Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

192results about How to "Avoid sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracturing method capable of improving sand-carrying performance of fracturing liquid

ActiveCN104405360AReduce sedimentation velocityImprove sand carrying capacityFluid removalFiberFracturing fluid

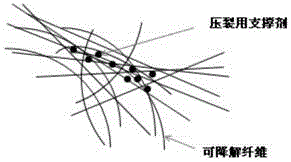

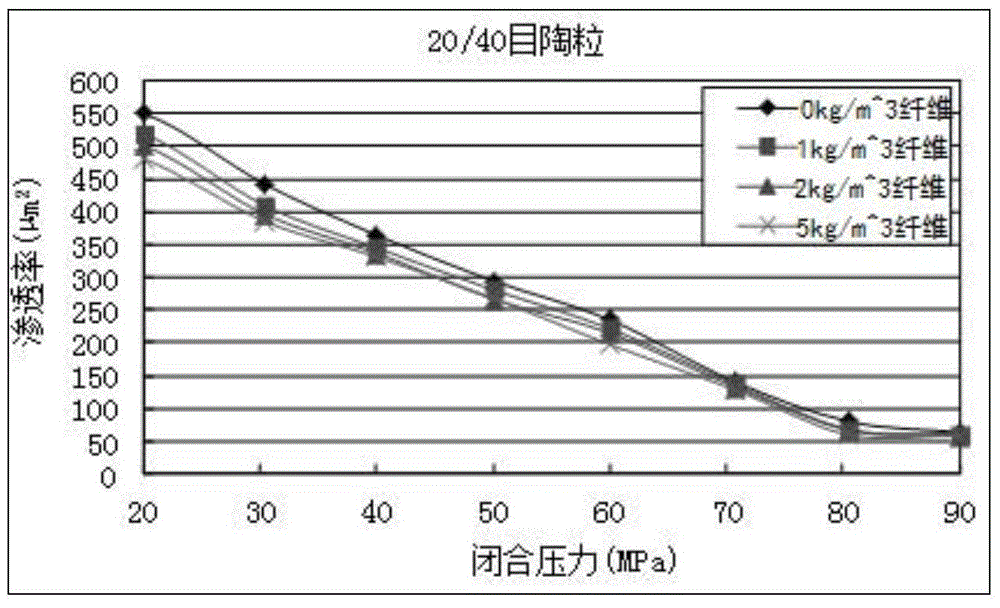

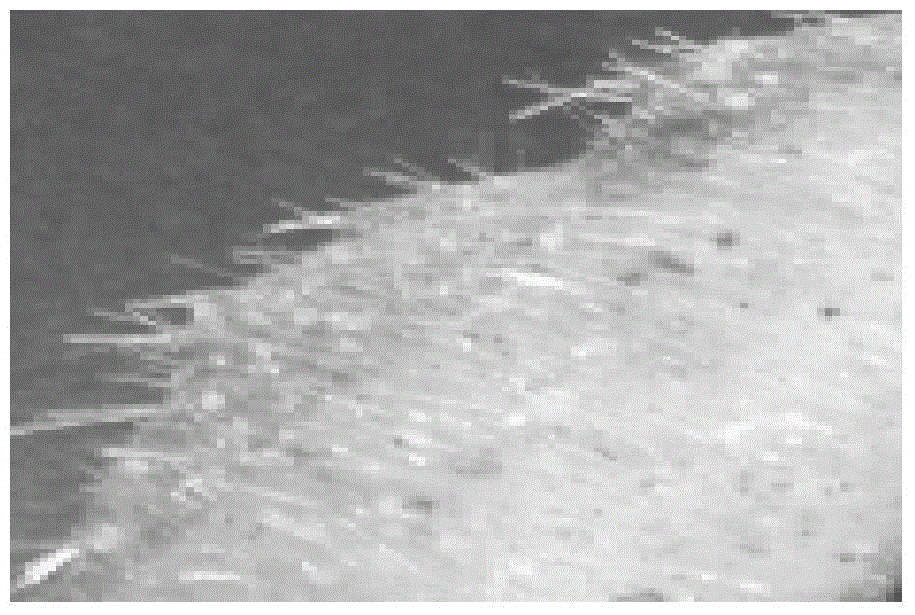

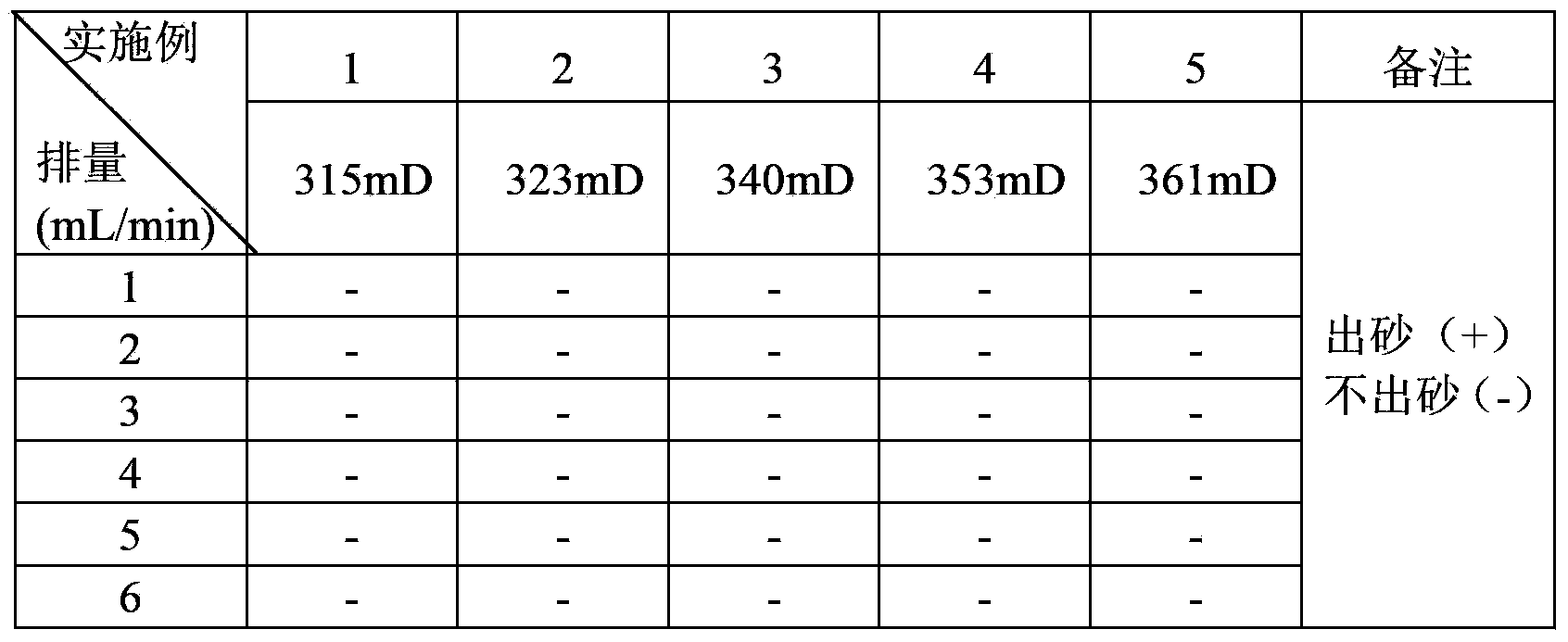

The invention provides a fracturing method capable of improving the sand-carrying performance of fracturing liquid. The method comprises the following steps: dispersing degradable fibers by virtue of a dispersion device, and uniformly dissolving the dispersed degradable fibers in a fracturing liquid base solution; pumping into a fracturing blender truck, and mixing with a propping agent for fracturing so as to form sand-carrying fluid; then pumping the sand-carrying fluid dissolved with the fibers into a strata so as to support a formed fracture geometry. When the degradable fibers added into the fracturing liquid are uniformly dispersed in the fracturing liquid, the fibers and a guanidine gum chain with a network structure form a tangled structure, so that the strength of the cross-linked network structure is enhanced, the sedimentation rate of the propping agent is reduced, the sand-carrying capacity of the fracturing liquid is improved, the propping agent is uniformly distributed in a whole crack, a supporting effect is fully realized, the crack is prevented from being closed and thus the fracturing period of validity is increased; furthermore, the added fibers are capable of effectively preventing the propping agent from flowing back and preventing formation sand flow; an oil gas flow passage is additionally increased, so that the fracturing yield-increasing effect is finally realized.

Owner:中石化胜利油田分公司采油工艺研究院 +1

Acidifying liquid capable of sand stabilization and plug removal, and preparation method thereof

ActiveCN104109528ARemove inorganic blockageInhibit migrationDrilling compositionHydrofluoric acidEther

The invention discloses an acidifying liquid capable of sand stabilization and plug removal and a preparation method thereof, which belongs to the technical field of oil exploitation. The acidifying liquid comprises, by weight, 6 to 15% of hydrochloric acid, 3 to 10% of fluorboric acid, 0.5 to 5% of hydrofluoric acid, 0.5 to 5% of an anti-swelling agent, 0.5 to 5% of an IS-130 corrosion inhibitor, 0.5 to 5% of an SCA iron ion stabilizing agent, 0.5 to 5% of an XT-05 cleanup additive, 0.5 to 5% of glycol monobutyl ether and 5 to 15% of an XT-23 sand control stabilizing agent, with the balance being water. The acidifying liquid is mainly used for strata with loose sandstone reservoirs, can remove inorganic obstruction of strata, forms a bonding covering on points and surfaces where silty-fine sandstone contacts with clay particles, strengthens skeleton gravels, inhibits migration of particles and reduces damage to reservoirs caused by formation sand production and particle migration obstruction due to loosening of a rock skeleton during various operations of an oil-water well; thus, the effective period of each measure is prolonged, construction procedures are simplified, operation cost is reduced, and the comprehensive effects of exploitation of oil reservoirs in loose sandstone are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing super-soft home textile fabric

ActiveCN102978959ANo pollution in the processRich sourcesBiochemical fibre treatmentDyeing processDefibrillationEnzyme

The invention aims to disclose a method for processing a super-soft home textile fabric. The method comprises the following steps: mixing, gray fabric pretreatment, primary fibrillation, enzyme treatment, dyeing, secondary fibrillation, softening and resin finishing. Compared with the prior art, the super-soft home textile fabric is formed by interweaving gossamer and high-grade cotton spun yarn, due to dyeing and finishing special process treatment, the gossamer fibrillation is controlled to obtain a flock effect, the style characteristics of the gossamer and cotton mixed fabrics are improved, enzyme treatment defibrillation is used for achieving the flock effect, the traditional napping process is avoided, the operation is simple, the process flow is shortened, the energy consumption is reduced, and the aim of the method is fulfilled.

Owner:SHANGHAI SHUIXING HOME TEXTILE

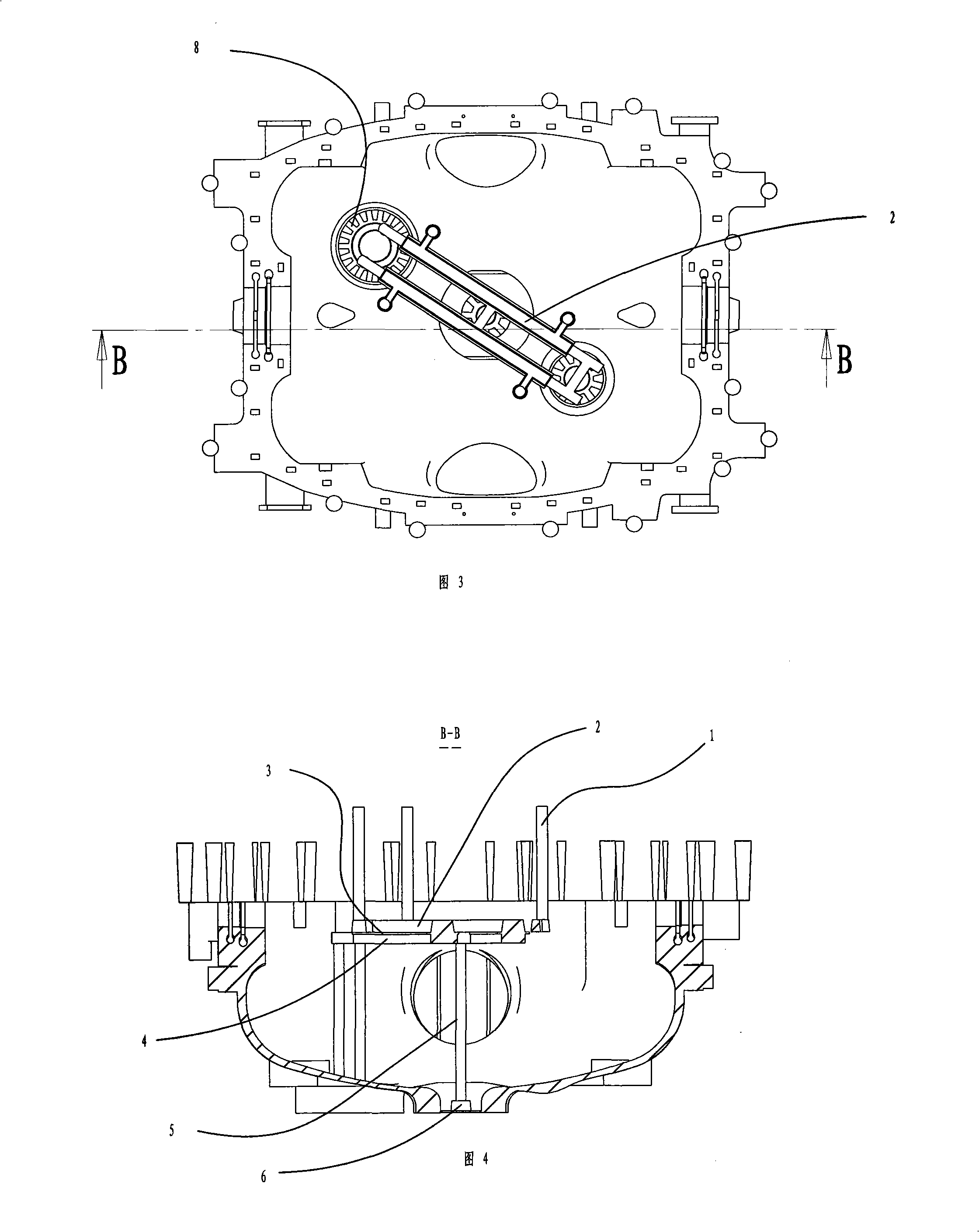

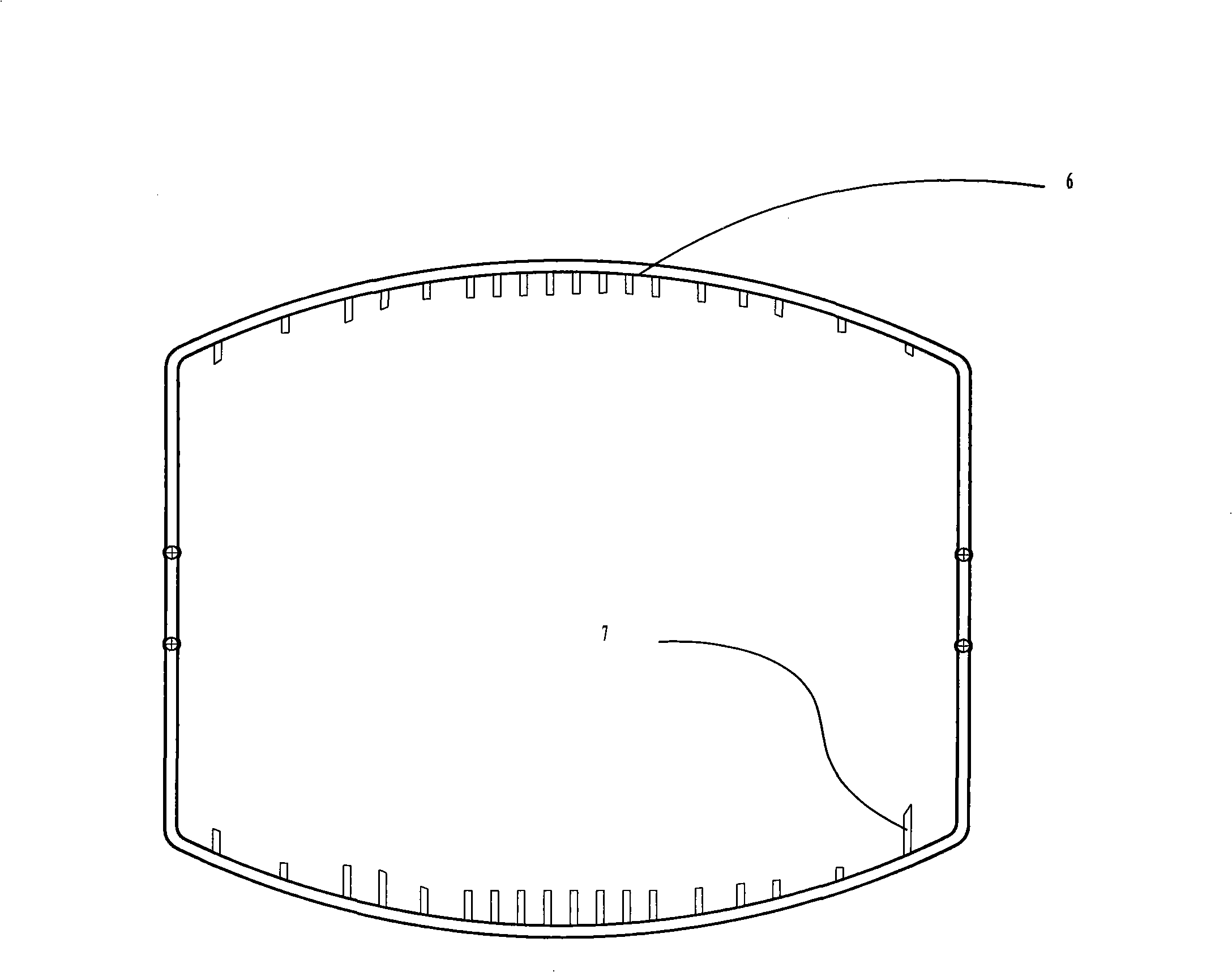

Medium-pressure heavy-section outer-cylinder iron casting gating system of steam turbine

The invention discloses a gating system of a large-section iron casting for an medium pressure external cylinder in a steam turbine; the gating system comprises a weighing ladle, a sprue, a runner and an ingate, the runner consists of an upper runner and a lower runner, a refractory ceramic filter is arranged between the upper runner and the lower runner, the minimum sectional area ratio of the sprue, the runner, a transition sprue, a transition runner and the ingate is 1.2:1.34:1:1.07:1.24; the sprue, the upper runner and the lower runner are arranged at the middle part of the casting, and the ingate of an ingate is arranged at the inner wall of an axle hole of the casting; and the gating system of the structure mainly plays a role in buffering, decompressing and steady entry of melted iron, the molding sand in the scour cast is avoided, the casting is heated evenly, with the advantages of being not easy to be mingled with impurities, carry sand, produce air gaps and cracks.

Owner:RIYUE HEAVY IND

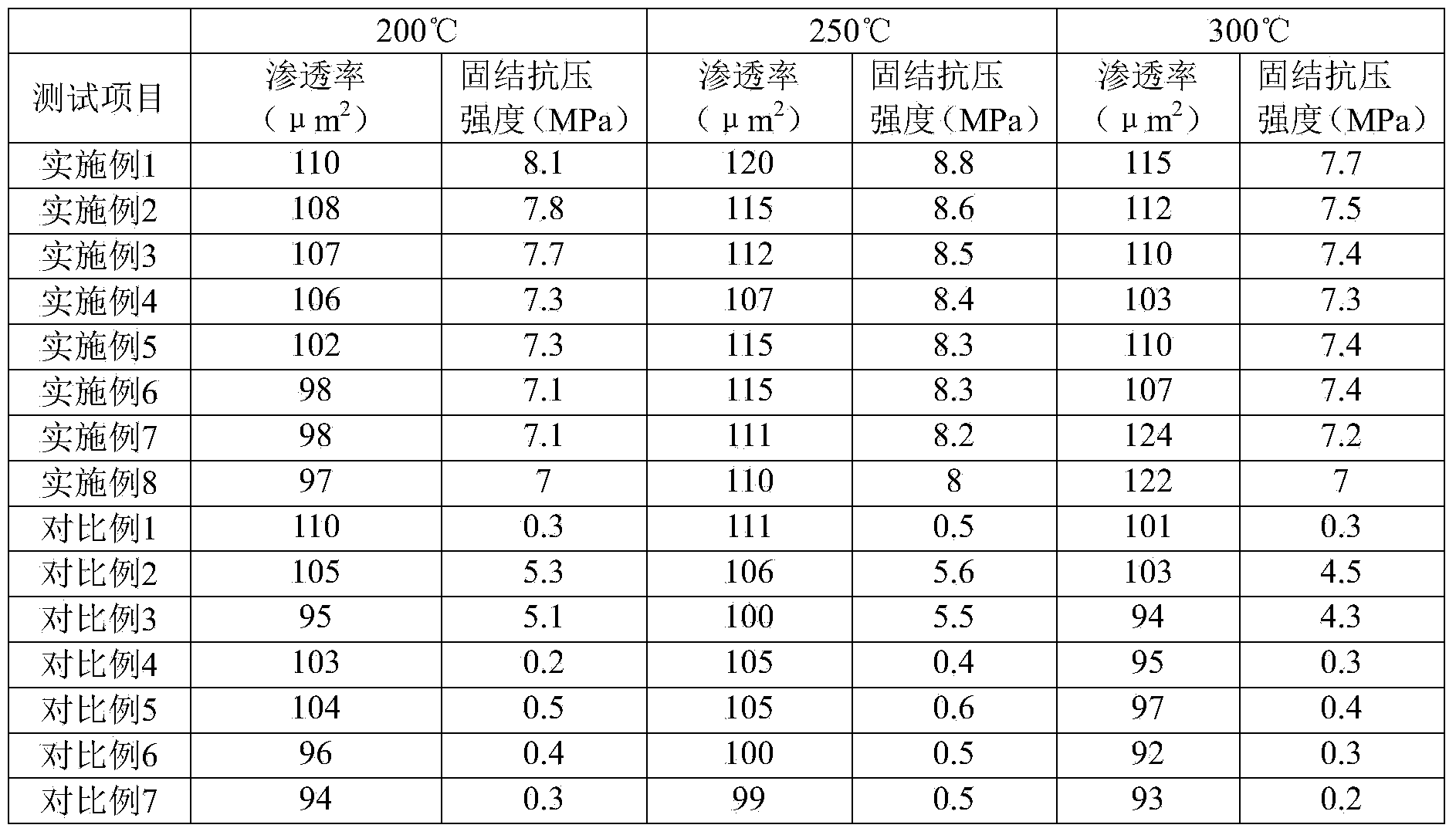

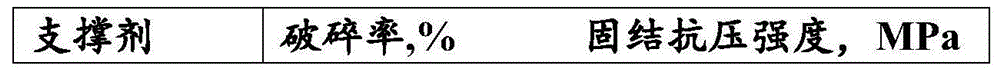

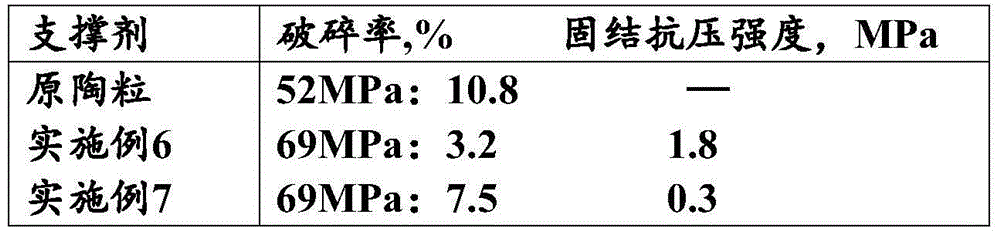

Coated proppant and preparation method thereof

InactiveCN104357042AAvoid sandingPrevent regurgitationFluid removalDrilling compositionPolyresinBisphenol

The invention discloses coated proppant which contains quartz sand and a resin layer, wherein the quartz sand is coated with the resin layer; the resin layer comprises a pre-cured resin layer and a curable resin layer from the inside out; the curable resin layer contains thermoplastic phenolic resin with the softening point of 85-110 DEG C and a phenolic resin curing agent; relative to 100 parts by weight of thermoplastic phenolic resin, the content of the phenolic resin curing agent is 10-30 parts by weight; the pre-cured resin layer is formed by curing bisphenol A epoxy resin with the epoxy value of 0.04-0.32 mol / 100 g, novolac epoxy resin with the epoxy value of 0.45-0.65 mol / 100 g and an epoxy resin curing agent. Through the technical scheme, the coated proppant provided by the invention can resist high temperature and can effectively prevent the phenomena of formation sand production and proppant return.

Owner:ELION RESOURCE GROUP +1

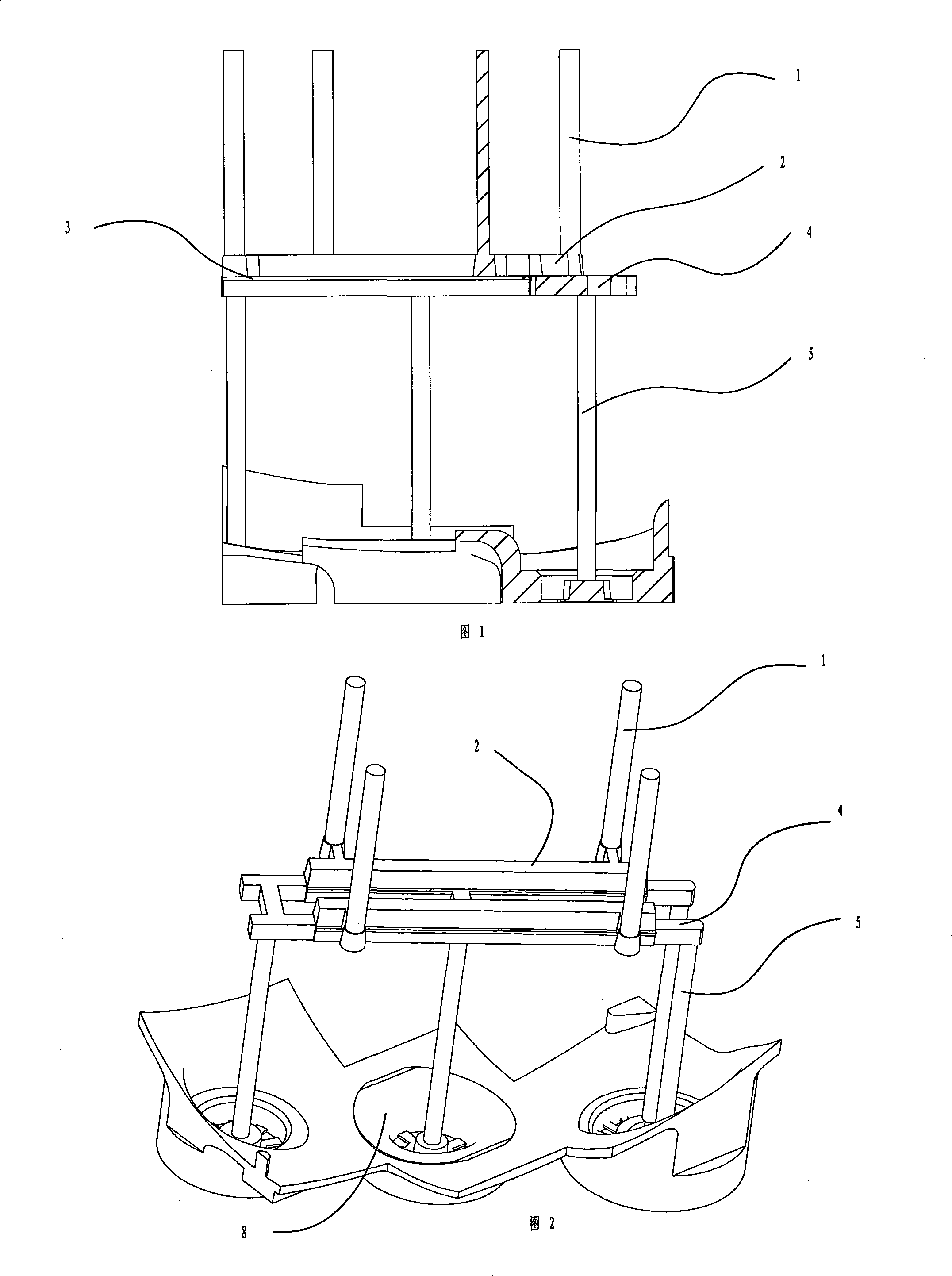

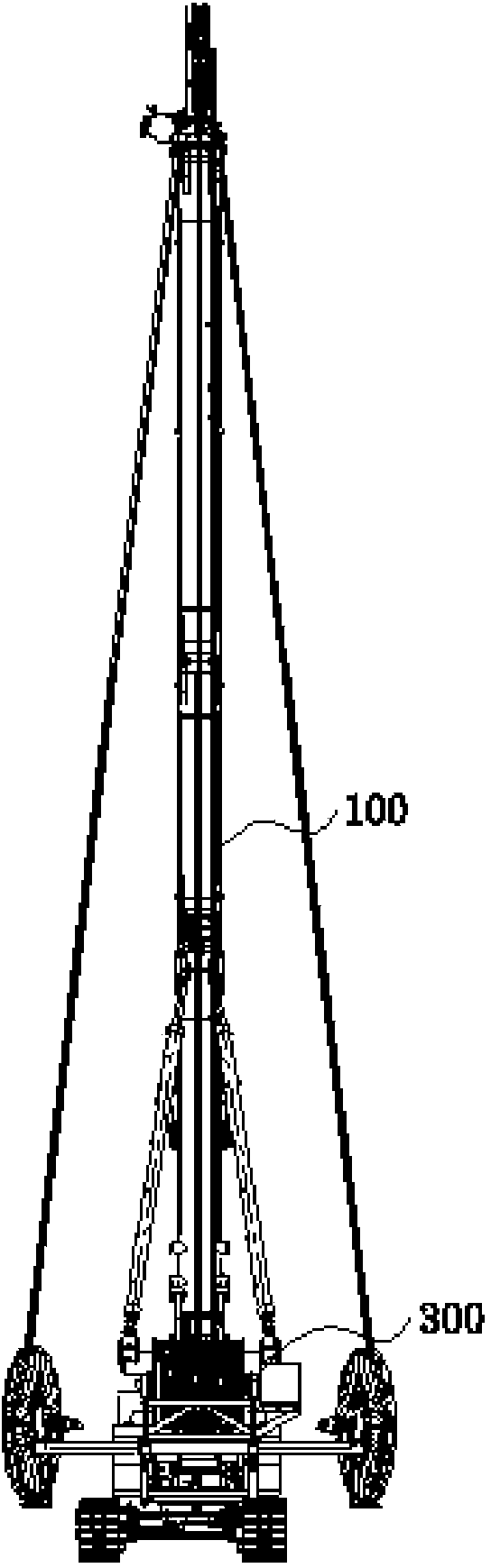

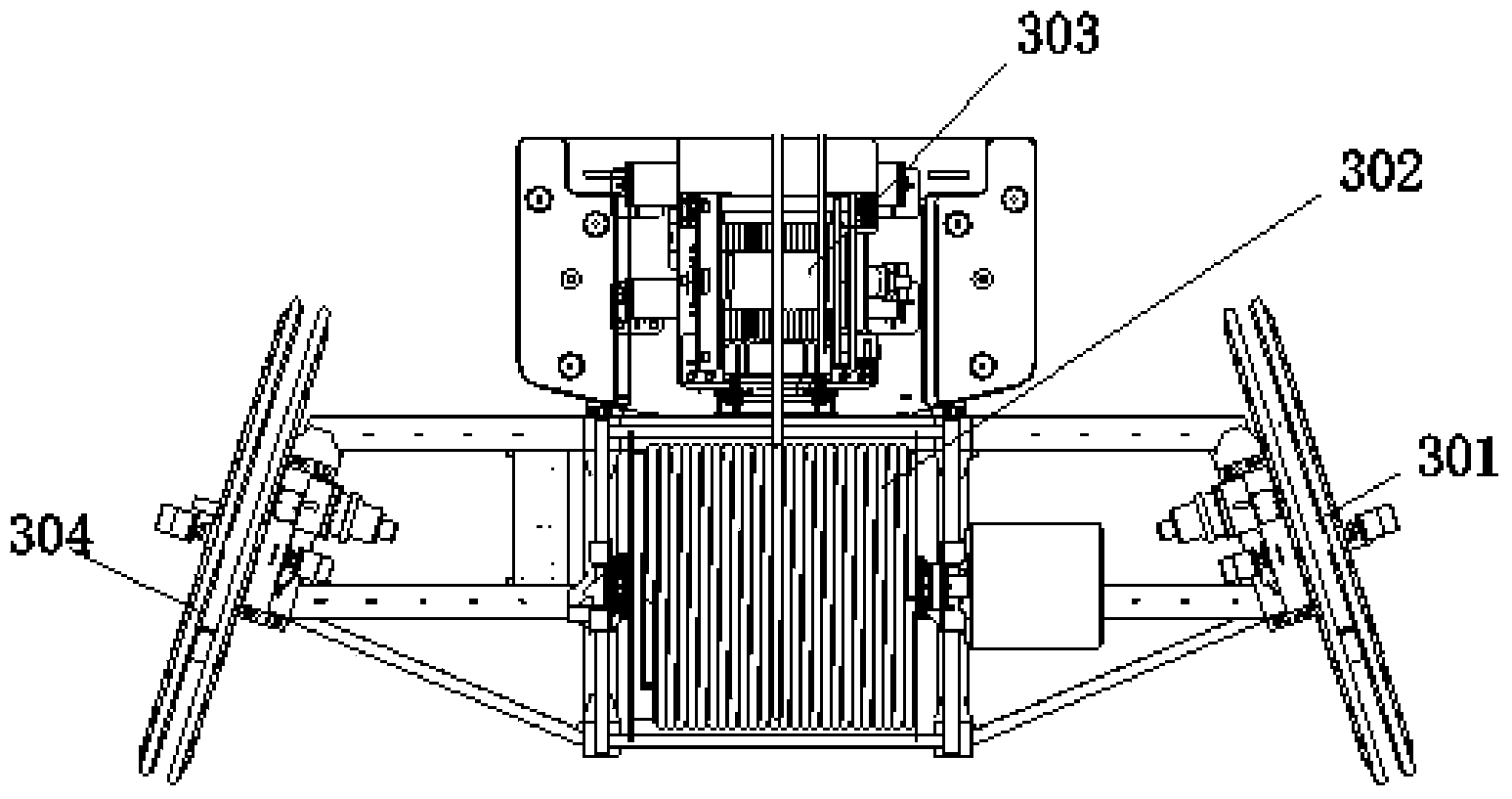

Vibro-replacement stone column machine and construction method thereof

ActiveCN104372788ASolve the hardening problemGuaranteed free expansionSoil preservationEngineeringConductor Coil

The invention discloses a vibro-replacement stone column machine and a construction method thereof. The vibro-replacement stone column machine comprises a crane system, an automatic feeding system, a drill rod system and a vibrator system. The method includes the steps that when the vibro-replacement stone column machine conducts vibrator ultra-deep construction, a steel wire rope winding device enables a vibrator connected below a telescopic guide rod to descend gradually by releasing sleeves in a column hole of the telescopic guide rod layer by layer; while the steel wire rope winding device enables the sleeves in the telescopic guide rod to be released layer by layer, a cable winding device, a water pipe winding device and a gas pipe winding device synchronously release a cable, a water pipe and a gas pipe placed in the telescopic guide rod; the vibrator vibrates downwards continuously through electric power, clear water and gas supplied by the cable, the water pipe and the gas pipe which descend synchronously along with the vibrator, so that an ultra-deep vibro-replacement stone column hole is formed; after the ultra-depth vibro-replacement stone column hole reaches a preset depth, the hole is cleaned up, stone is thrown into the hole, a column can be manufactured in a vibration and compaction mode, and thus an ultra-depth vibro-replacement stone column can be formed.

Owner:SINOHYDRO FOUND ENG

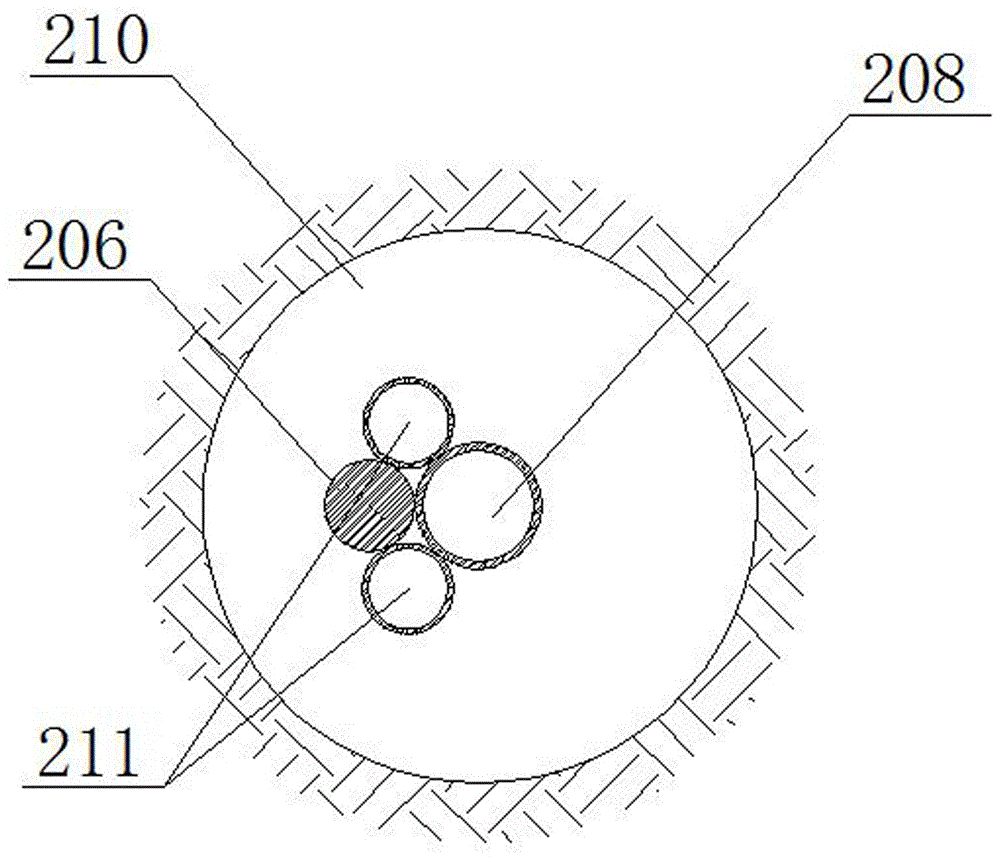

Fiber composite sand control process without sieve tube and treatment agent formula

The invention relates to a method for preventing sand in oil natural gas well, and the formula of relative processing agent, wherein the invention uses fiber to form three-dimension mesh structure, to control the process of discharging sand from storage layer and the formula of processing agent. The invention is characterized in that: first using crack machine and ground tube to extrude pretreatment liquid into storage layer; then using salt water clean liquid to crack; then using fiber composite to process main crack; extruding and completing sand prevention. The invention can eliminate the damage on former oil well storage layer, to improve the leakage condition; and the well eye is filled with fiber composite ring around; the invention can improve yield, realize non-screen sand prevention, and save cost.

Owner:PETROCHINA CO LTD

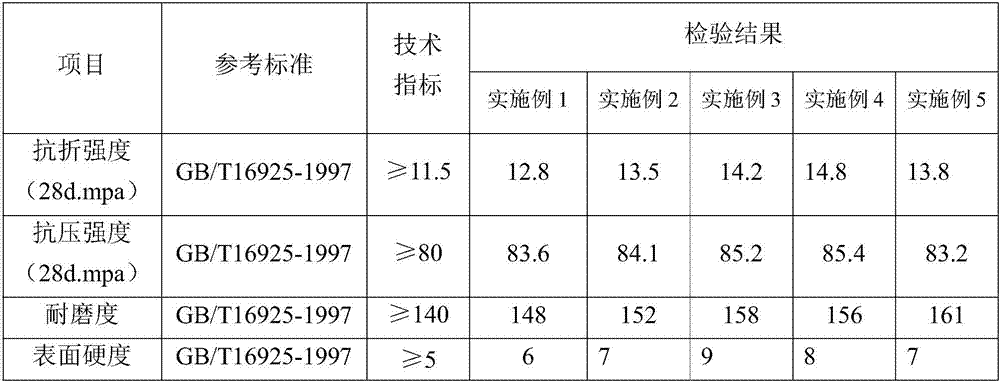

Concrete curing agent, preparation method and application thereof

The invention discloses a concrete curing agent. The concrete curing agent comprises the following materials in percentage by weight: 1%-30% of potassium silicate, 0.01%-0.5% of penetrating agent, 0.5%-1.5% of water repellent, 0.5%-1% of surface active agent, 0.3%-1% of surface modifying agent and the balance of water, wherein the modulus of the potassium silicate is more than 5. The invention also provides a preparation method of the concrete curing agent. The preparation method comprises the following steps of: uniformly mixing the components in the formula according to the mass percentage, stirring and obtaining the concrete curing agent. The invention also provide a construction method of the concrete curing agent. The construction method comprises the following steps of: polishing concrete floors, brushing the concrete floors with the curing agent, and then polishing. The concrete curing agent disclosed by the invention has the advantages that due to addition of the high-modulus potassium silicate, silicate ions in the curing agent reacts with unreacted free ions in concrete to generate a complex, and then the complex is filled in capillary pores in concrete, so that the blocking for fine pores of concrete structures, the effects of sealing and curing are achieved, the strength and the hardness of the concrete are improved to a greater extent, and the sanding of the concrete is prevented.

Owner:CHONGQING EP ANTICORROSION TECH CO LTD

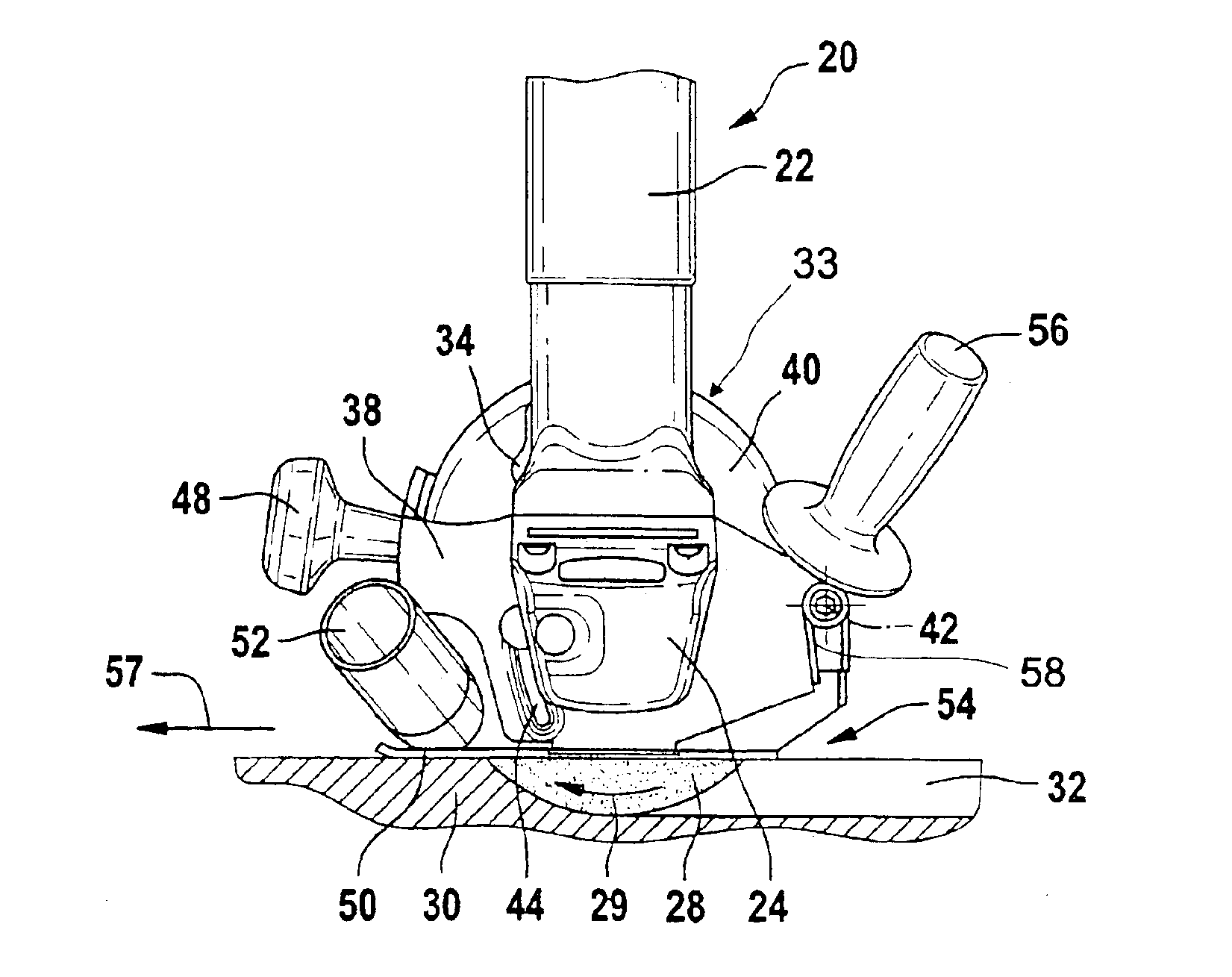

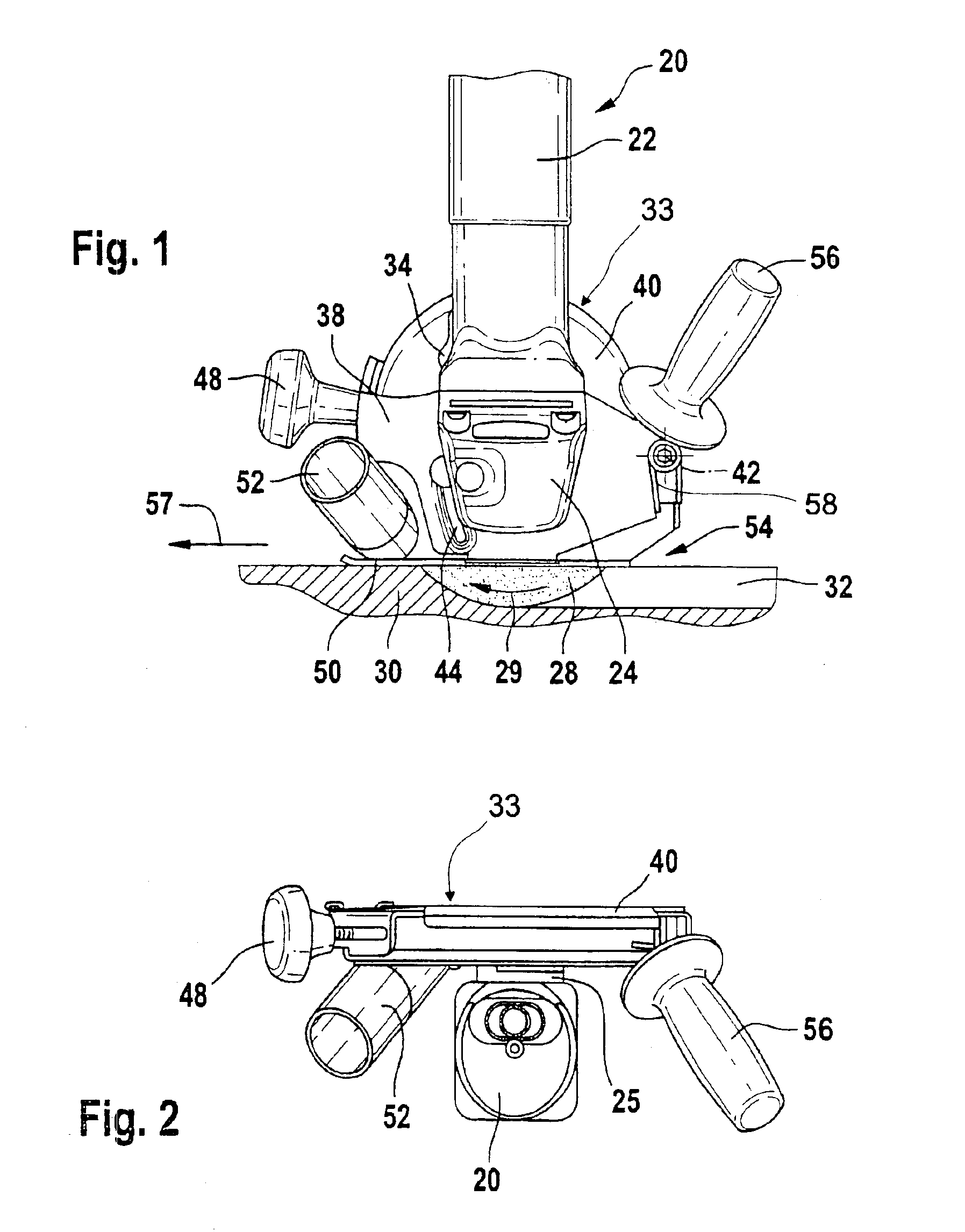

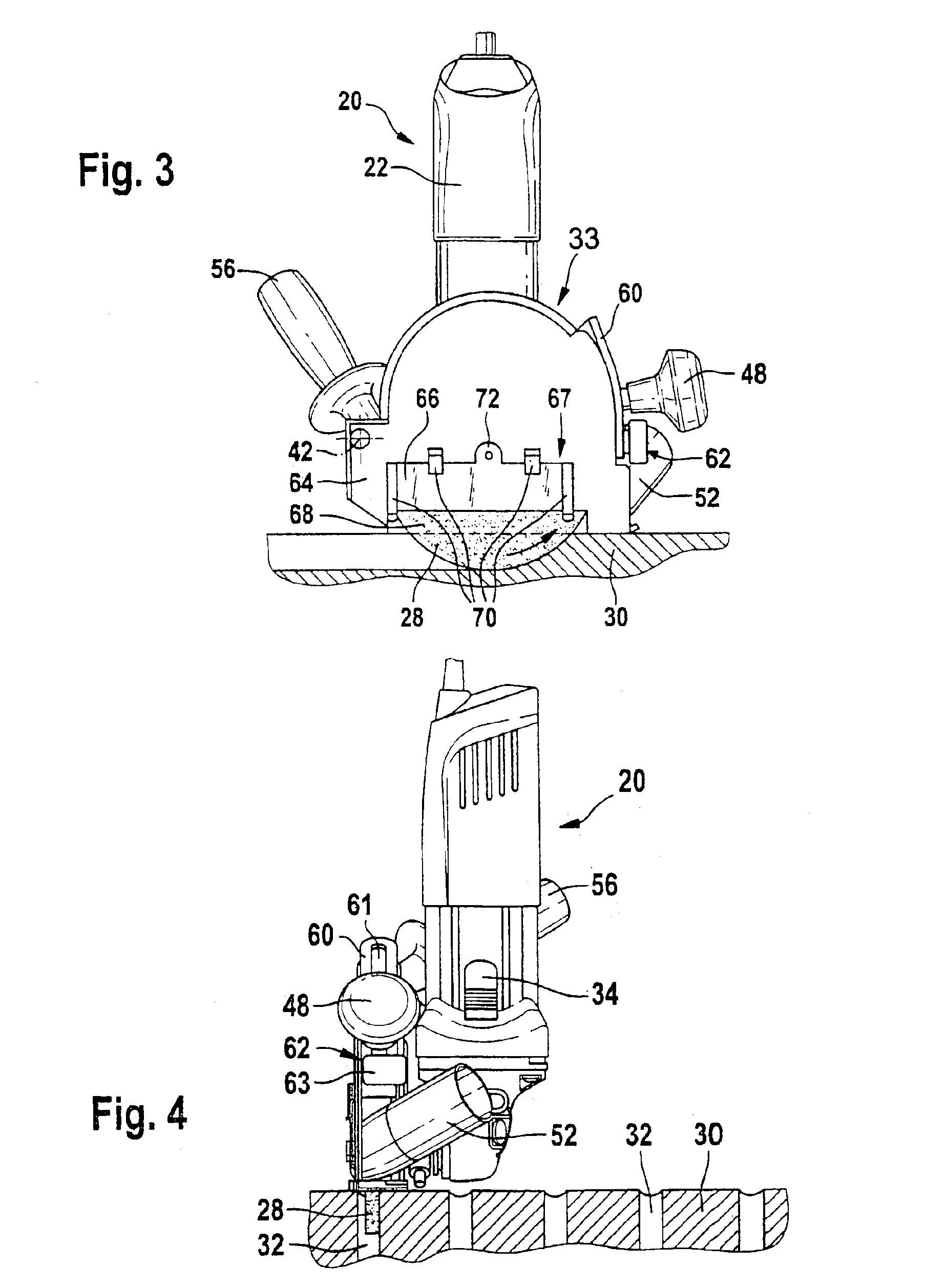

Protective device for a hand machine tool

InactiveUS6953394B2Sanding/grinding dust removal can be managed particularly effectivelyPrevent escapeMetal sawing devicesShearing machinesHand heldEngineering

A guard device for a hand power tool, in the form of a sanding / grinding hand power tool, has a wheel guard enclosing at least part of a rotating tool in a radial direction; a guide for guiding the wheel guard along a work piece, and comprising a fastening device for mounting the wheel guard on the hand power tool, wherein the guide is joined with the wheel guard in torsion-resistant fashion, and the wheel guard is mounted in a fashion that allows it to move relative to the fastening device; and a depth-of-cut stop limiting the relative movement of the wheel guard and fastening device, and being lockable in position with positive engagement in preselected stepped positions.

Owner:ROBERT BOSCH GMBH

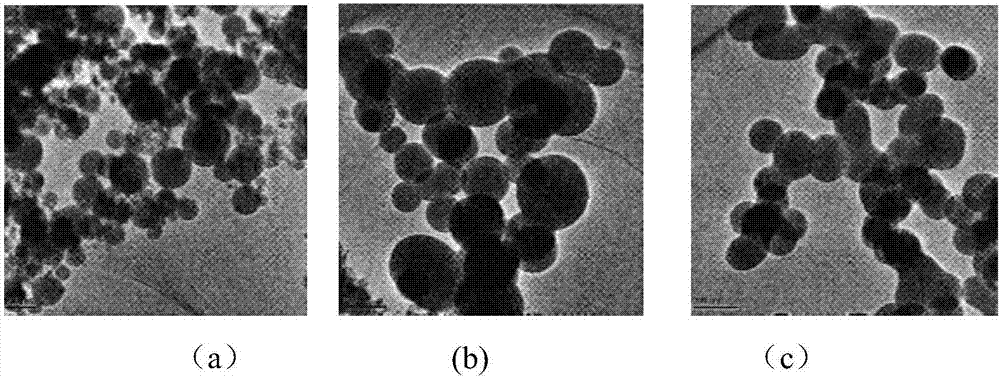

Preparation method of molybdenum metal grille

ActiveCN109014230AHigh sphericityIncrease heatAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strength3d printer

The invention discloses a preparation method of a molybdenum metal grille. The preparation method comprises the steps of 1, conducting cold isostatic pressing, high-temperature sintering, hot fine forging and straightening treatment on molybdenum powder to obtain a molybdenum rod; 2, machining the molybdenum rod into spherical molybdenum powder through plasma rotating electrode powder manufacturing equipment; and 3, preparing a molybdenum metal grille molded part with the spherical molybdenum powder as a raw material through a powder bed electron beam 3D printer and then conducting annealing,hot isostatic pressing and alkaline washing in sequence to obtain the molybdenum metal grille. According to the preparation method, the molybdenum powder is prepared into the spherical molybdenum powder; the molybdenum metal grille is prepared through the powder bed electron beam 3D printer; according to the characteristics that the spherical molybdenum powder is good in fluidity, compact and uniform in particle and tight in combination after quick melting and the heat of electron beams is high, the defects that molybdenum metal is high in strength, low in plasticity, very easy to oxidize andpoor in formability and is not likely to be machined into complex structural parts and functional parts are overcome, the specification and using properties of the molybdenum metal grille are improved, and the preparation cost is saved.

Owner:JINDUICHENG MOLYBDENUM CO LTD

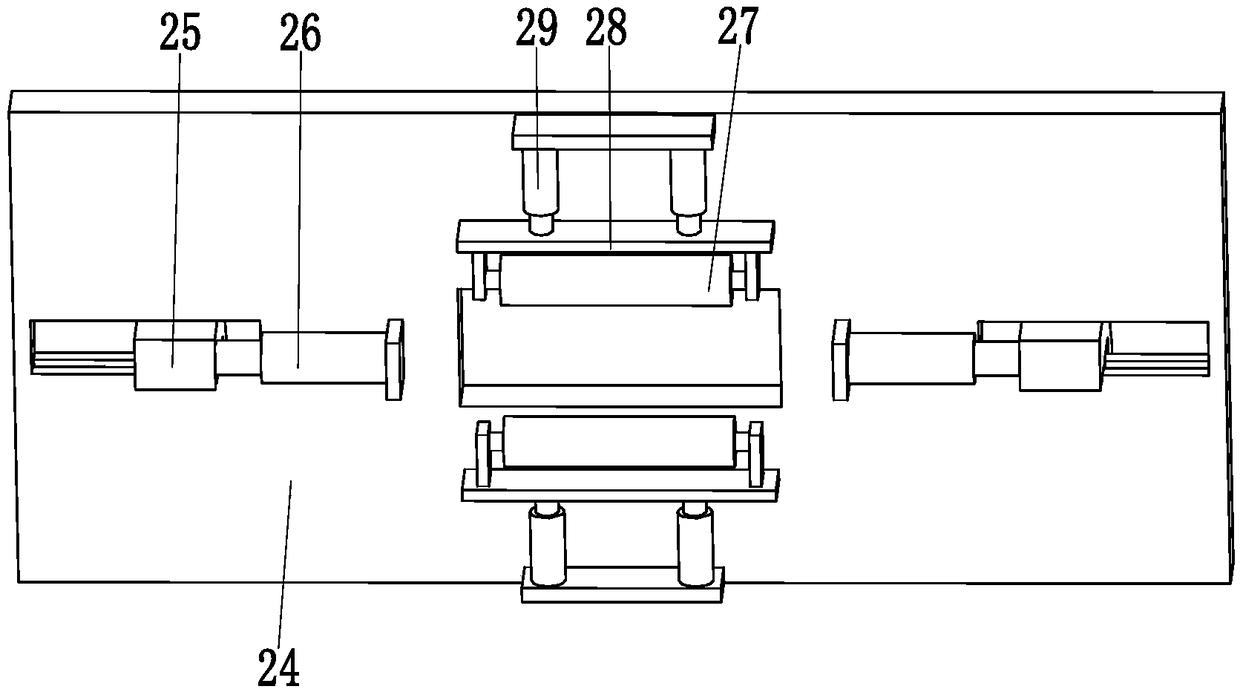

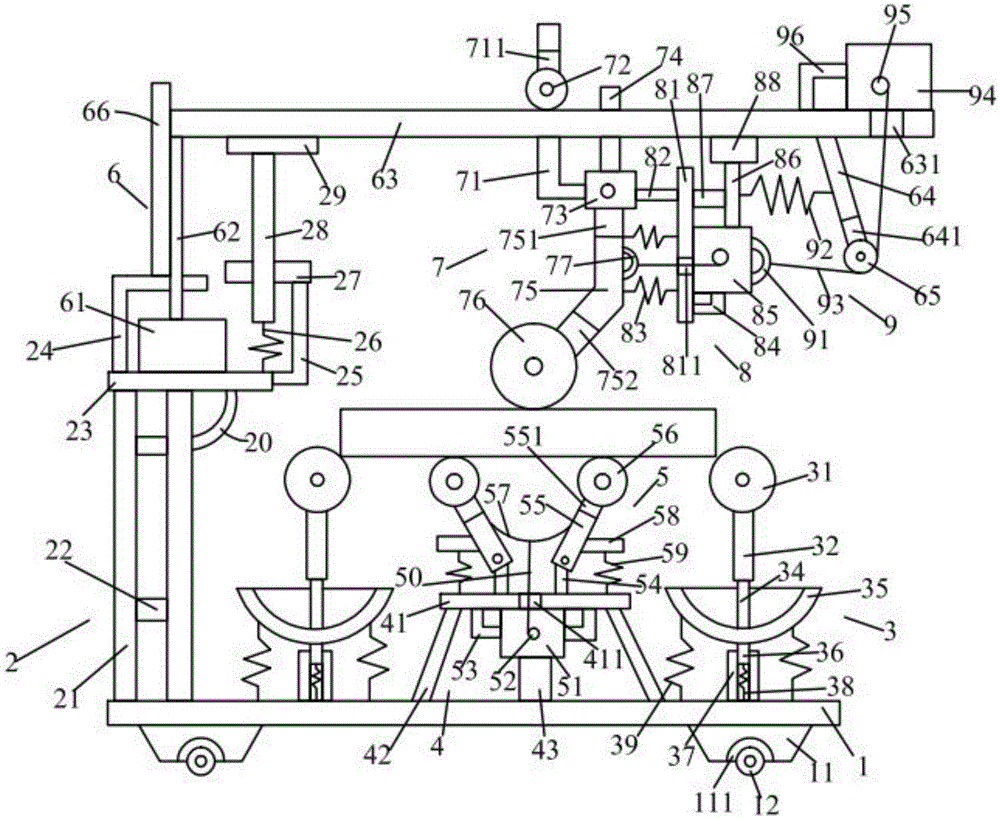

Municipal drainage three-way tube casting body cutting equipment

The invention relates to municipal drainage three-way tube casting body cutting equipment. The municipal drainage three-way tube casting body cutting equipment comprises a supporting bottom plate, a conveying device, fixing devices and a cutting device. The conveying device is mounted on the upper end surface of the middle of the supporting bottom plate. The two fixing devices are distributed on the left and right sides of the conveying device correspondingly and mounted at the outer end top of the supporting bottom plate. The cutting device is located on the rear side of the conveying deviceand mounted on the supporting bottom plate. The conveying device comprises a conveying electric sliding block, a conveying bottom plate, a conveying push rod, a conveying support plate, a storing frame, a storing push rod, a position correcting idler wheel, an idler wheel bracket and a position correcting push rod. According to the municipal drainage three-way tube casting body cutting equipment,the difficult problems that when an existing three-way flange tube is subjected to casted bulge cutting, the three-way flange tube cannot be automatically conveyed, the structure of the three-way flange tube cannot be fixed, the three-way flange tube is infirm in fixing and needs to be cut manually, and the cut three-way flange tube is poor in polishing effect can be solved.

Owner:平邑现代中药产业园有限公司

Method for completing well by cementing top of expandable screen

InactiveCN103089194ALow costShorter completion cycleFluid removalSealing/packingWell cementingEngineering

The invention relates to the technical field of oilfield well completion, in particular to a method for completing a well by cementing the top of an expandable screen. The method comprises the following steps of: running a casing string comprising a casing tail pipe, a drilling plug-free system and the expandable screen into the well, performing cementing operation on the top of the expandable screen, and running an expansion diameter variation device to expand the expandable screen to cling to the wall of the well, wherein a packing rubber sleeve, an inner pipe device, a cementing hole and a blind plate are machined on the drilling plug-free system. Compared with the conventional screen, the expandable screen has the advantage that the external diameter of the expandable screen is increased after the expandable screen is expanded to enlarge an open area between formation fluid and a shaft and increase a fluid inlet volume, so that the fluid yield of a single well can be improved; and in addition, the high expandability of the expandable screen is used for forming a sand prevention screen system, gravels are not required to be filled into a horizontal well, and when a perforation tunnel or the well is blocked by formation sand to reduce the yield, the perforation tunnel is not required to be pre-filled, so that the repeated operation of sand prevention and well washing is eliminated.

Owner:CHINA PETROLEUM & CHEM CORP +1

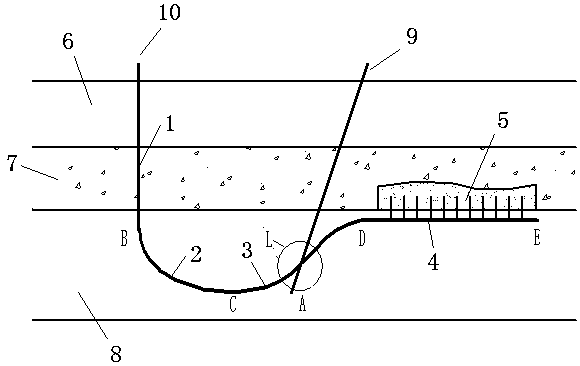

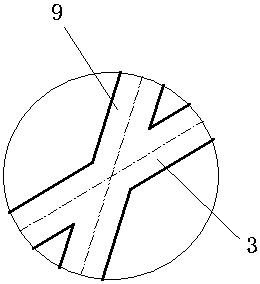

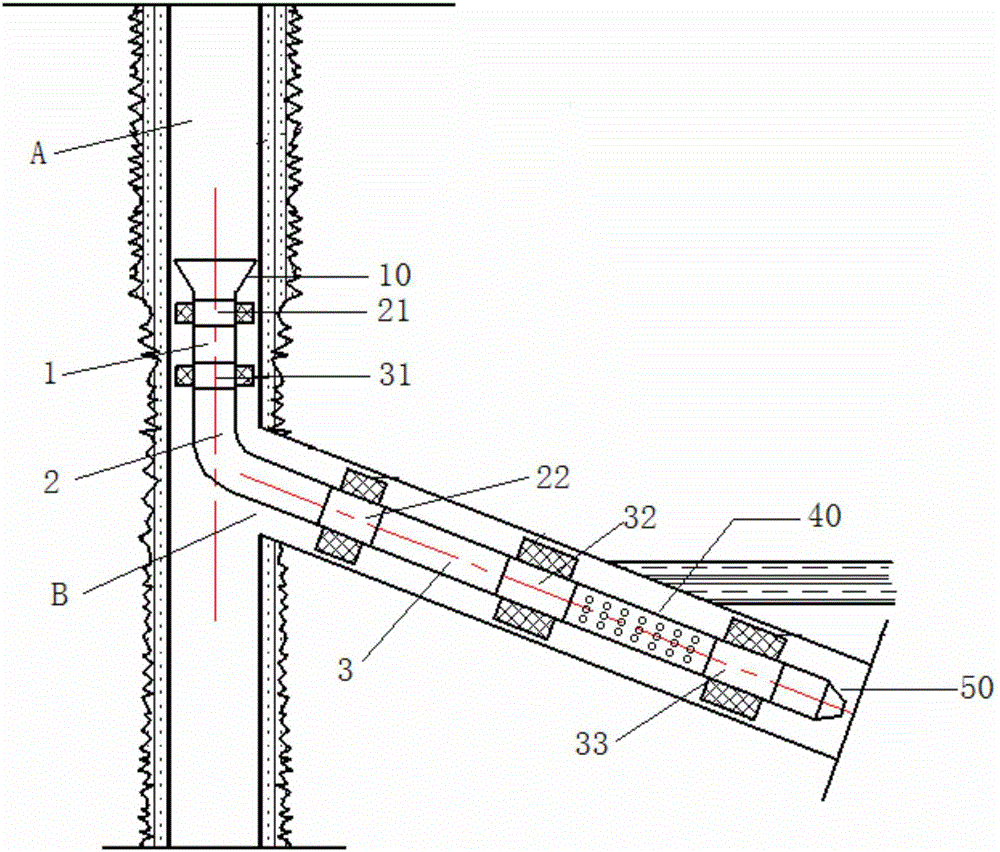

Method of using F type well group to exploit non-diagenetic type natural gas hydrates

ActiveCN108590595AEffectively deal with instability problemsPrevention and Control ComplexityConstructionsFluid removalEconomic benefitsPhase state

The invention relates to a method of using an F type well group to exploit non-diagenetic type natural gas hydrates. The method includes the following steps that step 1, a slant well is drilled, the slant well is slantly drilled from the upper face of an unstable stratum to a target spot A in an underling stable stratum of a natural gas hydrate reservoir, and then a casing pipe is lowered and cement is poured for well completion; step 2, a horizontal well is drilled and is provided with a vertical well section, a deflecting well section, an up-warp well section and a horizontal well section and the vertical well section is located on one side of the well bottom, in the slant direction, of the slant well; step 3, fracturing sand control construction is carried out on the horizontal well, the condition that fracturing seams extend into the reservoir is required, and chemical sand control agents are injected into the fracturing seams and the reservoir; and step 4, the slant well is closedby using a well opening, the horizontal well is opened, and the natural gas hydrates are exploited by adopting CO2 replacement or heat injection or depressurization or a mixing method. The stabilityand patency of a well shaft are improved, the contact area of the well shaft and the reservoir is enlarged, and changing of the phase state of the natural gas hydrates occurs in the stable well shaft;on the one hand, complex accidents and even a disaster caused by uncontrollable shakeout and the uncontrollable changing of the phase state of the natural gas hydrates and the unstable well shaft canbe effectively avoided, and on the other hand, well yield and economic benefits of the natural gas hydrates can be effectively improved.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Low-temperature sand-prevention resin coated propping agent for oil-gas well and preparation method of low-temperature sand-prevention resin coated propping agent

ActiveCN104449656AAvoid bondingPrevent regurgitationFluid removalDrilling compositionEpoxyPolyester resin

The invention relates to a low-temperature sand-prevention resin coated propping agent for an oil-gas well and a preparation method of the low-temperature sand-prevention resin coated propping agent. The low-temperature sand-prevention resin coated propping agent comprises a propping agent aggregate, a precuring reinforced resin membrane and a low-temperature sand-prevention resin membrane, wherein the precuring reinforced resin membrane is made of reinforced resin applied to the surface of the propping agent aggregate; the low-temperature sand-prevention resin membrane is made of low-temperature sand-prevention resin applied to the surface of reinforced resin; the reinforced resin is selected from epoxy resin and / or thermoplastic phenolic resin; the low-temperature sand-prevention resin is sulfonate polyester resin.

Owner:BEIJING QISINTAL NEW MATERIAL

Board section fixed grinding equipment applicable to the field of furniture processing

ActiveCN106625078AEffectively fixedFixed grinding is effectiveGrinding carriagesGrinding work supportsElectric machineEngineering

The invention discloses board section fixed grinding equipment applicable to the field of furniture processing. The board section fixed grinding equipment comprises a base plate, a support device, a supporting device, a fixed device, a first grinding device, a lifting device, a second grinding device, a first motor device and a second motor device, a first supporting block and a first idler wheel are arranged on the base plate, the support device comprises a first cross rod, a first supporting rod, a first cross plate, a first locating frame, a first support, a first spring, a second cross rod, a first abutting-leaning rod, a first abutting-leaning plate and a first bent rod, the support device comprises a abutting- wheel, a second abutting- leaning rod, a first vertical rod, a curving plate, a second vertical rod, a first location rod, a second spring, and a third spring, the fixed device comprises a second cross plate, a second supporting rod, and a third supporting rod, and the first grinding device comprises a first motor, a first output shaft, a second support, a fourth supporting rod, a rotating rod, a first grinding wheel and a first bracing wire. According to the board section fixed grinding equipment applicable to the field of furniture processing, effective fixation can be conducted on a panel when the panel is grinded, so that the grinding is more accurate.

Owner:GUANGZHOU LANGU HOUSEHOLD TECH CO LTD

Core making process of resin sand

The invention discloses a core making process of resin sand. The core making process comprises the following steps that s1, resin, a curing agent and roughing sand are mixed in proportion to form mixed sand; s2, a releasing agent is brushed on a mold; s3, after the releasing agent is dried, a core box is closed, a core bar, a chilling block and a moving block are put in the core box, the core boxis fast filled with the mixed sand, and the mixed sand is pounded; s4, after the mixed sand is pounded, an air outlet needle or an air outlet rope is pulled out to form an exhaust channel; s5, after the surface of the mixed sand is hardened, the core box is opened; s6, after the sand is cured, core finishing is carried out, rough edges and burrs on the surface of the sand are removed, unfilled corners and holes are checked, repair paste is used for repairing, and finished sand can be obtained; s7, ethyl alcohol is added into coating for mixing, and the surface of the finished sand is evenly coated with the coating through a brush; and s8, after coating is completed, the coating is immediately ignited, sufficient combustion is achieved, after cooling, the finished sand is dried, and a resinsand core is obtained. According to the core making process, the resin, the curing agent and the roughing sand are mixed in proportion, and the made sand core is good in adhesion effect, stable in structure and smooth in surface.

Owner:湖南精量重工科技有限公司

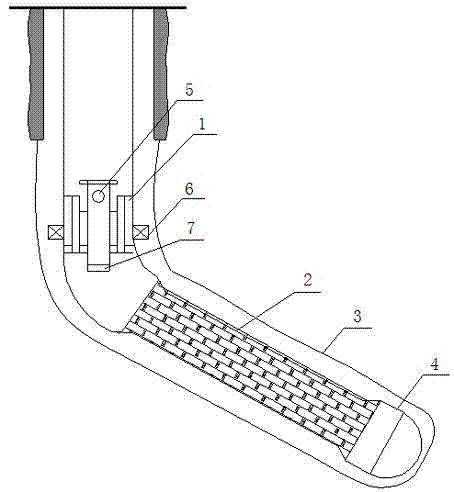

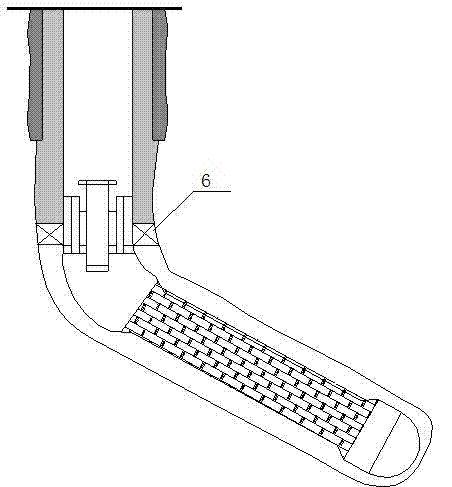

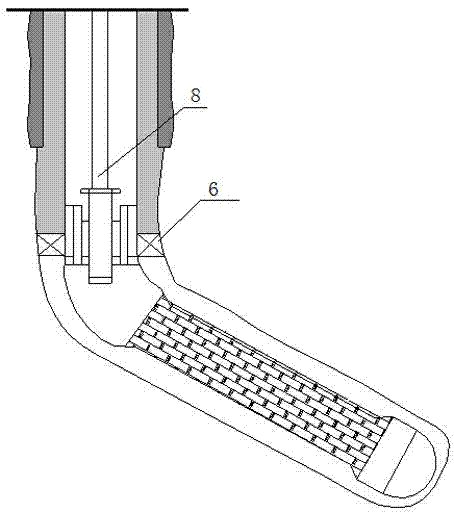

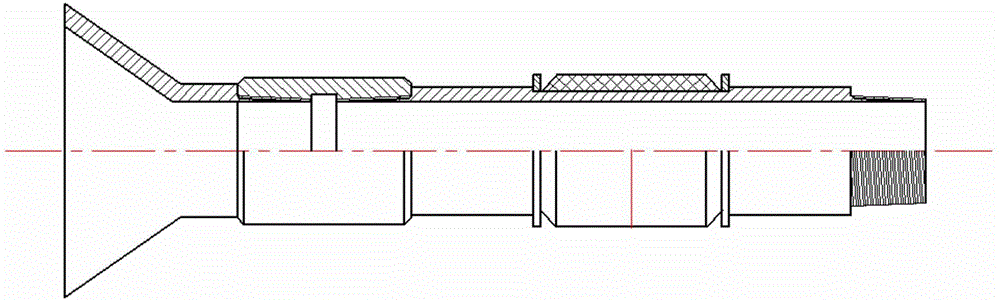

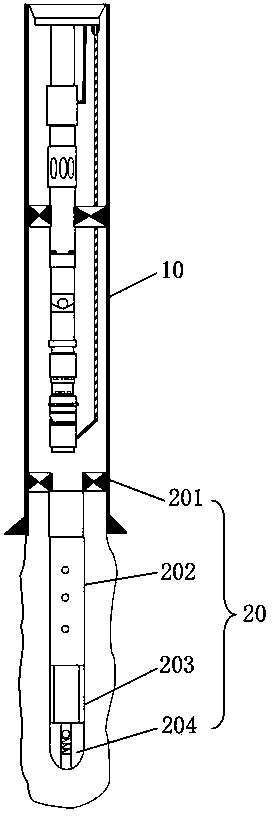

Uprighting and sand preventing integrated pipe column and operating method thereof

ActiveCN106121548AImprove permeabilityPrevent collapseDrilling rodsFluid removalEngineeringOil water

The invention discloses an uprighting and sand preventing integrated pipe column which comprises a suspension head, automatic expansion uprighting nipples, automatic expansion sealed uprighting nipples, a screen pipe, a guide cone and sleeves. The suspension head adopts a structure of an inverted cone cylinder. An internal thread is formed in the inner wall of a conic cylinder extension pipe, and is used for being connected with a rod body of a drill rod. The root of the conic cylinder extension pipe is in threaded connection with the automatic expansion uprighting nipples. The automatic expansion sealed uprighting nipples are connected with the automatic expansion uprighting nipples in sequence through the sleeves. The automatic expansion sealed uprighting nipples are in threaded connection with the screen pipe, the automatic expansion sealed uprighting nipples and the guide cone in sequence. A vulcanized automatic expansion rubber cylinder is arranged at the peripheries of the automatic expansion uprighting nipples / the automatic expansion sealed uprighting nipples. The uprighting and sand preventing integrated pipe column has the beneficial effects that the problem that a conventional sand preventing pipe column is not centered and sealed, so that the sand preventing failure problem or the sand preventing invalidation problem is caused is solved, the stratum can be stabilized, hole collapse or sand flow is prevented, the sand preventing effect is good, the period of validity is long, and oil-water well abandonment is avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Grinding machine for burrs of brake pad

ActiveCN105127859AAchieve grindingRealize automatic grindingEdge grinding machinesGrinding carriagesEngineeringBrake pad

The invention discloses a grinding machine for burrs of a brake pad. The grinding machine is characterized by comprises a rack, a first grinding mechanism and a second grinding mechanism, wherein the first grinding mechanism and the second grinding mechanism are arranged on the rack and are perpendicular to each other; the first grinding mechanism comprises a conveying chain, a groove grinding mechanism arranged above the conveying chain, and a top edge grinding mechanism, the groove grinding mechanism is arranged above the middle of the conveying chain, and the top edge grinding mechanism is close to the second grinding mechanism; and the second grinding mechanism comprises a conveying belt and a side edge grinding mechanism arranged above the conveying belt, a plurality of magnets are attracted to the conveying belt and are in contact, and the side edge grinding mechanism is arranged at the tail end of the conveying belt. The grinding machine can automatically grind the burrs of the brake pad.

Owner:苏州隆士丹自动化技术有限公司

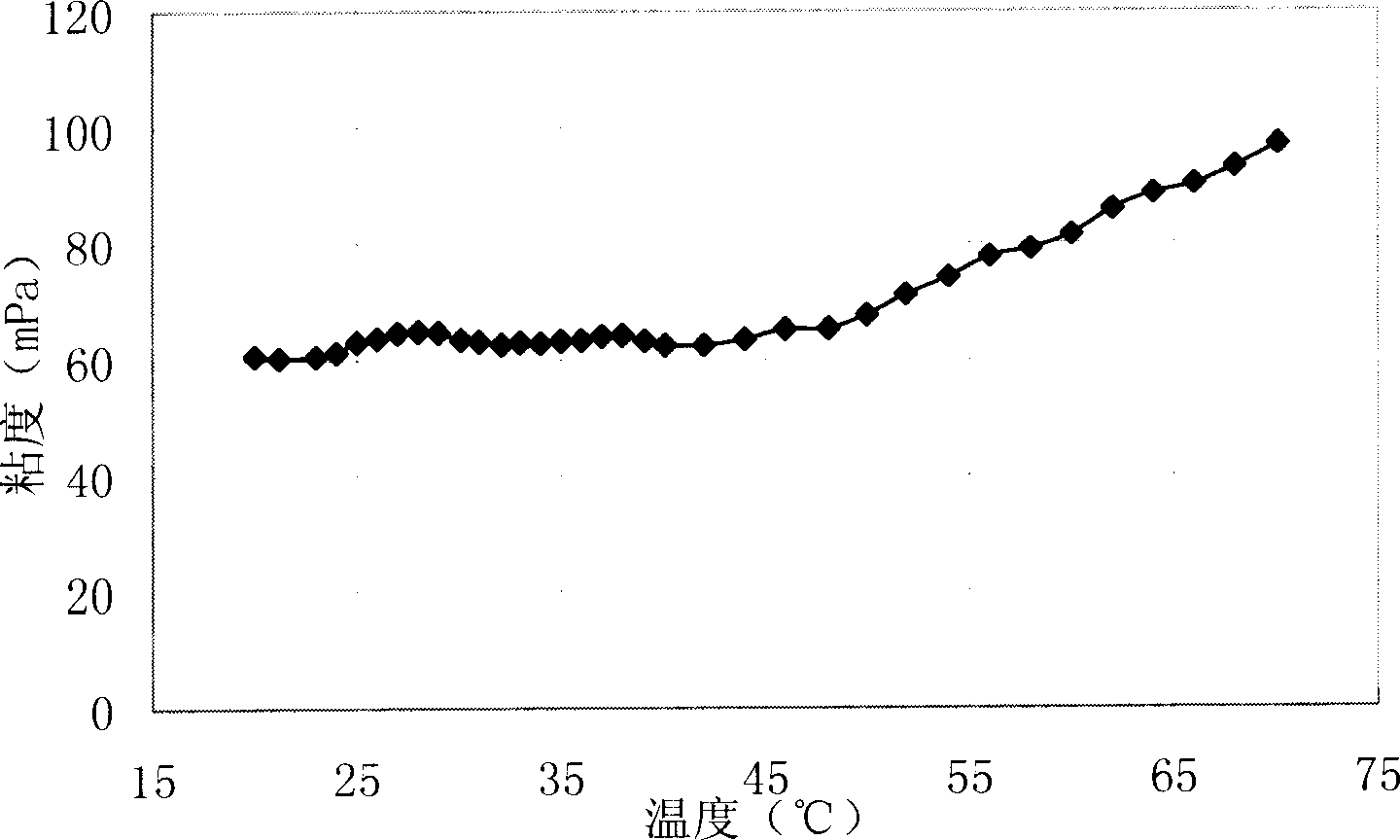

Novel crude oil drag reduction and viscosity reducing agent

The invention provides a formula used for oil field heavy oil exploitation and crude oil transportation, which can reduce the viscosity of crude oil and at the same time reduce the adhesion of crude oil on the pipe wall and formation surface. It contains carboxylated polyether, sodium carbonate, sodium alkylsulfonate and PF-C. The carboxylated polyether includes an organic initiator with active hydrogen to initiate the generation of polyoxypropylene polyoxyethylene ether block copolymer; or an organic initiator with active hydrogen to initiate the addition of copolymerized polyethylene oxide to generate polyoxyethylene vinyl ether. After adding a certain amount of the drag and viscosity reducing agent in oil wells or in crude oil pipelines, not only can the viscosity of crude oil be greatly reduced. And the adhesive force on the negative interface (including steel pipe, cement, silicate, etc.) becomes smaller, so that the resistance of crude oil in the process of exploitation and transportation is greatly reduced, and it is non-toxic, harmless and easy to use.

Owner:JIANGSU MAYSTA CHEM

Tantalum target material and treatment method of sputtering surface of tantalum target material

PendingCN112828541AQuality improvementAvoid sandingVacuum evaporation coatingSputtering coatingSurface roughnessMachining process

The invention provides a tantalum target material and a treatment method of a sputtering surface of the tantalum target material. The treatment method comprises turning and polishing which are carried out in sequence; in the turning process, a blade is adopted to feed from the edge to the center in the diameter direction of the tantalum target material, the turning comprises rough turning and finish turning which are carried out in sequence, the cutting depth is kept constant in the rough turning process and the finish turning process, the finish turning comprises 8 to 12 times of the turning, and the allowance of the finish turning is 0.3 to 0.6 mm; in the polishing process, abrasive paper is adopted firstly, then a scouring pad is adopted for polishing the turning surface of the tantalum target material, and the sputtering surface roughness Ra of the tantalum target material is less than or equal to 0.4 [mu]m. According to the treatment method, surface defects such as protrusions and pits on the surface of the target material in the machining process and a turning extrusion layer are effectively prevented, meanwhile, grinding wheel polishing in a later period is avoided, the quality of the target material is improved, and the service life is prolonged.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

High-bending-strength quartz-based expendable pattern paint modified by mica powder and preparation method of high-bending-strength quartz-based expendable pattern paint

InactiveCN105855460AImprove dispersion stabilityEvenly dispersedFoundry mouldsFoundry coresCarbon nanotubePolytetrafluoroethylene

The invention discloses high-bending-strength quartz-based expendable pattern paint modified by mica powder. The high-bending-strength quartz-based expendable pattern paint is prepared from the following raw materials in parts by weight: 100-102 parts of quartz powder, 0.9-1.1 parts of modified starch, 0.9-1.1 parts of carboxymethyl cellulose, 2.4-2.6 parts of sodium bentonite, 0.9-1 part of mica powder, 0.8-0.9 part of tetrapod ZnO whiskers, 0.9-1.1 parts of silicasol, 10-13 parts of ethanol, an appropriate amount of water, 0.8-1 part of carbon nanotubes, 2.3-2.5 parts of bauxite and 0.2-0.3 part of nanometer polytetrafluoroethylene. The carbon nanotubes and the nanometer polytetrafluoroethylene are used for modifying the bauxite, so that the smoothness of the bauxite is improved, the bauxite can be uniformly dispersed in the paint, and the heat resistance and the compactability of the paint are improved; hollow structures in the carbon nanotubes can also enable the air permeability to be improved, and the hardness and the bending strength of the paint after being dried are improved.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

Pipe wall bonding and molding method of air-inflation stretching arm

The invention discloses a pipe wall bonding and molding method of an air-inflation stretching arm, relating to the pipe wall bonding and molding method and aiming to solve the problem that the traditional common planar worktable can not be used for bonding arc-shaped reinforcing strips and planar hook and loop fasteners at the same time. The pipe wall bonding and molding method comprises the steps of: 1, grinding a laminated aluminum thin-film hasp bonding area, a pipe-molding bonding area A, a reinforcing strip bonding area and a pipe-molding bonding area B, and cleaning with acetone; 2, coating an adhesive, standing at room temperature for 30 min, bonding nylon hasps firstly and then bonding the reinforcing strips; and (3) increasing pressure in a cylindrical thin-film air bag to 20kPa, coating a laminated aluminum thin film on the air bag, winding bandages uniformly, increasing the pressure to 50kPa, standing at room temperature for 96h, reducing the pressure, removing bandages to complete the bonding and molding of the pipe wall. According to the invention, the average peel strength between the hook and loop fastener and the pipe wall of the air-inflation stretching arm is 0.25KN / m and is in increased by two times compared with that of the traditional bonding process. The pipe wall bonding and molding method is applied to the field of pipe walls of the air-inflation stretching arms.

Owner:HARBIN INST OF TECH

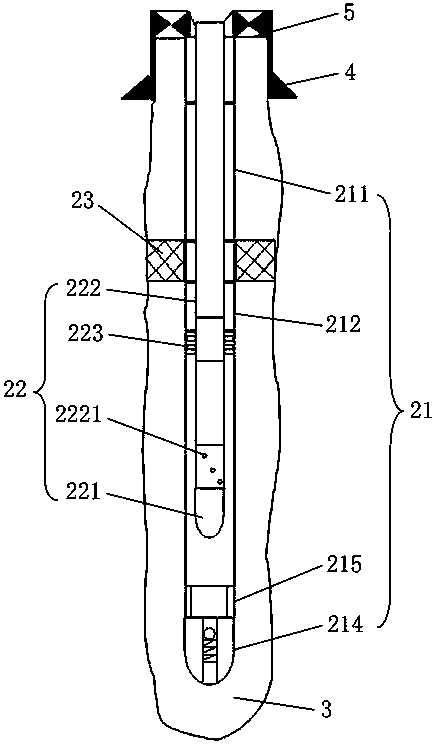

Open hole oil production technology and separated pipe string

ActiveCN103573229AMeasures to facilitate optionalityReduce workover costsFluid removalProduction stringOil production

Disclosed are an open hole oil production technology and a separated pipe string. The open hole oil production technology comprises the steps of drilling the reservoir well section; descending the separated pipe string; replacing the well completion fluid; taking the gel breaking or increase production measure; descending a production pipe string; performing well clearing and production. The separated pipe string is connected with the lower end of the production pipe string for open hole oil production and comprises an outer pipe string, an inner pipe string and an external packer; the outer pipe string comprises a screen pipe, a segmented sealing cylinder and a float shoe which are sequentially connected from top to bottom; the upper end of the screen pipe is connected with the lower end of the production pipe string through a top packer; the inner pipe string is arranged in the inner chamber of the outer pipe string; the top of the inner pipe string is connected with the top packer; the bottom of the inner pipe string is provided with a plug; a pipe body of the inner pipe string comprises at least two replaceable center pipes which are connected with each other; the pipe wall of at least one of the two center pipes is provided with a hole; segmented seals are arranged between the pipe walls of the center pipes and the pipe wall of the screen pipe; the external packer sleeves the outer wall of the screen pipe; the outer lateral side of the external packer abuts against the side wall of an open hole.

Owner:CHINA NAT OFFSHORE OIL CORP +1

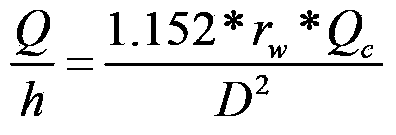

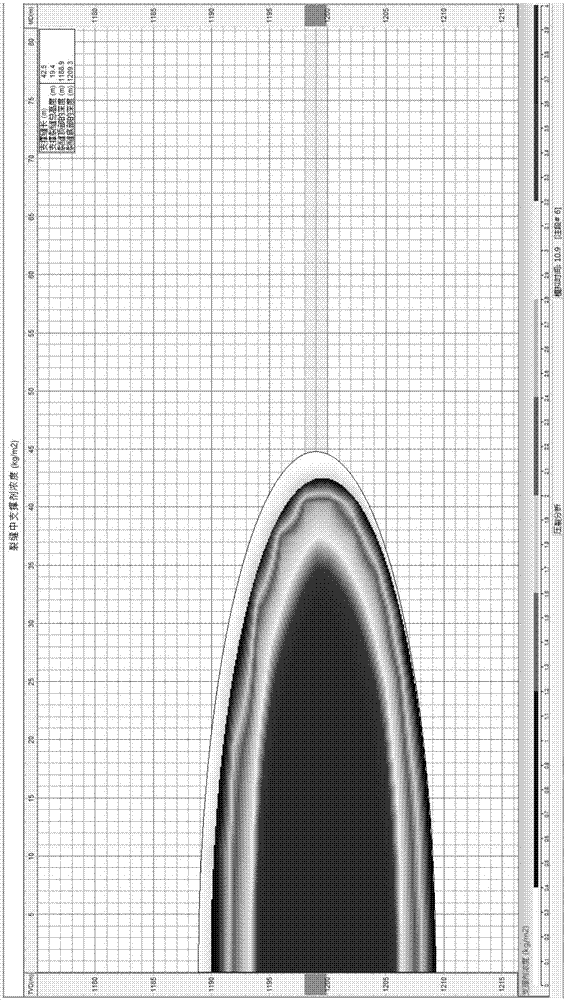

Blockage-removing method for polymer flooding blocking wells

ActiveCN106958438AReduce the impactImprove diversion capacityFluid removalDrilling compositionOil wellPolymer flooding

The invention relates to a blockage-removing method for polymer flooding blocking wells, and belongs to the field of fracturing reformation of oil wells. The blockage-removing method includes the steps of conducting fracturing construction to an blocked oil layer caused by polymer injection and controlling the length of an artificial fracture to 40-60 m, and the height to no more than 20 m, specifically, the fracturing construction is small-scale fracturing construction by sequentially injecting stratum treating fluid with a volume of 10-35 m3, injecting ahead fluid with a volume of 10-30m3, injecting particle loaded fluid with a volume of 40-60 m3, and injecting displacing fluid with a volume of 8-16m3. By reasonable selection of the polymer flooding to block wells, the pertinency and effectiveness of subsequent fracturing measure reformation are improved; by control of the length and the height of the artificial fracture, not only the permeability of a polymer blocked oil layer in near bore zones and effectiveness of the measures are improved, but also wastes of materials and labor cost caused by an excessive large construction scale are avoided, the validity of fracturing blockage-removing measures is increasingly prolonged, and the reservoir recovery is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Construction method for mounting layer-divided sinking apparatus in deep compressible soil layer

ActiveCN106049397AExpand the scope of usePrevent subsidenceIn situ soil foundationDistortionObservation data

The present invention discloses a construction method for mounting a layer-divided sinking apparatus in a deep compressible soil layer. The construction method comprises the following steps: 1) carrying out pre-boring of a borehole and burying a protection casing; 2) carrying out slip casting to a lower segment of the borehole to form the lower segment into a short pile reinforced body; 3) pulling up the protection casing after completing the slip casting and mounting a layer-divided sinking apparatus in the borehole where the short pile reinforced body is formed; 4) after complete mounting, correcting the reading of the layer-divided sinking apparatus, and starting filling construction and observation three days later. The construction method provided by the present invention overcomes the limitation that a layer-divided sinking apparatus must be placed on shallow bedrock at present, and allows mounting of a layer-divided sinking apparatus in a deep medium compressible or low compressible soil layer; the construction method is capable of solving the problem of distortion of an observation result of the layer-divided sinking apparatus caused by additional settlement due to dead weight of the apparatus; thus, real and efficient observation data can also be obtained when the layer-divided sinking apparatus is used in the deep medium compressible or low compressible soil layer.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Profile control and sand fixing integrated technology for heat oil production well

InactiveCN1587638ABlocking to prevent steam channelingIntegration of sand consolidationSealing/packingSection planeActive agent

The invention relates to a kind of integrated technology of profile control and fixing sand in the thermal production well. The invention has adopted proportionate mixture of the blast furnace water garrulous slay (BFS), activator, expanding agent, outer active agent, and dispersed packing, then mix them evenly with mixer thruogh mixing, crushing, finally screen to form to profile control sand-proof agent. Mix with clear water to form 30%-50% floating distributed system when applying, then inject it into the stratum to form integrated technology of profile control and fixing sand in the thermal production well. It is mainly used in the mining of compacted oil gas injection well. It can effectively control the surfacing of thermal production well, adjust gas-absorbing section, plug vapor and water fleeing, meanwhile prevent the oil well from producing sands. It has realized the integration of adjusting plug in high temperature and fixing sands, and solved the contradiction between adjusting plug and helping discharge when the two constructed separately, thus save the costs of the measures.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

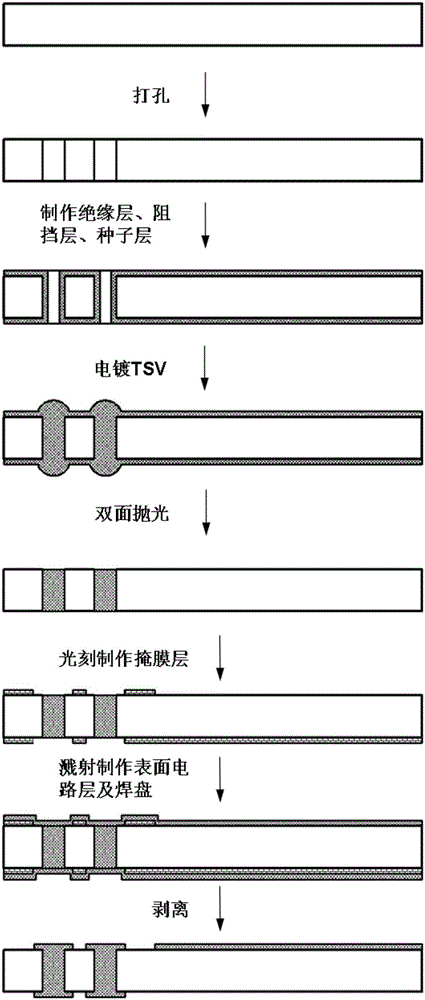

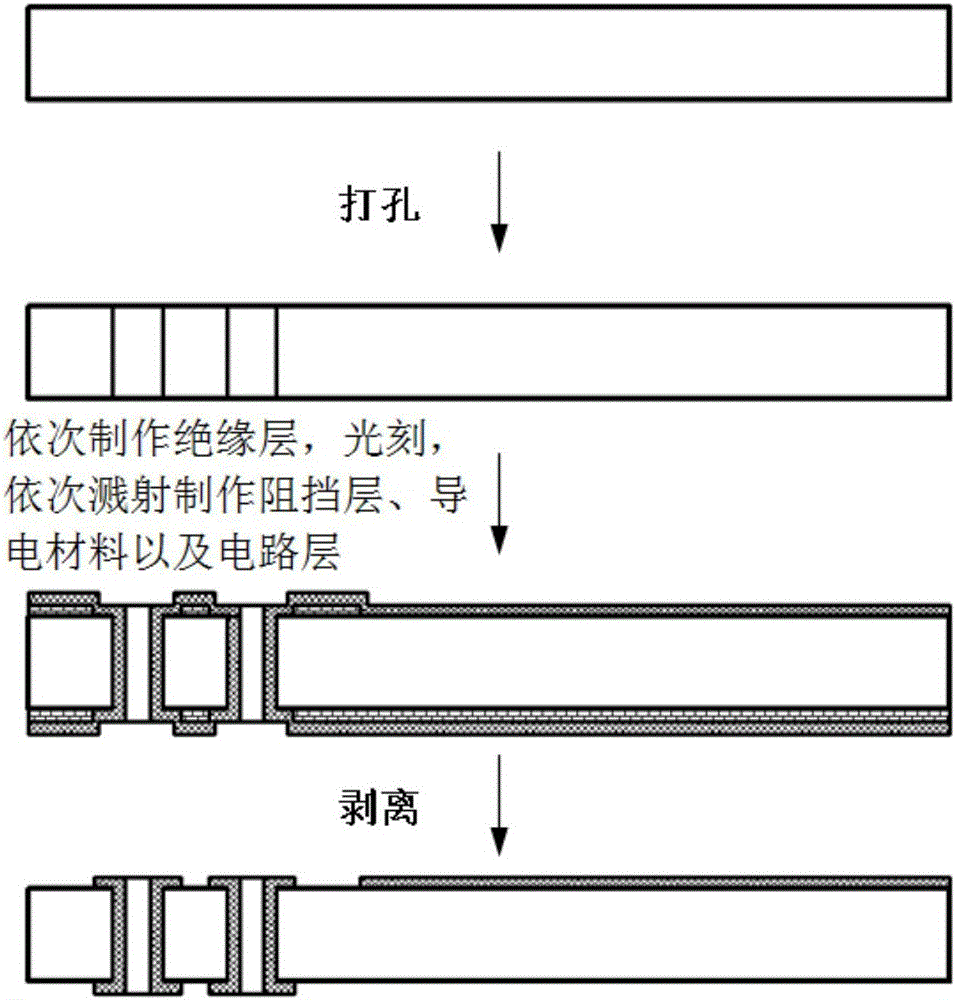

Semiconductor substrate, three-dimensional package chip and through-silicon via packaging method

InactiveCN106711095AAvoid deformationExtend your lifeSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

The invention discloses a semiconductor substrate, a three-dimensional package chip and a through-silicon via packaging method. The semiconductor substrate has a through-silicon via running through the semiconductor substrate; the internal surface of the through-silicon via is circumferentially deposited by a conductive material, the thickness of which is smaller than 2 mum; the volume fraction of the conductive material in the through-silicon via is 5 vol.%-95 vol.%; and the center of the through-silicon via has a gap running through the through-silicon via. Only the internal surface of the through-silicon via is circumferentially deposited by the conductive material, and the center of the through-silicon via in the semiconductor substrate still has a certain gap, so that the prepared three-dimensional package chip does not deform easily under hot and cold environment, yield is improved, and the service life of the three-dimensional package chip is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

Handicraft picture reinforcing agent and handicraft picture reinforcing method

InactiveCN106398488AShort curing timeMild curing reactionSpecial ornamental structuresPolyester coatingsTectorial membraneMoisture resistance

The present invention discloses a handicraft picture reinforcing agent and a handicraft picture reinforcing method. The handicraft picture reinforcing method comprises: S1, weighing 94-98% by mass of a transparent resin, 1-3% by mass of a curing agent and 1-3% by mass of an accelerator; S2, adding the weighed transparent resin to a magnetic stirring device while sequentially adding the accelerator and the curing agent, and stirring for 10-30 min at a temperature of 25 DEG C to obtain a reinforcing agent; S3, uniformly coating the reinforcing agent prepared in the step S2 onto a handicraft picture, and covering with a protection film; and S4, drying the handicraft picture treated in the step S3, and removing the protection film. According to the present invention, the reinforcing agent has characteristics of short curing time and mild reaction; the reinforcing agent is uniformly coated on the handicraft picture to form the resin protection layer, such that the sand-stone on the handicraft picture can be adhered while the effects of water resistance and moisture resistance can be provided; and after the reinforcing method is performed on the handicraft picture being subjected to the treatments such as wire inlay and enamel filling, the obtained handicraft picture forms the flat plane, the burnish process and the polishing process are avoided, the steps of the process are reduced, and the manpower and the cost are saved.

Owner:刘飞

Horizontal well fracturing device, horizontal well fracturing system and operation method of horizontal well fracturing system

InactiveCN107630690AImprove the transformation effectControl the position of the punch holeFluid removalMaterial PerforationPetroleum engineering

The invention provides a horizontal well fracturing device, a horizontal well fracturing system and an operation method of the horizontal well fracturing system. The operation method of the horizontalwell fracturing system comprises the steps that S50, liquid is injected into an oil pipe to increase the pressure in the oil pipe, and in the process that the liquid is injected into the oil pipe, when the pressure in the oil pipe rises to the locking pressure, a multistage and multi-cluster spray gun assembly of the horizontal well fracturing device is switched from the rotation state to the locked state in the axial direction of the multistage and multi-cluster gun assembly. The problems that in the prior art, during perforation operation of a horizontal well fracturing system, the sprayingdirection of a horizontal well fracturing device cannot be effectively controlled, thus sand out of a stratum enters an annulus, and operation of the horizontal well fracturing device is complex aresolved.

Owner:PETROCHINA CO LTD

Quick repairing material of airfield pavement and road, and preparation method and construction method of quick repairing material

PendingCN109384418AExcellent mix ratioGuarantee the construction qualityIn situ pavingsTemporary pavingsSodium BentoniteCrack resistance

The invention provides a quick repairing material of an airfield pavement and a road, and a preparation method and a construction method of the quick repairing material. The quick repairing material comprises the following ingredients in parts by weight: 30-35 parts of polymethyl methacrylate resin, 10-15 parts of calcium carbonate, 5-10 parts of bentonite, 1-5 parts of nano silicon oxide, 10-20 parts of quartz sand, 2-5 parts of inorganic pigment, 0.5-1 part of an anti-settling agent, 0.5-1 part of a thickening agent, 5-10 parts of bauxite and 5-10 parts of carborundum. The material takes thepolymethyl methacrylate resin, the bauxite, the bentonite, the thickening agent, the anti-settling agent, the quartz sand and the carborundum as main materials, has excellent performance of fast curing within 1h at -30 DEG C, ultra-high cohesion, excellent crack resistance, acid resistance, alkali resistance and chemical resistance; emission of VOCs (volatile organic compounds), heavy metals andthe like is lower; the environmental pollution is reduced; the problems of defects such as cracks, dusting and damage of a maintenance surface are avoided; and the traffic efficiency of the road is greatly improved.

Owner:TIANJIN BAISITE NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com