Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Penetration deep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

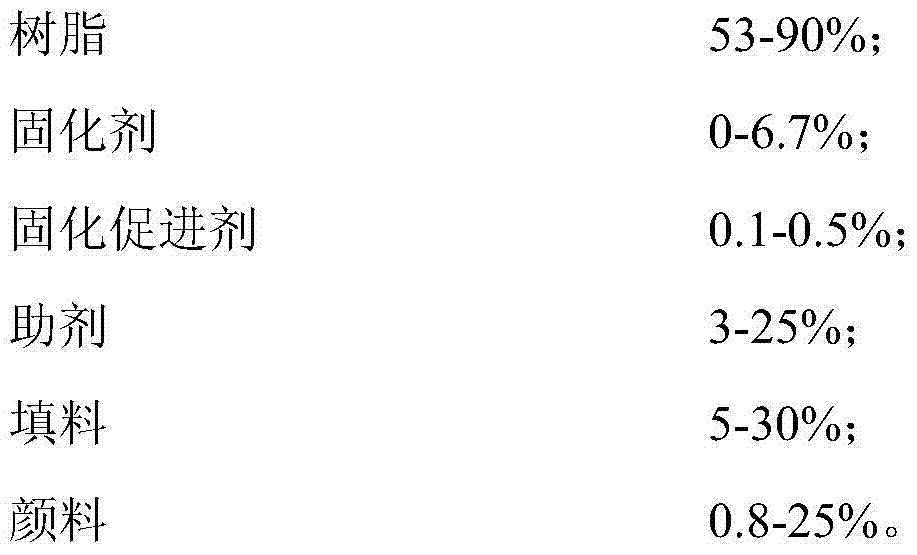

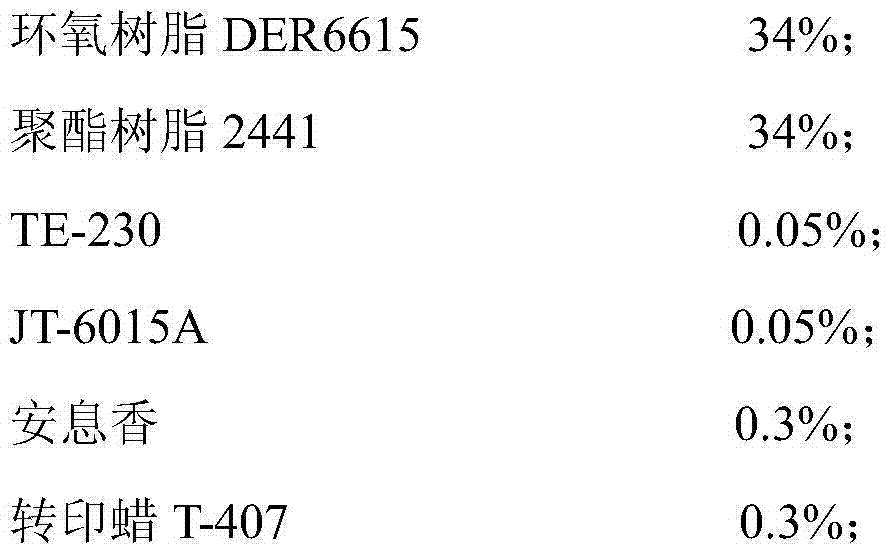

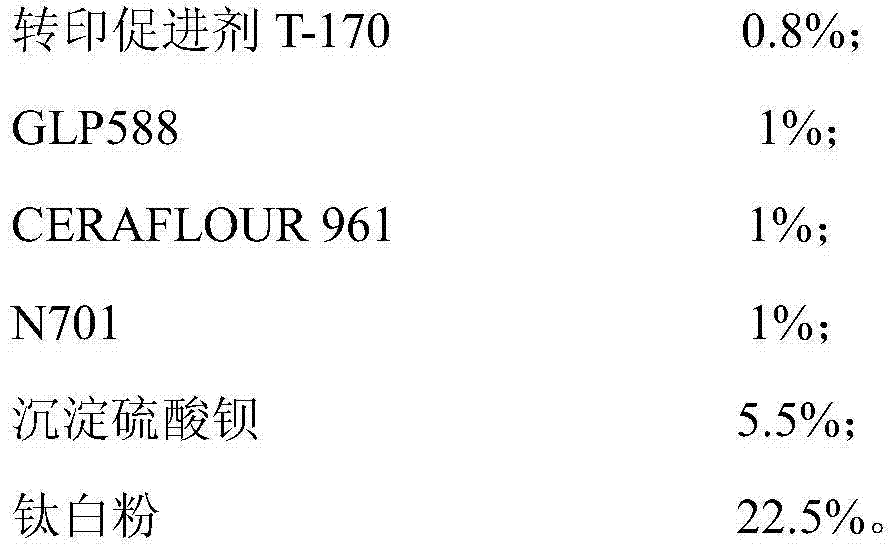

Powder coating for MDF transfer printing and application method of powder coating

PendingCN104497808AImprove texture clarityEasy to tear offDuplicating/marking methodsPowdery paintsWeather resistanceWear resistance

The invention relates to powder coating and particularly relates to powder coating for MDF transfer printing and an application method of the powder coating. The powder coating is prepared from the following raw materials in percentage by weight: 53-90% of resin, 0-6.7% of a curing agent, 0.1-0.5% of a curing accelerant, 3-25% of auxiliaries, 5-30% of filler and 0.8-25% of pigment. After the powder coating is used for transfer printing, the texture is clear, the penetration is deep, the third dimension is strong, the transfer printing paper can be easily uncovered, the thermal transfer printing product is durable in use, and the patterns are not dropped, cracked or faded; moreover, the thermal transfer printing only achieves a surface decoration effect without changing the characteristics of the original glossiness, the wear resistance, the weather resistance, the acid and alkali resistance, and the like of the product. The invention also provides an application method of the powder coating.

Owner:山东朗法博粉末涂装科技有限公司

Method for shortening cultivation period of needle mushroom during production

The invention relates to the field of new edible mushroom cultivation techniques, in particular to a method for shortening a cultivation period of needle mushroom during production. The method comprises the following steps of: with grains as a main raw material, preparing a culture matrix, wherein the grains are rich in nutrition, the culture matrix made of the grains is hardened so that inoculated strains can be easily dispersed and can penetrate into the culture matrix; inoculating by utilizing liquid strains, wherein the cultivation period of the liquid strains is short, the inoculation operation is convenient and fast; and carrying out shaking, clamping and other measures on the culture matrix in a bottle after inoculating so that the inoculated liquid strains are in full contact with the culture matrix in the bottle and cultivated hypha can fully grow in the bottle after 10-20 days. Through the embodiment of the invention, the whole period of the preparation of the mushroom culture matrix only need 25-27 days, but the whole period of the preparation of the mushroom culture matrix by the traditional method needs three months nearly, thus the production efficiency is largely improved; in addition, compared with the traditional method, the method has the advantages that the cultivated needle mushroom is two stubbles more than needle mushroom cultured by the traditional method and the utilization rate of the field is largely improved; and the method disclosed by the invention is more beneficial to industrial, intensive and extensive production of needle mushroom.

Owner:何寒

Wood bleaching device

InactiveCN101491909AWill not cause an explosionLow costWood treatment detailsBleachPulp and paper industry

The invention discloses a wood product bleaching device, which has the key technical points that: the device comprises a nozzle which is connected with an uptake pipe, and the top of the uptake pipe is connected with a retort which is higher than the nozzle and can make the nozzle produce a pressure high enough for injection; and the retort is open and contains a bleaching agent. The invention provides a wood product bleaching device which is safe, reliable, simple in structure, low in cost, aiming to overcome the drawback that the prior wood product bleaching device lacks safety.

Owner:中山市合兴奇典居家具有限公司

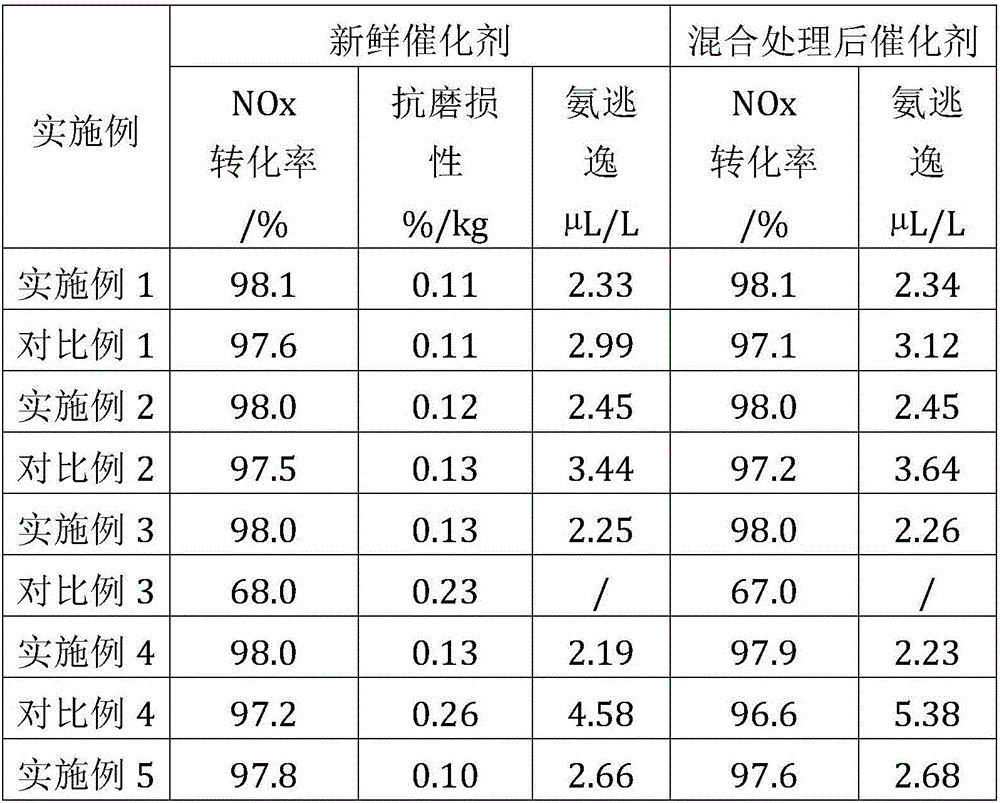

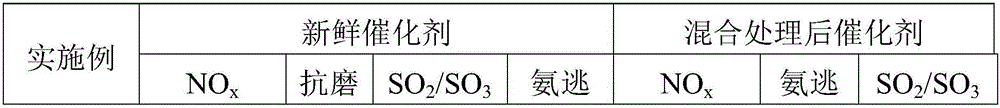

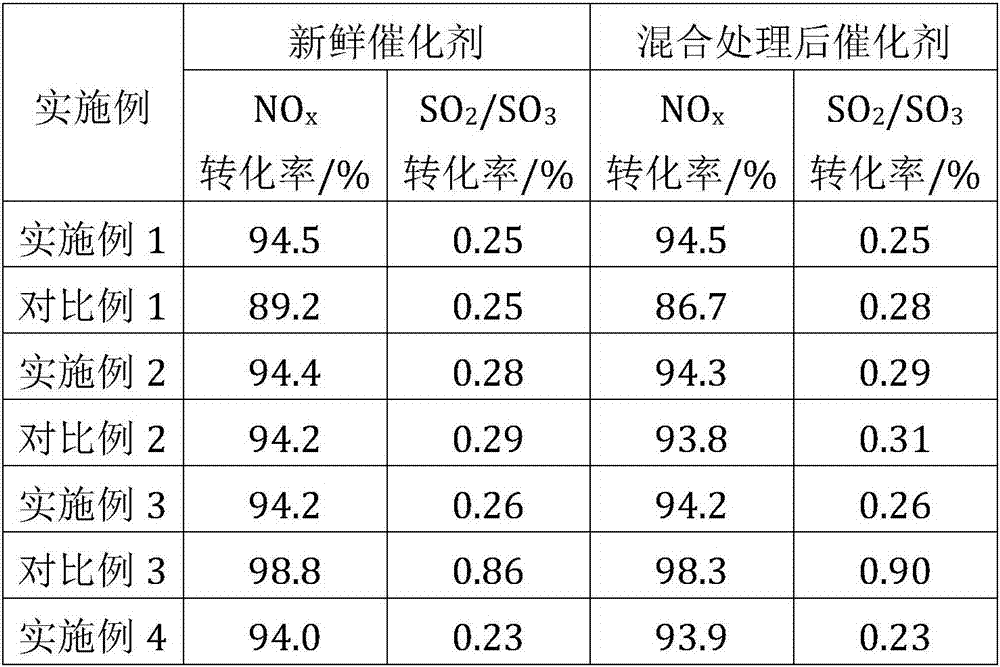

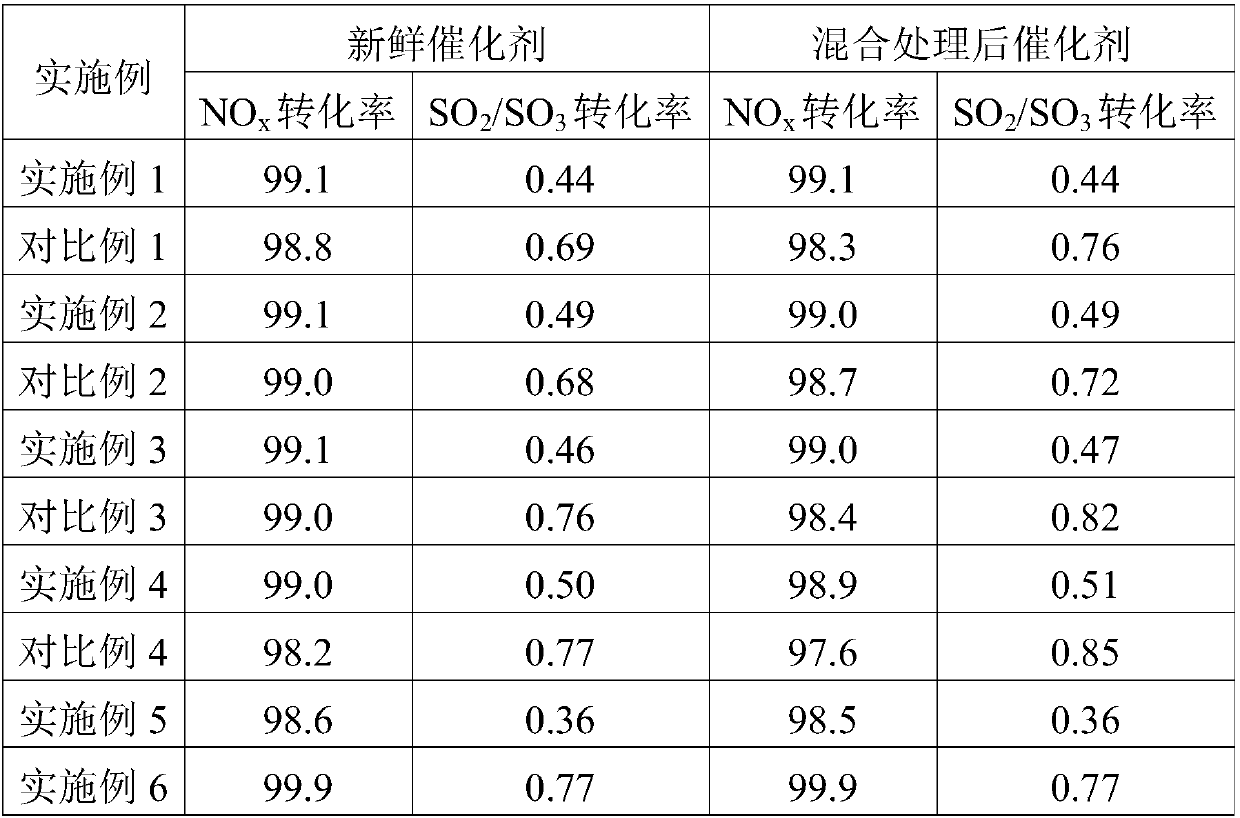

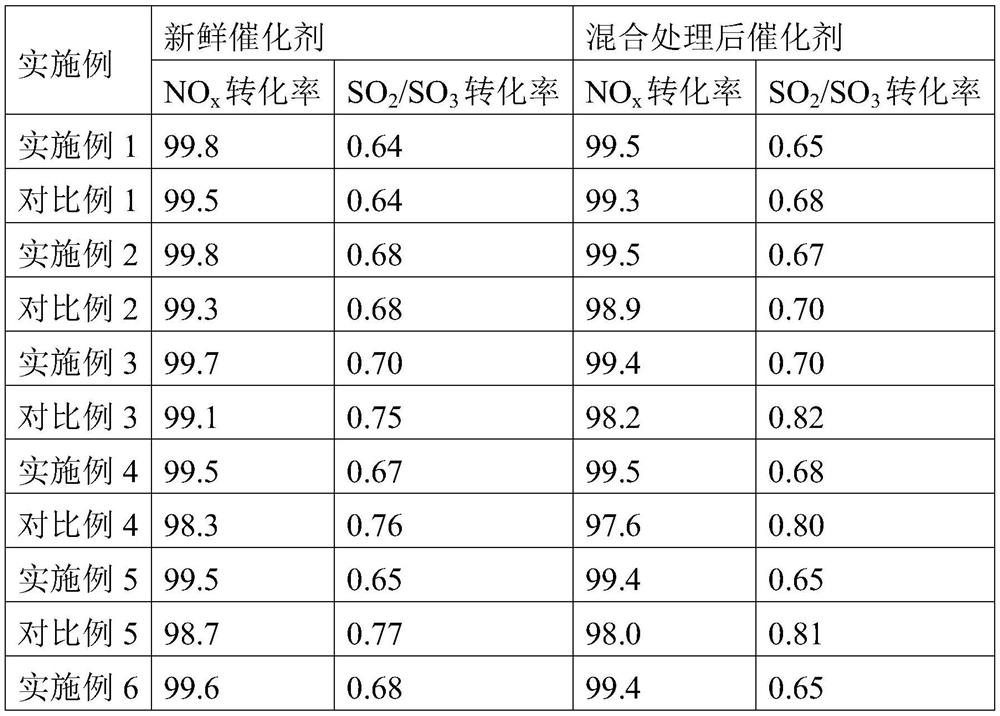

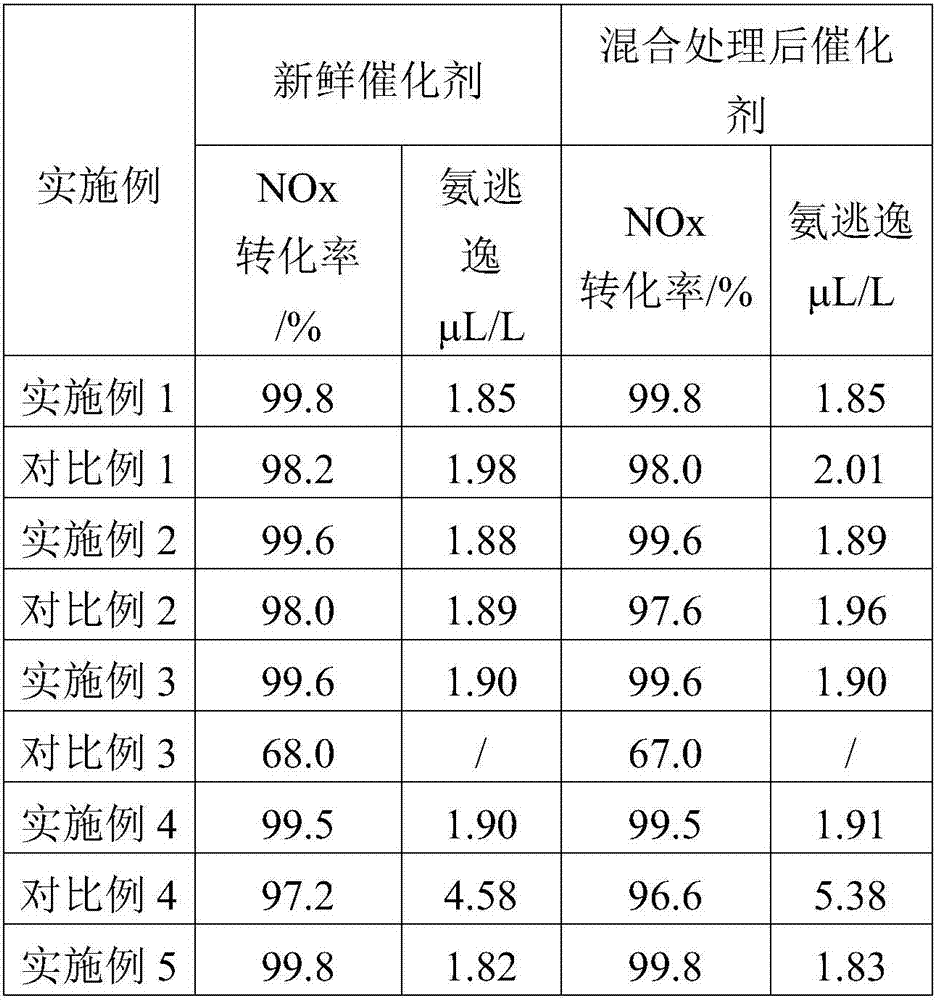

Anti-abrasion denitration catalyst and preparation method thereof

InactiveCN107175122ASmall and uniform particle sizeRaise the transition temperatureCatalyst activation/preparationSlurrySilicon dioxide

The invention discloses an anti-abrasion denitration catalyst and a preparation method thereof. The preparation method comprises the following steps of dissolving titanium source precursors into acid to form a solution; respectively dissolving molybdenum source precursors, phosphorus source precursors and magnesium source precursors to form solutions; uniformly mixing the solutions; regulating the pH value; performing precipitation, filtering and washing; then adding deionized water; preparing the materials into slurry; adding a vanadium source precursor solution; after uniform mixing, directly performing drying and roasting; grinding the materials into powder; next, adding extrusion auxiliary agents, a solution formed by the molybdenum source precursors and pore forming agents; adding water during the stirring to obtain paste; regulating the pH value; adding nanometer silicon dioxide, wollastonite, glass fiber and bonding agents; performing uniform mixing; extruding honeycomb-shaped blanks by an extruding machine; performing drying and roasting; then, obtaining a finished product. The prepared anti-abrasion denitration catalyst can overcome the defects of unstable activity, poor anti-abrasion performance and activity center unbalance of a denitration catalyst in flue gas in the prior art.

Owner:PETROCHINA CO LTD

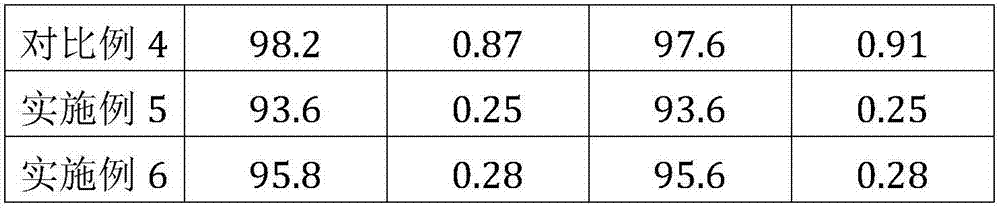

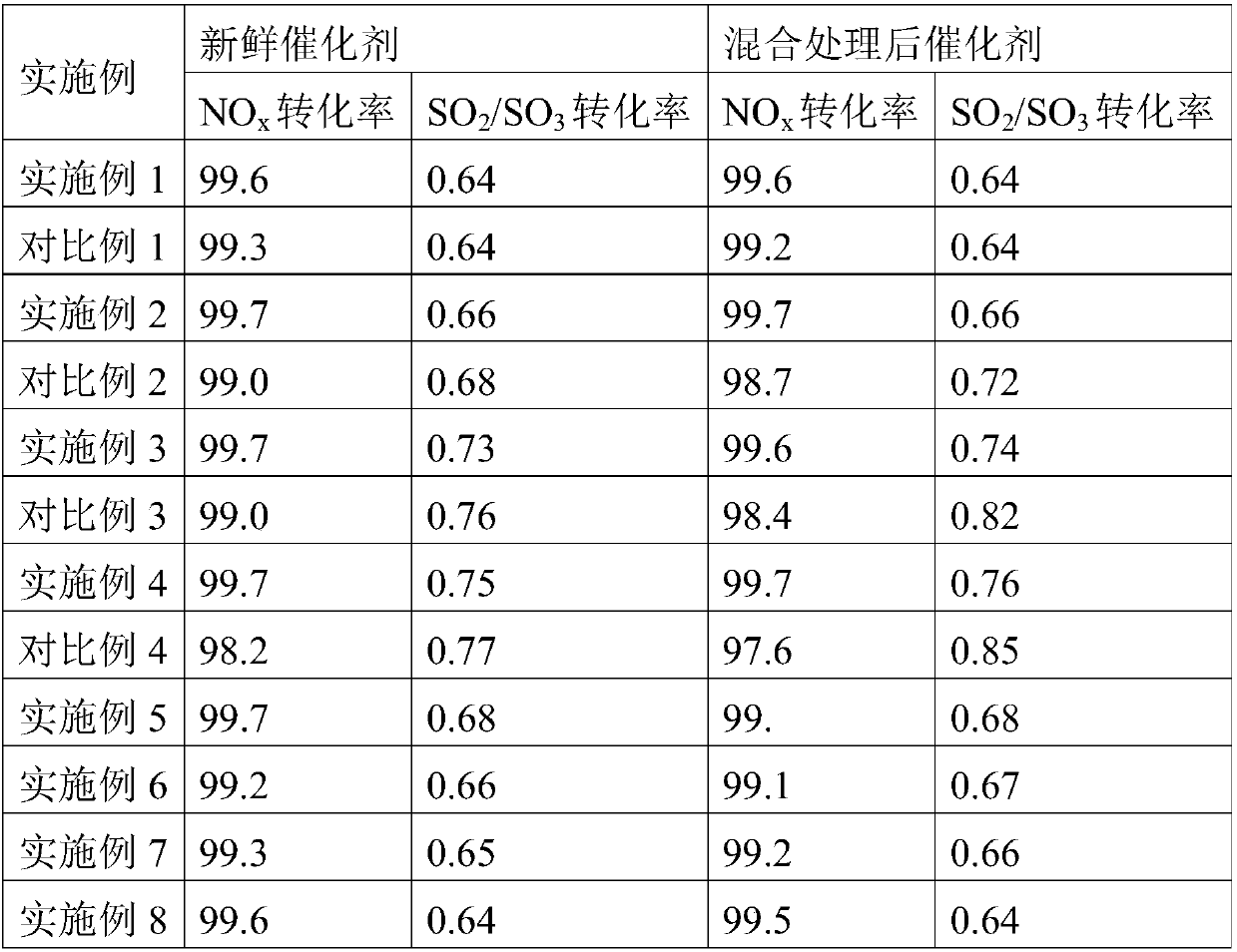

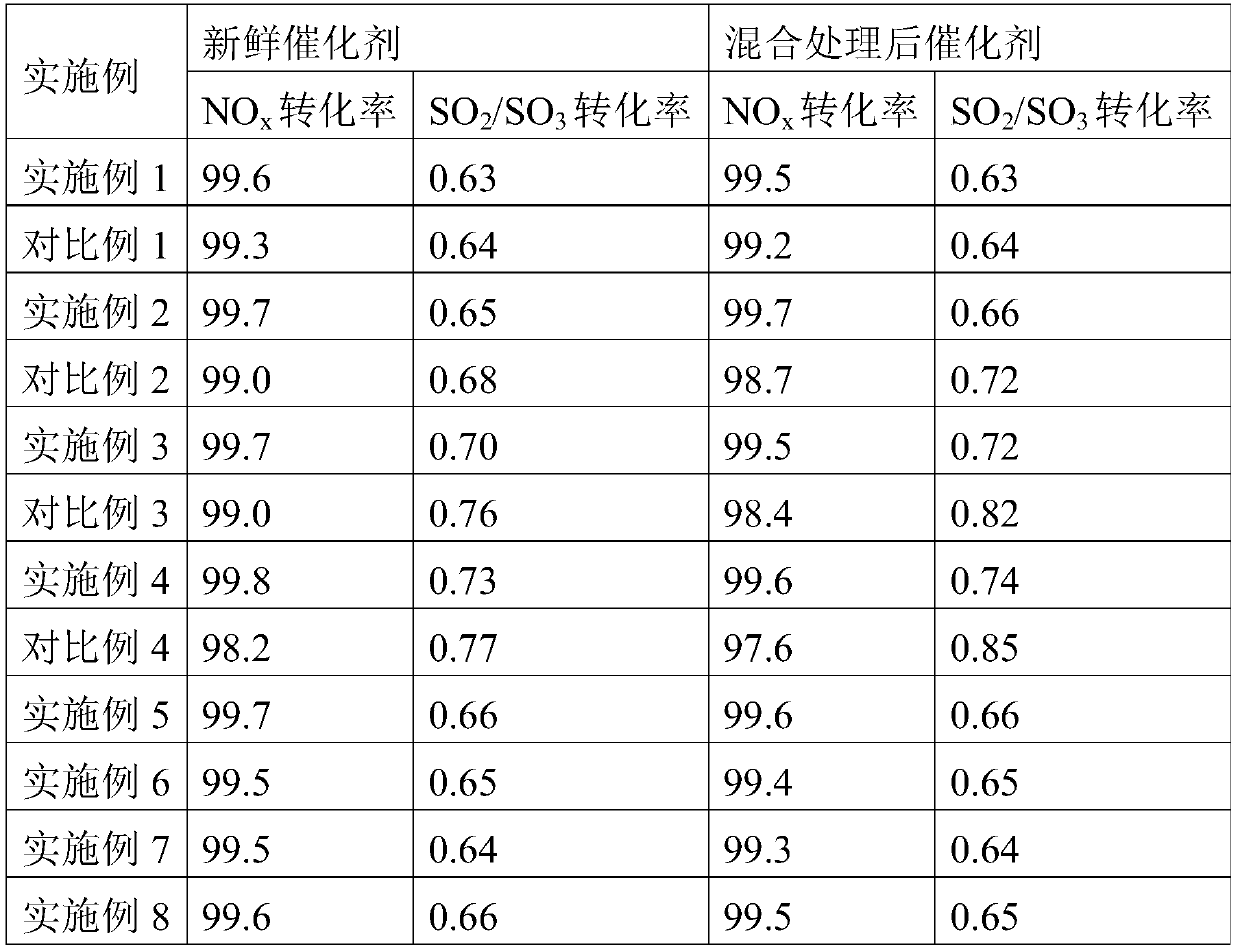

Antiwear honeycomb type denitration catalyst for reducing SO2 oxidation rate and preparation method thereof

InactiveCN107175121ASmall and uniform particle sizeRaise the transition temperatureDispersed particle separationCatalyst activation/preparationInstabilityPrecipitation

The invention discloses an antiwear honeycomb type denitration catalyst for reducing the SO2 oxidation rate and a preparation method thereof. The preparation method comprises the following steps that a titanium source precursor is dissolved in acid to form a solution; a molybdenum source precursor, a phosphorus source precursor and a magnesium source precursor are respectively dissolved to form solutions; the solutions are uniformly mixed; the pH value is regulated; precipitation and filtering are performed; then, deionized water and a vanadium source precursor solution are added; after being uniformly mixed, the mixture is directly dried, roasted and ground into powder; an extrusion aid and a solution formed by the molybdenum source precursor and a pore-forming agent are added into the powder; water is added while the stirring is performed until the paste shape is formed; then, nano-silicon dioxide, wollastonite, glass fiber and an adhesion agent are added and are uniformly mixed; a honeycomb type blank is extruded by an extruder; the dried blank is firstly put into a silicon source precursor solution to be soaked; after roasting, the finished product is obtained. The defects of active instability, poorer antiwear performance and unbalanced active center of the denitration catalyst in the flue gas in the prior art can be overcome.

Owner:PETROCHINA CO LTD

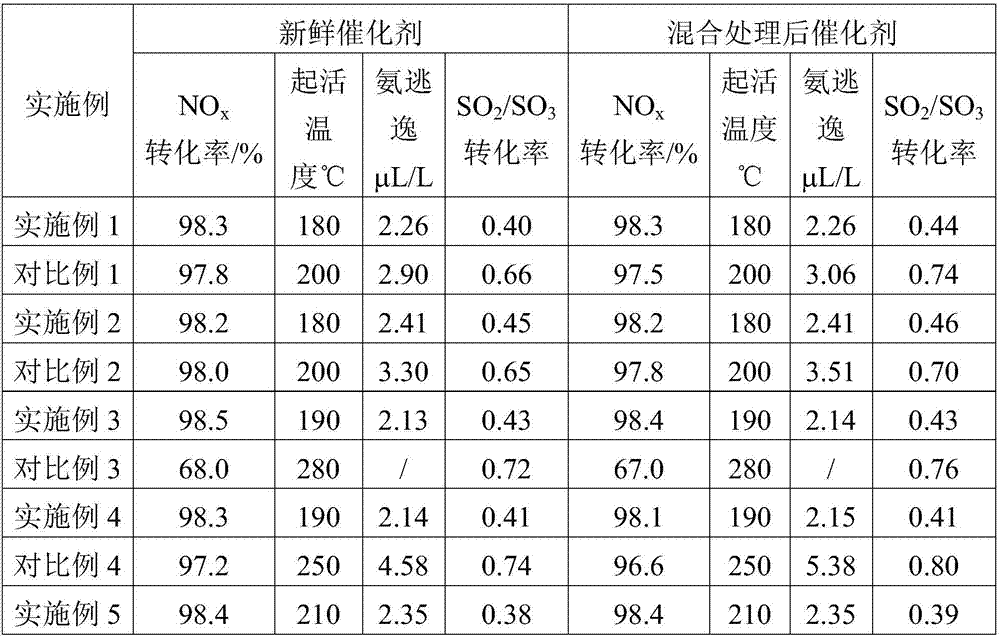

Denitration catalyst with improved low-temperature activity and preparation method of denitration catalyst

ActiveCN107321361AWell mixedHigh activityGas treatmentHeterogenous catalyst chemical elementsFlue gasRare earth

The invention discloses a denitration catalyst with improved low-temperature activity and a preparation method of the denitration catalyst. The preparation method comprises the steps as follows: (1) dissolving a titanium source precursor in acid to form a solution; (2) forming solutions from a manganese source precursor, an iron source precursor and a tungsten source precursor, and uniformly mixing the solutions with the solution in the step (1); (3) regulating pH of the evenly mixed solution obtained in the step (2) to 7-12, and performing precipitation and filtration; (4) adding deionized water to a filter cake obtained in the step (3), blending the mixture into slurry, and adding a rare earth source precursor, performing dry and roasting after uniform mixing, and grinding the mixture into powder; (5) mixing the powder obtained in the step (4) and a tungsten source precursor solution into slurry, stirring the slurry, adding a pore-forming agent, uniformly mixing the mixture, and performing drying and roasting to form the denitration catalyst. The denitration catalyst for improving low-temperature activity and the preparation method of the denitration catalyst are designed to overcome the defects of imbalanced low-temperature activity center and instable activity of the denitration catalyst in flue gas in the prior art.

Owner:PETROCHINA CO LTD

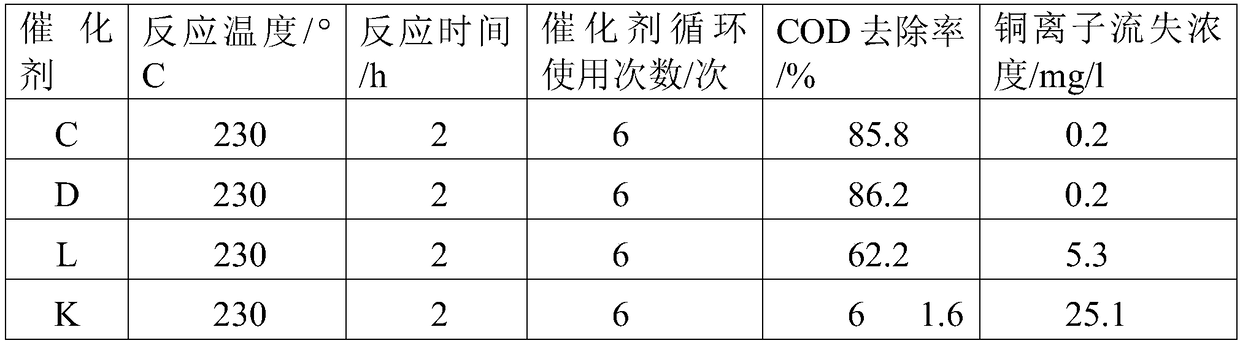

Preparation method for wet oxidation catalyst

ActiveCN108927166ATightly boundPacked tightlyCatalyst protectionWater contaminantsHigh concentrationSulfur

The invention discloses a preparation method for a wet oxidation catalyst. The preparation method includes the following steps: (1) processing active carbon by adopting carbohydrate, and performing pulping; (2) dissolving a copper source precursor into a solution; (2) dissolving a cerium source precursor into a solution; (4) mixing materials prepared by the step (1), (2) and (3), adjusting pH values to form deposition, and performing filtering, washing and drying, and roasting in an inert gas environment so that a powder material can be formed; and (5) mixing the powder material of the step (4) with a manganese source precursor solution into slurry, and adding a pore forming agent after stirring, performing seal standing to form the mixture into a clover shape through extruding after secondary stirring, coating nanometer zirconia after drying, and performing roasting in an inert gas environment to form a wet oxidation catalyst. The prepared wet oxidation catalyst can be used for high concentration organic wastewater, and has characteristics of large specific surface areas, strong sulfur tolerance and stable catalytic activity, etc.

Owner:PETROCHINA CO LTD

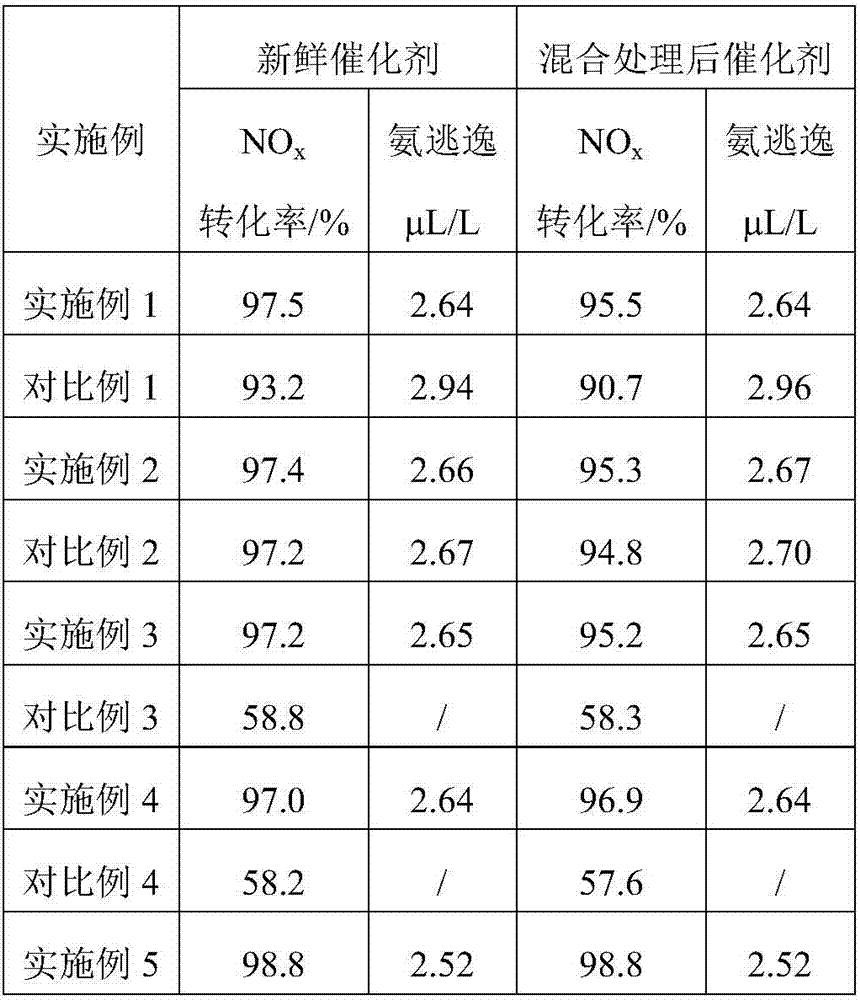

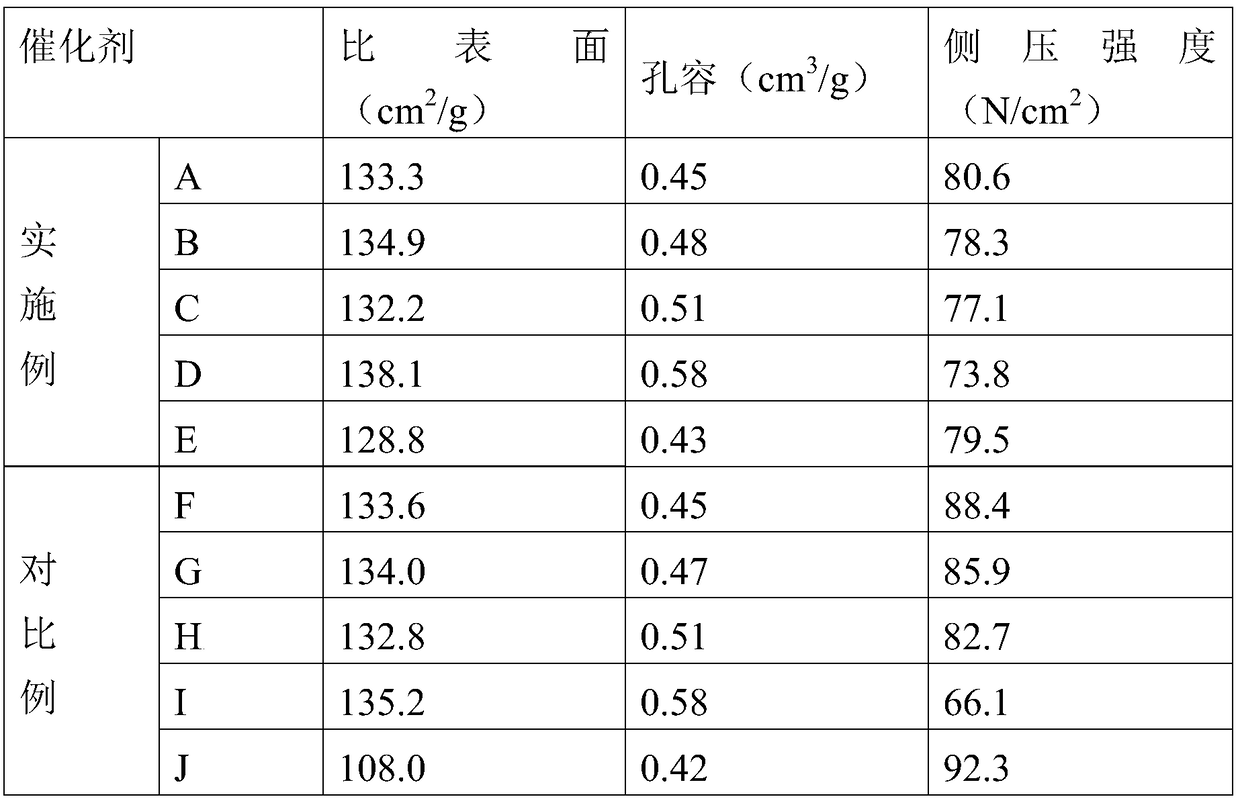

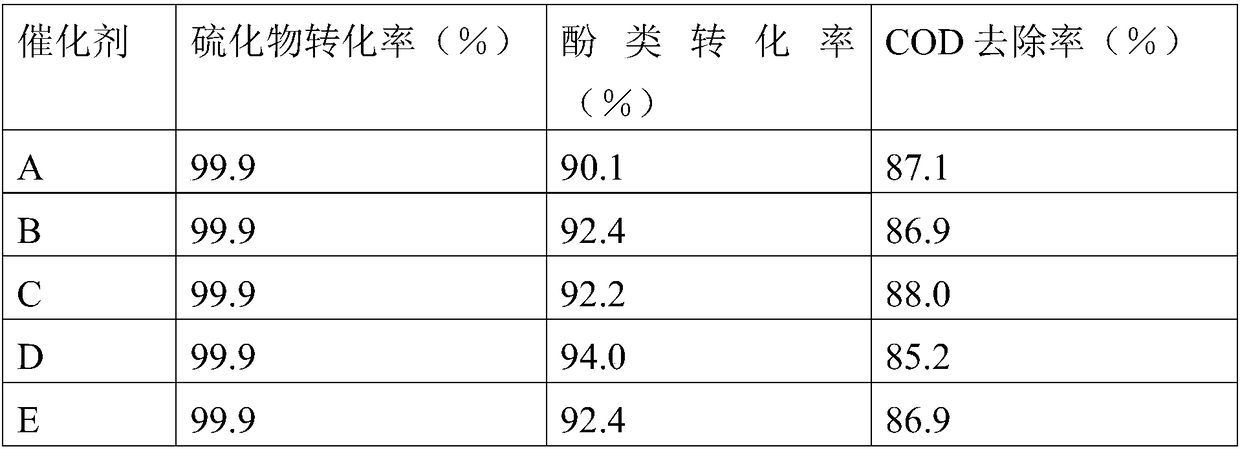

Honeycomb denitration catalyst with increased specific surface area and preparation method

ActiveCN107321344AHigh strengthHigh specific surface areaGas treatmentHeterogenous catalyst chemical elementsFlueHoneycomb

The invention discloses a honeycomb denitration catalyst with increased specific surface area and a preparation method. The preparation method comprises steps as follows: (1) beating active alumina; (2) dissolving a titanium source precursor; (3) dissolving a tungsten source precursor and mixing the dissolved tungsten source precursor with the materials in the steps (1) and (2); (4) adjusting pH of the material evenly mixed in the step (3) to 8-13, and performing precipitation, filtering and washing to obtain a filter cake; (5) adding water to the filter cake obtained in the step (4), mixing the filter cake into a slurry state, adding a vanadium source precursor solution, and performing mixing, drying and roasting to form powder; (6) mixing a solution formed by a molybdenum source precursor with the powder in the step (5) into a slurry, stirring the mixture, adding a pore-forming agent, performing secondary stirring, allowing the mixture to stand, squeezing the mixture into a honeycomb shape, performing drying, and coating the surface with nano-tungsten oxide for roasting to obtain the denitration catalyst. The prepared denitration catalyst has the advantages that the specific surface area can be increased, and non-uniform deposition of heavy metals in flue gas on the surface of the catalyst is prevented.

Owner:PETROCHINA CO LTD

Preparation method for high specific surface area wet oxidation catalyst

ActiveCN108927160AIncrease active siteHigh strengthWater contaminantsCatalyst activation/preparationActivated carbonCerium

The invention discloses a preparation method for a high specific surface area wet oxidation catalyst. The preparation method includes the following steps: (1) processing active carbon by adopting carbohydrate, and performing pulping; (2) dissolving a copper source precursor into a solution; (3) mixing materials of (1) and (2), adjusting pH values to form deposition, and performing filtering and washing; (4) dissolving a nickel source precursor into a solution, fulling mixing with (3), performing drying, baking the mixture in an inert gas environment to form a powdered material; and (5) mixingthe powdered material of the step (4) with a cerium source precursor into slurry, adding a pore forming agent after stirring, performing seal standing and drying after secondary stirring, baking the mixture in the inert gas environment to form a wet oxidation catalyst. The prepared wet oxidation catalyst can be used for oil refining or ethylene waste lye treatment, and has large specific surface areas and high catalytic activity.

Owner:PETROCHINA CO LTD

SO2 oxidation rate reducing honeycomb type vanadium-free flue gas denitration catalyst and preparation method thereof

InactiveCN107185520ASmall and uniform particle sizeRaise the transition temperatureGas treatmentHeterogenous catalyst chemical elementsGlass fiberFlue gas

The present invention discloses a SO2 oxidation rate reducing honeycomb type vanadium-free flue gas denitration catalyst and a preparation method thereof. The preparation method comprises: dissolving a titanium source precursor in an acid to form a solution; dissolving a tungsten source precursor to form a solution; uniformly mixing the two solutions, adjusting the pH value to 7-12, precipitating, filtering, adding deionized water and a rare earth precursor solution, uniformly mixing, directly drying, roasting, and grinding to obtain powder; adding the solution formed from an extrusion aid and the tungsten source precursor and a pore forming agent to the powder, adding water while stirring to form a paste, adding nano-silica, glass fiber and a binder, uniformly mixing, and extruding a honeycomb type billet by using an extruder; and placing the dried billet into a silicon source precursor solution, impregnating, and roasting to obtain the finished product. According to the present invention, the defects of unbalanced activity center, poor molding property and unstable activity of the denitration catalyst in the flue gas in the prior art can be overcome.

Owner:PETROCHINA CO LTD

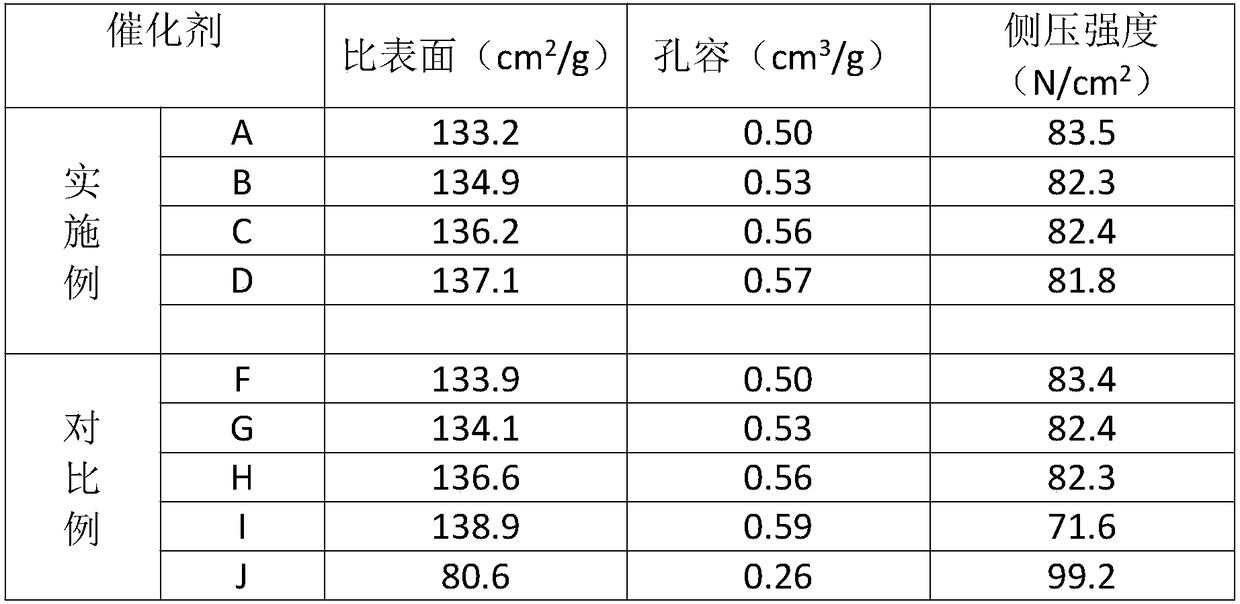

Honeycomb type flue gas denitrification catalyst and preparation method thereof

InactiveCN107081146ASmall and uniform particle sizeRaise the transition temperatureGas treatmentHeterogenous catalyst chemical elementsSlurryDenitrification

The invention discloses a honeycomb type flue gas denitrification catalyst and a preparation method thereof. The preparation method comprises the following steps: dissolving a titanium source precursor into acid, so as to form a solution; respectively dissolving a tungsten source precursor so as to form a solution; uniformly mixing the two solutions, adjusting the pH value of a mixed solution, settling, washing, and filtering so as to obtain a filter cake; blending to form slurry, adding a vanadium source precursor solution, uniformly mixing, directly drying and roasting, and grinding into powder; adding an extruding aid, the phosphorus source precursor solution and a pore forming agent into the powder, adjusting the pH value to be alkaline, adding nano-silica, glass fibers and a bonding agent, uniformly mixing, and extruding a honeycomb type blank by virtue of an extruding machine; and drying and roasting, so as to obtain a finished product. The honeycomb type flue gas denitrification catalyst prepared by virtue of the preparation method is capable of resisting heavy metal deposition in flue gas and simultaneously has high catalytic performance and low sulfur dioxide / sulfur trioxide conversion rate.

Owner:PETROCHINA CO LTD

Flue gas denitrification catalyst and preparation method thereof

ActiveCN107913699ASmall and uniform particle sizeRaise the transition temperatureHeterogenous catalyst chemical elementsDispersed particle separationFlue gasSlurry

The invention discloses a flue gas denitrification catalyst and a preparation method thereof. The catalyst has the specific surface area of 50-130 m<2> / g, has the pore volume of 0.30-0.70 cm<3> / g andis prepared from, in percentage by weight, 90%-97% of TiO2, 1%-10% of WO3 and 0.5%-5% of V2O5. The preparation method comprises steps as follows: (1) a titanium source precursor forms a solution; (2),a tungsten source precursor is dissolved and mixed with the solution obtained in the step (1); (3) the pH value of the solution obtained in the step (2) is adjusted, and precipitation, filtration andwashing are performed; (4) water is added to the filter cake obtained in the step (3), the filter cake is blended into slurry, a vanadium precursor solution is added, and the mixture is mixed, driedand roasted; (5) the solution formed by the tungsten source precursor is mixed with the powder obtained in the step (4) to form slurry, a pore-forming aid is added after the slurry is stirred, and thedenitrification catalyst is formed. The prepared denitrification catalyst can resist non-uniform deposition of vanadium oxide in flue gas on the surface, increase the specific surface area and the crushing strength of the catalyst, reduce the wear rate and improve the performance of the catalyst.

Owner:PETROCHINA CO LTD

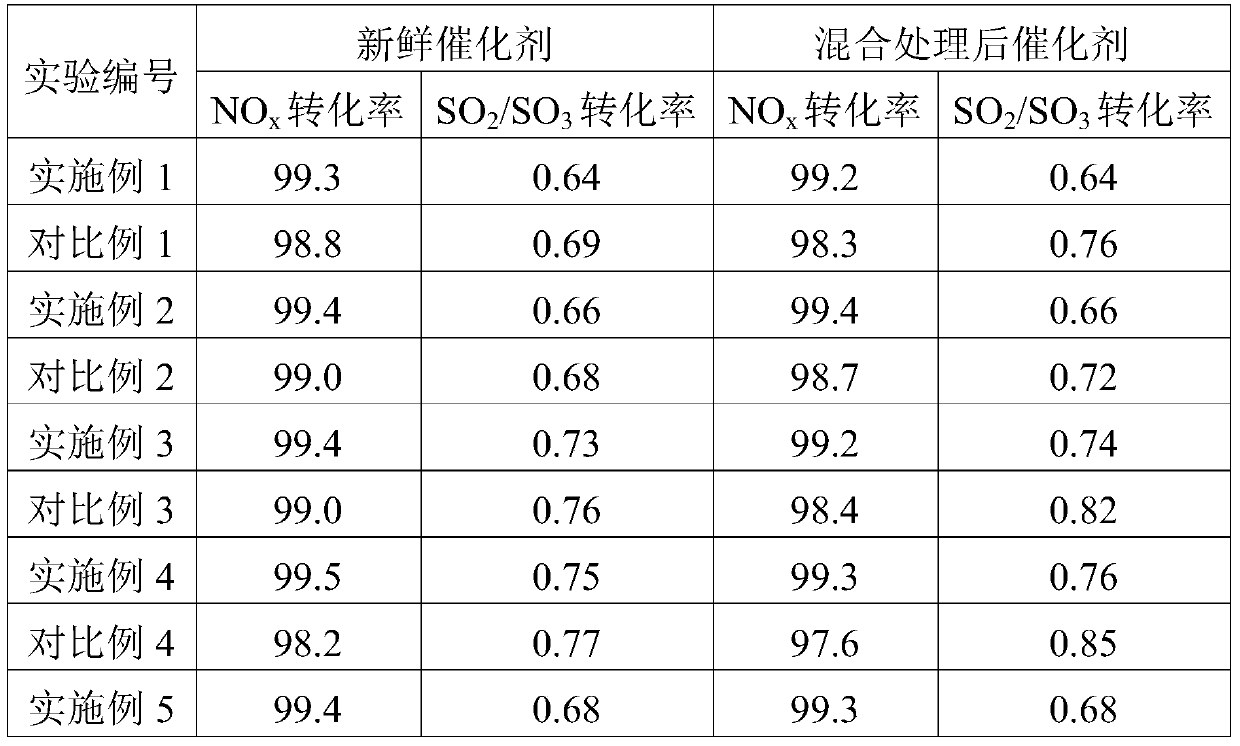

Vanadium-free denitration catalyst for reducing SO2 oxidization rate and preparation method thereof

InactiveCN107213890AHigh activityPenetration deepHeterogenous catalyst chemical elementsCatalyst activation/preparationFlue gasRare earth

The invention discloses a vanadium-free denitration catalyst for reducing SO2 oxidization rate and a preparation method thereof. The preparation method comprises the following steps of: (1) dissolving a titanium source precursor into an acid to form a solution; (2) dissolving a rare earth precursor and a co-catalytic component precursor formed by one or two of a tungsten source precursor and a molybdenum source precursor to form a solution and uniformly mixing the solution with the solution in the step (1); (3) adjusting the pH value of the solution which is uniformly mixed in the step (2) to 7-12, and precipitating, filtering, washing, drying and the roasting the solution, and grinding the precipitate to powder; (4) mixing the powder in the step (3) with one of the tungsten source precursor solution or the molybdenum source precursor solution to slurry, stirring the mixture, adding a pore forming material, and uniformly mixing the mixture and drying the same; and (5) immersing the dried product in the step (4) in a silicon source precursor solution, and then drying and roasting the mixture to form the denitration catalyst. The vanadium-free denitration catalyst disclosed by the invention can overcome the defects that in the prior art, the active centre of the denitration catalyst in flue gas is unbalanced and the activity is unstable.

Owner:PETROCHINA CO LTD

Denitration catalyst with wide temperature window and preparation method of denitration catalyst

ActiveCN107913697ASmall and uniform particle sizeRaise the transition temperatureGas treatmentHeterogenous catalyst chemical elementsFlue gasReaction temperature

The invention discloses a denitration catalyst with a wide temperature window and a preparation method of the denitration catalyst. The preparation method comprises the following steps: (1) a titaniumsource precursor is dissolved in acid, and a solution I is formed; (2) a molybdenum source precursor is dissolved to form a solution II, and the solution II is mixed with the solution I in step (1);(3) pH of the uniformly mixed solution obtained in step (2) is regulated to alkaline, precipitation, filtering and washing are performed, and a filter cake is obtained; (4) deionized water is added tothe filter cake obtained in step (3), the mixture is regulated into paste, a vanadium source precursor solution is added, the materials are uniformly mixed and directly dried and roasted, and powderis formed; (5) the molybdenum source precursor solution is mixed with the powder in step (4) into paste, the paste is stirred, a pore forming assistant is added, secondary stirring is performed, the mixture is sealed, left to stand, dried and roasted, and the denitration catalyst is formed. The prepared denitration catalyst has the advantages that vanadium oxide in flue gas can be prevented from non-uniformly depositing on the surface of the catalyst, and higher catalytic performance can be guaranteed in a wider reaction temperature range.

Owner:PETROCHINA CO LTD

Preparation method of honeycomb denitration catalyst with improved specific surface area

ActiveCN107096524AHigh strengthLarge specific surface areaGas treatmentHeterogenous catalyst chemical elementsCooking & bakingMixed materials

The invention discloses a preparation method of a honeycomb denitration catalyst with an improved specific surface area, and the preparation method comprises the following steps: (1) mixing and beating activated carbon and a sugar solution; (2) dissolving a titanium-source precursor; (3) dissolving a tungsten-source precursor, and mixing the tungsten-source precursor with the materials in the steps (1) and (2); (4) adjusting pH value of the mixed material in the step (3) to 8-13, precipitating, filtering and washing to obtain a filter cake; (5) regulating the filter cake in the step (4) to paste, adding a vanadium-source precursor solution, mixing, drying, under the protection of an inert gas baking to form powder; and (6) mixing a molybdenum-source precursor solution with the powder in the step (5) into paste, stirring, adding a pore forming agent, secondarily stirring, standing, extruding into a honeycomb shape, drying, coating surface with nano tungsten oxide, baking in an inert gas to obtain the catalyst. The specific surface area of the can be increased, uneven deposition of heavy metals on the catalyst in the flue gas can be resisted.

Owner:PETROCHINA CO LTD

Honeycomb flue gas denitrification catalyst capable of reducing activation temperature and SO2 oxidation rate and preparation method thereof

InactiveCN107243354AHigh activityPenetration deepGas treatmentDispersed particle separationFlue gasActivation temperature

A preparation method of a honeycomb flue gas denitrification catalyst capable of reducing activation temperature and SO2 oxidation rate comprises the following steps: dissolving a titanium source precursor into acid to form a solution; dissolving a molybdenum source precursor and a phosphorus source precursor to form solutions; uniformly mixing the solutions, adjusting the pH value to 7-12, precipitating, filtering, then adding deionized water, a vanadium source precursor solution, uniformly mixing, directly drying, roasting, and grinding into powder; adding an extrusion aid, the solution formed by the molybdenum source precursor and a pore-forming agent into the powder, adding water while stirring, blending into a paste, then adding nanometer silicon dioxide, glass fiber and a bonding agent, uniformly mixing, extruding into a honeycomb blank by using an extruder, impregnating the dried blank into a silicon source precursor solution, and roasting to obtain a finished product. The invention aims to overcome the defects that in the prior art, the denitrification catalyst is unbalanced in active centers in flue gas, high in SO2 oxidation rate and poor in poisoning resistance.

Owner:PETROCHINA CO LTD

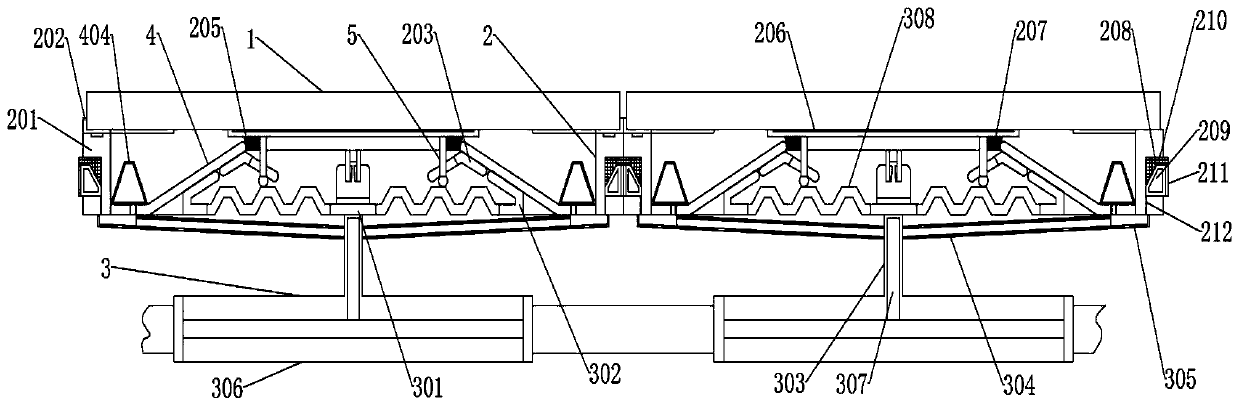

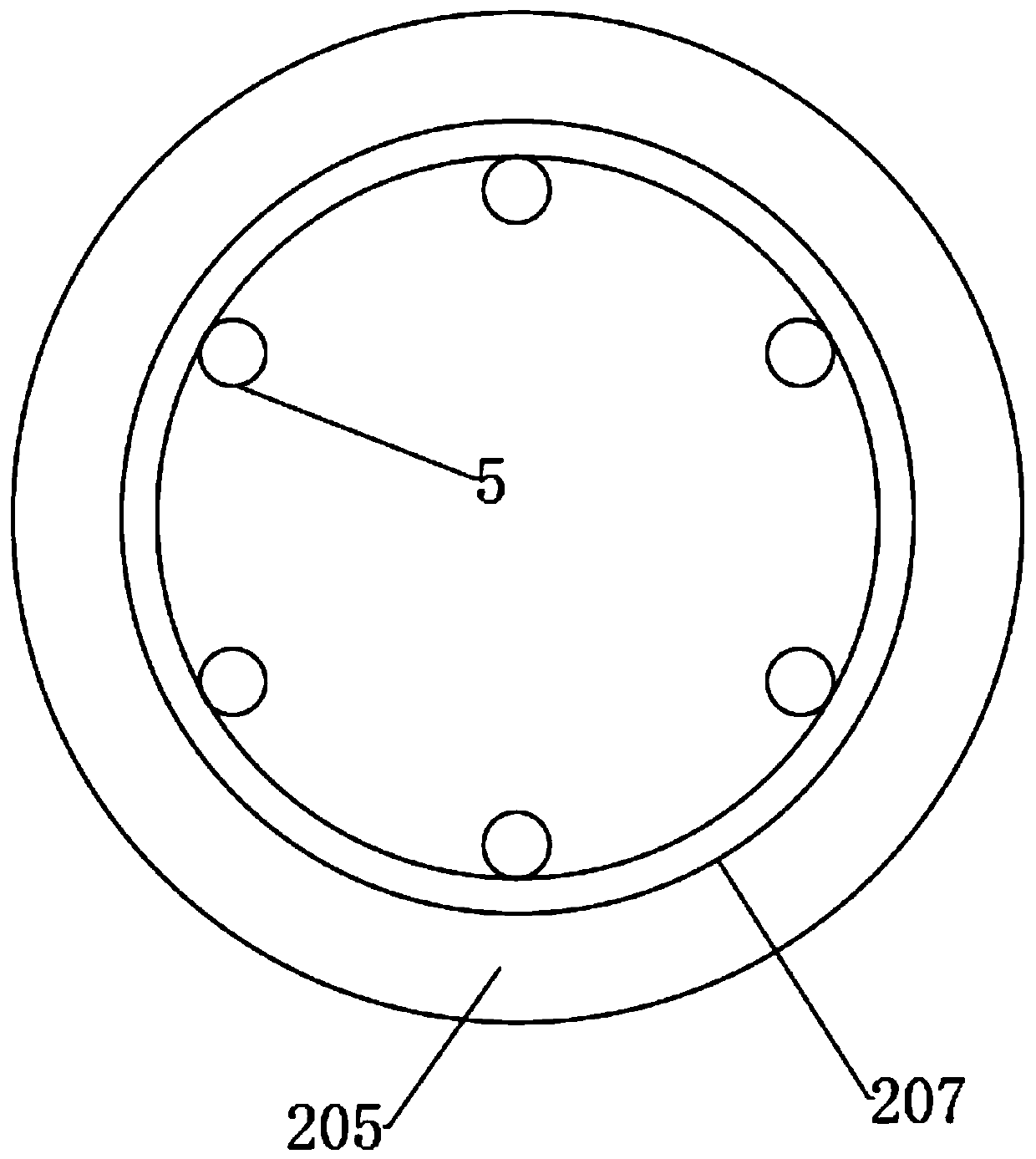

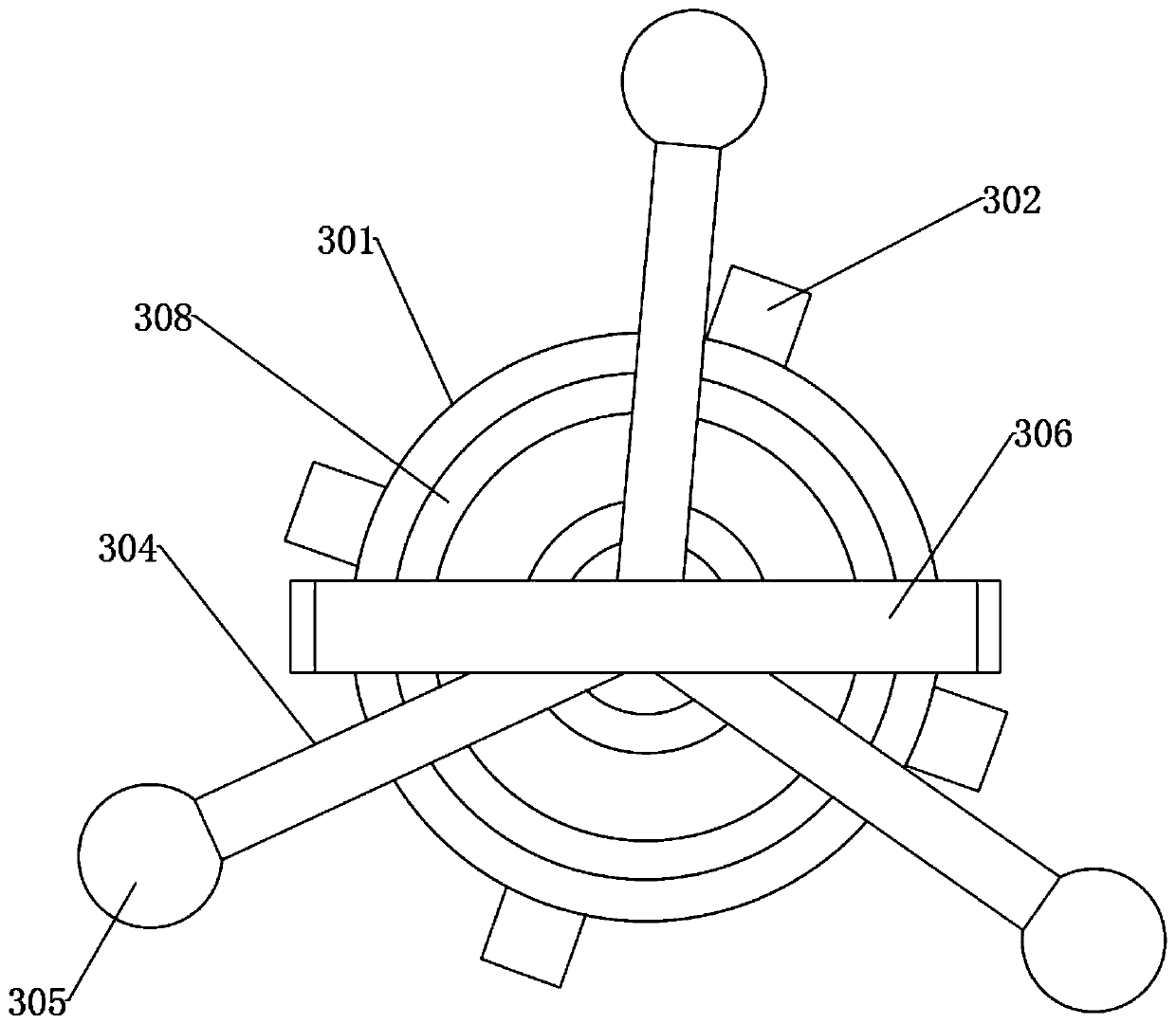

Floor waterproof structure for building decoration

ActiveCN111411755APlay a role in isolatingPenetration deepSewerage structuresFlooring insulationsRubber ringStructural engineering

An embodiment of the invention discloses a floor waterproof structure for building decoration. The floor waterproof structure for building decoration comprises floor tiles. Waterproof isolation mechanisms are installed on the bottom surfaces of the floor tiles, and water guiding supporting mechanisms are installed below the waterproof isolation mechanisms. Through raised head columns, water-proofcovers and correcting rings, the repeated operation of sealing and waterproofing the floor tiles is achieved, and meanwhile, the position correction operation of the floor tiles can be carried out toavoid the situation that the accumulated water cannot be discharged due to the fact that the floor tiles are tilted, during specific implementation, the floor tiles are clamped directly on the correcting rings to enable sealing rubber rings to seal the floor tiles, and at the moment, the raised head columns are embedded in through grooves in transition elastic pieces, so that the transition elastic pieces pull the floor tiles, even if gaps exist on the bottom of the floor, the situation that the accumulated water converges and cannot drained away due to the fact one side is tilted is not proneto occurring, and sealing rubber sleeves are pressed on the end parts of the water-proof covers to achieve further sealing, and the water-proof covers can play a role in isolation, so that the accumulated water does not penetrate deeper.

Owner:SHENZHEN ZSZ CONSTR GRP

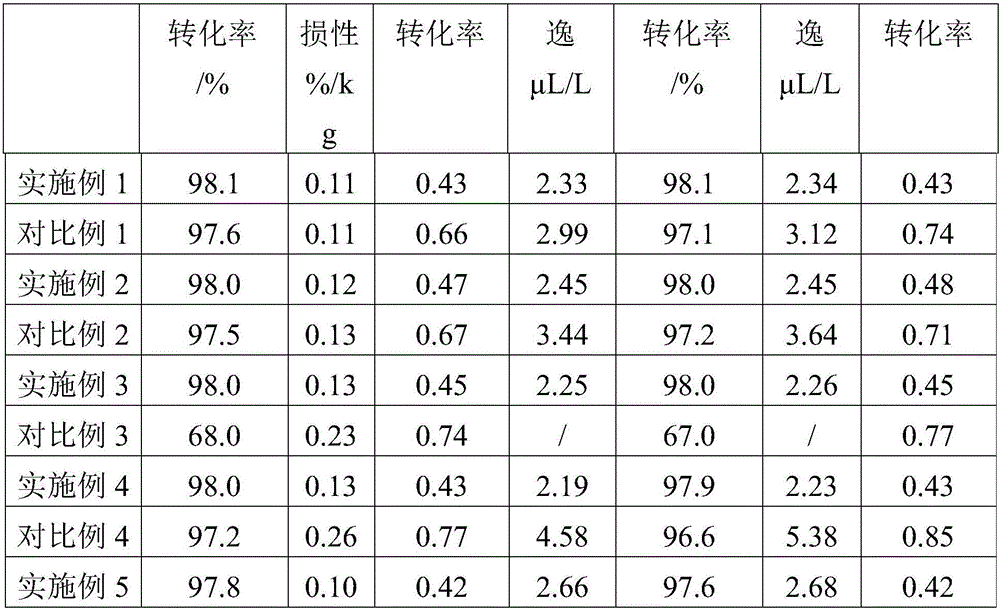

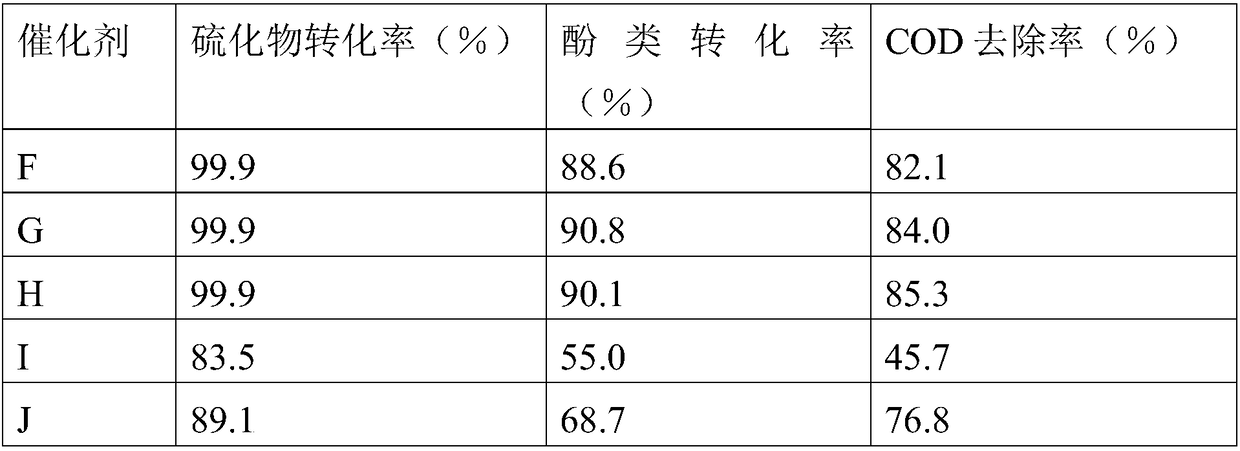

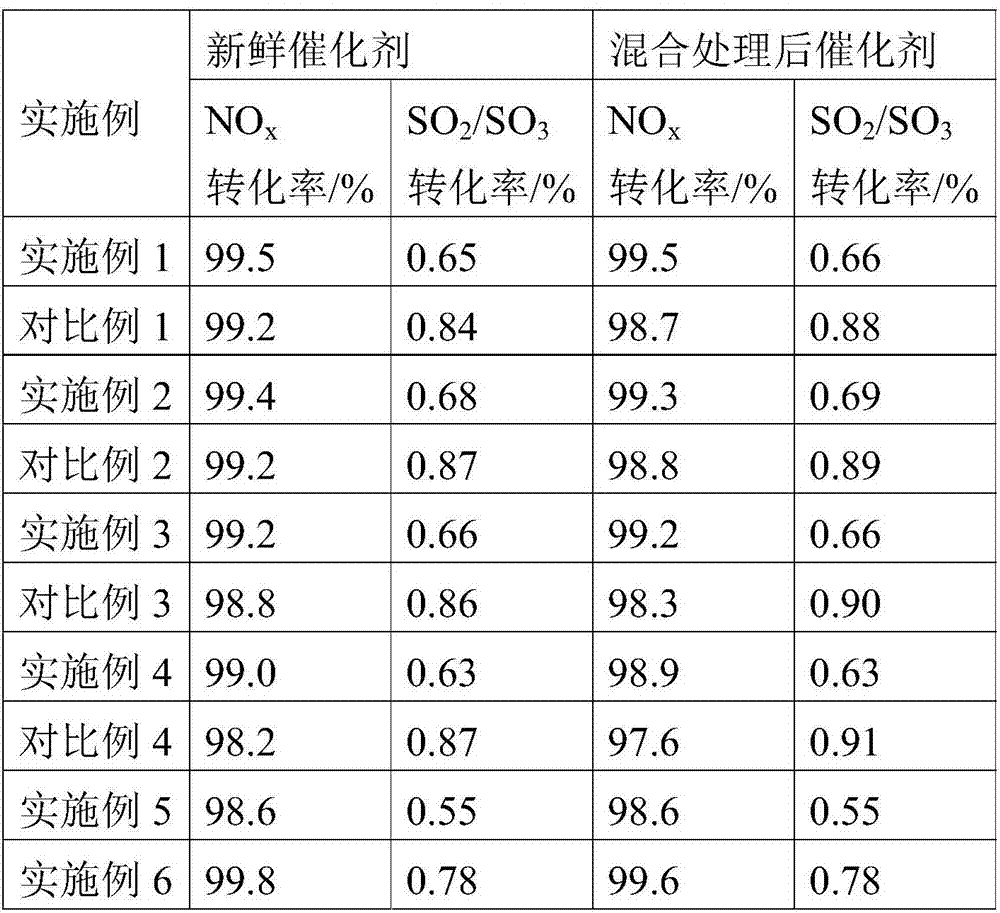

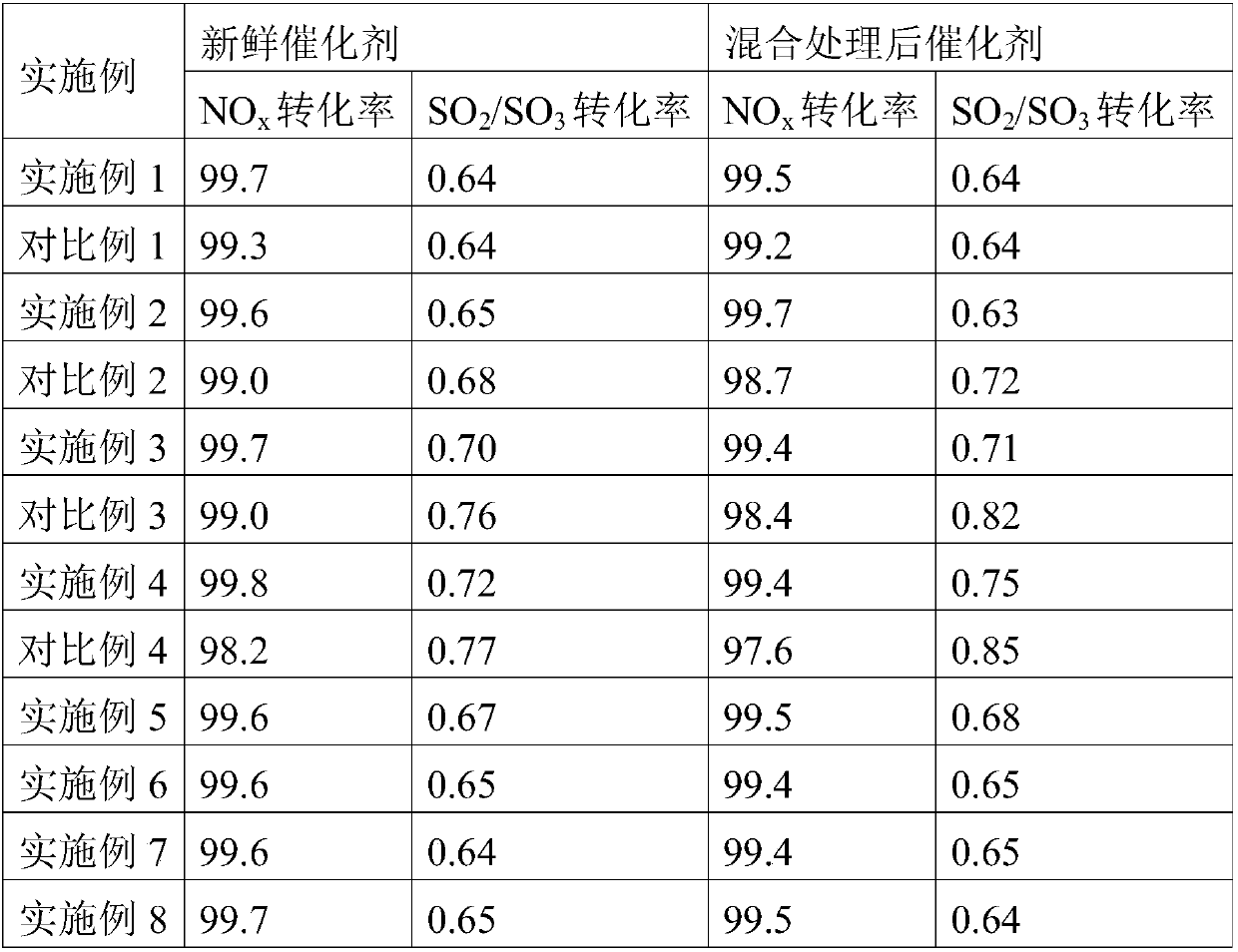

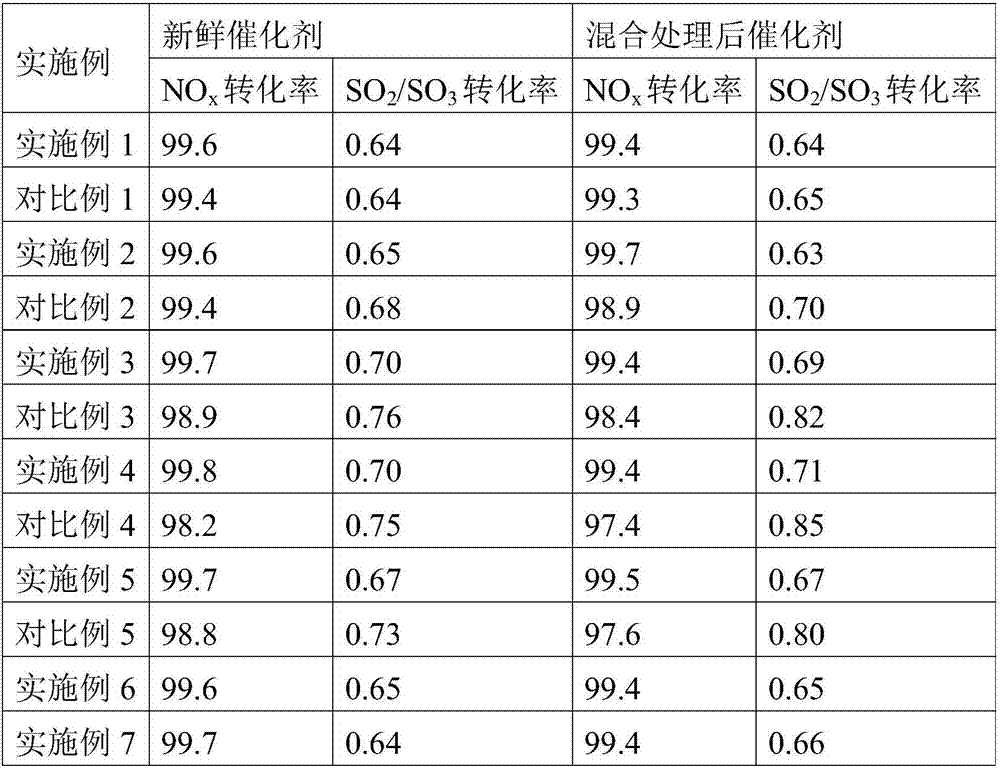

Denitration catalyst with resistance to sulfur dioxide oxidation and preparation method of denitration catalyst

ActiveCN107913696AHigh activityPenetration deepGas treatmentHeterogenous catalyst chemical elementsTitanium dioxideFlue gas

The invention discloses a denitration catalyst with resistance to sulfur dioxide oxidation and a preparation method of the denitration catalyst. The denitration catalyst contains 80%-98% by weight oftitanium dioxide, 1%-10% by weight of molybdenum trioxide, 0.3%-5% by weight of vanadium pentoxide and 0.1%-5% by weight of silicon dioxide. The preparation method comprises the following steps: (1) asolution I is formed from a titanium source precursor; (2) a solution II is formed from a molybdenum source precursor and mixed with the solution I in step (1); (3) pH of the solution obtained in step (2) is regulated, and the solution is filtered; (4) deionized water is added to a filter cake obtained in step (3), a vanadium source precursor solution is added, and the mixed solution is subjectedto mixed drying and roasting; (5) the molybdenum source precursor solution is mixed with powder in step (4), a pore-forming additive is added, and the mixture is dried; (6) a dried product in step (5) is dipped in a silicon source precursor solution and roasted. The prepared denitration catalyst has the advantages that vanadium oxide in flue gas can be prevented from non-uniform deposition on thesurface of the catalyst, high catalytic performance is guaranteed, and low sulfur dioxide / sulfur trioxide conversion rate is realized.

Owner:PETROCHINA CO LTD

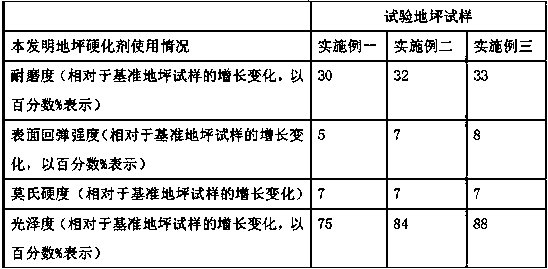

Osmotic floor hardener and preparation method thereof

PendingCN110003694AHigh hardnessImprove wear resistanceAntifouling/underwater paintsAlkali metal silicate coatingsSilicic acidSilanes

The invention relates-the technical field of building materials, and especially relates-an osmotic floor hardener and a preparation method thereof. The osmotic floor hardener comprises, by weight, 500-3000 parts of deionized water, 10-70 parts of lithium hydroxide, 1-50 parts of potassium hydroxide, 200-500 parts of silicic acid, 50-300 parts of methanesiliconic acid, 50-300 parts of a silane coupling agent, 5-50 parts of a silane polymer, 1-40 parts of a stabilizer and 1-7 parts of a surfactant. The hardener can penetrate the internal of the floor, seal the capillary tubes of concrete, improve the surface compactness of the concrete and enhance the impermeability, the strength and the hardness of the concrete, so the floor is non-dusty, waterproof and is impermeable, the surface of the floor is easy to clean, and the hardness is improved; and polishing of the floor significantly improves the glossiness.

Owner:广州康磊建材有限公司

Denitration catalyst with a low SO2/SO3 conversion rate and preparation method of denitration catalyst

ActiveCN107913700AHigh activityPenetration deepGas treatmentHeterogenous catalyst chemical elementsFlue gasSlurry

The invention discloses a denitration catalyst with a low SO2 / SO3 conversion rate and a preparation method of the denitration catalyst. The catalyst has a specific surface area of 40-120 m<2> / g and contains TiO2, WO3, V2O5 and SiO. The preparation method comprises the following steps: (1), forming a solution from a Ti source precursor; (2), forming a solution from a W source precursor, and mixingthe solution with the solution in (1); (3), adjusting pH of the solution obtained in (2) to be alkaline and performing precipitating; (4), adding water to filter cakes obtained in (3) to form slurry,adding a V source precursor solution, and performing drying and roasting to form powder; (5), mixing the W source precursor solution with the powder in (4) to form slurry, performing stirring, and adding a pore-forming aid for seal standing and drying; (6), immersing the dried product in (5) in a Si source precursor solution, and performing drying and roasting. The prepared denitration catalyst not only can resist uneven deposition of V oxide on the surface of flue gas, but also can ensure high catalyst performance and has low SO2 / SO3 conversion rate.

Owner:PETROCHINA CO LTD

Denitration catalyst and preparation method thereof

ActiveCN107913701ASmall and uniform particle sizeRaise the transition temperatureGas treatmentHeterogenous catalyst chemical elementsFlue gasSlurry

The invention discloses a denitration catalyst and a preparation method thereof. The preparation method comprises steps as follows: (1) a titanium source precursor is dissolved to form a solution; (2), a tungsten source precursor is dissolved and mixed with the solution obtained in the step (1) uniformly; (3) the pH value of the solution obtained after uniform mixing in the step (2) is adjusted tobe alkaline, precipitation, filtration and washing are performed, and a filter cake is obtained; (4) deionized water is added to the filter cake obtained in the step (3), the filter cake is blended to be slurry, a vanadium precursor solution is added, the mixture is mixed uniformly and directly dried and roasted, and powder is formed; (5) the solution formed by the tungsten source precursor is mixed with the powder obtained in the step (4) to form slurry, a citric acid-sesbania powder compound is added after the slurry is stirred, secondary stirring is performed, the mixture is sealed, left to stand, dried and roasted, and the denitration catalyst is formed. The prepared denitration catalyst can resist non-uniform deposition of vanadium oxide in flue gas on the surface and improve the intensity, mesh micropores and performance of the catalyst.

Owner:PETROCHINA CO LTD

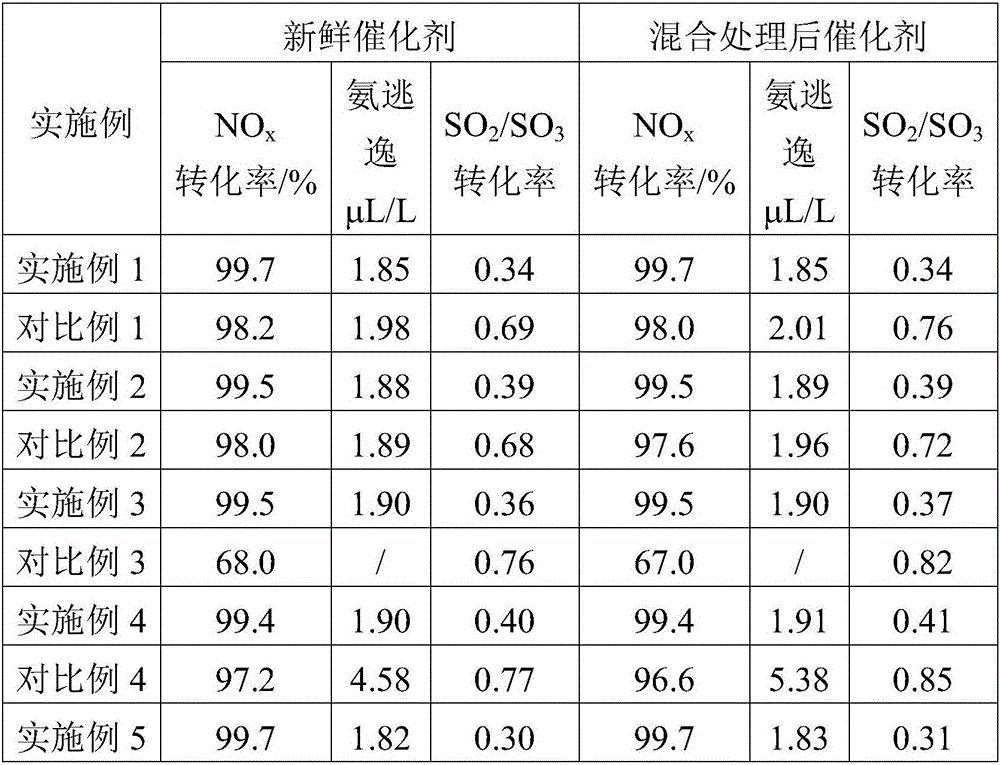

Denitration catalyst for reducing SO2 oxidation rate and preparation method thereof

InactiveCN107175117ALots of lattice defectsSmall and uniform particle sizePhysical/chemical process catalystsDispersed particle separationFlue gasAdditive ingredient

The invention discloses a denitration catalyst for reducing the SO2 oxidation rate and a preparation method thereof. The preparation method comprises the following steps that (1) a titanium source precursor forms a solution; (2) a fluorine source precursor and an assistant catalysis ingredient precursor formed by one or two kinds of a tungsten source precursor and a molybdenum source precursor are dissolved to form a solution; the solutions are uniformly mixed; (3) the pH value is regulated to 7 to 12; precipitation, washing and filtering are performed; (4) the mixture is prepared into a slurry state by adding water; a vanadium source precursor solution is added; after mixing, drying and roasting are performed; the mixture is ground into powder; (5) powdery substances in the step (4) and one of the tungsten source precursor solution or a molybdenum source precursor solution are mixed into the slurry state; after stirring, a pore-forming agent is added; drying is performed after mixing; (6) drying products in the step (5) are soaked in a silicon source precursor solution, and are dried and roasted to form the denitration catalyst. The prepared denitration catalyst can overcome the defects of high SO2 oxidation rate and unbalanced active center of the denitration catalyst in flue gas in the prior art.

Owner:PETROCHINA CO LTD

Flue gas denitrification catalyst and preparation method thereof

ActiveCN107913702ASmall and uniform particle sizeRaise the transition temperatureGas treatmentHeterogenous catalyst chemical elementsFlue gasSlurry

The invention discloses a flue gas denitrification catalyst and a preparation method thereof. The catalyst has the specific surface area of 50-160 m<2> / g and is prepared from, in percentage by weight,80%-92% of TiO2, 8%-15% of WO3 and 4%-10% of V2O5. The preparation method comprises steps as follows: (1) a titanium source precursor is dissolved to form a solution; (2), a tungsten source precursoris dissolved and mixed with the solution obtained in the step (1); (3) the pH value of the solution obtained in the step (2) is adjusted, and precipitation, filtration and washing are performed; (4)deionized water is added to the filter cake obtained in the step (3), the filter cake is blended into slurry, a vanadium precursor solution is added, and the mixture is mixed uniformly and directly dried and roasted; (5) the tungsten source precursor is mixed with the powder obtained in the step (4) to form slurry, sesbania powder is added after the slurry is stirred, secondary stirring is performed, the mixture is sealed, left to stand, dried and roasted, and the denitrification catalyst is formed. The prepared denitrification catalyst can resist non-uniform deposition of vanadium oxide in flue gas on the surface and improve the microporous structure and performance of the catalyst.

Owner:PETROCHINA CO LTD

Honeycomb denitration catalyst capable of lowering oxidation rate of SO2 and preparation method thereof

InactiveCN107159186ALots of lattice defectsSmall and uniform particle sizeHeterogenous catalyst chemical elementsDispersed particle separationRare earthSlurry

The invention discloses a honeycomb denitration catalyst capable of lowering the oxidation rate of SO2 and a preparation method thereof. The preparation method comprises the following steps: dissolving a titanium-source precursor in an acid to form a solution; separately dissolving a molybdenum-source precursor and a rare-earth precursor to form solutions; uniformly mixing the above solutions, adjusting the pH value of the mixed solution to 7 to 12, successively carrying out precipitation and filtering, then adding deionized water, carrying out blending to form slurry, adding a vanadium-source precursor solution, carrying out uniform mixing and then directly carrying out drying, roasting and grinding to obtain powder; adding an extrusion aid, the solution formed by the molybdenum-source precursor and a pore forming agent, adding water under stirring to obtain paste, then adding nanometer silica, glass fibers and a binder, carrying out uniform mixing and then carrying out extrusion with an extruder to obtain a honeycomb green body; and drying the honeycomb green body, dipping the honeycomb green body in a solution of a silicon-source precursor and carrying out roasting so as to obtain the finished honeycomb denitration catalyst. The honeycomb denitration catalyst provided by the invention can overcome the defects that conventional denitration catalysts have imbalanced active centers in flue gas, high oxidation rates of SO2 and instable activity.

Owner:PETROCHINA CO LTD

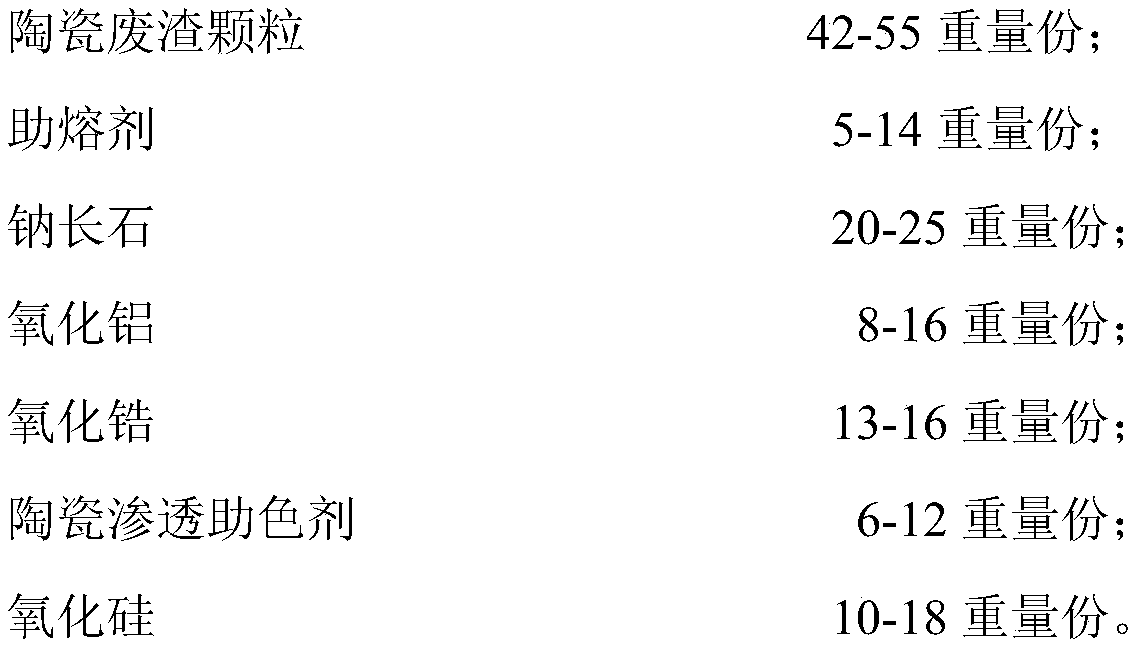

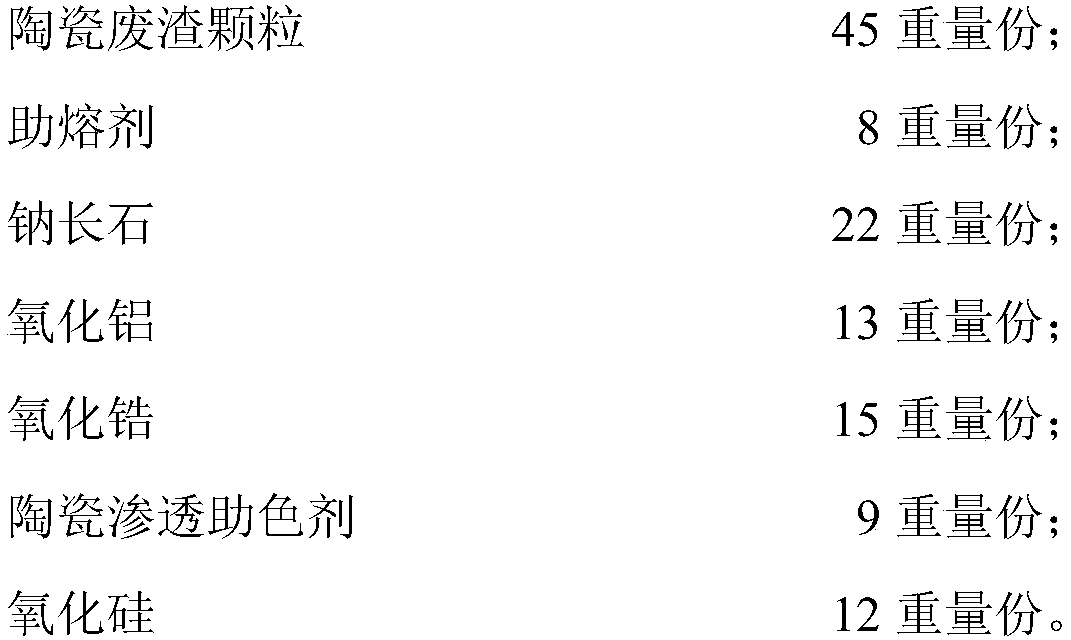

High-permeability coloring environment-friendly ceramic product and making method thereof

The invention belongs to the technical field of ceramics and in particular relates to a high-permeability coloring environment-friendly ceramic product and a making method thereof. The ceramic productcomprises a blank body and a permeation layer, wherein the permeation layer is arranged on the surface of the blank body; the blank body comprises the following raw materials in parts by weight: 23-38 parts of kaolin, 16-24 parts of aluminum oxide and 6-10 parts of wollastonite; the blank body comprises the following raw materials in parts by weight: 42-55 parts of ceramic waste residue granules,5-14 parts of a fluxing agent, 20-25 parts of albite, 8-16 parts of aluminum oxide, 13-16 parts of zirconium oxide, 6-12 parts of ceramic permeation coloring aids and 10-18 parts of silicon oxide. The making method comprises the following steps: S1, preparing raw materials; S2, making the blank body; S3, making the permeation layer; S4, carrying out firing. The ceramic product provided by the invention has the advantages of being high in permeability and coloring performance.

Owner:FUJIAN PROVINCE DEHUA COUNTY GRANGTOP CERAMICS CO LTD

A honeycomb denitration catalyst with increased specific surface area and preparation method thereof

ActiveCN107321344BHigh strengthLarge specific surface areaGas treatmentHeterogenous catalyst chemical elementsPtru catalystHoneycomb

The invention discloses a honeycomb denitration catalyst with increased specific surface area and a preparation method. The steps are as follows: (1) beating activated alumina; (2) dissolving titanium source precursor; (3) dissolving tungsten source precursor , and mix with the materials in steps (1) and (2); (4) Mix the materials in step (3) evenly and adjust the pH value to 8-13, precipitate, filter, and wash to obtain a filter cake; (5) Mix the materials in step (3) evenly to obtain a filter cake. 4) Add water to the obtained filter cake to make a slurry, add the vanadium source precursor solution, mix, dry and roast to form a powder; (6) Combine the solution formed by the molybdenum source precursor and the powder in step (5) Mix it into a slurry. After stirring, add a pore-forming agent. After stirring twice, let it stand and squeeze it into a honeycomb shape. After drying, the surface is coated with nanoscale tungsten oxide and roasted to obtain a denitration catalyst. The denitrification catalyst prepared by the invention can not only increase the specific surface area of the catalyst, but also resist the uneven deposition of heavy metals in the flue gas on its surface.

Owner:PETROCHINA CO LTD

Denitration catalyst for increasing specific area and preparation method

InactiveCN107213891AImprove catalyst strengthHigh specific surface areaHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonTungsten

The invention discloses a denitration catalyst for increasing a specific area and a preparation method. The method comprises the following steps: (1) mixing activated carbon with a sugar solution and pulping; (2) dissolving a titanium source precursor; (3) dissolving a tungsten source precursor and uniformly mixing the tungsten source precursor with the materials acquired in the steps (1) and (2); (4) uniformly mixing the material acquired in the step (3) and then adjusting the pH value of the solution to 8-13, precipitating, filtering and washing, thereby acquiring a filter cake; (5) adding water into the filter cake acquired in the step (4), preparing into pulp, adding a vanadium source precursor solution, mixing, drying and roasting under inert gas shielding, thereby forming powder; and (6) mixing the solution formed by a silicon source precursor with the powder acquired in the step (5) and forming slurry, adding a pore former, stirring for two times and then standing, drying and roasting under inert gas shielding, thereby acquiring the denitration catalyst. The product disclosed by the invention can increase the specific area of the catalyst and can reduce the conversion rate of SO2 / SO3.

Owner:PETROCHINA CO LTD

A kind of denitrification catalyst and preparation method thereof

ActiveCN106861673BSmall and uniform particle sizeRaise the transition temperatureHeterogenous catalyst chemical elementsDispersed particle separationFlue gasAmmonium metatungstate

The invention discloses a denitration catalyst and a preparation method thereof. (1) Dissolve the titanium source precursor in sulfuric acid to form a solution; (2) Dissolve the tungsten source precursor in water and add it to the solution in step (1). in; (3) After ultrasonic oscillation of the solution obtained in step (2), adjust the pH value to greater than 9.0 with ammonia water, precipitate, filter, and wash; (4) Add deionized water to the filter cake obtained in step (3), and adjust into a slurry, add the vanadium source precursor solution, oscillate with ultrasonic waves, and then directly dry and bake to form a powder; and (5) mix the powder in step (4) with the ammonium metatungstate solution into a slurry, and stir Finally, polyethylene oxide is added, and after secondary stirring, it is sealed and left to stand, dried, and roasted to form a denitration catalyst. The denitrification catalyst prepared by the invention can not only resist the uneven deposition of vanadium oxide in the flue gas on its surface, but also ensure high catalyst performance, and the catalytic performance is relatively stable.

Owner:PETROCHINA CO LTD

Denitration catalyst and preparation method thereof

InactiveCN107321370AClosely connectedEvenly dispersedGas treatmentDispersed particle separationChemistryTungsten

The invention discloses a denitration catalyst and a preparation method thereof. The method comprises steps are as follows: (1) a titanium source precursor is formed into a solution; (2) an assistant catalysis component precursor containing one or two of a tungsten source precursor and a molybdenum source precursor and a fluorine source precursor are formed into a solution, and the solution is mixed with the solution in the step (1) to form a mixed solution; (3) pH of the mixed solution is adjusted, precipitating, washing and filtering are performed, and a filter cake is obtained; (4) water is added to the obtained filter cake, a slurry I is formed, a vanadium source precursor solution is added, drying and roasting are performed after mixing, and the material is ground into powder; (5) the powder is mixed with one of the tungsten source precursor and the molybdenum source precursor, a slurry II is formed and stirred, a pore-forming agent is added, the mixture is evenly mixed, dried and roasted, and the denitration catalyst is formed. The prepared denitration catalyst can overcome the defects that the denitration catalyst in the prior art is uneven in activity center in flue gas and unstable in activity.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com