Piston with Ti-doping diamond multi-layer thick heat-insulating film on top face and preparation method and application of piston

A multi-layer heat insulation and titanium doping technology, which is applied in the direction of piston, metal material coating process, coating, etc., can solve the limitations of DLC film application and development, poor thermal stability, poor bonding force between the film layer and the substrate interface And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

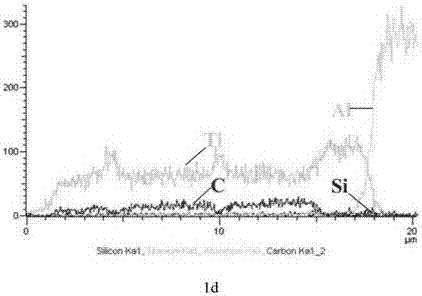

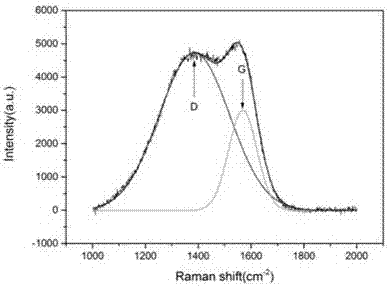

[0074] (a) Using the FCVA system, turn on the titanium power supply arc, adjust the arcing current to 100A, the magnetic field of the curved pipe is 2.0A, the magnetic field of the straight pipe is 3.5A, the duty cycle is 90%, and the negative pressure is -1000V, -800V, - 600V, -400V, -300V, deposit a Ti film layer on the surface of the pretreated substrate, where each negative pressure point is deposited for 30s, and when the negative pressure is -300V, deposit for 20 minutes;

[0075] (b) Turn on the titanium arc source, adjust the duty cycle to 20%, and open the gas flow switch to feed acetylene gas at the same time. The acetylene flow sequence adopts 10sccm, 20sccm, 30sccm, 40sccm, 50sccm, 60sccm, 70sccm, 80sccm deposition, each flow Spot deposition for 30s, when the acetylene flow rate is 80sccm, deposit for 15min to obtain TiC / DLC film layer;

[0076] (c) Turn on the titanium arc source, adjust the duty cycle to 90%, turn off the gas flow switch, and deposit for 3 minute...

Embodiment 2

[0082] (a) Using the FCVA system, turn on the titanium power supply arc, adjust the arcing current to 100A, the magnetic field of the curved pipe to 2.0A, the magnetic field of the straight pipe to 3.5A, the duty cycle is 90%, and the negative pressure is -1000V, -800V, -600V in sequence , -400V, -300V, deposit a Ti film layer on the surface of the pretreated substrate, where each negative pressure point is deposited for 30s, and when the negative pressure is -300V, deposit for 20min;

[0083] (b) Turn on the titanium arc source, adjust the duty cycle to 20%, and open the gas flow switch to feed acetylene gas at the same time. The acetylene flow sequence adopts 10sccm, 20sccm, 30sccm, 40sccm, 50sccm, 60sccm, 70sccm, 80sccm deposition, each flow Spot deposition for 30s, when the flow rate of acetylene is 80sccm, deposition for 22.5min / 16.25min / 10min, TiC / DLC film layer is obtained;

[0084] (c) Turn on the titanium arc source, adjust the duty cycle to 90%, turn off the gas flow...

Embodiment 3

[0088] (a) Using the FCVA system, turn on the titanium power supply arc, adjust the arcing current to 100A, the magnetic field of the curved pipe to 2.0A, the magnetic field of the straight pipe to 3.5A, the duty cycle is 90%, and the negative pressure is -1000V, -800V, -600V in sequence , -400V, -300V, deposit a Ti film layer on the surface of the pretreated substrate, where each negative pressure point is deposited for 30s, and when the negative pressure is -300V, deposit for 10min;

[0089] (b) Turn on the titanium arc source, adjust the duty cycle to 20%, and open the gas flow switch to feed acetylene gas at the same time. The acetylene flow sequence adopts 10sccm, 20sccm, 30sccm, 40sccm, 50sccm, 60sccm, 70sccm, 80sccm deposition, each flow Spot deposition for 30s, when the acetylene flow rate is 80sccm, deposit for 10min to obtain TiC / DLC film layer;

[0090] (c) Turn on the titanium arc source, adjust the duty cycle to 90%, turn off the gas flow switch, and deposit for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com