Belt type pellet roasting flue gas desulfurization and denitrification system and method

A desulfurization, denitrification and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low desulfurization efficiency, less floor space, less investment in semi-dry desulfurization process, and reduce NOx concentration. And the effect of sulfur oxide concentration, reducing fuel cost and improving treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

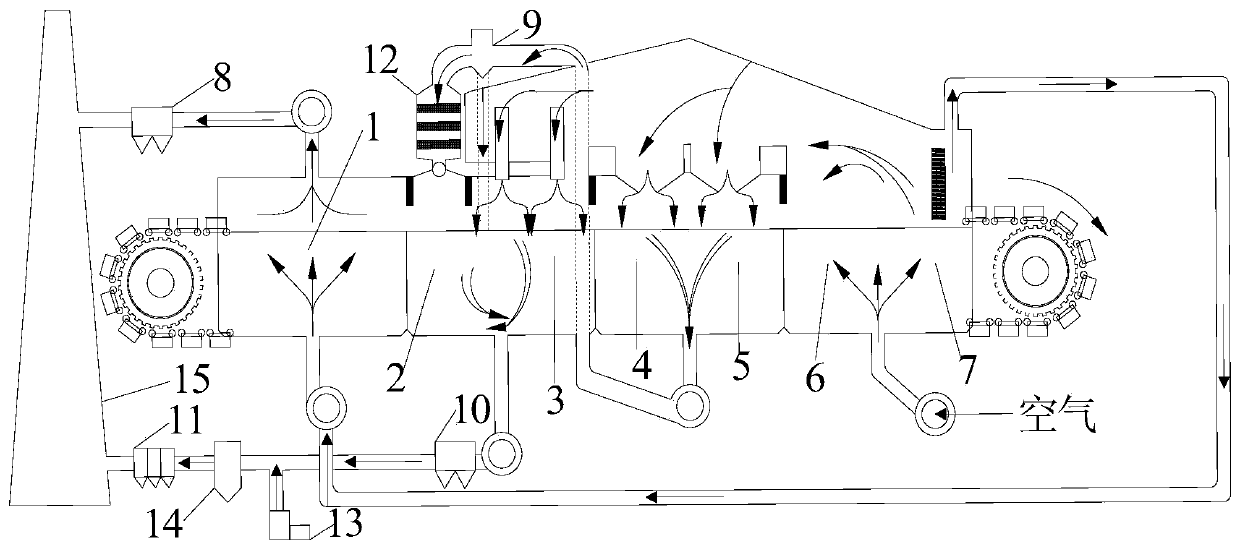

[0070] This embodiment provides a preferred technical solution of the flue gas desulfurization and denitrification system for belt-type pellet roasting of the present invention, including a belt-type roasting unit, an SCR denitrification device 12, an oxidation denitrification device, a desulfurization device 14, a dust removal unit and a chimney 15 .

[0071] The dust removal unit includes a first dust removal device 8 , a second dust removal device 9 , a third dust removal device 10 and a fourth dust removal device 11 .

[0072] The belt roasting unit includes a belt roaster and a supporting gas conveying device, and the belt roaster includes a blast drying section 1, a draft drying section 2, a preheating section 3, a roasting section 4, and a soaking section arranged in sequence. Section 5, the first cooling section 6 and the second cooling section 7.

[0073] The gas conveying device independently transports the external cold source to the first cold section 6 and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com