Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Diamond nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

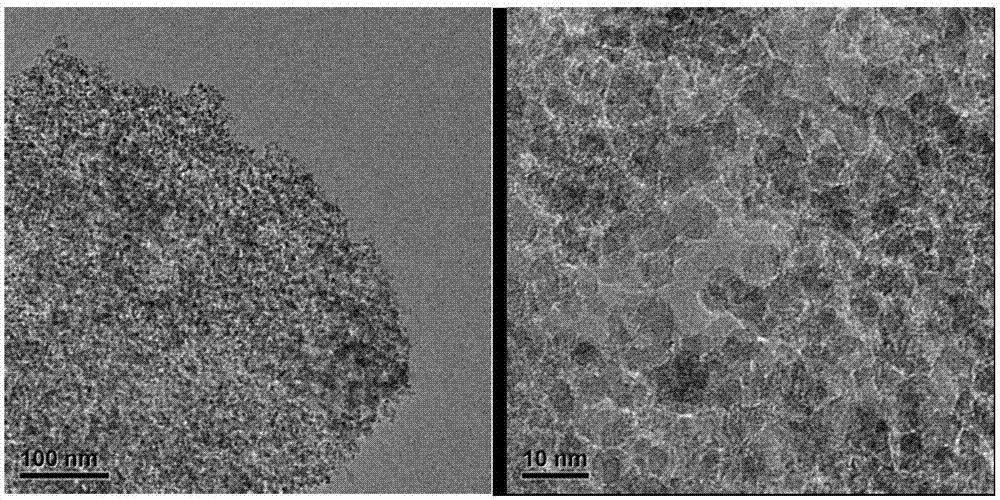

In vitro studies exploring the dispersion of diamond nanoparticles in cells have revealed that most diamond nanoparticles exhibit fluorescence and are uniformly distributed. Fluorescent nanodiamond particles can be mass produced through irradiating diamond nanocrystallites with helium ions.

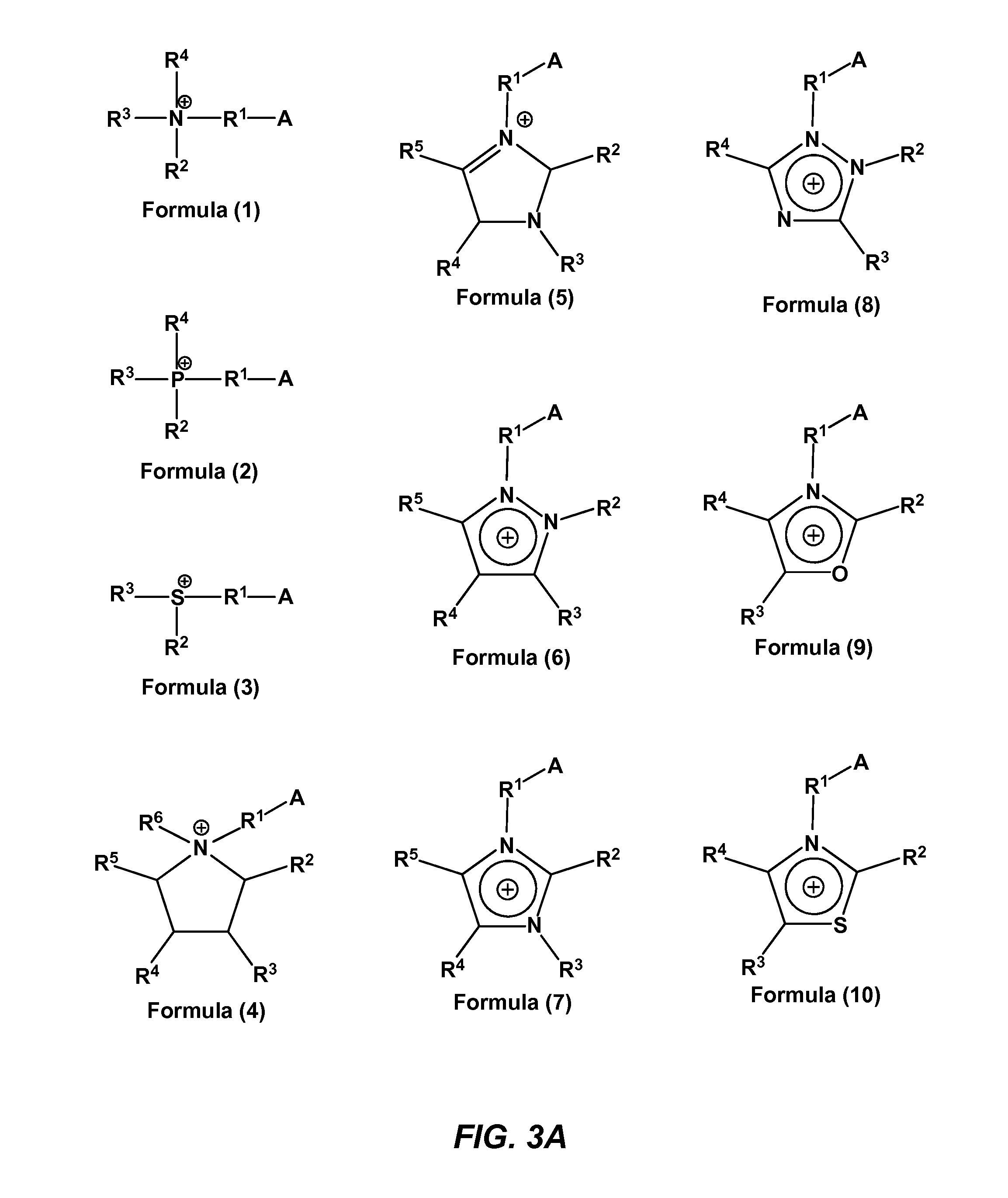

Diamond particles having organic compounds attached thereto, compositions thereof, and related methods

ActiveUS20120034464A1Material nanotechnologyPressurized chemical processSimple Organic CompoundsActive agent

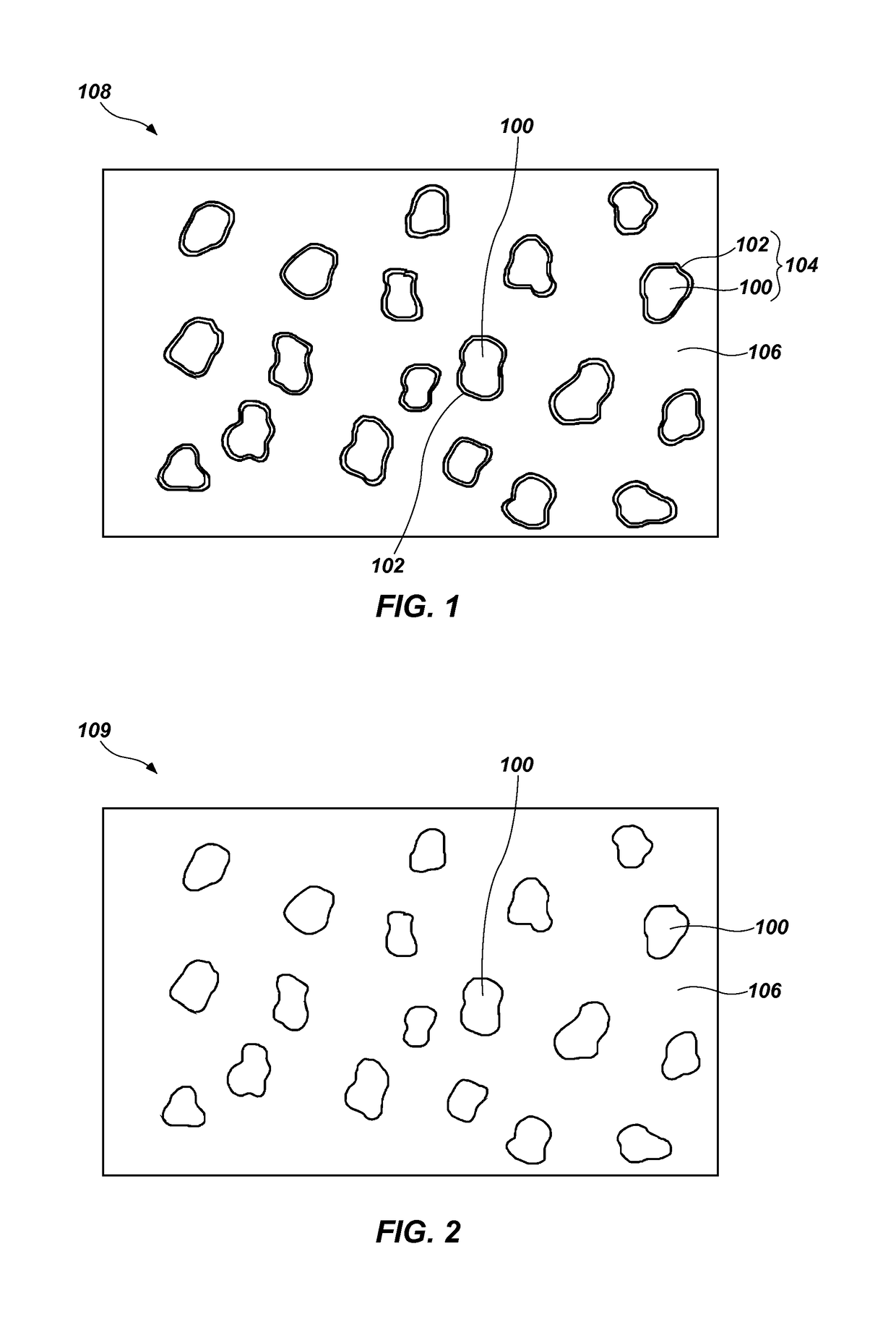

A substance includes diamond particles having a maximum linear dimension of less than about 1 μm and an organic compound attached to surfaces of the diamond particles. The organic compound may include a surfactant or a polymer. A method of forming a substance includes exposing diamond particles to an organic compound, and exposing the diamond particles in the presence of the organic compound to ultrasonic energy. The diamond particles may have a maximum linear dimension of less than about 1 μm. A composition includes a liquid, a plurality of diamond nanoparticles dispersed within the liquid, and an organic compound attached to surfaces of the diamond nanoparticles. A method includes mixing a plurality of diamond particles with a solution comprising a liquid solvent and an organic compound, and exposing the mixture including the plurality of diamond nanoparticles and the solution to ultrasonic energy.

Owner:BAKER HUGHES INC

Lubricant composition

ActiveUS20080248979A1Reduce coefficient of frictionImprove fuel economyMaterial nanotechnologyAdditivesInternal combustion engineOxygen

A lubricant composition applicable to a sliding section or sliding member of an automotive internal combustion engine or power transmission apparatus to significantly lower a friction coefficient. The lubricant composition contains a base oil for a lubricating oil, an oxygen-containing organic compound, a diamond nano-particle and a dispersant for the diamond nano-particle.

Owner:NISSAN MOTOR CO LTD

Composite coatings for groundwall insulation, method of manufacture thereof and articles derived therefrom

InactiveCN1992100AWindings insulation materialMaterial nanotechnologyNanoparticleThermosetting polymer

Disclosed herein is an article comprising an electrical component and an electrically insulating layer disposed upon the electrical component, wherein the electrically insulating layer comprises a thermosetting polymer and a nanosized filler, wherein the nanosized filler comprises metal oxide and diamond nanoparticles that have an average largest dimension of less than or equal to about 200 nanometers.

Owner:GENERAL ELECTRIC CO

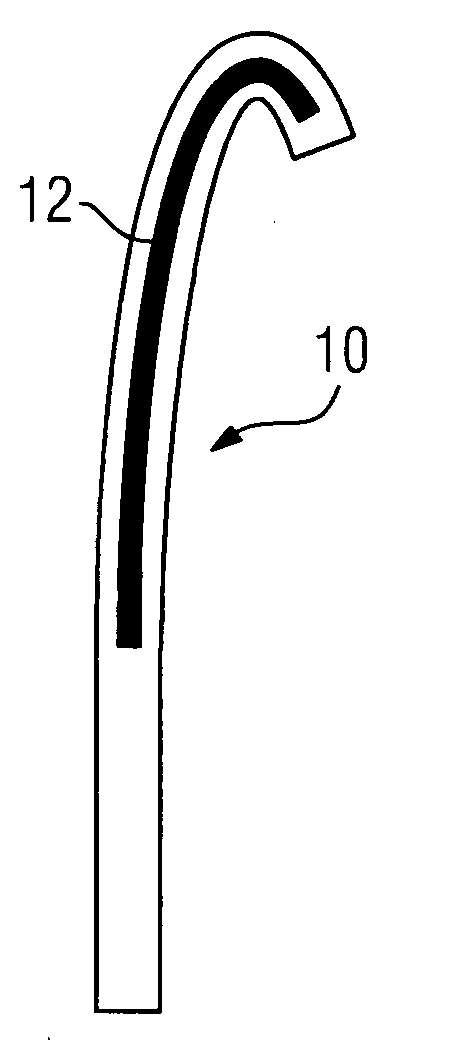

Method for delivering a catheter to a target in the brain of a patient and guide wire for a microcatheter for insertion in the brain of a patient

The movement of catheters and guide wires for catheters with the aid of magnets is known from the field of cardiology. Conventional magnets are, as a result of their size, not suited to being inserted into the brain of patient, because the vessels there are smaller than the cardiac vessels. To enable the navigation methods proven in cardiology also to be used in neurology, the invention provides a microcatheter having a guide wire, which features magnetic nanoparticles. The magnetic nanoparticles can be provided in the form of a ferrofluid or also as diamond nanoparticles in powder form. This enables navigation of the guide wire and thus ultimately of the catheter in the brain from the outside by way of magnetic fields.

Owner:SIEMENS AG

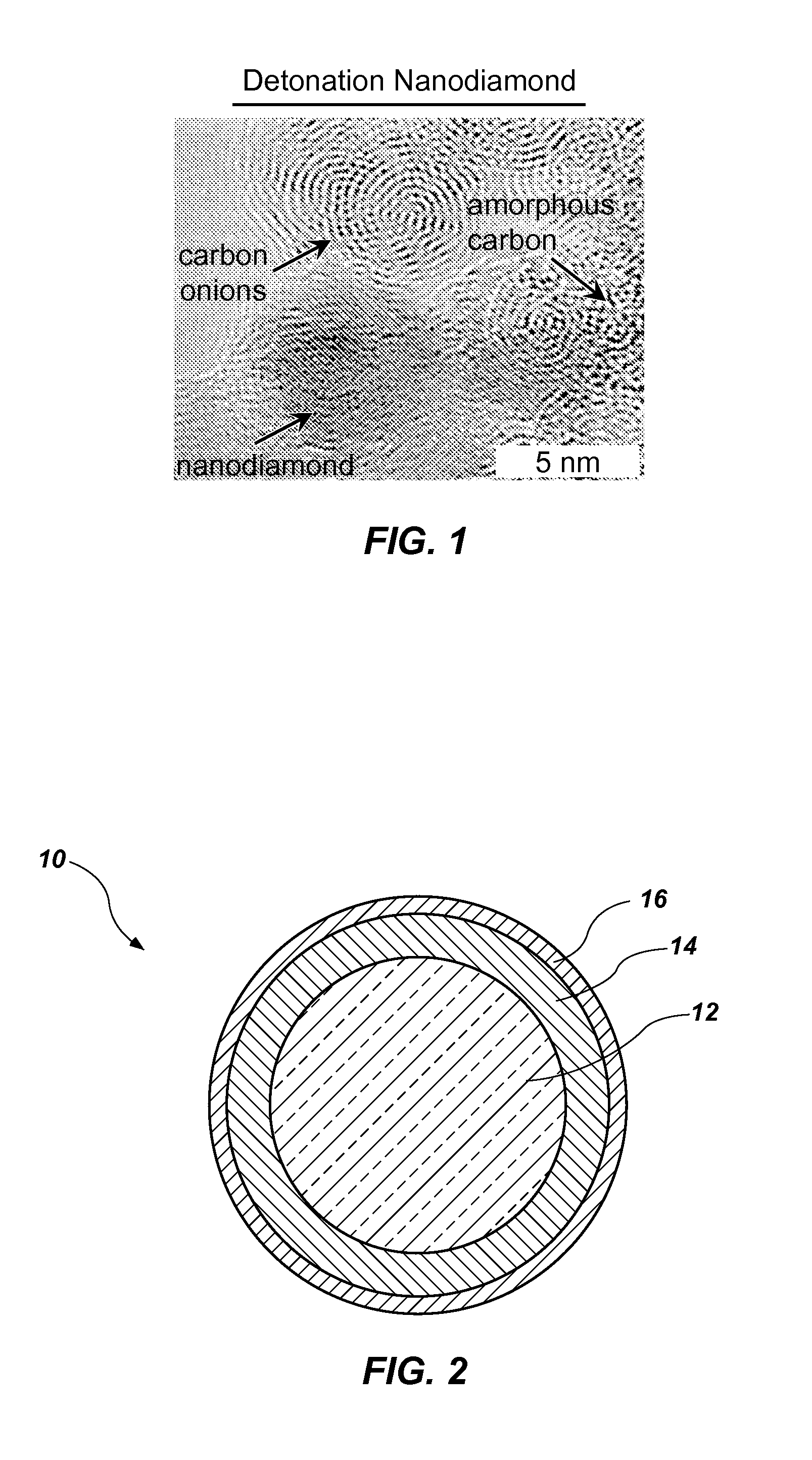

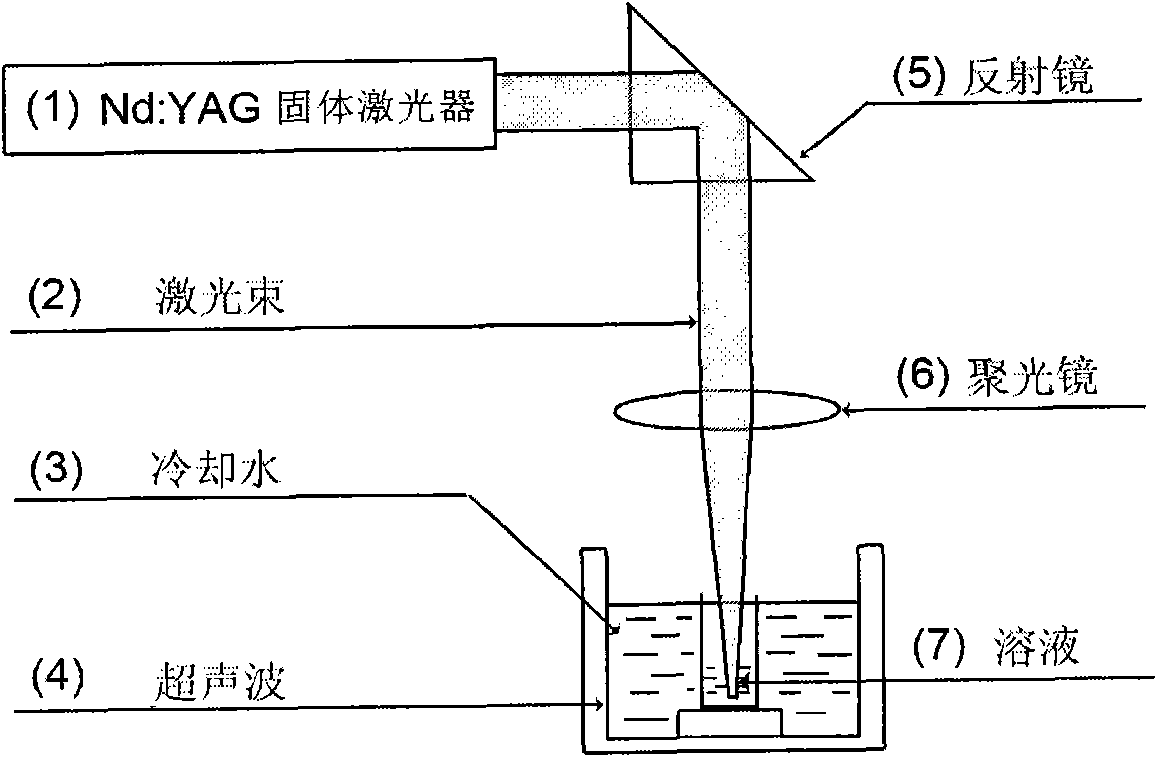

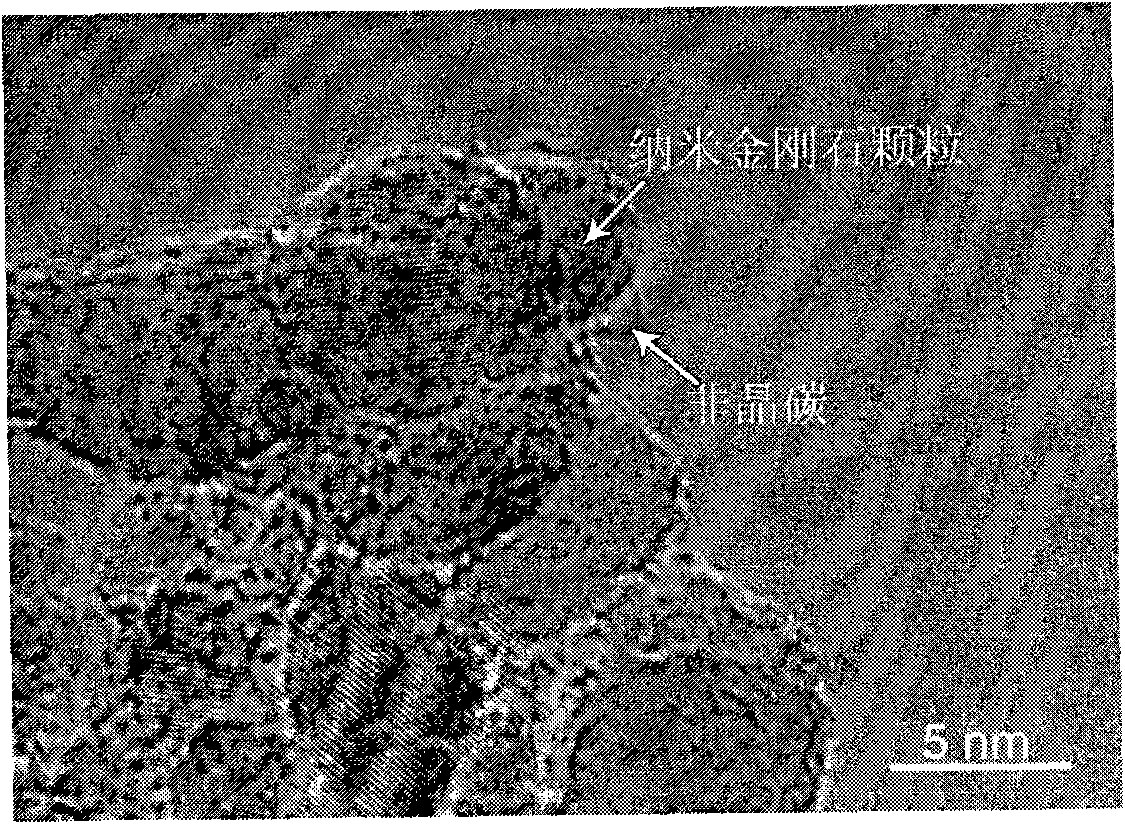

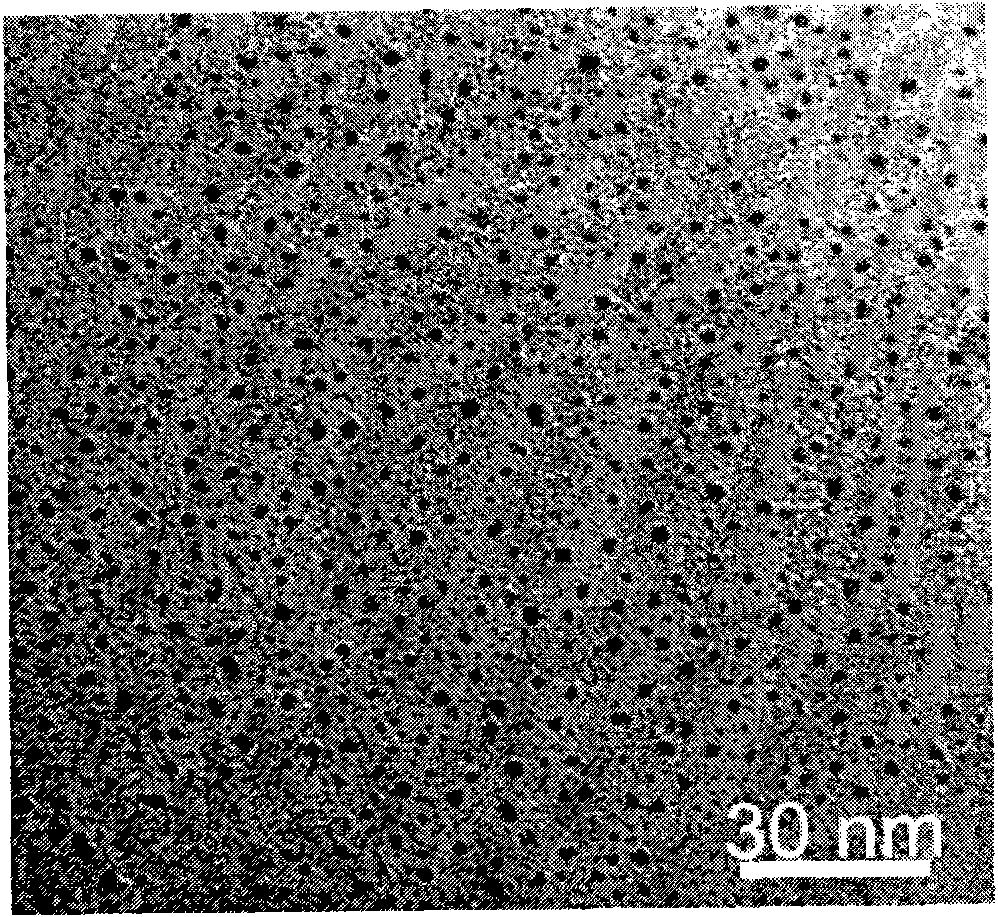

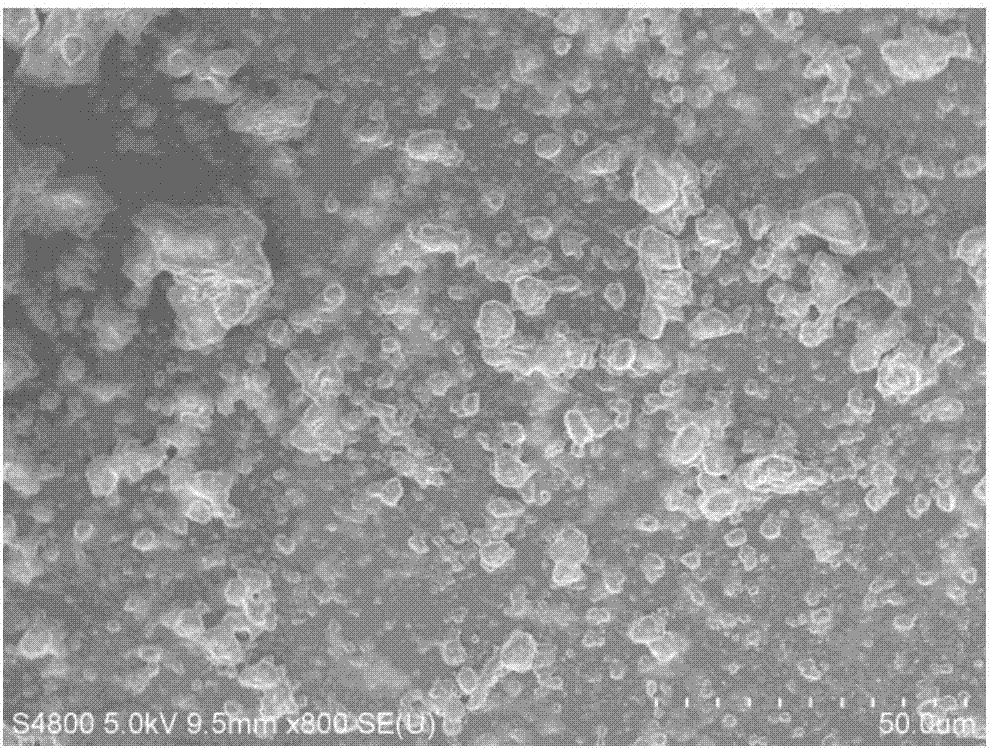

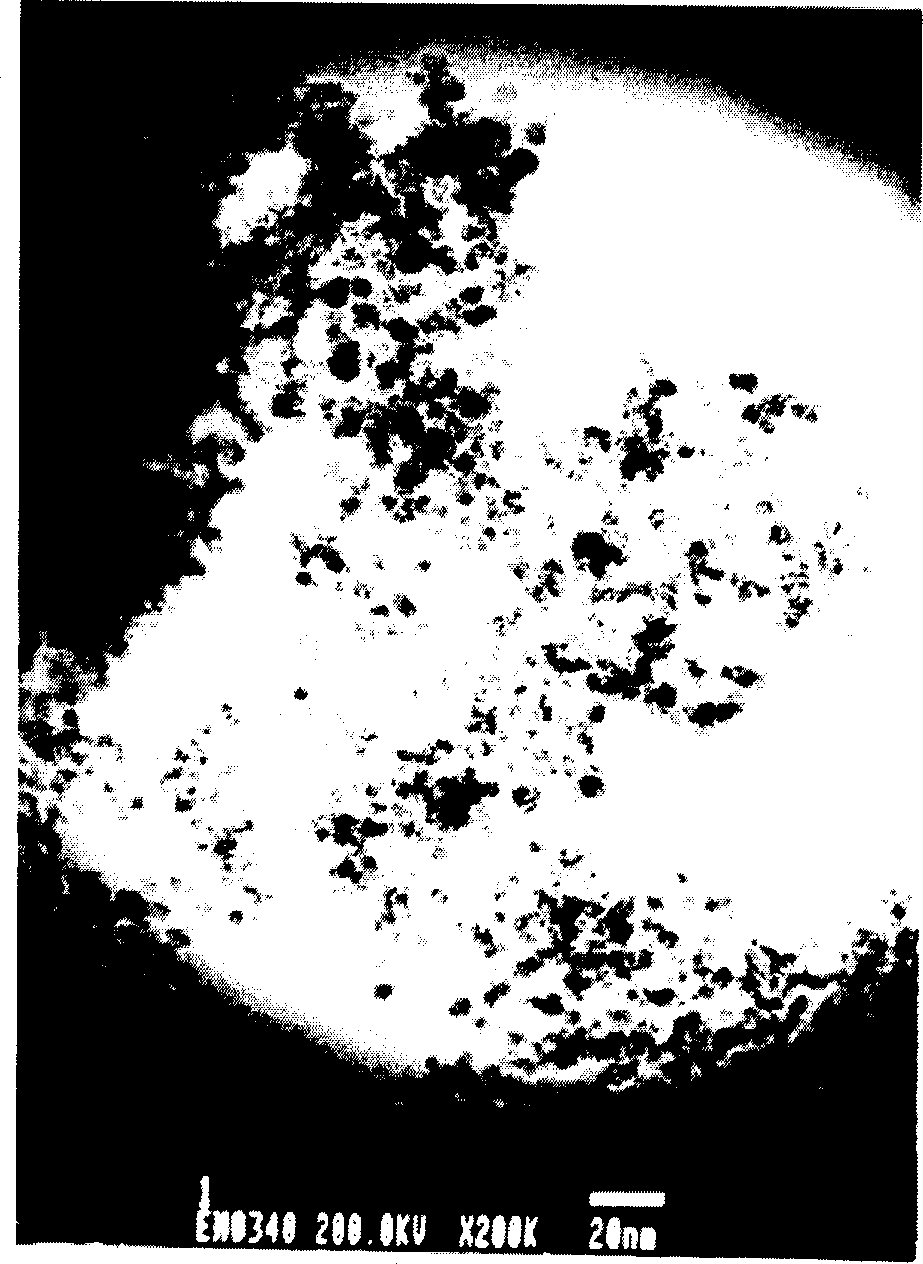

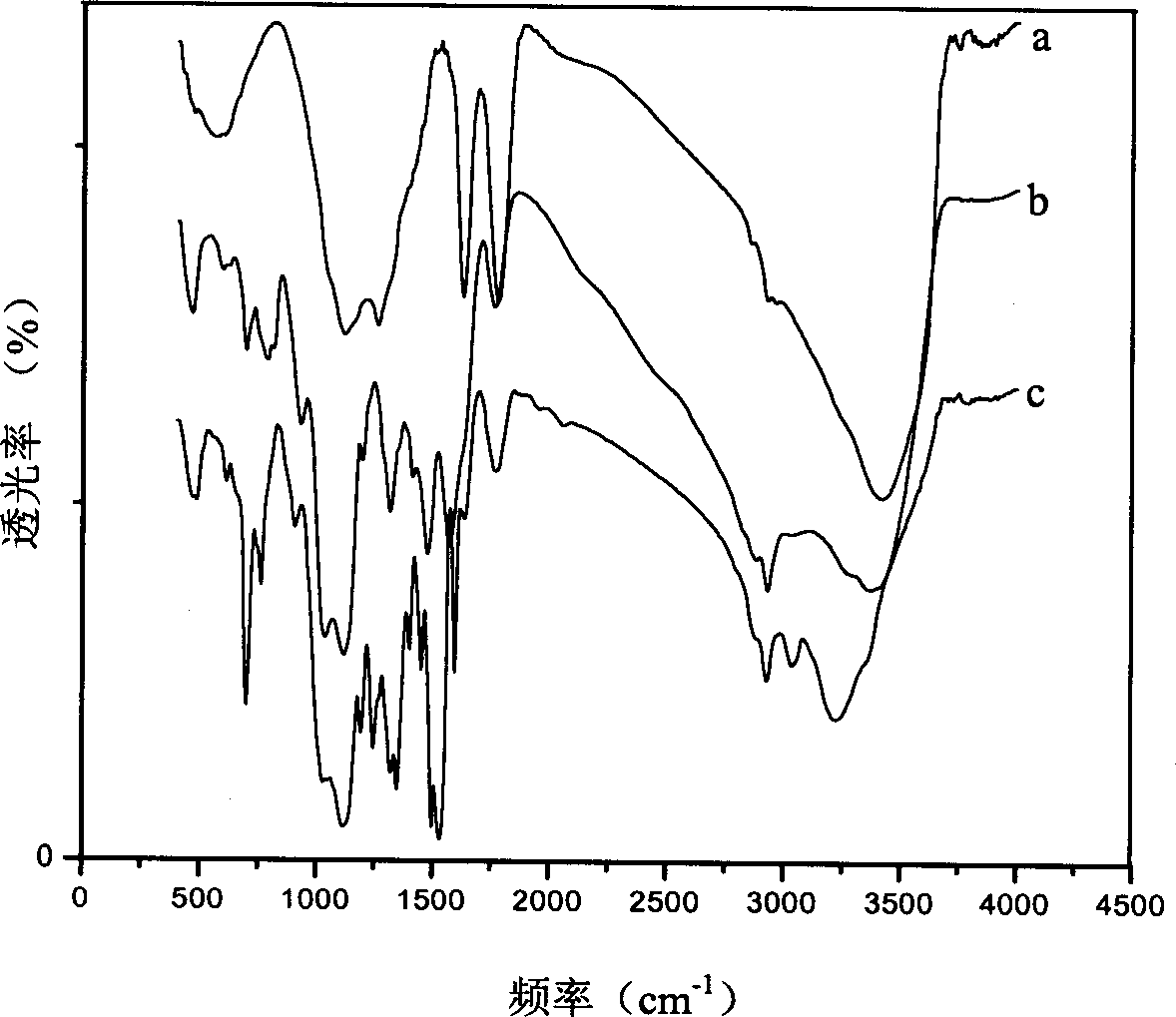

Method for dispersing detonation method nano-diamond in liquid phase

The invention discloses a method for dispersing a detonation method nano-diamond in a liquid phase. The method comprises the following steps of: a, mixing commercial detonation method nano-diamond powder serving as a raw material into a liquid medium for the ultrasonic processing to form a suspension; b, bombarding the suspension by using a pulse laser with a laser power density of 106W / cm<2> in the action area for 1 to 3h to obtain stable suspension with no precipitate; and c, oxidizing the product which is subjected to the laser bombardment by using strong acid. The method has the advantages of overcoming the problem of easy product pollution in the conventional process for dispersing the detonation method nano-diamond, and aggregating the aggregated detonation method nano-diamond in multiple kinds of solution to obtain monodisperse nano-diamond particles, along with simple process and safe and controllable laser action process. The method can be widely used in the fields of paint, polymer composites, lubrication and the like.

Owner:TIANJIN UNIV

Copper wire drawing lubricating fluid and preparation method thereof

InactiveCN103614221AImprove cooling effectExtended service lifeAdditivesManufacturing technologyPhosphate

The invention discloses a copper wire drawing lubricating fluid and a preparation method thereof. The lubricating fluid and the preparation method are characterized in that: the lubricating fluid is prepared from following raw materials by weight: 15-25 parts of palm oil, 2-3 parts of sodium petroleum sulfonate, 30-35 parts of polyethylene glycol, 1-2 parts of sulfurized calcium alkyl phenolate, 1-2 parts of a sodium naphthenate, 2-3 parts of a water soluble phosphate ester, 1-2 parts of sodium benzoate, 2-3 parts of triethanolamine oleate, 0.2-0.4 part of diamond nanoparticles, 10-14 parts of an antiwear agent and 1000 parts of water; nano aluminium nitride powder is added into the antiwear agent, thus promoting heat dissipation, enhancing cooling effects, enhancing film-forming property and prolonging the service lifetime; the service cycle of the lubricating fluid is long; and copper wires after wire drawing processes have significant characteristics of shining surfaces, capability of being stored for a long time, difficult surface oxidation, simple manufacturing technology, low technical requirements, and the like.

Owner:全威(铜陵)铜业科技有限公司

Document security, securities and article protection method using nanodiamonds with active NV centers

InactiveUS20100062144A1Non-fibrous pulp additionPaper-money testing devicesOptical propertyNanoparticle

The invention relates to the field of the protection of securities, documents, and articles. A method of protection of documents, securities, or articles using quantum markers based on active nitrogen vacancy centers in nanocrystals of diamonds is proposed in the invention. The technical result is an increase in the reliability of the protection of the object of protection against falsification. The technical result is achieved by the fact that, in a method of protection of documents, securities, and articles that consists in the fact that the optical properties of NV centers of nanoparticles of diamond are used for protection against counterfeits, during the fabrication of the object of protection, nanoparticles of diamond measuring from 5 to 150 nm are introduced into it or into its constituent components. 1 dependent claim, 2 illustrations.

Owner:OOO NOVYE ENERGETICHESKIE TEHNOLOGII

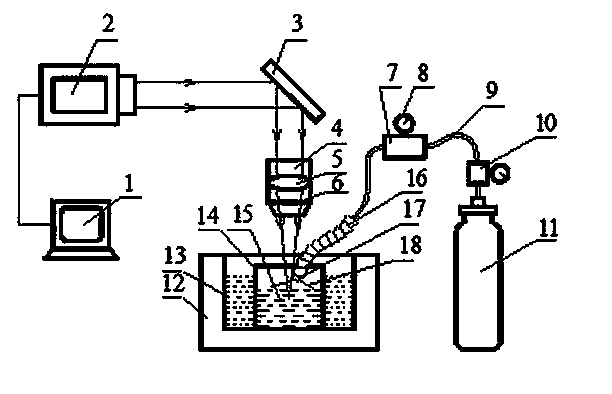

Method and device for nanosecond pulse laser-assisted preparation of nano-diamond

InactiveCN103508451AEnables continuous synthesisAchieve relative movementMaterial nanotechnologyDiamondNanoparticlePhysical chemistry

The invention relates to a method and device for nanosecond pulse laser-assisted preparation of nano-diamond. A mixed liquor of graphite powder and deionized water is exposed to nanosecond pulse laser irradiation generated by a laser generator, the graphite powder absorbs the laser energy and then rapidly generates high-temperature high-pressure plasmas, and during the nanosecond-level extremely non-equilibrium process, diamond nucleates and grows. Conical high-pressure gas jetted out of a conical nozzle forms a barrier to a trace amount of splashing liquid during the reaction, so as to protect a laser head and recover the splashing liquid and increase the synthesis efficiency of nano-diamond. The method and device provided by the invention solve the problem in the prior art that the synthetic diamond method has harsh conditions or low synthesis efficiency, achieves the effect of synthesizing diamond nanoparticles under normal temperature and normal pressure, ensures that the synthesized nano-diamond has good dispersion and uniformly size distribution, and has significant application in the aspects of ultra-precision machining and lubrication.

Owner:JIANGSU UNIV

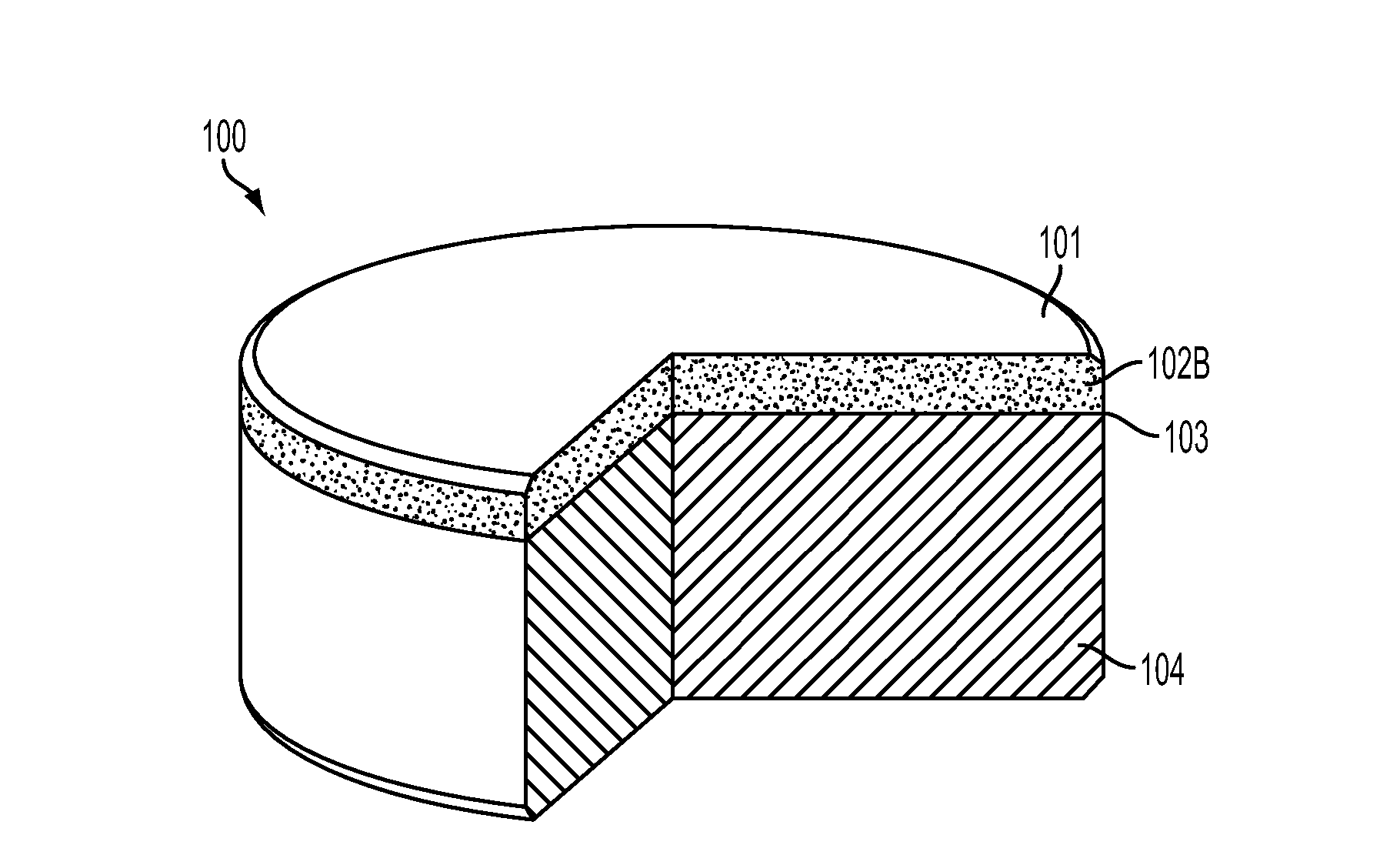

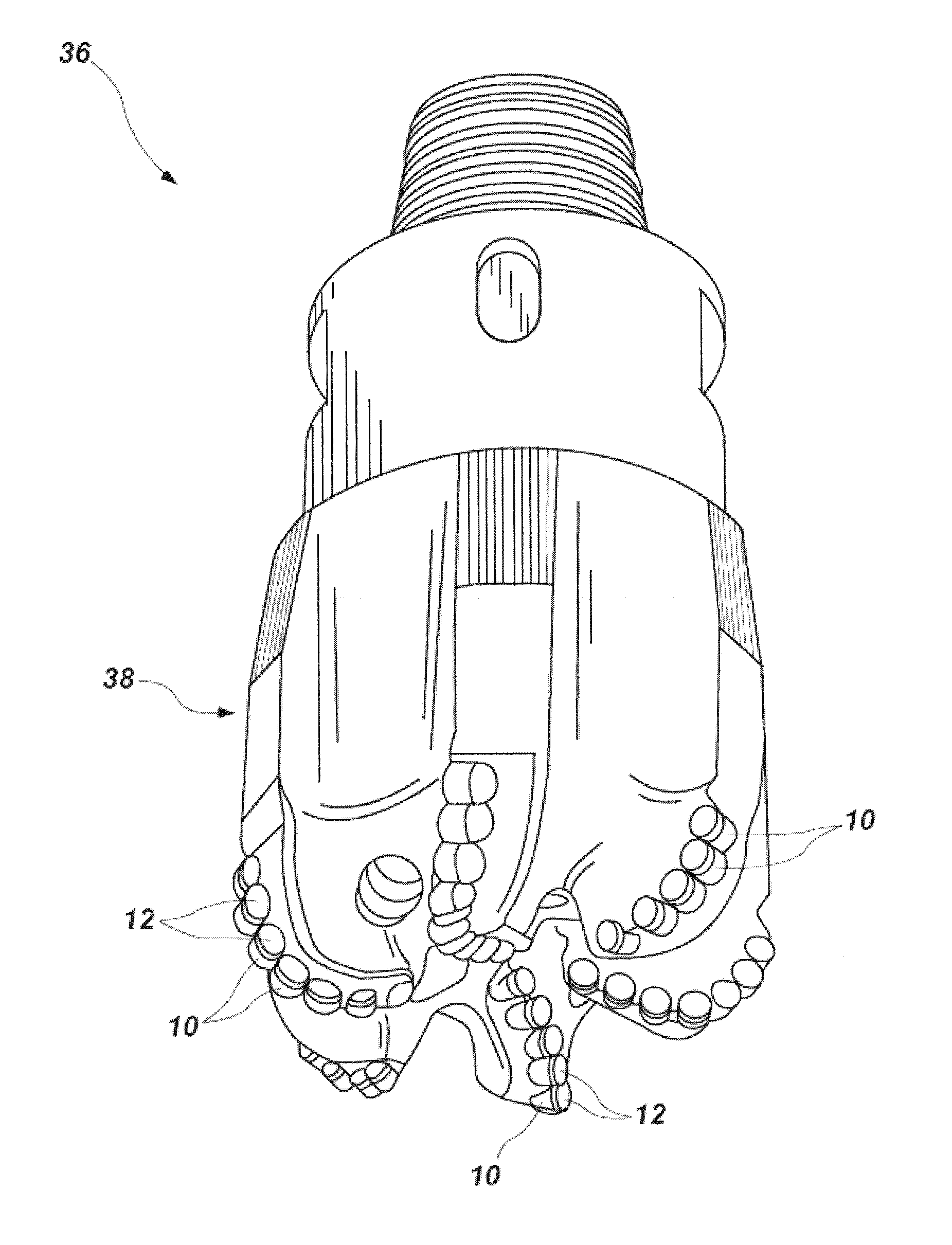

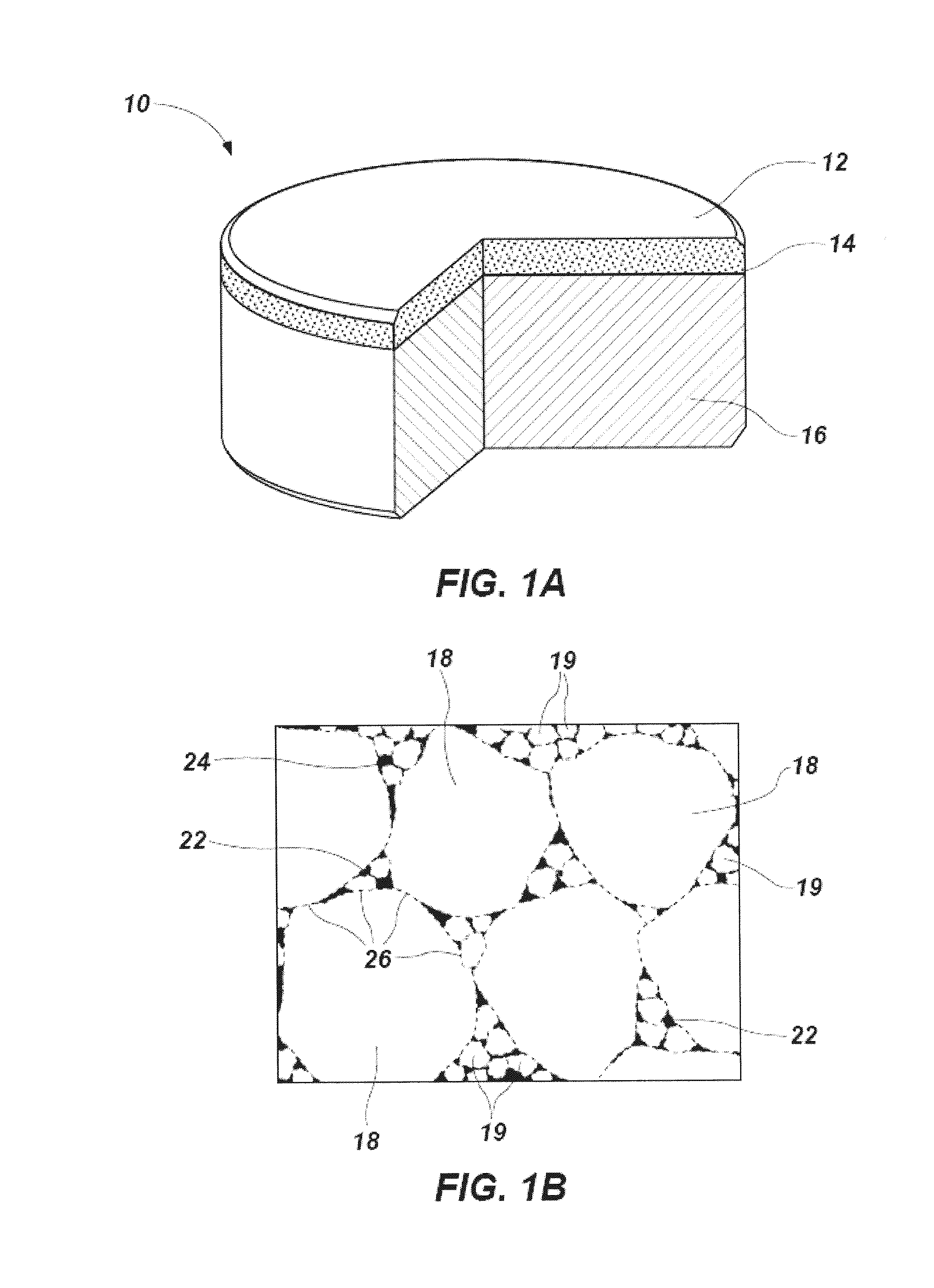

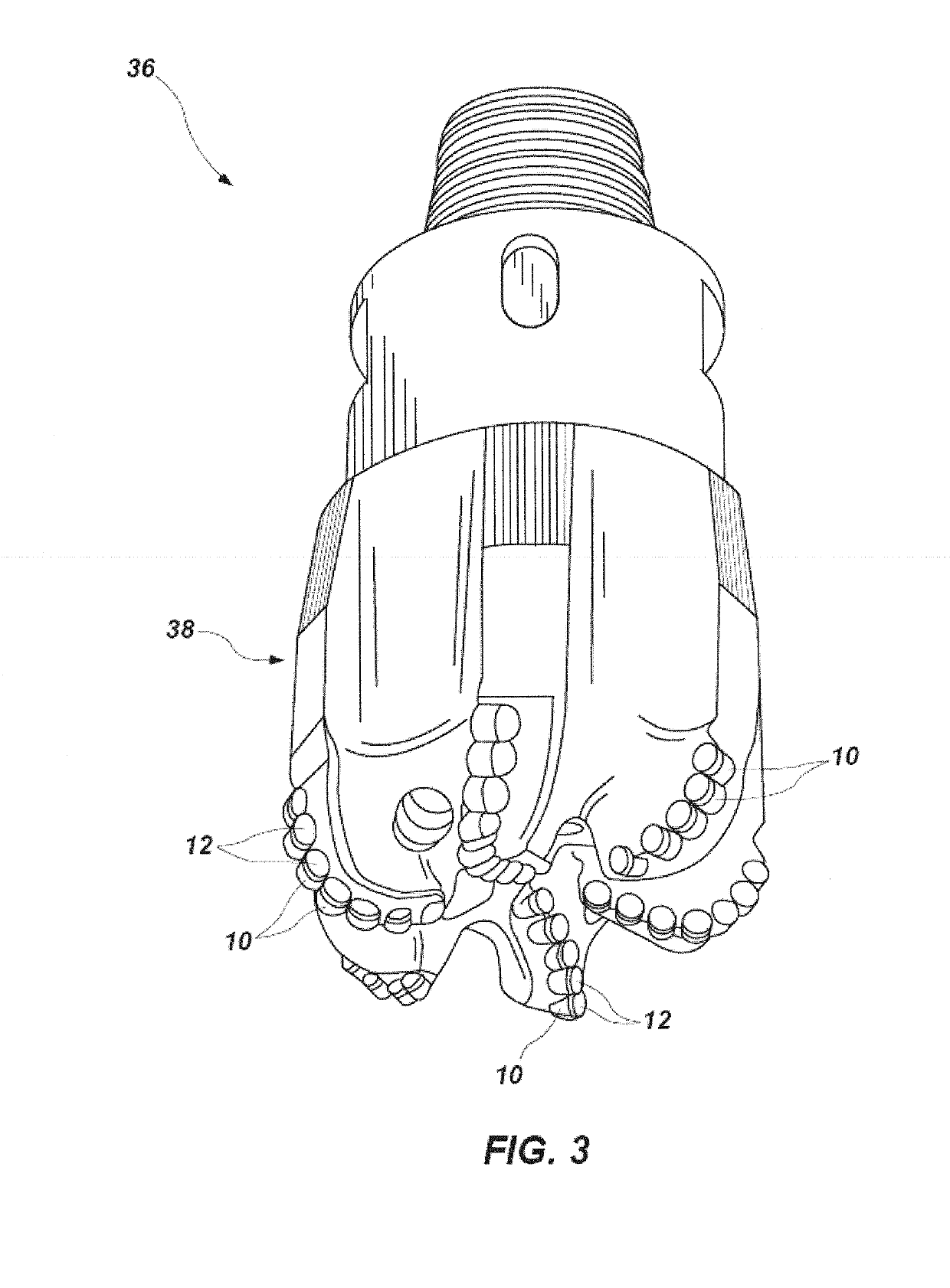

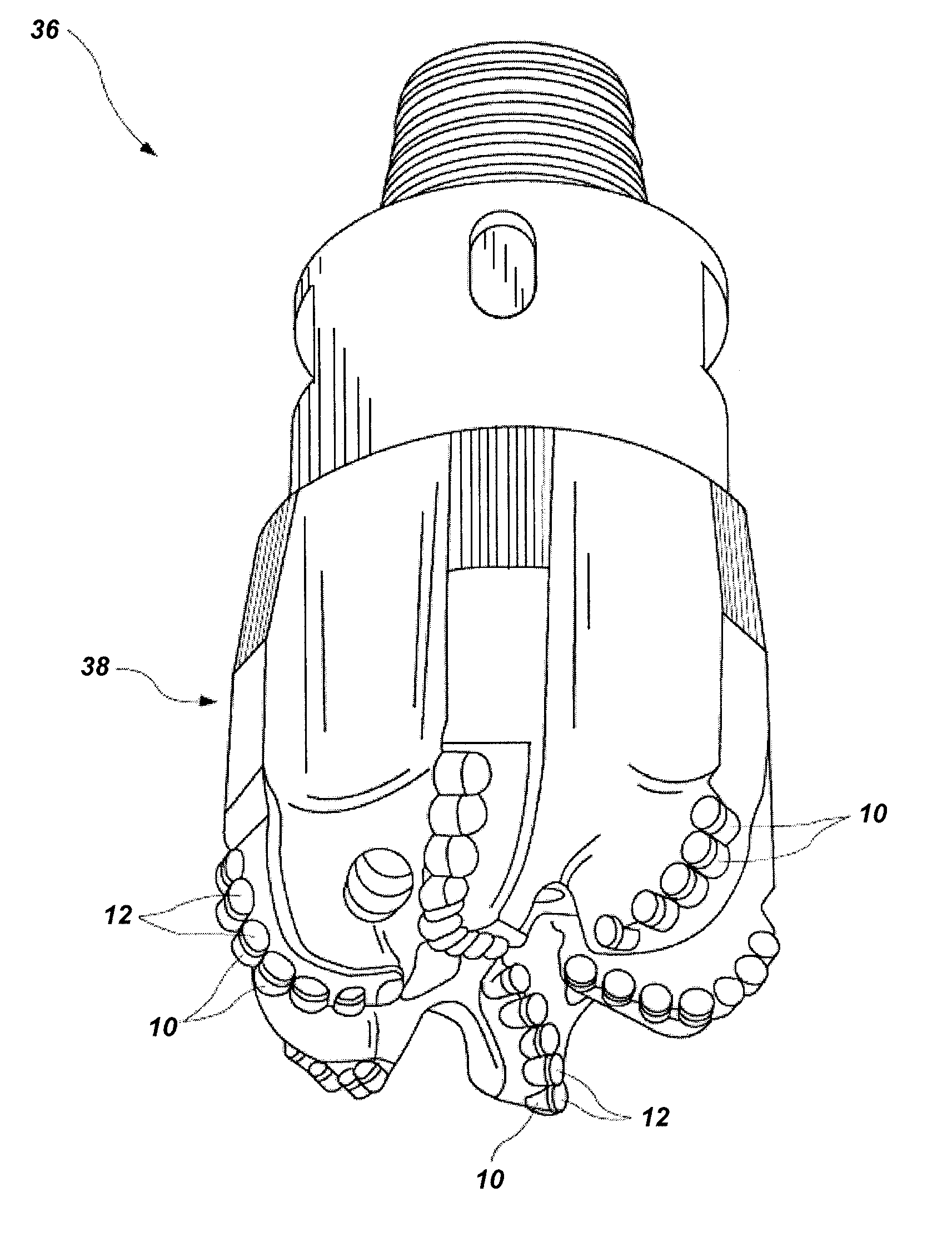

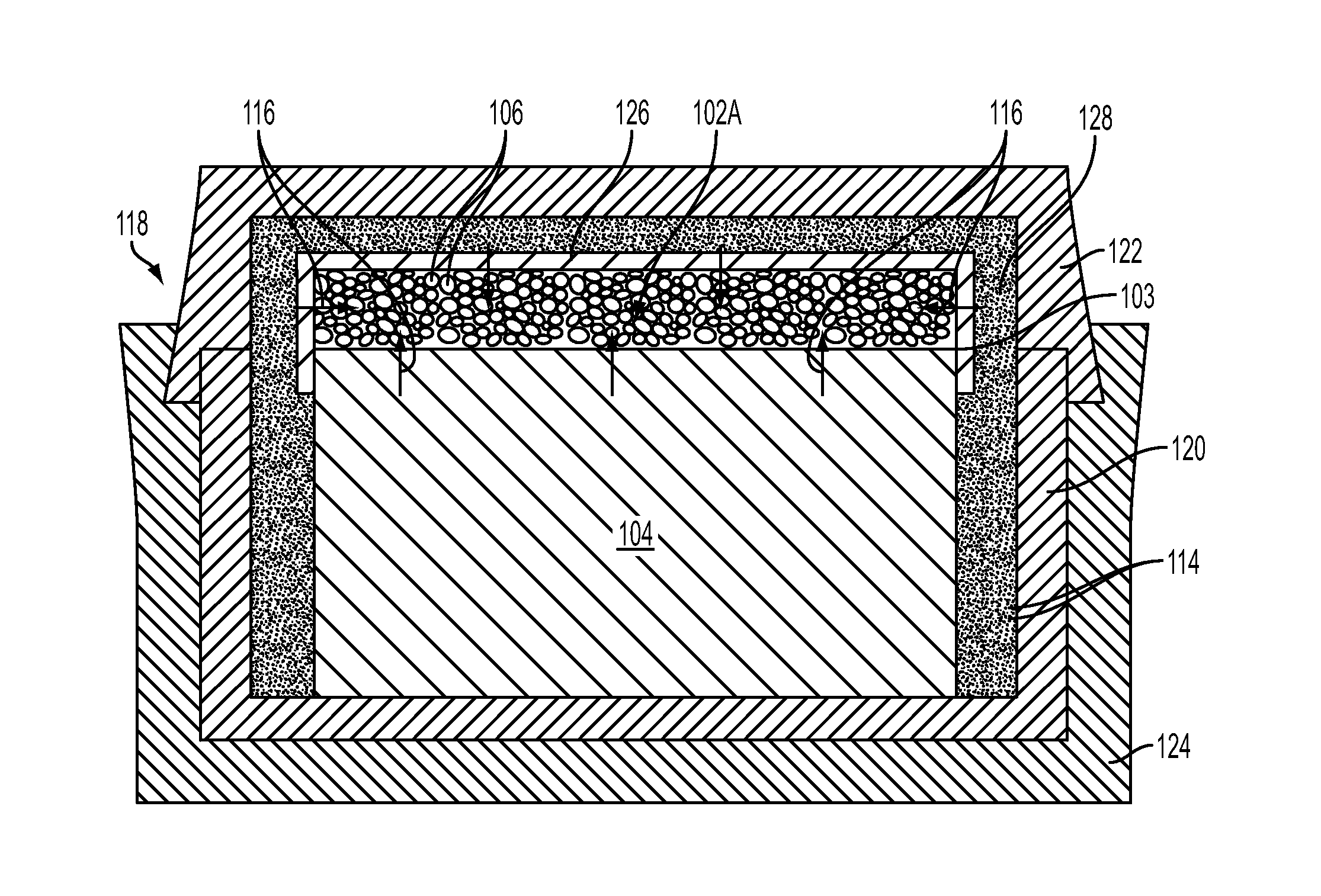

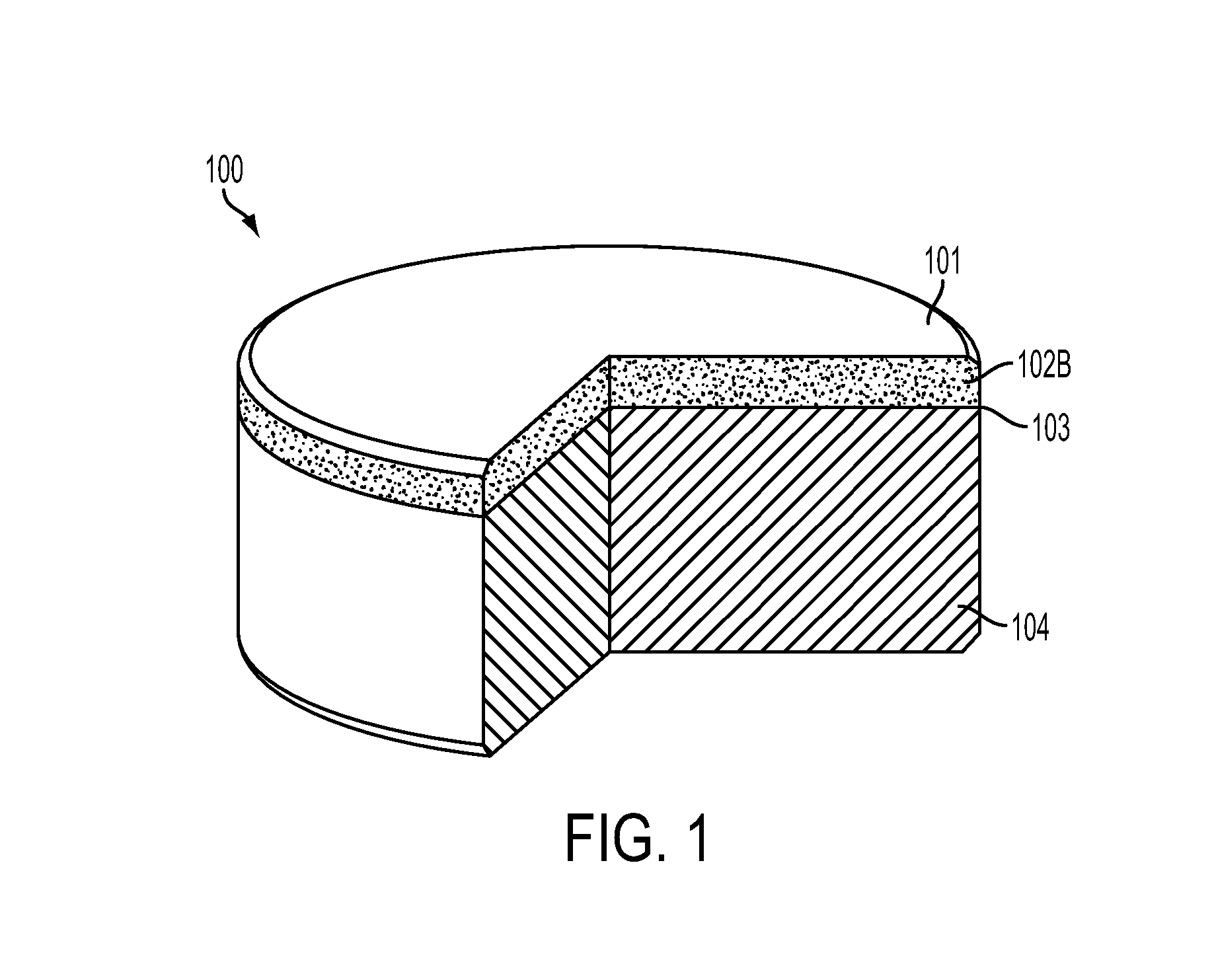

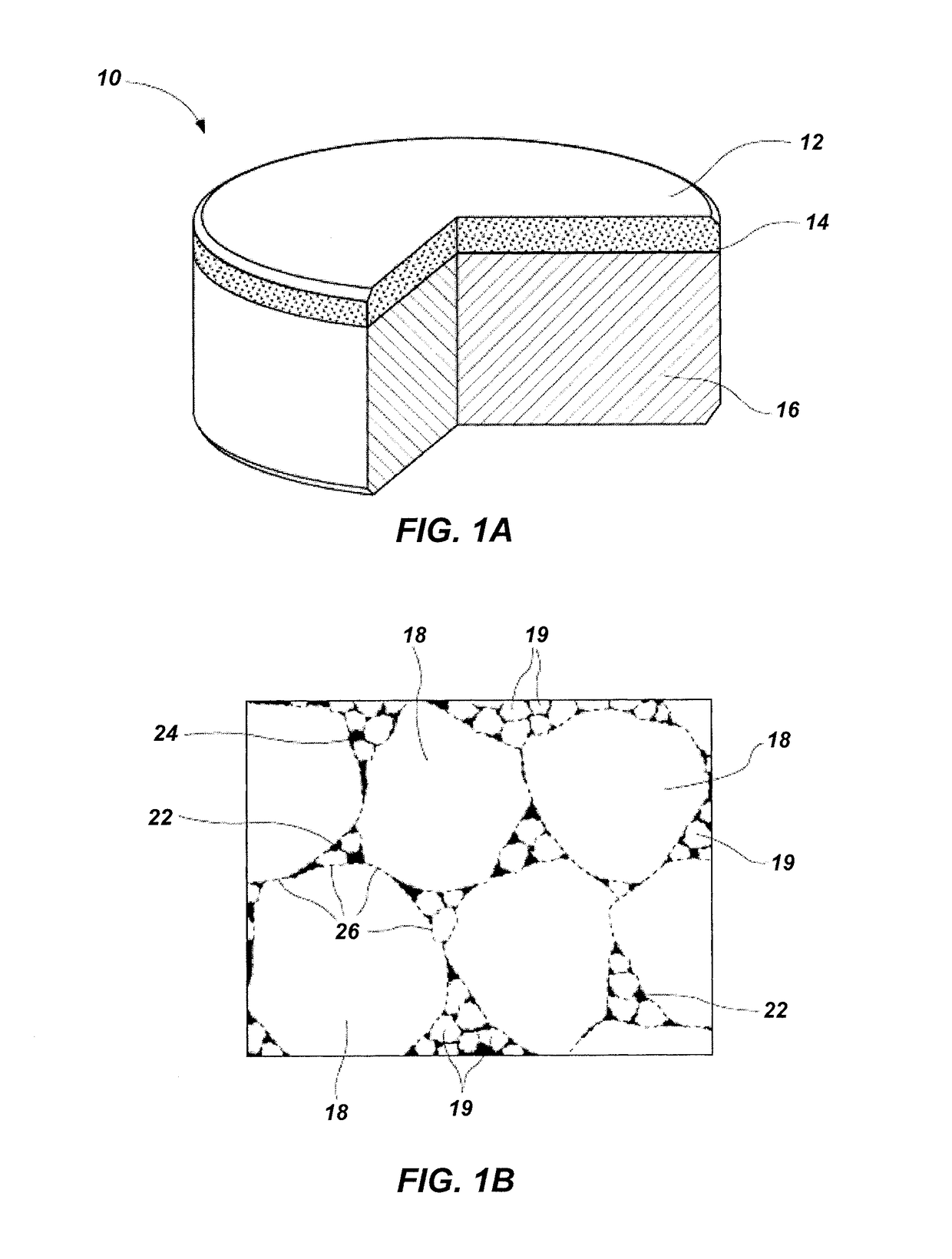

Methods of forming a cutting element for an earth-boring tool, a related cutting element, and an earth-boring tool including such a cutting element

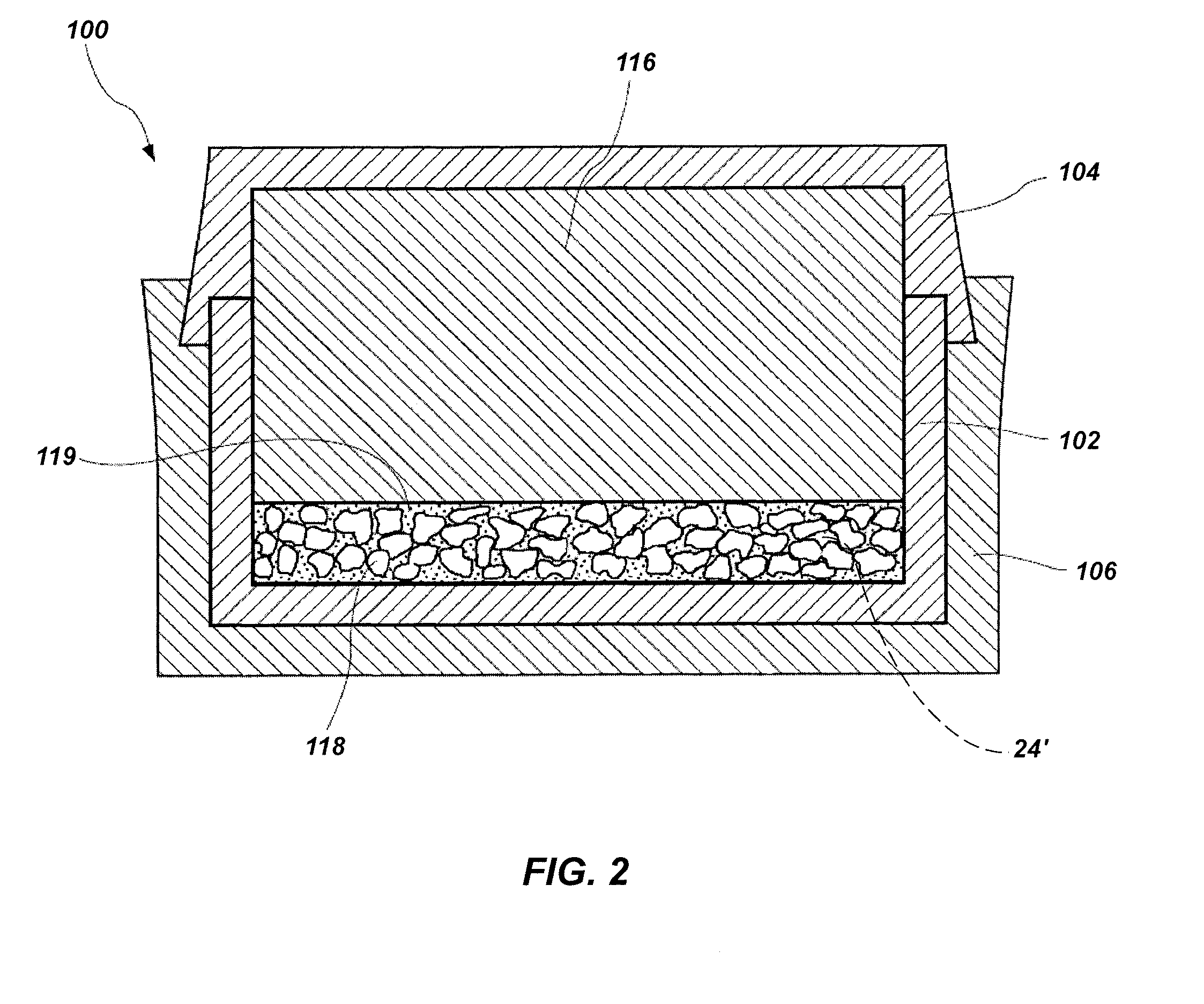

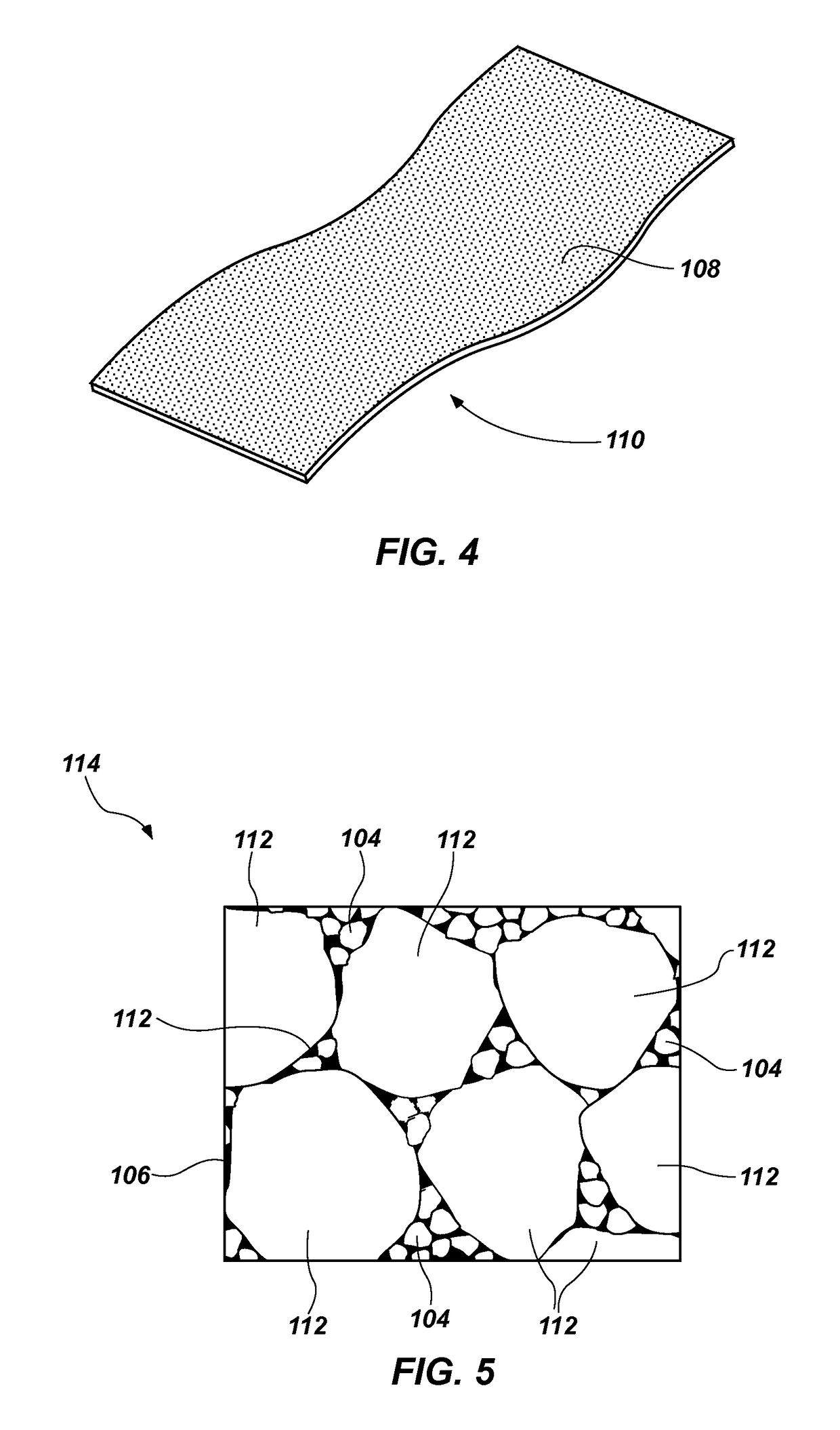

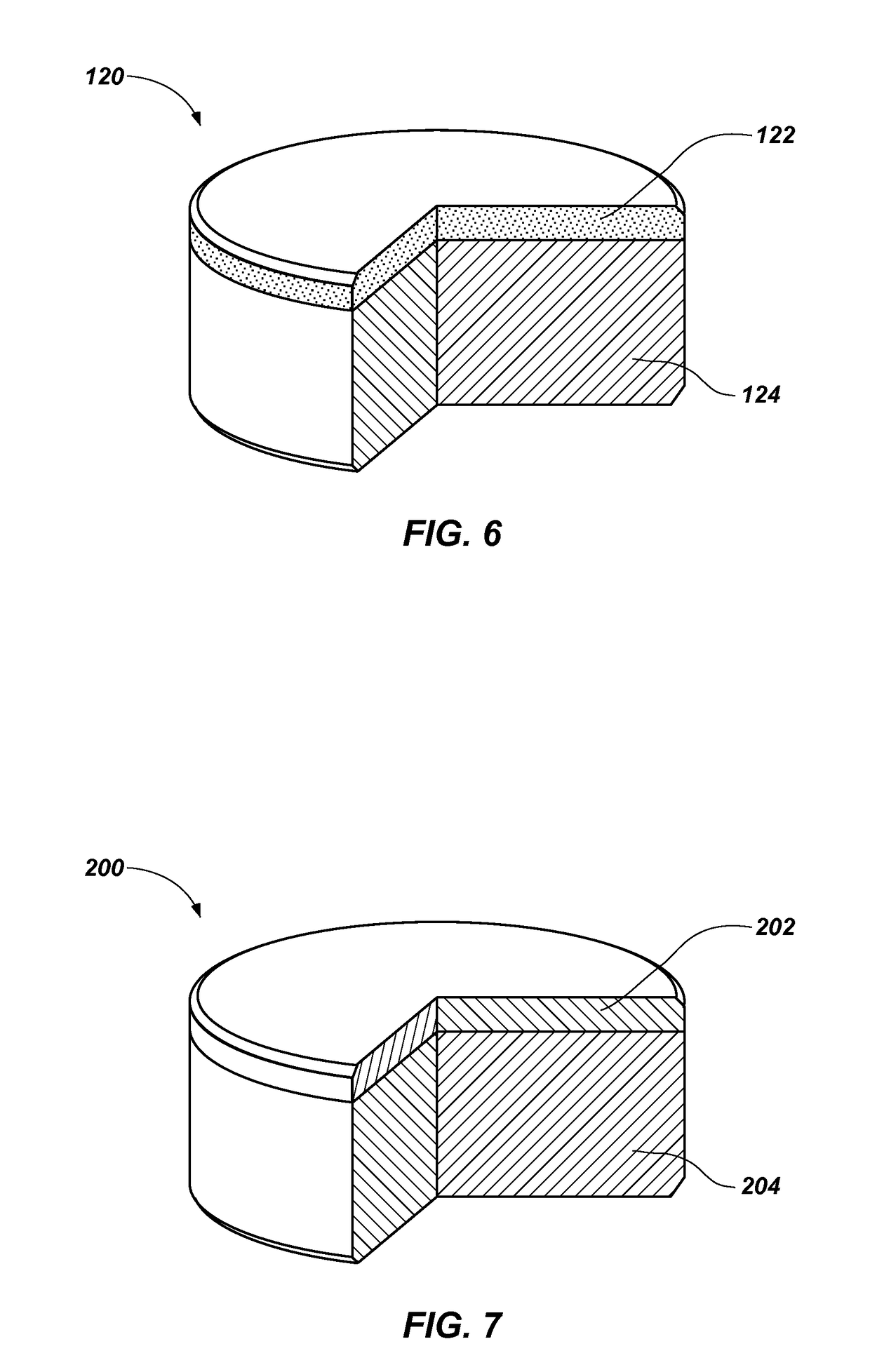

A method of forming a cutting element for an earth-boring tool. The method includes providing diamond particles on a supporting substrate, the volume of diamond particles comprising a plurality of diamond nanoparticles. A catalyst-containing layer is provided on exposed surfaces of the volume of diamond nanoparticles and the supporting substrate. The diamond particles are processed under high temperature and high pressure conditions to form a sintered nanoparticle-enhanced polycrystalline compact. A cutting element and an earth-boring tool including a cutting element are also disclosed.

Owner:ELEMENT SIX LTD +1

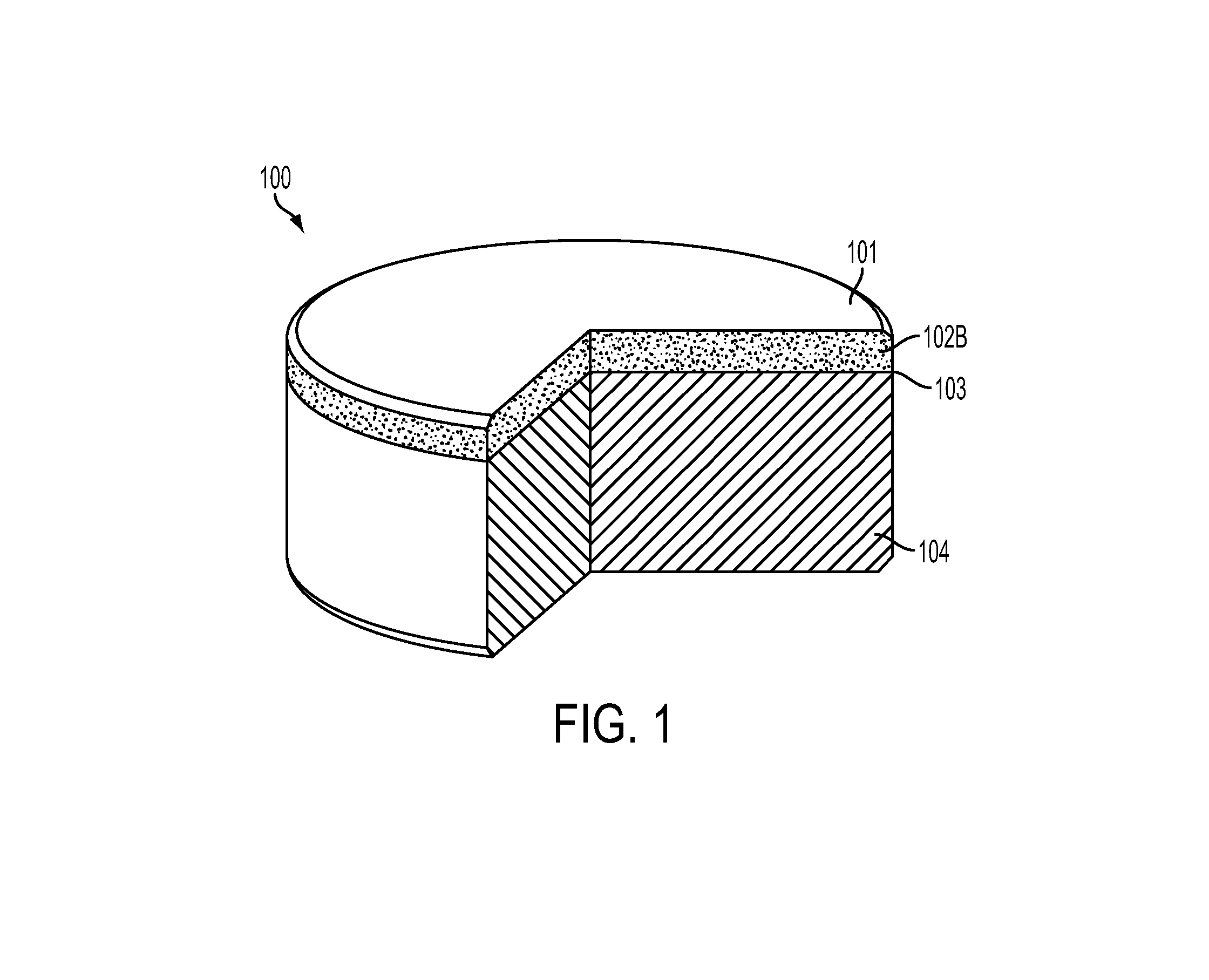

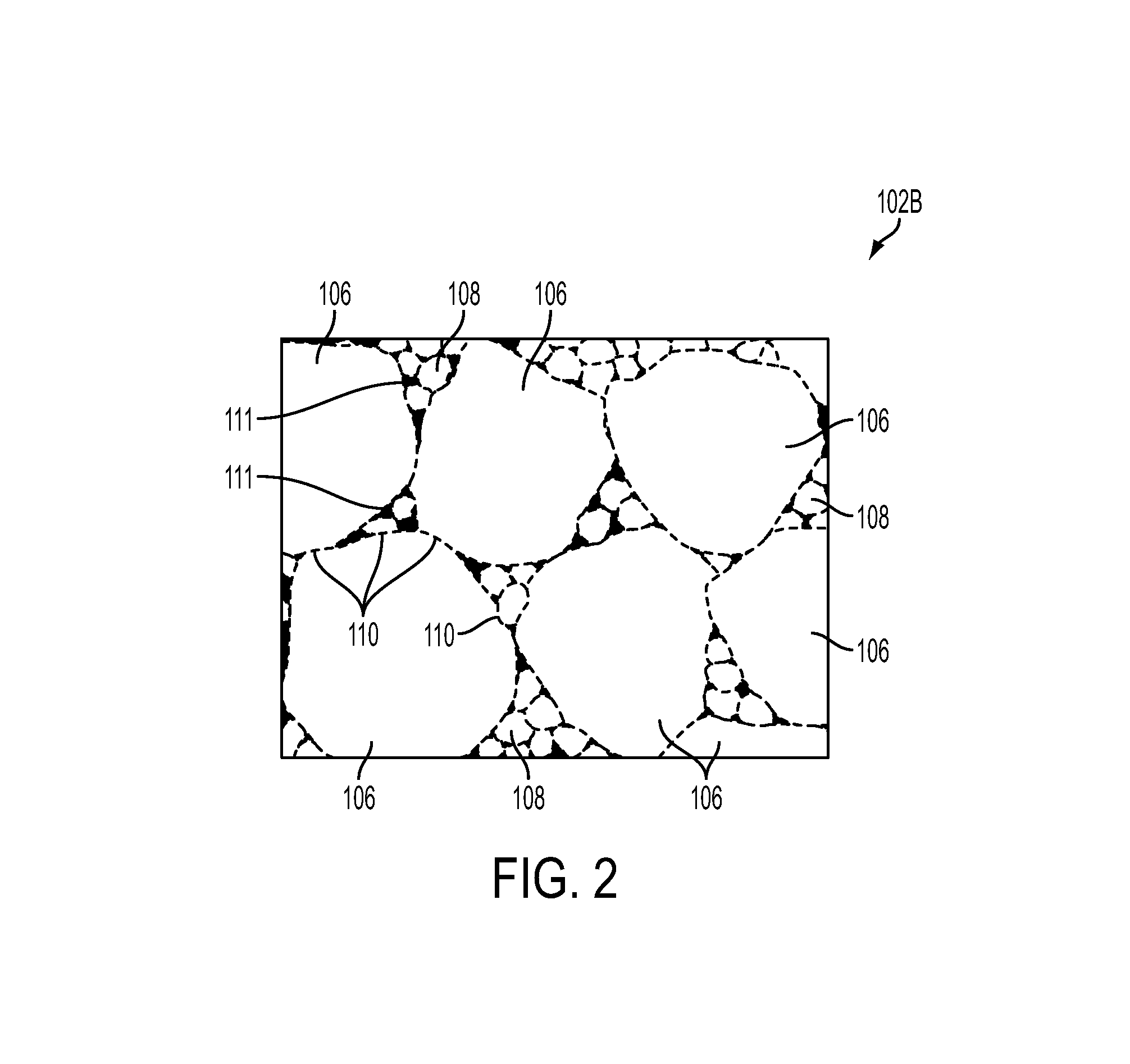

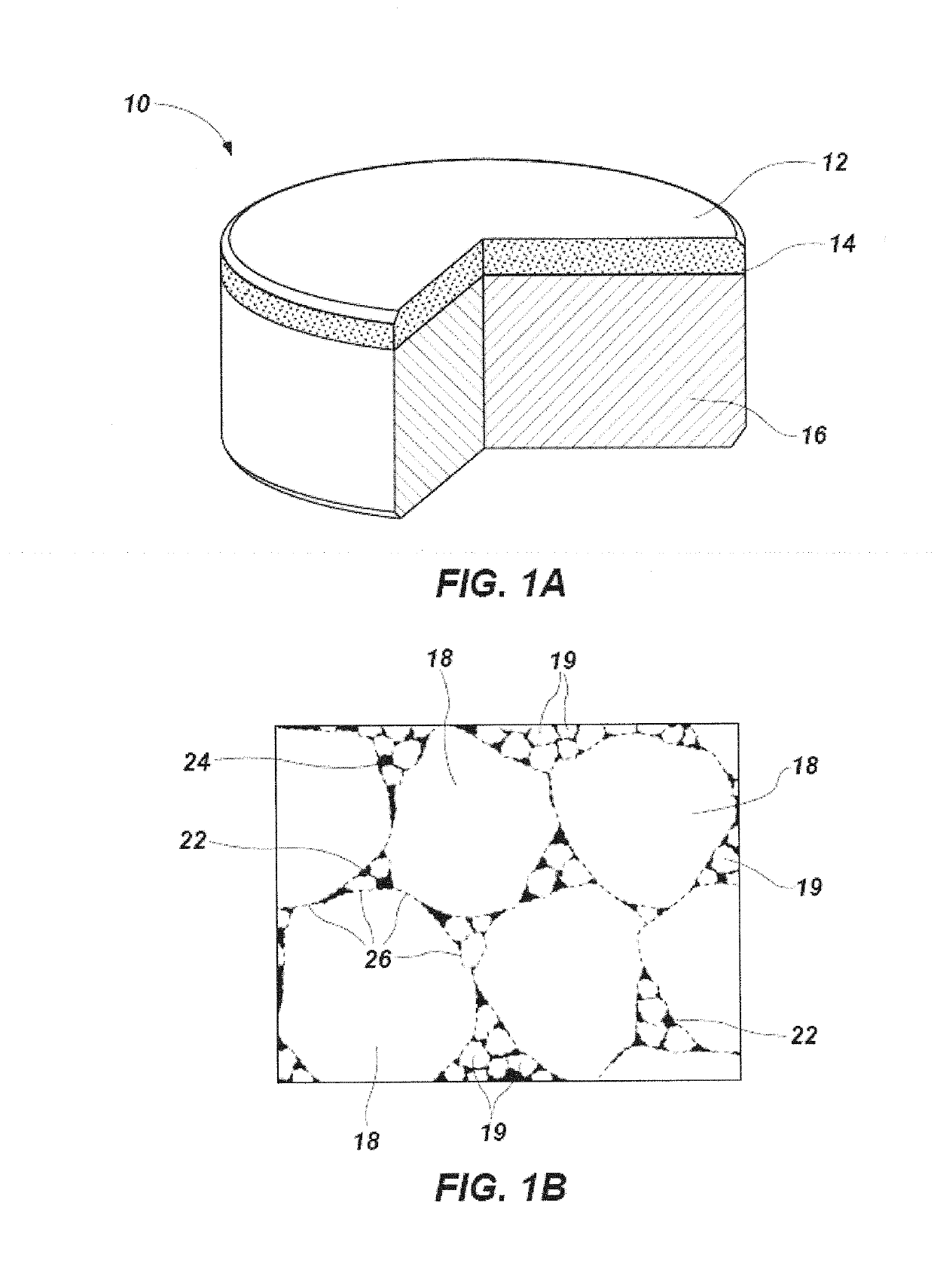

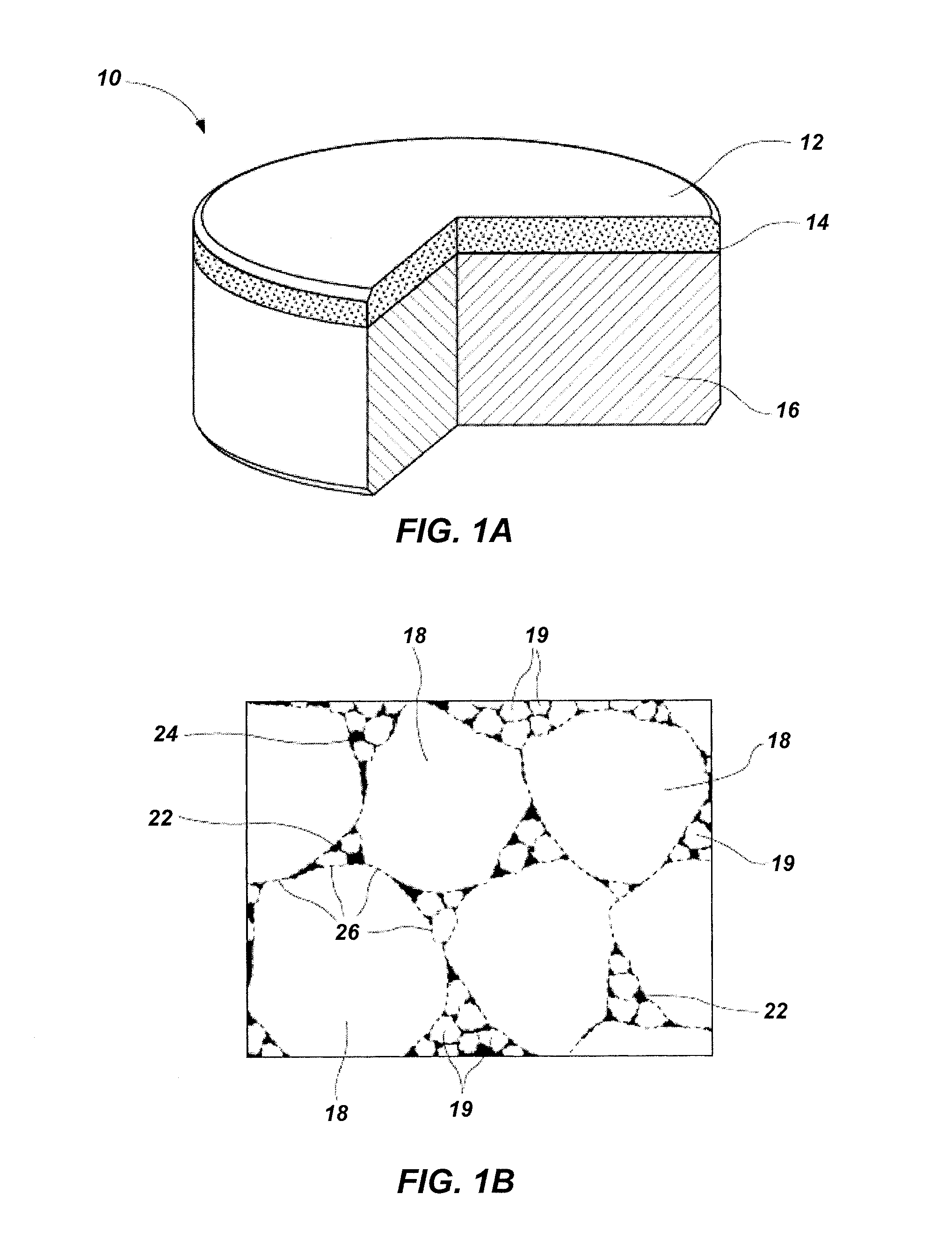

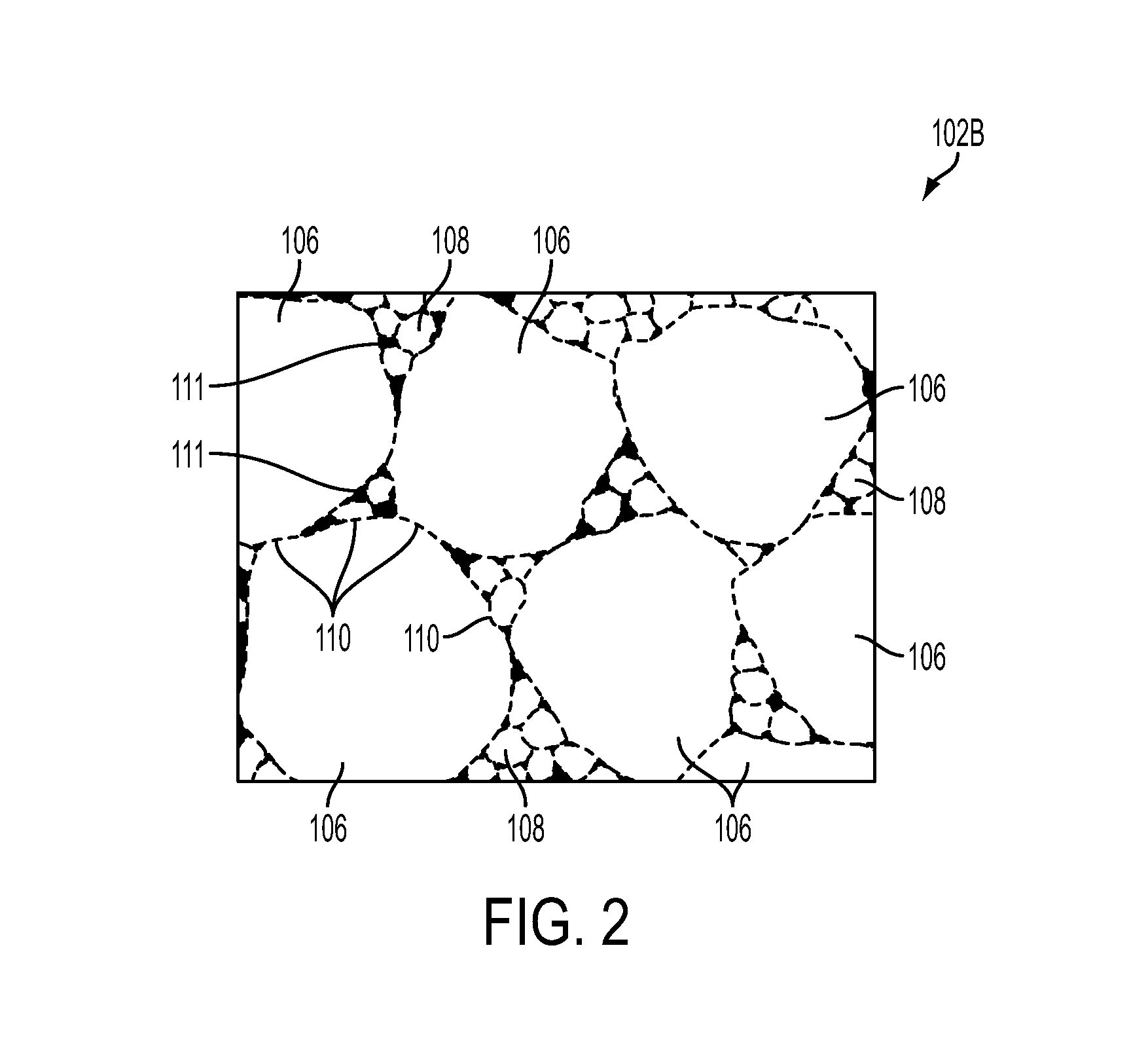

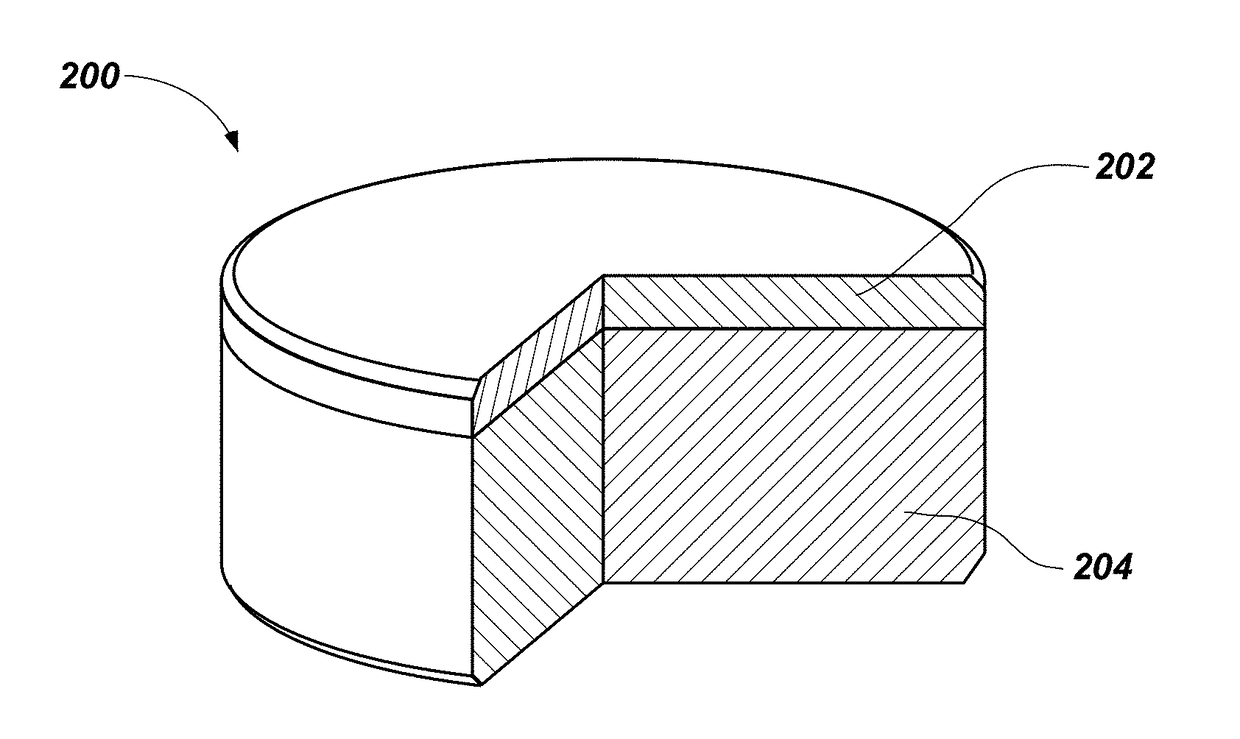

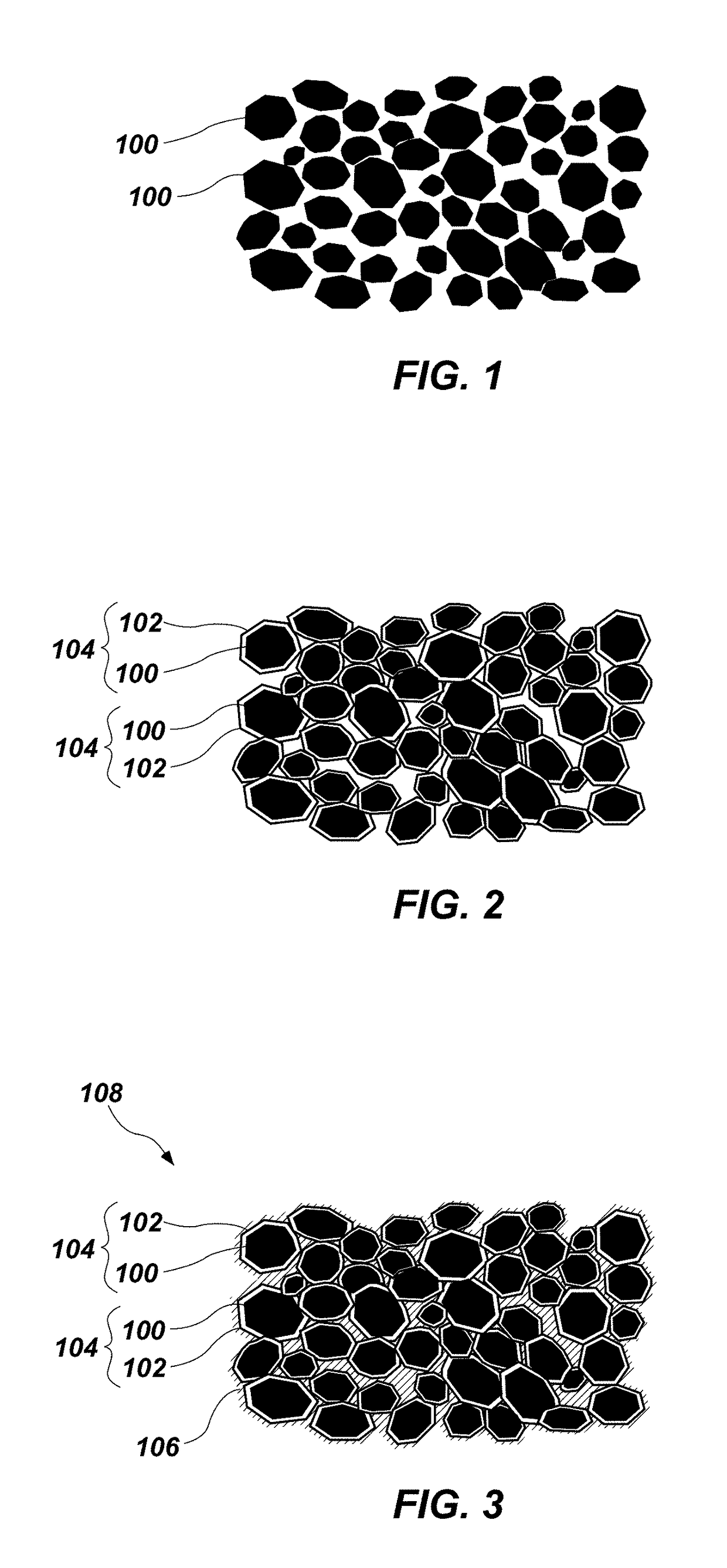

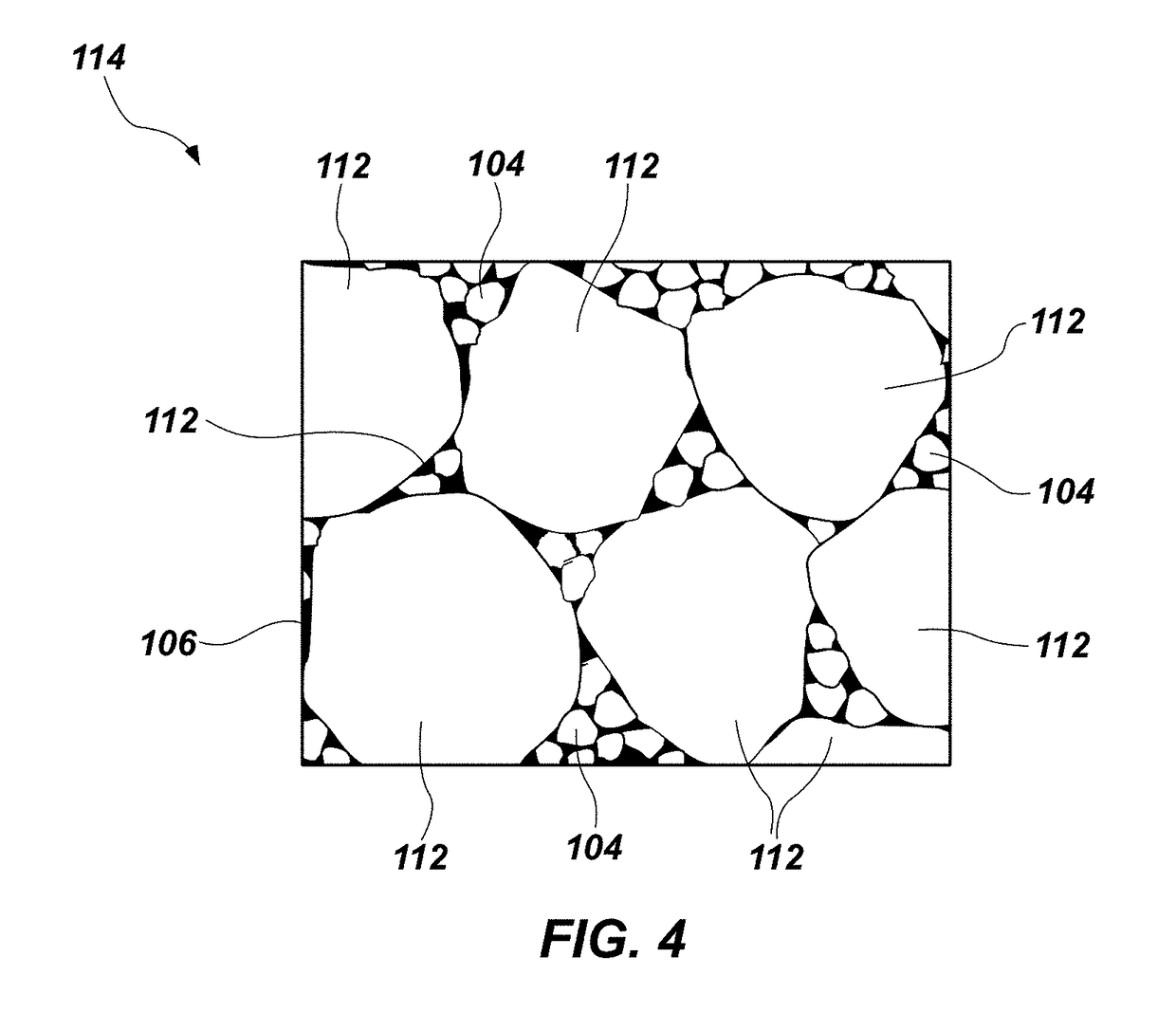

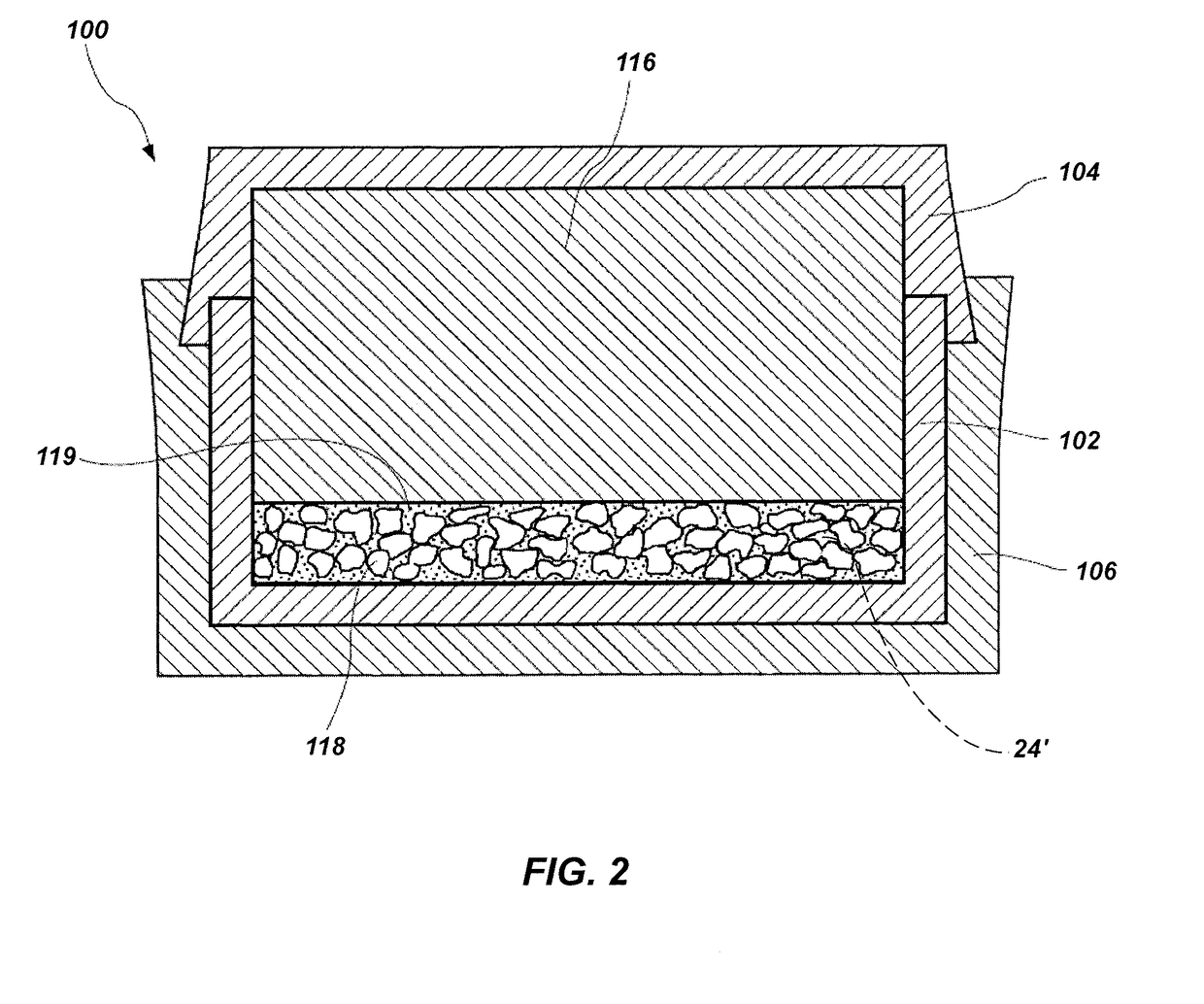

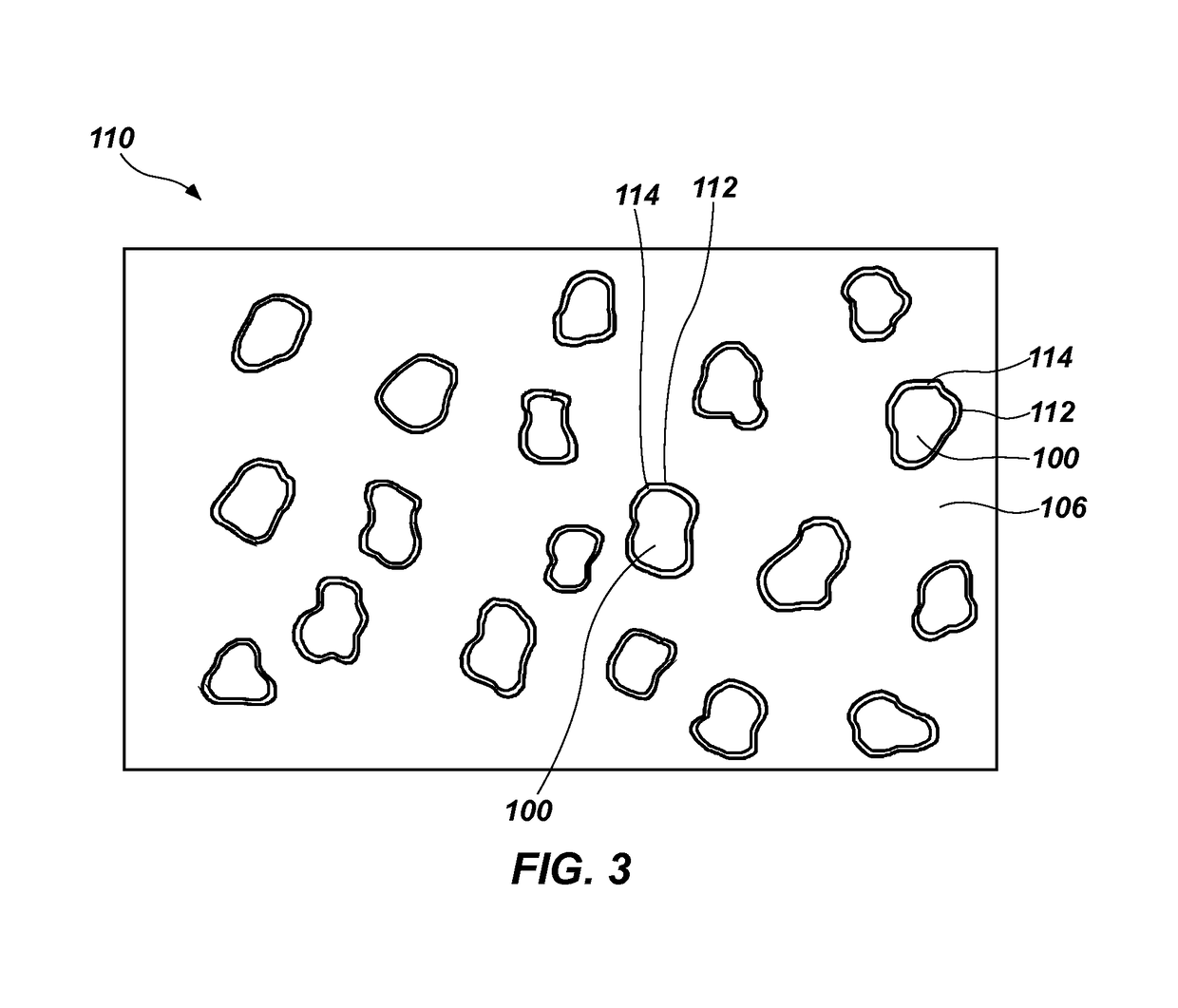

Polycrystalline compacts including diamond nanoparticles, cutting elements and earth-boring tools including such compacts, and methods of forming same

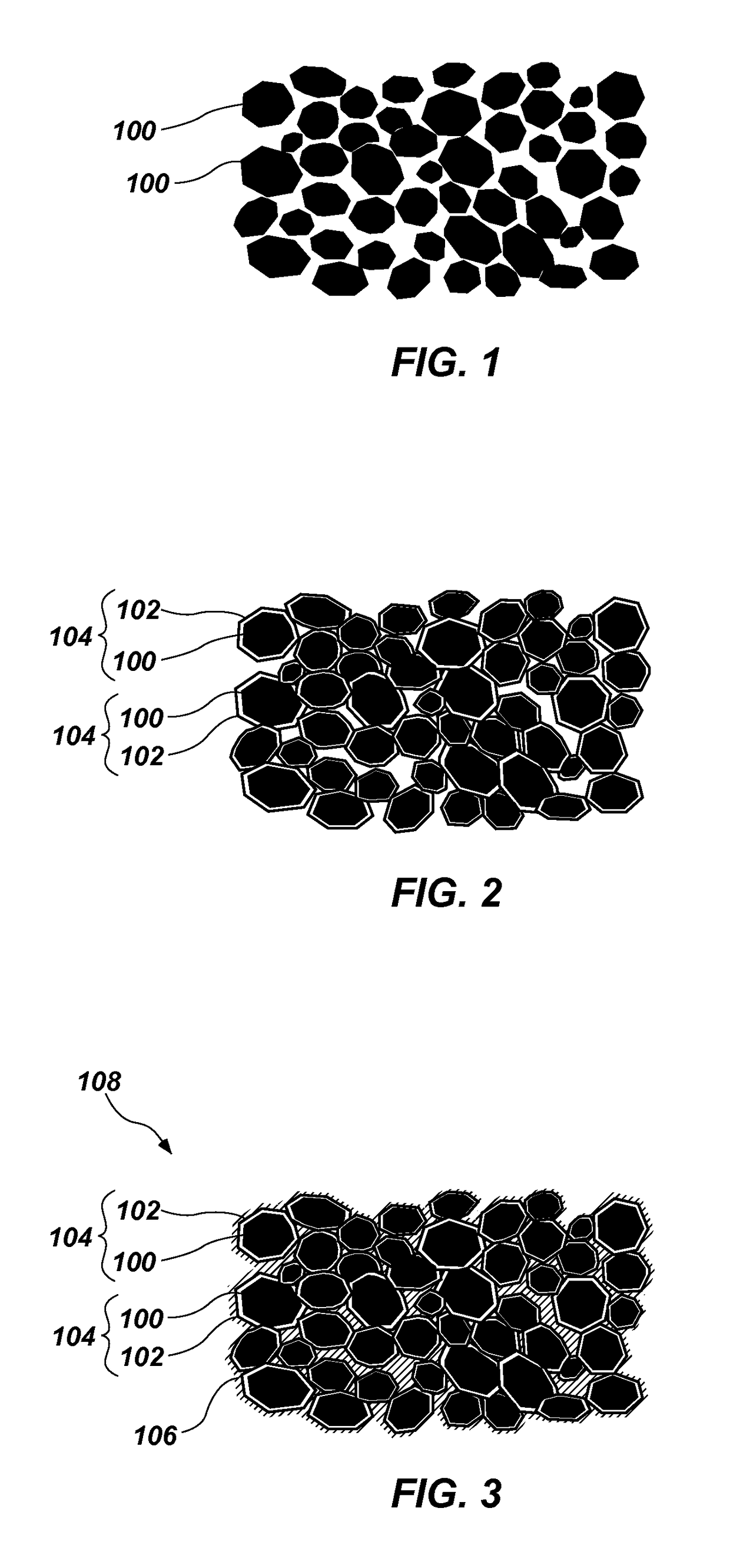

A polycrystalline compact comprises a plurality of diamond grains of micron size, submicron size, or both, and a plurality of diamond nanoparticles disposed in interstitial spaces between the plurality of diamond grains. A method of forming a polycrystalline compact comprises combining a plurality of micron and / or submicron-sized diamond grains and a plurality of diamond nanoparticles to form a mixture and sintering the mixture in a presence of a carburized binder to form a polycrystalline hard material comprising a plurality of inter-bonded diamond grains and diamond nanoparticles. Cutting elements comprising a polycrystalline compact and earth-boring tools bearing such compacts are also disclosed.

Owner:ELEMENT SIX LTD +1

Texturing processing composition

InactiveCN1985306AHigh densityImprove recording densityOther chemical processesLapping machinesNanoparticleSurface roughness

A composition of high processing rate that is capable of not only decreasing the post-texturing average surface roughness (Ra) of a glass-made magnetic disk surface and aluminum-made magnetic disk underlayer and forming minute texturing striation but also removing ''grinding traces'' and ''grinding scratch'' appearing on the underlayer and surface which are attributed to substrate grinding operation. There is provided a texturing processing composition used for texturing processing of an aluminum-made magnetic disk underlayer or glass-made magnetic disk surface, which composition comprises diamond nanoparticles of = 150 m2 / g specific surface area (A), a C10-C22 fatty acid or fatty acid metal salt (B), and an organic amine compound (C).

Owner:RESONAC HOLDINGS CORPORATION +1

Polycrystalline compacts including diamond nanoparticles, cutting elements and earth- boring tools including such compacts, and methods of forming same

Owner:ELEMENT SIX LTD +1

Lubricant composition

ActiveUS8598098B2Effectively overcome drawbacksReduce coefficient of frictionMaterial nanotechnologyAdditivesInternal combustion engineOxygen

A lubricant composition applicable to a sliding section or sliding member of an automotive internal combustion engine or power transmission apparatus to significantly lower a friction coefficient. The lubricant composition contains a base oil for a lubricating oil, an oxygen-containing organic compound, a diamond nano-particle and a dispersant for the diamond nano-particle.

Owner:NISSAN MOTOR CO LTD

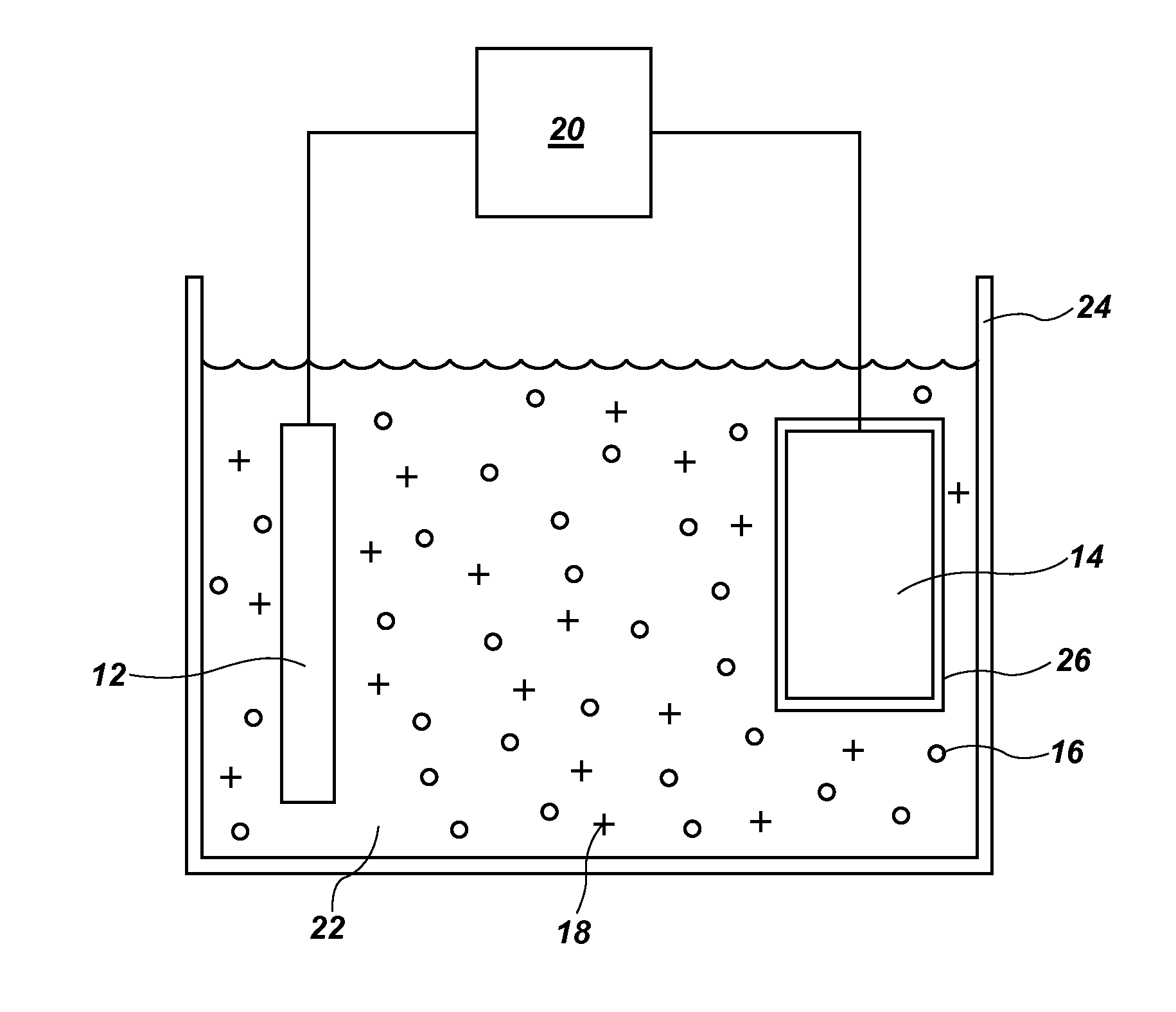

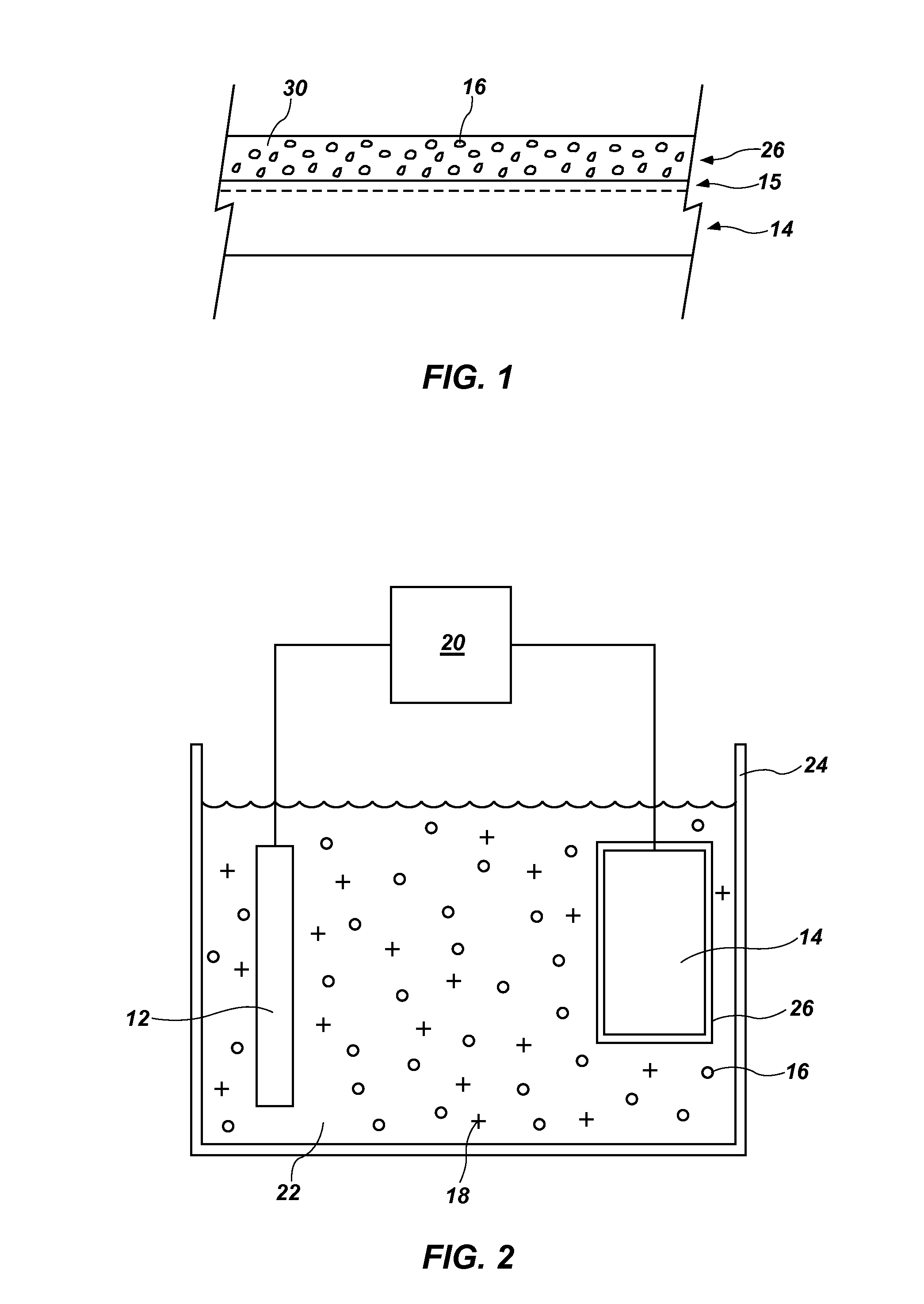

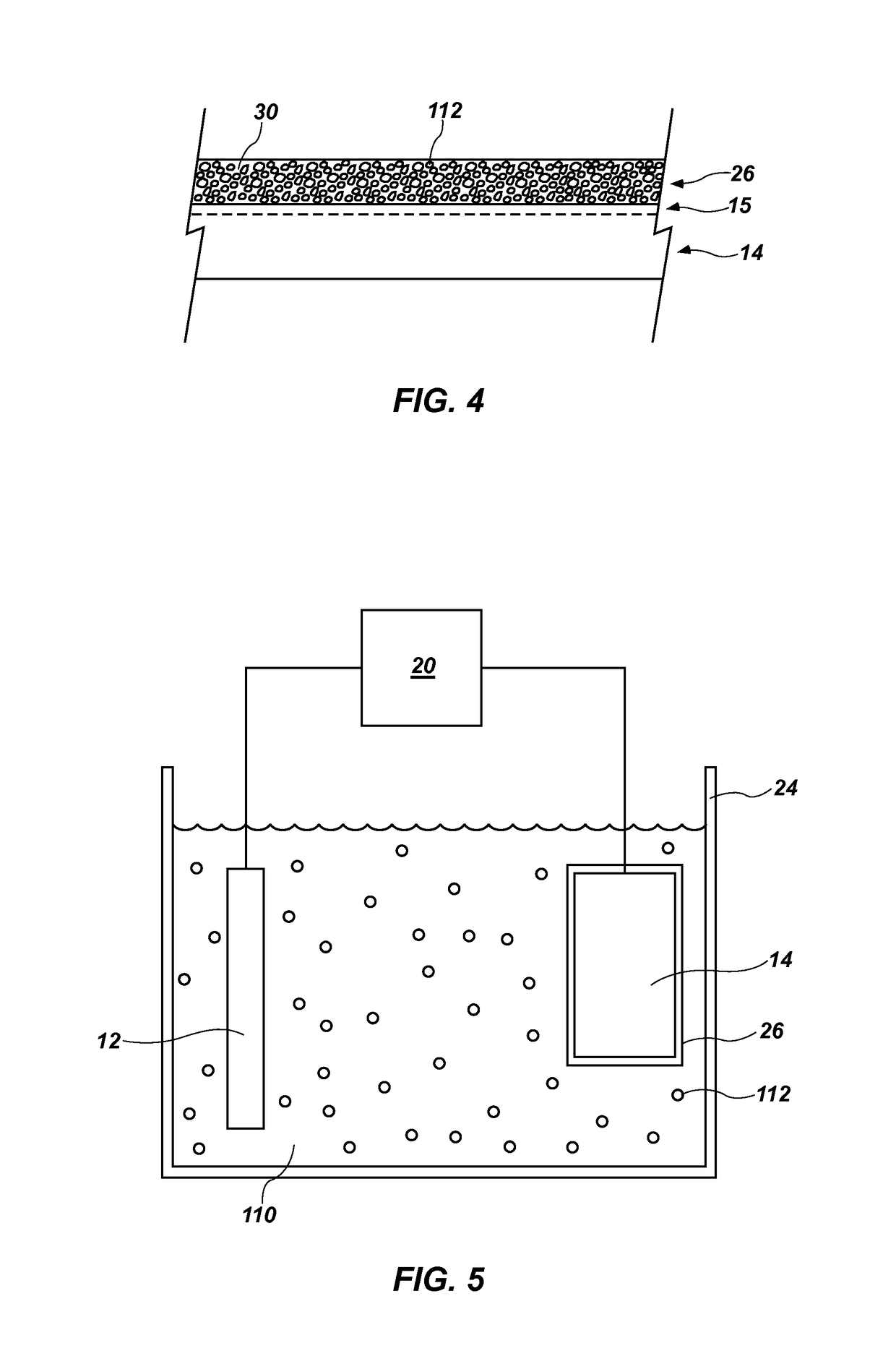

Methods of coating substrates with composite coatings of diamond nanoparticles and metal

ActiveUS20160083860A1Electrolytic inorganic material coatingLiquid/solution decomposition chemical coatingIonDiamond nanoparticles

A method of coating a substrate includes dispersing functionalized diamond nanoparticles in a fluid comprising metal ions to form a deposition composition; disposing a portion of the deposition composition over at least a portion of a substrate; and electrochemically depositing a coating over the substrate. The coating comprises the diamond nanoparticles and a metal formed by reduction of the metal ions in the deposition composition.

Owner:BAKER HUGHES INC

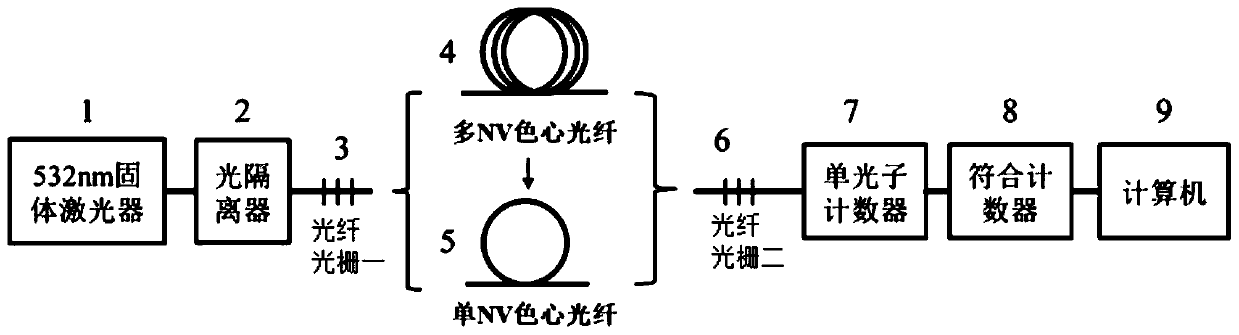

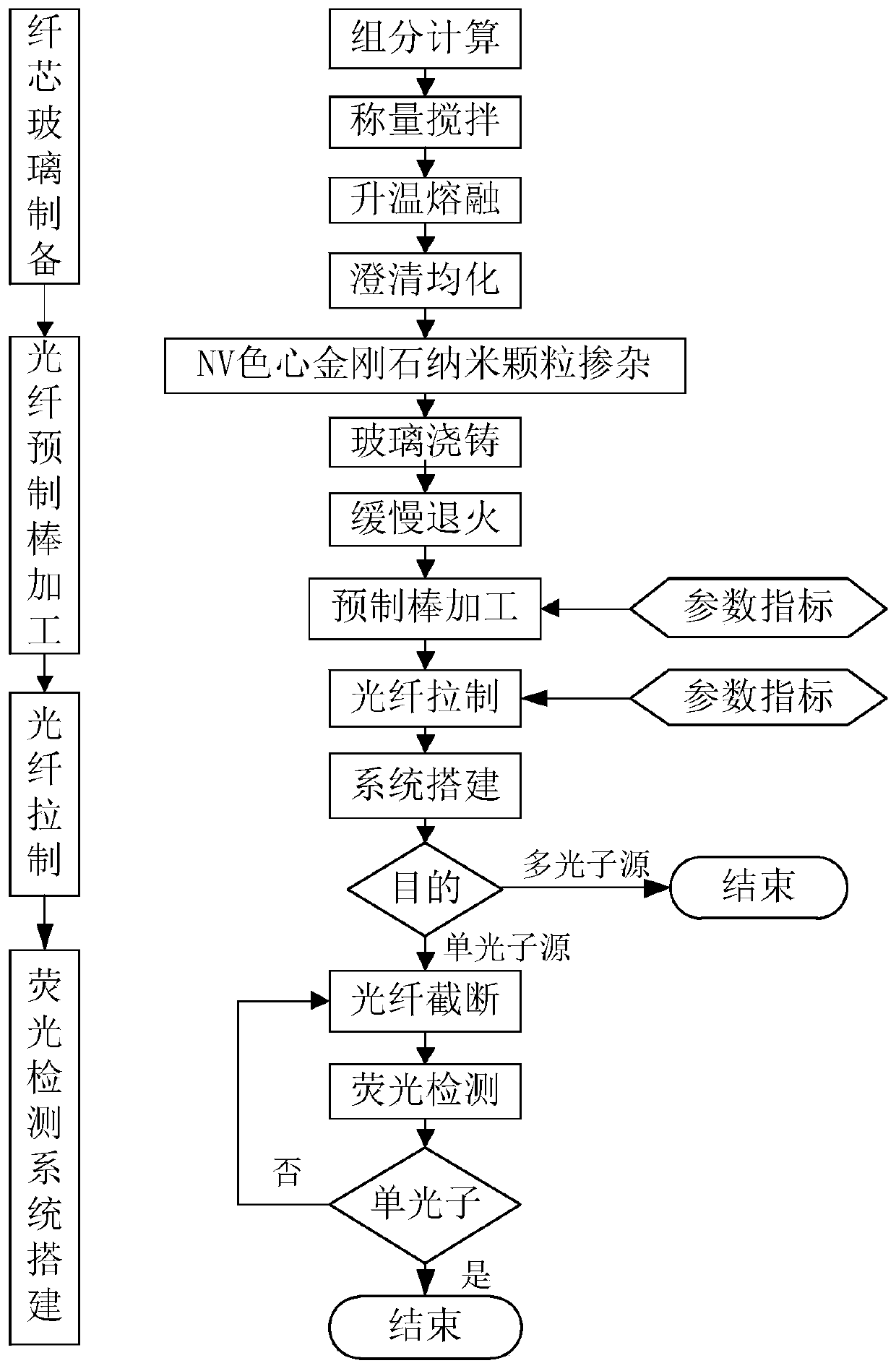

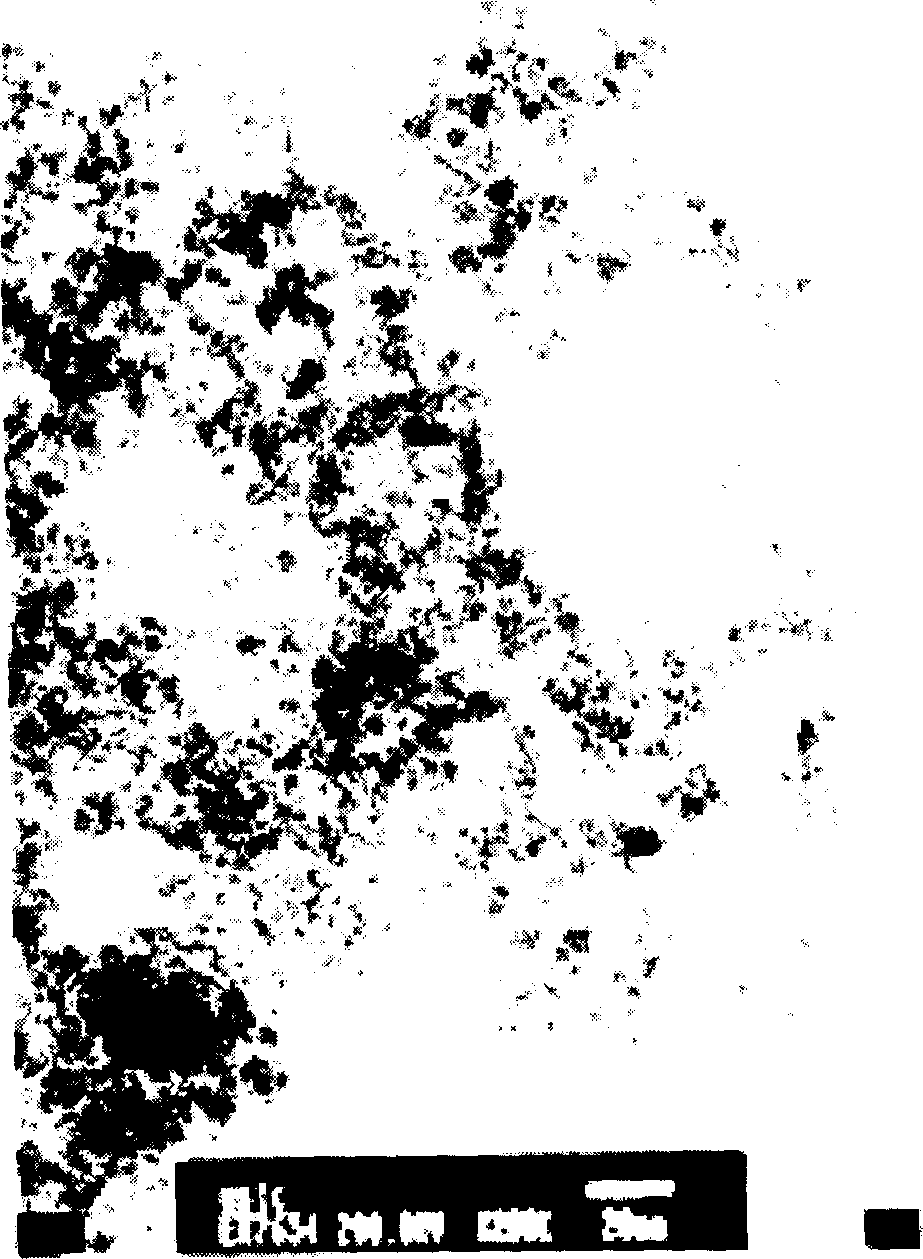

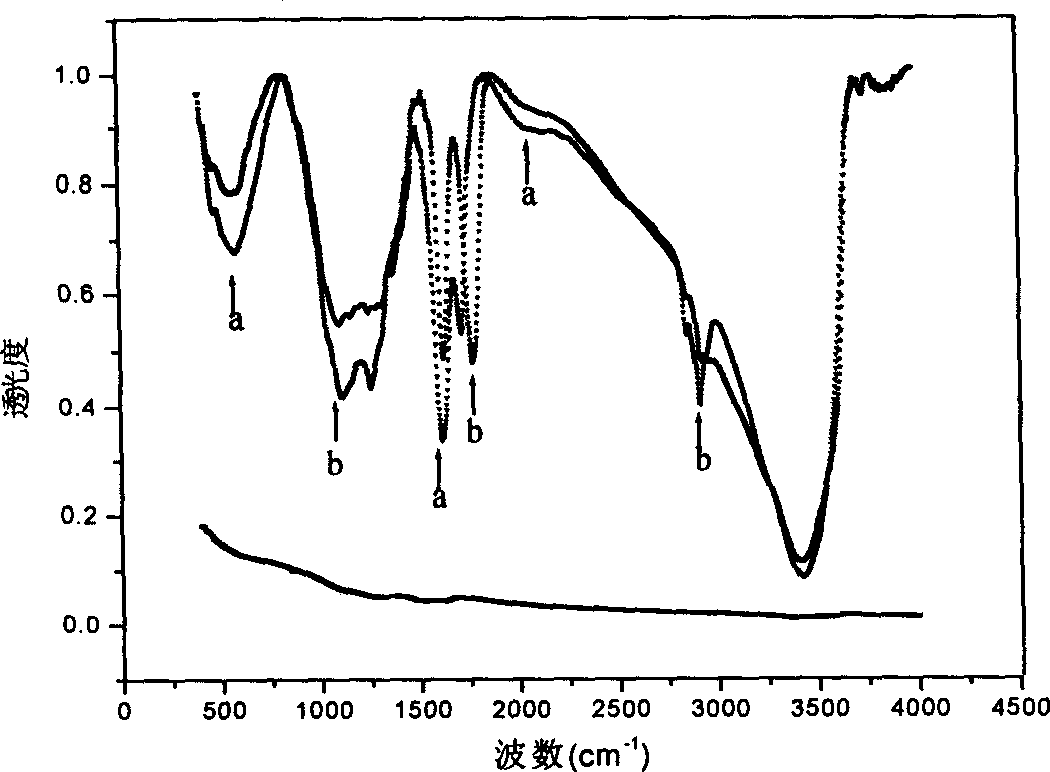

Preparation method of optical fiber NV color center single/multi-photon source

InactiveCN110510885AHigh transplantabilityReduce manufacturing costGlass making apparatusOptical elementsFiberColour centre

The invention discloses a preparation method of an optical fiber type NV color center single / multiphoton source. Diamond nanoparticles containing a NV color center are used as a luminescent medium, tellurite glass is prepared by a melt quenching method, the trace diamond nanoparticles are injected into glass liquid, fiber core glass is prepared, an optical fiber doped with NV color center diamondnanoparticles is drawn, and the NV color center is excited by a 532 nm solid laser to prepare the optical fiber type NV color center multiphoton source. On this basis, the multiphoton fiber with multiple color centers can be repeatedly cut in half and detected to prepare the optical fiber NV color center single photon source. The preparation method has low preparation cost, strong reliability andhigh portability.

Owner:LASER RES INST OF SHANDONG ACAD OF SCI

Method for producing nano diamond particles purified by cerium salt

InactiveCN1480252AEfficient purification methodEconomical purification methodUltra-high pressure processesCeriumCarbon Nanoparticles

A process for using cerium salt to purify diamond manoparticles includes adding carbon nanoparticles to cerium salt solution, waving at 30-70 deg.C for 24-48 hrs for adsorption, centrifugal separation of diamond nanoparticles, washing with sulfuric acid solution 3-5 times, washing with deionized water, and vacuum drying at 100-120 deg.C for 12-24 hrs.

Owner:SUN YAT SEN UNIV

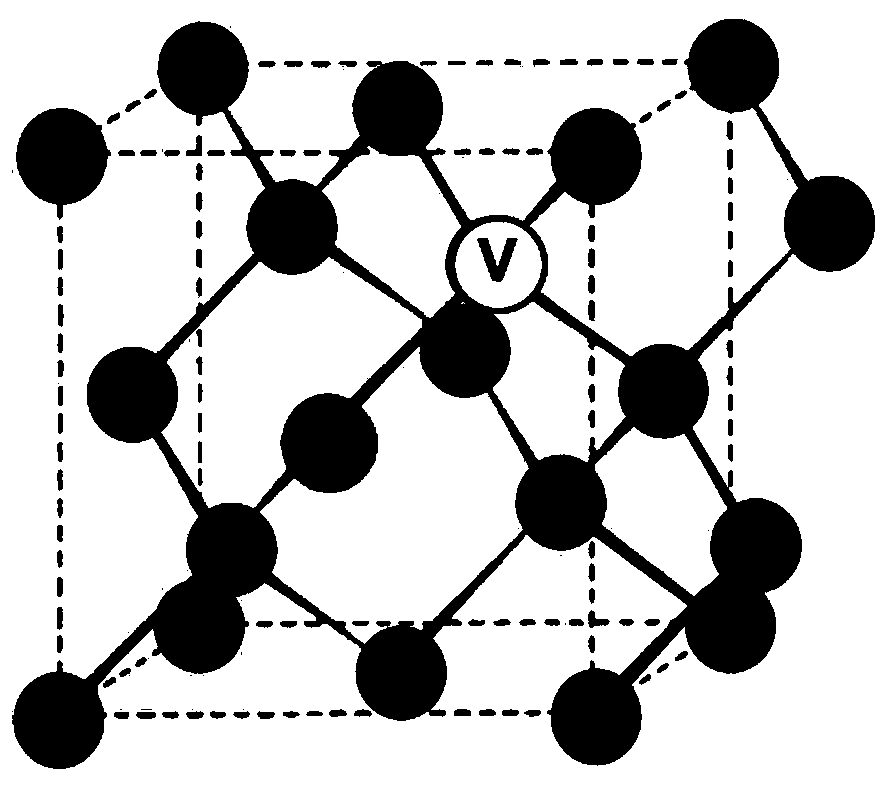

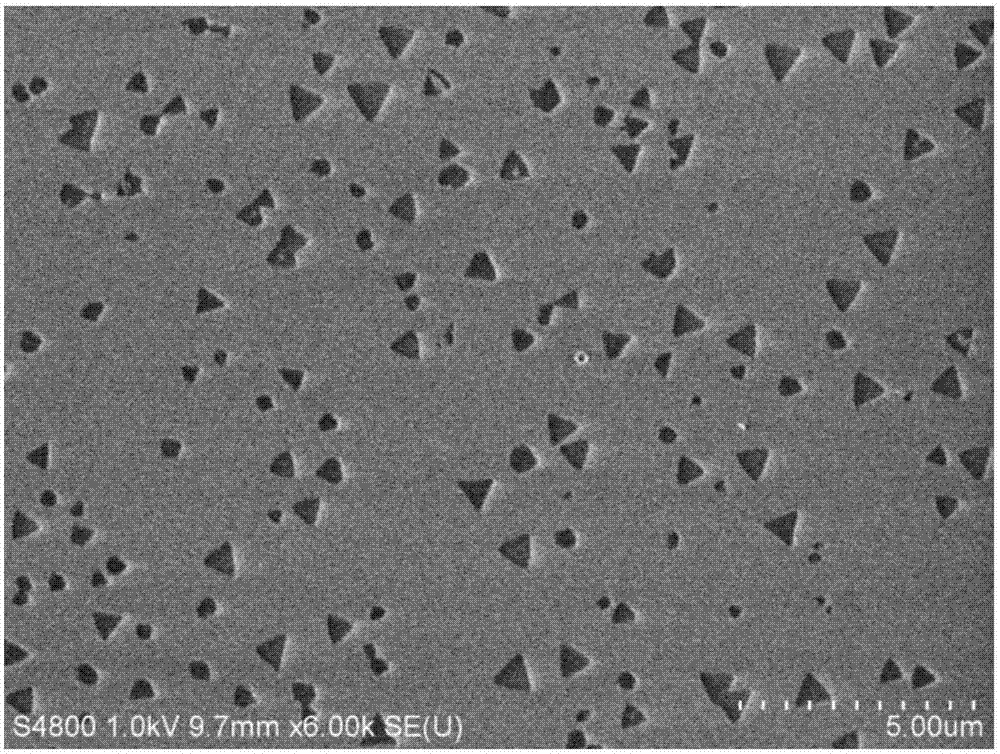

Secondary epitaxy method for preparing high-quality diamond single crystal by adopting nanostructure

ActiveCN110863243ATo achieve the purpose of removing impuritiesReduce defectsPolycrystalline material growthFrom chemically reactive gasesNanostructureSeed crystal

The invention discloses a secondary epitaxy method for preparing a high-quality diamond single crystal by adopting a nanostructure. The secondary epitaxy method comprises the growth steps: 1) selecting high-temperature and high-pressure diamond as a seed crystal; 2) carrying out etching pretreatment on surface defects and damages of the seed crystal; 3) controlling the pressure, microwave power, temperature, methane concentration and growth time of a reaction chamber, and carrying out epitaxy on a diamond film layer with the thickness of 2-40 [mu]m for the first time; 4) evaporating a metal Nifilm layer with the thickness of about 4-40 nm by electron beam evaporation; 5) carrying out high-temperature heat treatment to obtain a metal nanoparticle pattern; 6) carrying out plasma etching toobtain a diamond nanoparticle pattern layer; and 7) controlling the pressure, microwave power, temperature, methane concentration and growth time of the reaction chamber, and carrying out secondary epitaxy on a diamond film with the thickness of 5-200 [mu]m. The extension of defects in the diamond film is effectively inhibited, the defect density is reduced, and the flatness of the crystal surfaceis improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

Packing specially used for heat-resistant wear-resistant capacitor film and preparation method of packing

The invention discloses packing specially used for a heat-resistant wear-resistant capacitor film. The packing is prepared from the following raw materials in parts by weight: 4-6 parts of phosphite ester, 0.8-1 part of turpentine, 0.5-0.8 part of white oil, 0.1-0.2 part of butyl naphthalene sulfonic acid sodium salt, 0.1-0.2 part of hydroxyl alkylphenol ethoxylates, 0.4-0.7 part of maleic anhydride, 0.3-0.4 part of triethanolamine, 2-3 parts of diamond nanoparticle, 60-65 parts of clay, a proper amount of 4-6% hydrochloric acid, a proper amount of water and 15-20 parts of aids. According to the packing, due to addition of diamond nanoparticles, the wear resistance of the film is improved; due to addition of phosphite ester, the heat resistance of the film is improved; due to use of clay, the cost is reduced; and moreover, due to use of the aids, the dispersity and reinforcing performance of the packing can be improved, and the strength and impact toughness of the film can be improved.

Owner:ANHUI JIANGWEI PRECISION IND

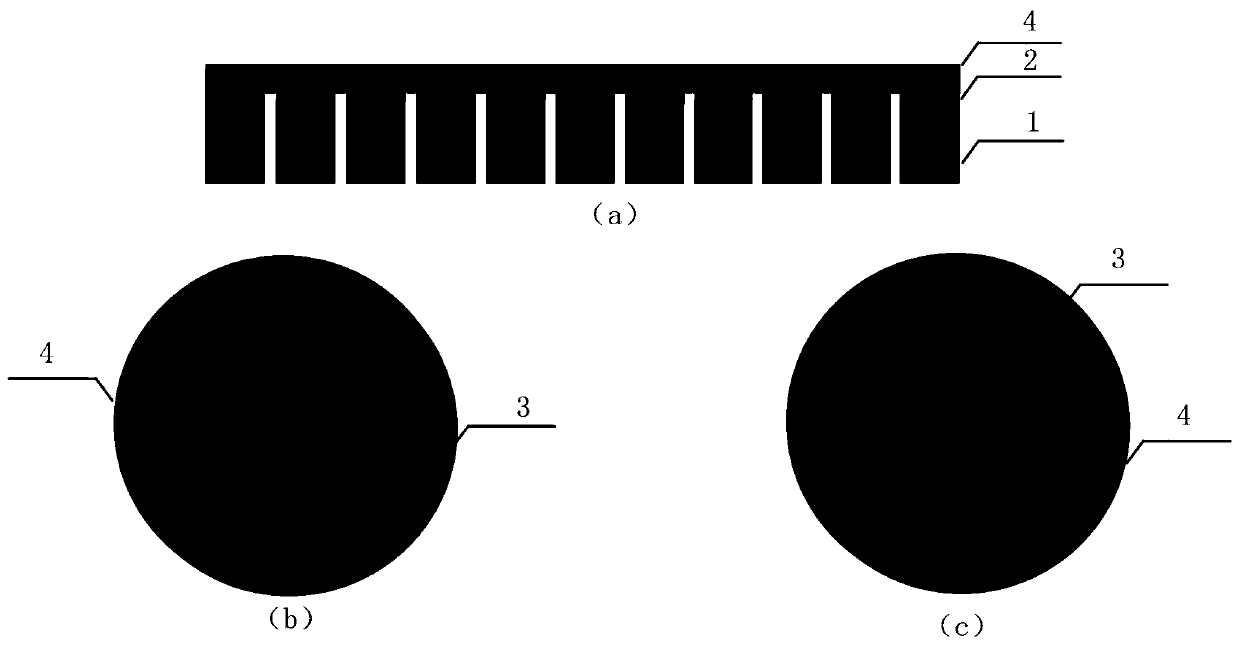

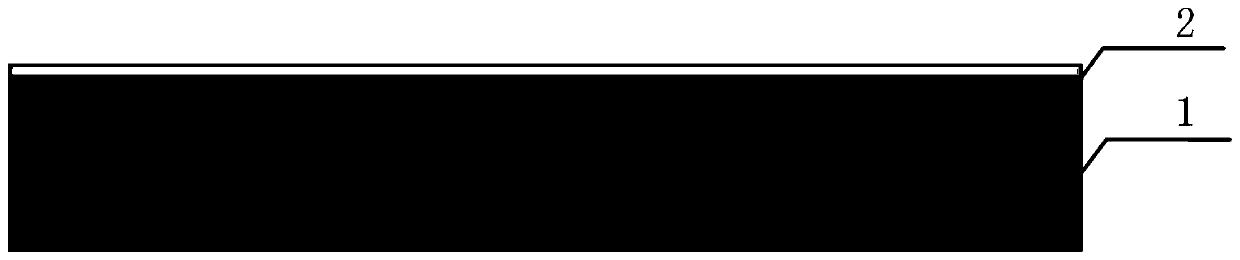

Micro-through-hole Cu-based CVD diamond heat sink sheet and preparation method thereof

ActiveCN110690186AIncrease nucleation densityThermal limitationsDecorative surface effectsSemiconductor/solid-state device detailsNanoparticleHeat sink

The invention discloses a micro-through-hole Cu-based CVD diamond heat sink sheet and a preparation method thereof. The micro-through-hole Cu-based CVD diamond heat sink comprises a Cu substrate, a metal transition layer and a CVD diamond film which are arranged in order from bottom to top, and micro-through-holes with the diameter ranging from 0.3 mm to 0.5 mm and the spacing ranging from 2 mm to3 mm are distributed in the Cu substrate in an array mode; and diamond nanoparticles are electrostatically assembled on the surface of the metal transition layer. The heat dissipation effect of the heat sink sheet is better than that of traditional heat sink sheets such as Ag, Cu and Al, and the adhesion between a diamond film and a Cu metal substrate and the nucleation density of diamond are improved; and the heat dissipation performance of the micro-channel Cu-based diamond heat sink sheet is better.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of platinum-diamond nanocomposite electrode

InactiveCN106885834AEvenly dispersedStructure has no effectMaterial electrochemical variablesPlatinumDispersity

The invention relates to a preparation method of a platinum-diamond nanocomposite electrode, and is characterized by solving the problem on dispersity of diamond nano-particles in the form of in-situ modification. Further functionalized modification is performed on the diamond nano-particles to obtain a composite material with excellent catalytic performances and advantages of a diamond electrode, to further prepare a modified electrode. According to the preparation method of the platinum-diamond nanocomposite electrode disclosed by the invention, not only preparation means of the diamond nano-particles are expanded, but also the problem on the dispersity of the diamond nano-particles is solved in the form of in-situ modification; and wide application of nano-diamond in catalization, electrochemical sensing and like fields is greatly promoted.

Owner:NINGXIA MEDICAL UNIV

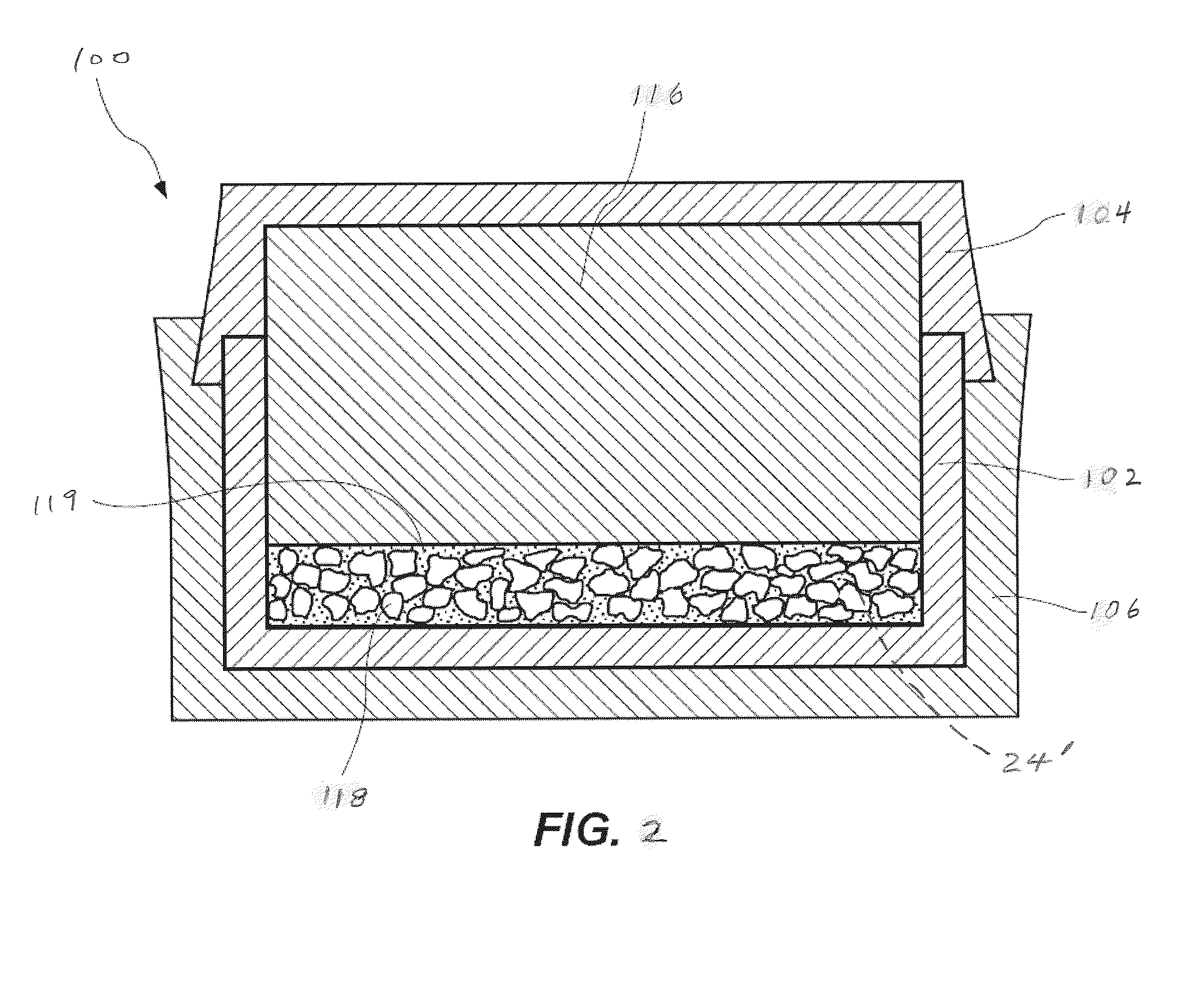

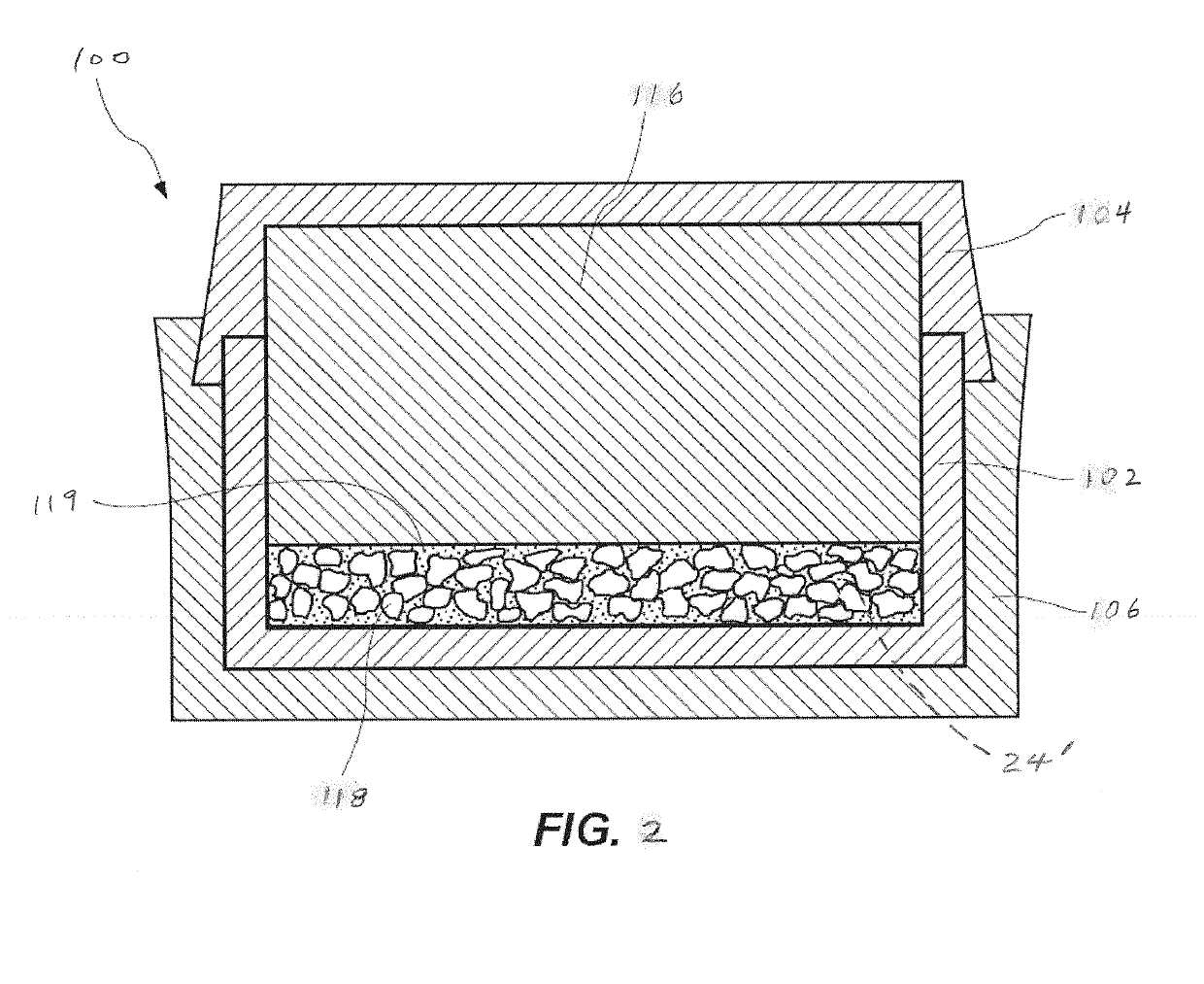

Polycrystalline compacts including crushed diamond nanoparticles, cutting elements and earth boring tools including such compacts, and methods of forming same

A polycrystalline compact comprises a plurality of diamond grains of micron size, submicron size, or both, and a plurality of crushed diamond nanoparticles disposed in interstitial spaces between the plurality of diamond grains. A method of forming a polycrystalline compact comprises combining a plurality of micron and / or submicron-sized diamond grains and a plurality of crushed diamond nanoparticles to form a mixture and sintering the mixture in a presence of a binder to form a polycrystalline hard material comprising a plurality of inter-bonded diamond grains and diamond nanoparticles. Cutting elements comprising a polycrystalline compact and earth-boring tools bearing such compacts are also disclosed.

Owner:BAKER HUGHES INC

Methods of forming a cutting element for an earth-boring tool, a related cutting element, and an earth-boring tool including such a cutting element

A method of forming a cutting element for an earth-boring tool. The method includes providing diamond particles on a supporting substrate, the volume of diamond particles comprising a plurality of diamond nanoparticles. A catalyst-containing layer is provided on exposed surfaces of the volume of diamond nanoparticles and the supporting substrate. The diamond particles are processed under high temperature and high pressure conditions to form a sintered nanoparticle-enhanced polycrystalline compact. A cutting element and an earth-boring tool including a cutting element are also disclosed.

Owner:ELEMENT SIX LTD +1

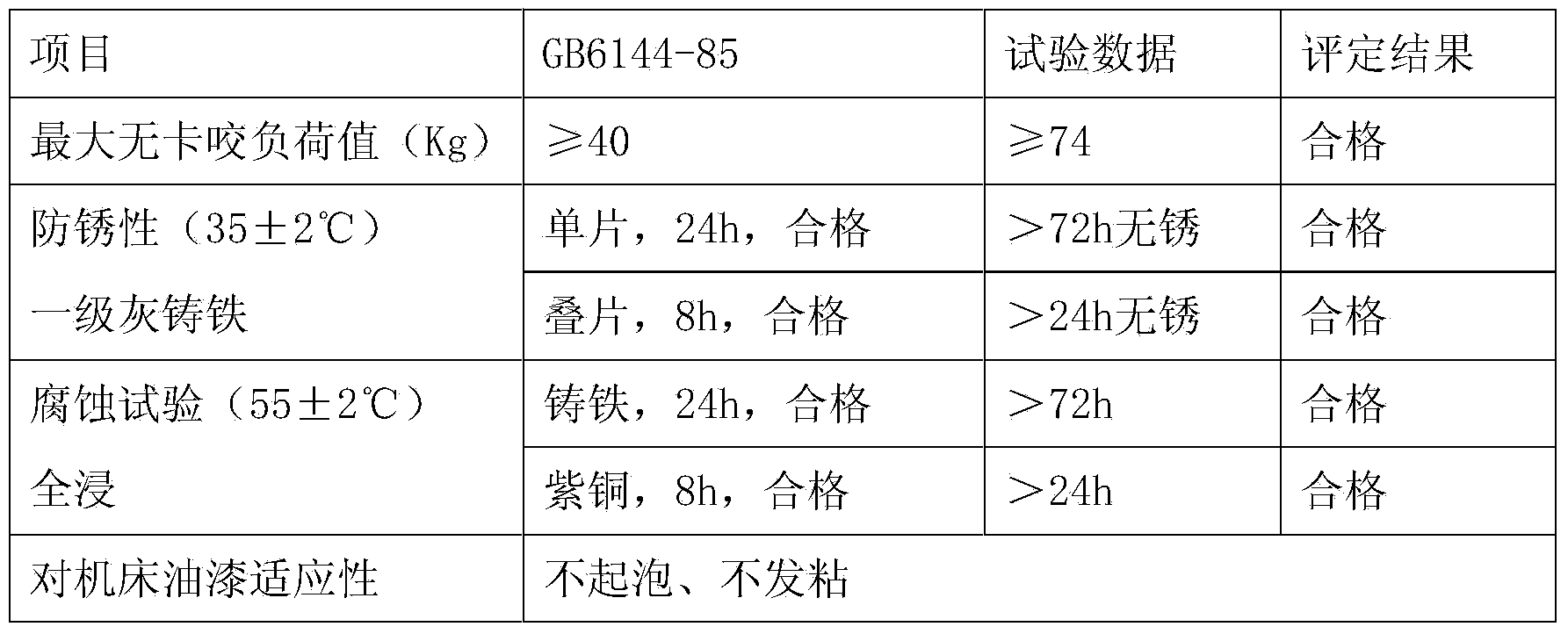

Corrosion-free anti-wear semi-synthetic cutting fluid and preparation method thereof

InactiveCN103666721AImprove wear resistanceImprove the lubrication effectLubricant compositionLanthanumFatty acid

A corrosion-free anti-wear semi-synthetic cutting fluid is prepared from the following raw materials: 12-14 parts of mineral oil, 3-4 parts of ricinoleic acid, 1-2 parts of diethanolamine, 10-12 parts of isopropanol, 3-4 parts of polyoxyethylene fatty acid, 1-2 parts of diamond nanometer particles, 1-2 parts of pentaerythritol, 2-3 parts of lauryl alcohol polyoxyethylene, 0.05-0.1 part of lanthanum acetate, 6-8 parts of an auxiliary agent and 200 parts of water. The cutting fluid provided by the invention has excellent antiwear performance by employing diamond nanometer particles; and the cutting fluid has the advantages of good lubricity and good cleaning performance, is stable in emulsion system, good in settlement resistance, does not corrode machine tools, is not easy to deteriorate and reek, and is long in service life.

Owner:MAANSHAN HENGYI MACHINERY MFG

Cutting elements and methods for fabricating diamond compacts and cutting elements with functionalized nanoparticles

A method of fabricating a diamond compact includes functionalizing surfaces of diamond nanoparticles with fluorine; combining the functionalized diamond nanoparticles with a non-group-VIII metal to form a particle mixture; and subjecting the particle mixture to high pressure and high temperature (HPHT) conditions to form inter-granular bonds between the diamond nanoparticles. A cutting element for an earth-boring tool includes a plurality of grains of diamond material; a plurality of diamond nanoparticles bonded to the plurality of grains of diamond material; and a non-group-VIII metal fluoride disposed within interstitial spaces between the grains of diamond material and the plurality of diamond nanoparticles. The cutting element is substantially free of a metal-solvent catalyst.

Owner:BAKER HUGHES INC

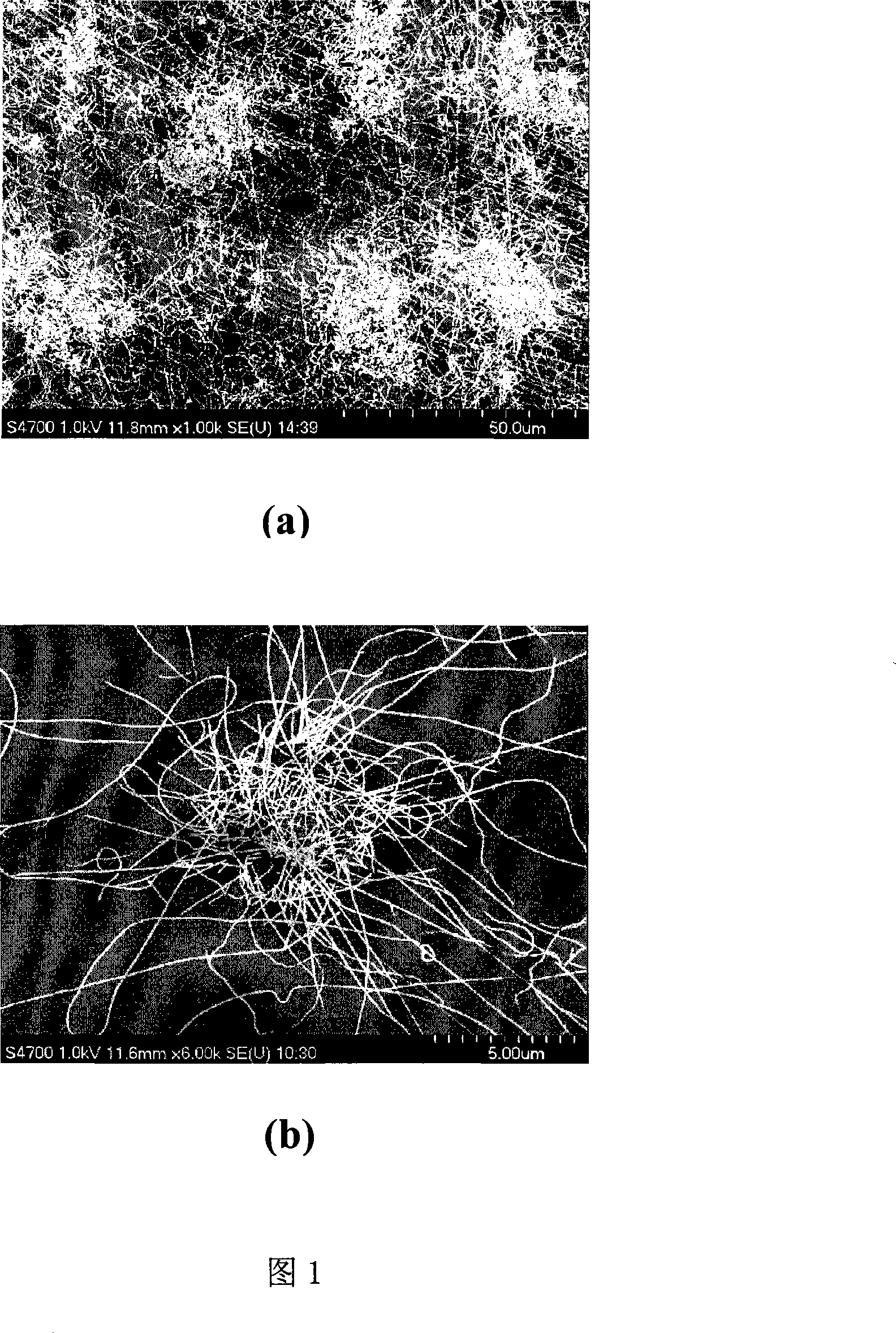

Method for preparing single-wall carbon nano-tube by employing diamond nano particles

The invention discloses a process for preparing single-walled carbon nano-tubes, which belongs to the preparing field of nanometer materials. The invention adopts diamond nanometer particles as catalyst or nucleating templates, uses feed gas containing carbons as the growth gas source of carbon nano-tubes, and uses chemical vapor deposition to prepare single-walled carbon nano-tubes in a horizontal resistance furnace. Because the invention adopts diamond nanometer particles as catalysts or nucleating templates to avoid pollution to the single-walled carbon nanotubes caused by non-carbon elements which are brought from adopting any metal catalyst to prepare single-walled carbon nanotubes. The invention has no need to concern about the problem that conventional metal catalysts lose catalytic effect by aggregation, and simultaneously has the advantages of high catalytic efficiency and simple operation.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Polycrystalline compacts including crushed diamond nanoparticles, cutting elements and earth boring tools including such compacts, and methods of forming same

A polycrystalline compact comprises a plurality of diamond grains of micron size, submicron size, or both, and a plurality of crushed diamond nanoparticles disposed in interstitial spaces between the plurality of diamond grains. A method of forming a polycrystalline compact comprises combining a plurality of micron and / or submicron-sized diamond grains and a plurality of crushed diamond nanoparticles to form a mixture and sintering the mixture in a presence of a binder to form a polycrystalline hard material comprising a plurality of inter-bonded diamond grains and diamond nanoparticles. Cutting elements comprising a polycrystalline compact and earth-boring tools bearing such compacts are also disclosed.

Owner:BAKER HUGHES HLDG LLC

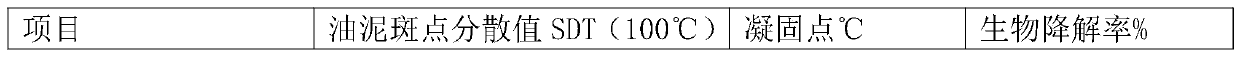

Process for preparing nano polymer chelating agent contg. thioureido

A nano-class high-molecular thioureido-containing chelating agent is prepared through ultrasonic dispersing of diamond nanoparticles containing amino or ethyldiamino groups on their surface in the solution of organic solvent containing benzene isosulfocyanate, stirring at 104-106 deg.C for 2-8 hr, centrifugal separation of nanoparticles, washing with organic solvent and then deionized water, and vacuum drying at 50-60 deg.c for 24-48 hr. Its advantages are high selectivity and high adsorption capacity.

Owner:SUN YAT SEN UNIV

Numerically-controlled machine tool lubricant and preparation method thereof

PendingCN111349507APlay a reinforcing roleInhibition of crystallization transitionAdditivesNumerical controlOrganic compound

The invention relates to the technical field of lubricating oil, and in particular, relates to a numerically-controlled machine tool lubricant and a preparation method thereof. The numerically-controlled machine tool lubricant is mainly composed of the following raw materials: an oxygen-containing organic compound, oxidized polyethylene, acrylic acid, vulcanized lard oil, an extrusion anti-wear agent, an antirust agent, a dispersing agent, a nanoparticle composition and the balance being base oil for lubricating oil. Cobalt powder and rhodium powder are matched for use; trace rhodium powder isadded into the cobalt powder; a new phase mainly containing rhodium is separated out under the action of high temperature; the phase exists in the form of a separate phase, and a binding phase whichis dissolved in the cobalt powder and the rhodium powder rarely play a reinforcing role on the bonding phase; the face-centered cubic structure of rhodium provides a stable structural environment forbeta-Co of the face-centered cubic structure; alpha-Co crystals are inhibited from being converted into beta-Co crystals to a certain extent, so that the composition composed of the cobalt powder andthe rhodium powder can replace diamond nano-particles, and the effect of extremely well reducing friction loss under the mixing and boundary lubricating conditions is achieved.

Owner:SHANDONG YISHUI MACHINE TOOL

Methods of fabricating polycrystalline diamond by functionalizing diamond nanoparticles, green bodies including functionalized diamond nanoparticles, and methods of forming polycrystalline diamond cutting elements

Method of fabricating polycrystalline diamond include functionalizing surfaces of diamond nanoparticles with fluorine, combining the functionalized diamond nanoparticles with a polymer to form a mixture, and subjecting the mixture to high pressure and high temperature (HPHT) conditions to form inter-granular bonds between the diamond nanoparticles. A green body includes a plurality of diamond nanoparticles functionalized with fluorine, and a polymer material interspersed with the plurality of diamond nanoparticles. A method of forming cutting element includes functionalizing surfaces of diamond nanoparticles with fluorine, and combining the functionalized diamond nanoparticles with a polymer to form a mixture. The mixture is formed over a body, and the mixture and the body are subjected to HPHT conditions to form inter-granular bonds between the diamond nanoparticles and secure the bonded diamond nanoparticles to the body.

Owner:BAKER HUGHES INC

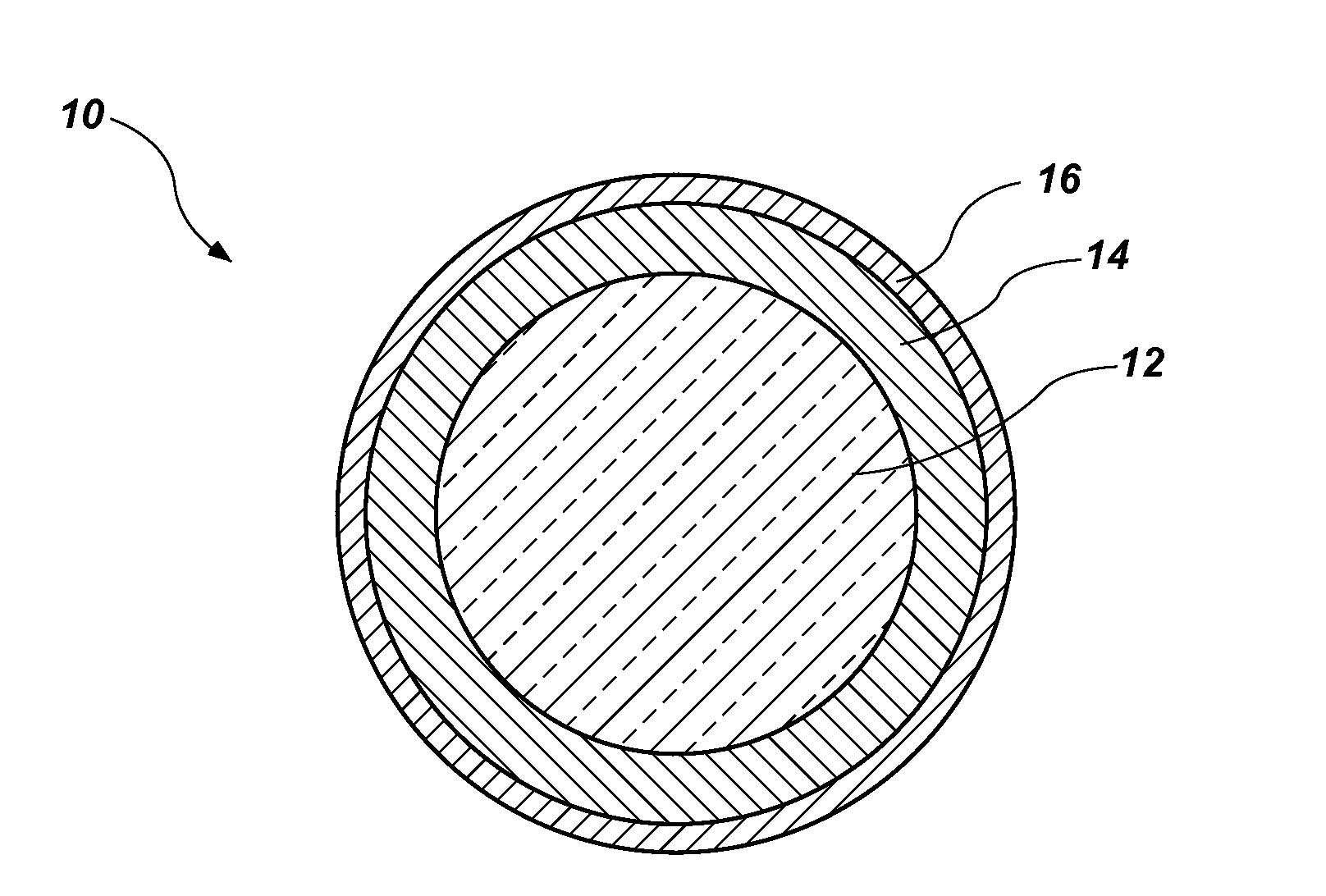

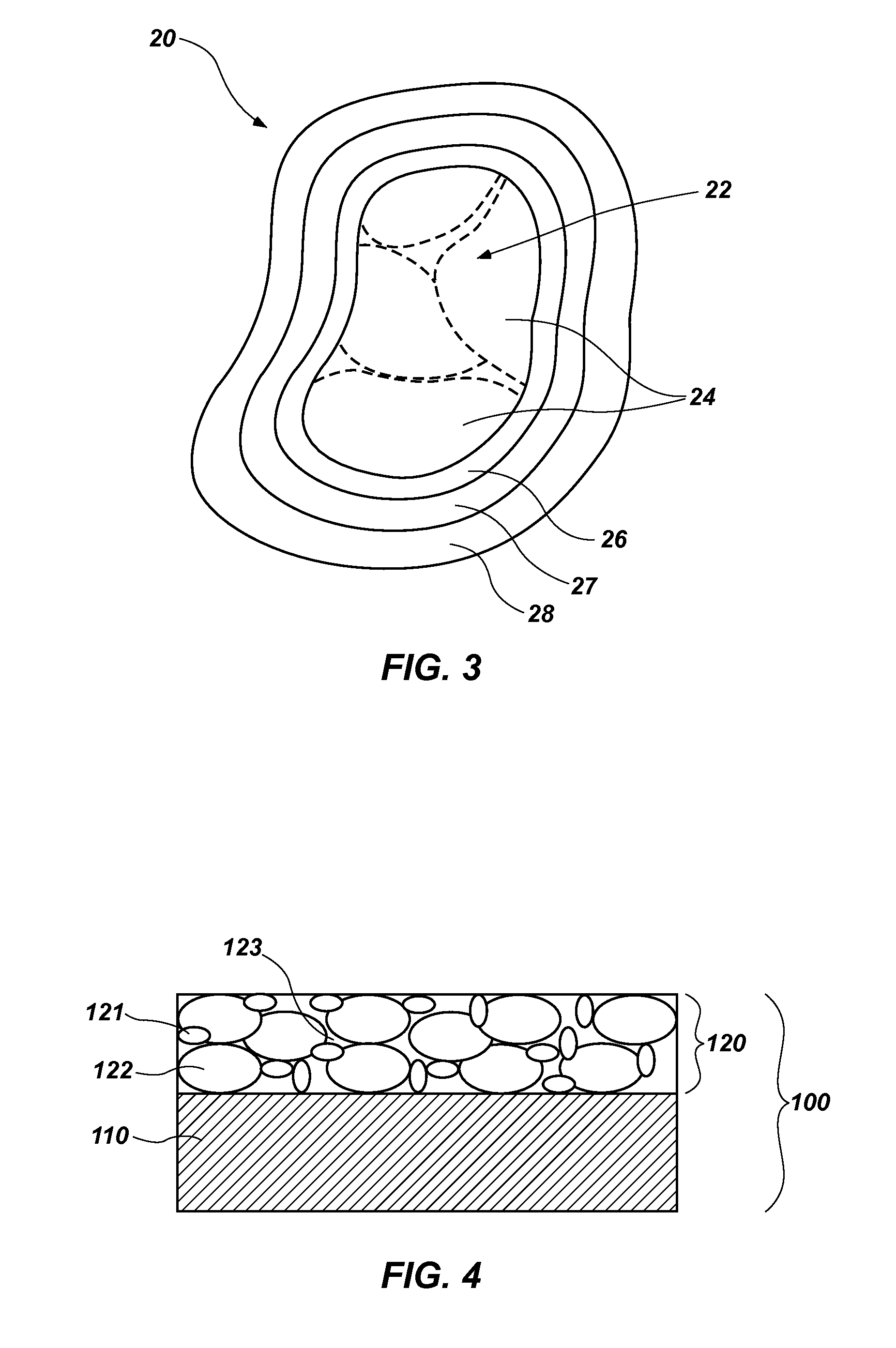

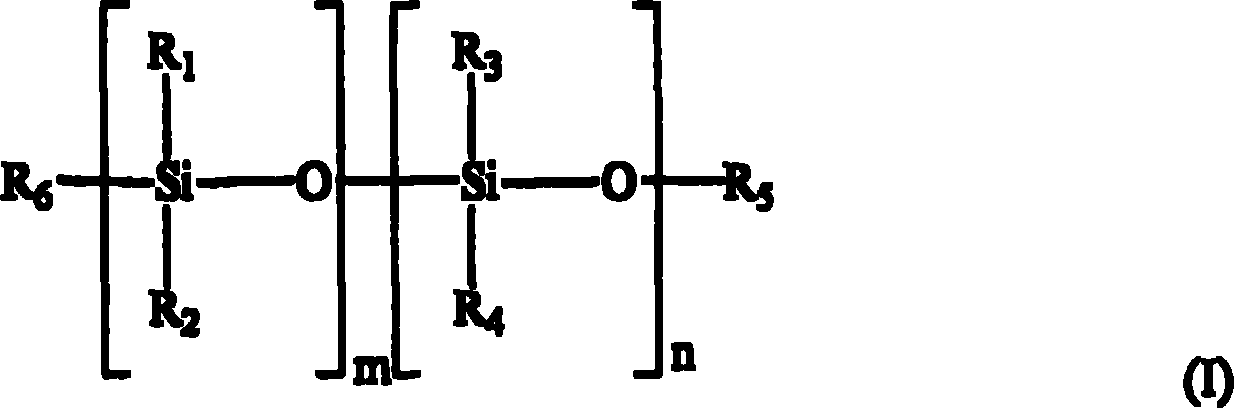

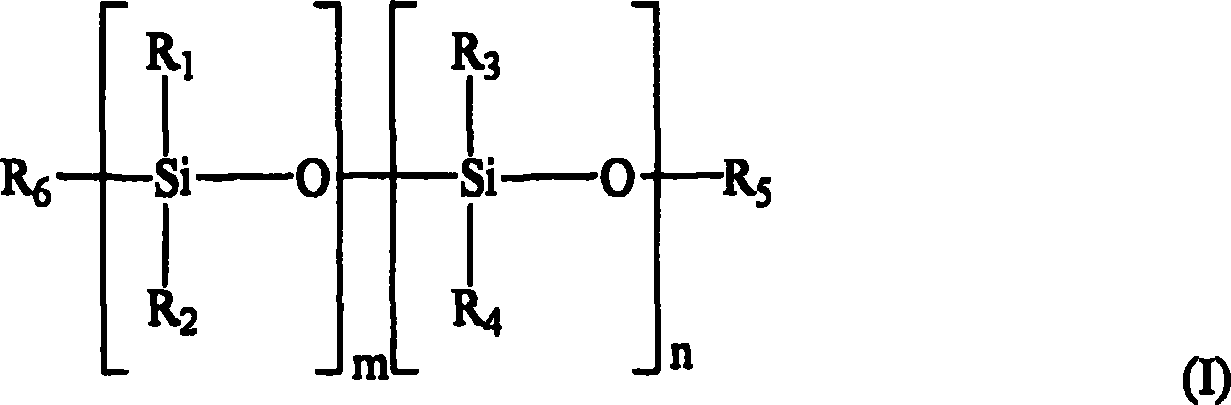

Compositions of coated diamond nanoparticles, methods of forming coated diamond nanoparticles, and methods of forming coatings

In a composition including a plurality of coated diamond nanoparticles, each diamond nanoparticle may have at least one silane functional group covalently bonded to a surface thereof. A method of forming coated diamond nanoparticles may include functionalizing surfaces of diamond nanoparticles with at least one of a fluorine-containing compound and an oxidant; dispersing the functionalized diamond nanoparticles in a solvent comprising a silane functional group; and forming covalent bonds between the silane functional group and the diamond nanoparticles. A method of forming a diamond coating may include depositing the diamond nanoparticles over a substrate.

Owner:BAKER HUGHES HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com