A-site high-entropy perovskite oxide MeTiO3 thermoelectric ceramic and preparation method thereof

A perovskite oxide, high-entropy technology, applied in the field of high-entropy oxides, can solve the problems that cannot be applied to the field of thermoelectric materials, high-entropy perovskite oxides do not have thermoelectric properties, etc., and achieve complete grains and dense structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

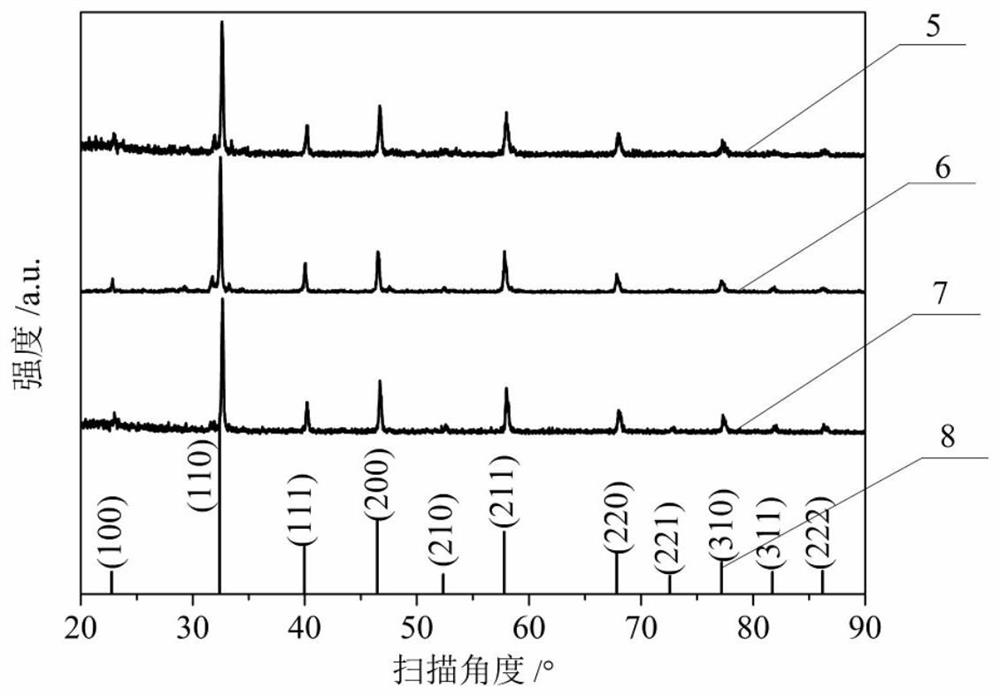

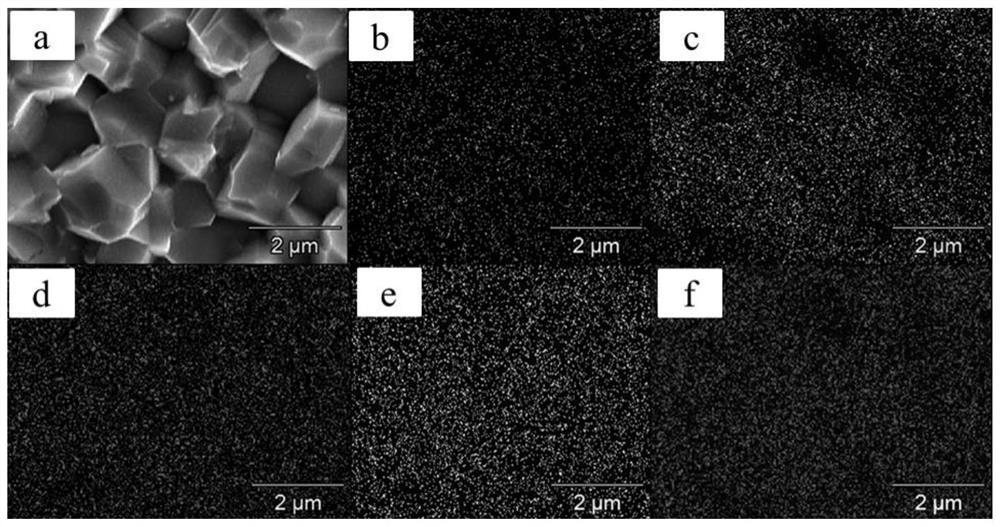

[0058] The invention is an A-site high-entropy perovskite oxide, and its technical characteristics are described in detail through five embodiments.

[0059] The chemical composition formula of the A-site high-entropy perovskite oxide is (Ca 0.2 Sr 0.2 Ba 0.2 La 0.2 Pb 0.2 )TiO 3 , (Ca 0.25 Sr 0.25 Ba 0.25 La 0.25 )TiO 3 , (Ca 0.25 Sr 0.25 Ba 0.25 Pb 0.25 )TiO 3 , (Ca 0.25 Sr 0.25 Ba 0.25 Nd 0.25 )TiO 3 , (Ca 0.25 Sr 0.25 Ba 0.25 SM 0.25 )TiO 3 , (Ca 0.25 Sr 0.25 Ba 0.25 Eu 0.25 )TiO 3 .

[0060] The chemical composition formula of each embodiment of table 1

[0061] Example chemical composition 1 (Ca 0.2 Sr 0.2 Ba 0.2 La 0.2 Pb 0.2 )TiO 3

2 (Ca 0.25 Sr 0.25 Ba 0.25 La 0.25 )TiO 3

3 (Ca 0.25 Sr 0.25 Ba 0.25 Pb 0.25 )TiO 3

4 (Ca 0.25 Sr 0.25 Ba 0.25 Nd 0.25 )TiO 3

5 (Ca 0.25 Sr 0.25 Ba 0.25 SM 0.25 )TiO 3

6 (Ca 0.25 Sr 0.25 Ba 0.25 Eu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com