Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Increase active site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

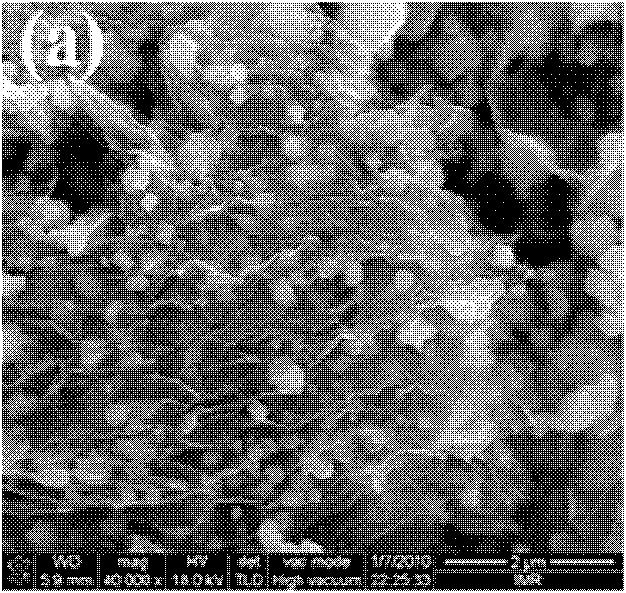

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Selective catalytic reducing NOx catalyst based on MnOx/TiO2 system at low-temperature and production thereof

InactiveCN1817448AAchieve removalIncreased dispersionDispersed particle separationCatalyst activation/preparationAlcoholProton

A catalyst based on MnOx / TiO2 system for low-temp selective catalytic reduction of NOx is proportionally prepared from alkoxy compound of Ti, alcohol solvent, water, protonic acid, soluble salt of Mn and the soluble salt of transition element through proportional mixing, stirring until sol becomes gel, drying, grinding and high-temp calcining.

Owner:ZHEJIANG UNIV

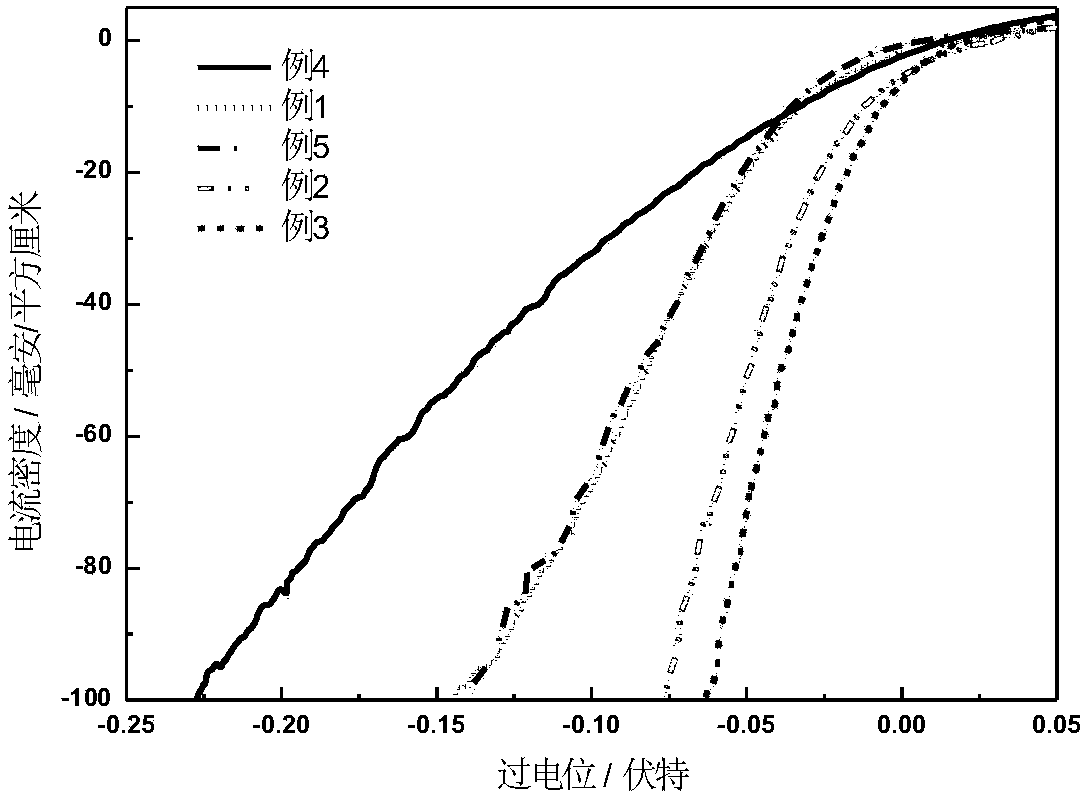

Hydrogen evolution electrode, preparation method and applications thereof

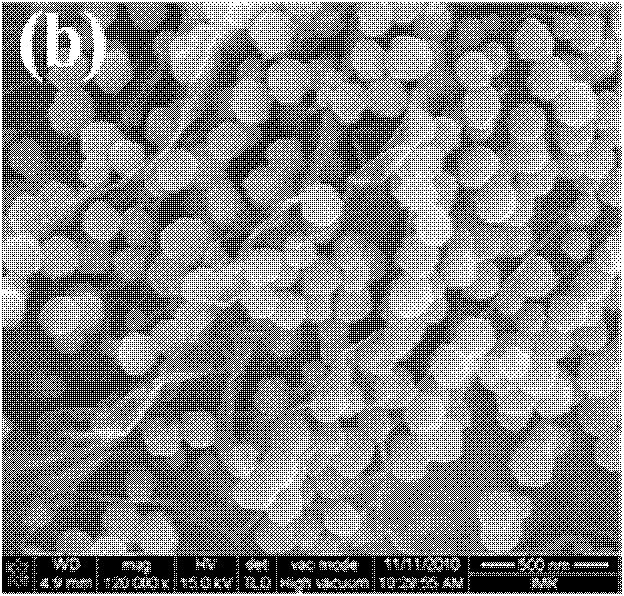

ActiveCN108172850ALarge specific surface areaIncrease active siteCell electrodesImmersion cellsAlloyCobalt

The invention relates to a hydrogen evolution electrode, a preparation method and applications thereof. The preparation method specifically comprises: washing a foam metal foam nickel as a substrate,and electrochemically depositing a layer of a granular alloy containing one or more than two selected from nickel, cobalt and molybdenum on the surface; carrying out room temperature aging in a solution containing chlorine ions to from a layer of a nano-sheet-like hydroxide with a nano-scale thickness on the surface of the electroplating layer, wherein the hydroxide is corresponding to the electrodeposition metal; and electrochemically depositing trace platinum, and continuously carrying out room temperature aging to increase the thickness of the hydroxide so as to obtain the hydrogen evolution electrode with the multi-level pore channel structure. According to the present invention, the prepared hydrogen evolution cathode has the low platinum loading, has the excellent hydrogen evolutionmass specific activity at the platinum loading of lower than 10 [mu]g / cm<2>, and has good stability in the application of magnesium-water batteries.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

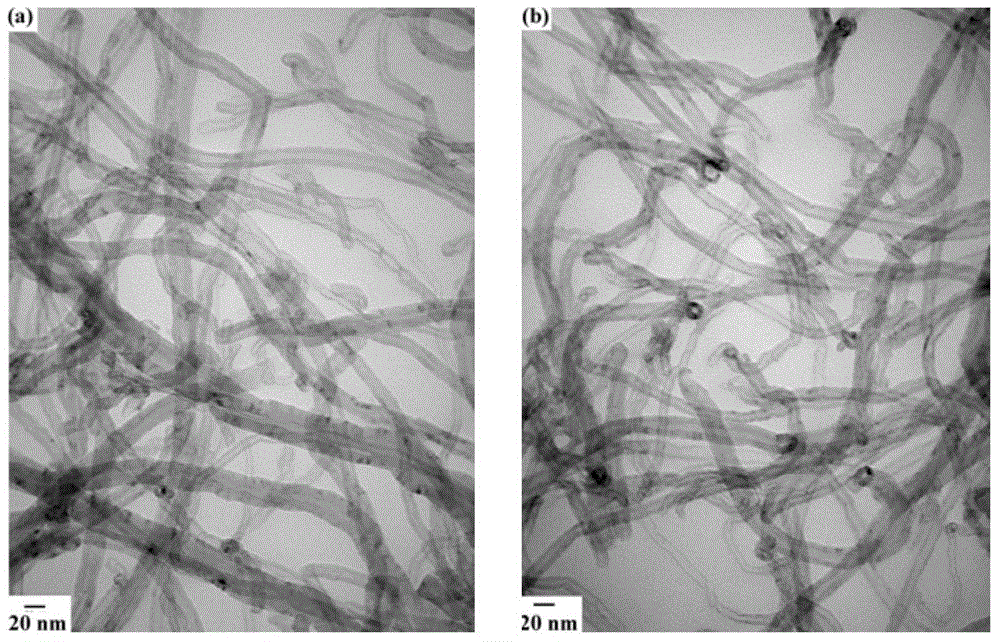

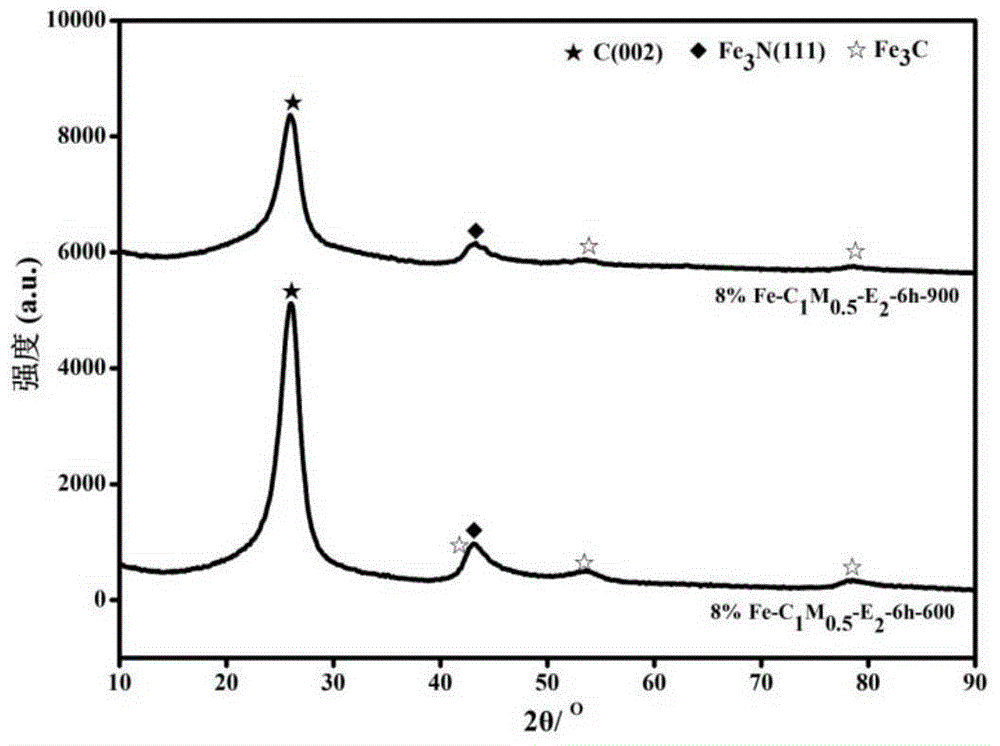

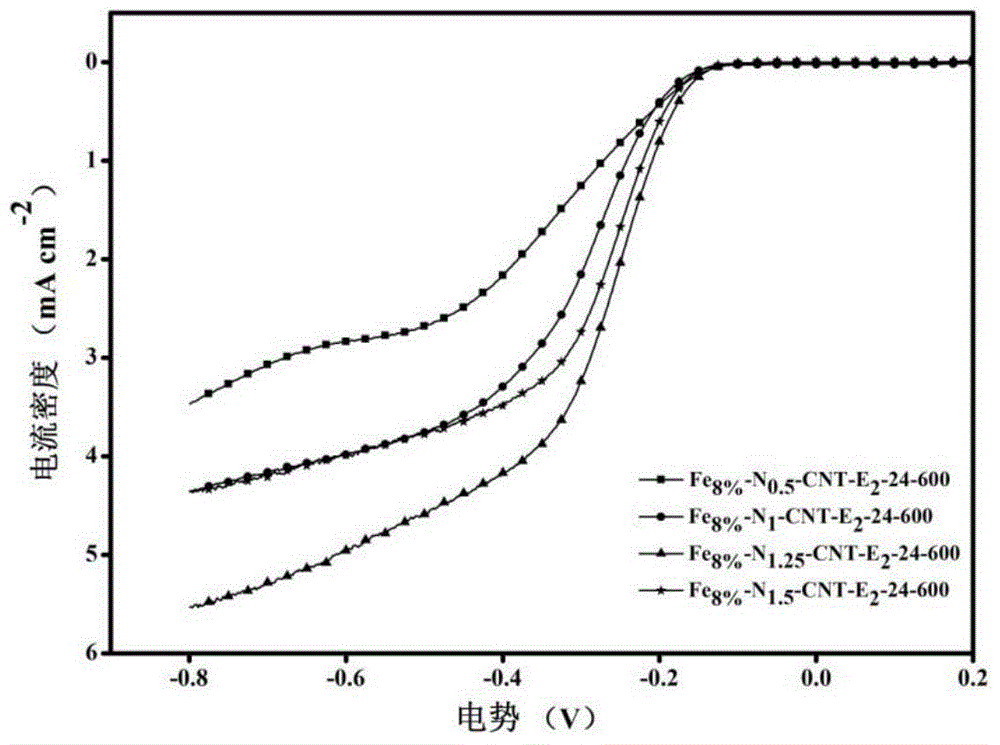

Preparation method for graphene-coated metal nanometer particle catalyst and application of graphene-coated metal nanometer particle catalyst

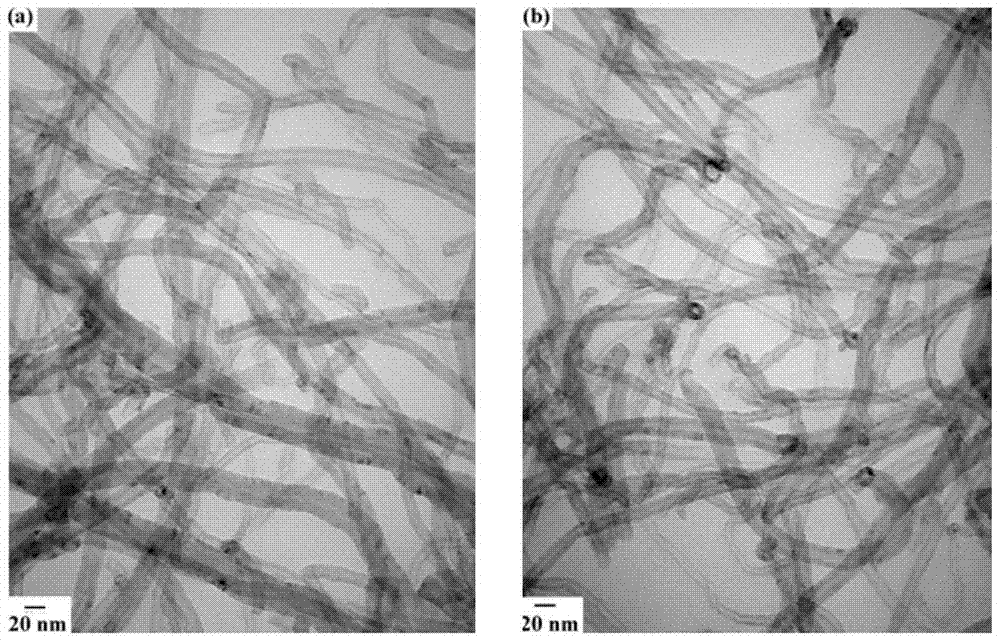

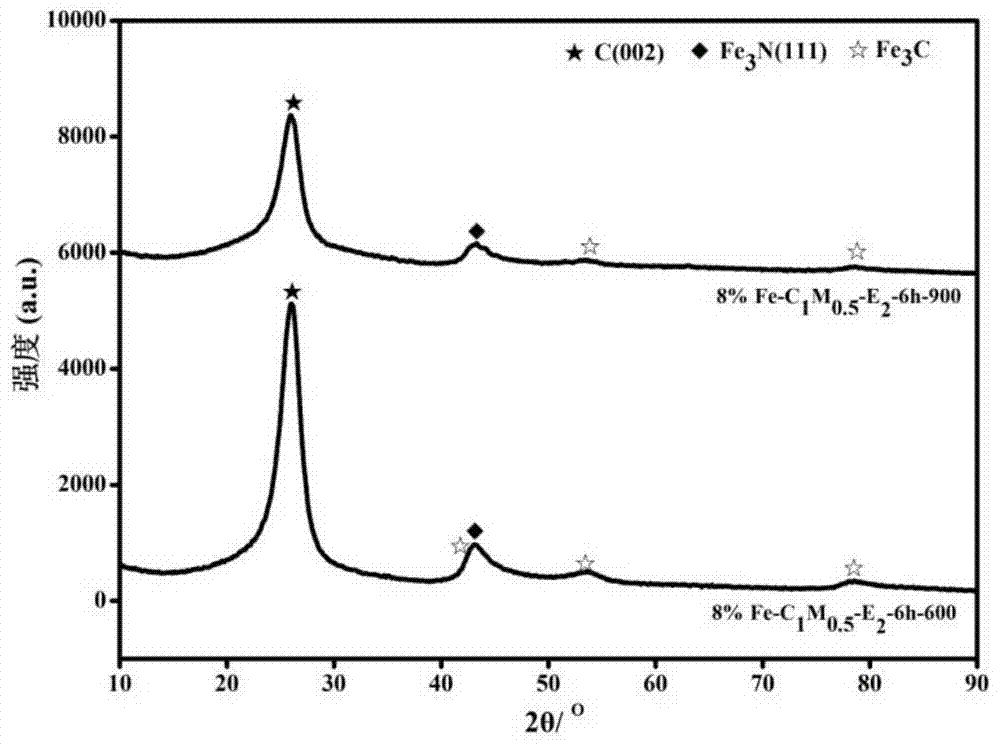

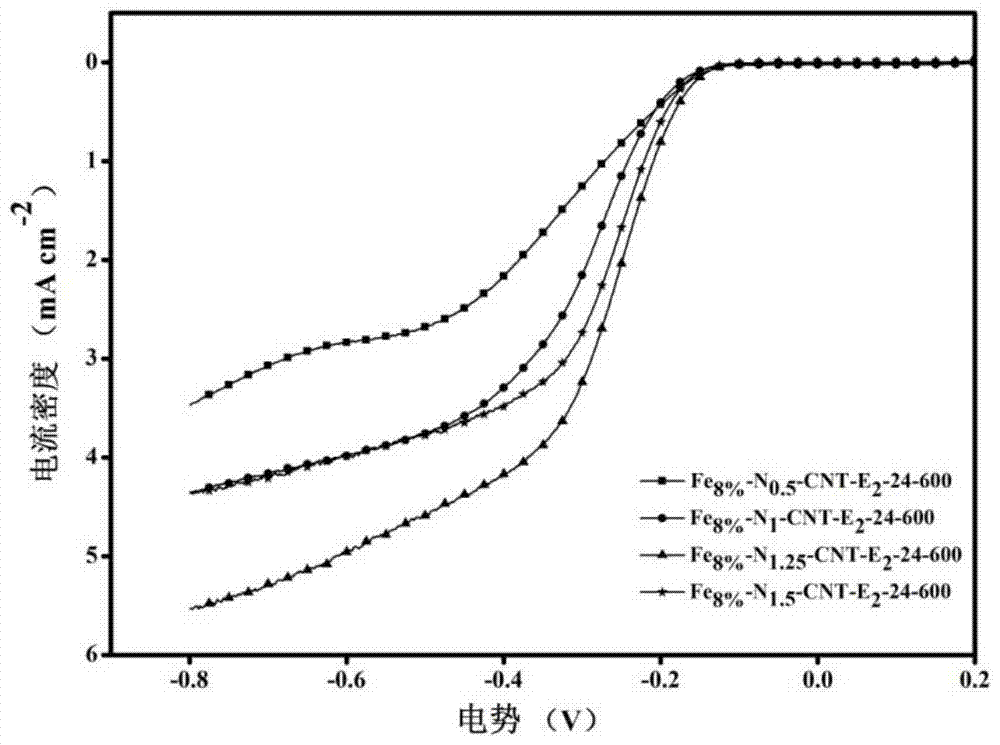

InactiveCN104923204ALarge specific surface areaImprove conductivityMaterial nanotechnologyPhysical/chemical process catalystsCarbon nanotubeMethanol

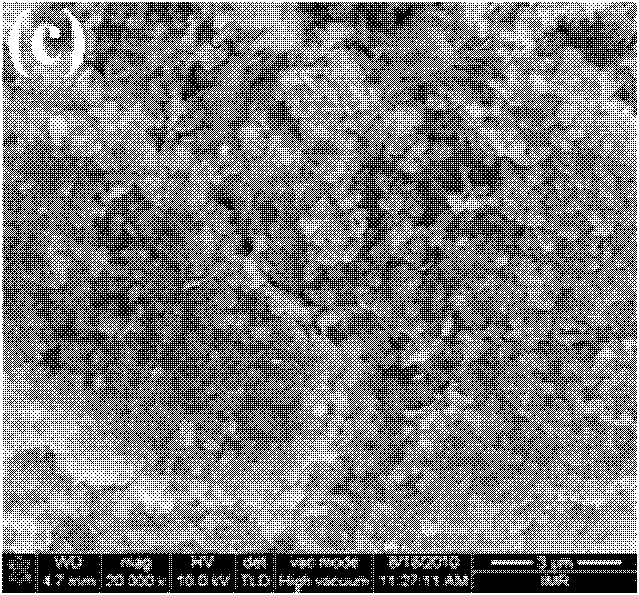

The invention relates to a preparation method for a graphene-coated iron-loaded and nitrogen-loaded active site catalyst on a carbon nano tube (CNT); sources of raw materials used for the method are extensive; carbon source and nitrogen source materials are low in cost; the sample yield is high; the production cost of a fuel cell is helped to be reduced; the content of Fe and N in the prepared catalyst is controllable, and meanwhile, bigger specific surface area is kept so as to overcome the problem that metal nanometer particles are easy to aggregate in the past. The preparation method comprises the following steps: (1) supporting Fe and N to the surface of the carbon nano tube to obtain Fe-N-CNT; (2) synthetizing a composite material, formed by coating the surface of the Fe-N-CNT with graphene precursors, by a hydrothermal method; (3) calcining the composite material to obtain Fe-N-CNT&GN. Compared with a traditional fuel cell cathode Pt / C catalyst, the catalyst prepared by the method disclosed by the invention is low in cost, relatively higher in catalytic activity, high in stability, high in methanol tolerance, and has a good commercial application prospect.

Owner:DALIAN UNIV OF TECH

Preparation method of siliceous mesocellular foams (MCFs) loaded nano Ni2P hydrogenation catalyst

InactiveCN104383948AAvoid cloggingFacilitated DiffusionCatalyst carriersDispersityHydrogenation reaction

The invention relates to a preparation method of a siliceous mesocellular foams (MCFs) loaded nano Ni2P hydrogenation catalyst. The catalyst is prepared by a complexation dipping mode and a hypophosphite low-temperature thermal decomposition method by selecting siliceous mesocellular foams with a three-dimensional oversized mesocellular structure and relatively high thermal stability as carriers. According to the preparation method, a complexing agent is introduced for highly dispersing nickel ions, and the complexed nickel ions can enter relatively large ducts of the MCFs, thereby preparing Ni2P nano particles with high dispersity. The catalyst is used for hydrogenation reaction of nitrobenzene, and shows very high catalytic activity and favorable reusability; the catalyst adopts a simple preparation process and mild conditions, and can achieve industrial production easily.

Owner:CHANGZHOU UNIV

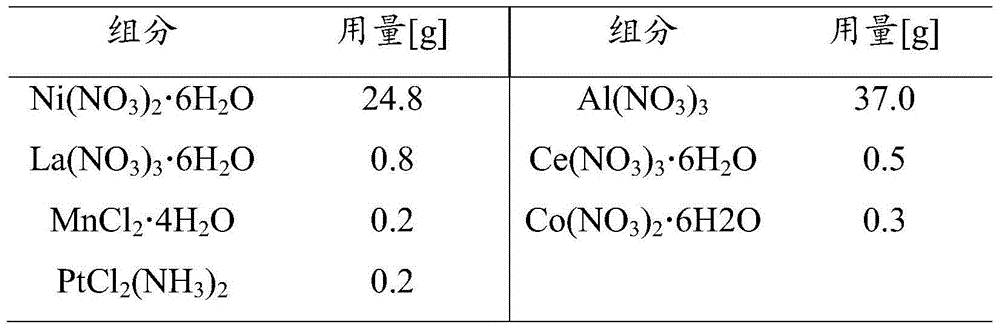

High-temperature-resistant methanation catalyst as well as preparation method thereof

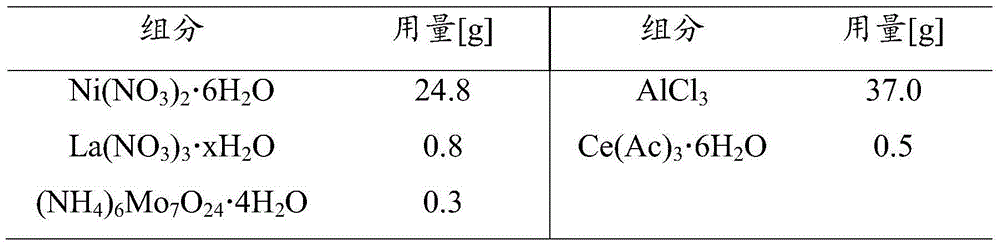

ActiveCN104399491AIncrease active siteLarge specific surface areaHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIncipient wetness impregnationOxide

The invention discloses a high-temperature-resistant methanation catalyst as well as a preparation method thereof. According to the catalyst, Al2O3 is used as a carrier, Ni is used as a primary active component, La and Ce are used as secondary components, and metallic oxides of Mn, Co, Fe, W or Mg are used as other active auxiliaries; the preparation method of the catalyst comprises the following steps: carrying out ultrasonic dispersion and coprecipitation on the primary active component Ni and a PEG (polyethylene glycol)-aqueous solution of a carrier precursor, and separating, drying and roasting to obtain a NiO-Al2O3 catalyst; then, loading the secondary components La and Ce and precursors of the active auxiliaries to the NiO-Al2O3 catalyst by adopting an incipient-wetness impregnation method; finally, roasting and carrying out reduction activation to obtain the high-temperature-resistant methanation catalyst; the catalyst has high specific surface area, and can reduce carbon deposition reaction and improve the selectivity of methane. The high-temperature-resistant methanation catalyst can maintain relatively high methanation catalytic activity for a long time at high temperatures and can be widely applied to a methanation process under a high-temperature environment.

Owner:广东省瀚思尔科技有限公司

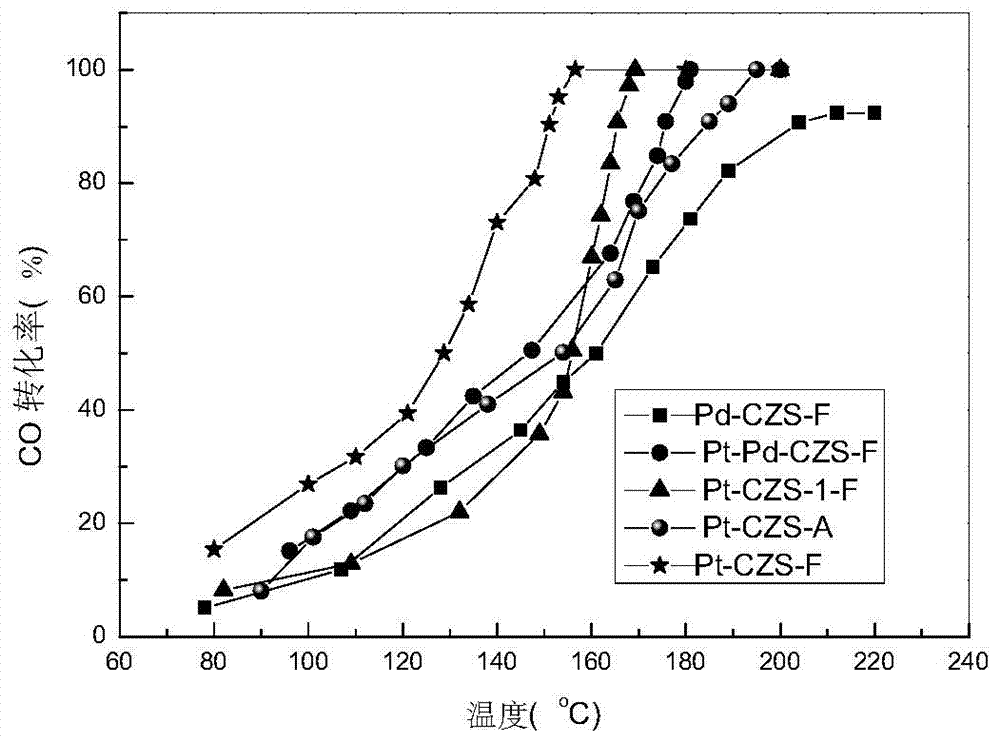

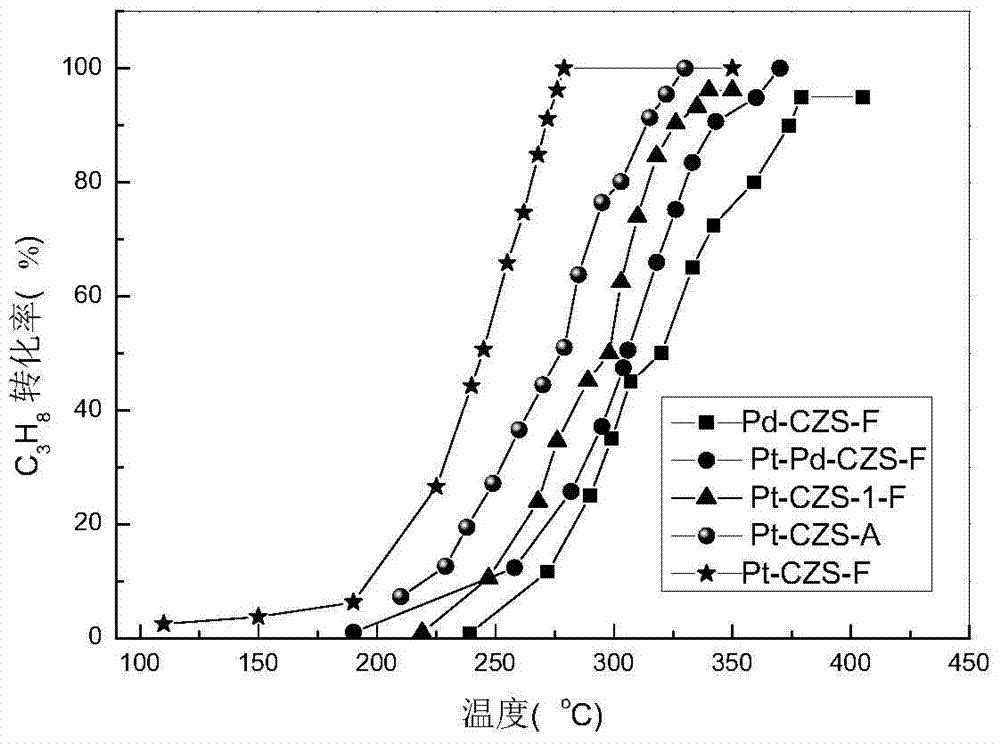

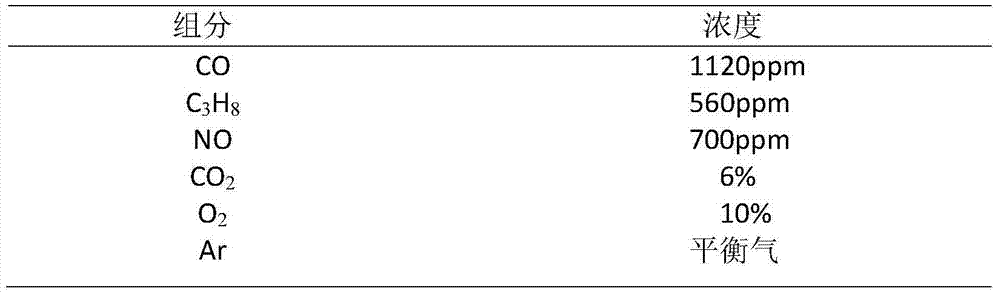

Preparation and application of oxidation catalyst taking cerium-zirconium-silicon composite oxide as carrier

InactiveCN104226309ALarge specific surface areaModerate pore sizeCatalyst carriersDispersed particle separationCeriumComposite oxide

The invention provides a preparation method of an oxidation catalyst taking a cerium-zirconium-silicon composite oxide as a carrier and application of the oxidation catalyst to the automotive vehicle emitted tail gas, and belongs to the technical field of automotive vehicle tail gas oxidation, catalysis and purification. The oxidation catalyst taking the cerium-zirconium-silicon composite oxide as the carrier is prepared by taking FeCrAl metal honeycomb or cordierite ceramic honeycomb as a matrix, taking a cerium-zirconium-silicon composite oxide as a coating and taking precious metal Pt and / or Pd as active substances. The carrier material of the prepared cerium-zirconium-silicon composite oxide is large in specific surface area, relatively large in pore volume and moderate in pore diameter, and is beneficial for increasing the active sites. For the hydrocarbon and the carbon monoxide in the automotive vehicle emitted tail gas, the prepared oxidation catalyst taking the cerium-zirconium-silicon composite oxide as the carrier has good oxidation catalytic activity, high conversion rate and low ignition temperature. At the same time, the preparation method is simple and suitable for industrial application.

Owner:广州市威格林环保科技有限公司

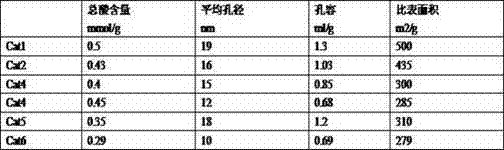

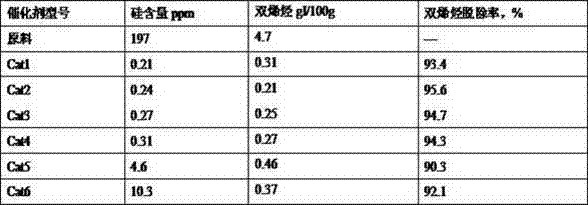

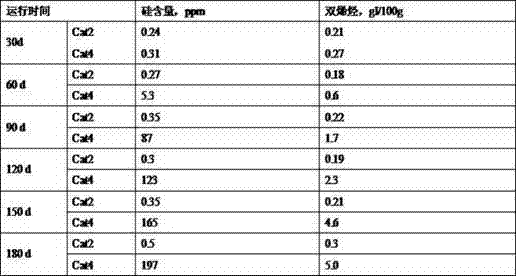

Coked gasoline desilication catalyst and preparation method thereof

ActiveCN104492450AEfficient removalLarge hole volumeOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsHydrogenActive component

The invention discloses a coked gasoline desilication catalyst and a preparation method thereof. The coked gasoline desilication catalyst disclosed by the invention contains an Al2O3-TiO2-B2O3 composite oxide as a carrier and Ni-Mo-W-Ce as an active component; the used Al2O3-TiO2-B2O3 carrier comprises the following components in percentage by weight: 10-20% of TiO2, 3-10% of B2O3, and the balance of Al2O3; and, in terms of the weight percentage of the catalyst, the active component comprises the following components in percentage by weight: 1.2-3.9% of NiO, 4.2-9.5% of MoO3, 5-15% of WO3, 1.5-2.5% of CeO2, and the balance of the carrier. The coked gasoline desilication catalyst disclosed by the invention is roasted in the atmosphere of water vapor, has a special pore diameter and higher pore volume, and is capable of effectively adsorbing and desorbing silicon impurities and protecting subsequent purification of the catalyst by mainly adding hydrogen into coked gasoline.

Owner:WUHAN KELIN FINE CHEM

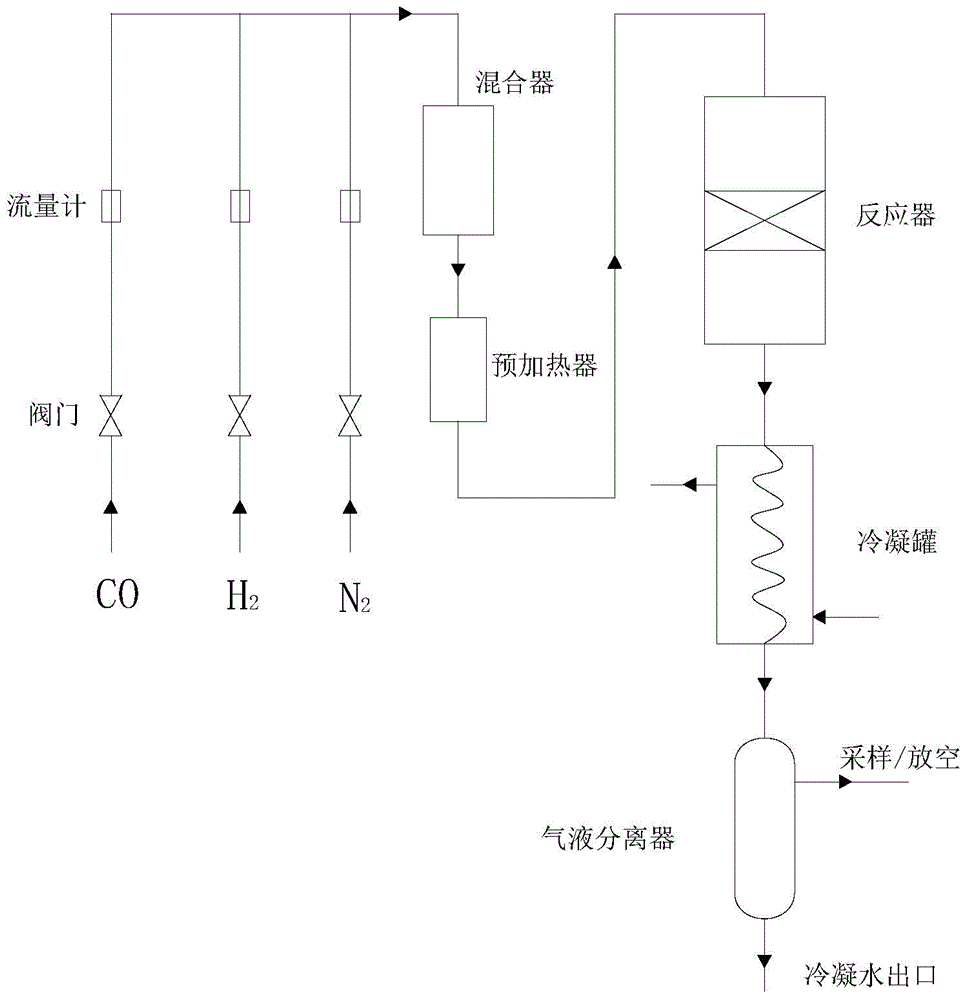

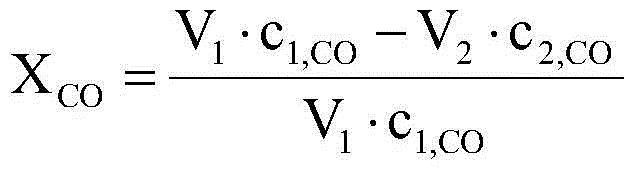

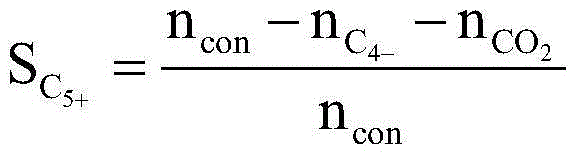

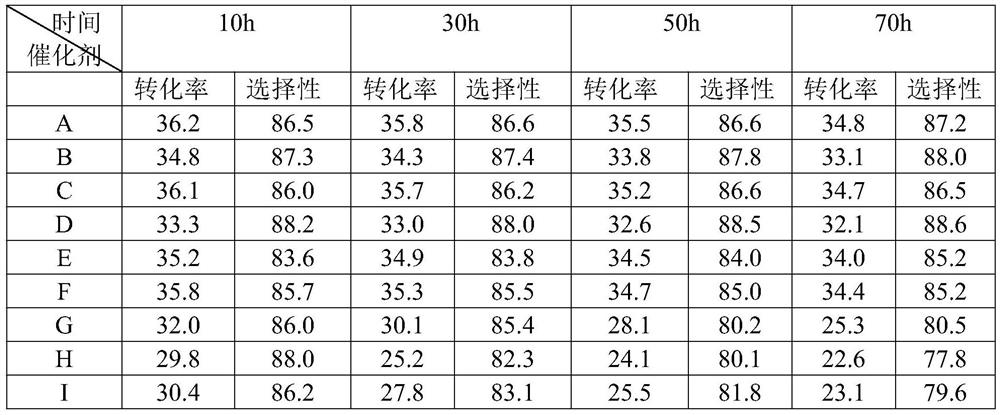

Fischer-Tropsch synthesis method

ActiveCN105087042AOvercoming the disadvantage of low selectivityHigh selectivityLiquid hydrocarbon mixture productionAlkaneSynthesis methods

The present invention provides a Fischer-Tropsch synthesis method. The method comprises: under Fischer-Tropsch synthesis conditions and in the presence of a Fischer-Tropsch synthesis catalyst, reacting synthesis gas in a supercritical medium. The supercritical medium is at least one medium selected from C3-C10 alkane, C3-C10 olefin, C6-C10 aromatic hydrocarbon and light oil produced by Fischer-Tropsch synthesis. By using the Fischer-Tropsch synthesis method provided by the present invention, a higher conversion rate of CO and higher C5+ selectivity can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

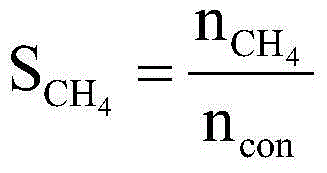

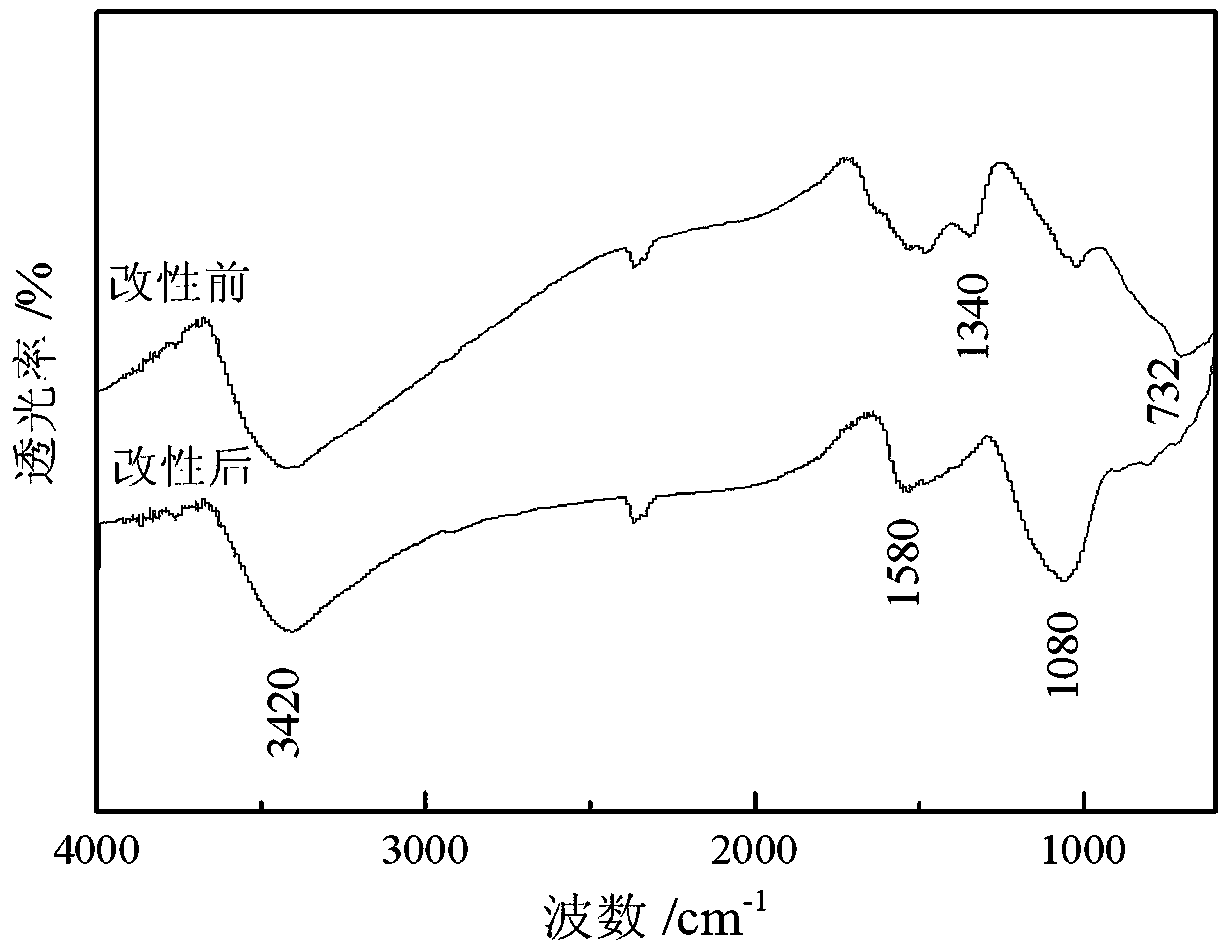

Removal method for dissolved oxygen in recycled water

InactiveCN109110852AEfficient removalEvenly dispersedWater contaminantsWater/sewage treatment by degassingActivated carbonFiber

The invention discloses a removal method for dissolved oxygen in recycled water. The removal method comprises the following steps: enabling the recycled water with dissolved carbohydrazide to pass through a reactor filled with a combined modified activated carbon fiber catalyst; catalyzing carbohydrazide reduction at the low temperature of 40 to 50 DEG C to remove the dissolved oxygen in the recycled water, wherein the combined modified activated carbon fiber catalyst is a catalyst obtained by carrying out high-pressure hydrothermal modification treatment on activated carbon fibers, immersingand loading an active metal salt precursor and roasting. According to the removal method disclosed by the invention, the reaction temperature of the dissolved oxygen in the carbohydrazide and the recycled water is effectively reduced, and the removal effect of the dissolved oxygen in the recycled water is improved; the removal method is especially suitable for removing the dissolved oxygen in output water of three-grade treatment of a sewage treatment plant.

Owner:TAIYUAN UNIV OF TECH

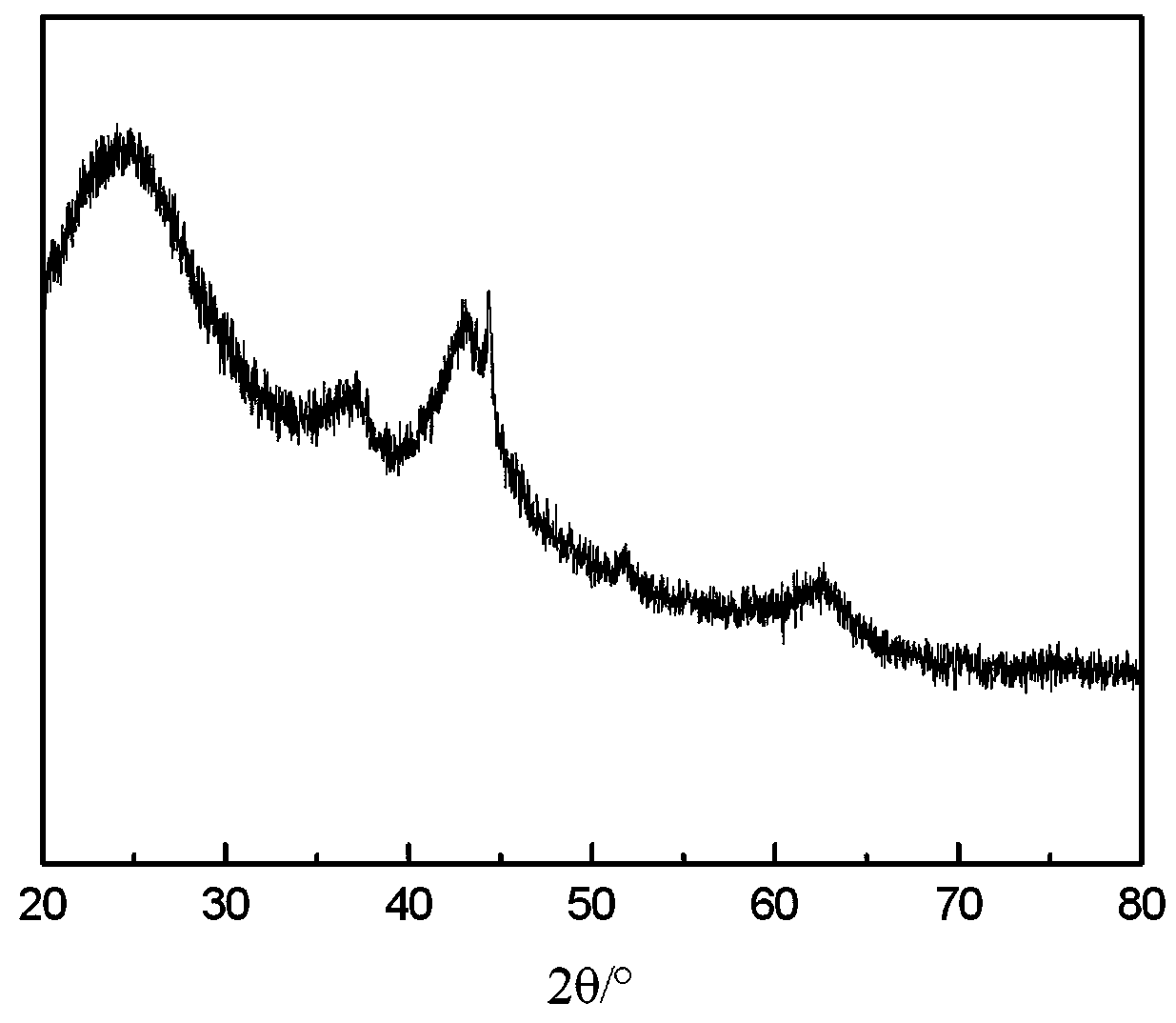

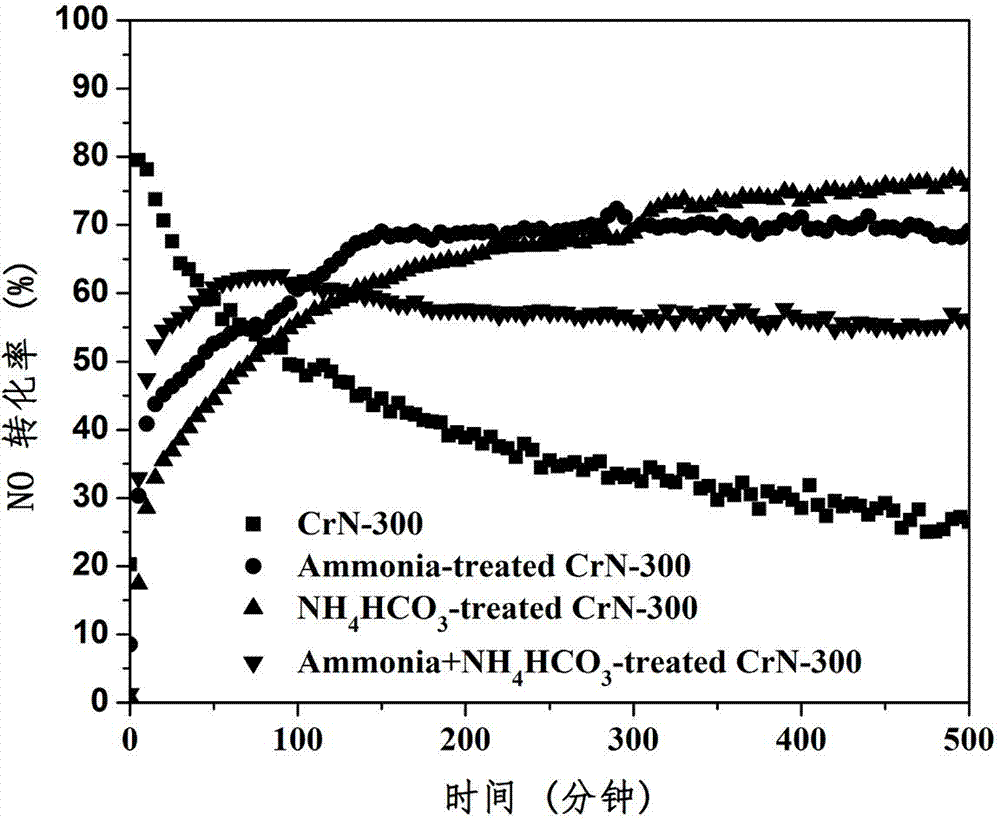

Chromic oxide catalyst for alkali liquor surface treatment as well as preparation method and application thereof

InactiveCN103506109BChange the crystal structure of the surfaceHigh reactivityDispersed particle separationCatalyst activation/preparationCatalytic oxidationHigh activity

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A kind of monolithic chromium oxide catalyst for alkali treatment and its preparation method and application

InactiveCN103657632BHigh activityImprove stabilityDispersed particle separationCatalyst activation/preparationPtru catalystCatalytic oxidation

The invention relates to an alkali liquor treated integral chrome oxide catalyst, a preparation method and an application. According to the catalyst, an active ingredient chrome is soaked to an inert carrier cordierite honeycomb ceramic with a soaking method, the specific surface area of the integral catalyst is increased with an alkali liquor treatment method after drying and roasting, the chemical state of the active ingredient is changed, the active site is increased, and NO catalytic oxidation reactivity and the long-time stability under normal pressure and temperature are improved. According to the catalyst, the preparation method and the application, the process is simple, raw materials are easy to obtain, and engineering application is realized.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

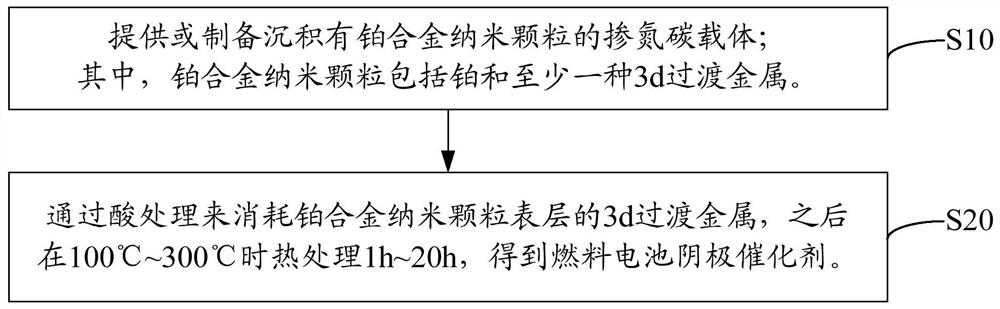

Fuel cell cathode catalyst and preparation method thereof, membrane electrode and fuel cell

ActiveCN111725524AReduce surface defectsImprove electronic propertiesCell electrodesFuel cellsPtru catalyst

The invention relates to a fuel cell cathode catalyst and a preparation method thereof, a membrane electrode and a fuel cell. The preparation method of the fuel cell cathode catalyst comprises the following steps: providing or preparing a nitrogen-doped carbon carrier deposited with platinum alloy nanoparticles, wherein the platinum alloy nanoparticles comprise platinum and at least one 3d transition metal; and carrying out acid treatment to consume the 3d transition metal on the surface layer of the platinum alloy nanoparticles, and then, carrying out heat treatment for 1-20 h at the temperature of 100-300 DEG C to obtain the fuel cell cathode catalyst. The fuel cell cathode catalyst prepared by the preparation method has excellent catalytic activity and stability, and is beneficial to industrial application.

Owner:QINGDAO CHUANGQI XINNENG CATALYSIS TECH CO LTD +1

Monolithic chromium oxide catalyst as well as preparation method and application thereof

InactiveCN103990448AEfficient oxidationHigh activityDispersed particle separationCatalyst activation/preparationCatalytic oxidationCordierite

The invention discloses a preparation method for a monolithic chromium oxide catalyst. The preparation method comprises the following steps: preparing a monolithic catalyst provided with a chromium oxide coating by adopting an impregnation method: weighing a chrome precursor and dissolving the chrome precursor in deionized water, stirring the solution at normal temperature, pouring the chrome precursor on a cordierite honeycomb ceramic carrier after the chrome precursor is dissolved uniformly, after the cordierite honeycomb ceramic carrier is impregnated repeatedly, drying at 100 DEG C, and roasting for 4 hours at 300 DEG C to obtain the monolithic catalyst provided with the chromium oxide coating; preparing the monolithic chromium oxide catalyst by an alkaline liquid processing method: soaking the monolithic catalyst provided with the chromium oxide coating prepared by the step (1) in an alkaline liquid in an excessive impregnating way, wherein the PH of the alkaline liquid is 8 to 10, soaking the monolithic catalyst provided with the chromium oxide coating, roasting the monolithic catalyst provided with the chromium oxide coating for 2 to 6 hours after being dried for 12 hours, thereby obtaining the alkaline liquid surface processed monolithic chromium oxide catalyst. The catalytic oxidation of a NO reaction at normal temperature is realized; NO can be eliminated at the normal temperature; the engineering application is realized. The catalyst disclosed by the invention has a good application prospect because raw materials are easily available and the process is simple.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

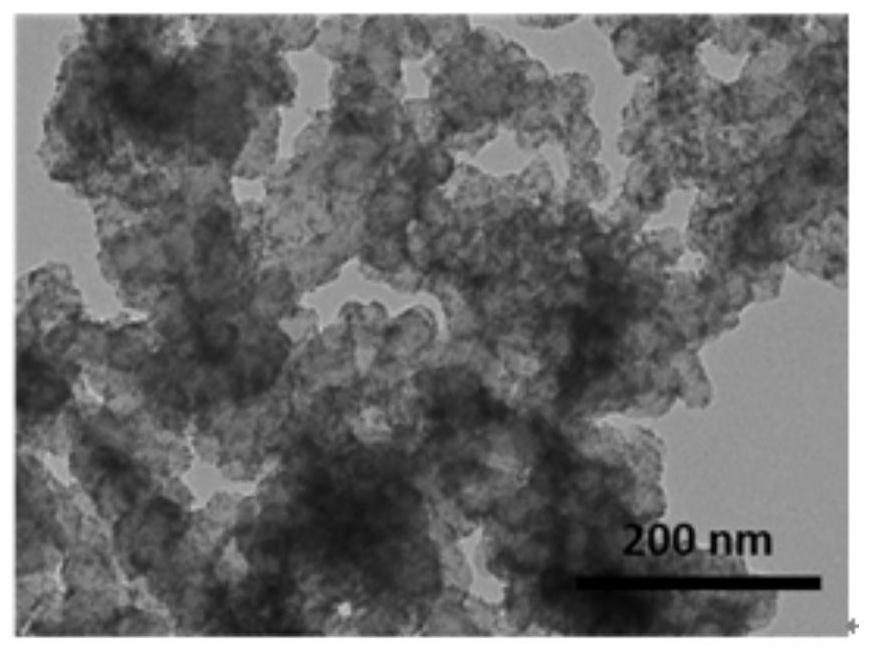

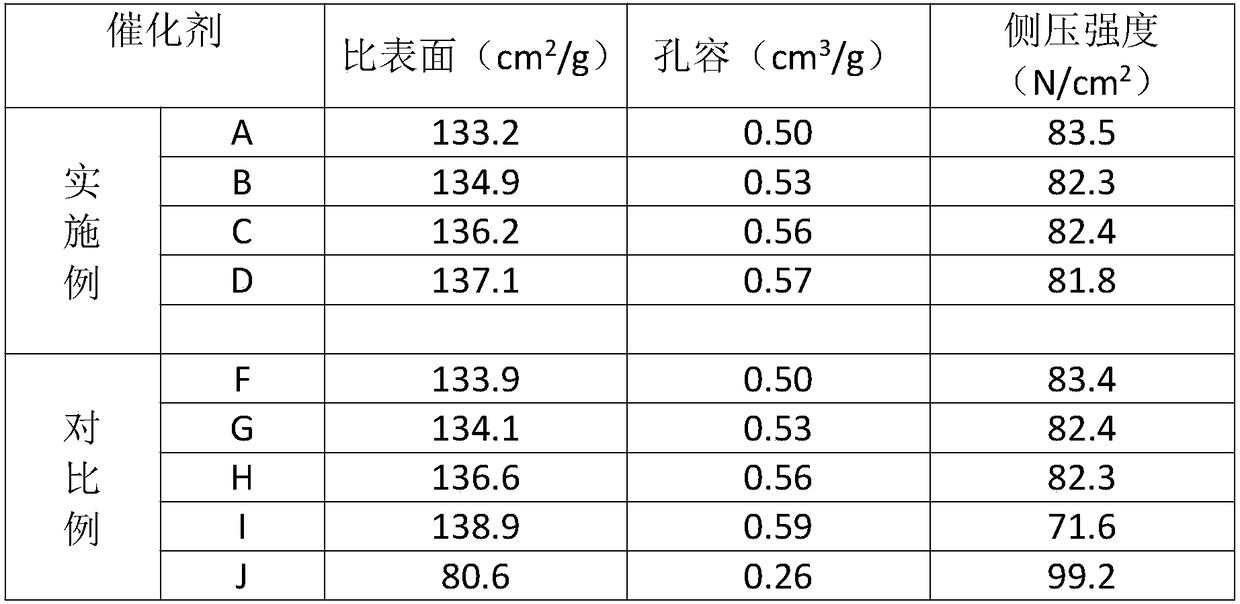

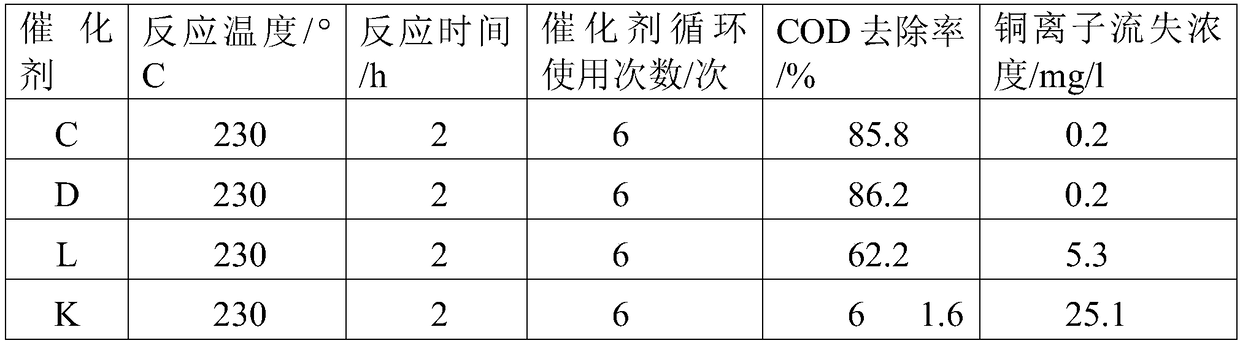

Preparation method for wet oxidation catalyst

ActiveCN108927166ATightly boundPacked tightlyCatalyst protectionWater contaminantsHigh concentrationSulfur

The invention discloses a preparation method for a wet oxidation catalyst. The preparation method includes the following steps: (1) processing active carbon by adopting carbohydrate, and performing pulping; (2) dissolving a copper source precursor into a solution; (2) dissolving a cerium source precursor into a solution; (4) mixing materials prepared by the step (1), (2) and (3), adjusting pH values to form deposition, and performing filtering, washing and drying, and roasting in an inert gas environment so that a powder material can be formed; and (5) mixing the powder material of the step (4) with a manganese source precursor solution into slurry, and adding a pore forming agent after stirring, performing seal standing to form the mixture into a clover shape through extruding after secondary stirring, coating nanometer zirconia after drying, and performing roasting in an inert gas environment to form a wet oxidation catalyst. The prepared wet oxidation catalyst can be used for high concentration organic wastewater, and has characteristics of large specific surface areas, strong sulfur tolerance and stable catalytic activity, etc.

Owner:PETROCHINA CO LTD

Honeycomb denitration catalyst with increased specific surface area and preparation method

ActiveCN107321344AHigh strengthHigh specific surface areaGas treatmentHeterogenous catalyst chemical elementsFlueHoneycomb

The invention discloses a honeycomb denitration catalyst with increased specific surface area and a preparation method. The preparation method comprises steps as follows: (1) beating active alumina; (2) dissolving a titanium source precursor; (3) dissolving a tungsten source precursor and mixing the dissolved tungsten source precursor with the materials in the steps (1) and (2); (4) adjusting pH of the material evenly mixed in the step (3) to 8-13, and performing precipitation, filtering and washing to obtain a filter cake; (5) adding water to the filter cake obtained in the step (4), mixing the filter cake into a slurry state, adding a vanadium source precursor solution, and performing mixing, drying and roasting to form powder; (6) mixing a solution formed by a molybdenum source precursor with the powder in the step (5) into a slurry, stirring the mixture, adding a pore-forming agent, performing secondary stirring, allowing the mixture to stand, squeezing the mixture into a honeycomb shape, performing drying, and coating the surface with nano-tungsten oxide for roasting to obtain the denitration catalyst. The prepared denitration catalyst has the advantages that the specific surface area can be increased, and non-uniform deposition of heavy metals in flue gas on the surface of the catalyst is prevented.

Owner:PETROCHINA CO LTD

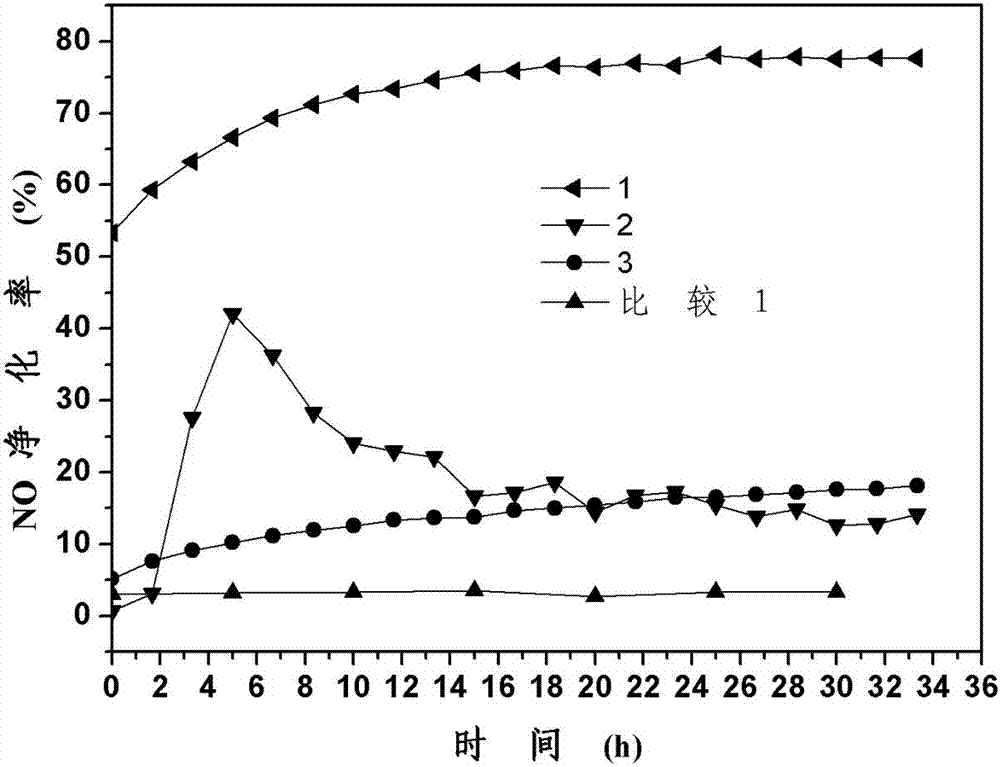

Preparation method of heavy oil hydrodemetallization catalyst

ActiveCN111821993AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetal catalyst

The invention discloses a preparation method of a heavy oil hydrodemetallization catalyst, and the method comprises the following steps: (1) pulverizing a waste hydrotreating catalyst, and roasting; (2) soaking the material obtained in the step (1) into an ammonium bicarbonate aqueous solution, carrying out sealed heat treatment, drying, soaking with a polyethylene glycol solution, and drying to obtain a pretreated material A; (3) performing high-temperature activation treatment on kaolin, then soaking into an ammonium bicarbonate aqueous solution, performing sealed heat treatment, and dryingthe material subjected to heat treatment to obtain a pretreated material B; and (4) kneading and molding pseudo-boehmite, the pretreated material A and the pretreated material B, drying and roasting the molded product to obtain a carrier, and loading a hydrogenation active component onto the carrier to obtain the catalyst. According to the method, the hydrodemetallization catalyst is prepared fromthe waste catalyst and kaolin, environmental pollution is reduced while the production cost is reduced, the content of macropores of the hydrodemetallization catalyst is appropriate, and the hydrodemetallization catalyst has high hydrodemetallization activity and hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

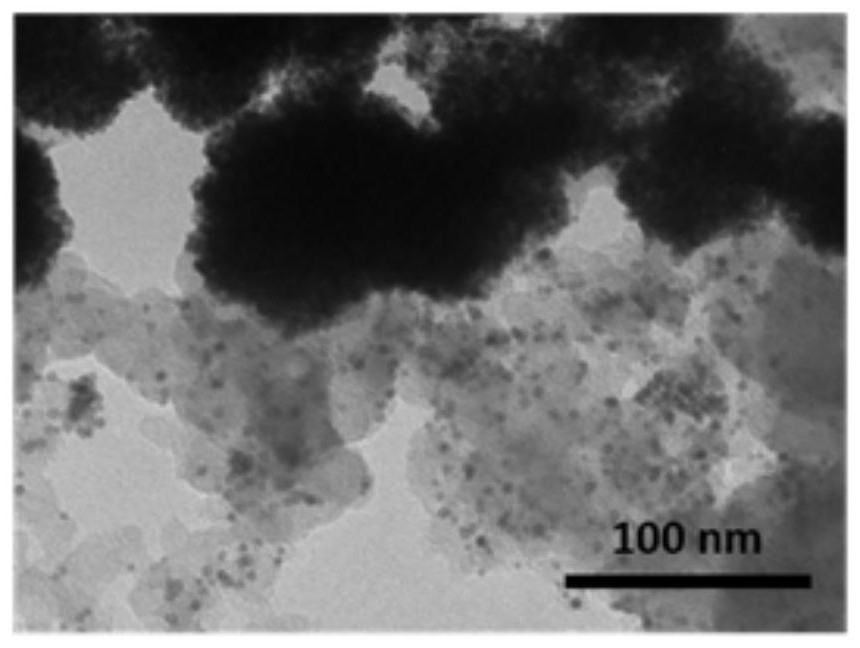

Preparation method for high specific surface area wet oxidation catalyst

ActiveCN108927160AIncrease active siteHigh strengthWater contaminantsCatalyst activation/preparationActivated carbonCerium

The invention discloses a preparation method for a high specific surface area wet oxidation catalyst. The preparation method includes the following steps: (1) processing active carbon by adopting carbohydrate, and performing pulping; (2) dissolving a copper source precursor into a solution; (3) mixing materials of (1) and (2), adjusting pH values to form deposition, and performing filtering and washing; (4) dissolving a nickel source precursor into a solution, fulling mixing with (3), performing drying, baking the mixture in an inert gas environment to form a powdered material; and (5) mixingthe powdered material of the step (4) with a cerium source precursor into slurry, adding a pore forming agent after stirring, performing seal standing and drying after secondary stirring, baking the mixture in the inert gas environment to form a wet oxidation catalyst. The prepared wet oxidation catalyst can be used for oil refining or ethylene waste lye treatment, and has large specific surface areas and high catalytic activity.

Owner:PETROCHINA CO LTD

Clean production method of 2,4-di-tert-butylphenol

PendingCN111205172AIncrease active siteAvoid it happening againOrganic chemistryMolecular sieve catalystsSide productMolecular sieve

The invention provides a clean production method of 2,4-di-tert-butylphenol, wherein the clean production method comprises the steps: A) mixing phenol and a catalyst, stirring, heating, adding isobutene, and carrying out a reaction to obtain 2,4-di-tert-butylphenol, wherein the catalyst is a transition metal oxide doped molecular sieve, the transition metal oxide is La2O3 and CeO2, the molecular sieve is an X-type molecular sieve and / or a Y-type molecular sieve, and the mass fraction of the transition metal oxide in the catalyst is 6-20%; and B) mixing the used catalyst with a new catalyst, adding phenol and isobutene, carrying out a reaction again, repeating for several times, extracting and recovering the catalyst by using an organic solvent, and then drying and calcining to finish regeneration and recycling of the catalyst. The molecular sieve catalyst doped with the transition metal is used for alkylation reaction of phenol and isobutene, the catalytic activity is high, byproductsgenerated by reaction of a target product and isobutene molecules can be reduced, and the reaction selectivity is improved.

Owner:SHANDONG LINYI SUNNY WEALTH CHEM CO LTD +1

Preparation method of demetalization catalyst

ActiveCN111821994AHigh activityImprove stabilityCatalyst activation/preparationChemical recyclingPtru catalystMetal catalyst

The invention discloses a preparation method of a demetalization catalyst, and the method comprises the following steps: (1) pulverizing a waste hydrotreating catalyst, and roasting; (2) immersing thematerial obtained in the step (1) into an ammonium bicarbonate aqueous solution, carrying out sealed heat treatment, filtering, drying the material, soaking with a polyethylene glycol solution, filtering, and drying to obtain a pretreated material A; and (3) subjecting pseudo-boehmite and the pretreated material A to kneading molding, drying and roasting the molded product so as to obtain a carrier, and loading a hydrogenation active component onto the carrier so as to obtain the demetalization catalyst. According to the method, the hydrodemetallization catalyst is prepared from the waste catalyst, so that the production cost is reduced, the environmental pollution is reduced, the activity of the catalyst is guaranteed, the catalyst has good stability, and the operation period of a devicecan be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of honeycomb denitration catalyst with improved specific surface area

ActiveCN107096524AHigh strengthLarge specific surface areaGas treatmentHeterogenous catalyst chemical elementsCooking & bakingMixed materials

The invention discloses a preparation method of a honeycomb denitration catalyst with an improved specific surface area, and the preparation method comprises the following steps: (1) mixing and beating activated carbon and a sugar solution; (2) dissolving a titanium-source precursor; (3) dissolving a tungsten-source precursor, and mixing the tungsten-source precursor with the materials in the steps (1) and (2); (4) adjusting pH value of the mixed material in the step (3) to 8-13, precipitating, filtering and washing to obtain a filter cake; (5) regulating the filter cake in the step (4) to paste, adding a vanadium-source precursor solution, mixing, drying, under the protection of an inert gas baking to form powder; and (6) mixing a molybdenum-source precursor solution with the powder in the step (5) into paste, stirring, adding a pore forming agent, secondarily stirring, standing, extruding into a honeycomb shape, drying, coating surface with nano tungsten oxide, baking in an inert gas to obtain the catalyst. The specific surface area of the can be increased, uneven deposition of heavy metals on the catalyst in the flue gas can be resisted.

Owner:PETROCHINA CO LTD

Sulfur nitrogen harmful elements in coal orientated transformation additive and its application method

An additive for directionally transforming the harmful elements (S and N) in coal is a mixture of Ca-contained compound, Fe and Na contained compound with modifying function, SiO2 and others. It can change the route of oxidizing the precursors of SOx and NOx to make it toward harmless direction. Its application method is mixing it with coal before gasifying.

Owner:TAIYUAN UNIV OF TECH

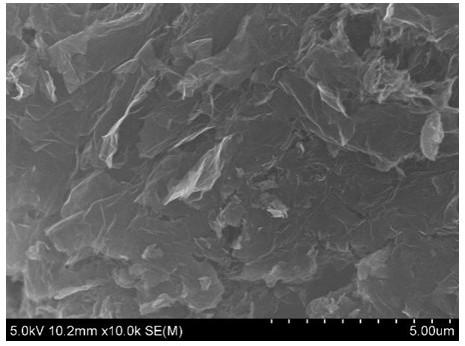

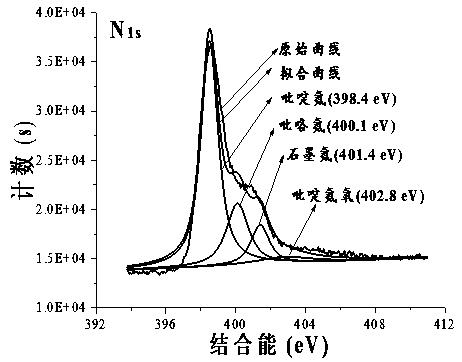

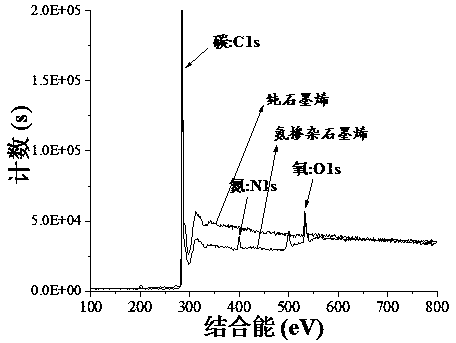

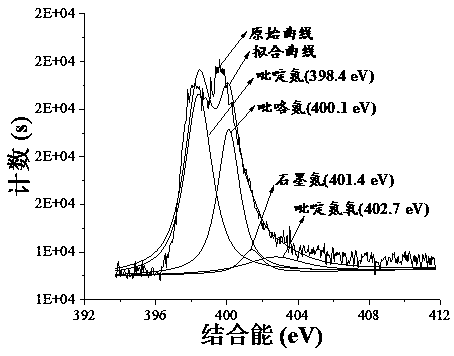

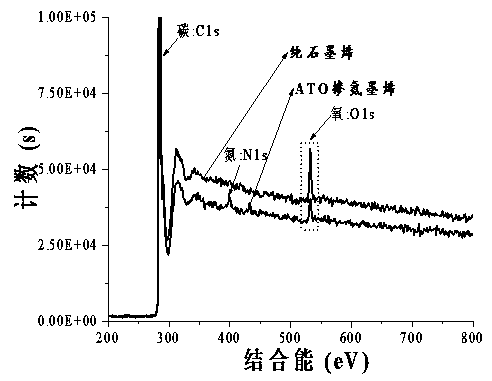

Preparation method of nitrogen-doped graphene material based on 5, 5'-diamino-3, 3'-1, 2, 4-triazole

The invention discloses a preparation method of a nitrogen-doped graphene material based on 5, 5'-diamino-3, 3'-1, 2, 4-triazole. The method comprises the following steps: dispersing graphene into N,N '-dimethylformamide, adding an N, N'-dimethylformamide solution of 5, 5 '-diamino-3, 3'-1, 2, 4-triazole, heating at 50-100 DEG C for 30-60 minutes, cooling to 0-4 DEG C, and drying to obtain a graphene-coated 5, 5 '-diamino-3, 3'-1, 2, 4-triazole eutectic; grinding 5, 5 '-diamino-3, 3'-1, 2, 4-triazole eutectic into powder, and heating the powder at 500-800 DEG C for 3-5 hours to obtain a nitrogen-doped graphene material; according to the preparation method, the graphene is uniformly coated on the surface of the 5, 5 '-diamino-3, 3'-1, 2, 4-triazole crystal, and additives such as an adhesive are not needed, so that the surface performance of the 5, 5 '-diamino-3, 3'-1, 2, 4-triazole crystal is completely maintained.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Preparation method of nitrogen-doped graphene material containing 3, 5-diamino-1H-1, 2, 4-triazole

The invention discloses a preparation method of a nitrogen-doped graphene material containing 3, 5-diamino-1H-1, 2, 4-triazole. The method comprises the following steps: dispersing graphene in deionized water, adding a 3, 5-diamino-1H-1, 2, 4-triazole ethanol solution into the graphene solution, heating the solution at 50-100 DEG C for 30-60 minutes, cooling the solution to 0-4 DEG C, drying the solution to obtain a graphene-coated 3, 5-diamino-1H-1, 2, 4-triazole eutectic material, grinding the 3, 5-diamino-1H-1, 2, 4-triazole eutectic material into powder, and heating the powder at 500-800 DEG C for 3-5 hours to obtain a nitrogen-doped graphene material. According to the preparation method disclosed by the invention, 3, 5-diamino-1H-1, 2, 4-triazole is utilized to react with graphene, sothat the graphene material with relatively high nitrogen doping content is obtained. According to the material, the graphene uniformly coats the surface of the 3, 5-diamino-1H-1, 2, 4-triazole crystal, and additives such as an adhesive and the like are not needed, so that the surface performance of the 3, 5-diamino-1H-1, 2, 4-triazole crystal is completely maintained.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Preparation method of nitrogen-doped graphene material based on 4-amino-1,2,4-triazole-5-one

InactiveCN111017917AGuaranteed Surface PropertiesChange structureCarbon compoundsDoped grapheneAdhesive

The invention discloses a preparation method of a nitrogen-doped graphene material based on 4-amino-1,2,4-triazole-5-one. The method comprises the steps: dispersing graphene into deionized water; adding a 4-amino-1,2,4-triazole-5-one aqueous solution, heating for 30-60 min at the temperature of 50-100 DEG C, cooling to room temperature, and drying to obtain a graphene-coated 4-amino-1,2,4-triazole-5-one eutectic material; and grinding into powder, and heating for 1.5-6 h in a tubular furnace at the temperature of 500-800 DEG C to obtain the nitrogen-doped graphene material. The surface of the4-amino-1,2,4-triazole-5-one crystal is uniformly coated with graphene in the material obtained by the preparation method disclosed by the invention, and additives such as an adhesive and the like arenot needed, so that the surface performance of the 4-amino-1,2,4-triazole-5-one crystal is completely maintained.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

A honeycomb denitration catalyst with increased specific surface area and preparation method thereof

ActiveCN107321344BHigh strengthLarge specific surface areaGas treatmentHeterogenous catalyst chemical elementsPtru catalystHoneycomb

The invention discloses a honeycomb denitration catalyst with increased specific surface area and a preparation method. The steps are as follows: (1) beating activated alumina; (2) dissolving titanium source precursor; (3) dissolving tungsten source precursor , and mix with the materials in steps (1) and (2); (4) Mix the materials in step (3) evenly and adjust the pH value to 8-13, precipitate, filter, and wash to obtain a filter cake; (5) Mix the materials in step (3) evenly to obtain a filter cake. 4) Add water to the obtained filter cake to make a slurry, add the vanadium source precursor solution, mix, dry and roast to form a powder; (6) Combine the solution formed by the molybdenum source precursor and the powder in step (5) Mix it into a slurry. After stirring, add a pore-forming agent. After stirring twice, let it stand and squeeze it into a honeycomb shape. After drying, the surface is coated with nanoscale tungsten oxide and roasted to obtain a denitration catalyst. The denitrification catalyst prepared by the invention can not only increase the specific surface area of the catalyst, but also resist the uneven deposition of heavy metals in the flue gas on its surface.

Owner:PETROCHINA CO LTD

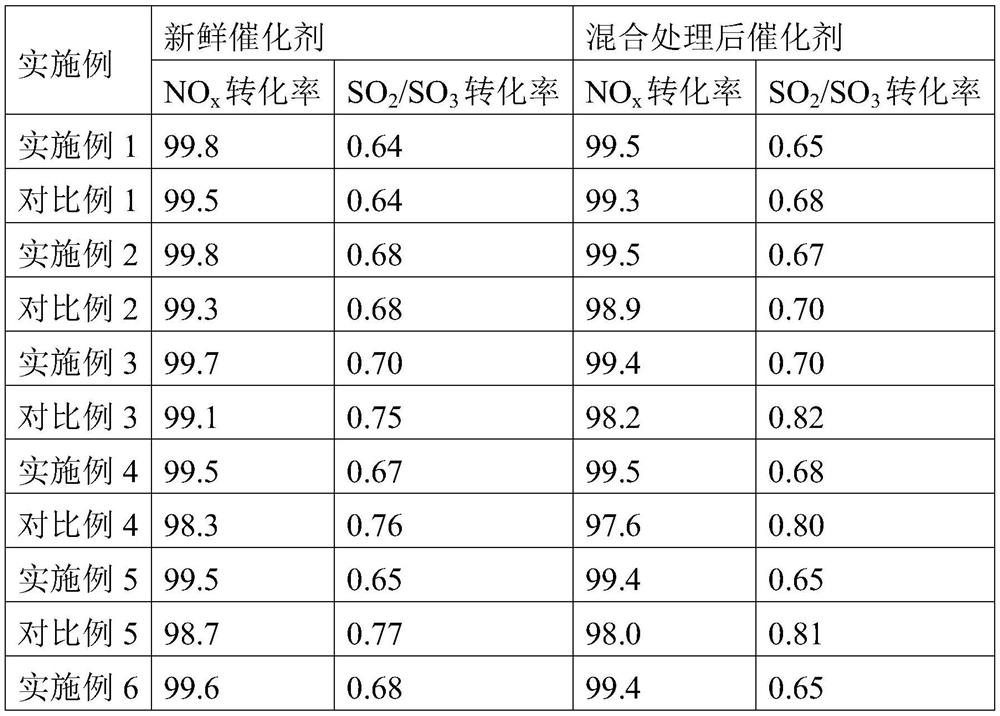

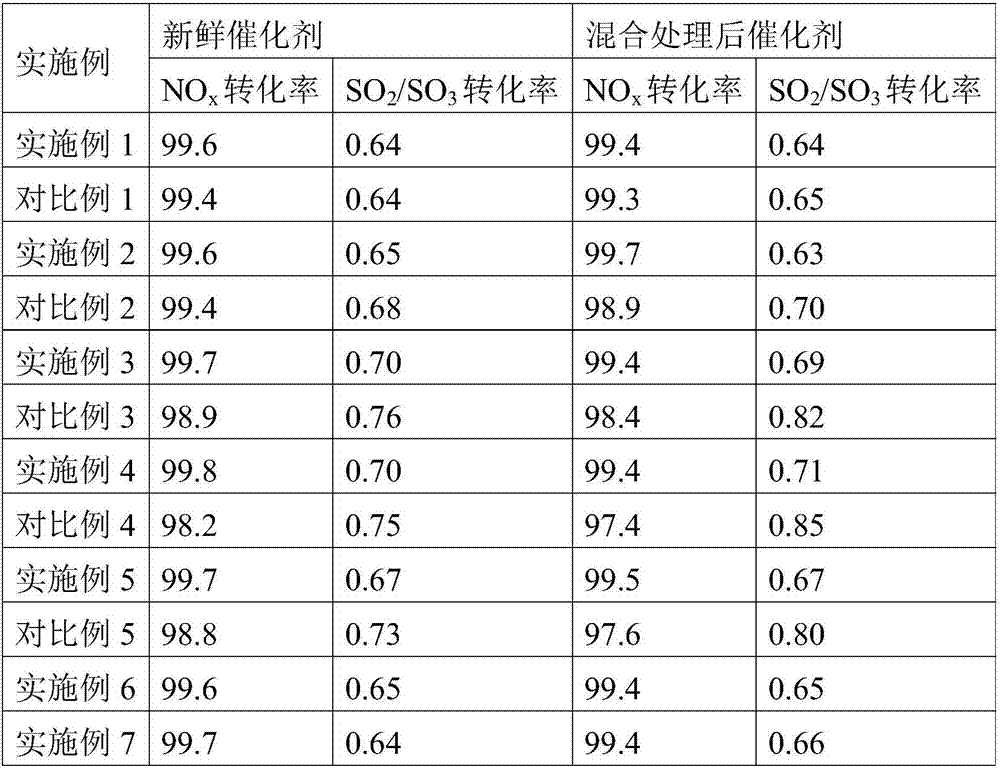

Denitration catalyst for increasing specific area and preparation method

InactiveCN107213891AImprove catalyst strengthHigh specific surface areaHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActivated carbonTungsten

The invention discloses a denitration catalyst for increasing a specific area and a preparation method. The method comprises the following steps: (1) mixing activated carbon with a sugar solution and pulping; (2) dissolving a titanium source precursor; (3) dissolving a tungsten source precursor and uniformly mixing the tungsten source precursor with the materials acquired in the steps (1) and (2); (4) uniformly mixing the material acquired in the step (3) and then adjusting the pH value of the solution to 8-13, precipitating, filtering and washing, thereby acquiring a filter cake; (5) adding water into the filter cake acquired in the step (4), preparing into pulp, adding a vanadium source precursor solution, mixing, drying and roasting under inert gas shielding, thereby forming powder; and (6) mixing the solution formed by a silicon source precursor with the powder acquired in the step (5) and forming slurry, adding a pore former, stirring for two times and then standing, drying and roasting under inert gas shielding, thereby acquiring the denitration catalyst. The product disclosed by the invention can increase the specific area of the catalyst and can reduce the conversion rate of SO2 / SO3.

Owner:PETROCHINA CO LTD

Sulfur nitrogen harmful elements in coal orientated transformation additive and its application method

Owner:TAIYUAN UNIV OF TECH

A kind of preparation method and application of graphene-coated metal nanoparticle catalyst

InactiveCN104923204BLarge specific surface areaImprove conductivityMaterial nanotechnologyPhysical/chemical process catalystsCarbon nanotubeMethanol

The invention relates to a preparation method for a graphene-coated iron-loaded and nitrogen-loaded active site catalyst on a carbon nano tube (CNT); sources of raw materials used for the method are extensive; carbon source and nitrogen source materials are low in cost; the sample yield is high; the production cost of a fuel cell is helped to be reduced; the content of Fe and N in the prepared catalyst is controllable, and meanwhile, bigger specific surface area is kept so as to overcome the problem that metal nanometer particles are easy to aggregate in the past. The preparation method comprises the following steps: (1) supporting Fe and N to the surface of the carbon nano tube to obtain Fe-N-CNT; (2) synthetizing a composite material, formed by coating the surface of the Fe-N-CNT with graphene precursors, by a hydrothermal method; (3) calcining the composite material to obtain Fe-N-CNT&GN. Compared with a traditional fuel cell cathode Pt / C catalyst, the catalyst prepared by the method disclosed by the invention is low in cost, relatively higher in catalytic activity, high in stability, high in methanol tolerance, and has a good commercial application prospect.

Owner:DALIAN UNIV OF TECH

A kind of low-carbon alkane dehydrogenation catalyst and preparation method thereof

ActiveCN108295847BReduce acidityDiffusion fastCatalystsHydrocarbon preparation catalystsAlkanePtru catalyst

The invention provides a low-carbon alkane dehydrogenation catalyst. The catalyst is prepared from a platinum component and an alkali metal component, wherein an aluminum oxide based carrier containing an Sn-M-O solid solution is adopted; based on platinum oxide and based on alkali metal oxide, the catalyst comprises the following components in parts by weight: 0.1 to 2 parts of the platinum oxide, 0.1 to 5 parts of the alkali metal oxide, 90 to 99 parts of aluminum oxide and 0.1 to 8 parts of the Sn-M-O solid solution; M is selected from one or more metal elements in fourth, fifth, sixth andseventh periods of a periodic table of elements. According to the low-carbon alkane dehydrogenation catalyst provided by the invention, Sn and M elements in the prepared solid solution have a synergistic effect, so that the acidity of the catalyst is easy to reduce, the catalyst is rapidly dispersed from an intermediate product, and the selectivity of the catalyst is improved; meanwhile, uniform dispersion of Pt is promoted, active sites are increased, and the conversion rate is improved.

Owner:REZEL CATALYSTS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com