Osmotic floor hardener and preparation method thereof

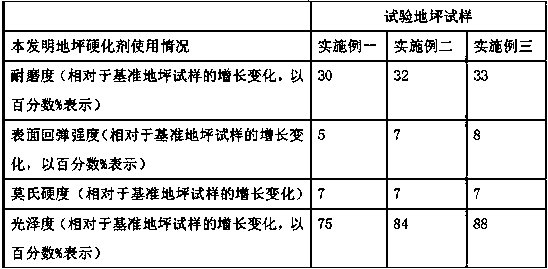

A hardener and penetrating technology, which is applied in biocide-containing paints, anti-fouling/underwater coatings, alkali metal silicate coatings, etc. It can solve the problem of poor anti-permeation performance, inability to clean thoroughly, and easy penetration of oil stains into the floor Internal and other problems, to achieve the effect of improving gloss, preventing sanding, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] A preparation method of a permeable floor hardener, comprising the following steps:

[0091] Step 1: adding lithium hydroxide and potassium hydroxide into the reactor, then adding deionized water, and stirring for 15 to 60 minutes to obtain a mixed alkali solution of lithium hydroxide and potassium hydroxide;

[0092] Step 2: Add methyl silicic acid and silicic acid to the mixed alkali solution of lithium hydroxide and potassium hydroxide obtained in step 1, heat, and stir for 60 to 120 minutes to obtain lithium silicate, potassium silicate, and methyl silicon A mixed solution of lithium acid and potassium methyl silicate;

[0093] Step 3: Add deionized water to the mixed solution obtained in Step 2, and stir for 10 to 50 minutes;

[0094] Step 4: Add a silane coupling agent to the solution obtained in Step 3, and stir for 15 to 60 minutes;

[0095] Step 5: Add siloxane polymer to the solution in Step 4, and stir for 90 to 150 minutes;

[0096] Step 6: adding a stabi...

Embodiment 1

[0115] Example 1: Add 500 grams of deionized water into the reactor, start stirring, weigh 40 grams of lithium hydroxide and 10 grams of potassium hydroxide, add them to the reactor in batches, and stir for 60 minutes to obtain a uniform and transparent alkali solution . Raise the temperature to 70°C, add 300 g of silicic acid and 100 g of methyl silicic acid, stir and react for 120 minutes to obtain a mixed solution of lithium silicate, potassium silicate, lithium methyl silicate and potassium methyl silicate. Then add 1000 grams of deionized water into the reactor, lower the temperature to 40 degrees Celsius, and drop 100 grams of silane coupling agent KH560 within 120 minutes. Ethoxysilane, after the dropwise addition, continue to keep warm for 30 minutes to obtain a uniform and transparent solution. Add 20 grams of stabilizer polyethylene glycol, 2 grams of surfactant alkyl alcohol polyoxyethylene ether sulfate, obtain the product of the present invention.

Embodiment 2

[0116] Example 2: Add 500 grams of deionized water into the reactor, start stirring, weigh 45 grams of lithium hydroxide and 5 grams of potassium hydroxide, add them to the reactor in batches, and stir for 60 minutes to obtain a uniform and transparent alkali solution . The temperature was raised to 70 degrees Celsius, 320 g of silicic acid and 80 g of methyl silicic acid were added, and the reaction was stirred for 120 minutes to obtain a mixed solution of lithium silicate, potassium silicate, lithium methyl silicate and potassium methyl silicate. Then add 1000 grams of deionized water into the reactor, lower the temperature to 40 degrees Celsius, add 100 grams of silane coupling agent γ-aminopropyltriethoxysilane dropwise within 120 minutes, and continue the heat preservation reaction for 30 minutes after the addition is completed. Then 30 g of polymethyltriethoxysilane was added dropwise, and after the dropwise addition was completed, the reaction was continued for 30 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com