Multi-component doping high-performance beryllium oxide ceramic material and preparation method

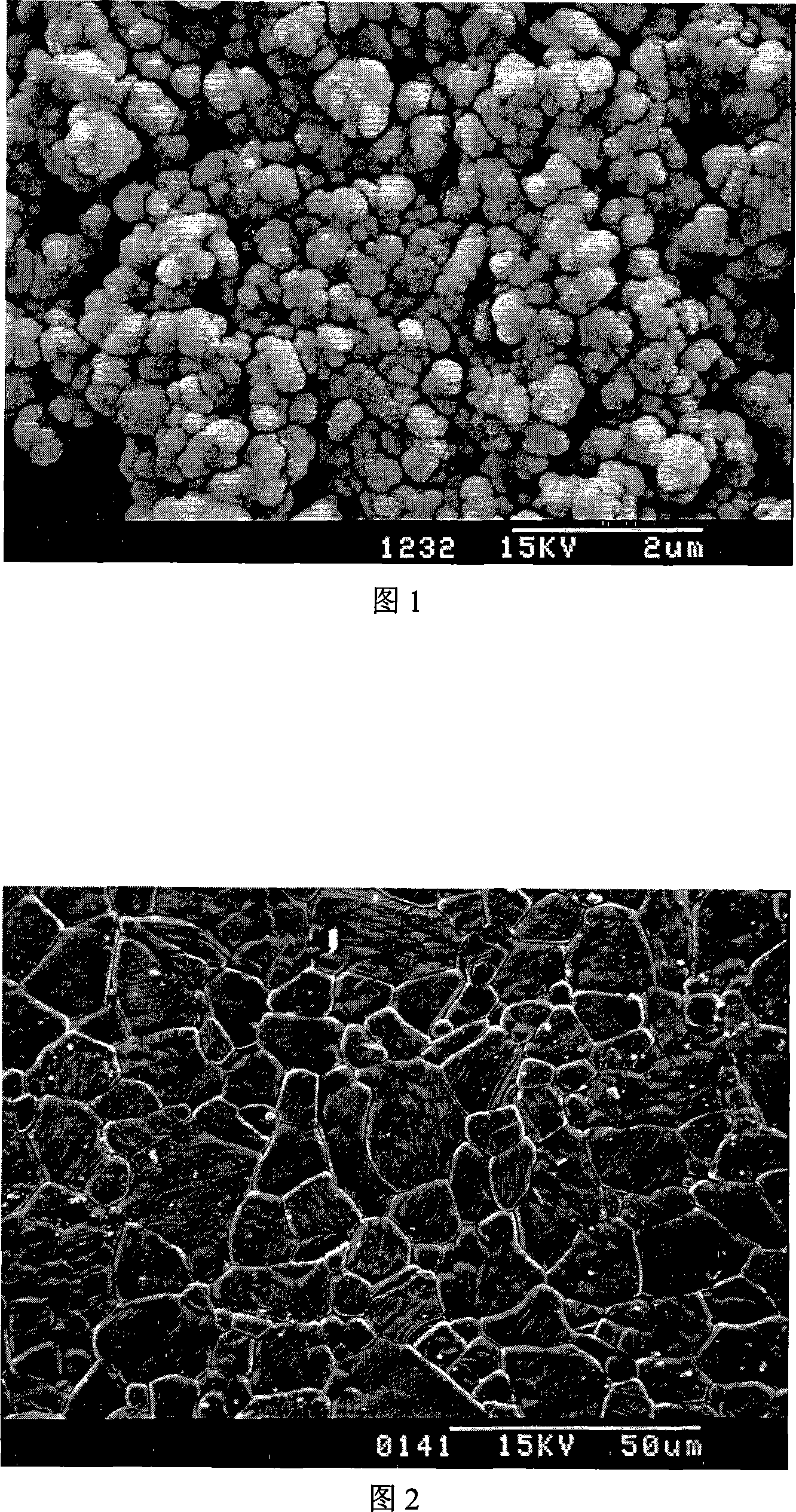

A high-performance technology of beryllium oxide ceramics, which is applied in the field of multi-doped beryllium oxide ceramic materials and preparation technology, can solve the problems of unsatisfactory thermal conductivity and high sintering temperature of ceramic materials, and achieve less pores, uniform grain size, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] By weight percentage MgO (5 ~ 40wt%), Al 2 o 3 (25~55wt%), CaO: (0.1~5wt%), Y 2 o 3 (0.01~0.5wt%) can be converted into Mg(NO 3 ) 2 , Al(NO 3 ) 3 , Ca(NO 3 ) 2 , Y 2 o 3 According to the calculated amount, accurately weigh the Mg(NO 3 ) 2 , Al(NO 3 ) 3 , Ca(NO 3 ) 2 , Y 2 o 3 Dissolve in concentrated nitric acid, heat and evaporate the solvent to obtain reaction mixed solution A, and control the temperature of solution A (65°C-95°C). By weight percent SiO 2(10~65wt%), accurately measure tetraethyl orthosilicate, stabilizer, dehydrated alcohol and mix uniformly in proportion (stabilizer adopts acetylacetone, tetraethyl orthosilicate: ethanol range 2: 1~1: 3; Ethyl tetrasilicate: stabilizer ranges from 5:1 to 5:2 to obtain mixed solution B. When A solution is heated and concentrated to a certain extent (about 1.5 times the volume of B solution), A is poured into B and continuously Stir to make it fully react. Put the sol in an oven, adjust the temperat...

Embodiment 2

[0036] By weight percentage MgO (5 ~ 40wt%), Al 2 o 3 (1~5wt%), ZnO: (0~0.5wt%), La 2 o 3 (0.01~0.5wt%), can be converted into Mg(NO 3 ) 2 , Al(NO 3 ) 3 , Zn(NO 3 ) 2 , La 2 o 3 According to the calculated amount, accurately weigh the Mg(NO 3 ) 2 , Al(NO 3 ) 3 , Zn(NO 3 ) 2 , La 2 o 3 Dissolve in concentrated nitric acid, heat and evaporate the solvent to obtain reaction mixed solution A, and control the temperature of solution A (65°C-95°C). By weight percent SiO 2 (10~65wt%), accurately measure tetraethyl orthosilicate, stabilizer, dehydrated alcohol and mix uniformly in proportion (stabilizer adopts acetylacetone, tetraethyl orthosilicate: ethanol range 2: 1~1: 3; Ethyl tetrasilicate: stabilizer ranges from 5:1 to 5:2 to obtain mixed solution B. When A solution is heated and concentrated to a certain extent (about 1.5 times the volume of B solution), A is poured into B and continuously Stir to make it fully react. Put the sol in an oven, adjust the tempe...

Embodiment 3

[0038] By weight percentage MgO (5 ~ 40%), Al 2 o 3 (0~5wt%), CaO: (0.1~0.5wt%), La 2 o 3 (0.01~0.5wt%), can be converted into Mg(NO 3 ) 2 , Al(NO 3 ) 3 , Ca(NO 3 ) 2 , La 2 o 3 According to the calculated amount, accurately weigh the Mg(NO 3 ) 2 , Al(NO 3 ) 3 , La 2 o 3 Dissolve in concentrated nitric acid, heat and evaporate the solvent to obtain reaction mixed solution A, and control the temperature of solution A (65°C-95°C). By weight percent SiO 2 (10~65wt%), accurately measure ethyl orthosilicate, stabilizer, dehydrated alcohol and mix uniformly in proportion (stabilizer adopts ethylene glycol ether, orthosilicate: ethanol range 2: 1~1: 3; Orthosilicate: stabilizer ranges from 1:1 to 1:2 to obtain mixed solution B. When solution A is heated and concentrated to a certain extent (about 1.5 times the volume of solution B), pour A into B , Stir continuously to make it fully react. Put the sol into the oven, adjust the temperature to 50-130°C, form a gel aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com