Method and device for nanosecond pulse laser-assisted preparation of nano-diamond

A nanosecond pulsed laser, nanodiamond technology, applied in diamond, nanotechnology, nanotechnology and other directions, can solve the problems of difficult to obtain granular diamond, complicated purification process of detonation ash, poor surface stability of suspension, etc. Good, the effect of increasing the effective laser action area and increasing the effective action area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

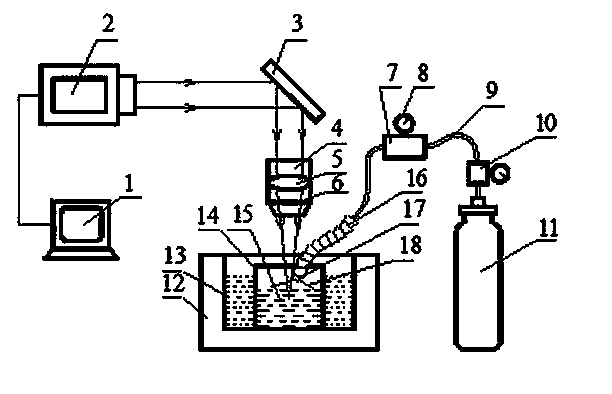

[0033] Embodiment 1: adding 0.4g flake graphite powder with a particle diameter of 2 to 4mm into 20ml of deionized water to make a 0.02g / ml graphite mixture, put the container containing the graphite mixture into an ultrasonic cleaning machine, and set the ultrasonic cleaning The power of the machine is 120W, the frequency is 50Hz, open the flow valve of the nitrogen liquid storage tank and adjust the liquid level of the graphite mixture, and the gas booster device sets the nitrogen gas pressure to 40MPa, turn on the computer and the Nd:YAG laser and set the wavelength to 1064nm, the energy to 5J, and the frequency to 5Hz , the spot diameter of the laser on the surface of the graphite mixed liquid is 3 mm. After the laser is applied for 2 hours, the power supply is disconnected and the gas storage tank is turned off; the product is dried and purified by acid boiling for 3 hours, and then washed with water for several times and dried to obtain nano-diamond particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com