deionized water, add 965g gamma-Al2O3 powder into it, stir quickly and evenly, let stand for more than 30min, and then vacuum dry at 90°C to Constant weight, and then roasted at 500°C for 2 hours to obtain precious metal powder. Mix the precious metal-containing powder with a binder, add a certain amount of deionized water, and ball mill to make a slurry, which is evenly coated on catalyst 1 with a coating amount of 1.1186g, dried and calcined to obtain the target catalyst.

Embodiment 3

[0039] Add a binder to 49g of γ-Al2O3 and 490g of molecular sieve, add a certain amount of deionized water, and ball mill to make a slurry. The obtained slurry is uniformly coated on a hole number of 400cell / in 2 , on a cordierite honeycomb ceramic carrier with a volume of 13.16ml, the coating amount was 1.1186g, vacuum-dried at 80°C, and calcined at 500°C for 1h to obtain Catalyst 1. Weigh platinum nitrate and palladium nitrate salt solutions (containing 12.0g of Pt and 48.0g of Pd) respectively, add deionized water, add 965g of γ-Al2O3 powder into it, stir quickly and evenly, let it stand for more than 30min, and then vacuum dry at 90°C to Constant weight, and then roasted at 500°C for 2 hours to obtain precious metal powder. Mix the precious metal-containing powder with a binder, add a certain amount of deionized water, and ball mill to make a slurry, which is evenly coated on the catalyst 1 with a coating amount of 0.658g, dried and calcined to obtain the target catalyst....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com