Low-temperature sintered high-permeability NiCuZn ferrite material

A technology of ferrite materials and high magnetic permeability, which is applied in the field of low-temperature sintered high magnetic permeability NiCuZn ferrite materials, can solve the problems of easy re-agglomeration, particle size reduction, cost reduction, etc., and achieve improved mechanical strength, Improve sintered density and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

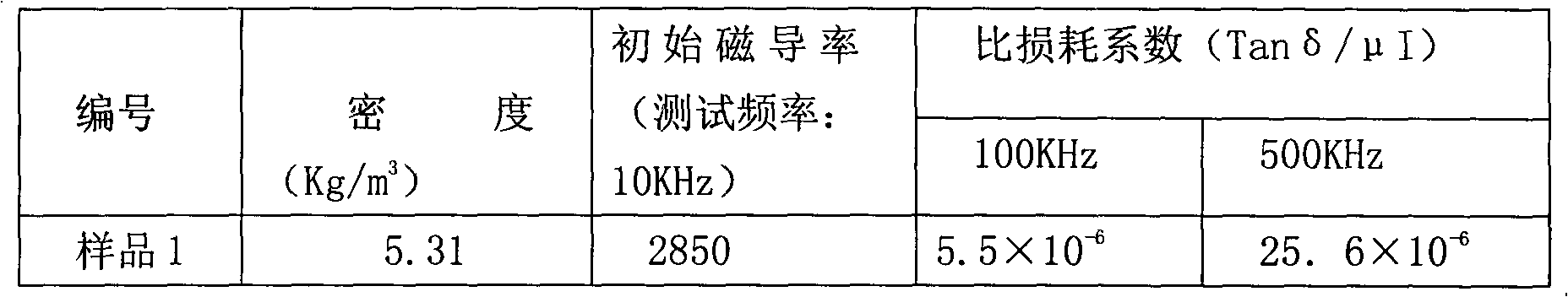

Embodiment 1

[0048] (1) Selection of raw materials: The raw materials of the low-temperature sintered NiCuZn ferrite materials are selected from industrially pure Fe 2 o 3 , ZnO, NiO, CuO.

[0049] (2) Composition design and weighing: according to the main component Fe 2 o 3 49.2mol%, ZnO 37mol%, CuO 10mol%, NiO 3.8mol%, weigh the corresponding weight of Fe 2 o 3 , ZnO, CuO and NiO.

[0050] (3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water of equal weight, and sand mill for 0.5 hour.

[0051] (4) One-time spray drying granulation:

[0052] Add about 10% PVA solution (concentration is about 10%) in raw material slurry, carry out spray drying granulation once.

[0053] (5) Pre-burning:

[0054] The primary spray-dried granulated powder is pre-fired through a rotary kiln at a temperature of 750°C.

[0055] (6) Auxiliary ingredients added:

[0056] NaCO 3 : 0.60wt%, B 2 o 3 : 0.08wt%, Ta 2 o 5 : 0.25wt%.

[0057] (7) Secondary san...

Embodiment 2

[0069] (1) Material selection: The raw material of the low-temperature sintered NiCuZn ferrite material is selected from industrially pure Fe 2 o 3 , ZnO, NiO and CuO.

[0070] (2) Composition design and weighing: according to Fe 2 o 3 46 mol%, ZnO 32 mol%, CuO 15 mol%, NiO 7 mol%, weigh the corresponding weight of Fe 2 o3 , ZnO, CuO and NiO.

[0071] (3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water of equal weight, and sand mill for 0.5 hour.

[0072] (4) One-time spray drying granulation:

[0073] Add about 10% PVA solution (concentration is about 10%) in raw material slurry, carry out spray drying granulation once.

[0074] (5) Pre-burning:

[0075] The primary spray-dried granulated powder is pre-fired through a rotary kiln at a temperature of 730°C.

[0076] (6) Auxiliary ingredients added:

[0077] NaCO 3 : 0.25wt%, B 2 o 3 : 0.20wt%, Ta 2 o 5 : 0.18wt%.

[0078] (7) Secondary sanding:

[0079] Put the ferri...

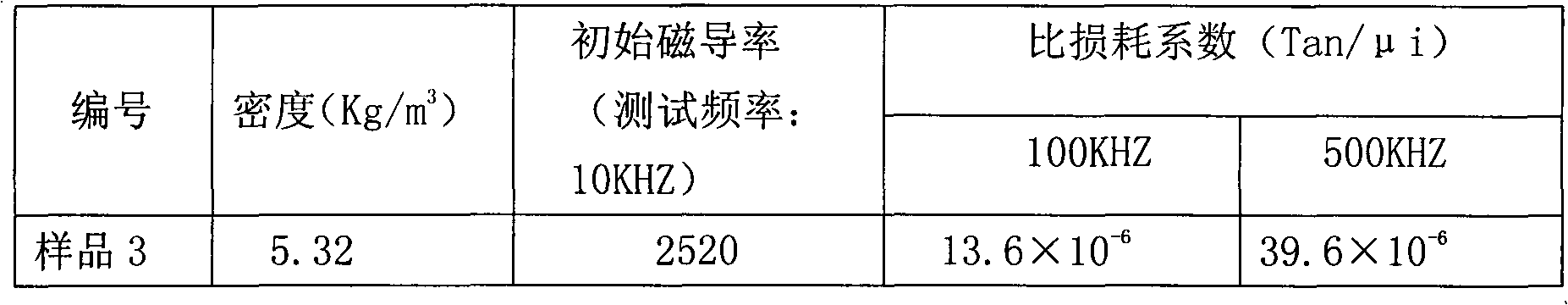

Embodiment 3

[0090] (1) Material selection: The raw material of the low-temperature sintered NiCuZn ferrite material is selected from industrially pure Fe 2 o 3 , ZnO, NiO and CuO.

[0091] (2) Composition design and weighing: according to the formula Fe 2 o 3 41mol%, ZnO 30mol%, CuO 19mol%, NiO 10mol%, weigh the corresponding weight of Fe 2 o 3 , ZnO, CuO and NiO.

[0092] (3) Mixing of raw materials: Put the weighed raw materials into a sand mill, add deionized water of equal weight, and sand mill for 0.5 hour.

[0093] (4) One-time spray drying granulation:

[0094] Add about 10% PVA solution (concentration is about 10%) in raw material slurry, carry out spray drying granulation once.

[0095] (5) Pre-burning:

[0096] The primary spray-dried granulated powder is pre-fired through a rotary kiln at a temperature of 710°C.

[0097] (6) Auxiliary ingredients added:

[0098] NaCO 3 : 0.10wt%, B 2 o 3 : 0.35wt%, Ta 2 o 5 : 0.08wt%.

[0099] (7) Secondary sanding:

[0100] Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com