Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Avoid separation steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

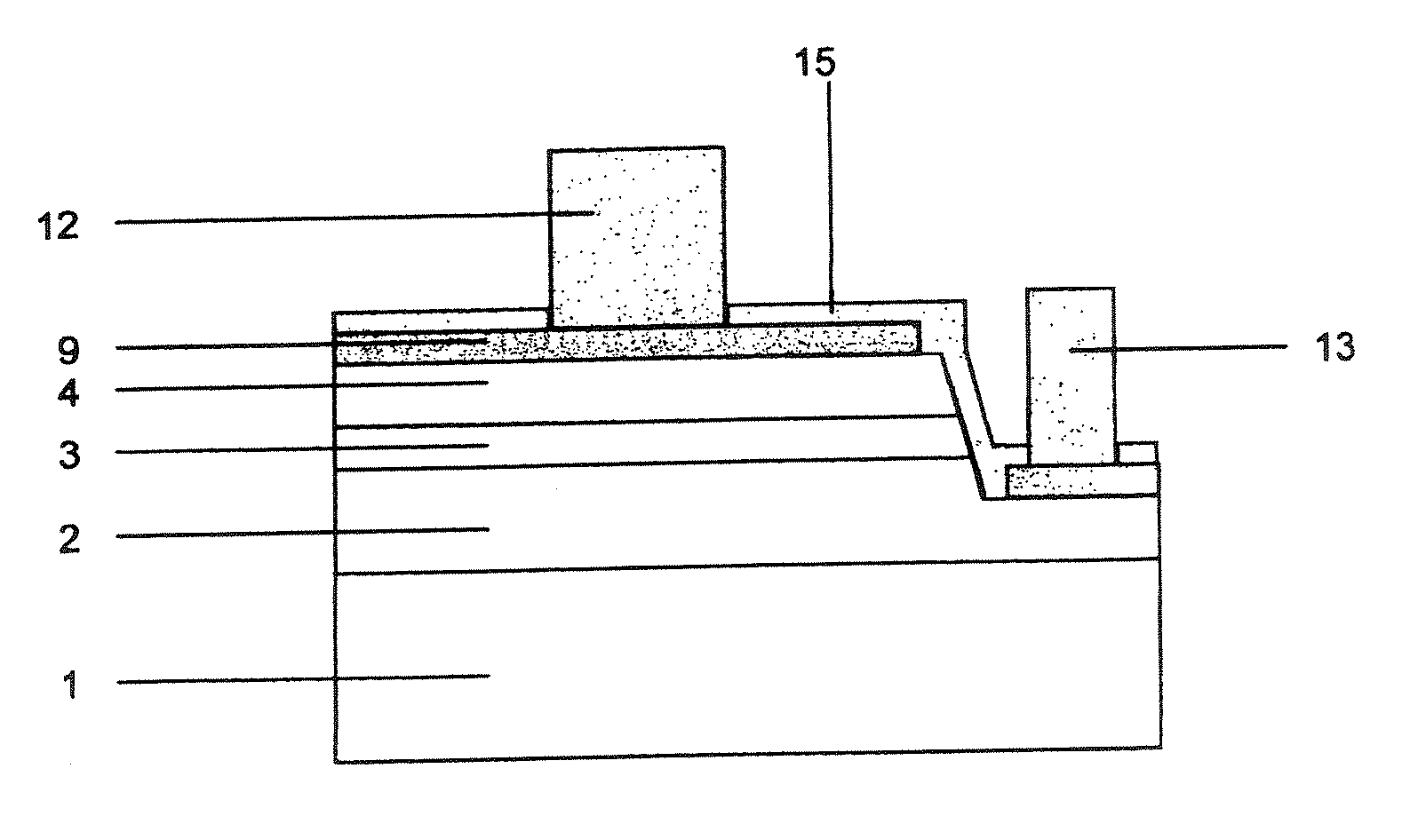

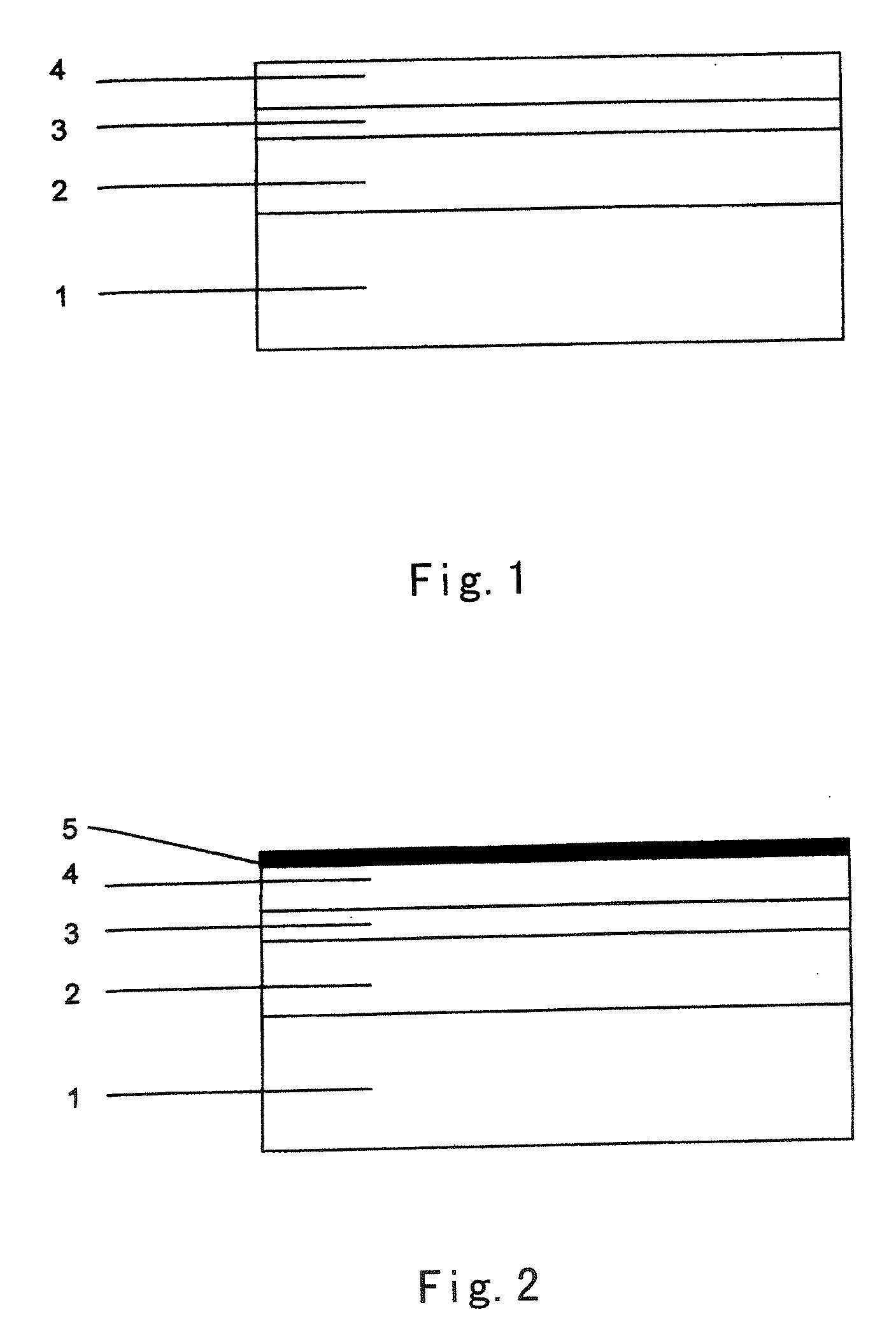

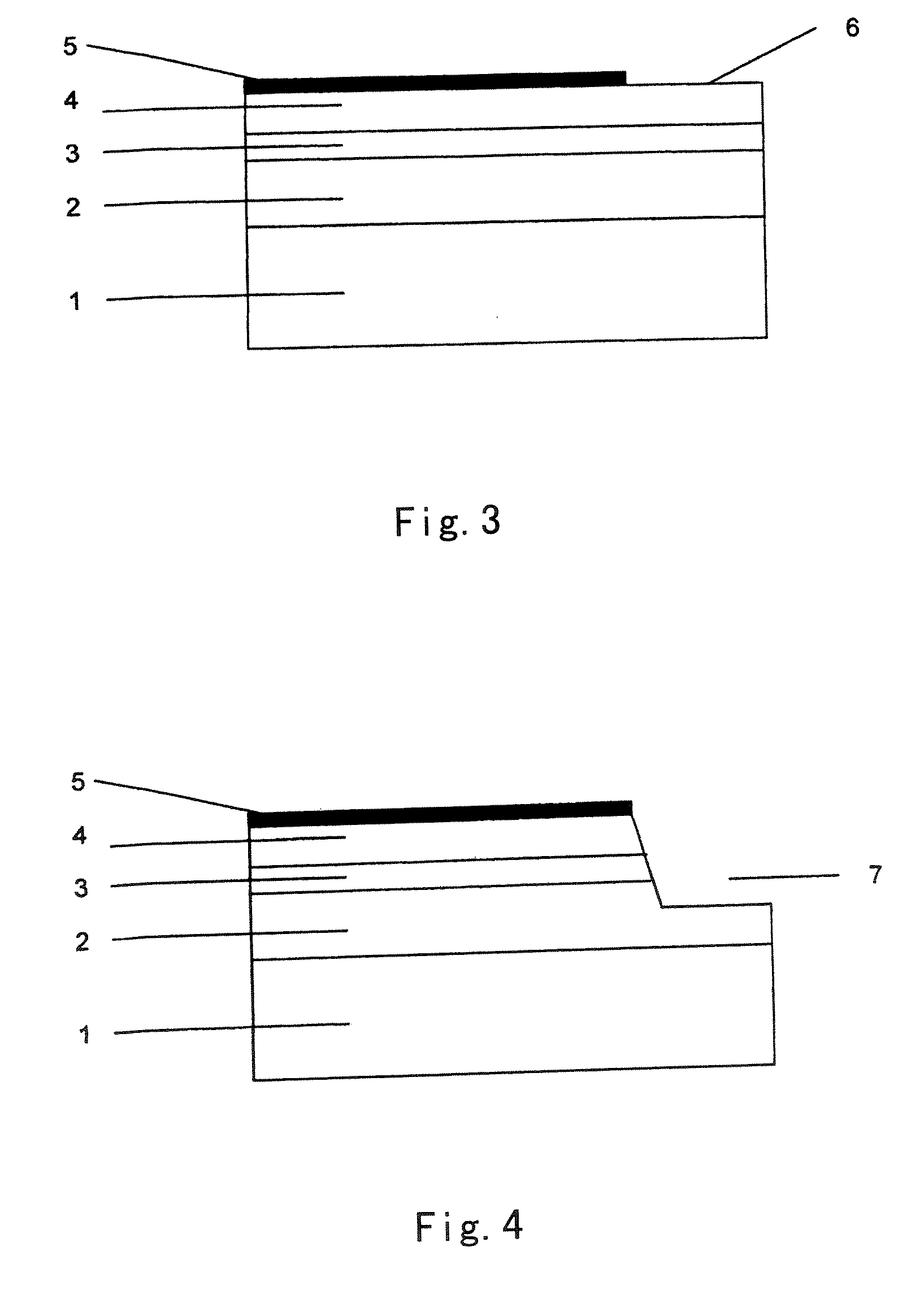

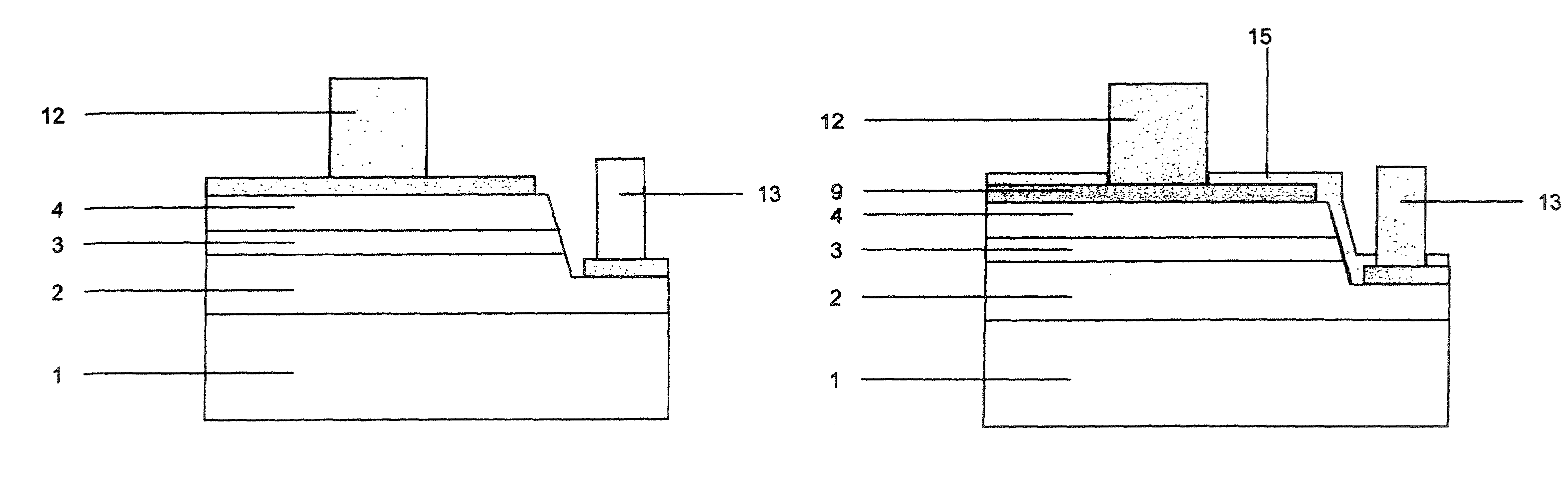

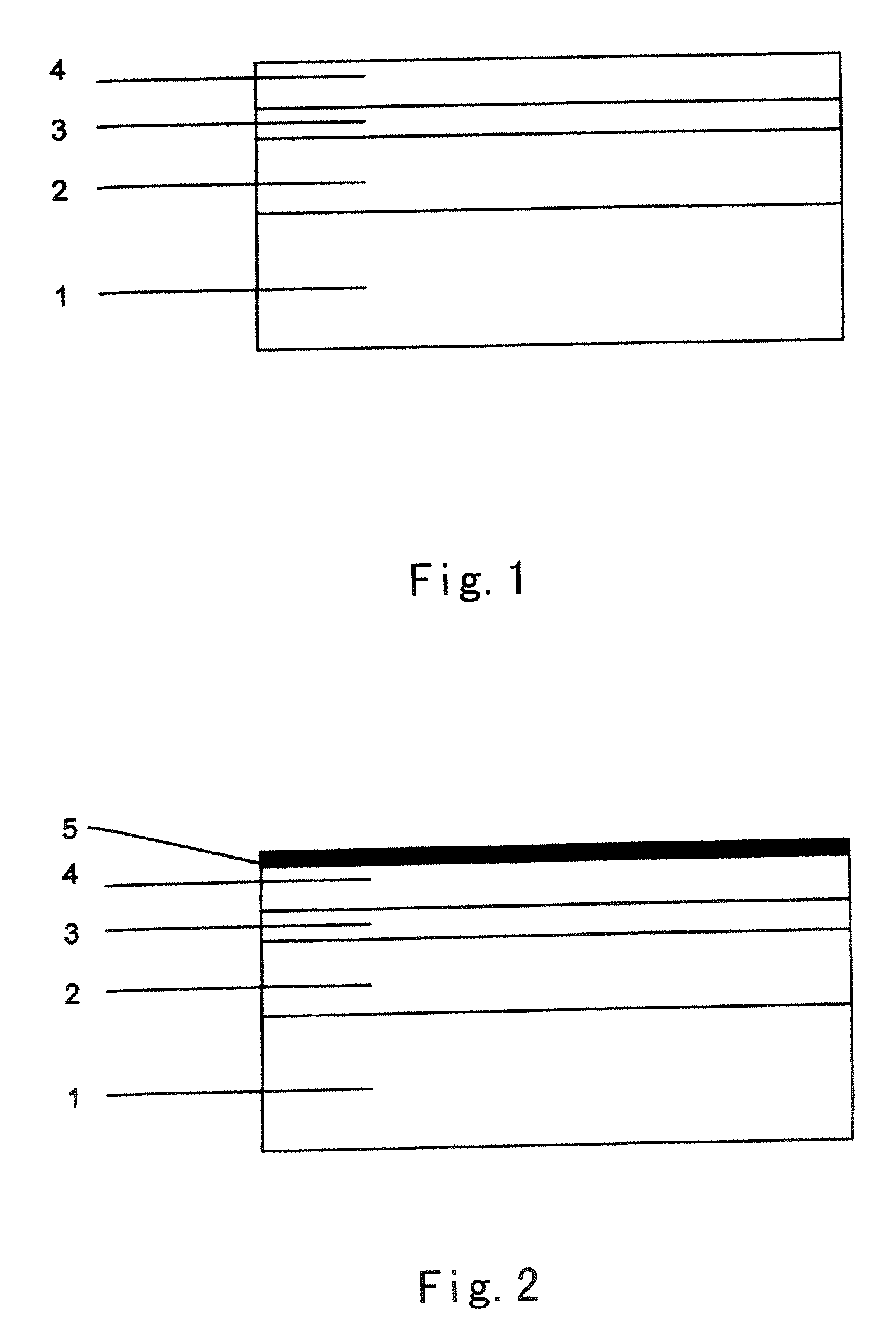

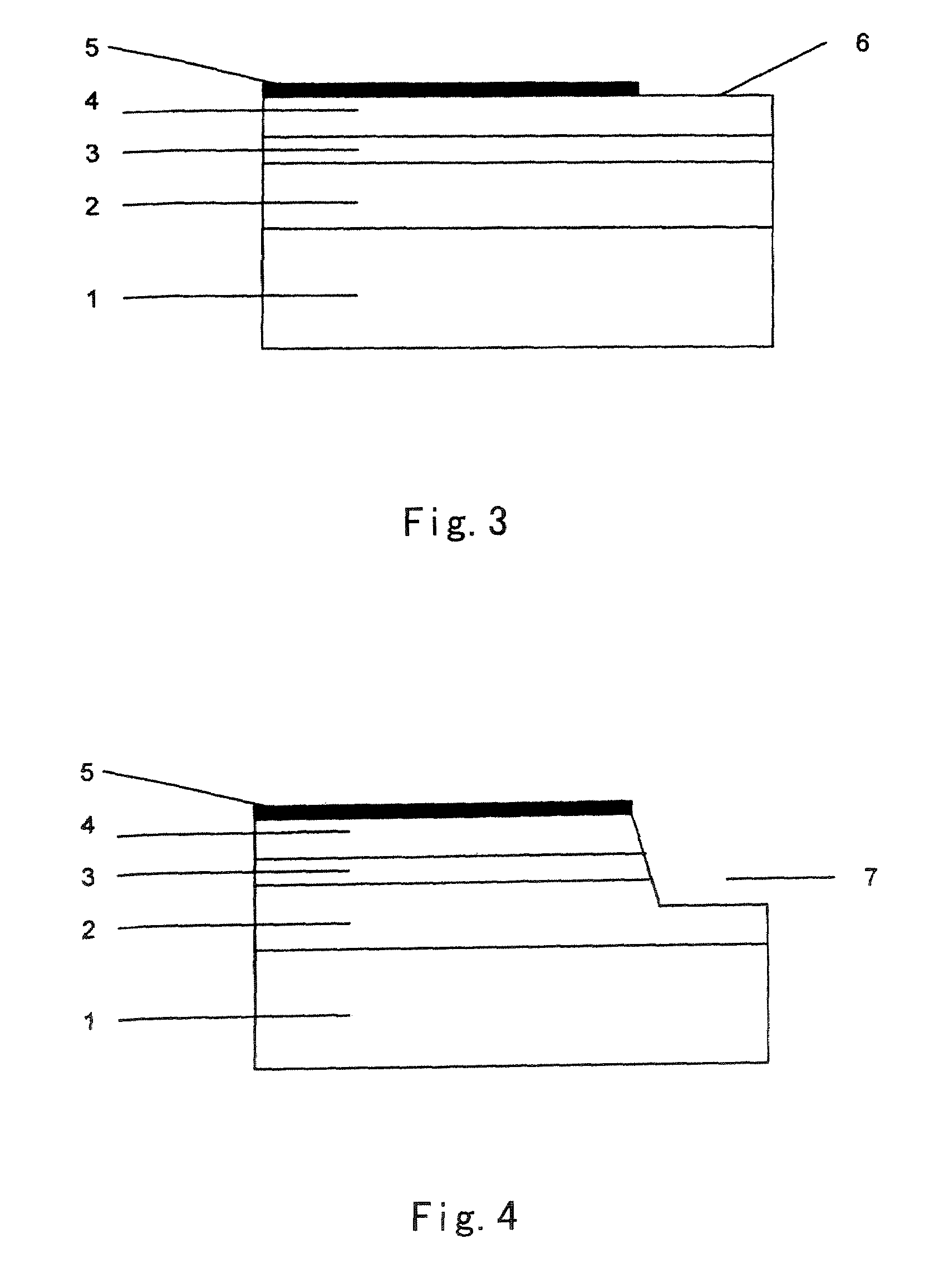

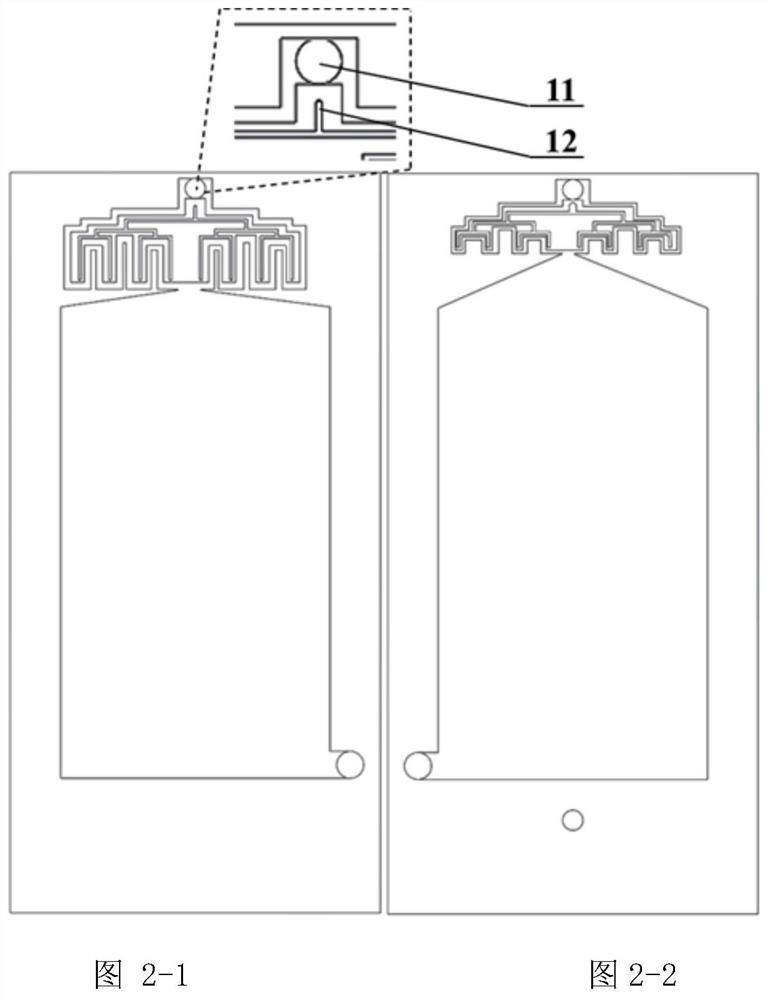

Fabrication Method of GaN Power LEDs with Electrodes Formed by Composite Optical Coatings

ActiveUS20090029495A1High densityPrevent leakageSemiconductor/solid-state device manufacturingSemiconductor devicesOptical coatingEvaporation

Fabrication method of GaN power LED with electrodes formed by composite optical coatings, comprising epitaxially growing N—GaN, active, and P—GaN layers successively on a substrate; depositing a mask layer thereon; coating the mask layer with photoresist; etching the mask layer into an N—GaN electrode pattern; etching through that electrode pattern to form an N—GaN electrode region; removing the mask layer and cleaning; forming a transparent, electrically conductive film simultaneously on the P—GaN and N—GaN layers; forming P—GaN and N—GaN transparent, electrically conductive electrodes by lift-off; forming bonding pad pattern for the P—GaN and N—GaN electrodes by photolithography process; simultaneously forming thereon bonding pad regions for the P—GaN and N—GaN electrodes by stepped electron beam evaporation; forming an antireflection film pattern by photolithography process; forming an antireflection film; thinning and polishing the backside of the substrate, then forming a reflector thereon; and completing the process after scribing, packaging and testing.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

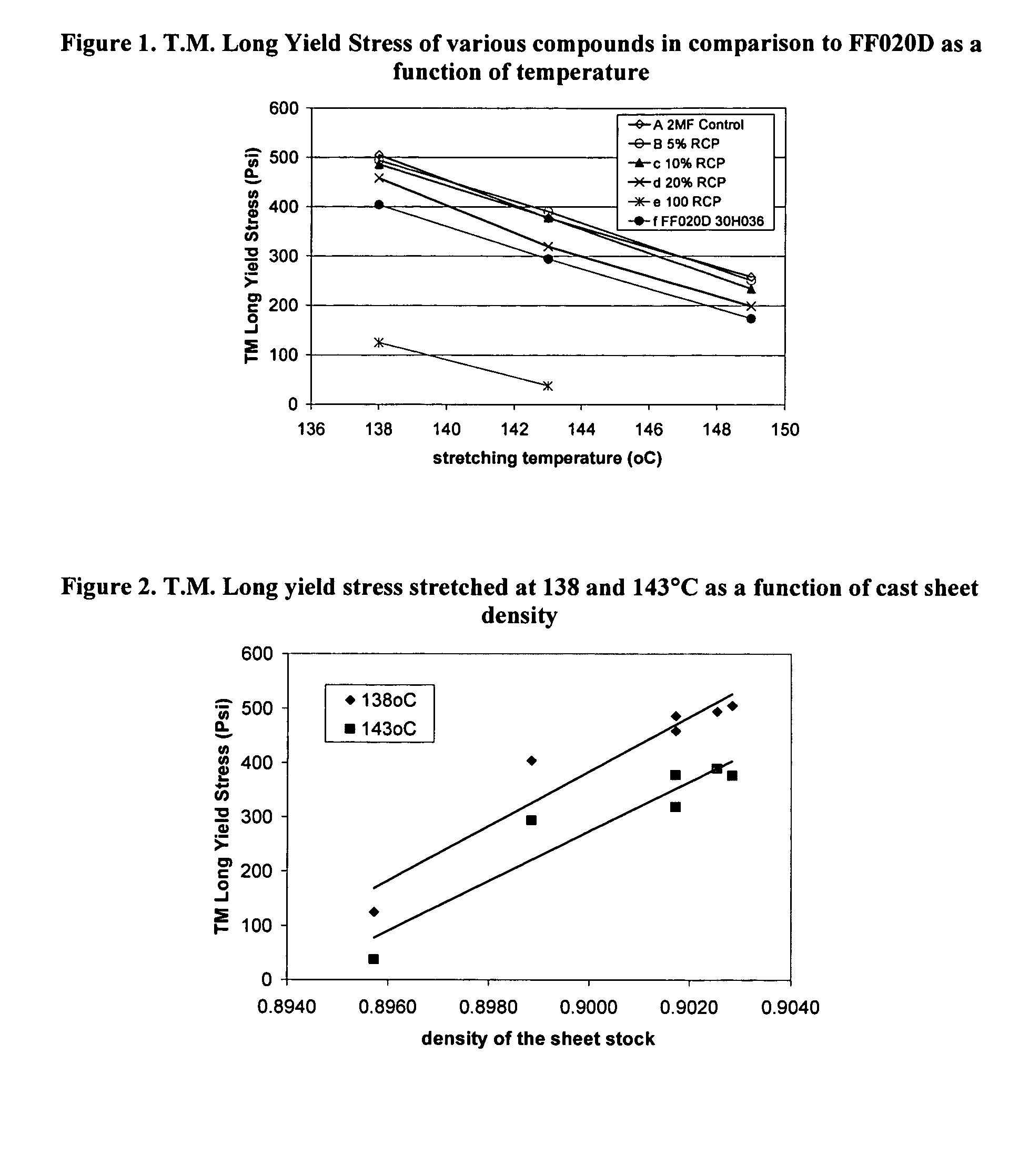

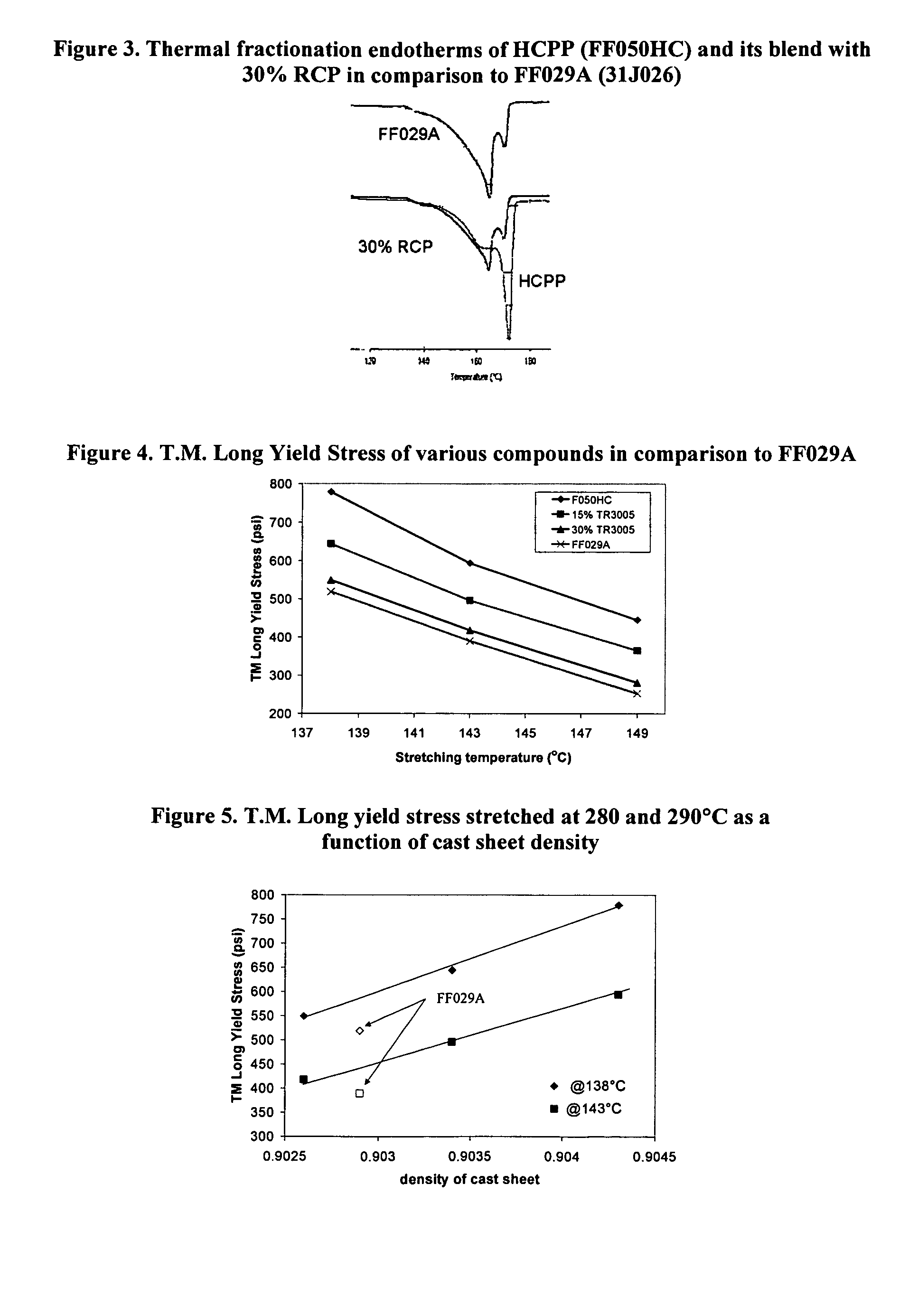

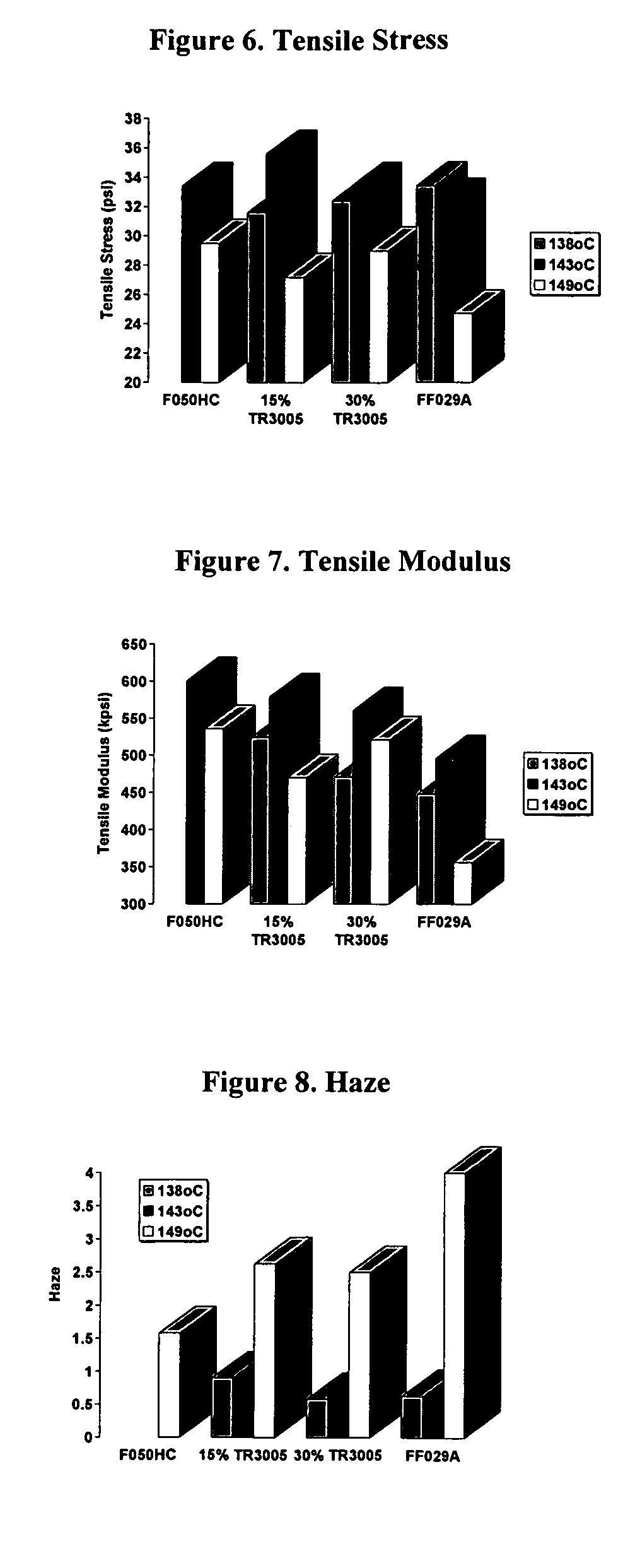

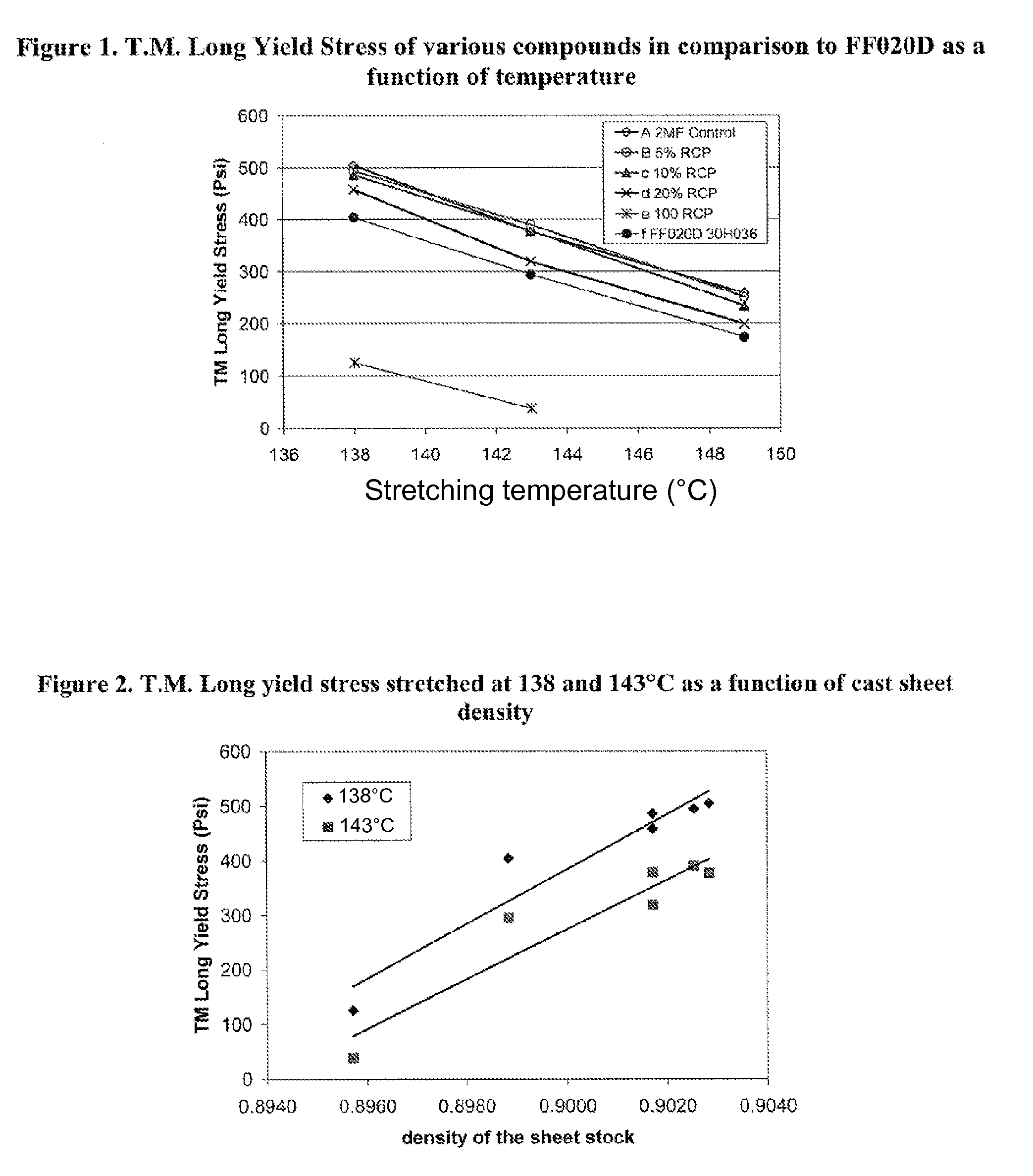

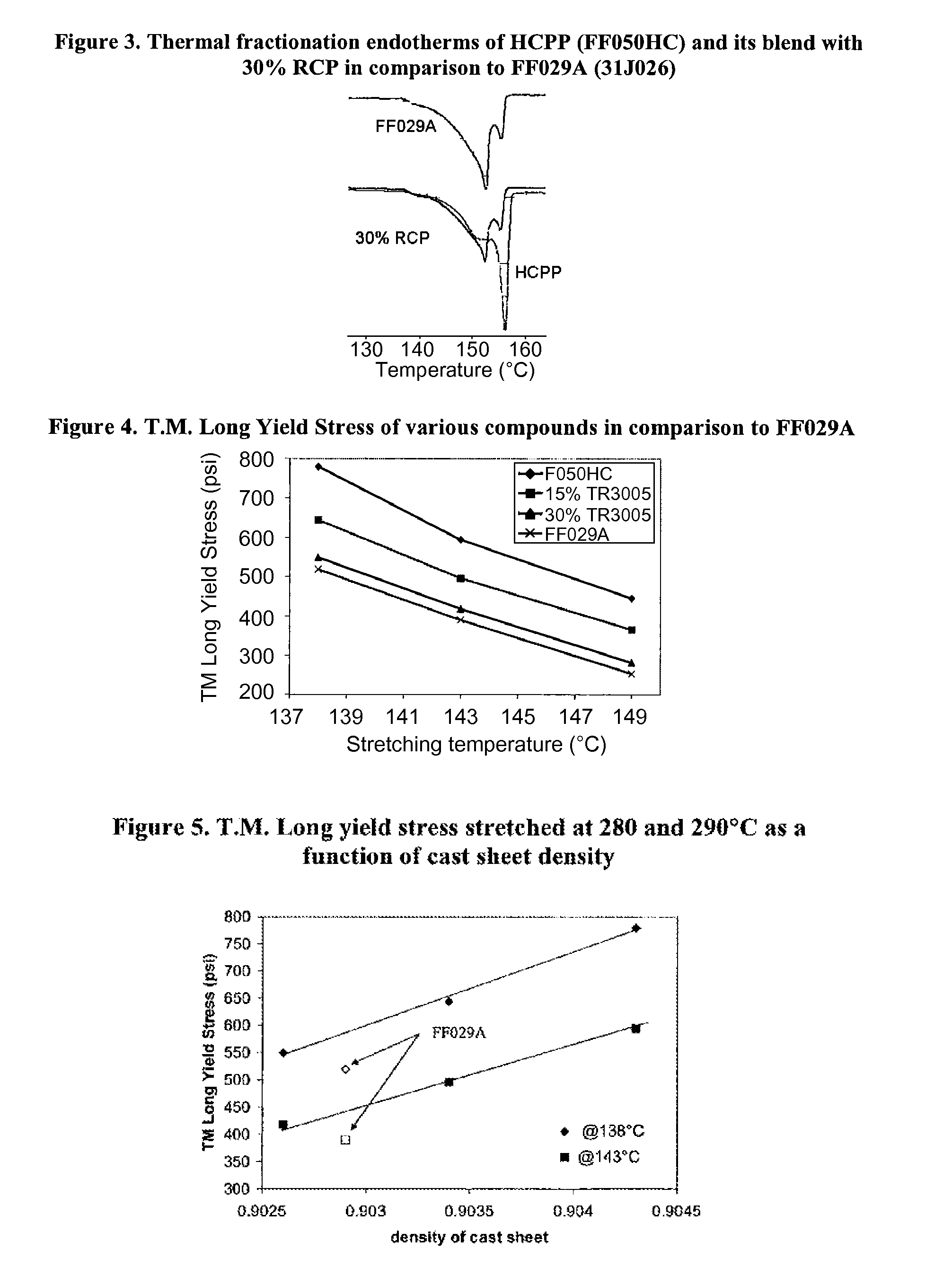

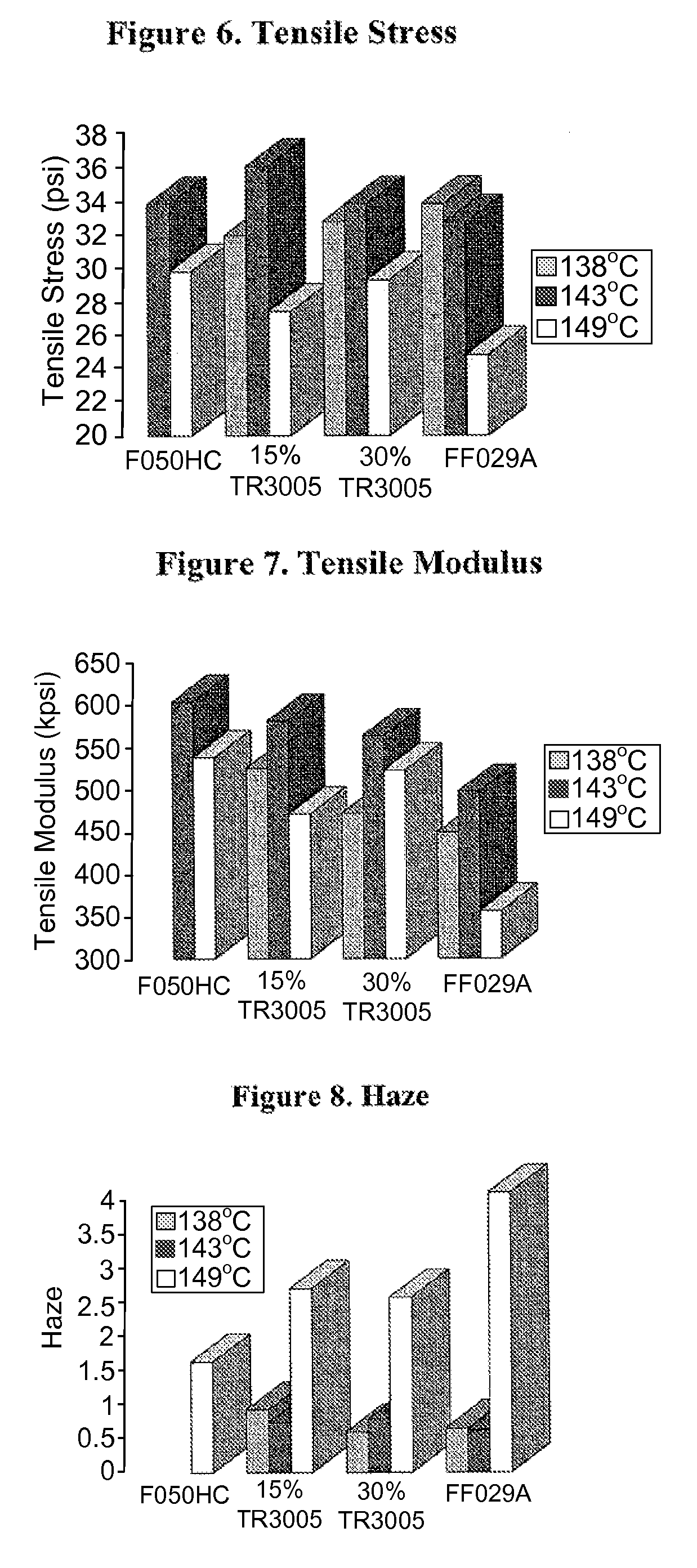

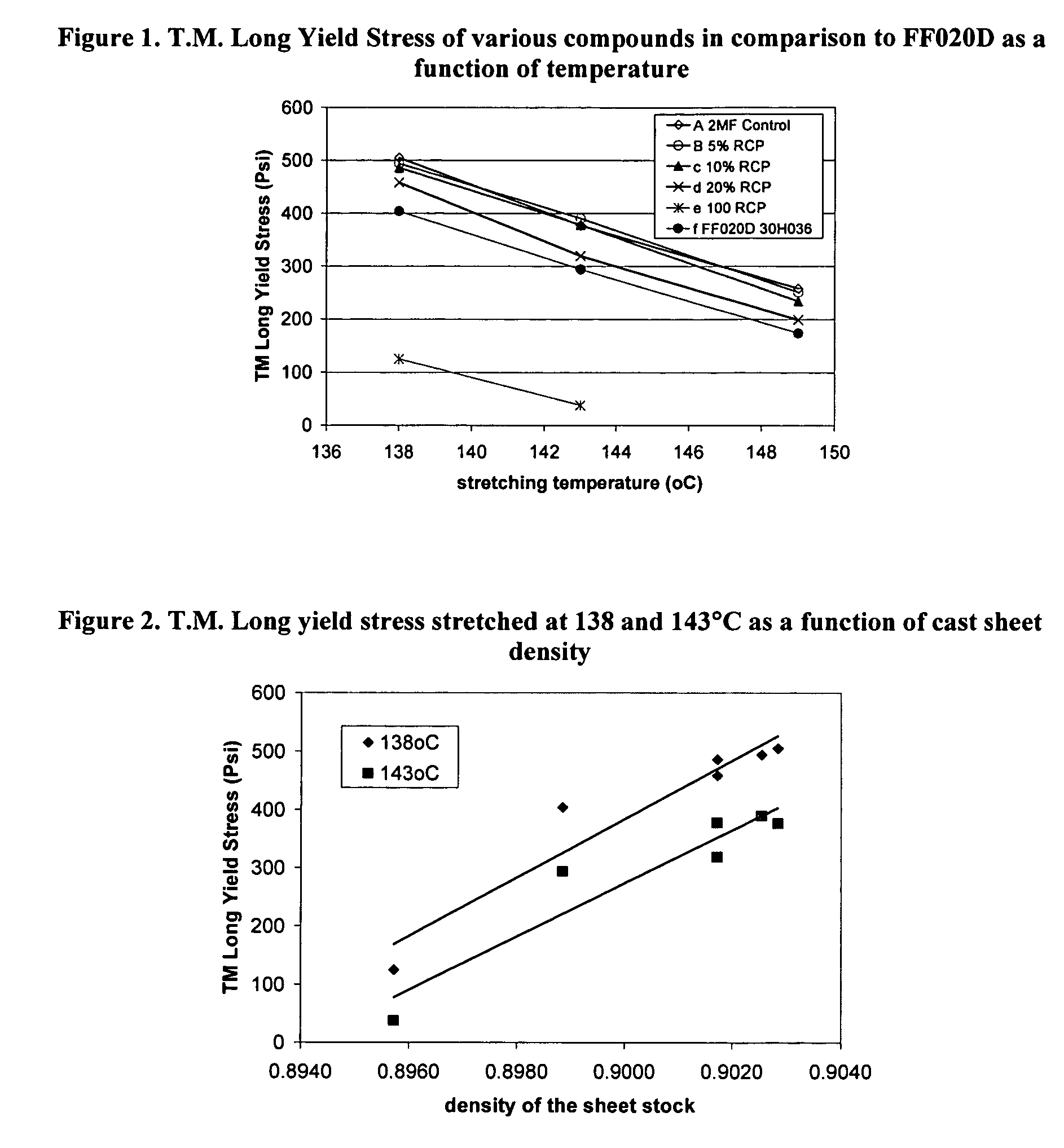

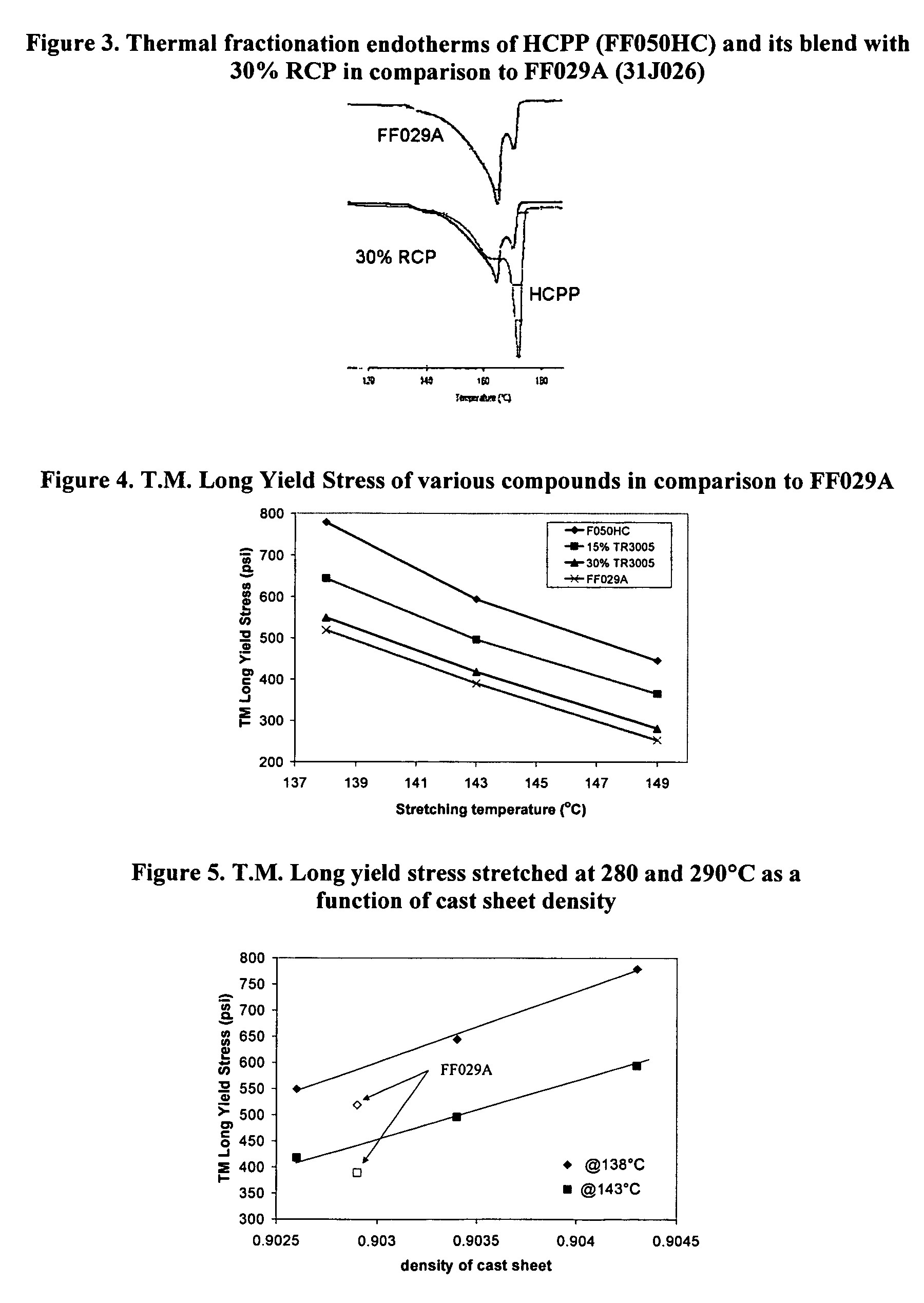

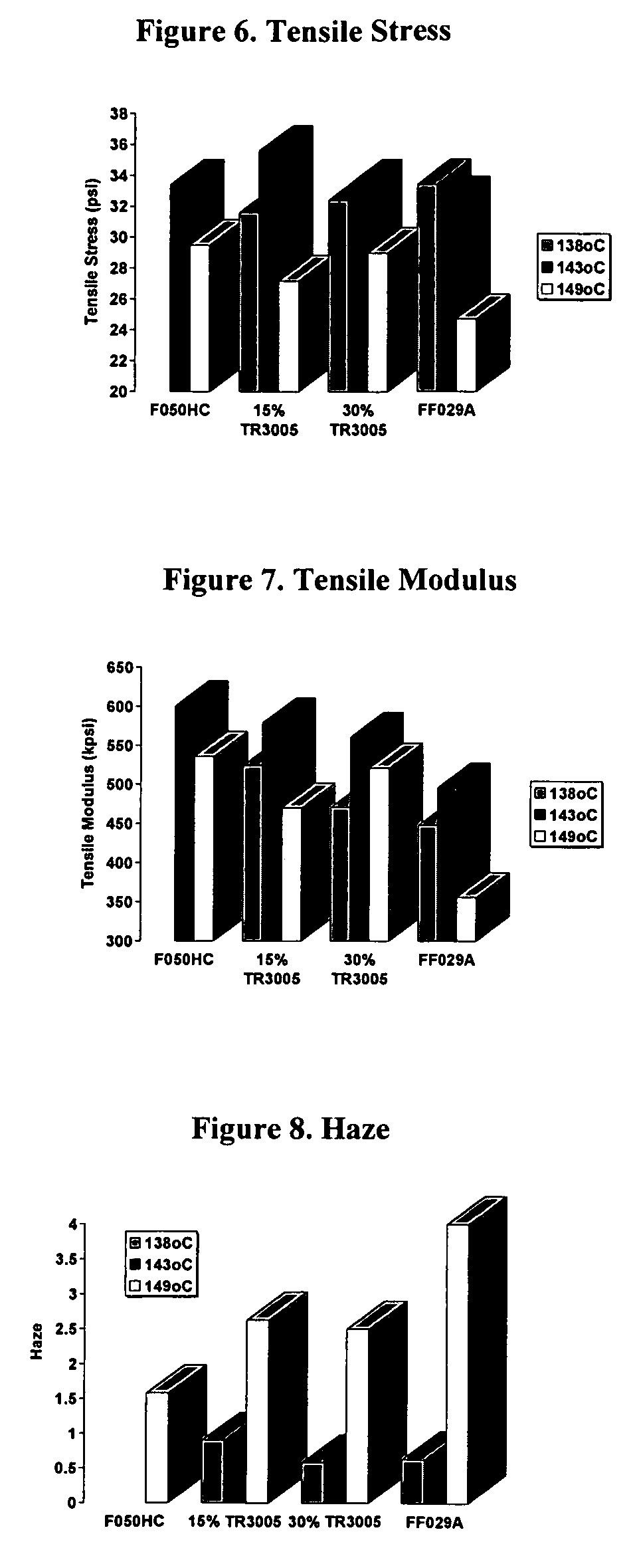

In-reactor produced polypropylene blends

Polypropylene resin compositions are provided that are useful in the production of thermoformed articles and biaxially oriented polypropylene films (BOPPs), tapes and fibers. The resins of the present invention are blends of high crystalline (low solubles) polypropylene homopolymer and an ethylene / propylene random copolymer (RCP). These blends can be used to replace standard high solubles BOPP grade polypropylene homopolymers. In addition, the use of high crystalline polypropylene homopolymers in the blends imparts improved stiffness to the finished films while maintaining good processability of the blends. Such polypropylene compositions are effectively produced by in-reactor blending of a high crystalline propylene homopolymer and a propylene / ethylene random copolymer.

Owner:BRASKEM AMERICA

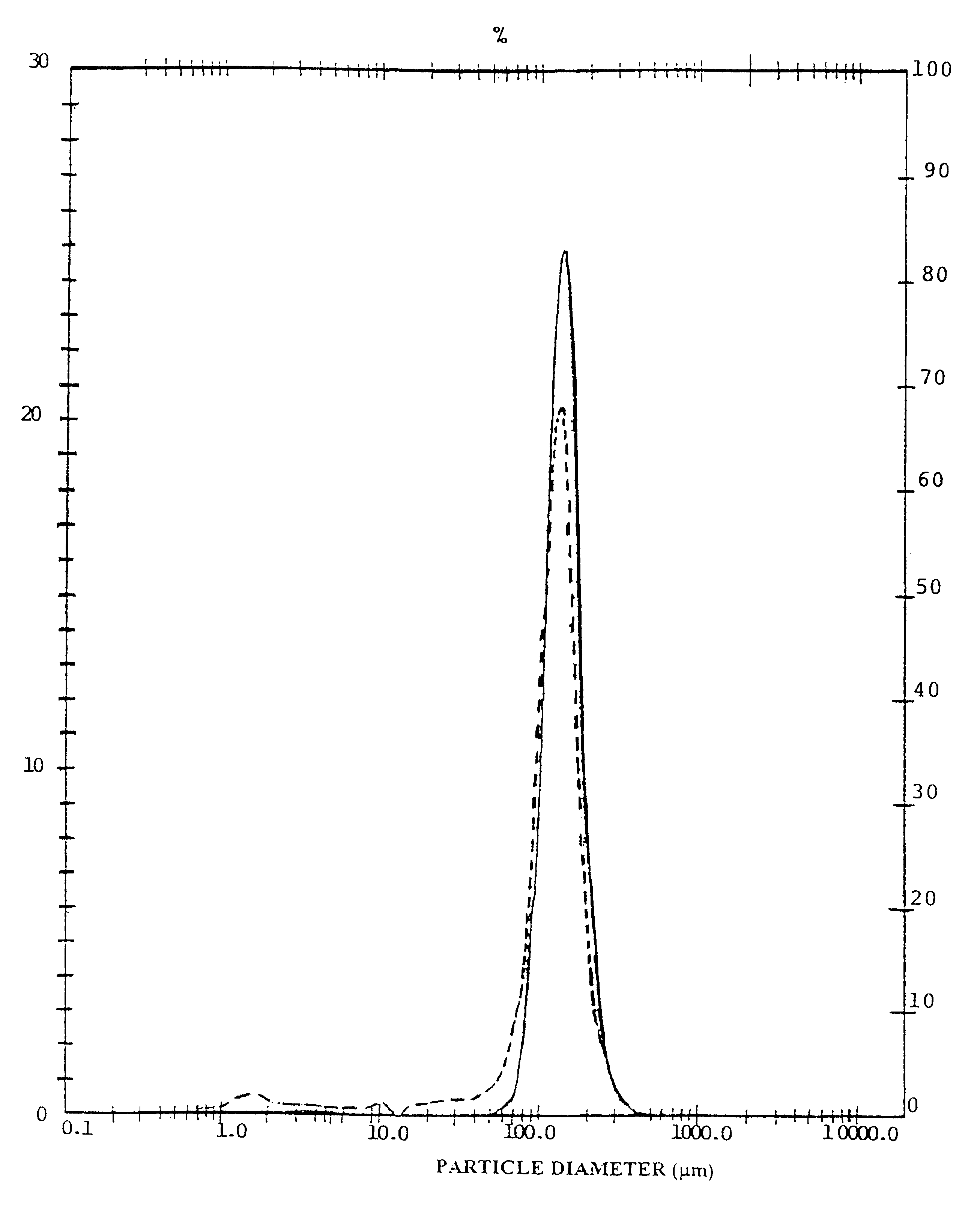

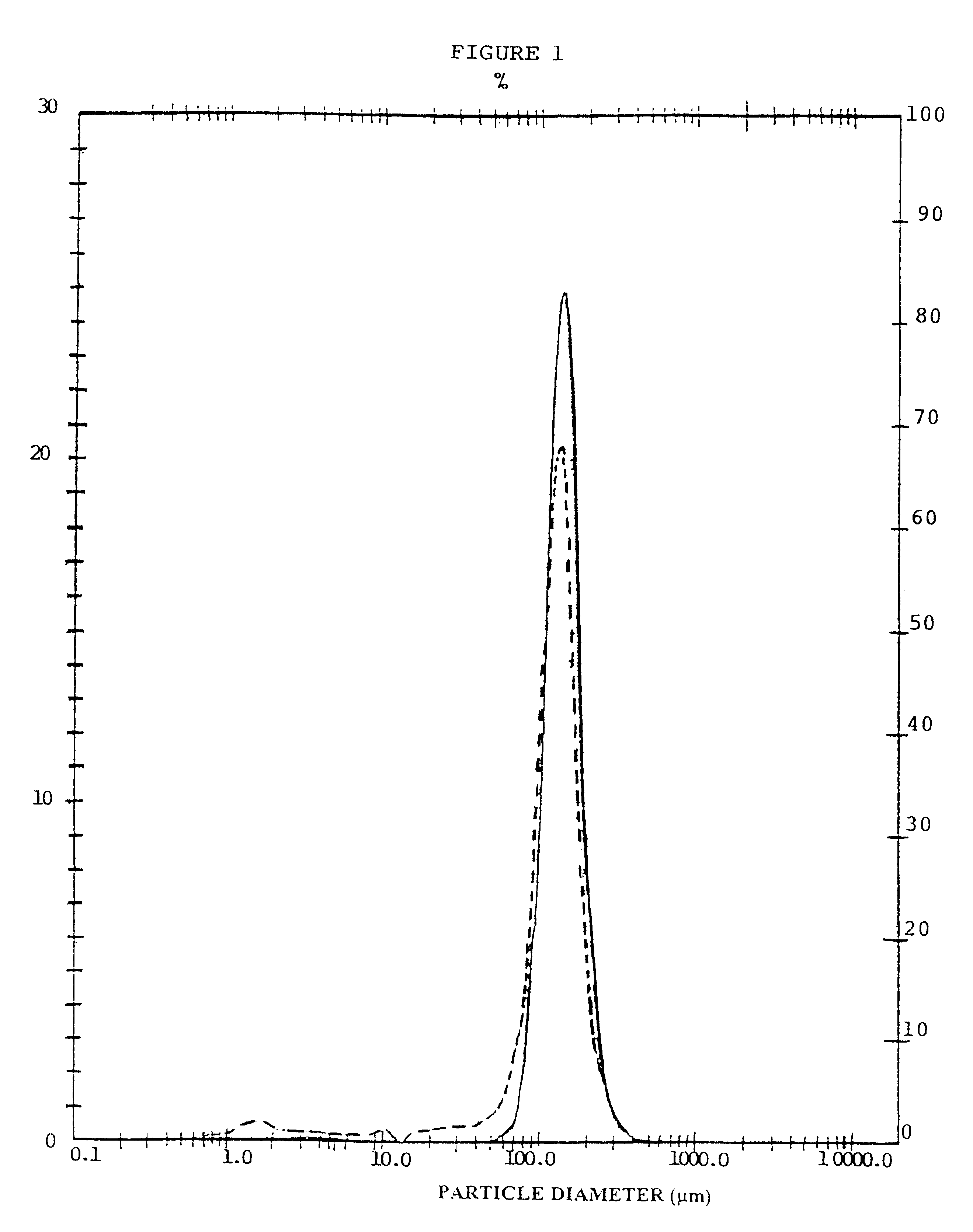

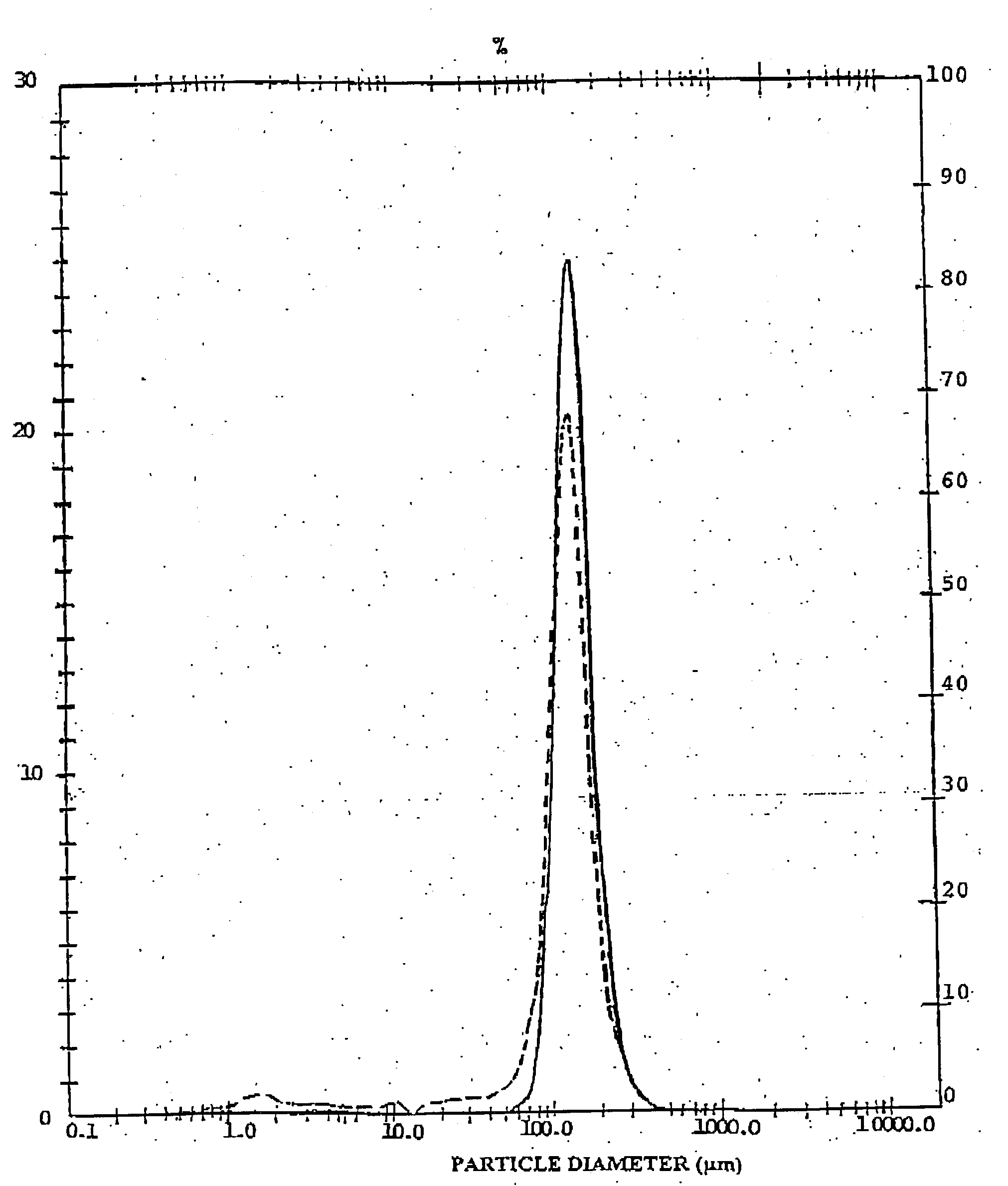

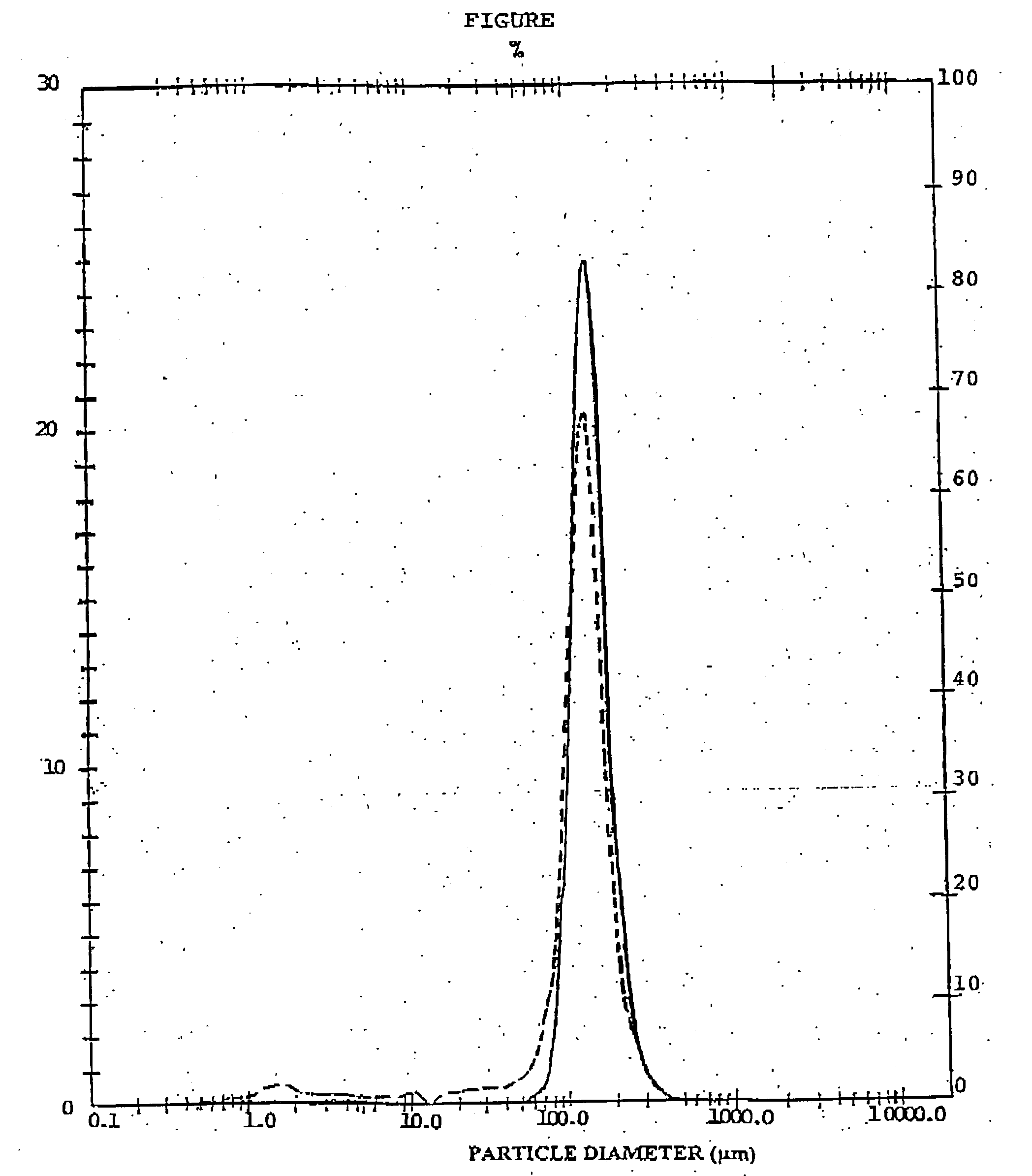

Modified carrier particles for use in dry powder inhalers

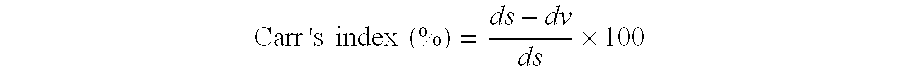

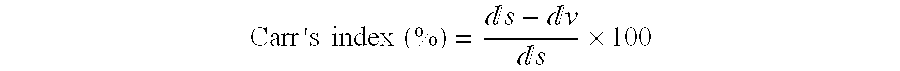

InactiveUS6641844B1Mild conditionsAvoid separation stepsPowder deliveryGranular deliveryMedicineActive particles

The invention relates to carrier particles for use in pharmaceutical compositions for the pulmonary administration of medicaments by means of dry powder inhalers. In particular, the invention relates to a novel technological process for obtaining a carrier modified so as to improve the efficiency of redispersion of active particles and hence increase the respirable fraction. After the treatment of the invention, the surface of said modified carrier particles can also be coated with a suitable additive so as to further improve the respirable fraction.

Owner:CHIESI FARM SPA

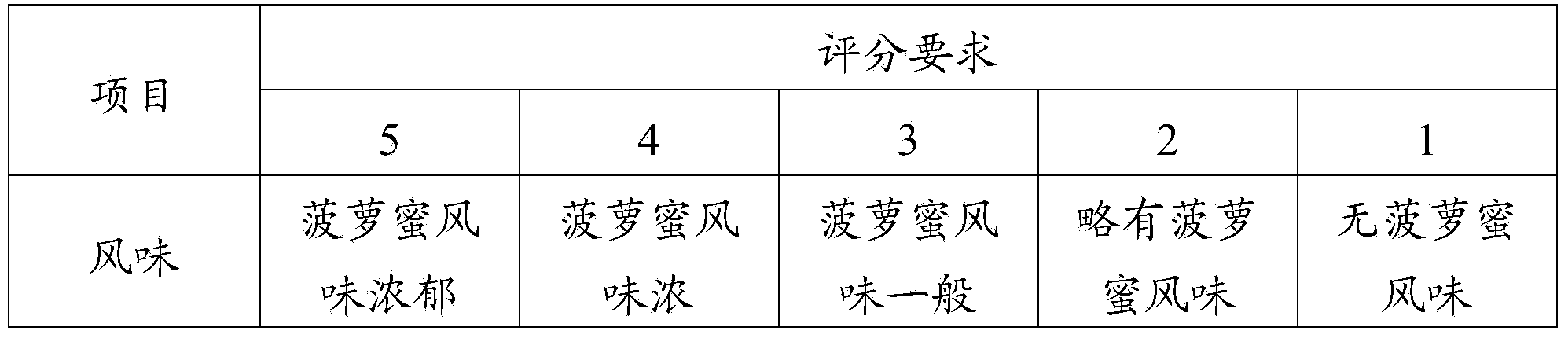

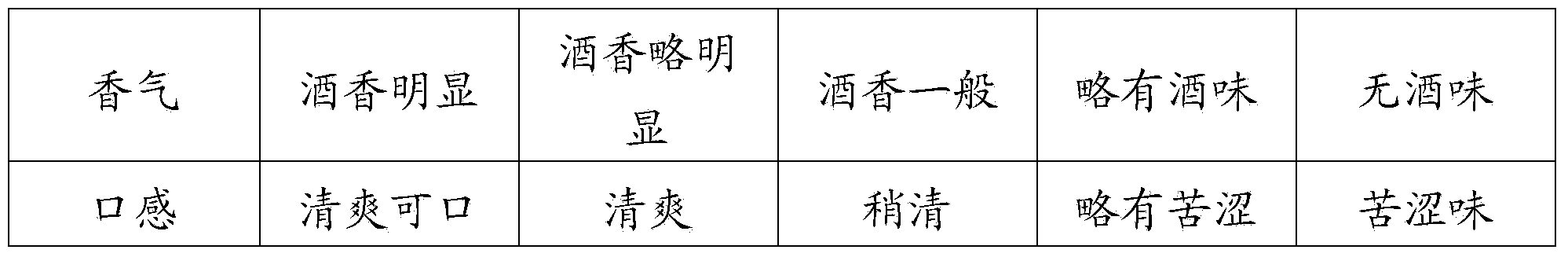

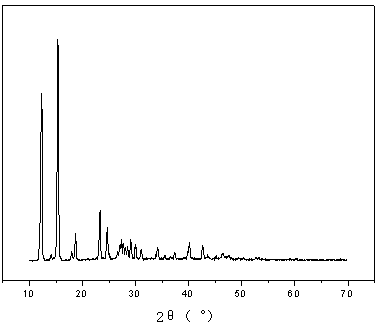

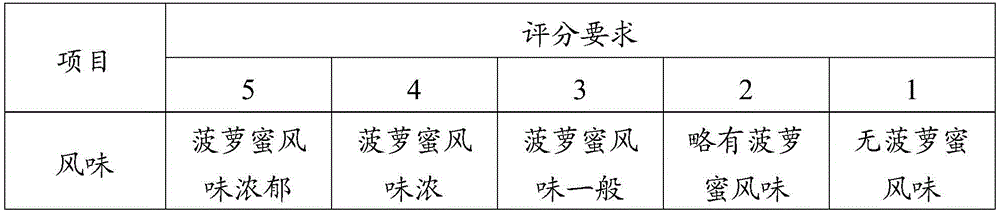

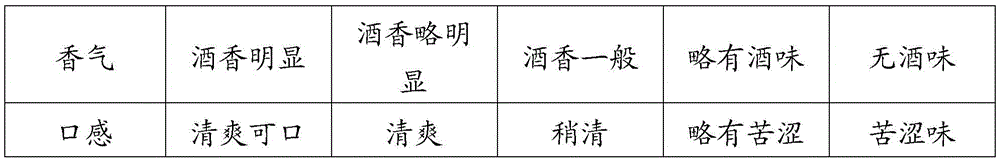

Jack fruit wine and preparation method thereof

ActiveCN103710214ARich flavorHigh alcohol contentAlcoholic beverage preparationFruit wineHydrolysate

The invention relates to the technical field of making wine, and particularly relates to jack fruit wine and a preparation method of the jack fruit wine. The method comprises steps of mixing peeled jack fruit with water and preparing into pulp; then adding amylase, cellulose and pectinase into the pulp for enzymolysis so as to obtain enzymatic hydrolysate; then mixing with water and sugar, sterilizing so as to obtain mixed liquor; adding saccharomycetes into the mixed liquor for anaerobic fermentation so as to obtain fermented liquid; filtering, sterilizing and ageing the fermented liquid so as to obtain the jack fruit wine. The preparation method is simple and has high use ratio of the fruit; the jack fruit wine prepared by the method has low alcoholic strength, rich jack fruit flavor and highlighted bouquet, and is fresh and cool.

Owner:广东桑醇酒业有限公司

Fabrication method of GaN power LEDs with electrodes formed by composite optical coatings

ActiveUS7704764B2High densityPrevent leakageSemiconductor/solid-state device manufacturingSemiconductor devicesOptical coatingEvaporation

Fabrication method of GaN power LED with electrodes formed by composite optical coatings, comprising epitaxially growing N—GaN, active, and P—GaN layers successively on a substrate; depositing a mask layer thereon; coating the mask layer with photoresist; etching the mask layer into an N—GaN electrode pattern; etching through that electrode pattern to form an N—GaN electrode region; removing the mask layer and cleaning; forming a transparent, electrically conductive film simultaneously on the P—GaN and N—GaN layers; forming P—GaN and N—GaN transparent, electrically conductive electrodes by lift-off; forming bonding pad pattern for the P—GaN and N—GaN electrodes by photolithography process; simultaneously forming thereon bonding pad regions for the P—GaN and N—GaN electrodes by stepped electron beam evaporation; forming an antireflection film pattern by photolithography process; forming an antireflection film; thinning and polishing the backside of the substrate, then forming a reflector thereon; and completing the process after scribing, packaging and testing.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

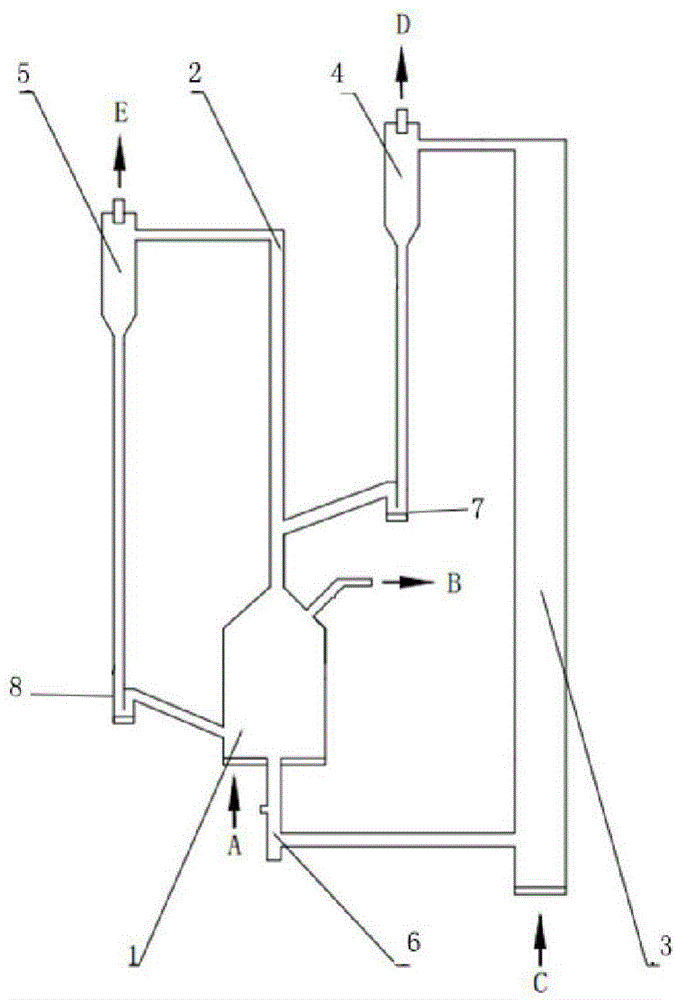

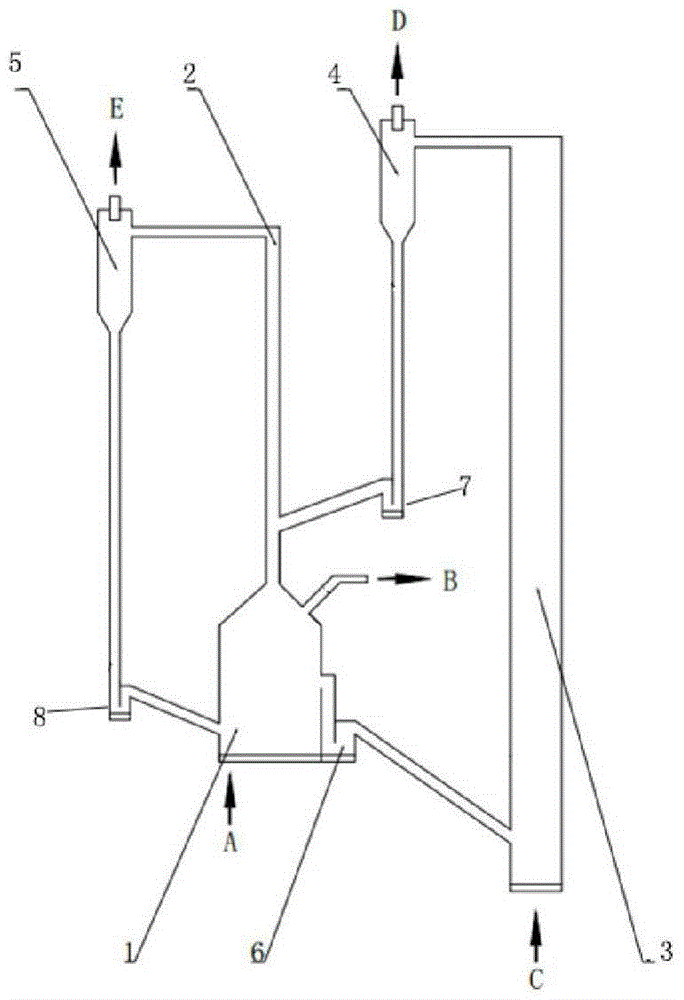

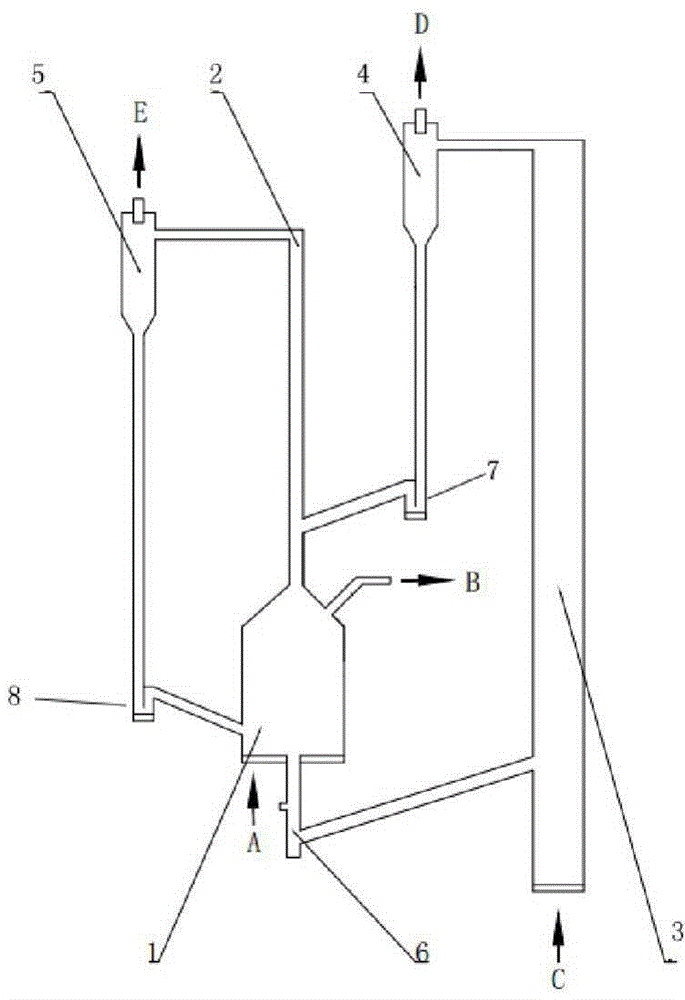

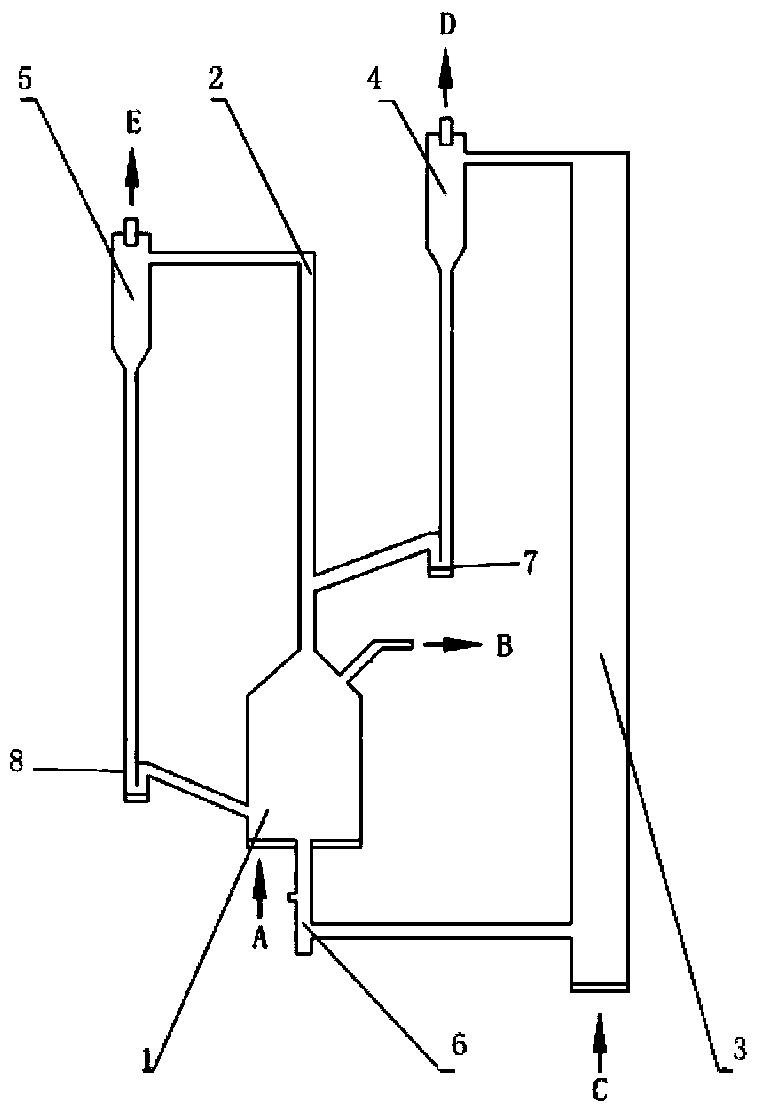

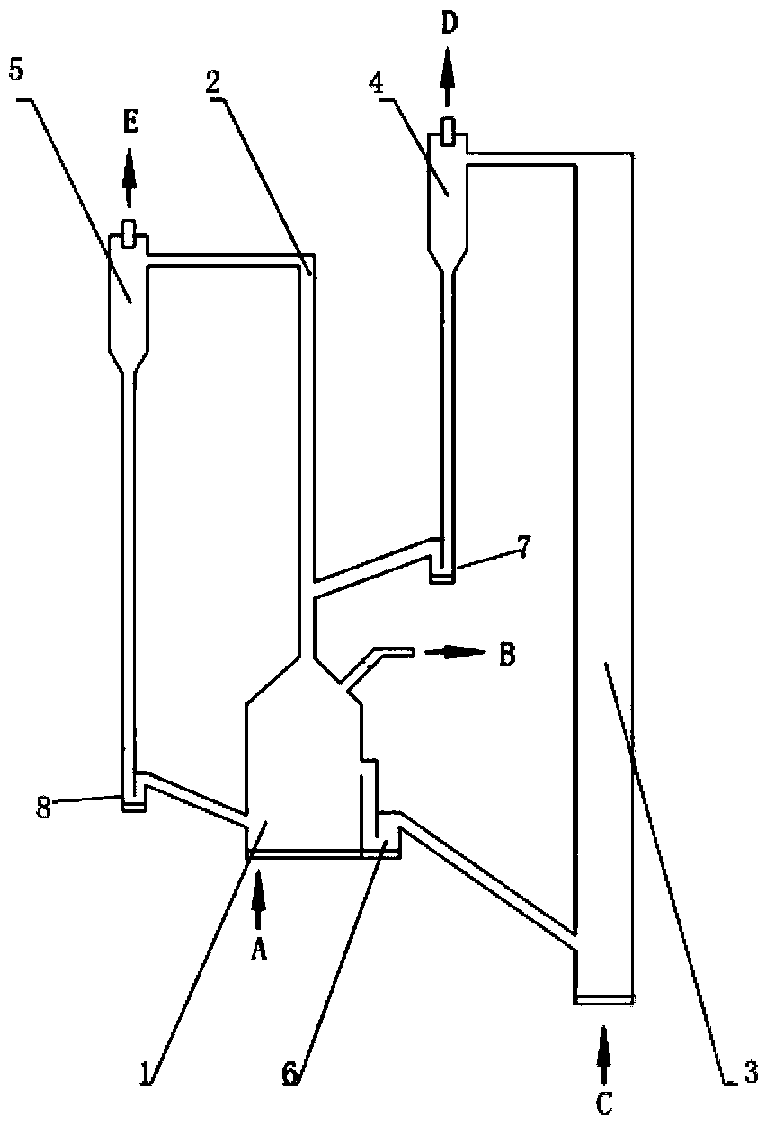

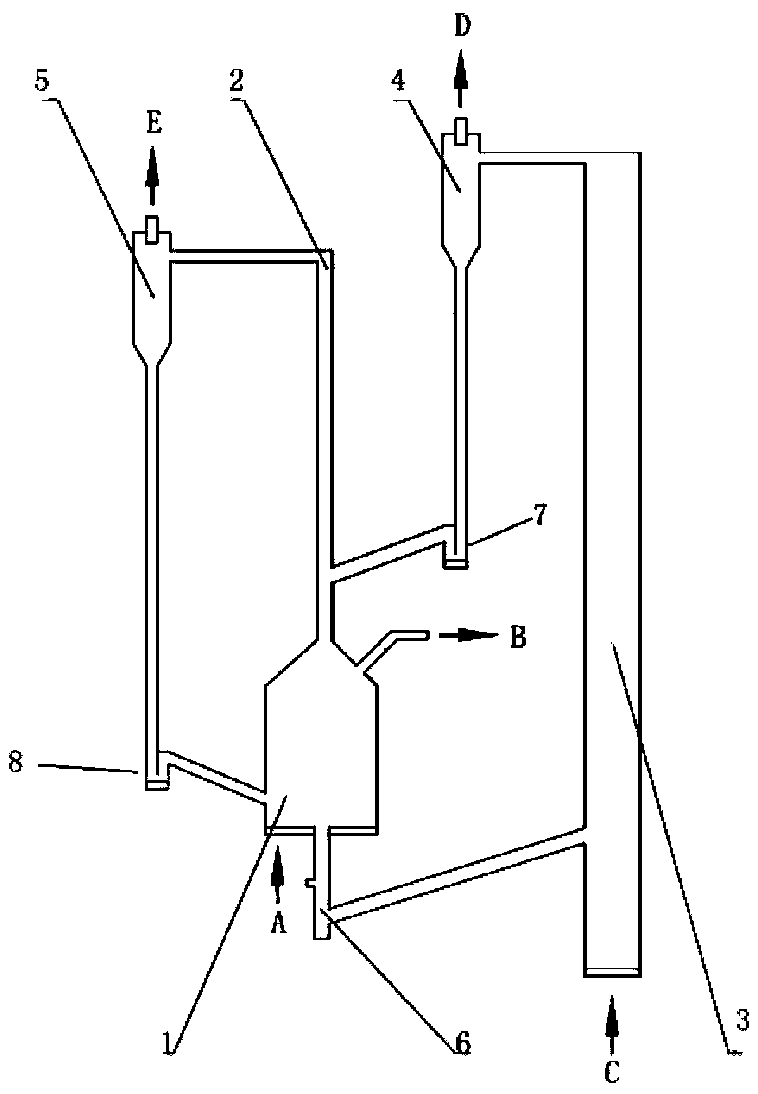

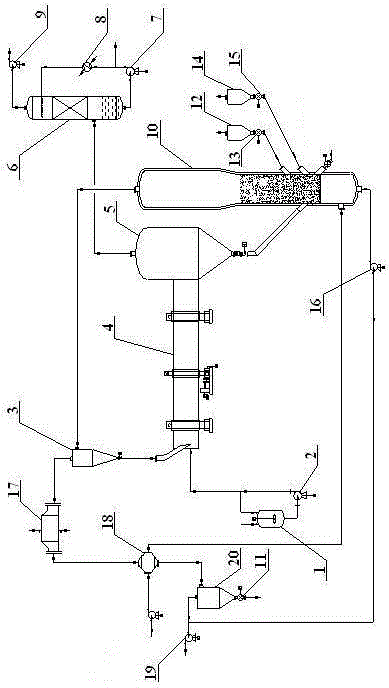

Apparatus for preparing synthetic gas with adjustable H2/CO proportion by methane-rich gas and method thereof

InactiveCN104401938AAvoid secondary adjustmentsFacilitate the subsequent synthesis processNitrogen purification/separationCarbon compoundsCycloneSyngas

The invention discloses an apparatus for preparing synthetic gas with adjustable H2 / CO proportion by methane-rich gas and a method thereof. The apparatus comprises a fuel reactor, an air reactor, a first cyclone separator, a second cyclone separator, a material returning valve 1, a material returning valve 2 and a material returning valve 3; a bubbling fluidized bed is arranged at bottom of the fuel reactor, a lifting pipe is arranged at upper part of the fuel reactor; the bubbling fluidized bed is connected to the air reactor through the material returning valve 1, the upper part of the air reactor is connected to the first cyclone separator, a blanking tube of the first cyclone separator is connected to the lifting pipe through the material turning valve 2, the upper part of the lifting pipe is connected to the second cyclone separator, and the blanking tube of the second cyclone separator is connected to the lower part of the bubbling fluidized bed through the material turning valve 3. By adjusting the circulation volume of oxygen carrier and stay time in the bubbling fluidized bed, the reduction depth of the oxygen carrier in the bubbling fluidized bed can be controlled, proportion of H2 / CO at a synthetic gas outlet can be adjusted, subsequent synthesis technology is convenient, CO2 can be instantly separated and captured, and separating step can be avoided.

Owner:SOUTHEAST UNIV

Modified carrier particles for use in dry powder inhalers

InactiveUS20040009127A1Mild conditionsDecrease in flowabilityPowder deliveryMechanical working/deformationMedicineActive particles

Owner:CHIESI FARM SPA

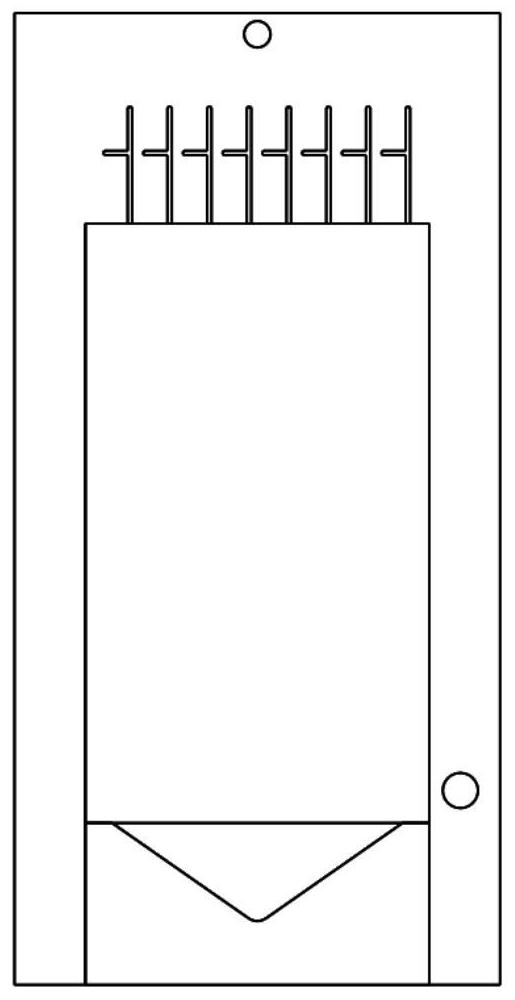

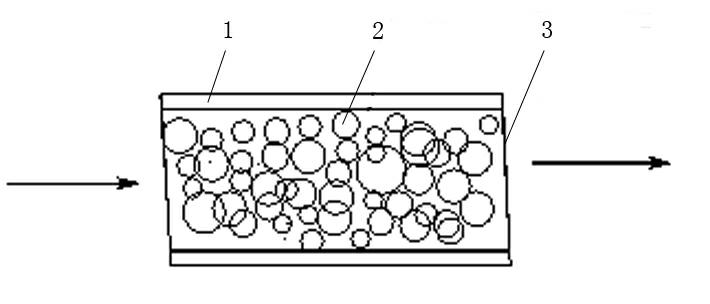

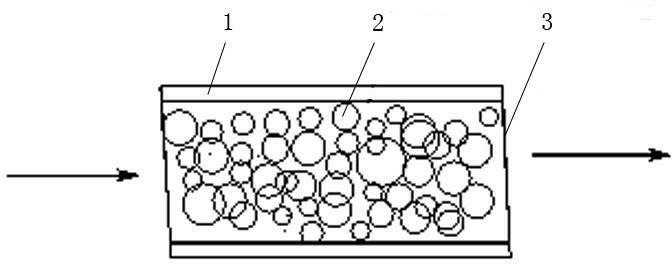

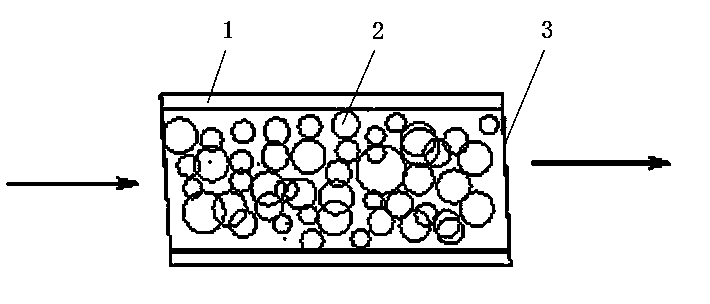

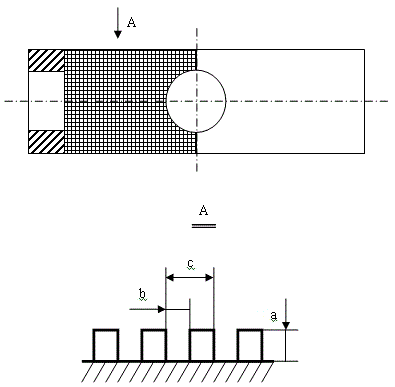

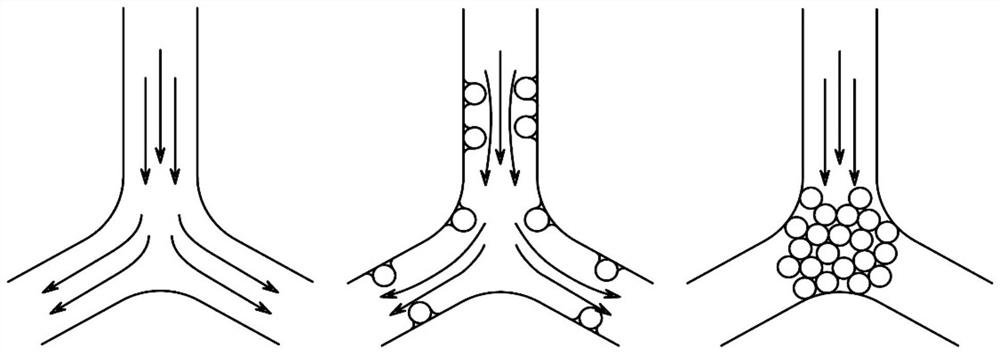

Chip type structure catalysis multiphase microreactor

InactiveCN113058521AImprove efficiencyLarge specific surface areaChemical/physical/physico-chemical microreactorsPetrochemicalHomogeneous catalysis

The invention relates to a chip type structure catalysis multiphase microreactor which comprises a microreaction chip and a structure catalyst and comprises a gas-liquid two-phase reactant distributor, a multiphase catalysis reaction chamber, heat exchange channels on two sides of the catalysis reaction chamber and heat exchange channels on two sides of the gas-liquid two-phase reactant distributor; and gas-liquid or liquid-liquid is uniformly distributed to an inlet of a catalyst with a high-precision structure at the rear end by utilizing a dendritic distribution form and T-shaped shear mixing, and flowing heat exchange areas are respectively arranged on the upper side and the lower side of the catalytic reaction chamber. By optimizing the structural design of the reactor, the reactor has the advantages of excellent mass transfer and heat transfer characteristics, controllable reactant retention time, narrow retention time distribution, personalized design of a catalyst structure according to a reaction system, easiness in amplification and the like, and solves the bottleneck problem that a homogeneous catalyst or a fine powder catalyst is difficult to separate from a product; and the chip type structure catalysis multiphase microreactor is widely applicable to petrochemical, chemical, pharmaceutical, environmental protection, food and other fields.

Owner:EAST CHINA UNIV OF SCI & TECH

Polypropylene blends for non-woven production

InactiveUS20110021708A1High crystallinityReduce contentNon-woven fabricsMonocomponent polyolefin artificial filamentFiberPolymer science

Polypropylene resin compositions are provided that are useful in the production of thermoformed articles and biaxially oriented polypropylene films (BOPPs), tapes and fibers. The resins of the present invention are blends of high crystalline (low solubles) polypropylene homopolymer and an ethylene / propylene random copolymer (RCP). These blends can be used to replace standard high solubles BOPP grade polypropylene homopolymers. In addition, the use of high crystalline polypropylene homopolymers in the blends imparts improved stiffness to the finished films while maintaining good processability of the blends. Such polypropylene compositions are effectively produced by in-reactor blending of a high crystalline propylene homopolymer and a propylene / ethylene random copolymer.

Owner:BRASKEM AMERICA

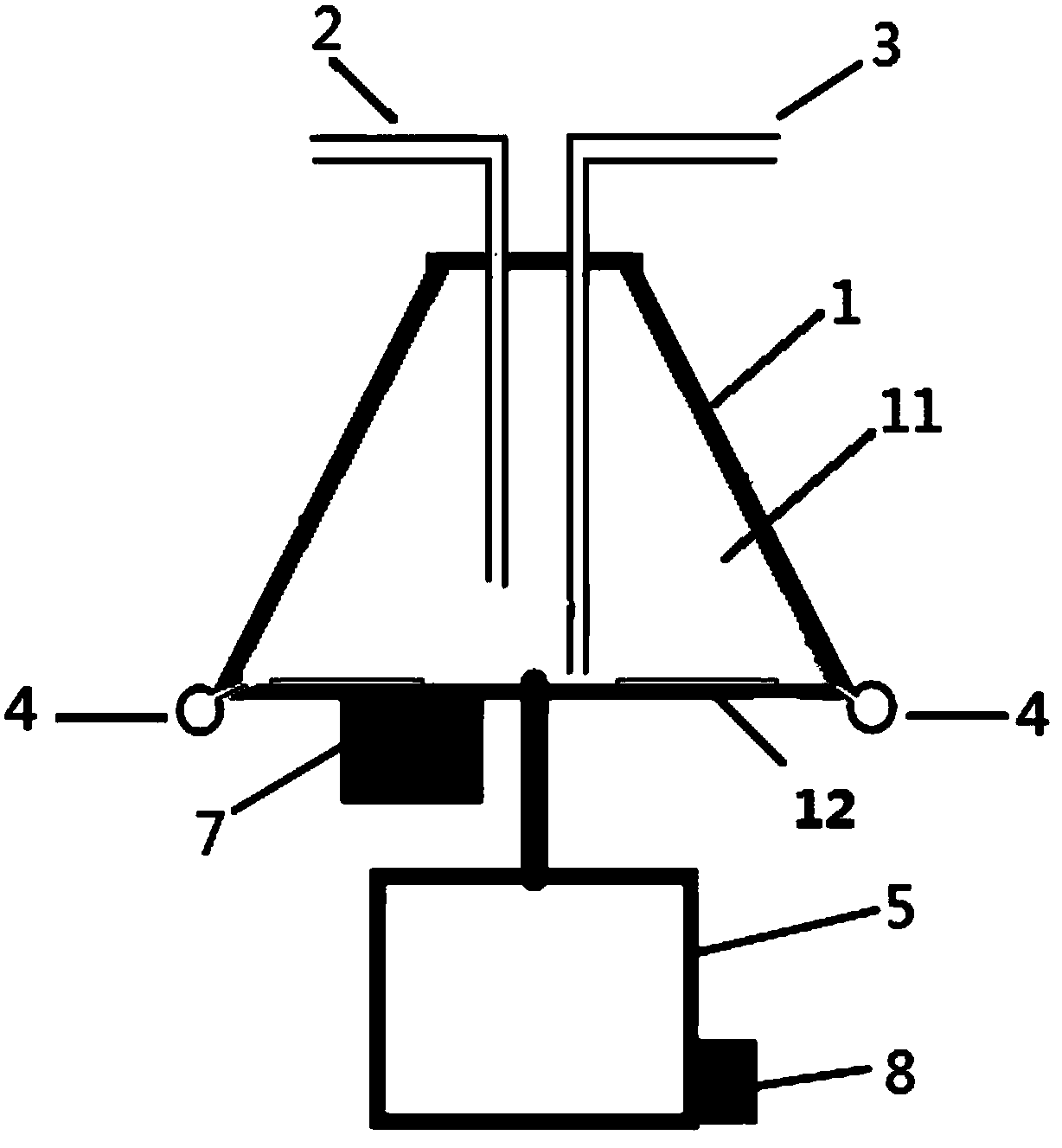

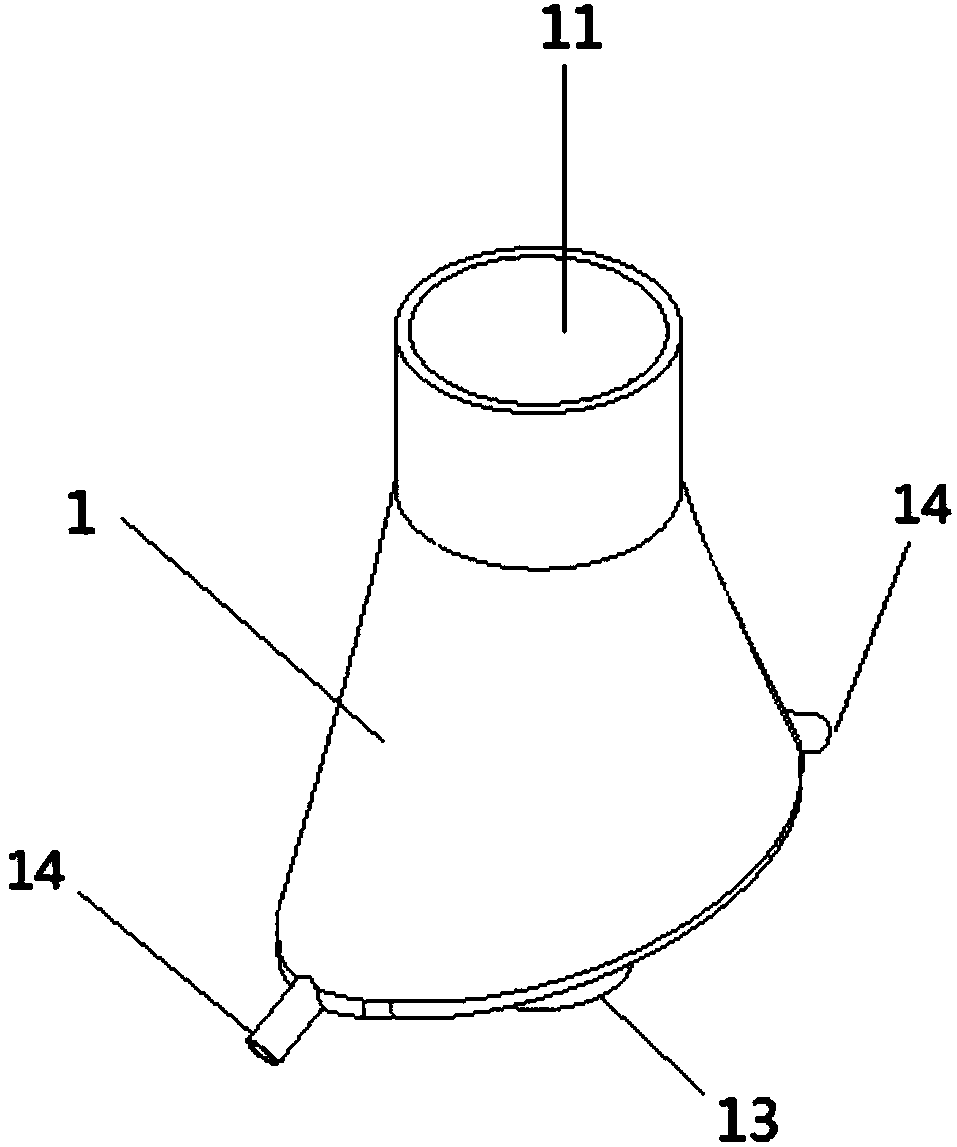

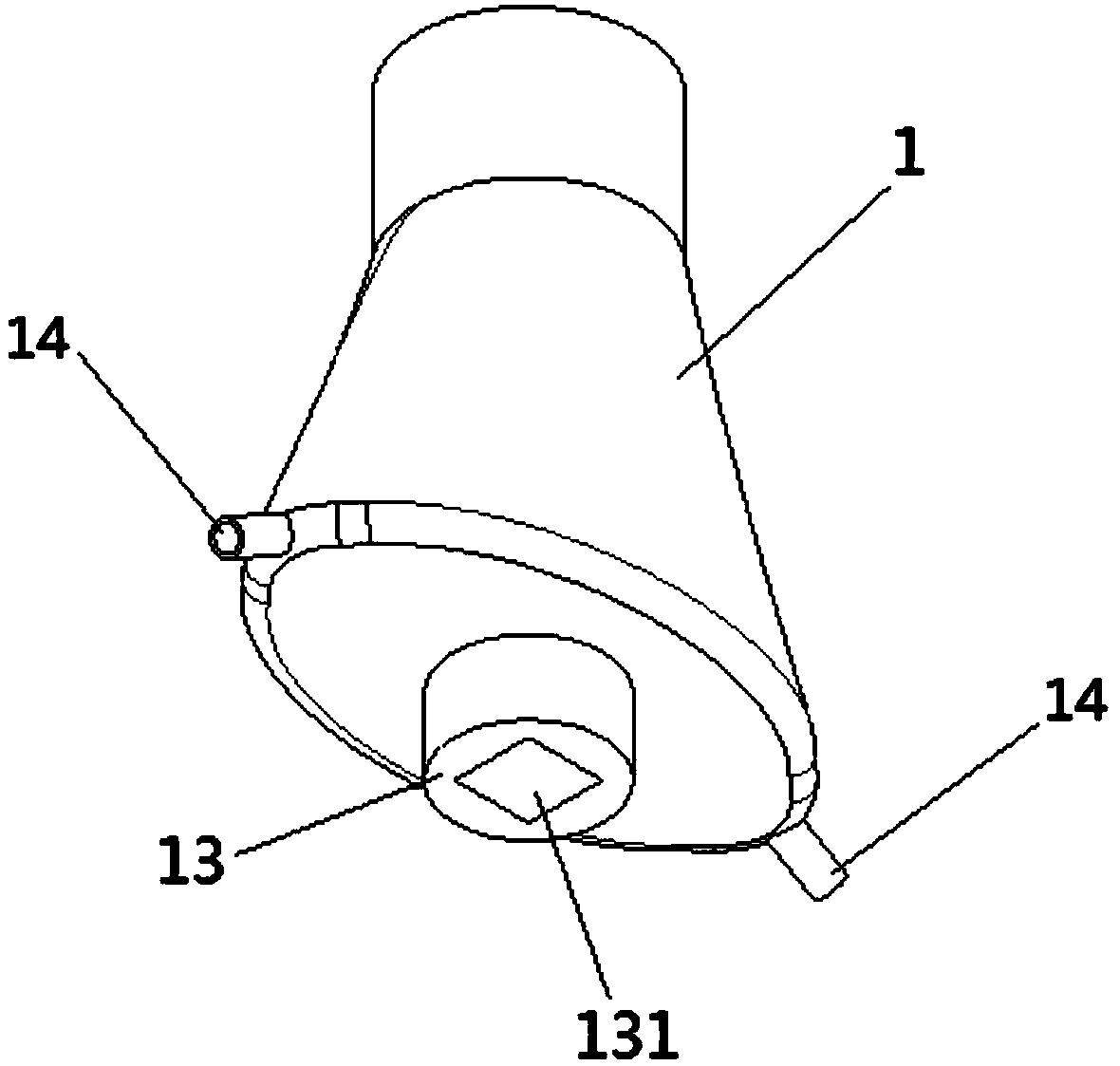

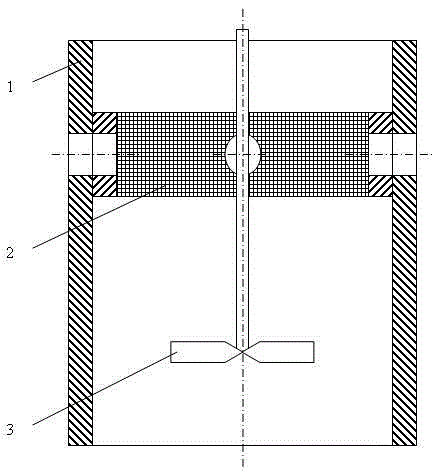

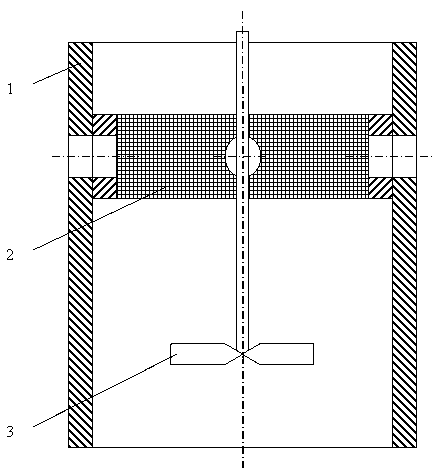

Stem cell separating device

PendingCN109988700AAvoid pollutionAchieve safe aseptic separationBioreactor/fermenter combinationsBiological substance pretreatmentsFully automaticStem cell

The invention provides a stem cell separating device, which comprises a tank and a a driving device, wherein a conical reaction cavity is formed in the tank; an injection conduit and an suction conduit, which are hermetically communicated with the conical reaction cavity, are arranged at the top of the tank; stem cell collecting parts, which are communicated with the conical reaction cavity, are arranged at the lower part of the tank; the stem cell collecting parts and the tank perform exchanging with external substances through the injection conduit and the suction conduit; and the driving device is arranged outside the bottom wall of the tank in a detachable manner, and is used for driving the tank to rotate for vibration or centrifugal separation. The device has the advantages of simplestructure, low cost, fully automatic operation and capability of accurately controlling the efficient separation and extraction of stem cells.

Owner:肖锷

In-reactor produced polypropylene blends

Polypropylene resin compositions are provided that are useful in the production of thermoformed articles and biaxially oriented polypropylene films (BOPPs), tapes and fibers. The resins of the present invention are blends of high crystalline (low solubles) polypropylene homopolymer and an ethylene / propylene random copolymer (RCP). These blends can be used to replace standard high solubles BOPP grade polypropylene homopolymers. In addition, the use of high crystalline polypropylene homopolymers in the blends imparts improved stiffness to the finished films while maintaining good processability of the blends. Such polypropylene compositions are effectively produced by in-reactor blending of a high crystalline propylene homopolymer and a propylene / ethylene random copolymer.

Owner:BRASKEM AMERICA

Process for preparing polysucrose

The invention discloses a process for preparing polysucrose. The process includes following steps: placing sucrose, distilled water and epibromohydrin after mixing into a device loaded with strong-base anion exchange resin; subjecting the mixture to polymerization reaction on the strong-base anion exchange resin at the temperature of 25 DEG C to 30 DEG C, heating to 60 DEG C to 65 DEG C for re-reaction, eluting the product after the reaction with the distilled water, and absorbing low cross-linked polysucrose of the product on the resin; purifying the product with acetone, and subjecting the purified product to graded eluting with anhydrous ethanol and selecting proper low cross-linked polysucrose; mixing the proper low cross-linked polysucrose with the distilled water and the epibromohydrin, dissolving dispersant into oil phase to be added to the mixture, adjusting the pH of the system with sodium hydroxide solution, performing water bath heating reaction, heating and solidifying; and filtering the obtained product and repeatedly washing with the anhydrous ethanol and the distilled water to get transparent polysucrose granule. The process for preparing the polysucrose is simple, easy to implement and higher in reaction activity, so that productivity and purity of the polysucrose are improved.

Owner:ADANA FOOD TECH LIUZHOU

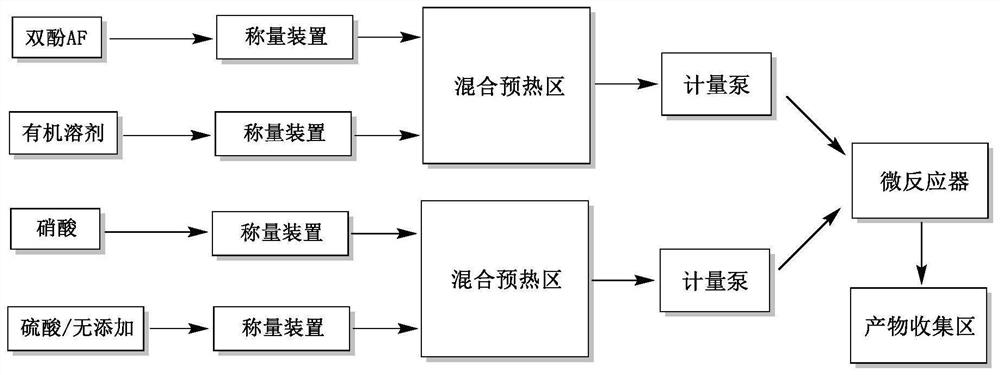

Method for preparing 2, 2-bis (3-nitro-4-hydroxyphenyl) hexafluoropropane by microchannel reactor

PendingCN113105331AUniform responseReduce backmixingChemical/physical/physico-chemical microreactorsNitro compound preparationContinuous flowPhenyl group

The invention discloses a method for preparing 2, 2-bis (3-nitro-4-hydroxyphenyl) hexafluoropropane by a microchannel reactor. The method comprises the following steps: (1) fully mixing and preheating bisphenol AF and an organic solvent to obtain a bisphenol AF solution, and respectively introducing the bisphenol AF solution and a preheated nitrating agent as two strands of materials into a continuous flow microchannel reactor through a metering pump; (2) controlling the flow rate of the material through a metering pump, enabling the bisphenol AF solution and the nitrating agent to respectively enter a micro-channel reactor module for mixed reaction, and enabling a product to flow out from an outlet of the reactor; and (3) carrying out post-treatment on the material obtained from the outlet of the microchannel reactor to obtain a pure product of 2, 2-bis (3-nitro-4-hydroxyphenyl) hexafluoropropane. The method provided by the invention can realize continuous production, has mild reaction conditions, high reaction efficiency and high yield, and is suitable for industrial production.

Owner:海南夸克科技有限公司

A device and method for advanced treatment of tertiary effluent of sewage

InactiveCN104150657BLarge amount of processingGood removal effectMultistage water/sewage treatmentThree levelUltrafiltration

The invention relates to a sewage three-level effluent advanced treatment device. The device mainly comprises a coagulating basin, wherein the upper end of the coagulating basin is connected with a chemical dosing device, the water outlet of the coagulating basin is connected with a surface turbulence filtering device, the water outlet of the surface turbulence filtering device is connected with a photocatalytic degradation reaction device, the water outlet of the photocatalytic degradation reaction device is connected with a secondary nanometer aeration advanced oxidation device, and the water outlet of the secondary nanometer aeration advanced oxidation device is connected with an ultrafiltration device. The invention also discloses a sewage three-level effluent advanced treatment method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

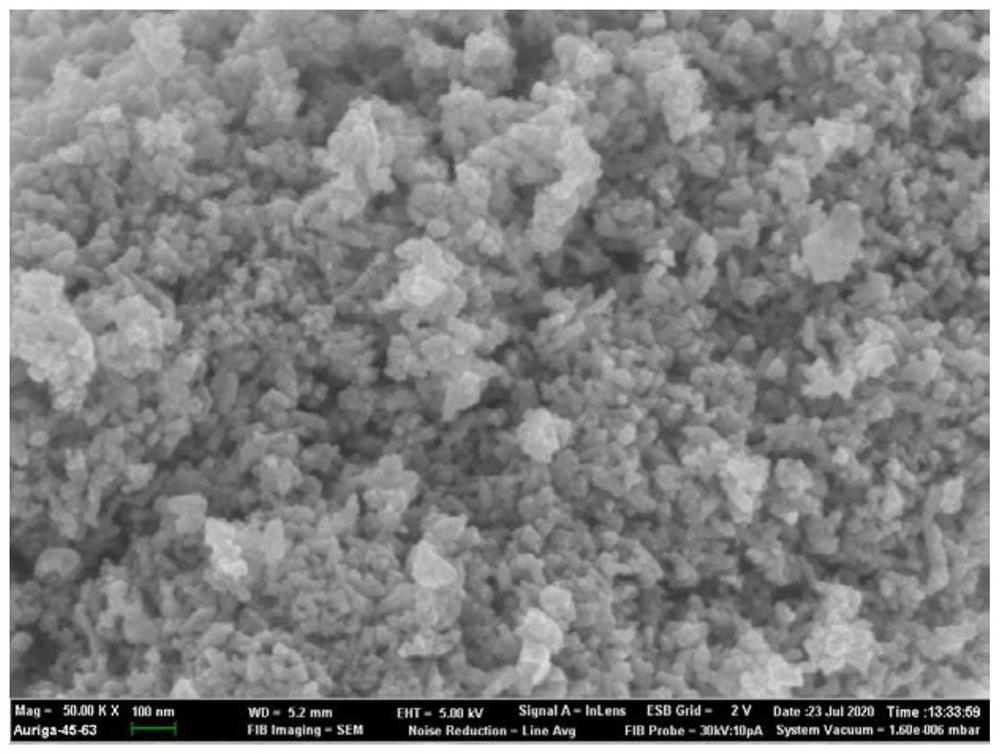

Electrochemical recycling method for indium gallium zinc oxide target material

PendingCN111979563ASimple processAvoid separation stepsElectrolysis componentsGallium/indium/thallium compoundsGalliumIndium

The invention relates to an electrochemical recycling method for an indium gallium zinc oxide target material. The method comprises the following steps of (1) a constant potential electrolytic process: performing constant potential electrolysis under protection of inert gas to obtain an indium gallium zinc alloy by taking indium gallium zinc oxide as a raw material, a fused salt comprising calciumchloride as an electrolyte, a first graphite electrode as a first cathode and a second graphite electrode as a first anode; (2) a constant current electrolytic process: performing constant current electrolysis to obtain an indium gallium zinc hydroxide precipitate by taking the indium gallium zinc alloy as a second cathode and an ammonium chloride aqueous solution as an electrolytic solution; and(3) a calcining process: calcining the indium gallium zinc hydroxide precipitate to obtain nanoscale indium gallium zinc oxide composite powder.

Owner:ZHENGZHOU UNIV

Process for preparing polysucrose

The invention discloses a process for preparing polysucrose. The process includes following steps: placing sucrose, distilled water and epibromohydrin after mixing into a device loaded with strong-base anion exchange resin; subjecting the mixture to polymerization reaction on the strong-base anion exchange resin at the temperature of 25 DEG C to 30 DEG C, heating to 60 DEG C to 65 DEG C for re-reaction, eluting the product after the reaction with the distilled water, and absorbing low cross-linked polysucrose of the product on the resin; purifying the product with acetone, and subjecting the purified product to graded eluting with anhydrous ethanol and selecting proper low cross-linked polysucrose; mixing the proper low cross-linked polysucrose with the distilled water and the epibromohydrin, dissolving dispersant into oil phase to be added to the mixture, adjusting the pH of the system with sodium hydroxide solution, performing water bath heating reaction, heating and solidifying; and filtering the obtained product and repeatedly washing with the anhydrous ethanol and the distilled water to get transparent polysucrose granule. The process for preparing the polysucrose is simple, easy to implement and higher in reaction activity, so that productivity and purity of the polysucrose are improved.

Owner:ADANA FOOD TECH LIUZHOU

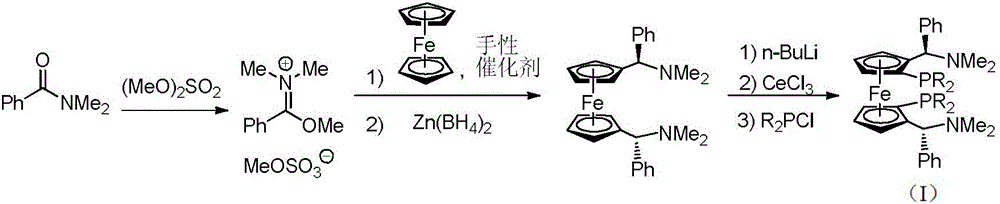

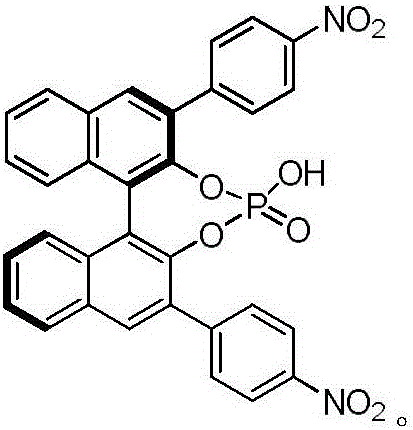

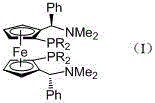

Method for synthesizing C2-symmetrical chiral ferrocenyl phosphine compound

ActiveCN106046065AAvoid intermediate isolation stepsGuaranteed stereoselectivityMetallocenesButyl lithiumDimethyl sulfate

The invention discloses a method for synthesizing a C2-symmetrical chiral ferrocenyl phosphine compound and belongs to the field of organic synthesis. The method comprises the following implementation steps: (1) subjecting ferrocene, which serves as a starting raw material, to a reaction with a complex of N,N-dimethyl benzamide and dimethyl sulfate in the presence of a chiral catalyst, and then, carrying out reduction by zinc borohydride so as to obtain 1,1'-bis[(R)-(dimethylamido)(phenyl)methyl]ferrocene; and (2) subjecting 1,1'-bis[(R)-(dimethylamido)(phenyl)methyl]ferrocene to a reaction with n-butyl lithium, then, subjecting a reaction product to an action with cerium trichloride, and then, carrying out a reaction with R2PCl, thereby obtaining the C2-symmetrical chiral ferrocenyl phosphine compound. Compared with the prior art, the method has the advantages of simple steps and high yield, thereby being more applicable to industrial production. After the prepared C2-symmetrical chiral ferrocenyl phosphine compound is subjected to complexation with metal, an asymmetric organic reaction can be catalyzed, so that the C2-symmetrical chiral ferrocenyl phosphine compound is applied to the field of synthesis of pharmaceutical intermediates.

Owner:PUYANG HUICHENG ELECTRONICS MATERIAL

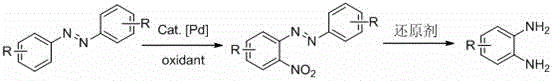

A kind of preparation method of o-phenylenediamine and its derivatives

ActiveCN104262166BAvoid separation stepsAvoid pollutionPreparation by N-O/N-N bondsSynthesis methodsOrganic compound

The present invention specifically relates to a method for synthesizing organic compounds. In order to solve the problems in the current method for synthesizing o-phenylenediamine derivatives, such as complex process routes, many by-products that are difficult to purify, harsh reaction conditions, and serious environmental pollution, the present invention proposes an ortho-phenylenediamine derivative. The preparation method of phenylenediamine and its derivatives uses azobenzene and its derivatives as raw materials, synthesizes o-nitroazobenzene and its derivatives through the joint action of catalysts, oxidants, and nitrating agents, and then reduces them to o-nitroazobenzene and its derivatives by reducing reagents. The synthesis method of the phenylenediamine and its derivatives has the advantages of cheap and easy-to-obtain raw materials, simple and safe operation, short synthesis steps, simple purification, and no large amount of waste acid pollution.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Device and method for preparing synthesis gas with adjustable h2/co ratio from methane-rich gas

InactiveCN104401938BAvoid secondary adjustmentsFacilitate the subsequent synthesis processNitrogen purification/separationCarbon compoundsCycloneSyngas

Owner:SOUTHEAST UNIV

Processing method of low-value fish collagen peptide powder

InactiveCN107334095ARapid dissolutionFully dissolvedProtein composition from fishAnimal proteins working-upProcessing costCollagen VI

The present invention discloses a processing method of low-value fish collagen peptide powder. The method comprises the following steps: low-value fish pretreating, cooking, collagen filtering and separating, concentrating and dehydrating, and spray drying to obtain the collagen peptide powder. Beneficial effects are as follows: the prepared low-value fish collagen peptide powder is less in technological processes, no catalysts or enzymes is added in the processes, and a separating step is avoided; low-value fish with extensive sources is used as a raw material and a processing cost is reduced; a high temperature cooking is used to enable collagen in the low-value fish to be rapidly and fully dissolved, then the macromolecular collagen is vapor-hydrolyzed into small molecular protein peptides, the processes are safe and non-toxic, and the prepared collagen peptide powder is high in quality and good in quality stability; and an addition of active polypeptides improves antibacterial effects of the products and the low-value fish collagen peptide powder has good economic benefits.

Owner:ZHEJIANG FENGYU MARINE BIOLOGICAL PROD

Preparation method of polypeptide extract capable of inhibiting cancer cells

InactiveCN107987121AHigh yieldHave a bactericidal effectPeptide preparation methodsCancer cellSalt water

The invention discloses a preparation method of a polypeptide extract capable of inhibiting cancer cells. The method comprises the following steps: pre-treating low-valued fishes, preparing proteins,decomposing, separating and purifying the proteins. The method has the beneficial effects that no catalyst or enzyme is added, the separation step is avoided, the low-valued fishes are cooked with salt water, the effect of sterilizing the low-valued fishes is achieved, the proteins in the low-valued fishes under the temperature can be moderately denatured, the good conditions are provided for thesubsequent high-pressure cooking, and the prepared polypeptides can effectively inhibit the proliferation of the cancer cells.

Owner:金华市飞凌生物科技有限公司

Method for preparing o-nitrophenol through phenol nitration selectivity

InactiveCN102942487BGood ortho selectivityEasy to handlePhysical/chemical process catalystsNitro compound preparationWater vaporHeteropoly acid

The invention discloses a method for preparing o-nitrophenol, which comprises the following steps: nitrating phenol in mild conditions with silica loaded heteropoly acid cesium as a catalyst and low-concentration nitric acid as a nitrating agent; and successively performing extraction, distillation, steam distillation and recrystallization to obtain the o-nitrophenol. The silica loaded heteropoly acid cesium is formed by loading 1% to 40% (wt%) of heteropoly acid cesium to silica. The method for preparing o-nitrophenol has the advantages of high phenol conversion rate, high o-phenol nitration selectivity, easiness in preparation of the catalyst, high catalytic activity, easy separation of the catalyst after the action, reusability and broad application prospects.

Owner:LIAOCHENG UNIV

A kind of pineapple fruit wine and preparation method thereof

ActiveCN103710214BRich flavorHigh alcohol contentAlcoholic beverage preparationFruit wineHydrolysate

Owner:广东桑醇酒业有限公司

Comprehensive utilization method of coal-based oil residue

ActiveCN103468288BImprove qualityShort stayEnergy inputCoking carbonaceous materialsHeat carrierCombustion

The invention relates to a comprehensive utilization method of a coal-based oil residue. According to the method, a heated solid heat carrier is mixed with the coal-based oil residue by using a solid heat carrier method; the oil residue is heated and gasified and partially pyrolyzed by using sensible heat of high-temperature solids; heavy liquefied oil in the coal-based oil residue is recovered after being pyrolyzed and gasified; the residual un-gasified residue enters a hot blast heater of a circulating fluidized bed to fully burn; one part of heat generated by combustion is used for heating the solid heat carrier; the other part of heat is recovered through a waste heat boiler. The comprehensive utilization method is small in investment, easy to implement, and high in overall efficiency.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

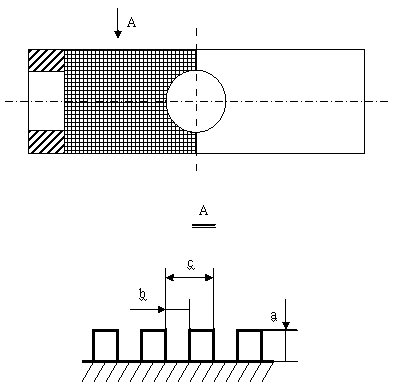

A superfine pulverization method for household soybean milk machine

ActiveCN102935401BSolve the problem that it is difficult to achieve ultra-fine grindingAvoid separation stepsBeverage vesselsGrain treatmentsStructural engineeringMechanical engineering

The invention relates to a soybean processing method, in particular to a superfine grinding method for a household soybean milk machine. The principle is: the soybean particles to be crushed are accelerated by the high-speed rotating blades, and the liquid-solid two-phase fluid flows through the fixed hole to be further accelerated, and a rack-shaped fixed knife is set in front of the hole facing the direction of the liquid flow. , the rack-shaped fixed knife is made of wear-resistant metal material, and its surface is made into shallow groove-like grids, with square micro-cutting edges between the grids. The material flowing through the surface of the rack-shaped fixed knife and the fixed knife The micro-cutting edge on the surface breaks the material due to friction and impact, which effectively avoids the possibility of the fixed knife being damaged by the collision of other high-speed rotating parts, and the cleaning of the fixed knife is also very convenient due to the shallow groove on the surface.

Owner:盐城贝尔德厨房设备制造有限公司

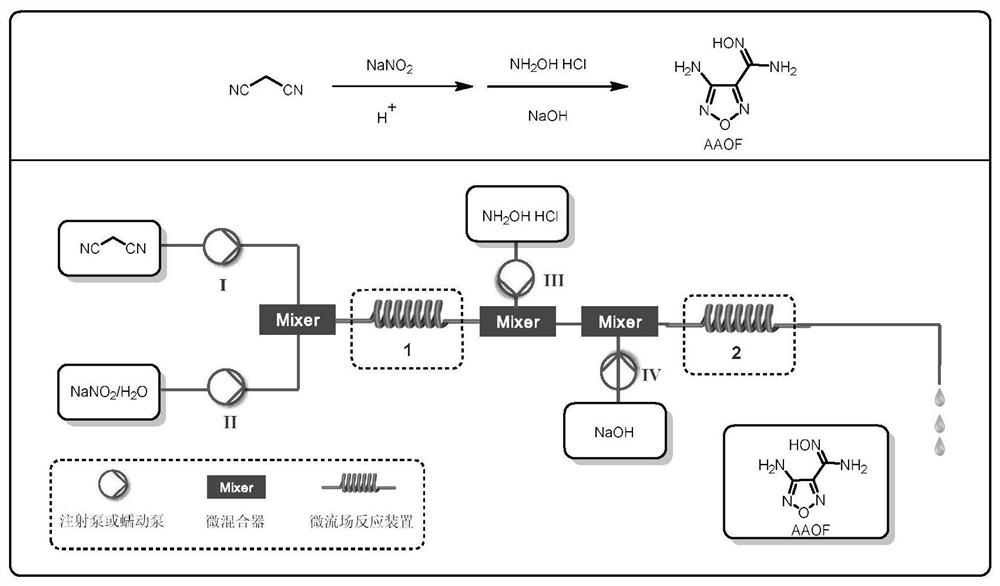

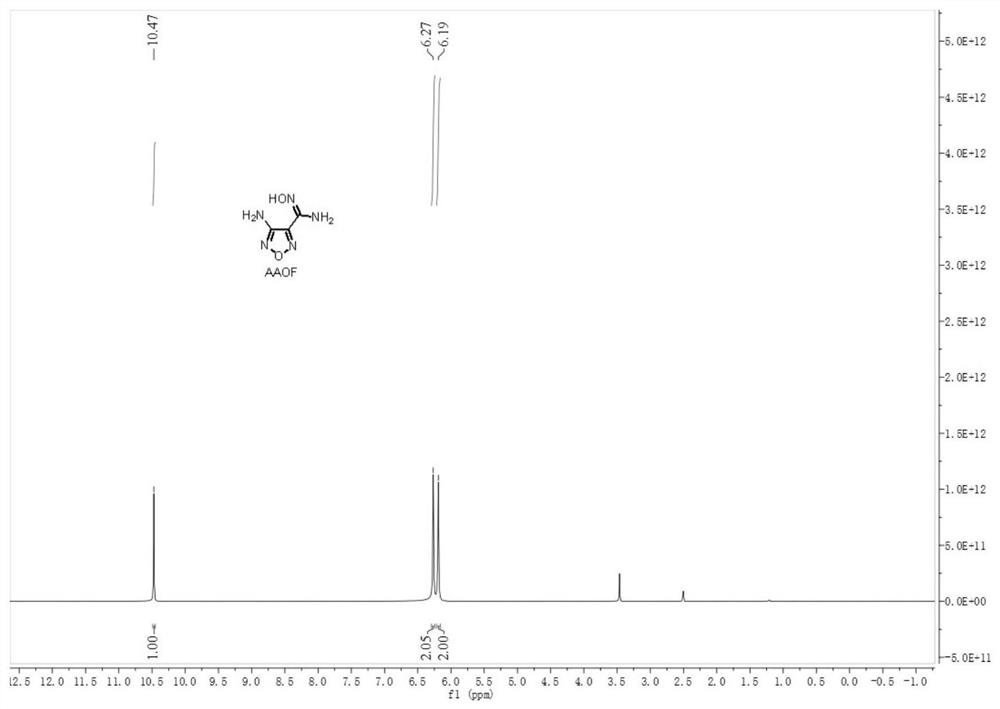

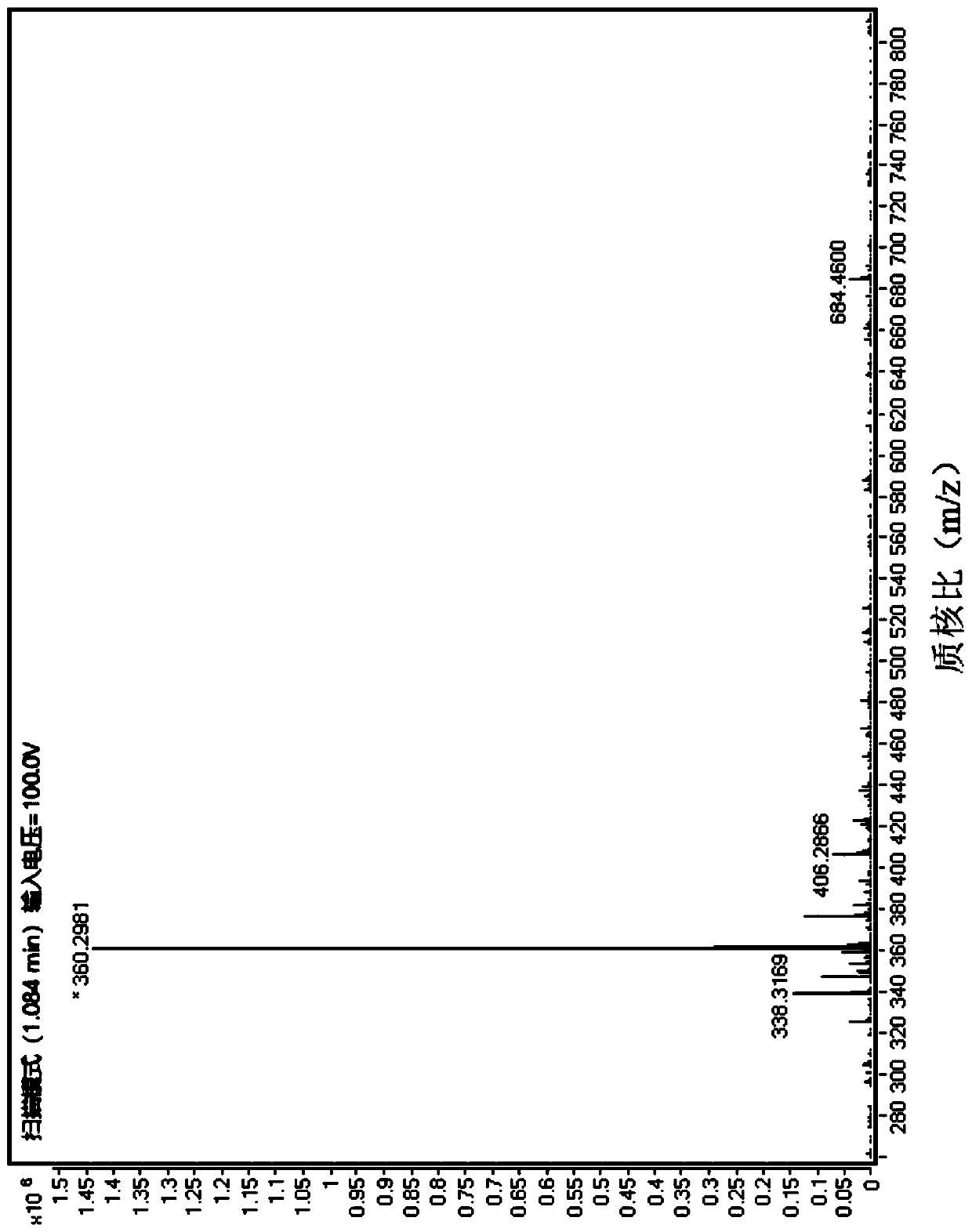

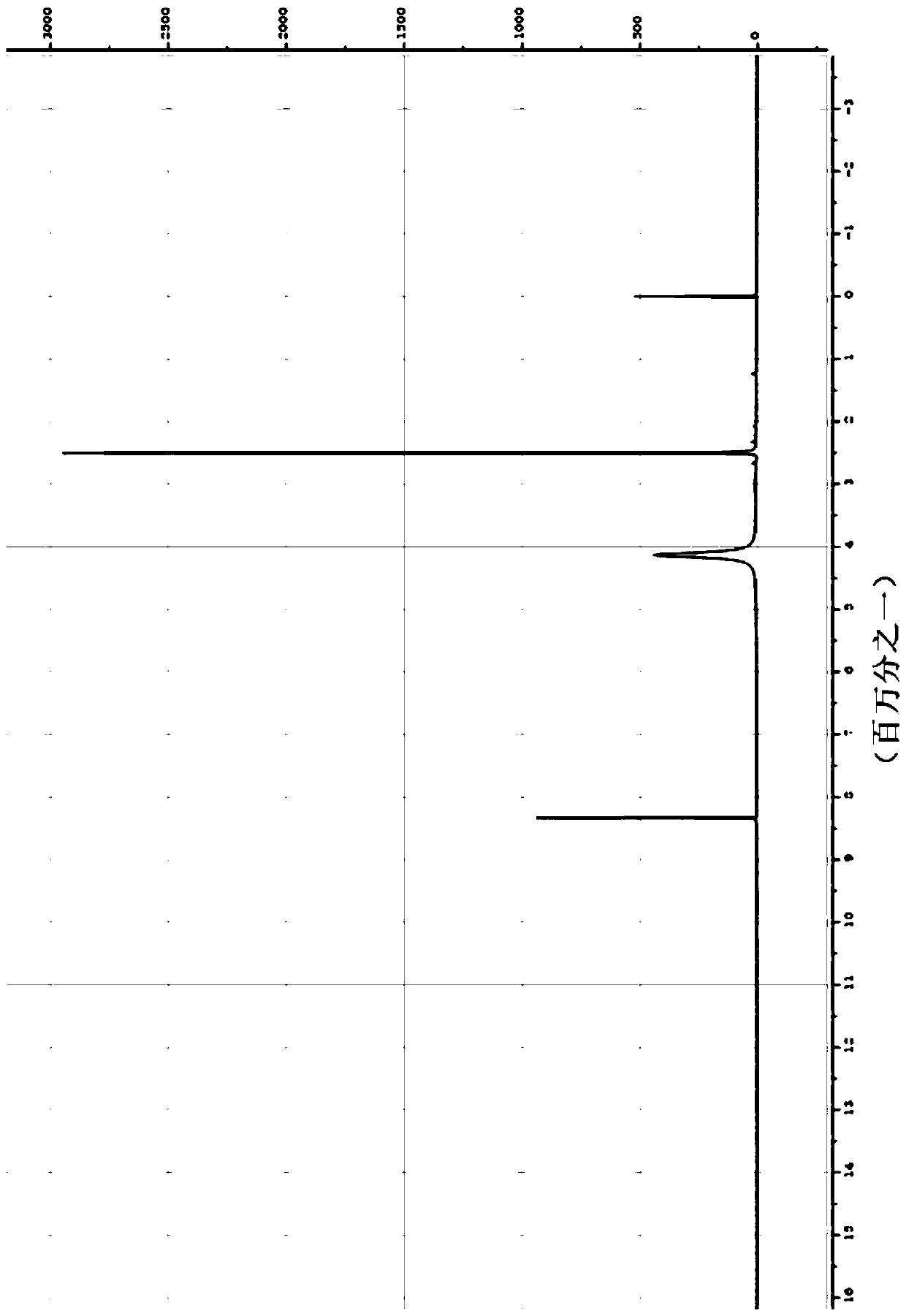

Method for preparing 3-amino-4-amidoxime furazan by using micro-flow field reaction technology

ActiveCN112341403AEnables continuous synthesisAvoid separation stepsOrganic chemistryChemical/physical/physico-chemical microreactorsFurazanHydroxylamine

The invention discloses a method for preparing 3-amino-4-amidoxime furazan by using a micro-flow field reaction technology. The method comprises the following steps: (1) respectively pumping a malononitrile solution and a sodium nitrite aqueous solution into a first micro-mixer in a micro-flow field reaction device at the same time, mixing, and introducing into a first module to carry out a firstreaction; (2) while the step (1) is carried out, respectively and simultaneously pumping the hydroxylamine hydrochloride aqueous solution and the effluent of the first module into a second micro-mixerin the micro-flow field reaction device for mixing; and (3) while the step (2) is carried out, respectively pumping the sodium hydroxide aqueous solution and the effluent of the second micro-mixer into a third micro-mixer in the micro-flow field reaction device at the same time, mixing, and introducing into a second module to carry out a second reaction, thereby obtaining the reaction liquid containing the 3-amino-4-amidoxime furazan. The problems that a traditional feeding process is tedious, the reaction time is long, and ice bath energy consumption is high are solved.

Owner:NANJING UNIV OF TECH

Aromatic heterocyclic compound 2,4,6,8-tetraamino-1,5-naphthalenediol hydrochloride and synthesis method thereof

InactiveCN110437082AHigh selectivityQuick responseOrganic compound preparationAmino-hyroxy compound preparationSynthesis methodsOrganic compound

The invention relates to an aromatic heterocyclic compound 2,4,6,8-tetraamino-1,5-naphthalenediol hydrochloride and a synthesis method thereof, and belongs to the technical field of organic compound preparation. A purpose of the present invention is to solve the problems of poor performance, harsh and complicated synthesis conditions and high cost of the existing aromatic heterocyclic polymer monomers. According to the present invention, the chemical formula of the aromatic heterocyclic compound 2,4,6,8-tetraamino-1,5-naphthalenediol hydrochloride is C10H16Cl4N4O2; the preparation method comprises: preparing a 2,4,6,8-tetranitro-1,5-naphthalenediol crude product, preparing a 2,4,6,8-tetranitro-1,5-naphthalenediol pure product, dissolving the pure product in absolute ethanol, adding a Pd / Ccatalyst, carrying out a hydrogenation reaction, filtering out the catalyst, introducing concentrated hydrochloric acid containing stannous chloride into the filtrate, is crystallizing, filtering, anddrying; the synthesized monomer has characteristics of novel structure and good physical and chemical properties; and the preparation method has characteristics of simple method, short cycle, high conversion rate, no pollution and low cost, and is used in the field of synthesis of aromatic heterocyclic polymer monomers.

Owner:HARBIN INST OF TECH

Superfine grinding method for domestic soybean milk machine

ActiveCN102935401ASolve the problem that it is difficult to achieve ultra-fine grindingAvoid separation stepsBeverage vesselsGrain treatmentsStructural engineeringWear resistance

The present invention relates to a soybean processing method, specifically to a superfine grinding method for a domestic soybean milk machine. The principle is that: high speed rotating blades are adopted to accelerate soybean particles requiring grinding, a liquid-solid two-phase fluid flows through a fixed hole to further accelerate, and a rack-shaped fixed cutter facing the liquid flowing direction is arranged in front of the hole, wherein the rack-shaped fixed cutter is manufactured from a wear resistance metal material, the surface is made into a shallow groove-like grid, and the square micro-cutting edge is arranged between the grids. According to the present invention, a material is grinded through friction and impact of the material flowing through the surface of the rack-shaped fixed cutter at a high speed and the micro-cutting edge on the surface of the fixed cutter, such that the possibility of damage on the fixed cutter by impacts of other high speed rotation parts is effectively avoided, and fixed cutter cleaning is convenient due to the groove on the surface.

Owner:盐城贝尔德厨房设备制造有限公司

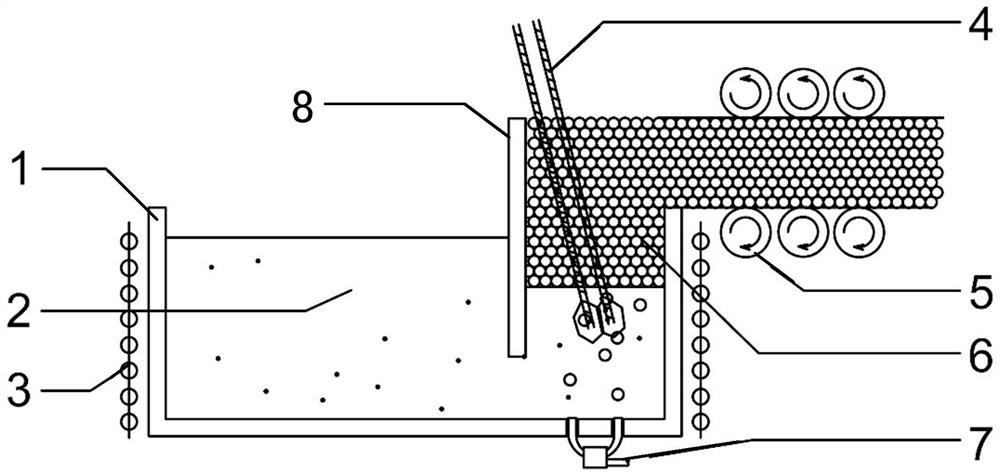

A method and device for preparing foamed aluminum from semi-solid slurry based on the blowing method

A method and device for preparing aluminum foam from a semi-solid slurry based on the blowing method. The method is: (1) adopting a near-liquidus method to prepare an aluminum alloy semi-solid slurry; (2) continuously transporting it into a crucible, and The coil is heated and kept warm; the partition divides the crucible into a liquid storage chamber and a foaming chamber, and a stirring paddle is set in the foaming chamber and a liquid-permeable hole is arranged at the bottom; (3) Stirring is carried out by the stirring paddle, and air is sprayed into the liquid-permeable hole, Foam is formed in the aluminum alloy semi-solid slurry; (4) The foam floats up to the outside of the crucible and collapses, gradually solidifies and is transported out by the traction wheel. The device includes a crucible and a partition inside, and there is a gap edge between the bottom edge of the partition and the inner bottom of the crucible; a stirring paddle is arranged in the foaming chamber, and a liquid-permeable hole is arranged at the bottom; the bottom blowing nozzle communicates with the liquid-permeable hole. The method and device of the invention avoid the separation step of the ceramic particles and the aluminum alloy material, and avoid the separation step of the ceramic particles and the aluminum alloy material in the recovery process, thereby reducing costs.

Owner:NORTHEASTERN UNIV LIAONING

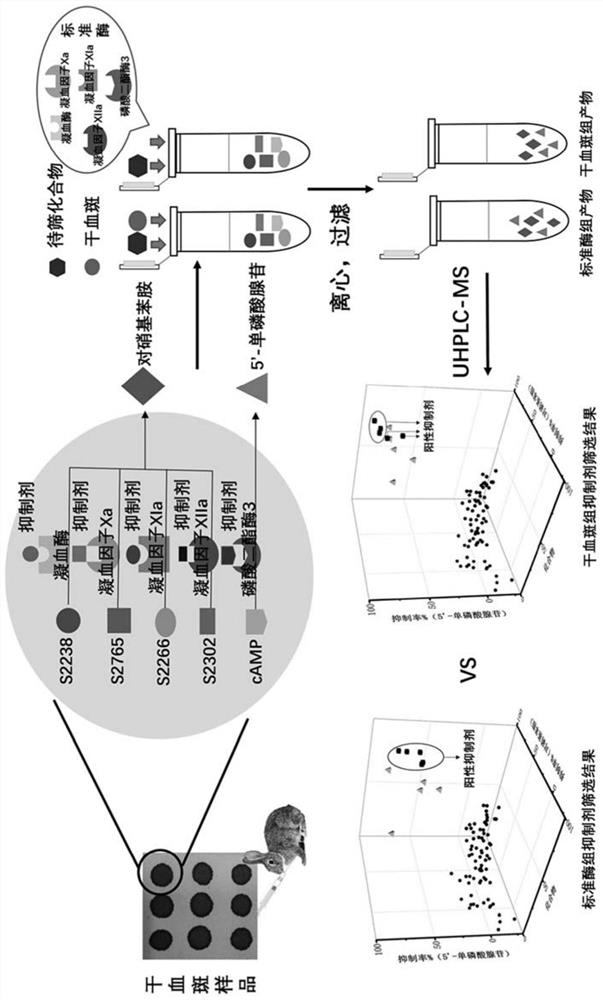

A liquid chromatography-mass spectrometry screening method for multi-target antithrombotic active substances

ActiveCN110568117BGood effectGood curative effectComponent separationLiquid chromatography mass spectroscopyThrombus

Owner:MARINE BIOMEDICAL RES INST OF QINGDAO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com