Environment-friendly paint for thermal-insulation decorative boards and preparation method thereof

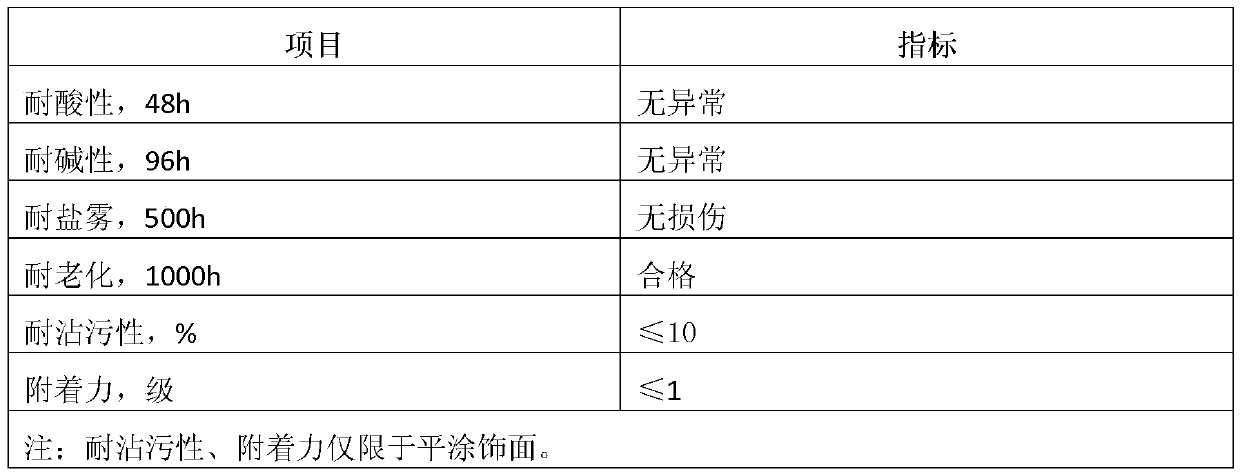

A technology for thermal insulation decorative panels and environmentally friendly coatings, applied in the direction of anti-corrosion coatings, coatings, etc., can solve problems such as unsatisfactory coatings and difficult performance requirements for coatings, and achieve high scratch resistance and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Specifically, the preparation method of the environmentally friendly coating for the thermal insulation decorative board may include the following steps:

[0022] Step A, according to wetting agent: anti-settling agent: leveling agent: dispersant: defoamer: rutile titanium dioxide: heavy calcium powder: pH regulator: water dispersible hydroxyacrylic acid: alkali swelling thickener: association Type thickener: water = 0.2: 0.3: 0.3: 1 ~ 2.3: 0.3: 20 ~ 30: 12: 0.1: 45 ~ 55: 0.3 ~ 0.5: 0.2 ~ 0.4: 9 ~ 12 parts by weight, respectively Wetting agent, anti-settling agent, leveling agent, dispersant, defoamer, rutile titanium dioxide, heavy calcium powder, pH regulator, water dispersible hydroxyacrylic acid, alkali swelling thickener, associative thickener agent and water. Wherein, the wetting agent can adopt H anionic surfactant H in the prior art, for example: alkyl sulfonate, fatty acid, H fatty acid ester H sulfate, carboxylic acid soap, phosphoric acid ester etc.; Descri...

Embodiment 1

[0029] A preparation method for an environmentally friendly coating for a thermal insulation decorative board may comprise the steps of:

[0030] Step A1, in parts by weight, weigh 0.2 parts of fatty acid ester sulfate as a wetting agent, 0.3 parts of hectorite clay as an anti-settling agent, 0.3 parts of macromolecular acrylic acid as a leveling agent, and 2.3 parts of sodium polyacrylate Salt as dispersant, 0.3 parts of silicone emulsion as defoamer, 26 parts of rutile titanium dioxide R902+, 6 parts of heavy calcium powder, 0.1 part of pH regulator, 55 parts of water dispersible hydroxyacrylic acid, 0.3 parts of alkali swelling thickener DR-72, 0.2 parts of associative thickener and 9 parts of water.

[0031]Step B1, add 8% water into the dispersion tank, and add wetting agent, anti-sedimentation agent, leveling agent, dispersant, defoamer and pH regulator into the dispersion tank at a speed of 300-500rpm ; After dispersing at a speed of 500-1000rpm for 10-20 minutes, add ...

Embodiment 2

[0035] A preparation method for an environmentally friendly coating for a thermal insulation decorative board may comprise the steps of:

[0036] Step A2, in parts by weight, weigh 0.2 parts of H phosphate ester H as a wetting agent, 0.3 parts of hectorite clay as an anti-settling agent, 0.3 parts of modified polysiloxane as a leveling agent, and 1.8 parts of non- Ionic fatty acid derivative as dispersant, 0.5 part of polyether siloxane and silicon dioxide mixture as defoamer, 30 parts of rutile titanium dioxide R706, 12 parts of heavy calcium powder, 0.1 part of pH regulator, 45 parts of water dispersible Hydroxy acrylic acid, 0.5 parts of alkali swelling thickener DR-72, 0.3 parts of associative thickener and 9 parts of water.

[0037] Step B2. Add 8% water into the dispersion tank, and add wetting agent, anti-sedimentation agent, leveling agent, dispersant, defoamer and pH regulator into the dispersion tank at a speed of 300-500 rpm ; After dispersing at a speed of 500-100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com