Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Decrease in flowability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

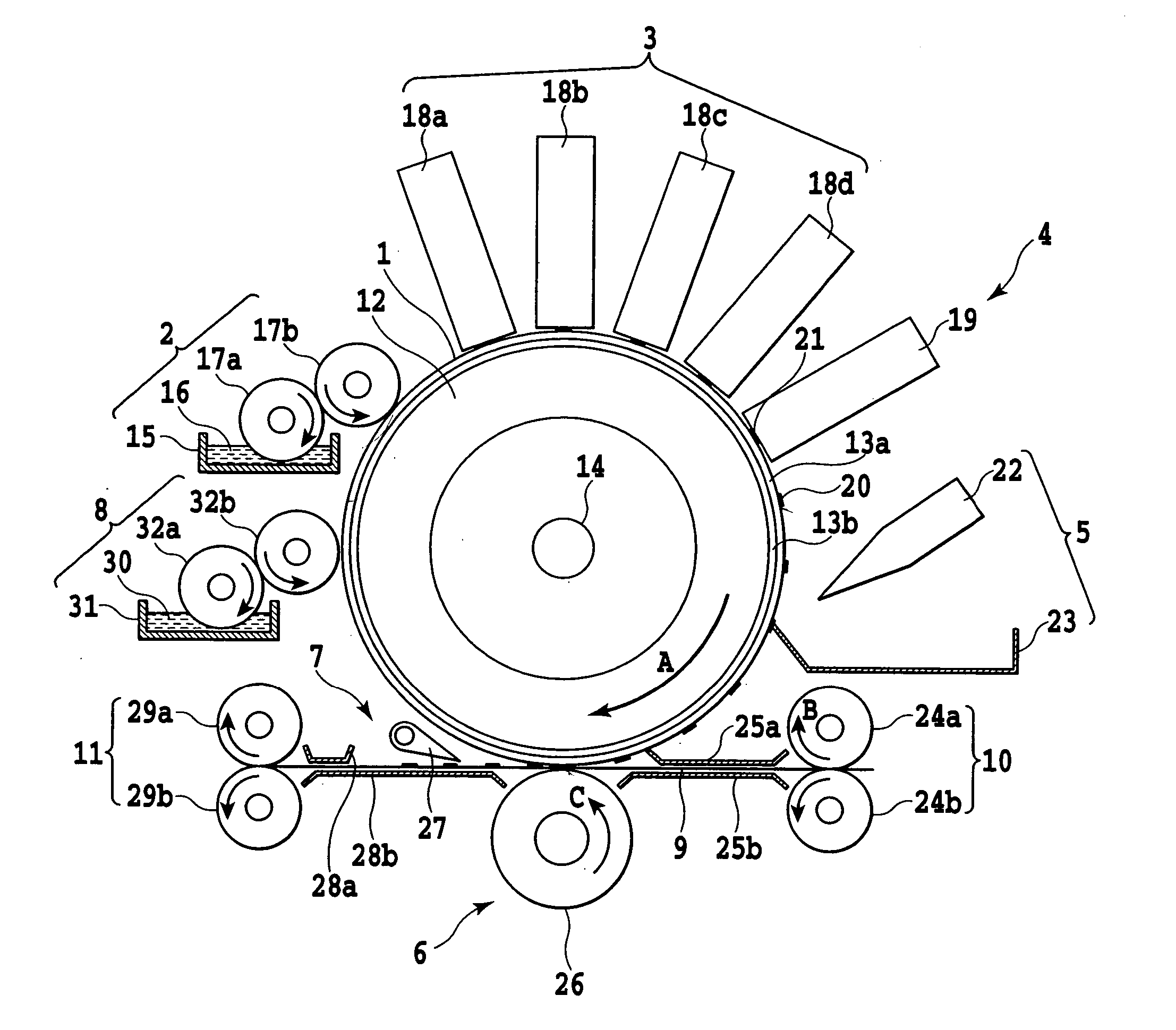

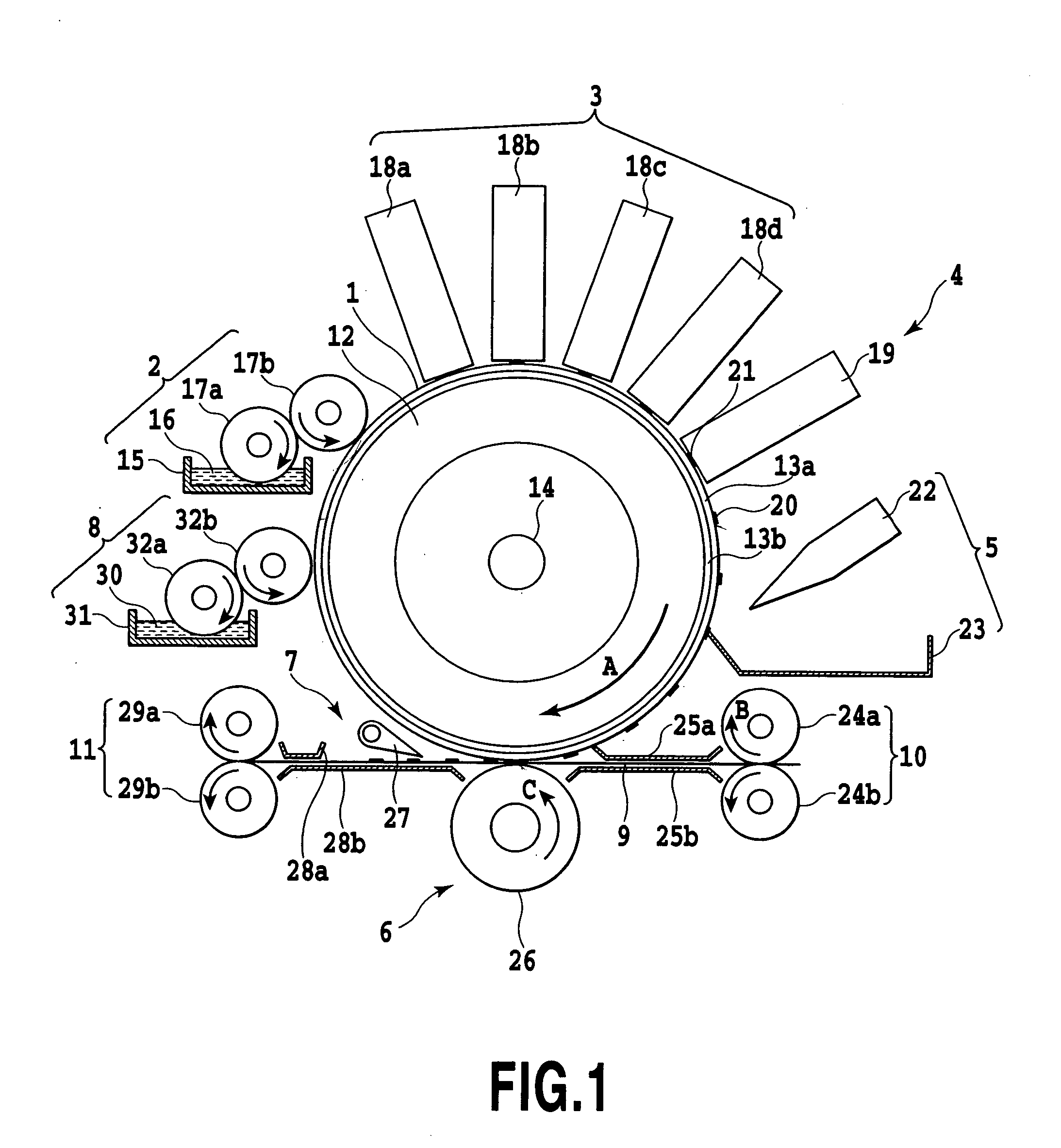

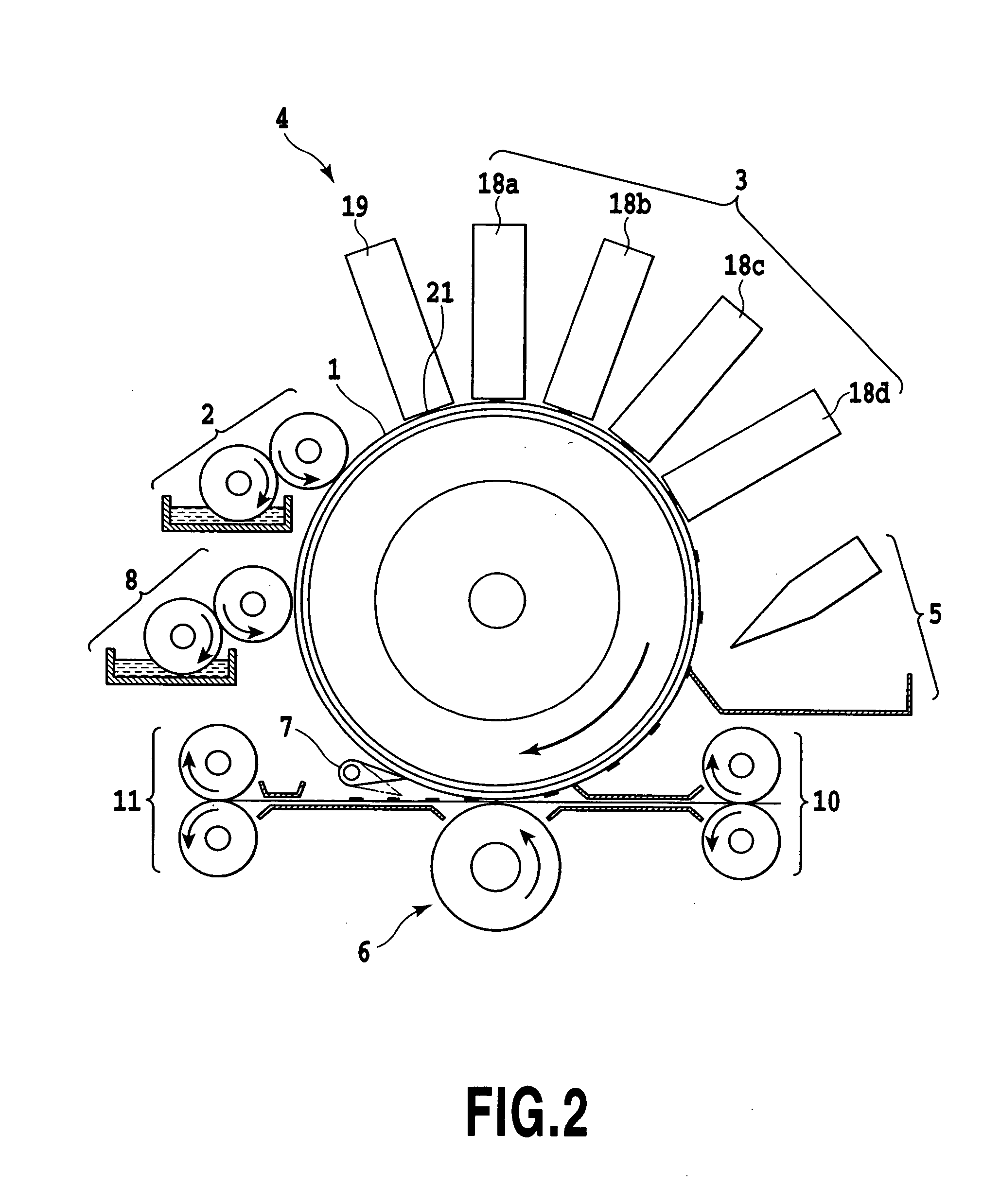

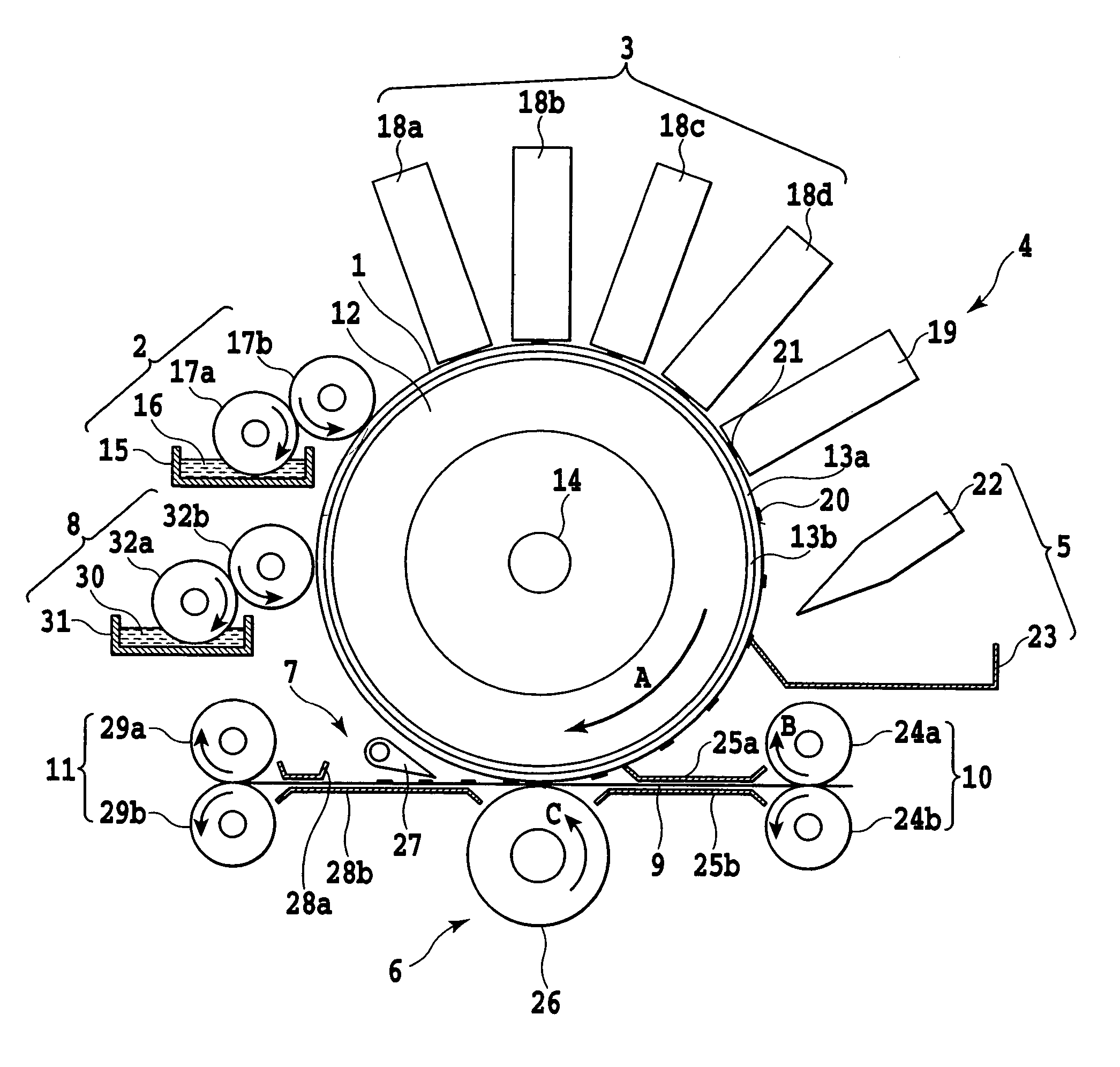

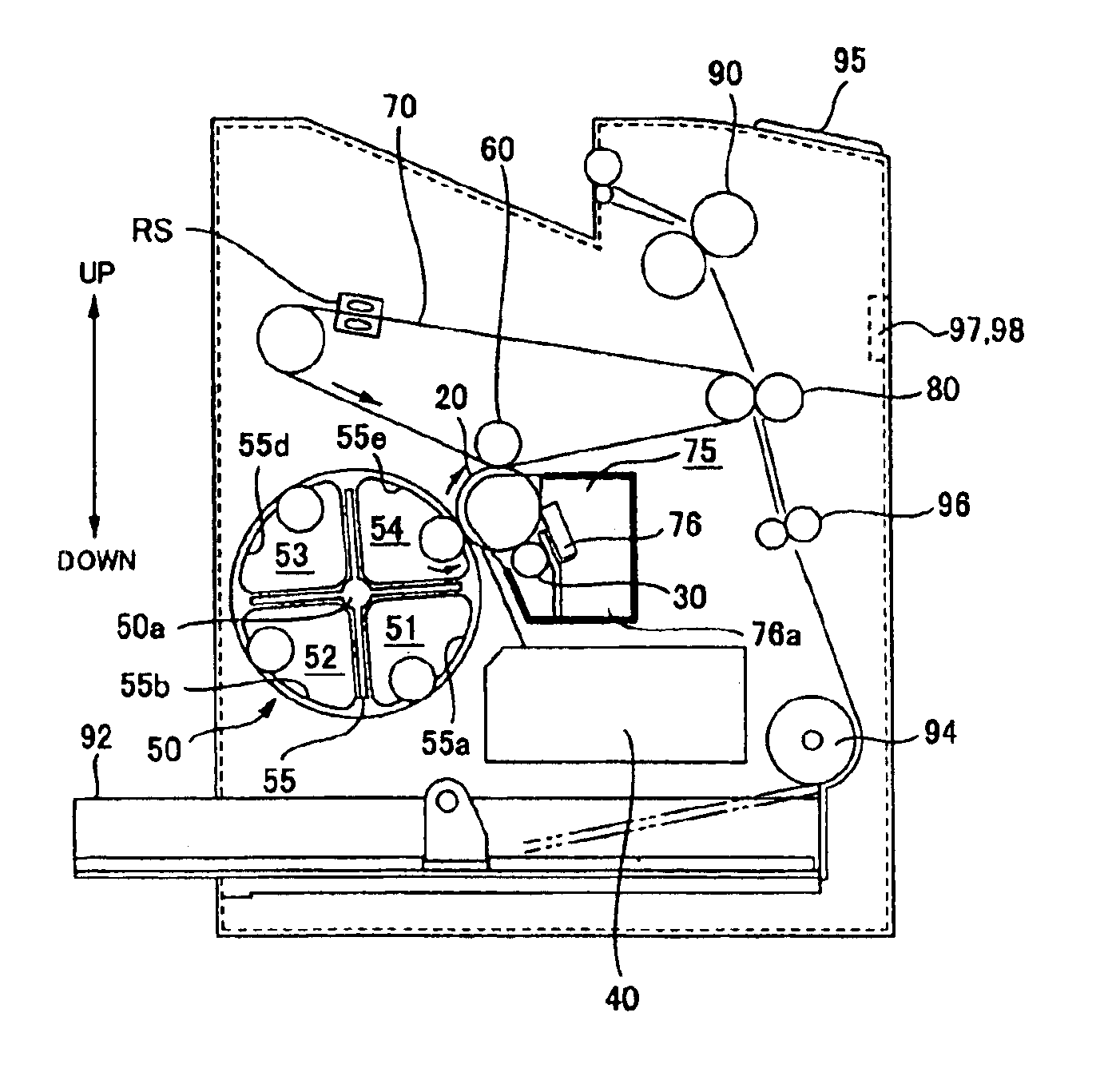

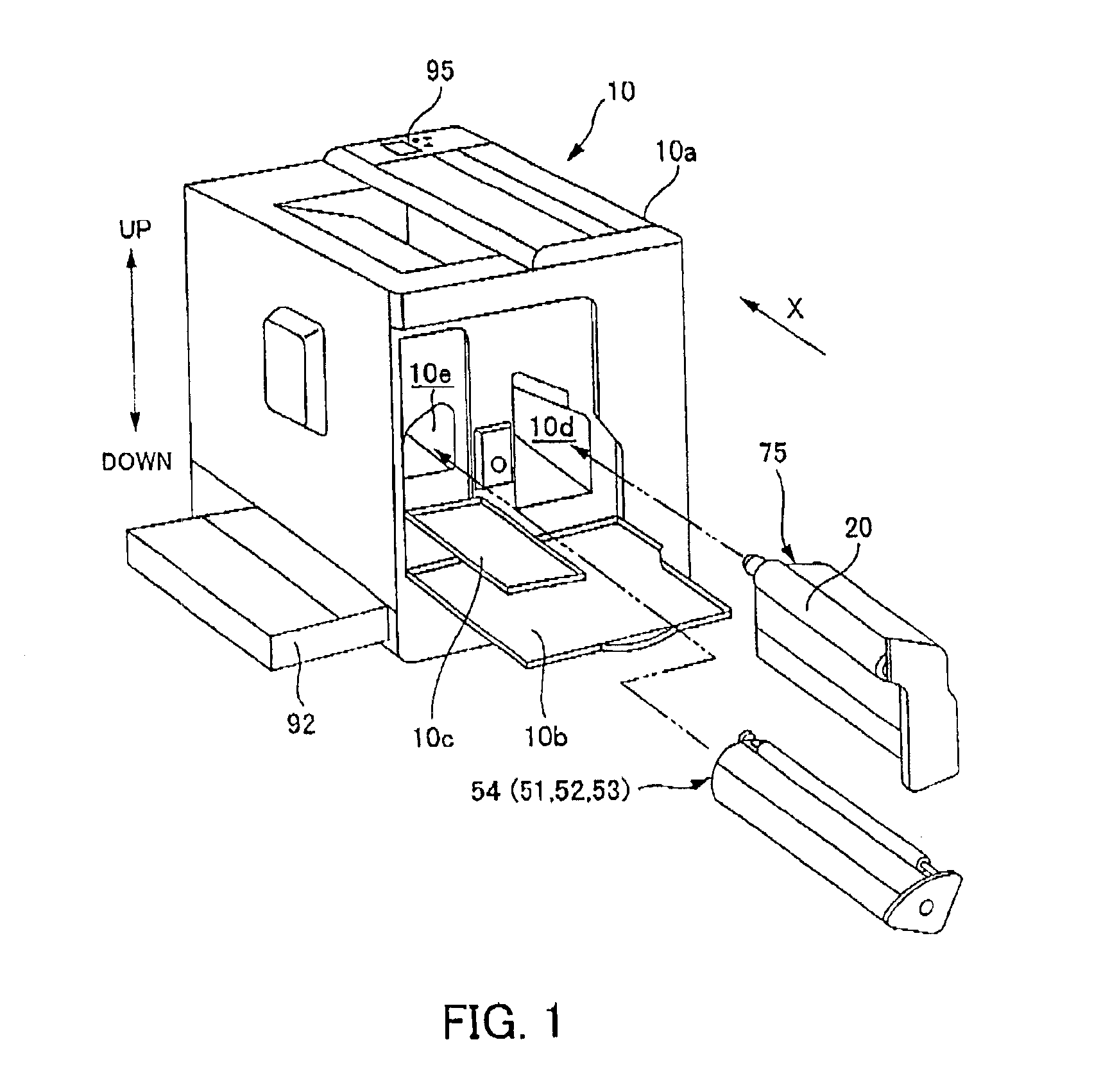

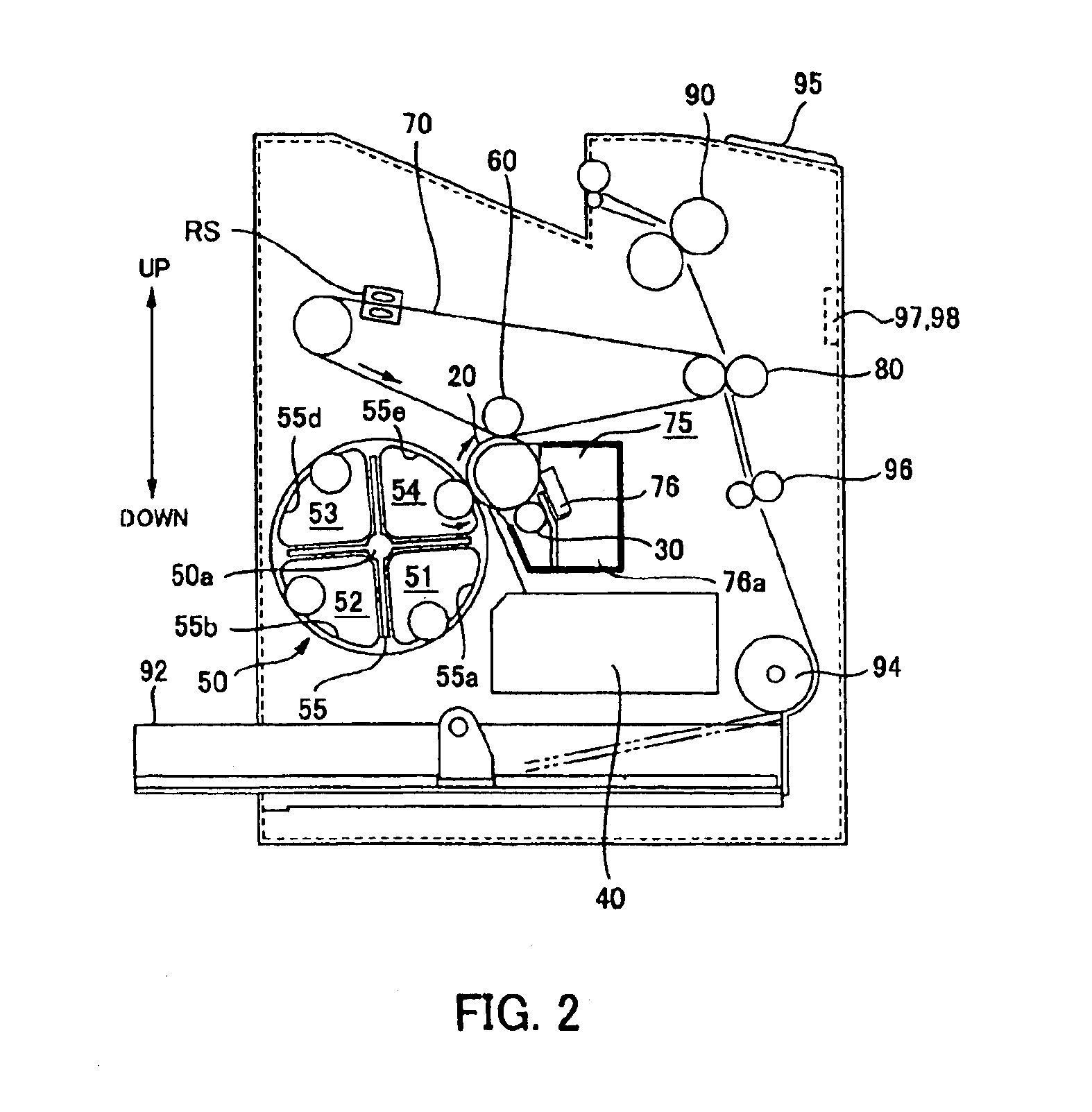

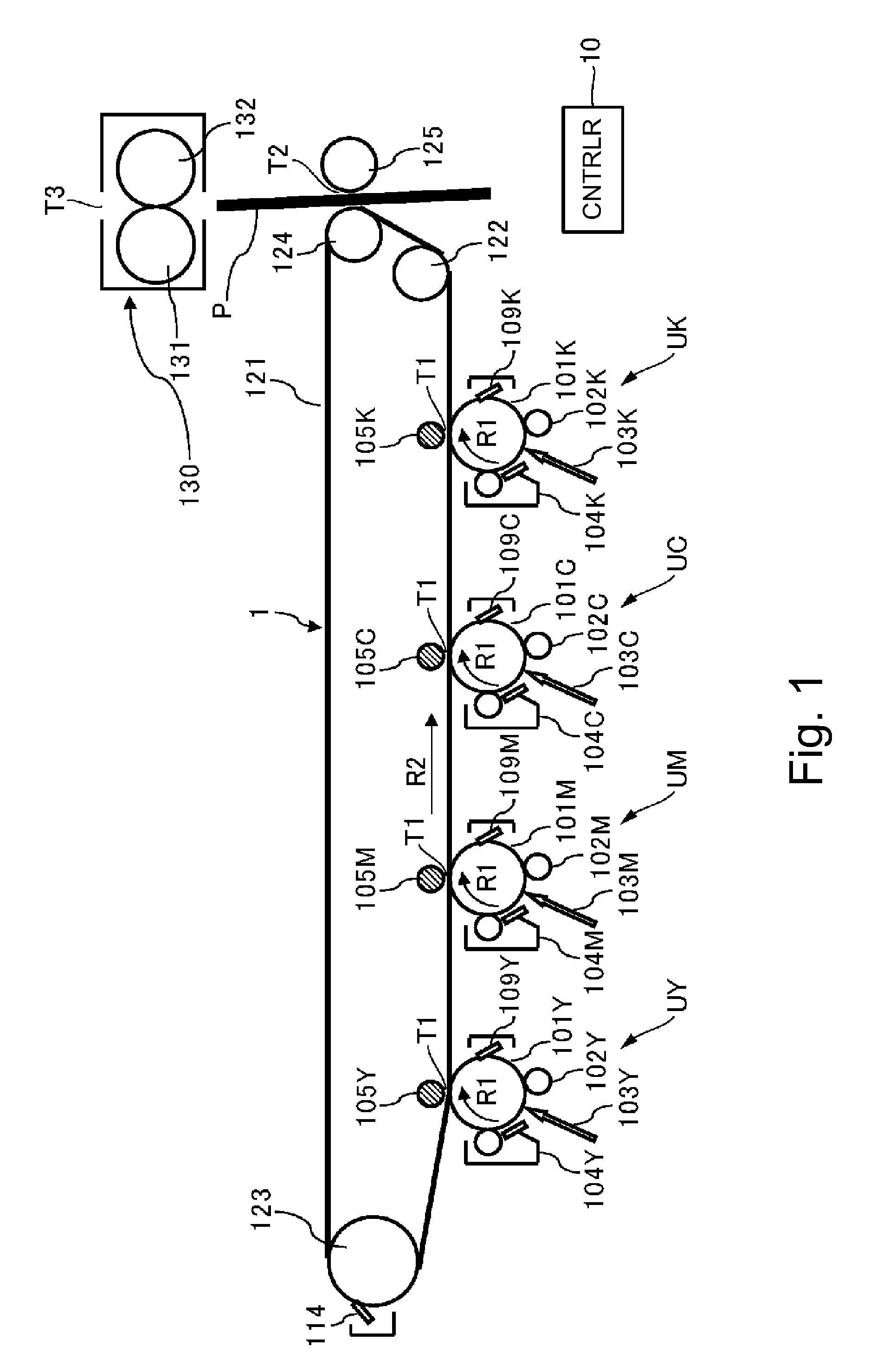

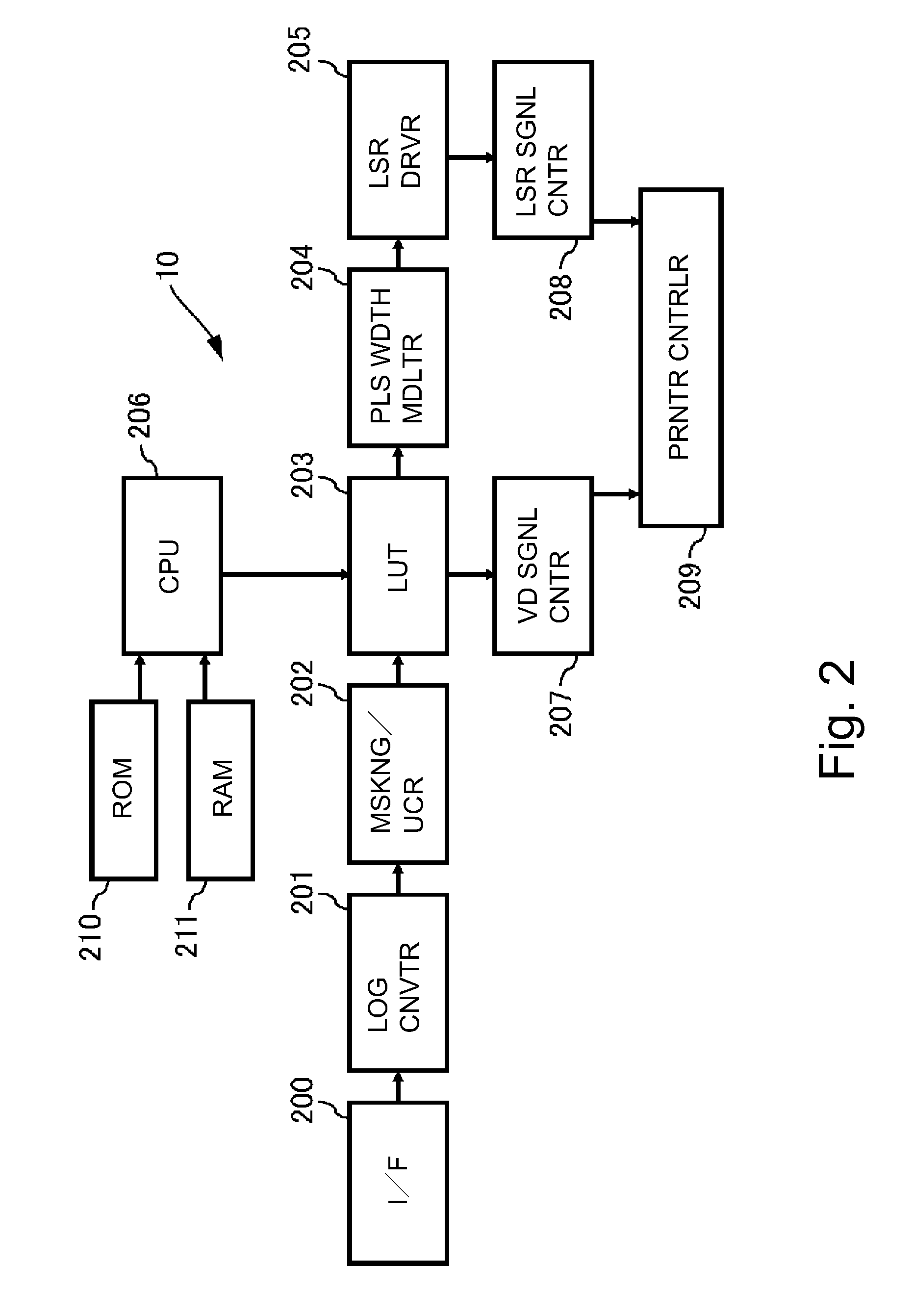

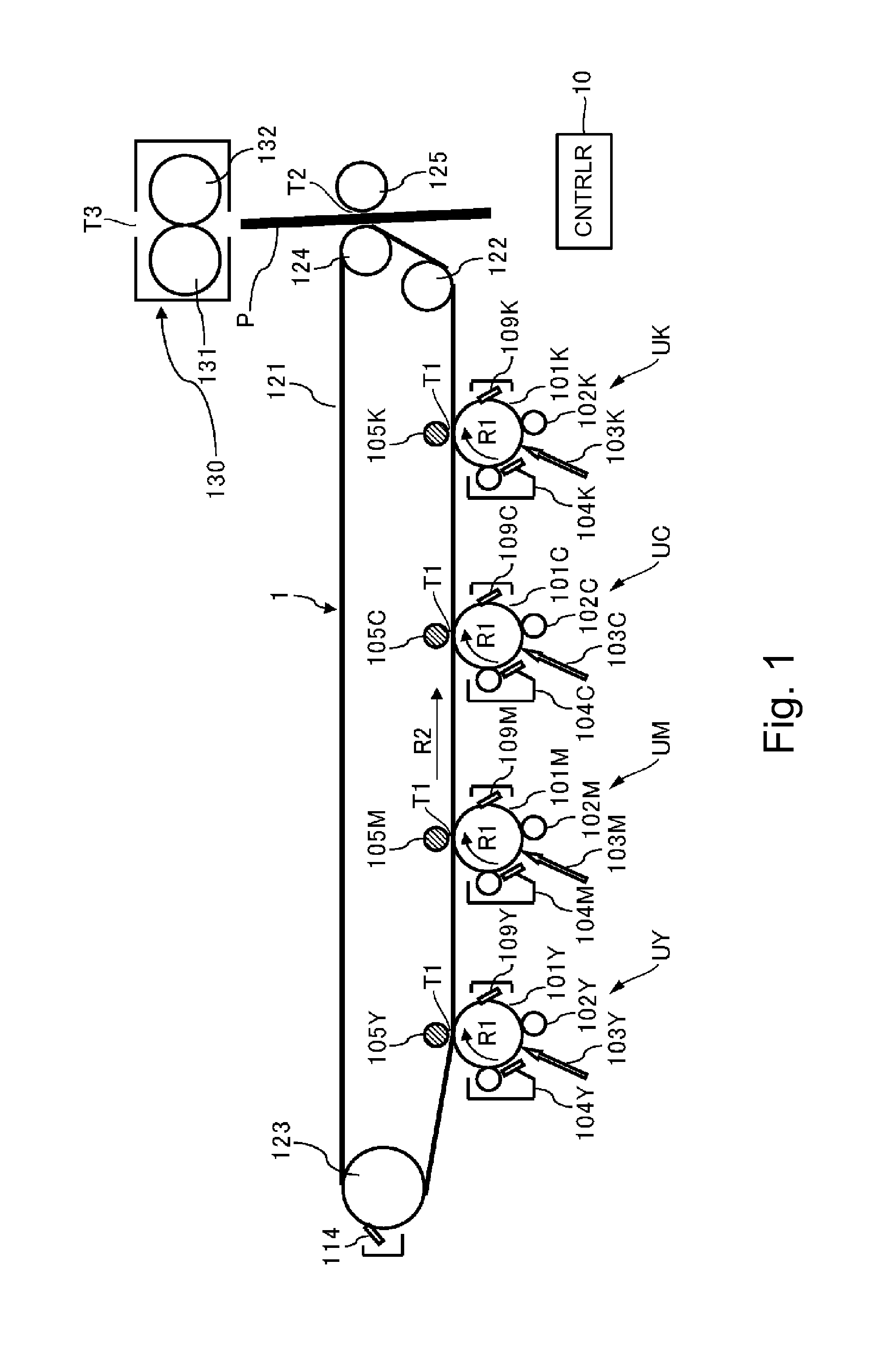

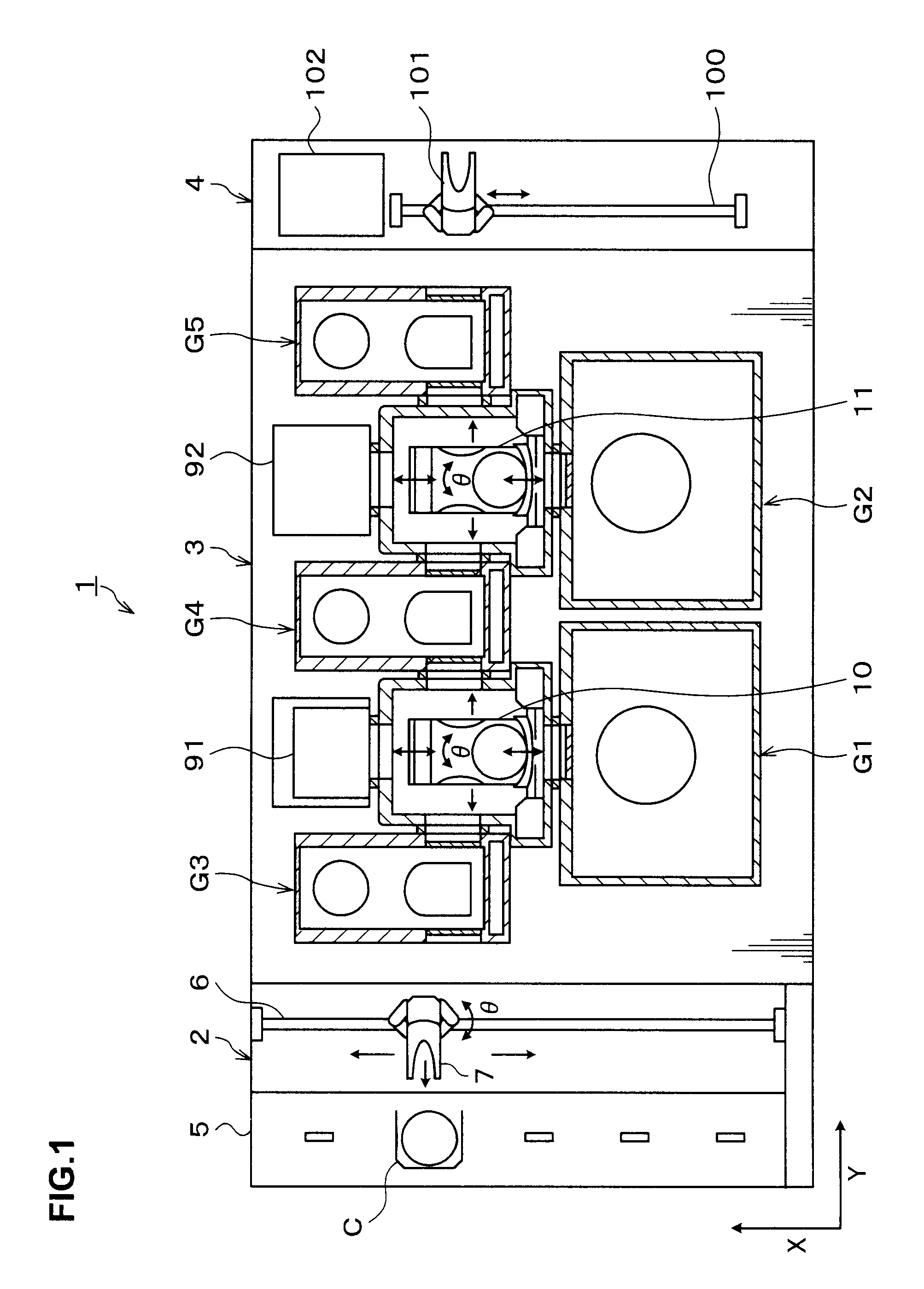

Ink-jet recording method and ink-jet recording apparatus

ActiveUS20050110856A1Quality improvementImprove wear resistanceDuplicating/marking methodsInksEngineeringWear resistance

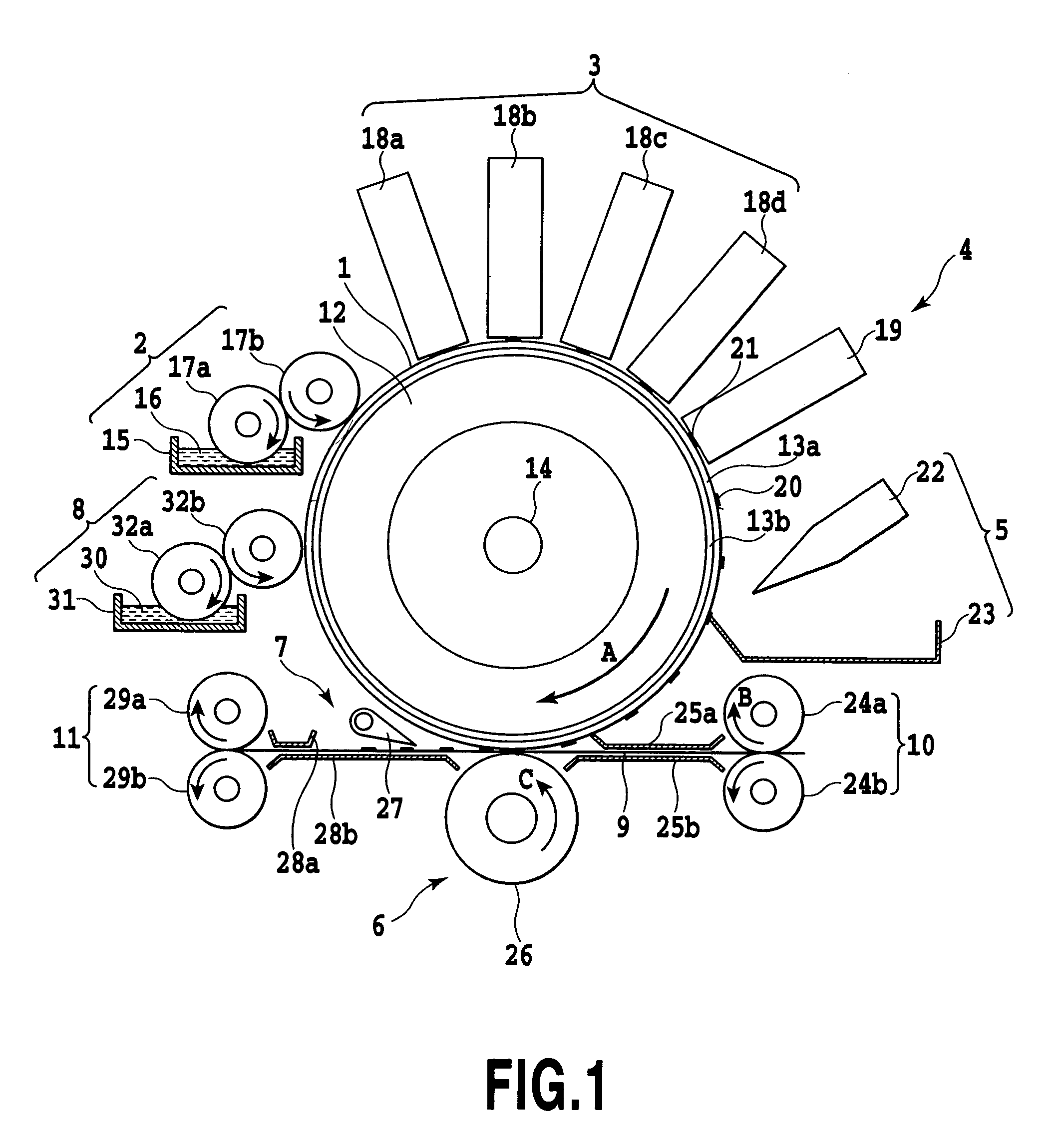

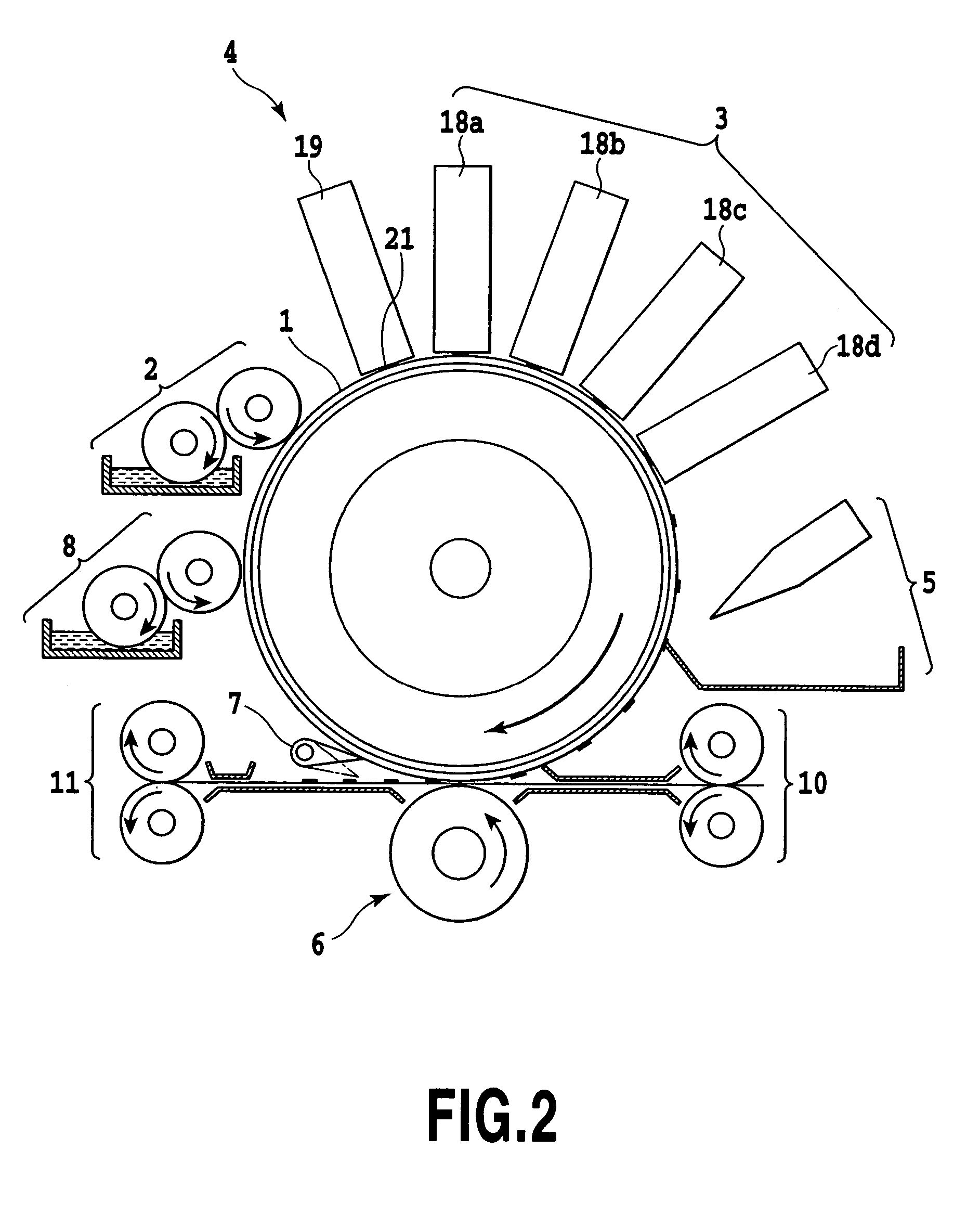

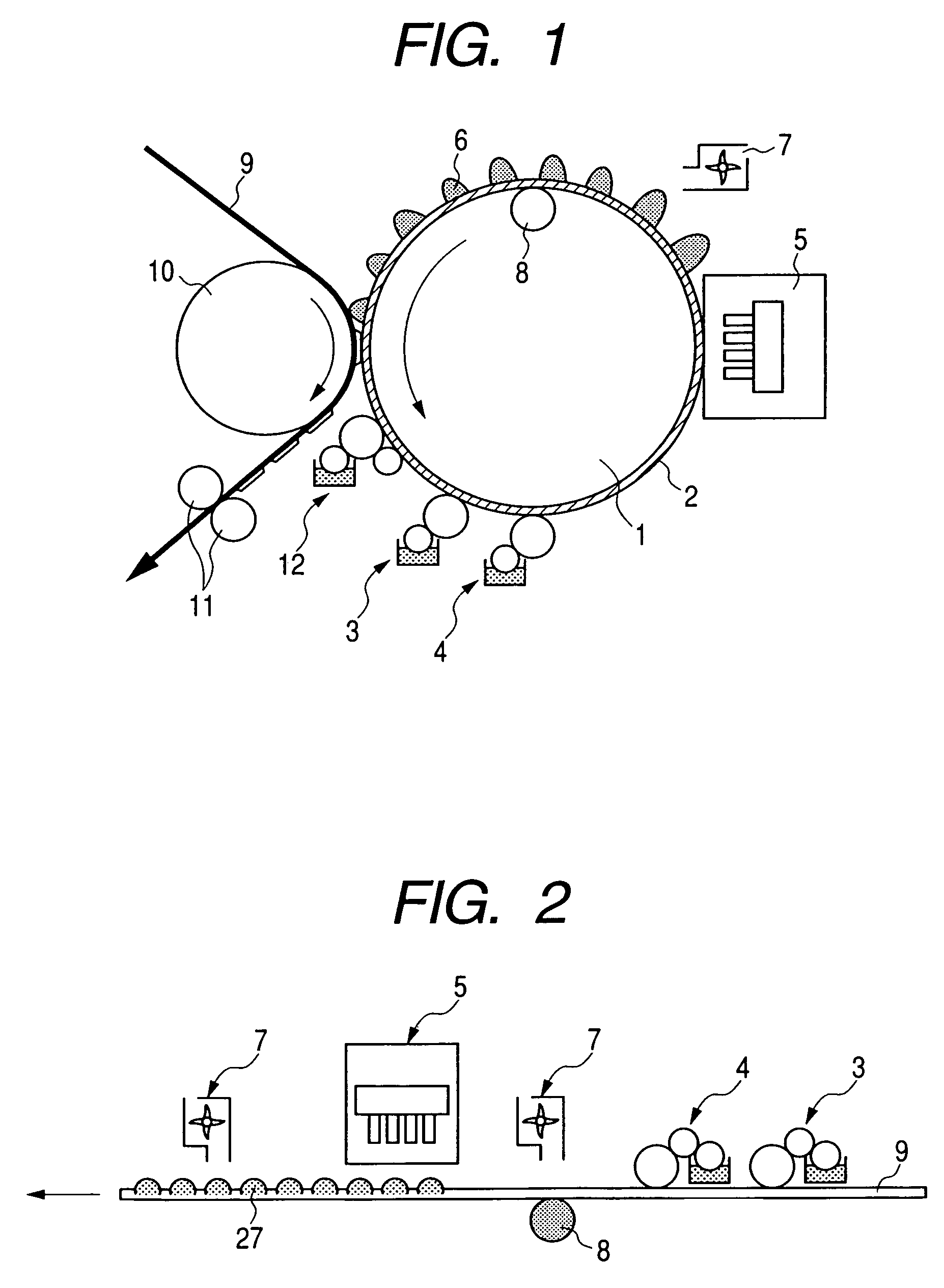

An ink-jet recording method and an ink-jet recording apparatus, wherein ink image with high quality and good abrasion resistance without generation of beading and bleeding are formed on recording media, in ink-jet recording using an intermediate transfer body, are provided. An ink image is formed by applying an image fixing component (for example reacting liquid) to an intermediate transfer body, and then applying inks of colors, Y, M, C, and K, from print heads corresponding each color. Then a supplementary liquid is applied to the ink image, and the ink image is transferred to a recording media.

Owner:CANON KK

Ink-jet recording method and ink-jet recording apparatus

ActiveUS7281790B2Quality improvementImprove wear resistanceDuplicating/marking methodsInksEngineeringWear resistance

An ink-jet recording method and an ink-jet recording apparatus, wherein ink image with high quality and good abrasion resistance without generation of beading and bleeding are formed on recording media, in ink-jet recording using an intermediate transfer body, are provided. An ink image is formed by applying an image fixing component (for example reacting liquid) to an intermediate transfer body, and then applying inks of colors, Y, M, C, and K, from print heads corresponding each color. Then a supplementary liquid is applied to the ink image, and the ink image is transferred to a recording media.

Owner:CANON KK

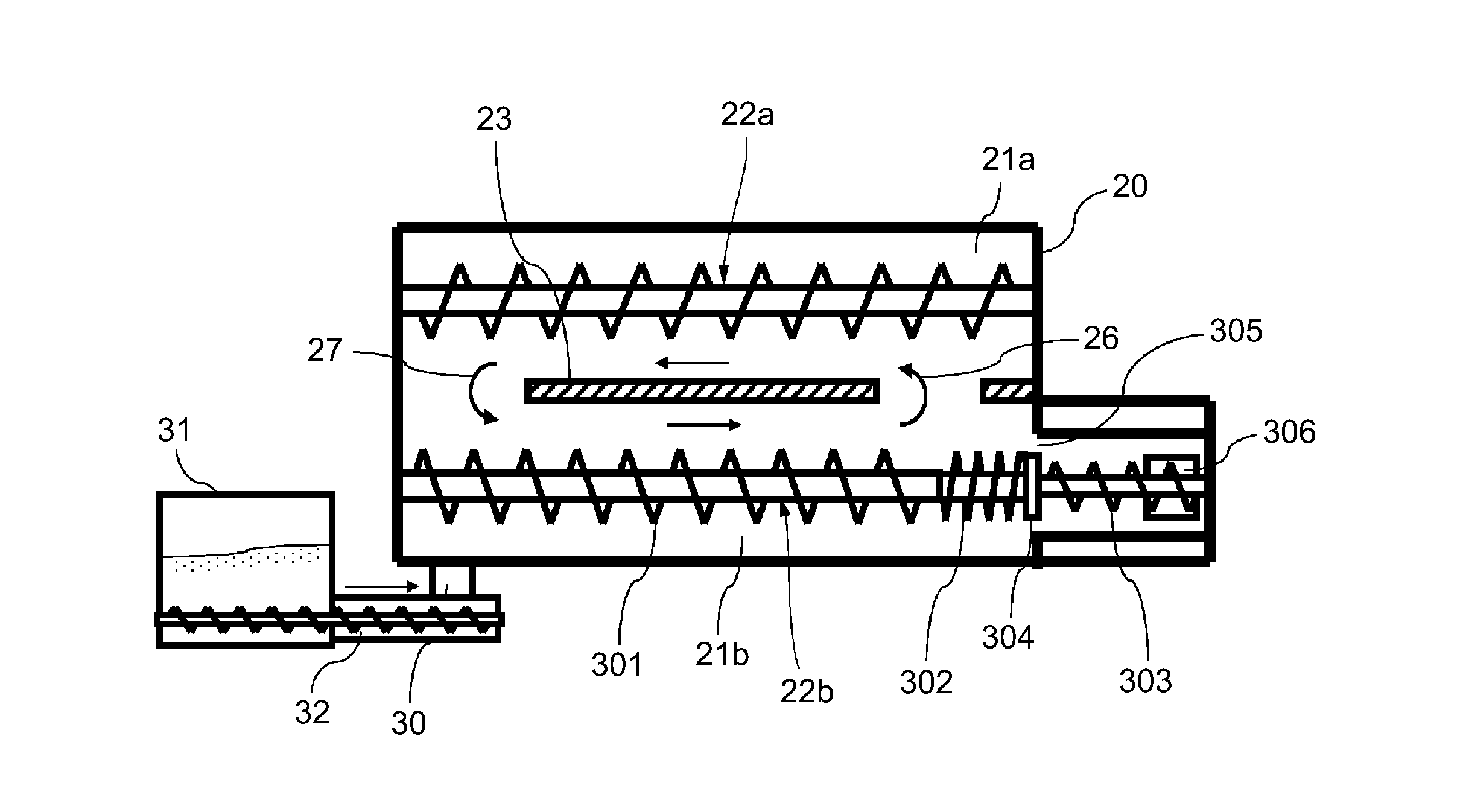

Image forming process and image forming apparatus

InactiveUS20060164488A1High recording flexibility of recordingImprove surface wettabilityMeasurement apparatus componentsDecorative surface effectsImage formationComputer science

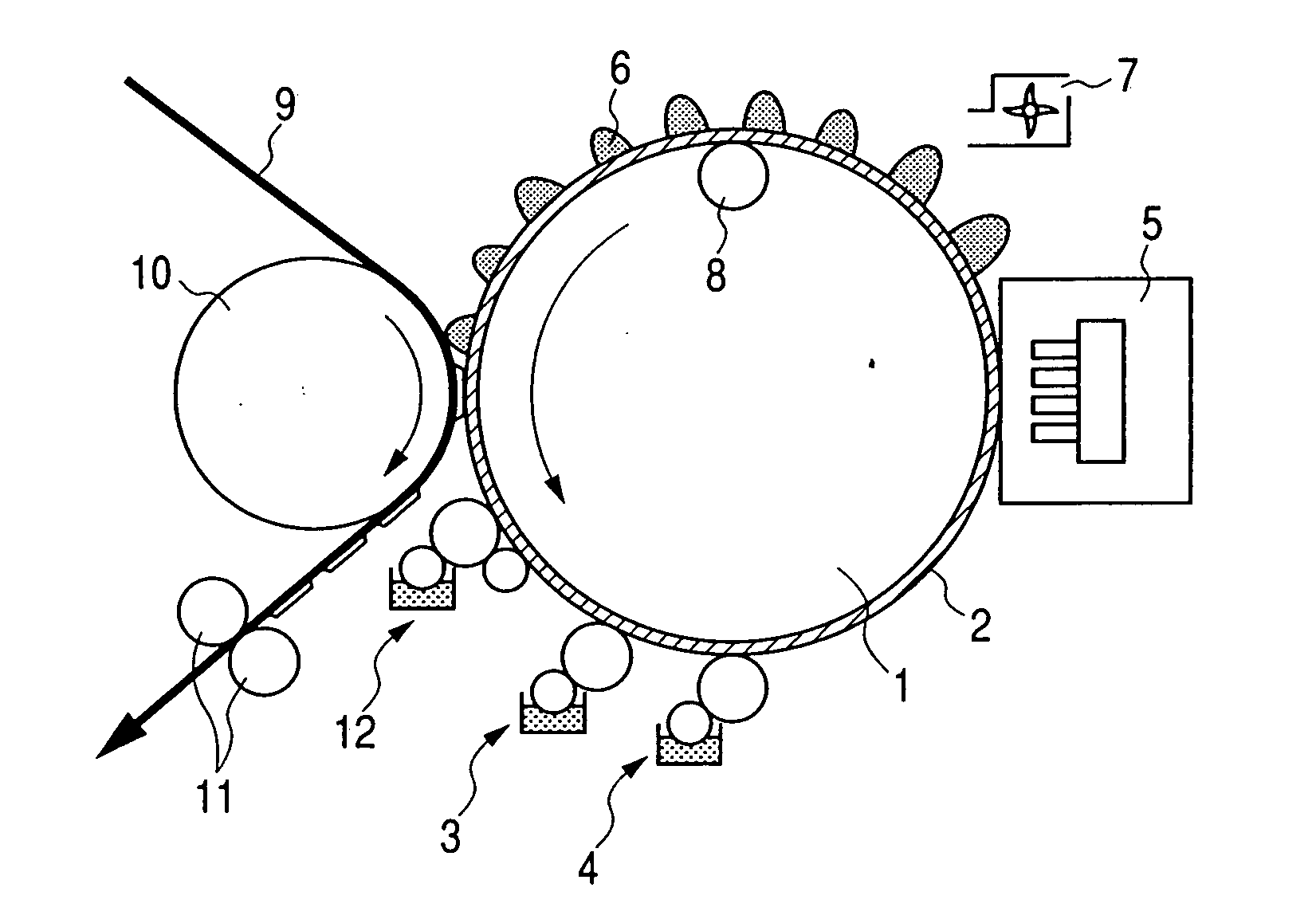

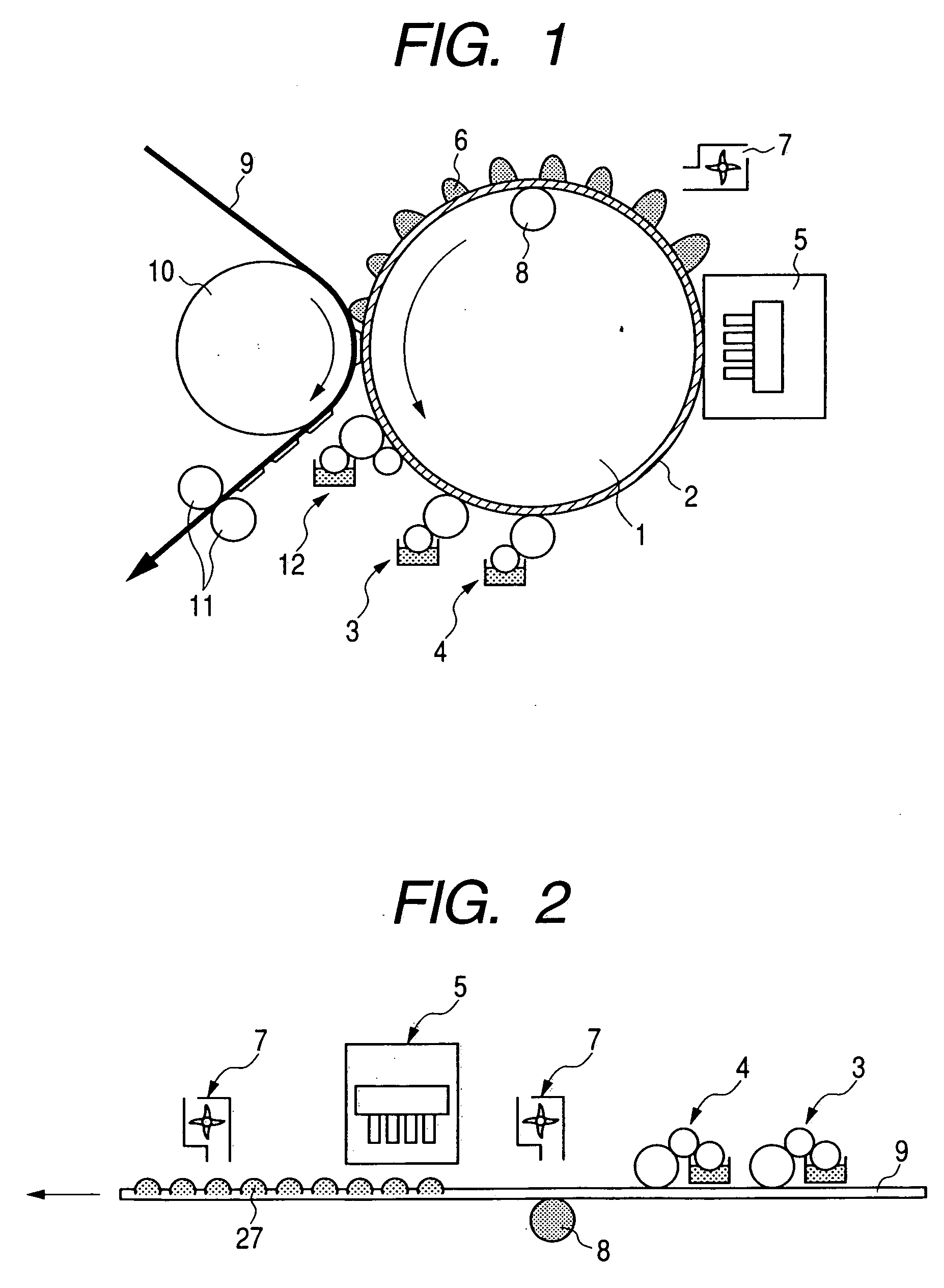

Disclosed herein is an image forming process comprising the steps of applying a first material for improving the wettability of the surface of an intermediate transfer medium to the intermediate transfer medium, applying a second material for lowering the flowability of an ink to the intermediate transfer medium to which the first material has been applied, applying the ink to the intermediate transfer medium, to which the first material and second material have been applied, from an ink-jet recording head to form an image of the ink on the intermediate transfer medium, and transferring the ink image formed to a recording medium.

Owner:CANON KK

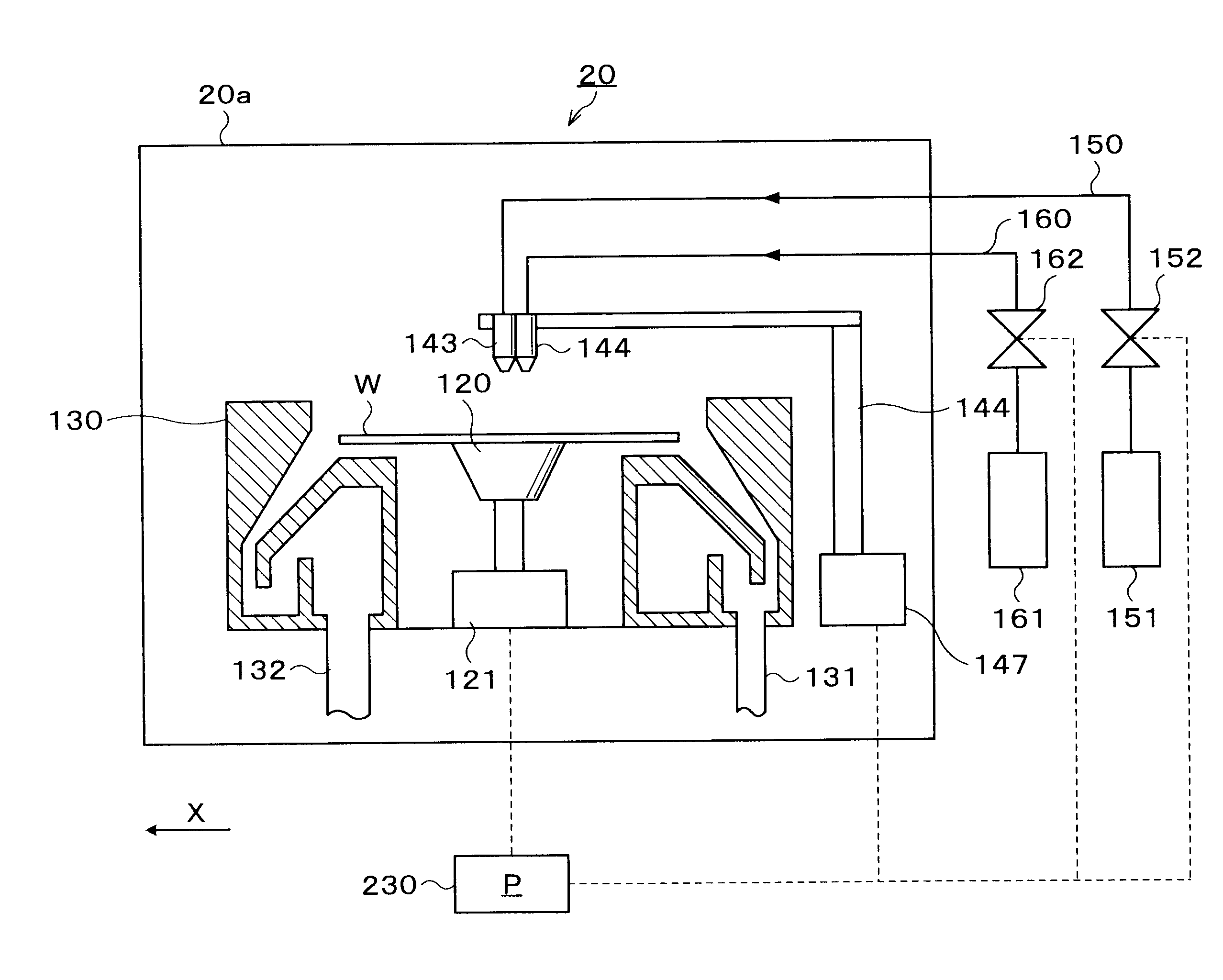

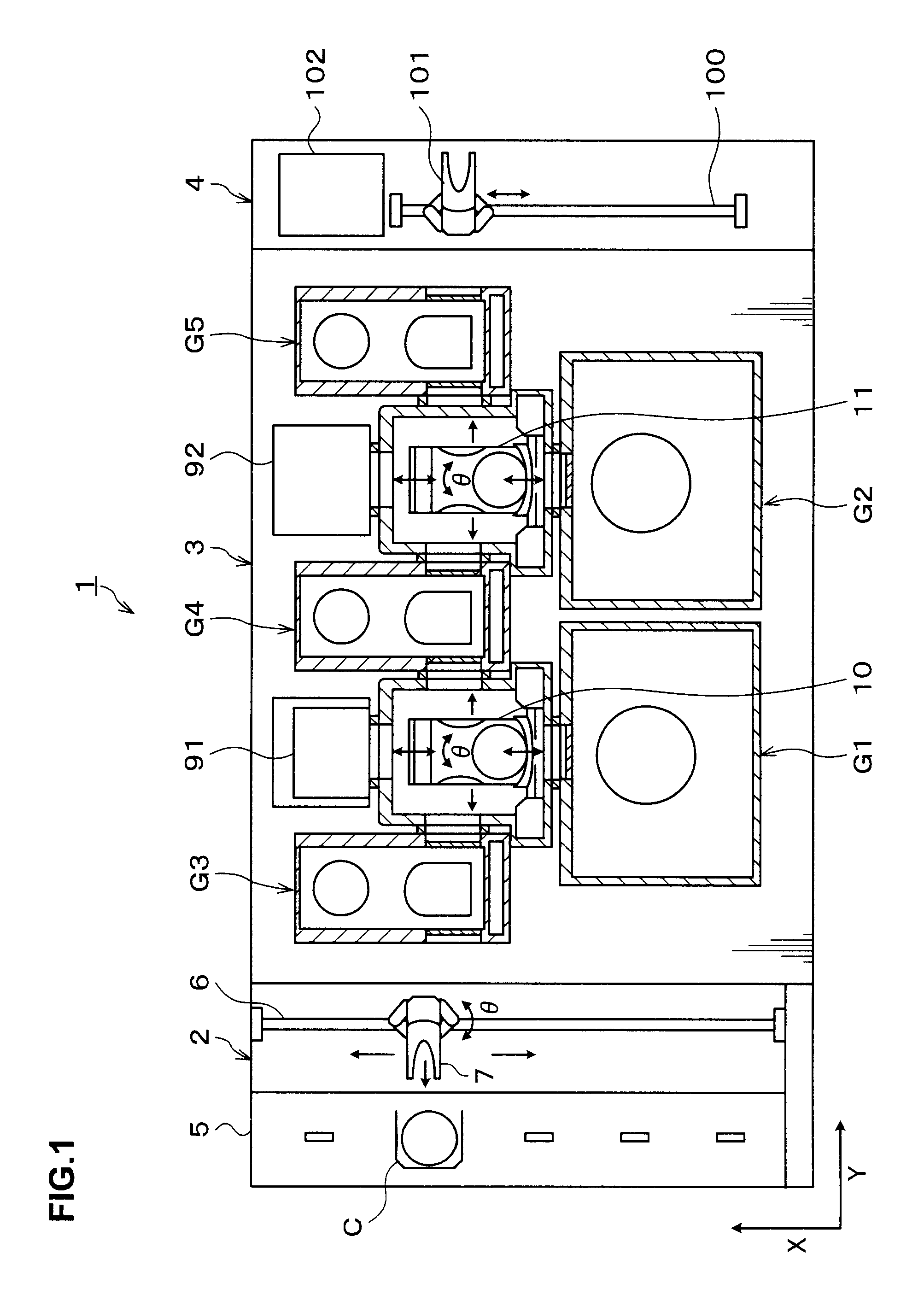

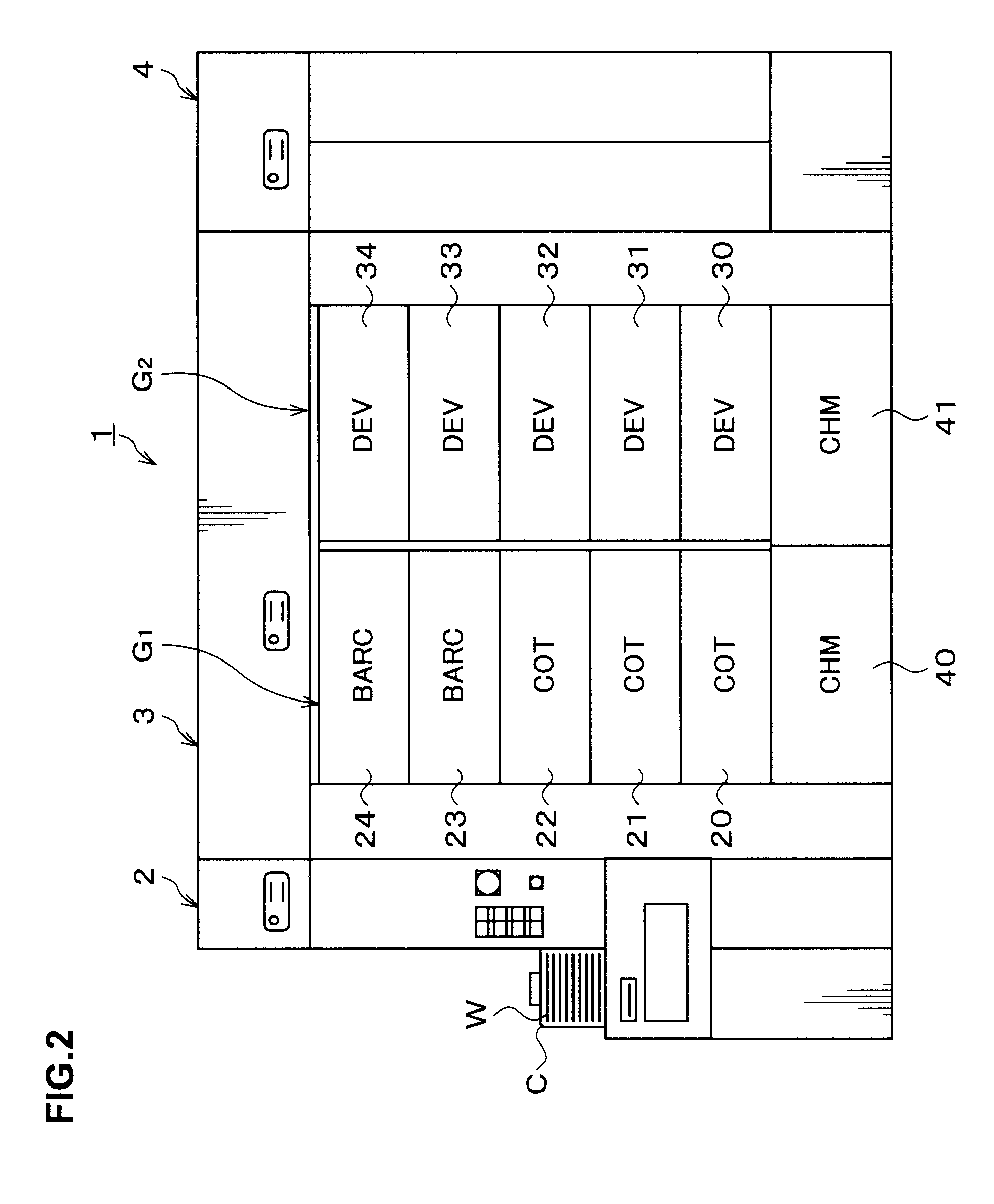

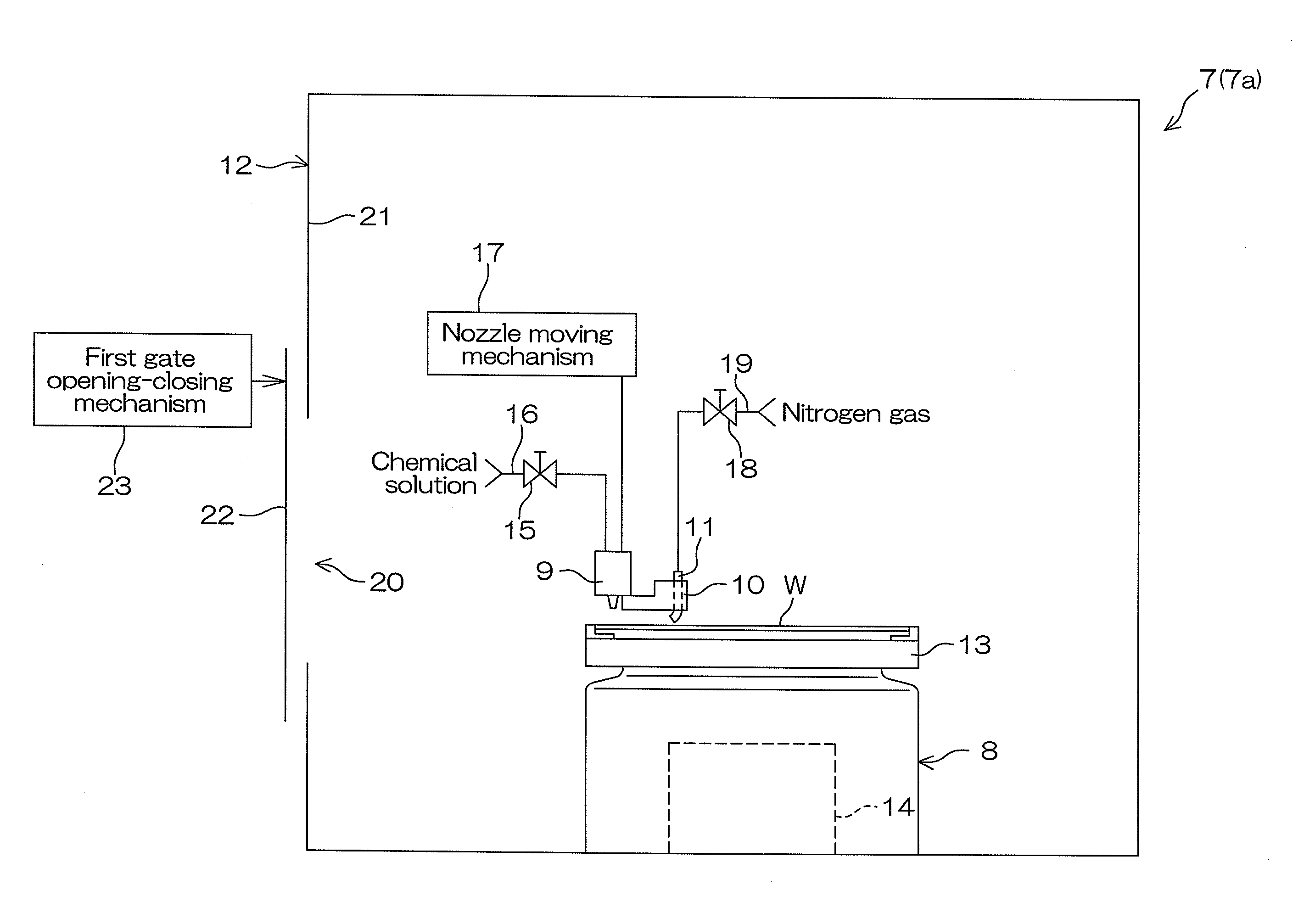

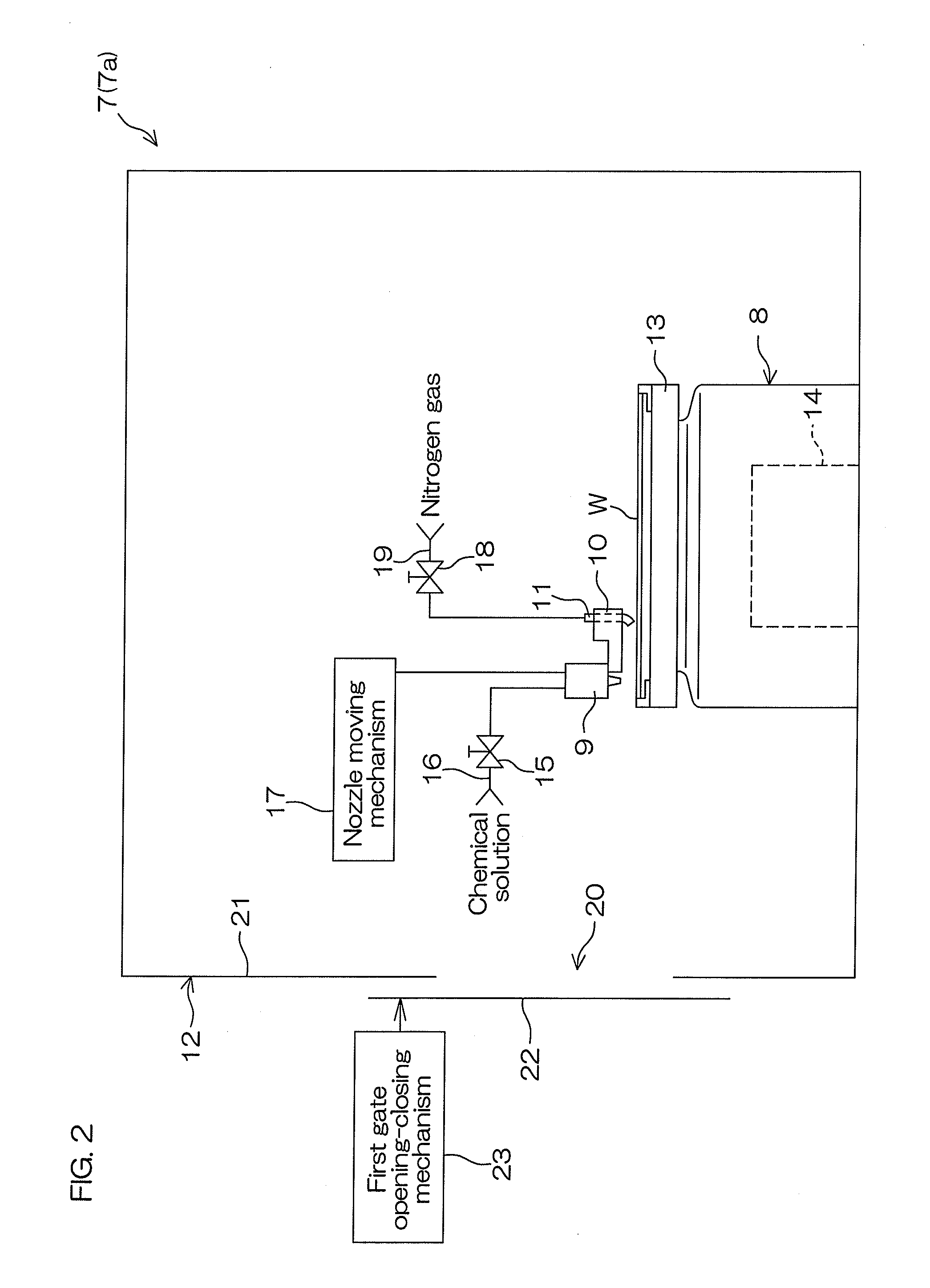

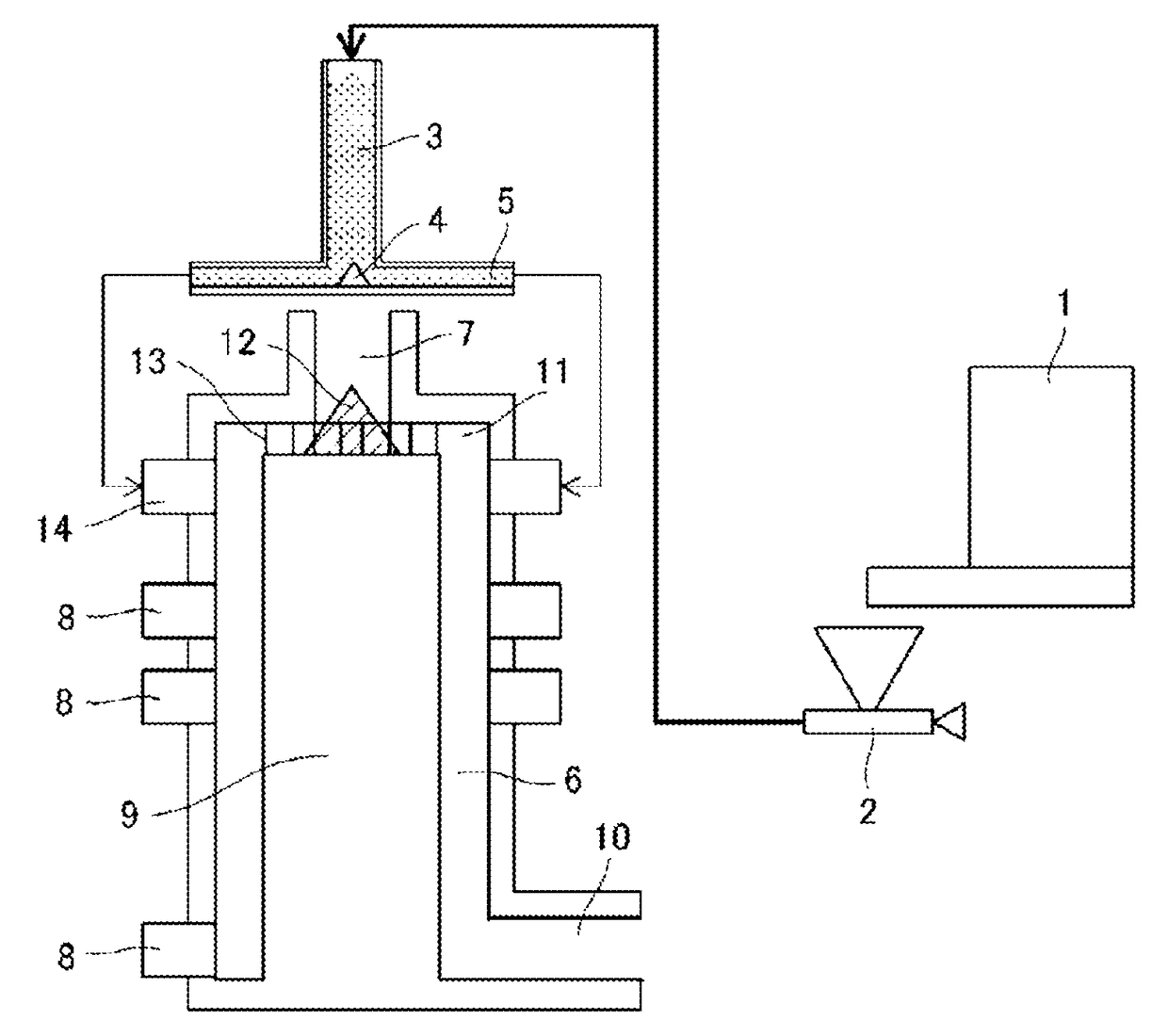

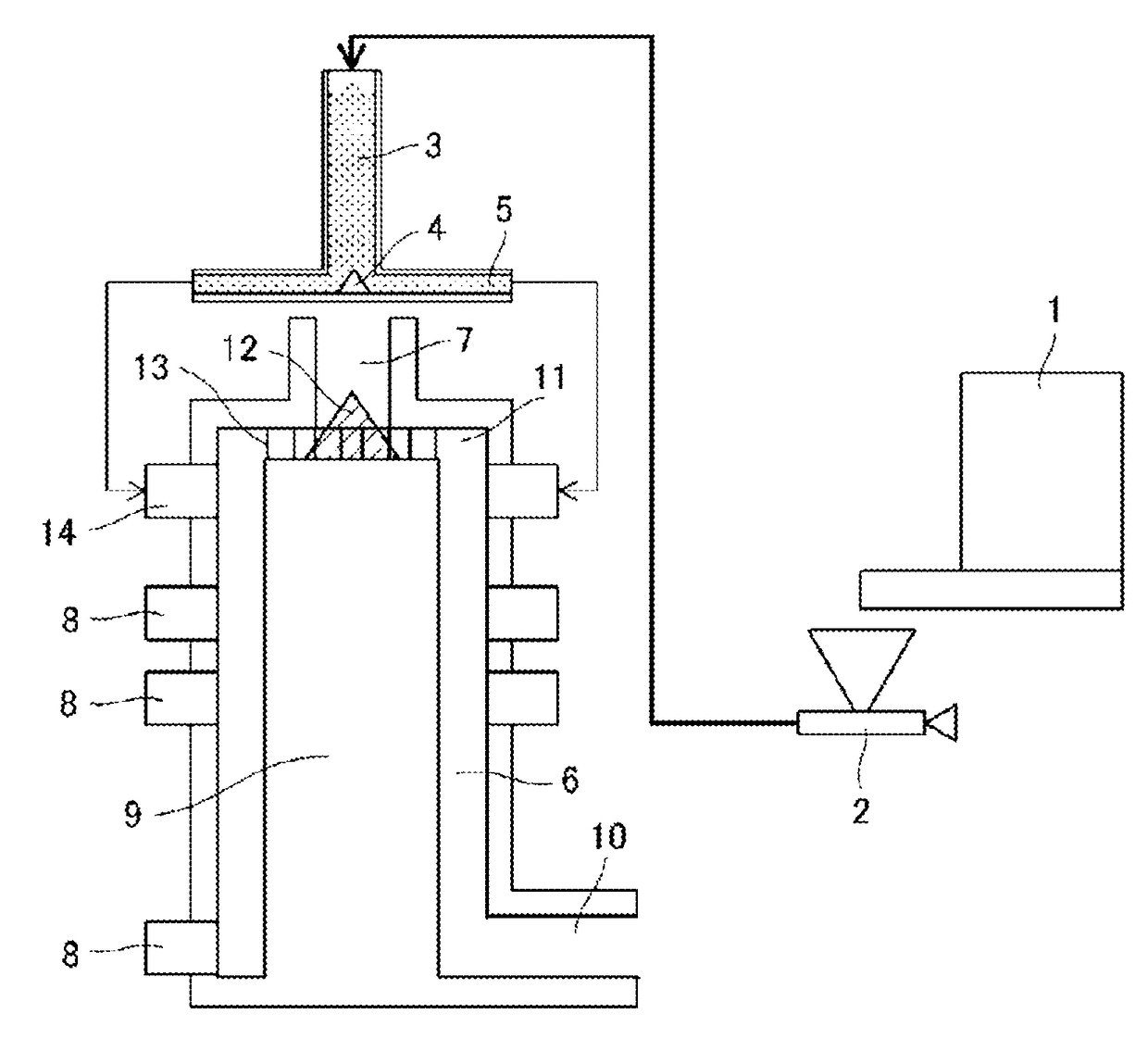

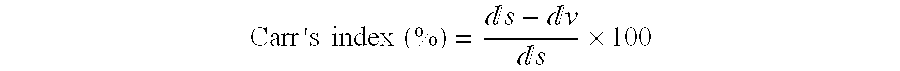

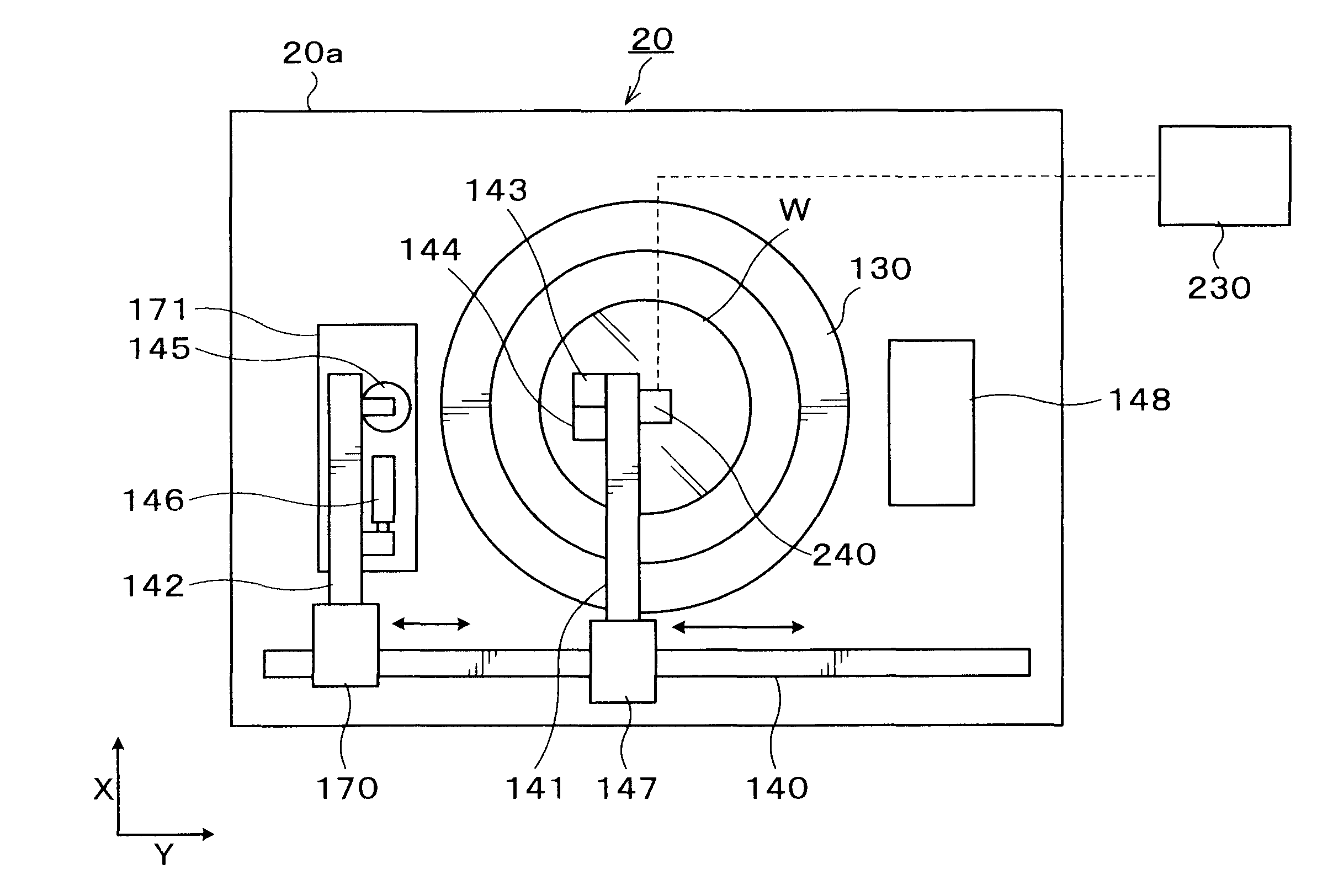

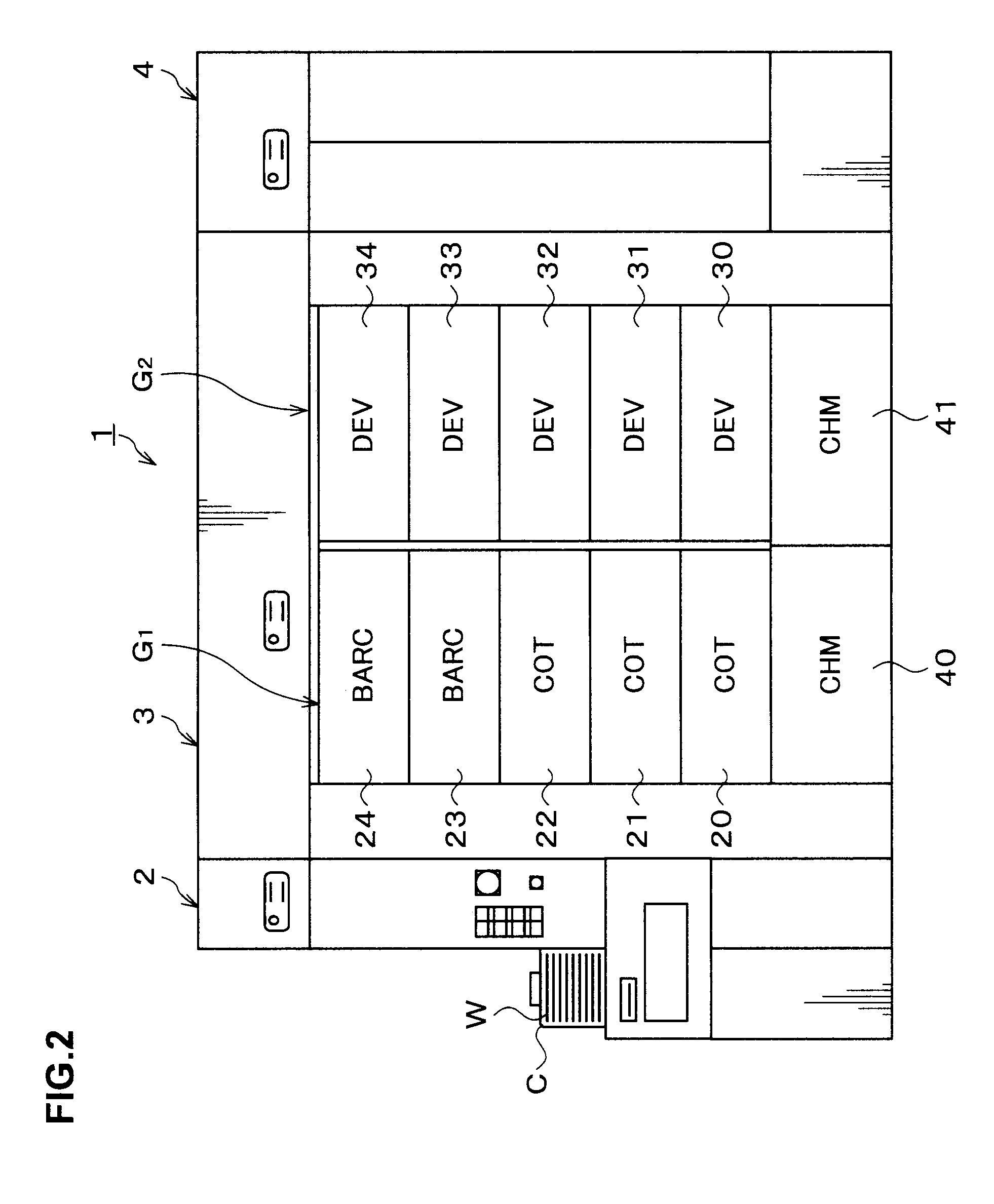

Coating treatment method, computer-readable storage medium, and coating treatment apparatus

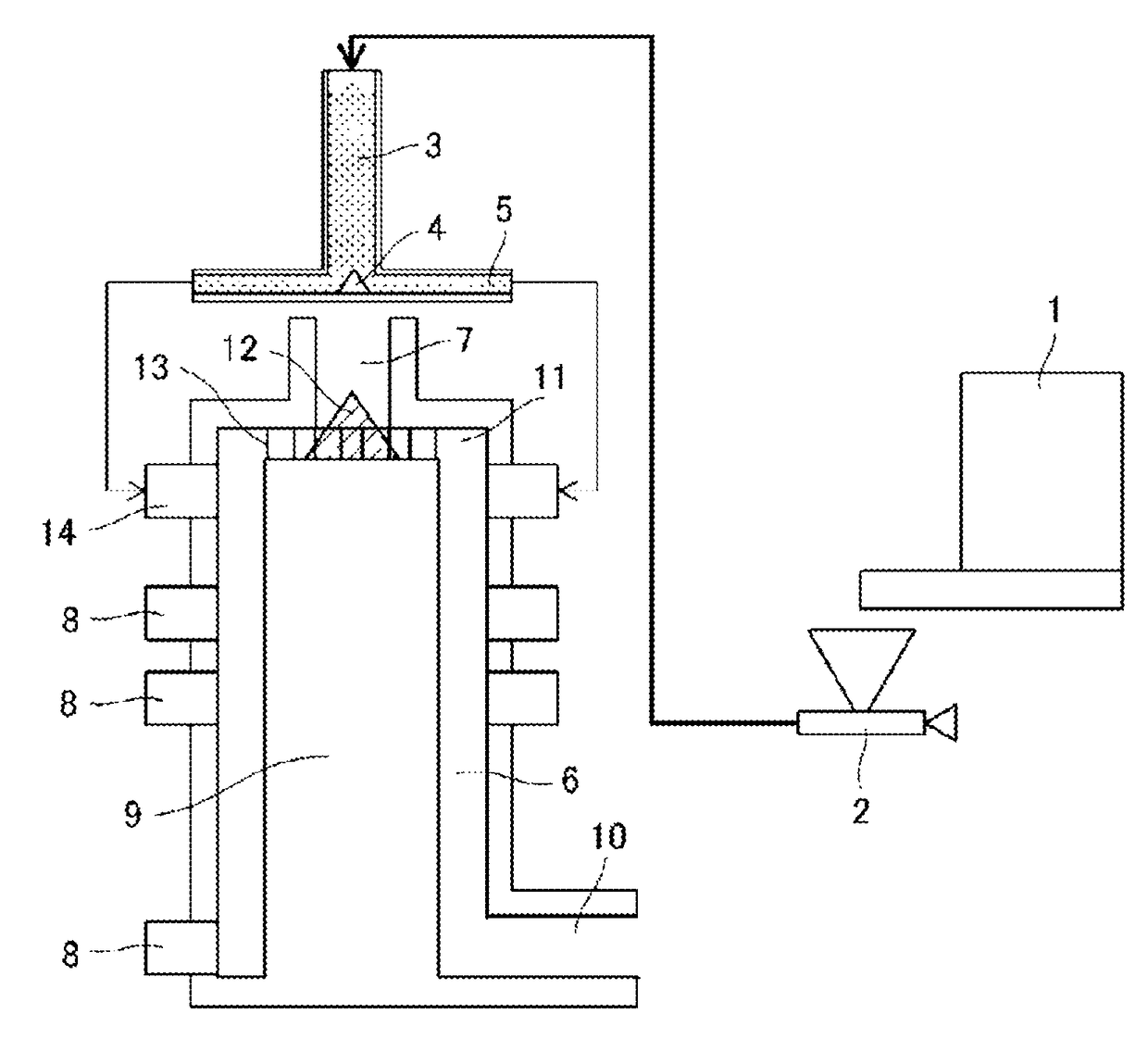

ActiveUS20080057194A1Improve liquidityReduce thicknessMovable spraying apparatusPhotomechanical apparatusResistLow speed

In the present invention, a substrate is first rotated at a first rotation speed, and a resist solution is applied to the rotated substrate. Subsequently, the rotation of the substrate is decelerated to a second rotation speed lower than the first rotation speed so that the substrate is rotated at the low speed to smooth the resist solution on the substrate. The rotation of the substrate is then accelerated to a third rotation speed higher than the second rotation speed, and a solvent for the coating solution and / or a dry gas are / is supplied to the resist solution on the substrate. In this event, the solvent gas is supplied to a portion of the resist solution on the substrate thicker than a set thickness, and the dry gas is supplied to a portion of the coating solution on the substrate thinner than the set thickness. This thins the thicker portion of the resist solution and thickens the thinner portion to uniform the resist solution.

Owner:TOKYO ELECTRON LTD

Polyolefin composition with low clte

The invention relates to novel polyolefin compositions having a low coefficient of thermal expansion (CLTE), high stiffness and high flowability. The novel compositions comprise a heterophasic propylene copolymer, an inorganic filler, an ethylene / alpha-olefin elastomer and at least two different alpha-nucleating agents.

Owner:BOREALIS AG

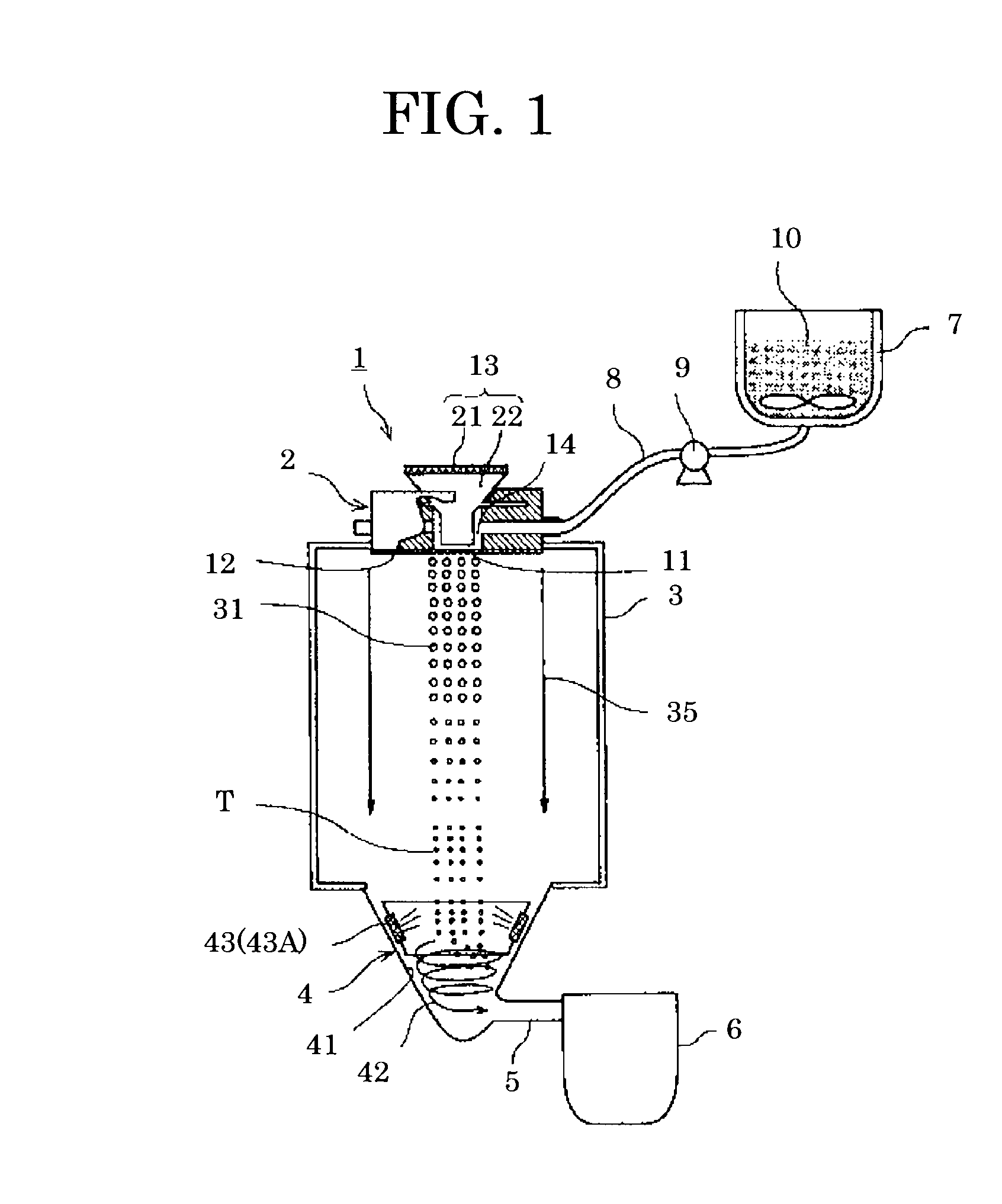

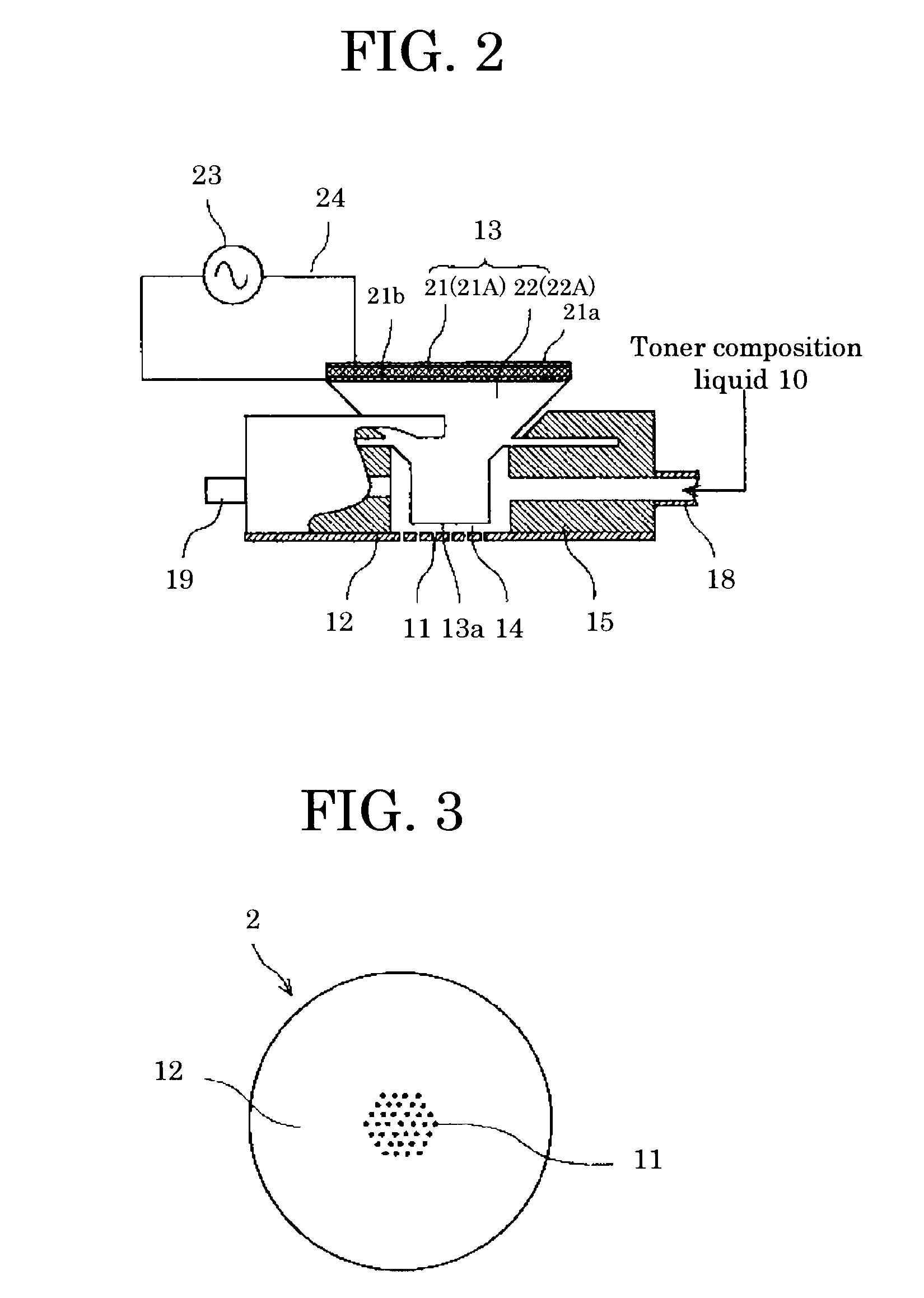

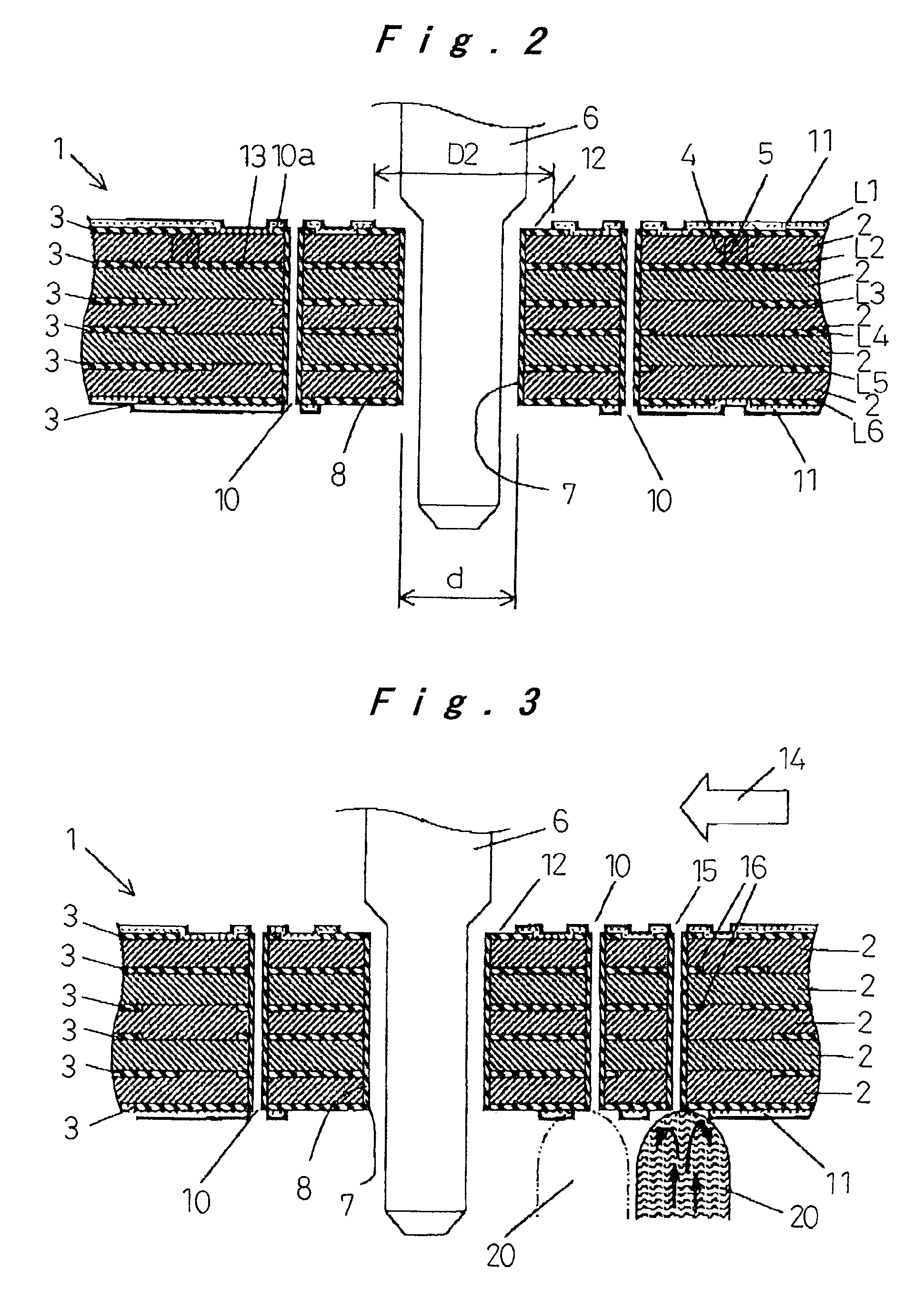

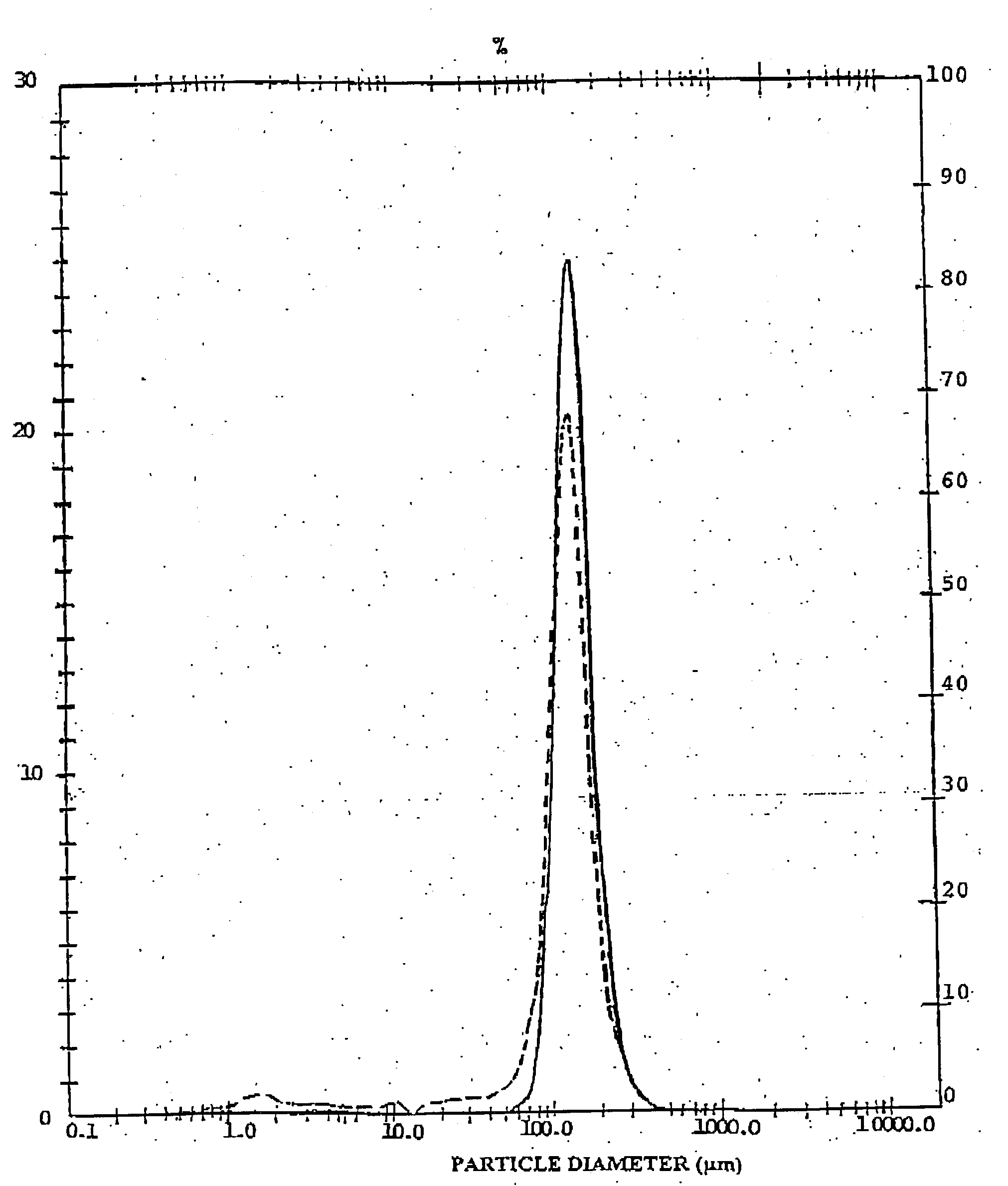

Method for producing toner, and toner

A method for producing a toner, the method including discharging a toner composition liquid from a plurality of nozzles to form liquid droplets thereof, the toner composition liquid being prepared by dissolving or dispersing in a solvent a toner composition containing at least a binder resin, a colorant, an acid-modified hydrocarbon wax and an unmodified hydrocarbon wax, the waxes serving as a releasing agent, and solidifying the liquid droplets so as to form solid particles.

Owner:RICOH KK

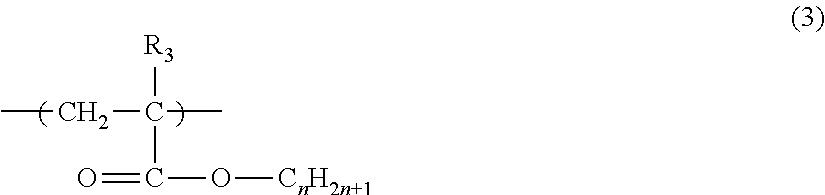

Acrylic adhesive composition having excellent impact resistance, optical film using the adhesive composition, and liquid crystal display comprising the optical film

InactiveUS20060234074A1Reduce the degree of crosslinkingPoor durabilitySynthetic resin layered productsEster polymer adhesivesChemistryLiquid-crystal display

An acrylic adhesive composition, an optical film and a liquid crystal display using the same, wherein the acrylic adhesive composition has excellent impact resistance, which improves resistance to external impact of an optical film, increases the wide viewing angle and brightness of an image display, such as a liquid crystal display, and increases durability of the optical film under heat and moist heat conditions. The acrylic adhesive composition having excellent impact resistance includes (a) 100 parts by weight of an acrylic copolymer, (b) 0.01˜10 parts by weight of a crosslinking agent, and (c) 0.5˜20 parts by weight of a polymer having an amino group, the acrylic copolymer being obtained by copolymerizing (1) 0.5˜10 wt % of a vinylic monomer having no carboxyl group, (2) 0.5˜20 wt % of a vinylic monomer having a carboxyl group, and (3) a balance of a (meth)acrylic acid ester monomer having a C1˜C12 alkyl group.

Owner:LG CHEM LTD

Oil spill recovery method using surface-treated iron powder

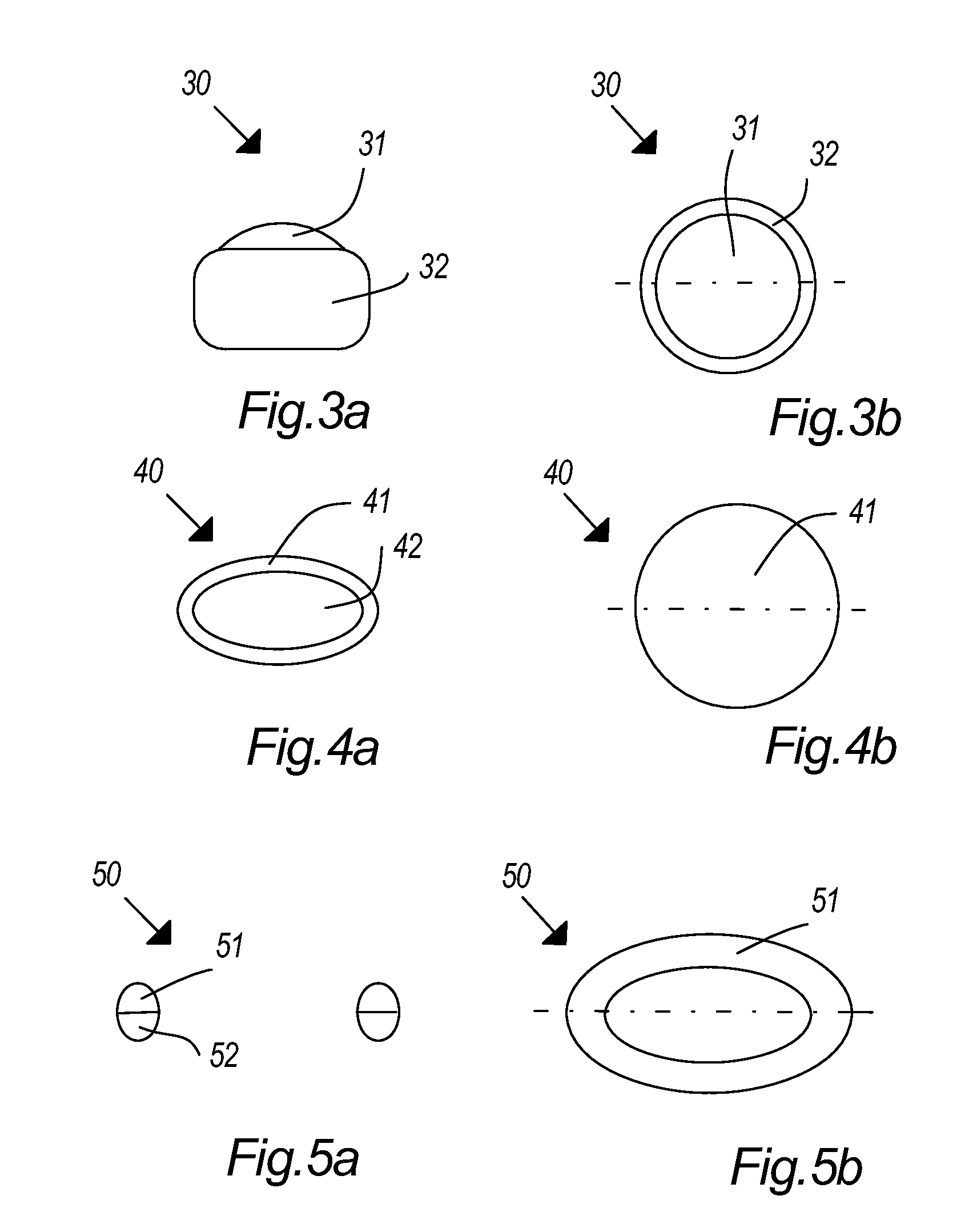

ActiveUS7303679B2Great potentialDecrease in flowabilityFerroso-ferric oxidesSedimentation separationRecovery methodIron powder

A method of recovering spilled hydrocarbon fluids from a body of water utilizing the increased oleophilic properties of reacted iron particles suspended in a magnetorheological (MR) fluid. The iron particles normally used to create MR fluids, are reacted with an organic compound containing an oleophilic chain end which attaches to the surface of the iron, prior to suspension in a liquid vehicle such as an organic oil. The reacted iron particles in the MR fluid are then applied to and mixed with a hydrocarbon spill on a body of water such as an oil spill, whereby subsequent exposure to a significant magnetic field provides for subsequent recovery of both the reacted magnetic particles and the hydrocarbon spill.

Owner:GM GLOBAL TECH OPERATIONS LLC

Oil spill recovery method using surface-treated iron powder

ActiveUS20050139550A1Great potentialDecrease in flowabilityFerroso-ferric oxidesSedimentation separationRecovery methodSimple Organic Compounds

A method of recovering spilled hydrocarbon fluids from a body of water utilizing the increased oleophilic properties of reacted iron particles suspended in a magnetorheological (MR) fluid. The iron particles normally used to create MR fluids, are reacted with an organic compound containing an oleophilic chain end which attaches to the surface of the iron, prior to suspension in a liquid vehicle such as an organic oil. The reacted iron particles in the MR fluid are then applied to and mixed with a hydrocarbon spill on a body of water such as an oil spill, whereby subsequent exposure to a significant magnetic field provides for subsequent recovery of both the reacted magnetic particles and the hydrocarbon spill.

Owner:GM GLOBAL TECH OPERATIONS LLC

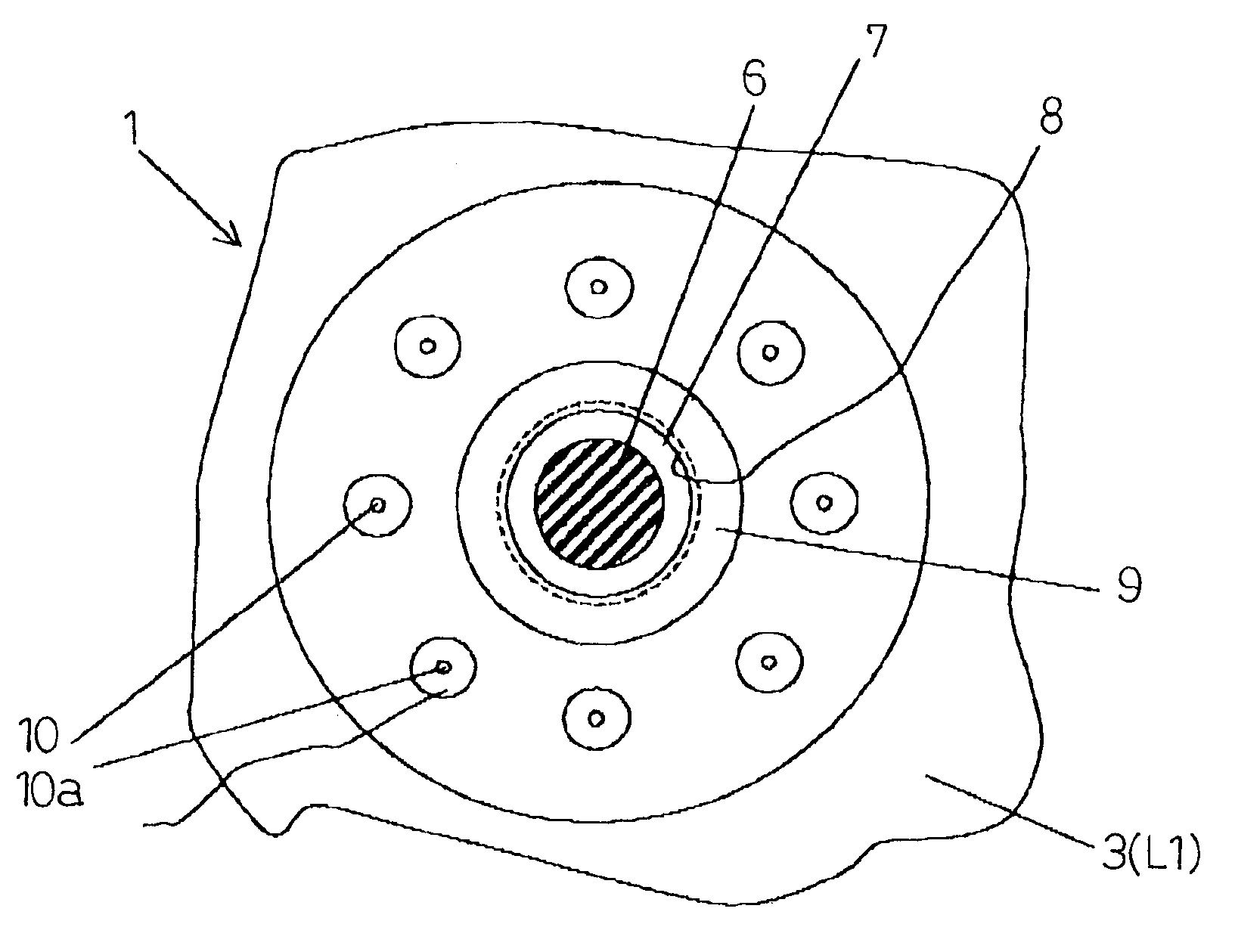

Printed circuit board and soldering method and apparatus

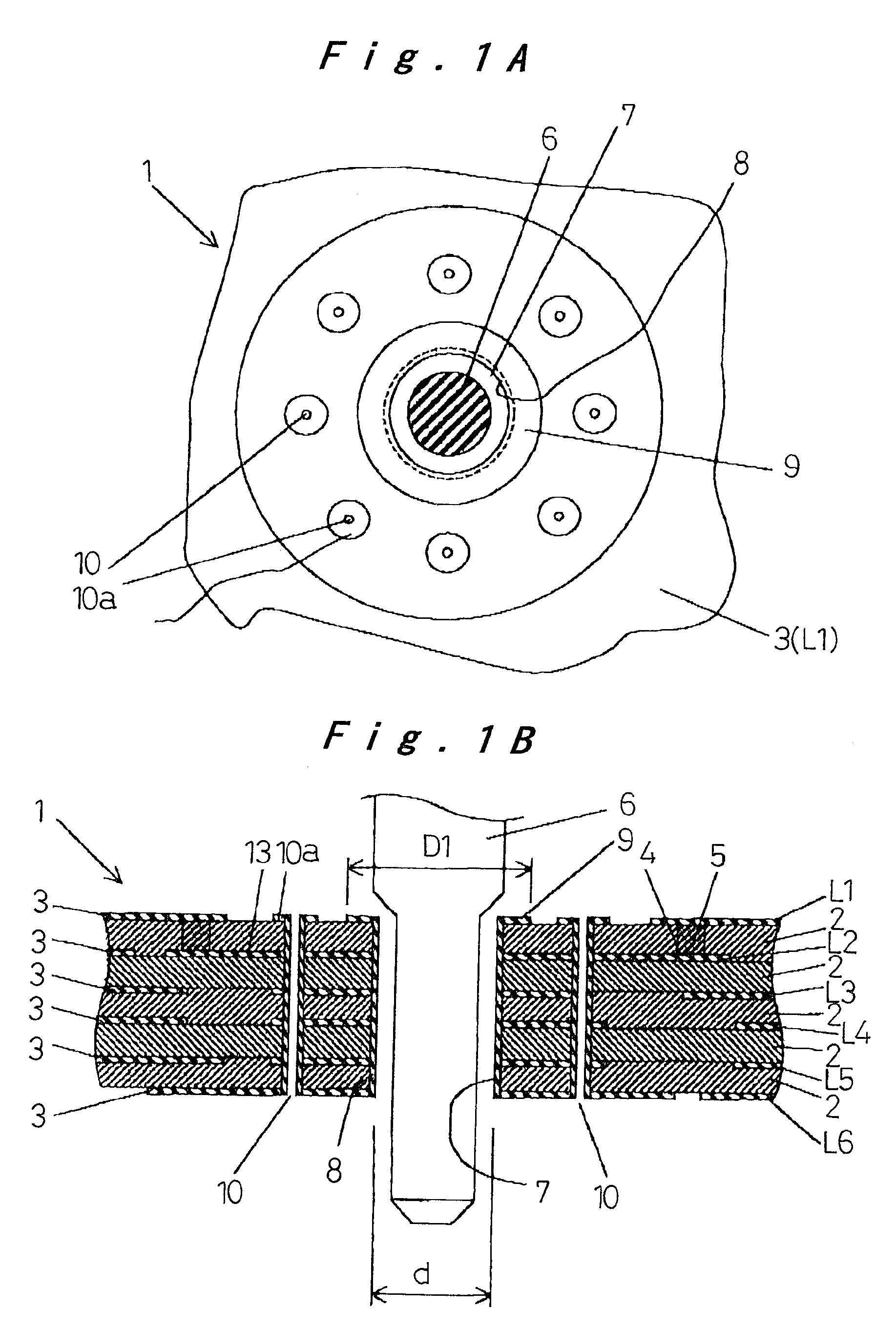

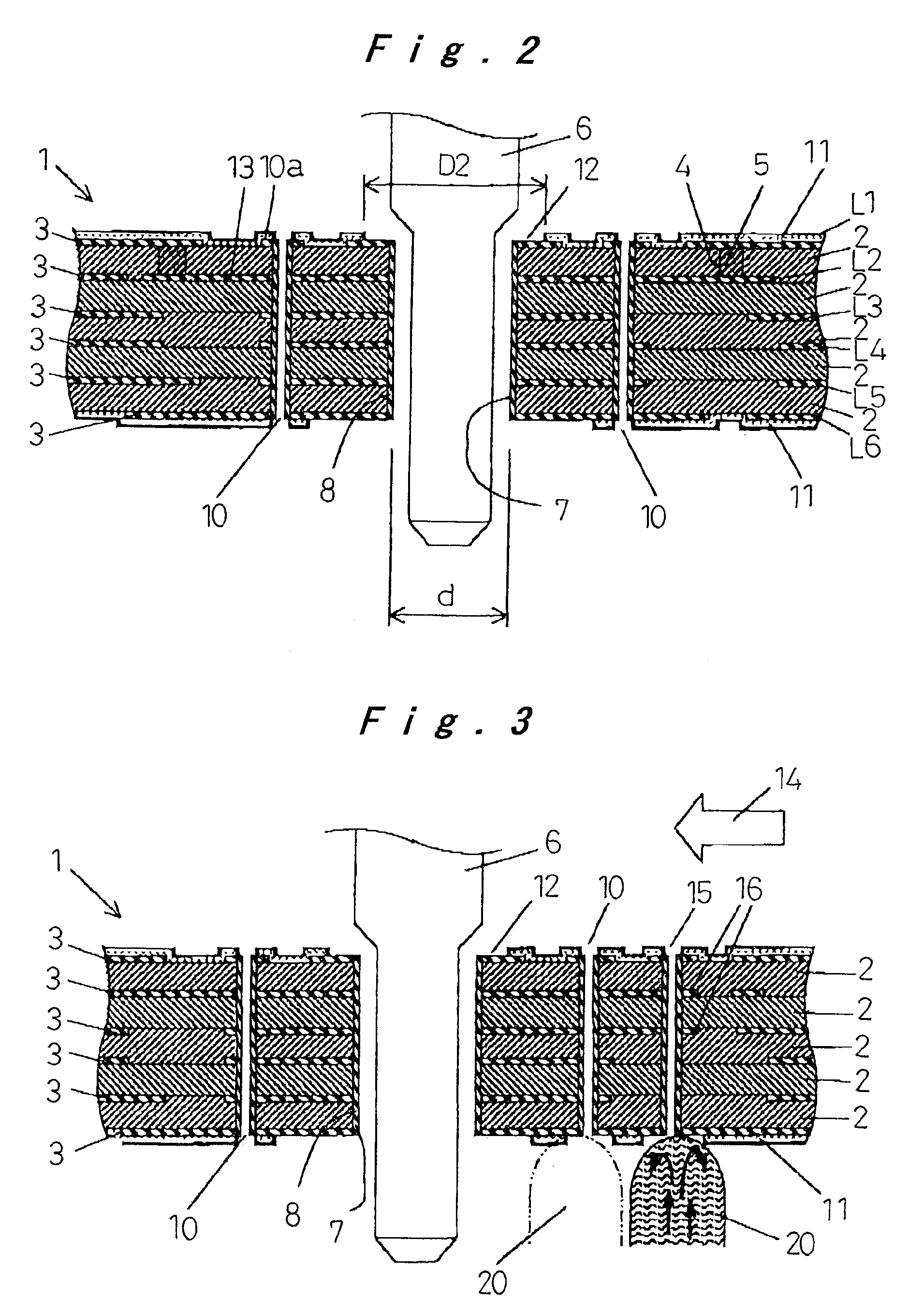

InactiveUS20070029108A1Heat fatigue resistance is improvedSolder wicking is enhancedPrinted circuit assemblingPrinted electric component incorporationSolderingPrinted circuit board

A printed circuit board suitable for dip soldering of component leads in through holes using lead free solder. The printed circuit board includes a plurality of via holes arranged around each through hole in which a component lead is inserted, whereby solder wicking up into the through hole is enhanced and air entrapment is prevented during the dip soldering operation, and heat fatigue resistance of solder joints is improved.

Owner:PANASONIC EV ENERGY CO LTD

Chewing Gum Tablet And Method Of Dosing Pharmaceutically Active Ingredients In Such Chewing Gum Tablet

ActiveUS20100266666A1Well mixedDecrease in flowabilityCosmetic preparationsOrganic active ingredientsAdditive ingredientBULK ACTIVE INGREDIENT

A method of dosing pharmaceutically active ingredients in a compressed chewing gum tablet includes the steps of: providing one or more pharmaceutically active ingredients, mixing a chewing gum composition including the one or more pharmaceutically active ingredients and chewing gum granules, the chewing gum granules including gum base, and dosing the chewing gum composition to obtain a desired weight of the chewing gum composition and thereby obtaining a desired dose of the pharmaceutically active ingredient in the chewing gum tablet.

Owner:FERTIN PHARMA AS

Toner production method and polymer

A toner production method including: a melt-kneading step of melt-kneading a resin composition including a binder resin, a colorant, a wax, and a wax dispersant to obtain a melt-kneaded product; and a pulverizing step of pulverizing the melt-kneaded product. Where the temperature of the melt-kneaded product at the end of the melt-kneading step is Tk (° C.), and the softening point of the wax dispersant is Tm (° C.), the relationship of −18≤[Tk−Tm]≤10 is satisfied. The wax dispersant is a polymer in which a styrene acrylic polymer is graft-polymerized to a polyolefin. The styrene acrylic polymer has a monomer unit derived from α-methylstyrene and a monomer unit derived from a cycloalkyl (meth)acrylate.

Owner:CANON KK

Image forming process and image forming apparatus

InactiveUS7494213B2Increase flexibilityImprove surface wettabilityMeasurement apparatus componentsDecorative surface effectsImage formationEngineering

An image forming process comprises the steps of applying a first material for improving the wettability of the surface of an intermediate transfer medium to the intermediate transfer medium, applying a second material for lowering the flowability of an ink to the intermediate transfer medium to which the first material has been applied, applying the ink to the intermediate transfer medium, to which the first material and second material have been applied, from an ink-jet recording head to form an image of the ink on the intermediate transfer medium, and transferring the ink image formed to a recording medium.

Owner:CANON KK

Plasticized films based on polyvinyl acetal having an increased glass transition temperatuare and improved flow properties

InactiveUS20100206374A1Sufficient flowabilityThe glass transition temperature Tg increasesGranular deliveryGlass/slag layered productsPolymer sciencePlasticizer

Plasticizer-containing films of polyvinyl acetal having a plasticizer content of a maximum of 26% by weight and containing a mixture of at least one high-viscosity polyvinyl acetal having a viscosity of 40-300 mPas and at least one low-viscosity polyvinyl acetal having a viscosity of 5-500 mPas are suitable for the production of photovoltaic modules.

Owner:KURARAY EURO GMBH

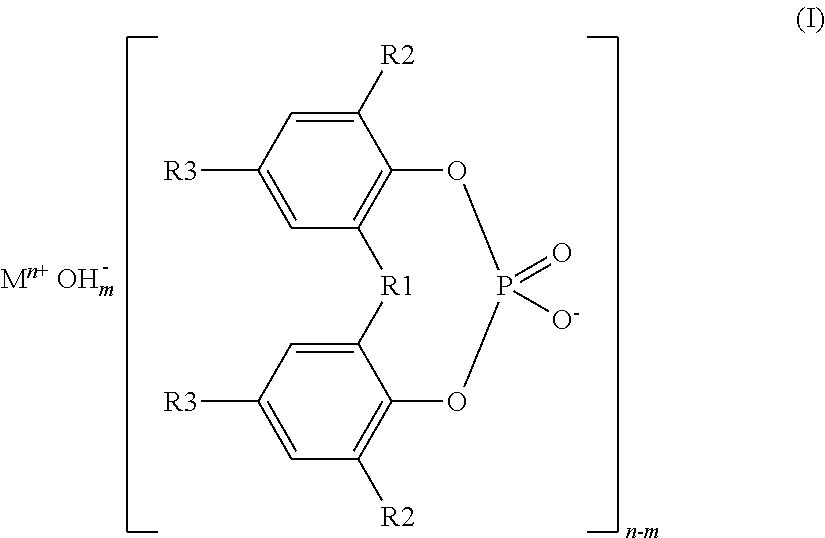

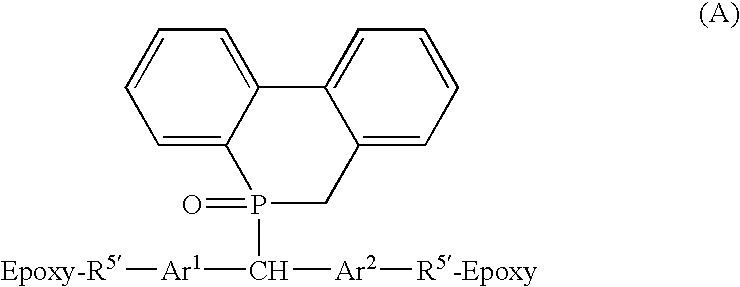

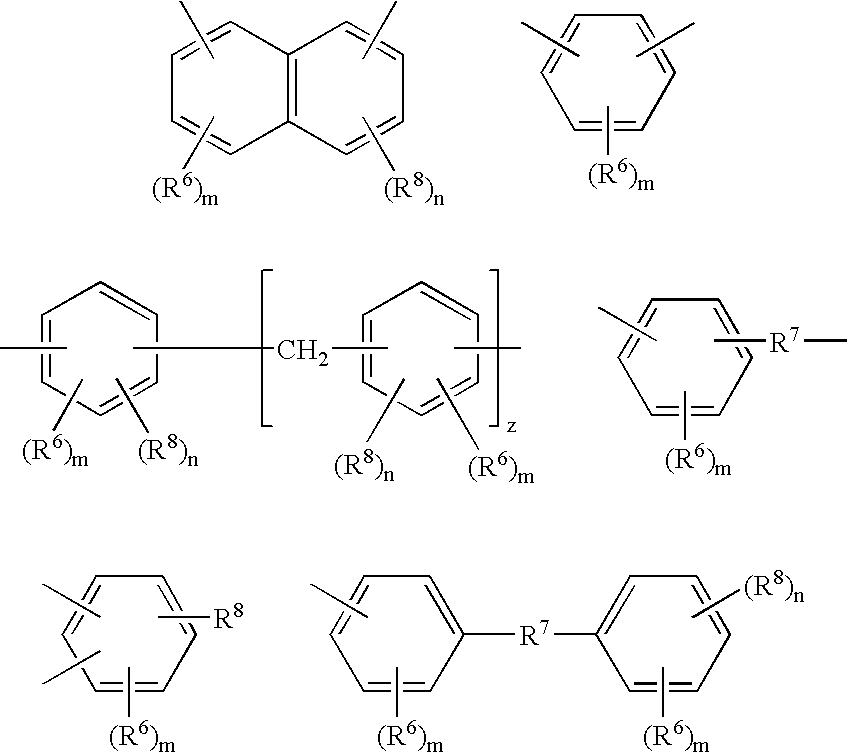

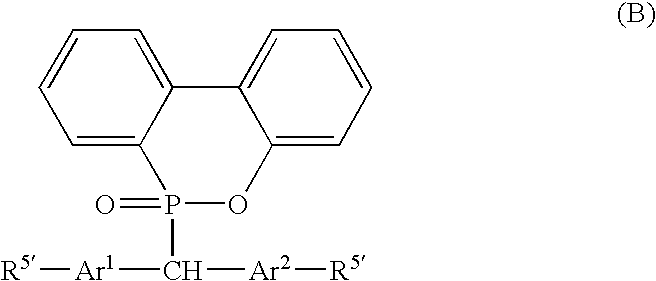

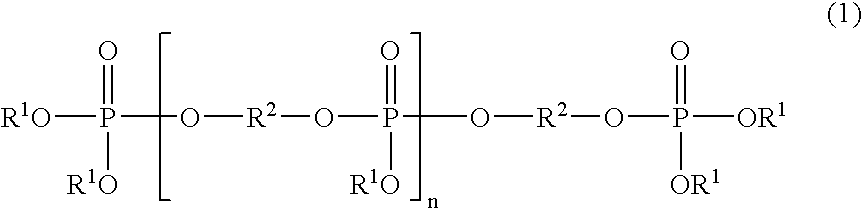

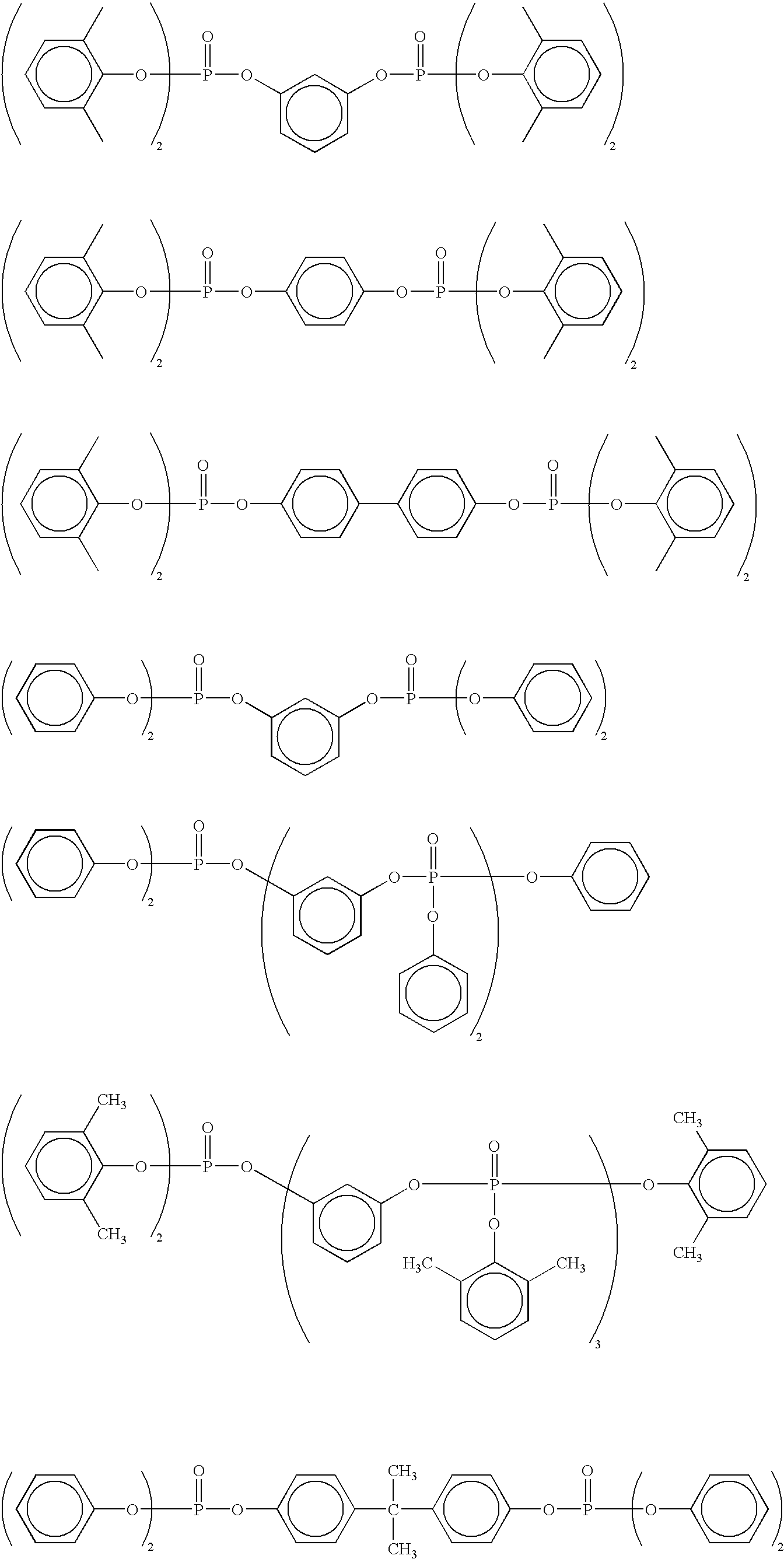

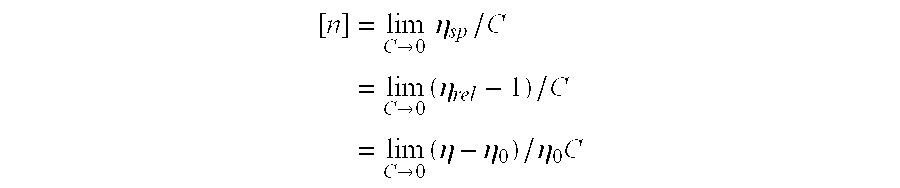

Flame retardant resin and flame retardant composition containing the same

InactiveUS7064157B2Small differenceDecrease in flowabilityPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsEpoxyHydrogen

The present invention relates to a phosphorus-containing epoxy resin, which is an epoxy resin modified with a side chain having a reactive phosphorus-containing compound. Also, the present invention relates to a flame-retardant resin composition, which comprises:(1) the phosphorus-containing epoxy resin,(2) a halogen-free hardener having a reactive hydrogen capable of reacting with the epoxy group in epoxy resin, and(3) a hardener promoter.The flame-retardant resin composition described above has improved excellent heat resistance and flame retardant property, and is especially suitable for adhesive laminates, composite materials, printed circuit boards, adhesive material for copper foils, and is suitable for IC packaging materials.

Owner:CHANG CHUN PLASTICS CO LTD

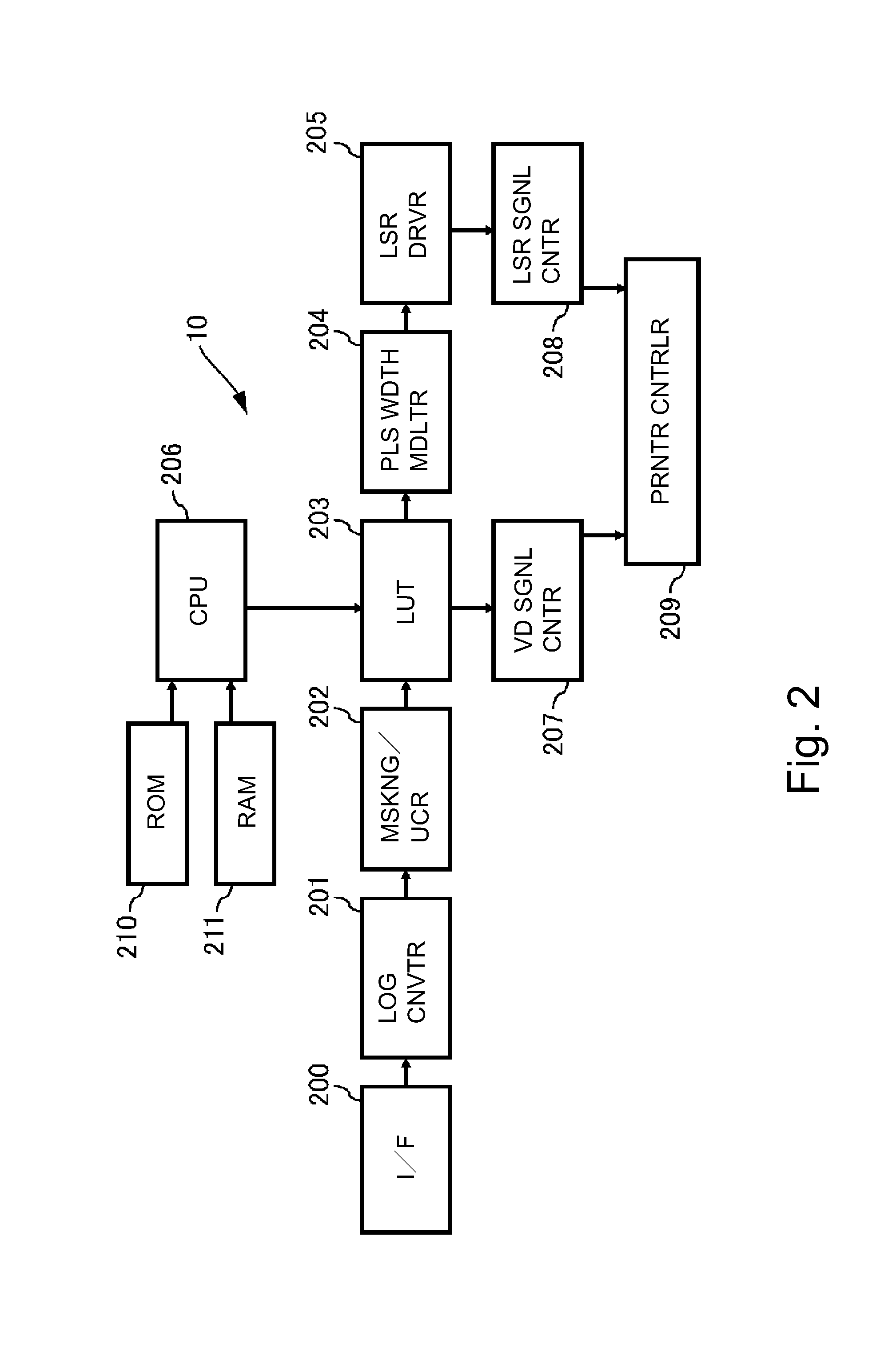

Image-forming apparatus and computer system

InactiveUS6889024B2Decrease in flowabilityElectrographic process apparatusElectrical conductorLatent image

An image-forming apparatus includes a photoconductor on which a latent image can be formed, and a moving member having attaching / detaching sections to / from each of which one of developing units can be attached / detached. Each of the developing units has a developer container for containing developer that is capable of developing the latent image formed on the photoconductor. The developer in the developer container is stirred by moving the moving member when none of the developing units attached to each of the attaching / detaching sections is developing a latent image formed on the photoconductor, and a timing for moving the moving member to stir the developer in the developer container is variable.

Owner:SEIKO EPSON CORP

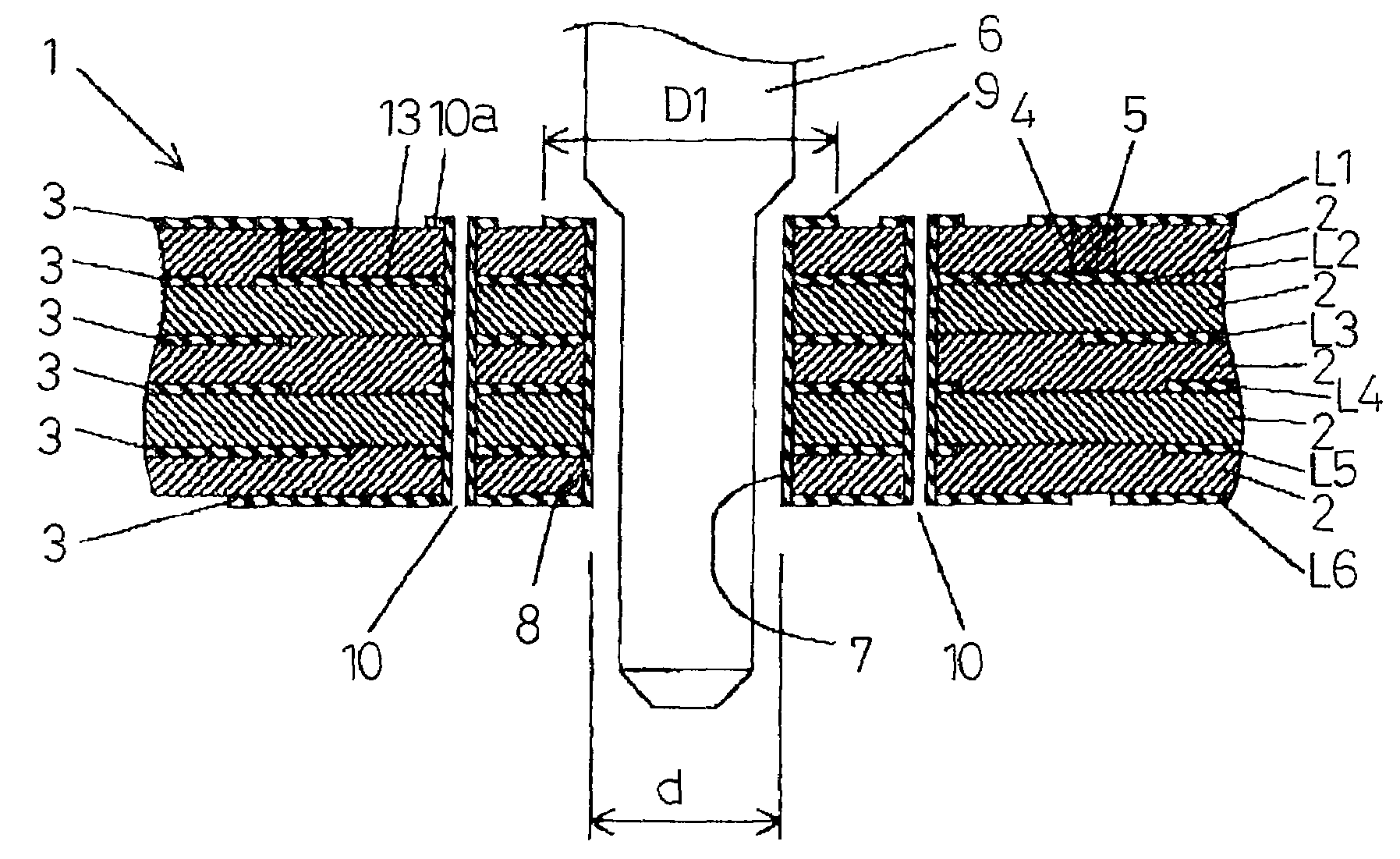

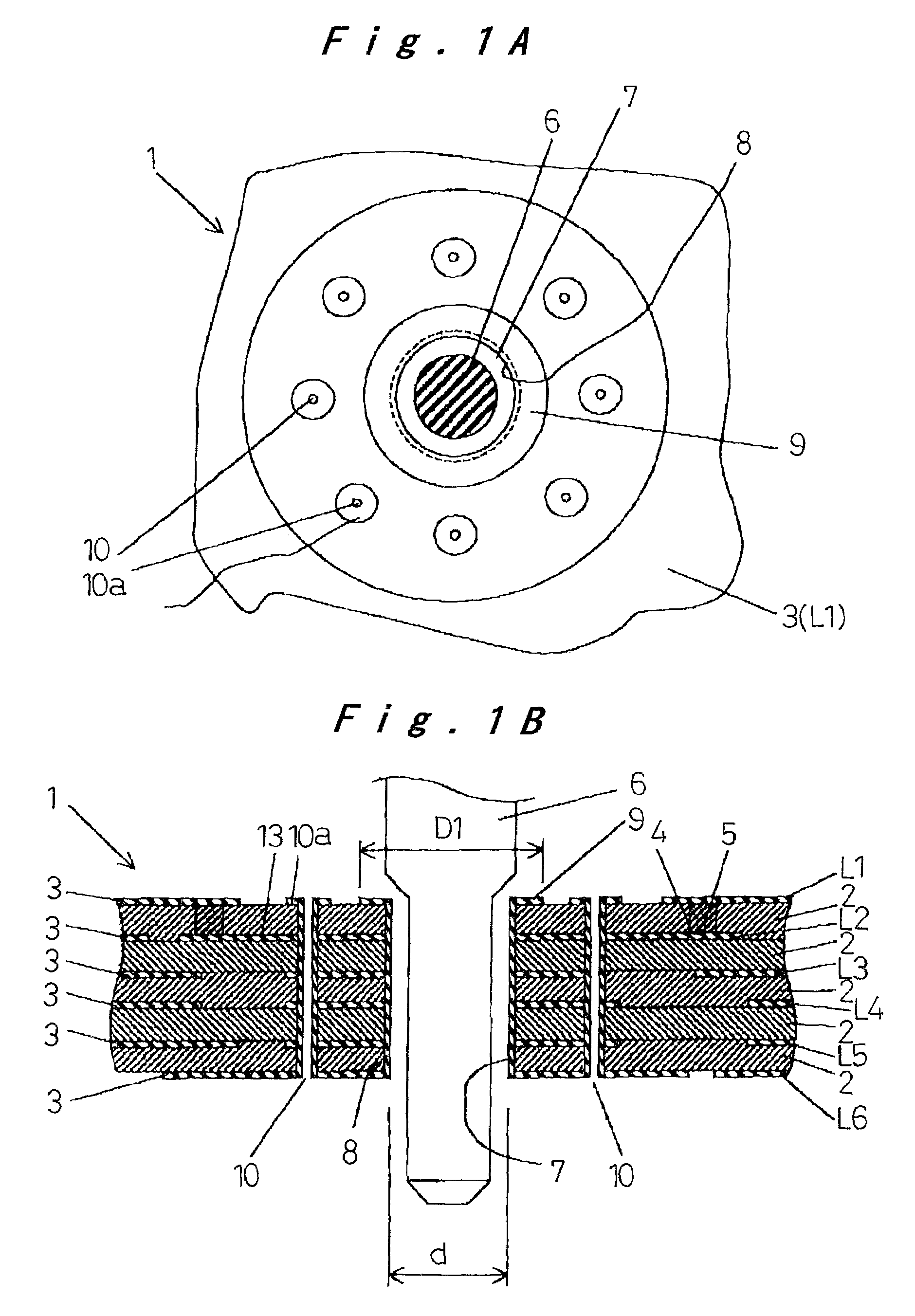

Fuel cell separator and a method for manufacturing the same

InactiveUS20050277009A1Lower resistanceLow costFinal product manufactureElectrode carriers/collectorsFuel cellsShear viscosity

A first resin is prepared which has a content of electrically conductive particles adjusted in the range from 60 wt % to 90 wt %, and a melt shear viscosity adjusted in the range from 1×103 Pa.sec to 1×107 Pa.sec. A second resin is prepared which has a content of electrically conductive particles that is adjusted in the range from 50 wt % to less than 90 wt % and that is less than that of the first resin. The second resin has a melt shear viscosity adjusted in the range from 1×102 Pa.sec to less than 1×105 Pa.sec. A resin block prepared from the first resin is placed in a mold, and the second resin is injection molded into the mold while heating the mold to the melting temperature of the first resin or above.

Owner:MITSUBISHI ELECTRIC CORP

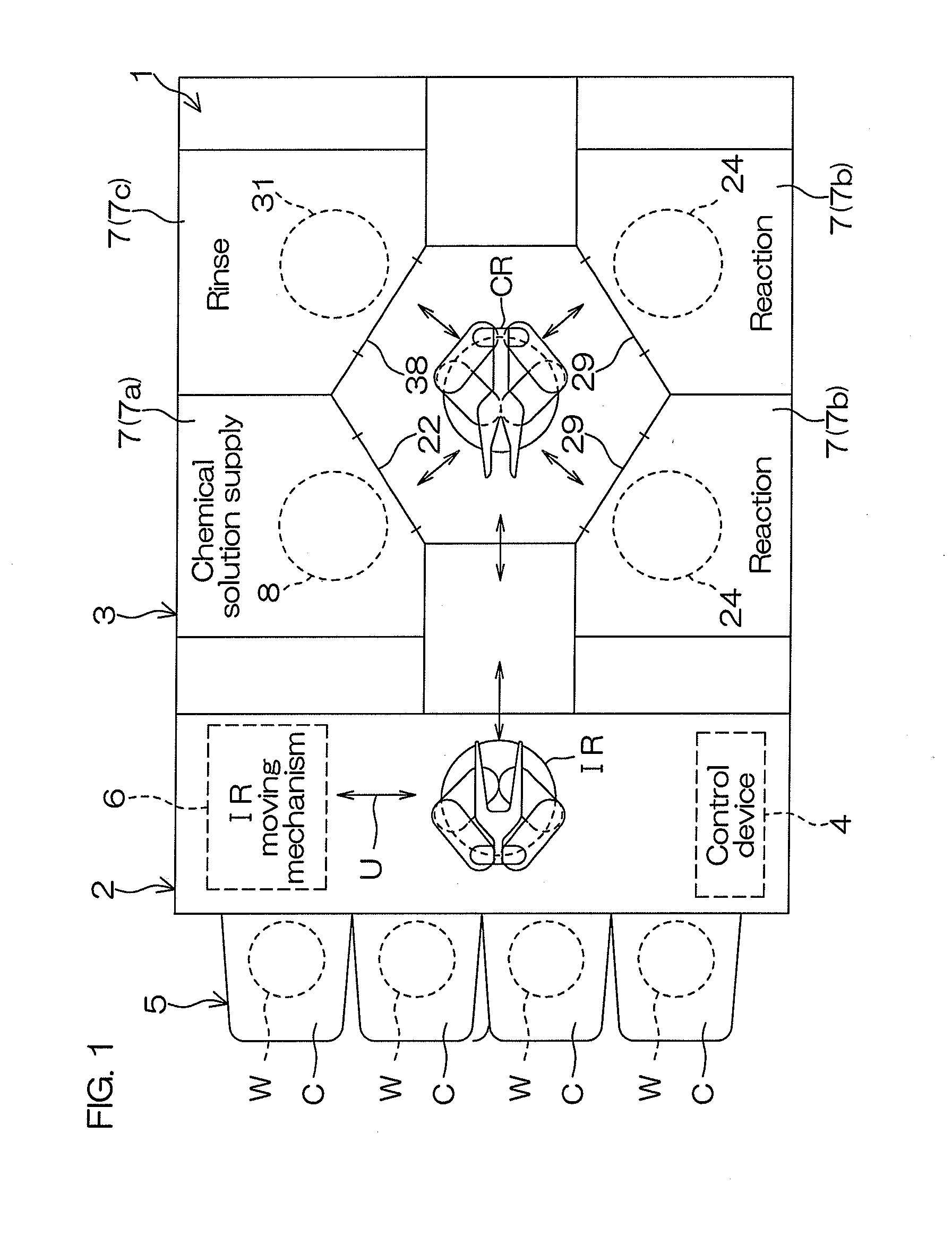

Substrate processing apparatus and substrate processing method

ActiveUS20120223054A1High viscosityFlowability of solution is loweredLiquid surface applicatorsDecorative surface effectsChemical solutionChemistry

A substrate processing apparatus includes a first processing chamber and a second processing chamber, a first substrate holding unit that holds a substrate in the first processing chamber, a chemical solution supply unit that supplies a chemical solution containing an etching component and a thickening agent to the substrate held by the first substrate holding unit, a substrate transfer unit that transfers the substrate from the first processing chamber to the second processing chamber in a state in which the chemical solution is held on the substrate, and a second substrate holding unit that holds a plurality of substrates on each of which the chemical solution is held in the second processing chamber.

Owner:MITSUBISHI GAS CHEM CO INC +1

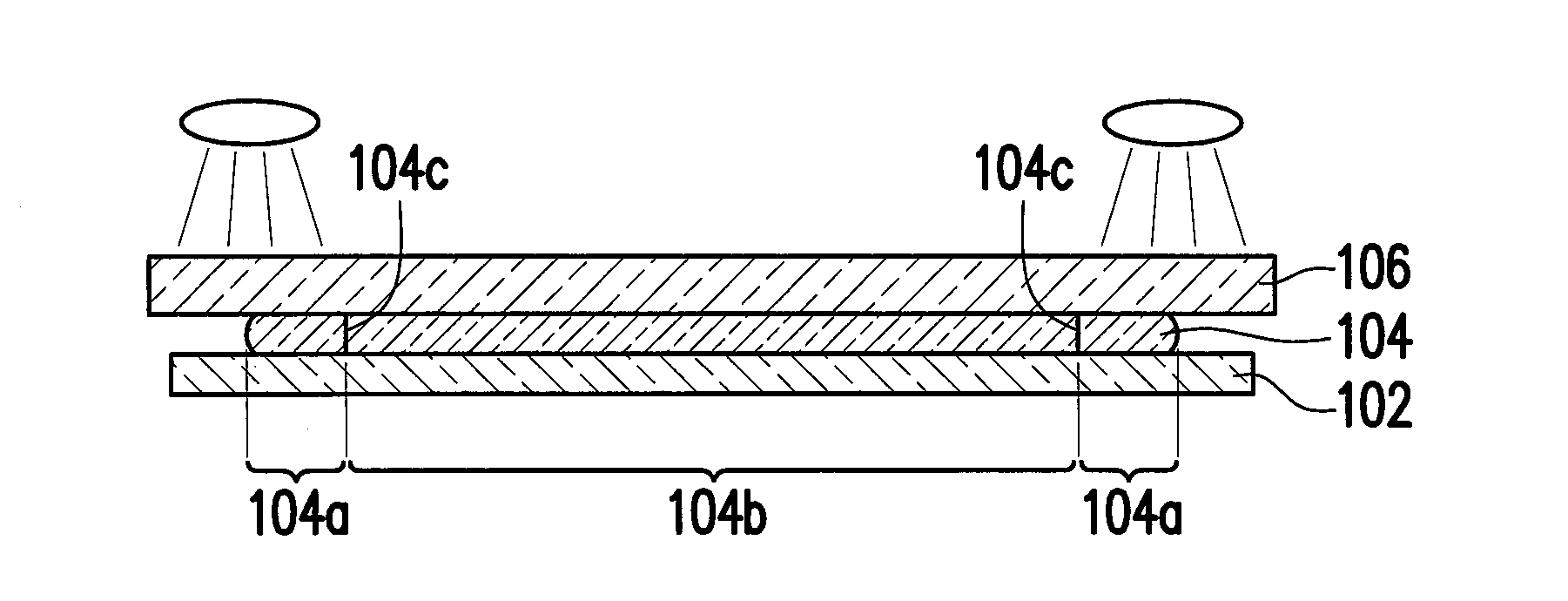

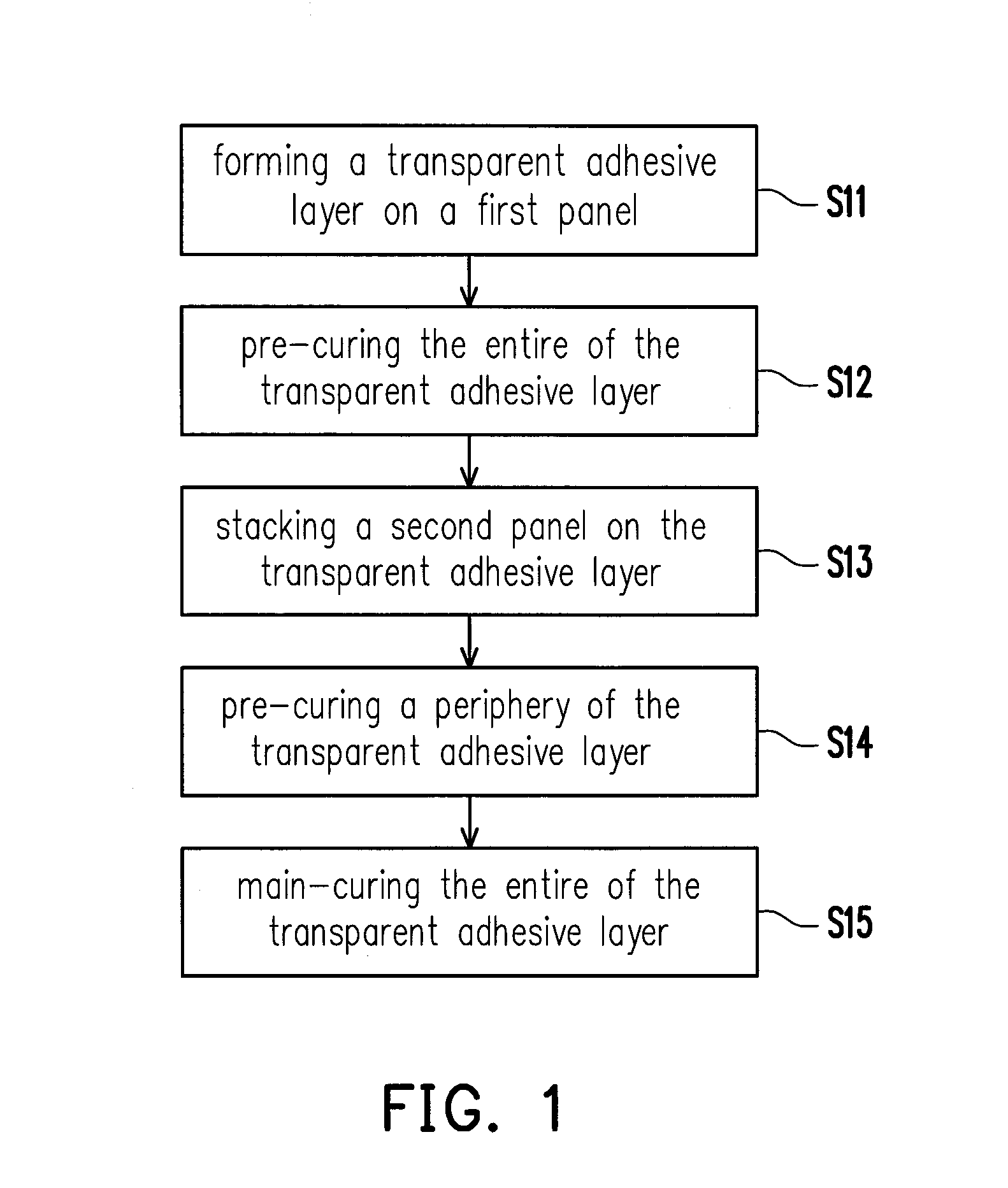

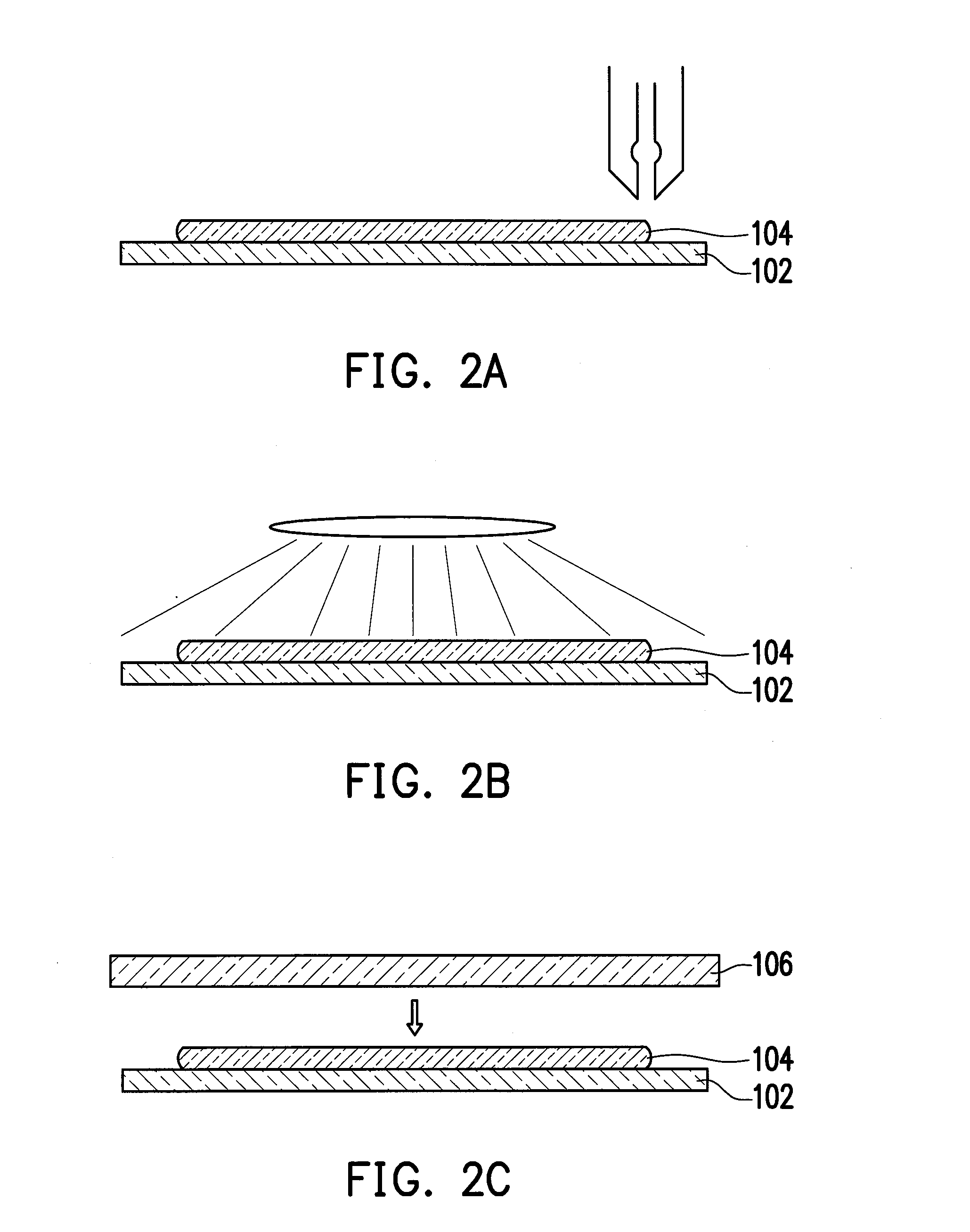

Panel laminating method, panel assembly and electronic device

ActiveUS20150230361A1Simplify Manufacturing ComplexityDecrease in flowabilityLamination ancillary operationsLayered product treatmentEngineeringViscosity

A panel laminating method is provided with the following steps. A transparent adhesive layer is formed on a first panel. At least a portion of the transparent adhesive layer is pre-cured to increase the viscosity of the transparent adhesive layer. After the transparent adhesive layer is pre-cured, a second panel is stacked on the transparent adhesive layer. After the second panel is stacked on the transparent adhesive layer, the entire of the transparent adhesive layer is main-cured so that the second panel is laminated to the first panel through the transparent adhesive layer. Besides, a panel assembly and an electronic device are also provided.

Owner:HTC CORP

Flame-retardant polyester artificial hair

InactiveUS20070184264A1Improve spin performanceLow mechanical strengthFlame-proof filament manufactureWigsPolyesterBromine

Owner:KANEKA CORP

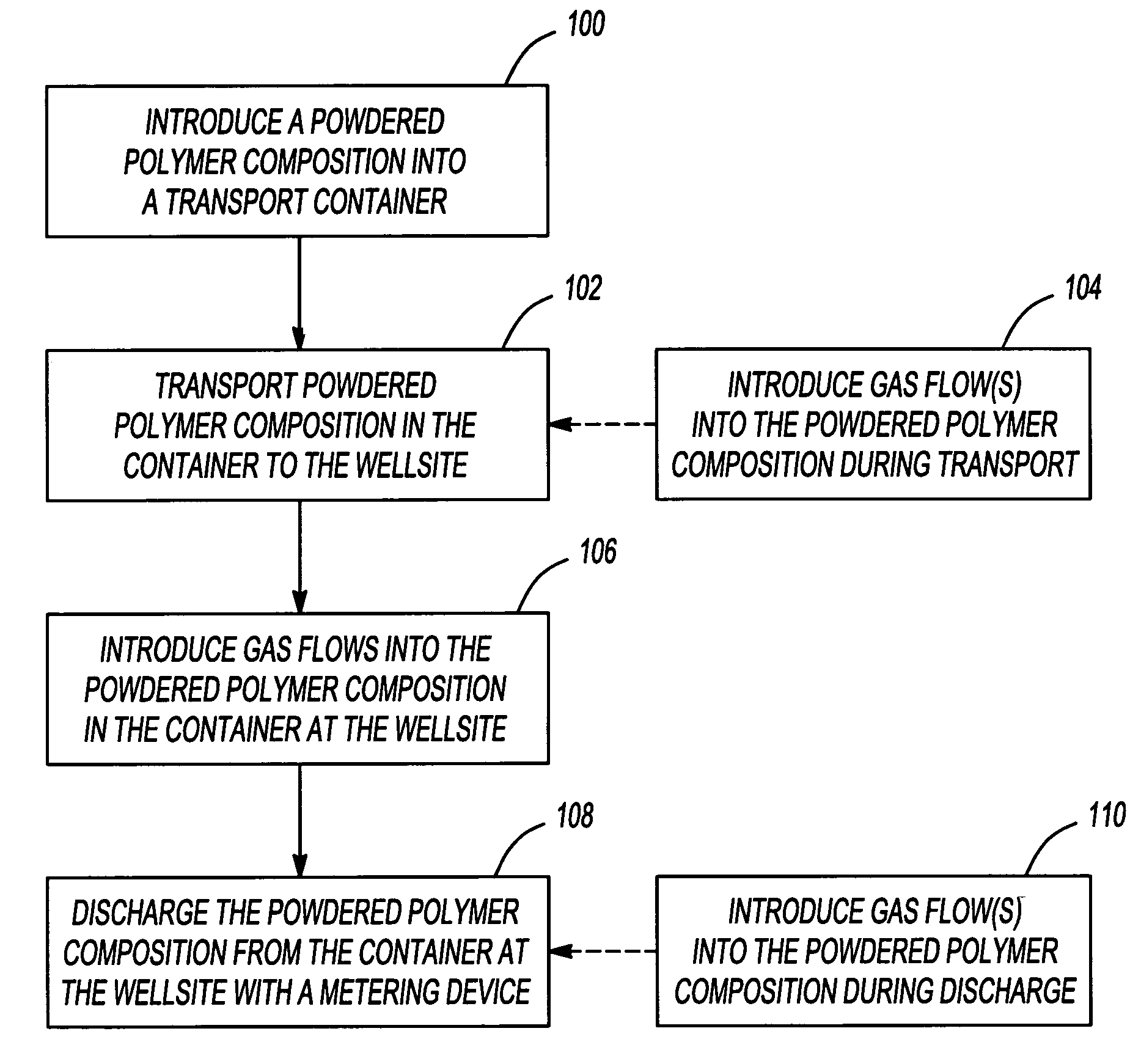

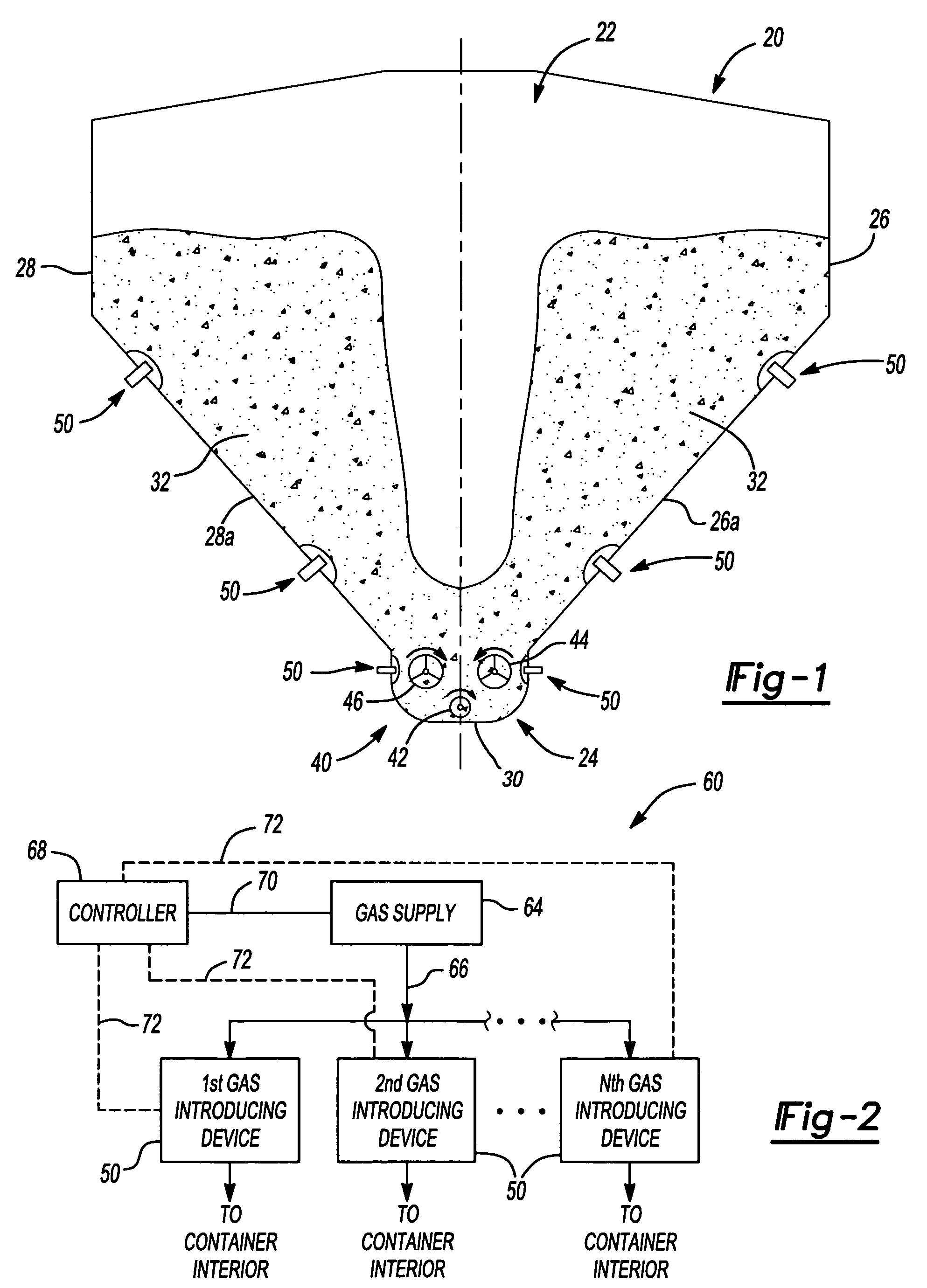

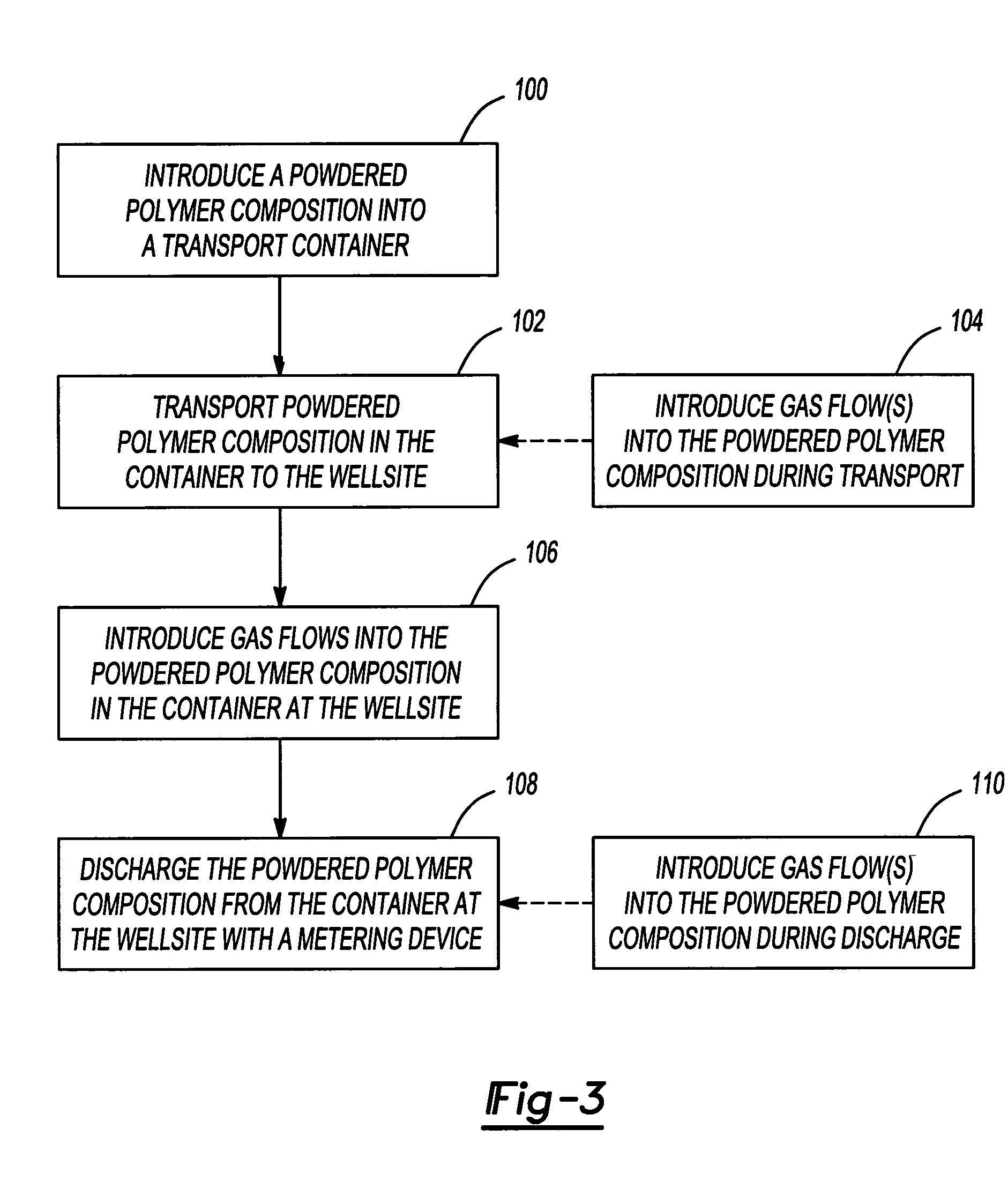

Method of supplying a powdered chemical composition to a wellsite

InactiveUS7540308B2Reduce disadvantagesPrevent the powder chemical composition from adequately flowingFluid removalSolid materialChemical compositionMaterials science

A method of conditioning a compacted polymeric powder to a flowable and meterable state. The polymeric powder is compacted during transport such that the flowability is hindered. To increase flowability, gas is introduced into the polymeric powder to condition the same to an improved flowable and meterable state.

Owner:SCHLUMBERGER TECH CORP

Paint for forming insulating film, and plasma display panel using the paint and method of manufacturing the same

InactiveUS20020063527A1Improve wettabilityLow costSynthetic resin layered productsAlternating current plasma display panelsOrganic solventInorganic materials

The present invention provides a paint for forming an insulating film, which has a good wettability to a surface to be coated with the paint and has no voids or pin-holes after being fired; a plasma display panel including a dielectric layer formed using the paint; and a method of manufacturing the plasma display panel. The paint contains inorganic fine particles, a binder resin, and an organic solvent that has a good wettability to glass such as a glass substrate, ceramic as an Ag electrode, and a metal compound such as an ITO film and forms a contact angle of less than 5° with these inorganic materials. Accordingly, the paint has a good wettability to a glass substrate, an Ag electrode, and an ITO film and the resultant insulating film thus has no voids or pin-holes.

Owner:PANASONIC CORP

Chewing gum tablet and method of dosing pharmaceutically active ingredients in such chewing gum tablet

ActiveUS8722022B2Well mixedDecrease in flowabilityOrganic active ingredientsCosmetic preparationsAdditive ingredientBULK ACTIVE INGREDIENT

A method of dosing pharmaceutically active ingredients in a compressed chewing gum tablet includes the steps of: providing one or more pharmaceutically active ingredients, mixing a chewing gum composition including the one or more pharmaceutically active ingredients and chewing gum granules, the chewing gum granules including gum base, and dosing the chewing gum composition to obtain a desired weight of the chewing gum composition and thereby obtaining a desired dose of the pharmaceutically active ingredient in the chewing gum tablet.

Owner:FERTIN PHARMA AS

Toner production method and polymer

A toner production method including: a melt-kneading step of melt-kneading a resin composition including a binder resin, a colorant, a wax, and a wax dispersant to obtain a melt-kneaded product; and a pulverizing step of pulverizing the melt-kneaded product. Where the temperature of the melt-kneaded product at the end of the melt-kneading step is Tk(° C.), and the softening point of the wax dispersant is Tm(° C.), the relationship of −18≦[Tk−Tm]≦10 is satisfied. The wax dispersant is a polymer in which a styrene acrylic polymer is graft-polymerized to a polyolefin. The styrene acrylic polymer has a monomer unit derived from α-methylstyrene and a monomer unit derived from a cycloalkyl (meth)acrylate.

Owner:CANON KK

Developing device

ActiveUS9405229B1Improve abilitySmoothly feeding developerElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

Printed circuit board and soldering method and apparatus

InactiveUS7554040B2Solder wicking is enhancedAir entrapment is preventedPrinted circuit assemblingPrinted electric component incorporationDip solderingSoldering

A printed circuit board suitable for dip soldering of component leads in through holes using lead free solder. The printed circuit board includes a plurality of via holes arranged around each through hole in which a component lead is inserted, whereby solder wicking up into the through hole is enhanced and air entrapment is prevented during the dip soldering operation, and heat fatigue resistance of solder joints is improved.

Owner:PANASONIC EV ENERGY CO LTD

Developing device

ActiveUS20160216640A1Improve abilitySmoothly feeding developerElectrographic process apparatusEngineeringMechanical engineering

Owner:CANON KK

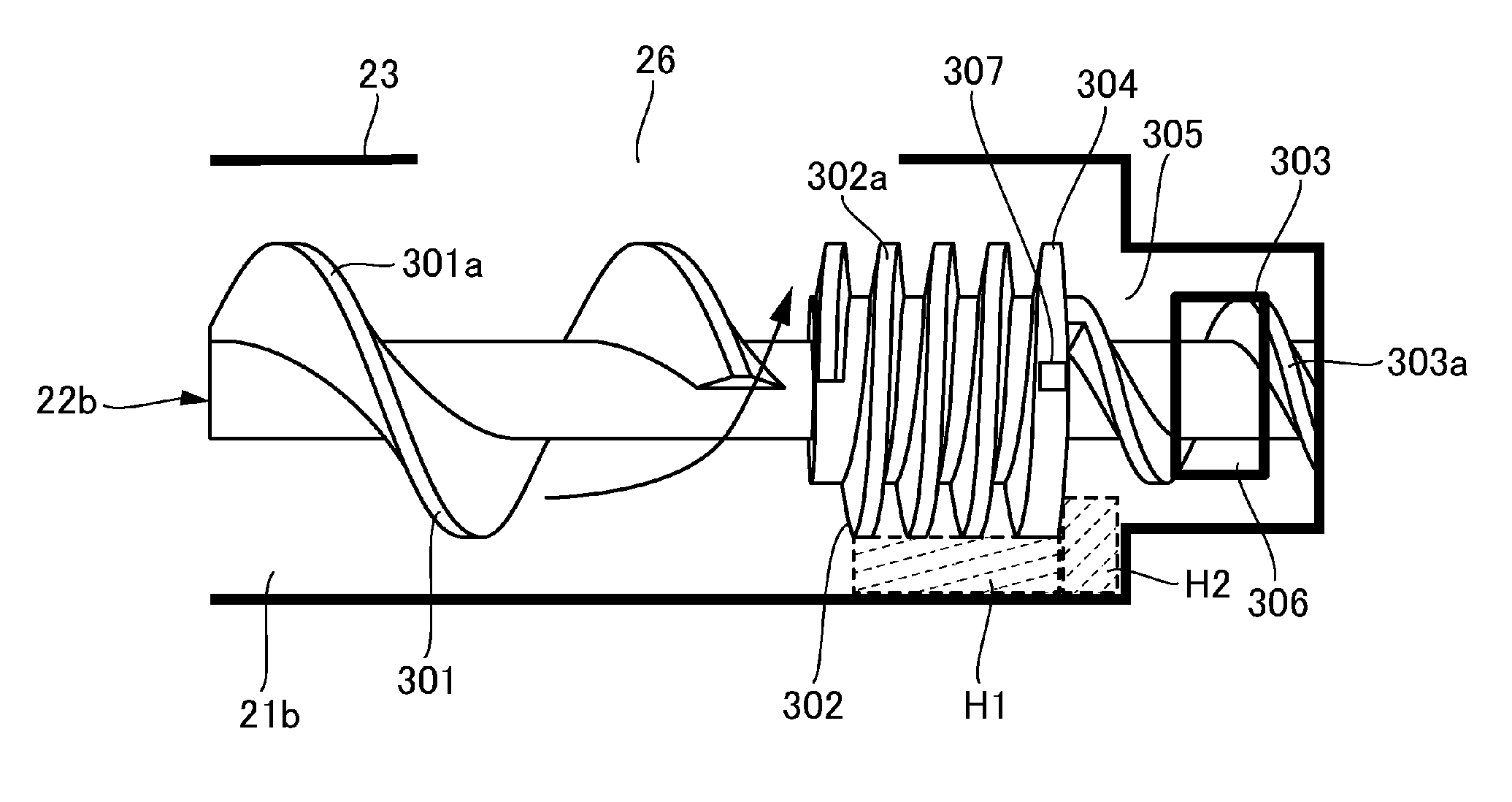

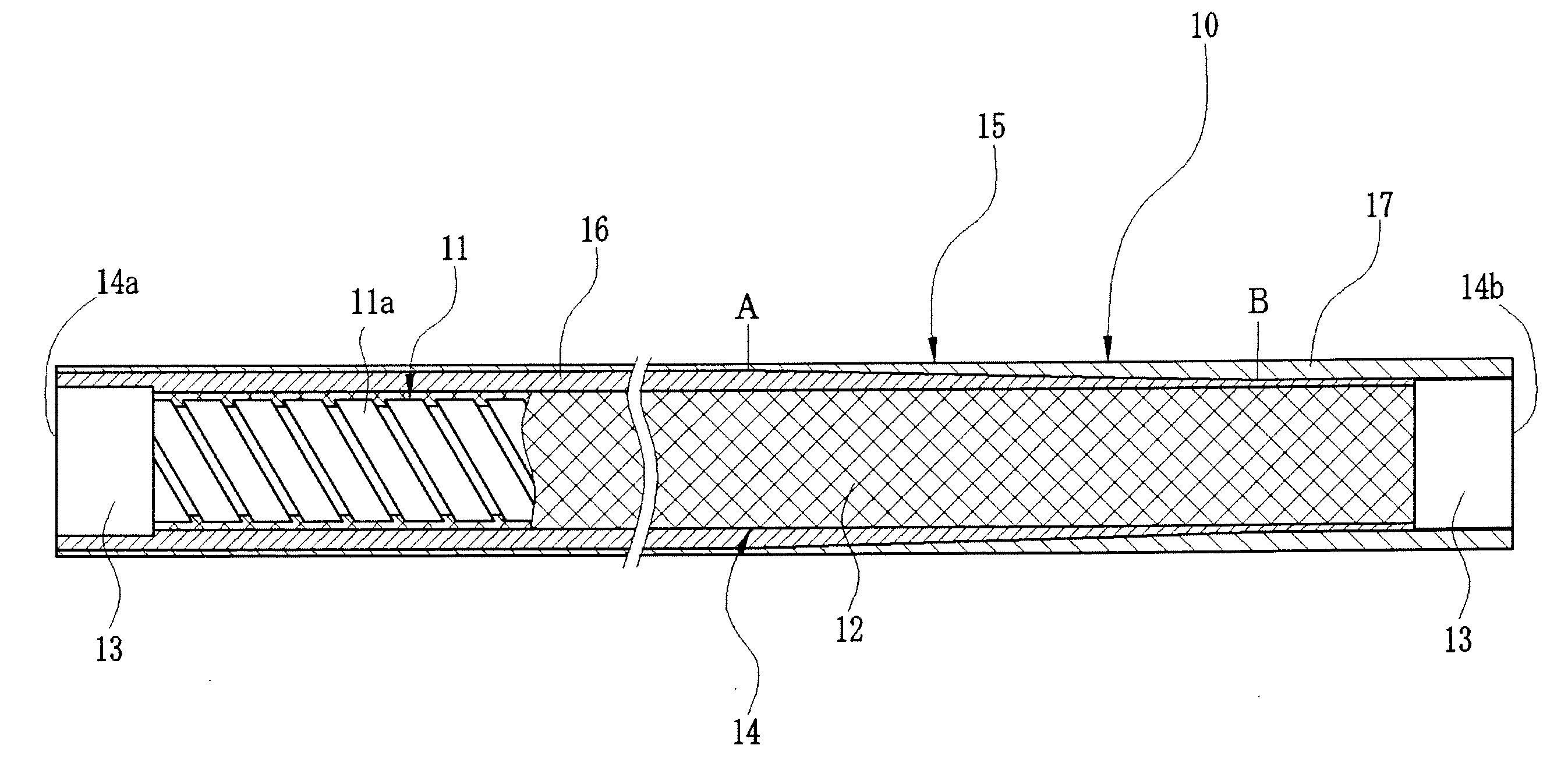

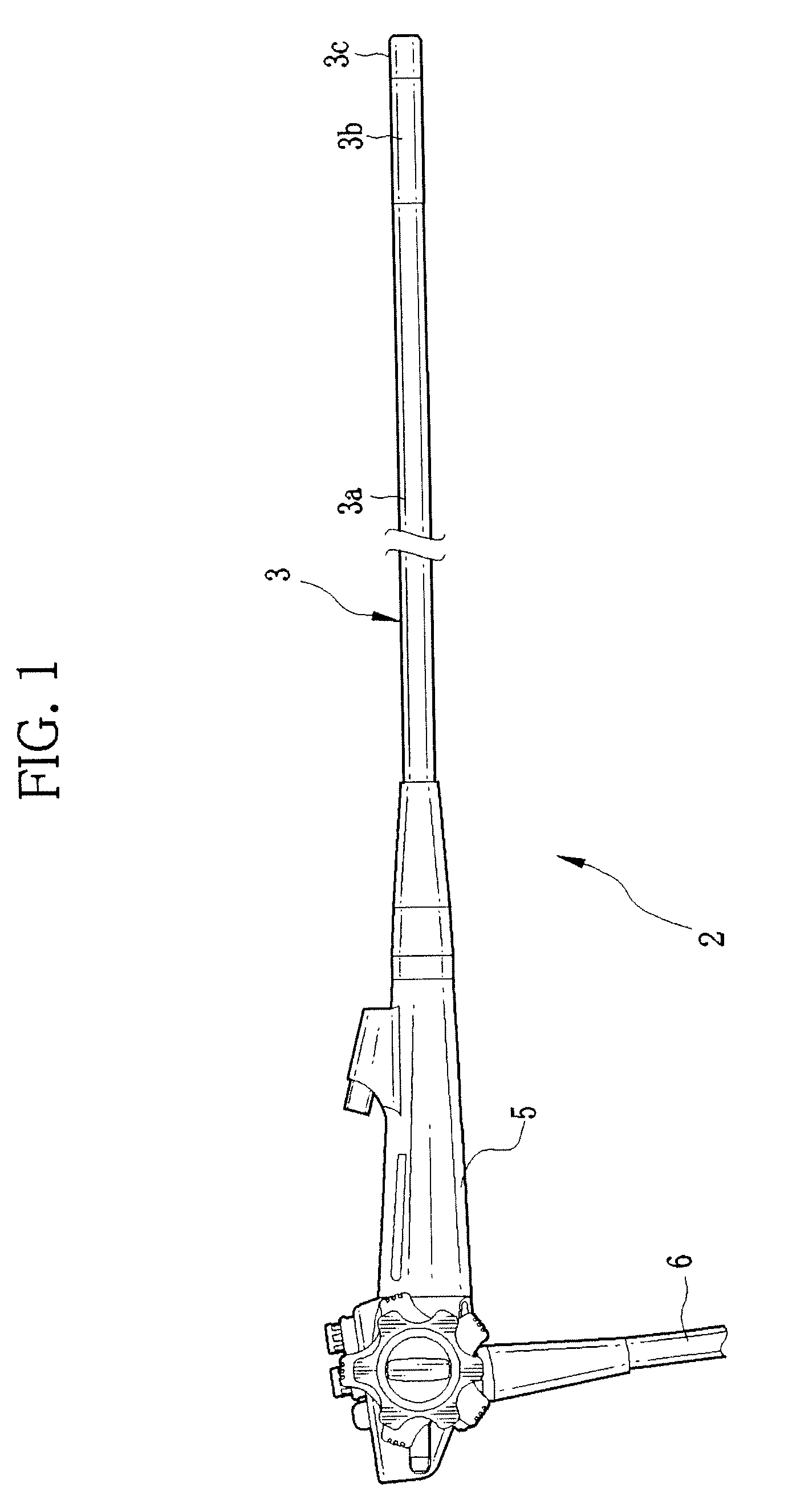

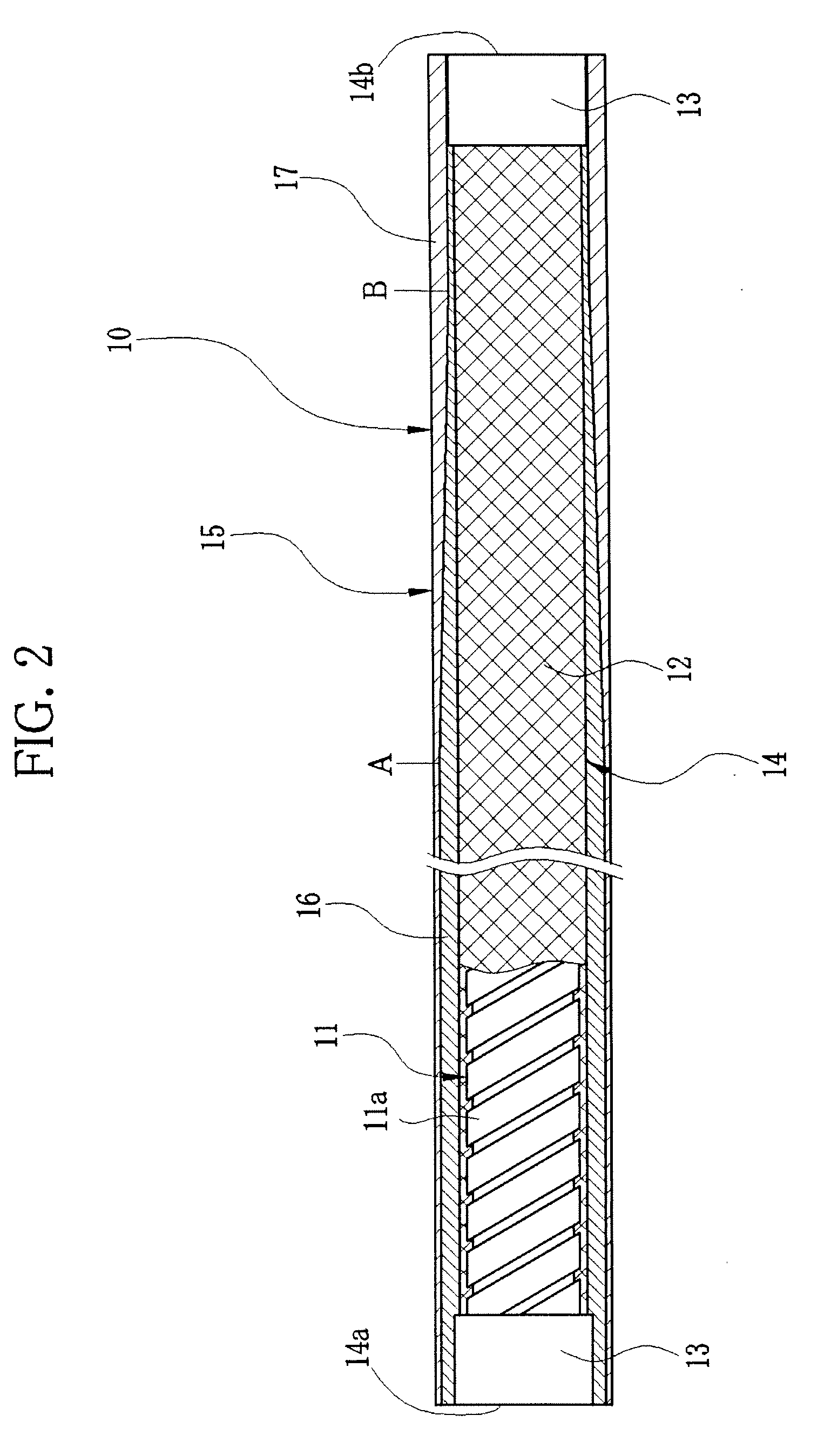

Method for production of flexible tube for endoscope

Upon starting continuous extrusion, the temperature of a hard resin and a soft resin is increased in extrusion sections. A screw of the extrusion section of the hard resin is set at high rpm at first. The hard resin reaches a maximum temperature α(° C.) by heating of friction with the screw, and comes to have high flowability. Upon starting conveyance of an assembly, a large amount of molten hard resin and a small amount of molten soft resin are extruded onto the periphery of a tubular structure. Upon passage of a point A of the tubular structure under annular discharge throats, the extrusion amount of the hard resin starts gradually decreasing, and the extrusion amount of the soft resin starts gradually increasing. Since the temperature of the hard resin starts dropping a short time after the decrease in the extrusion amount, the hard resin maintains the high flowability.

Owner:FUJIFILM CORP

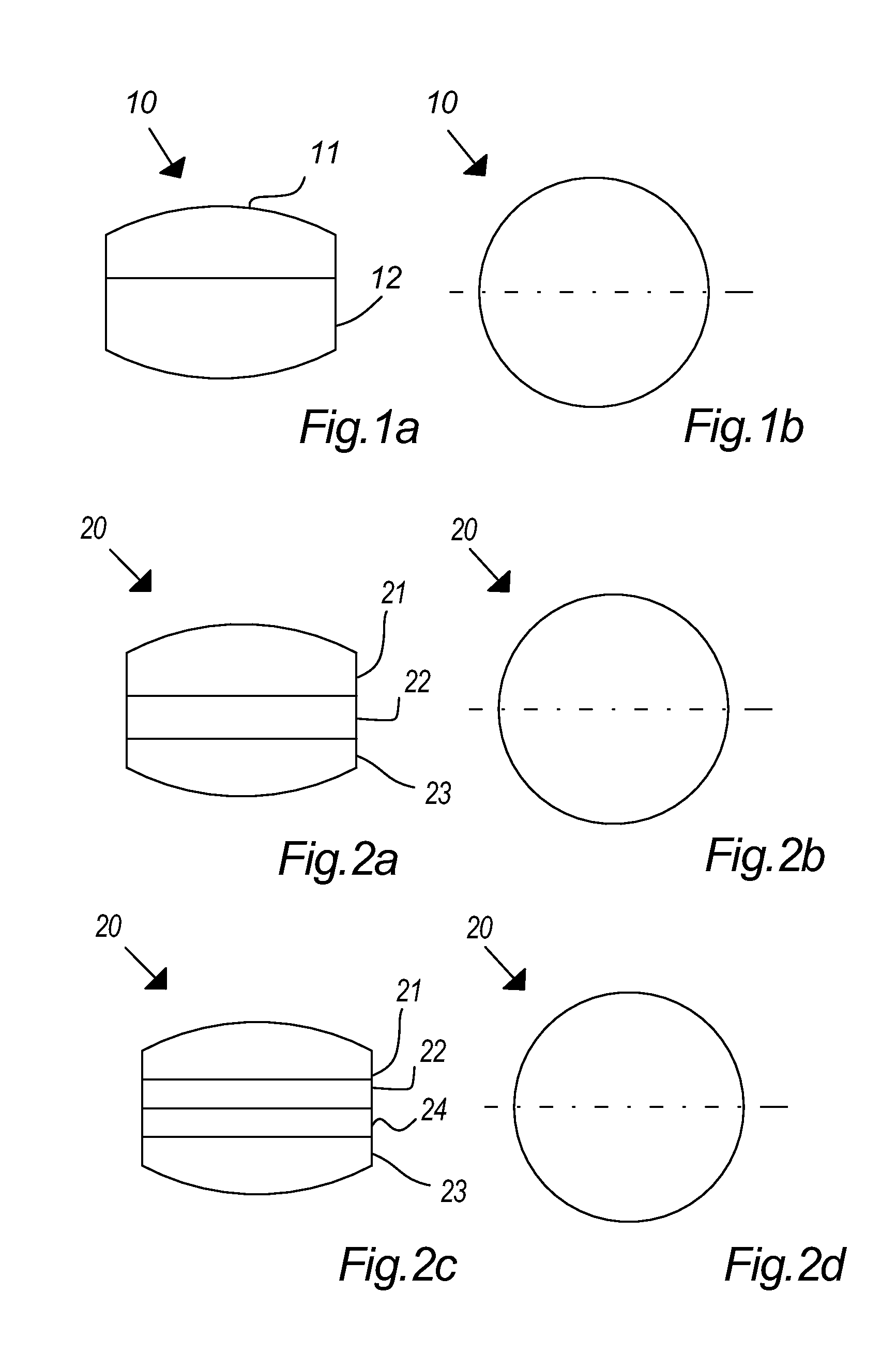

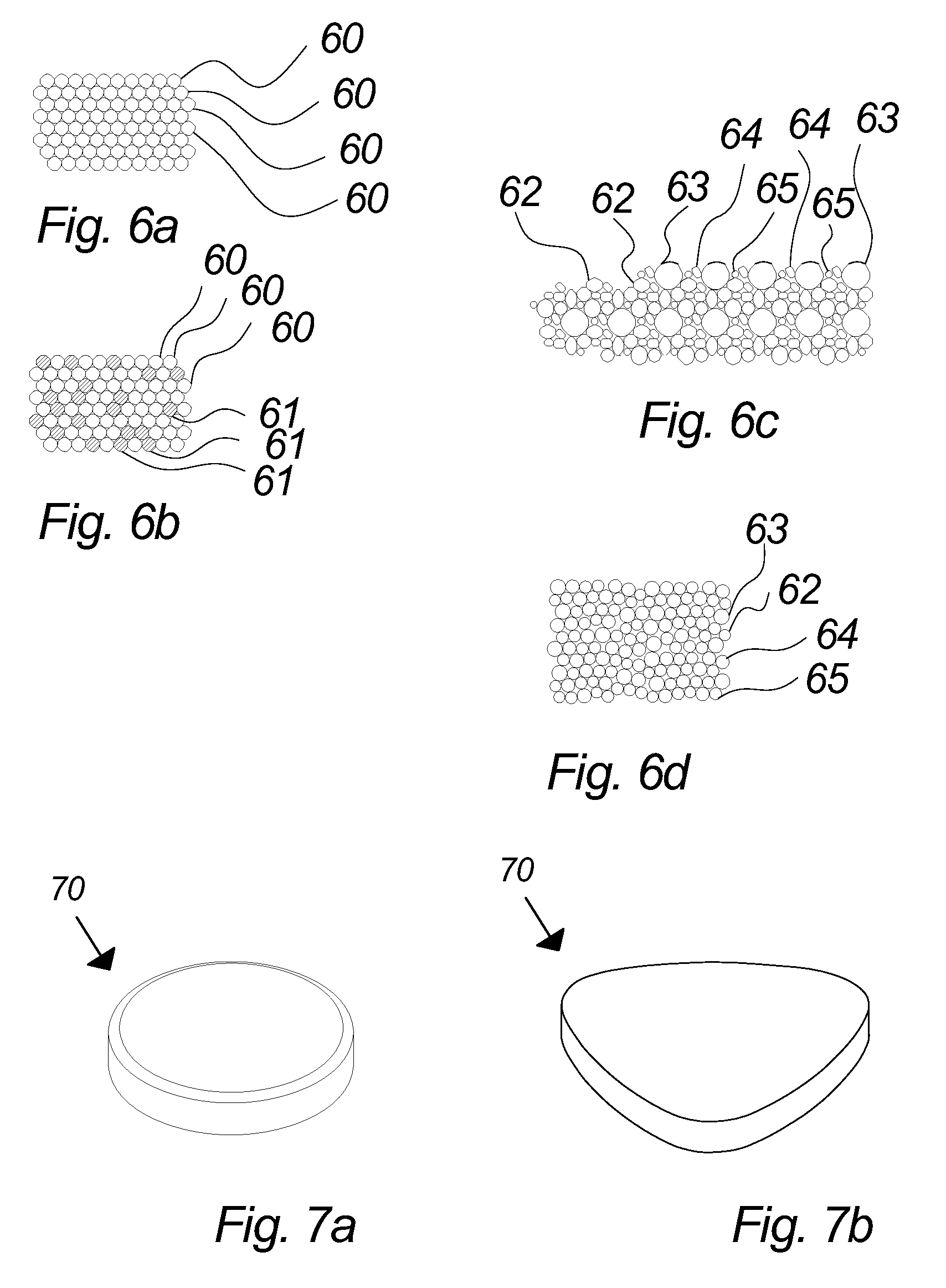

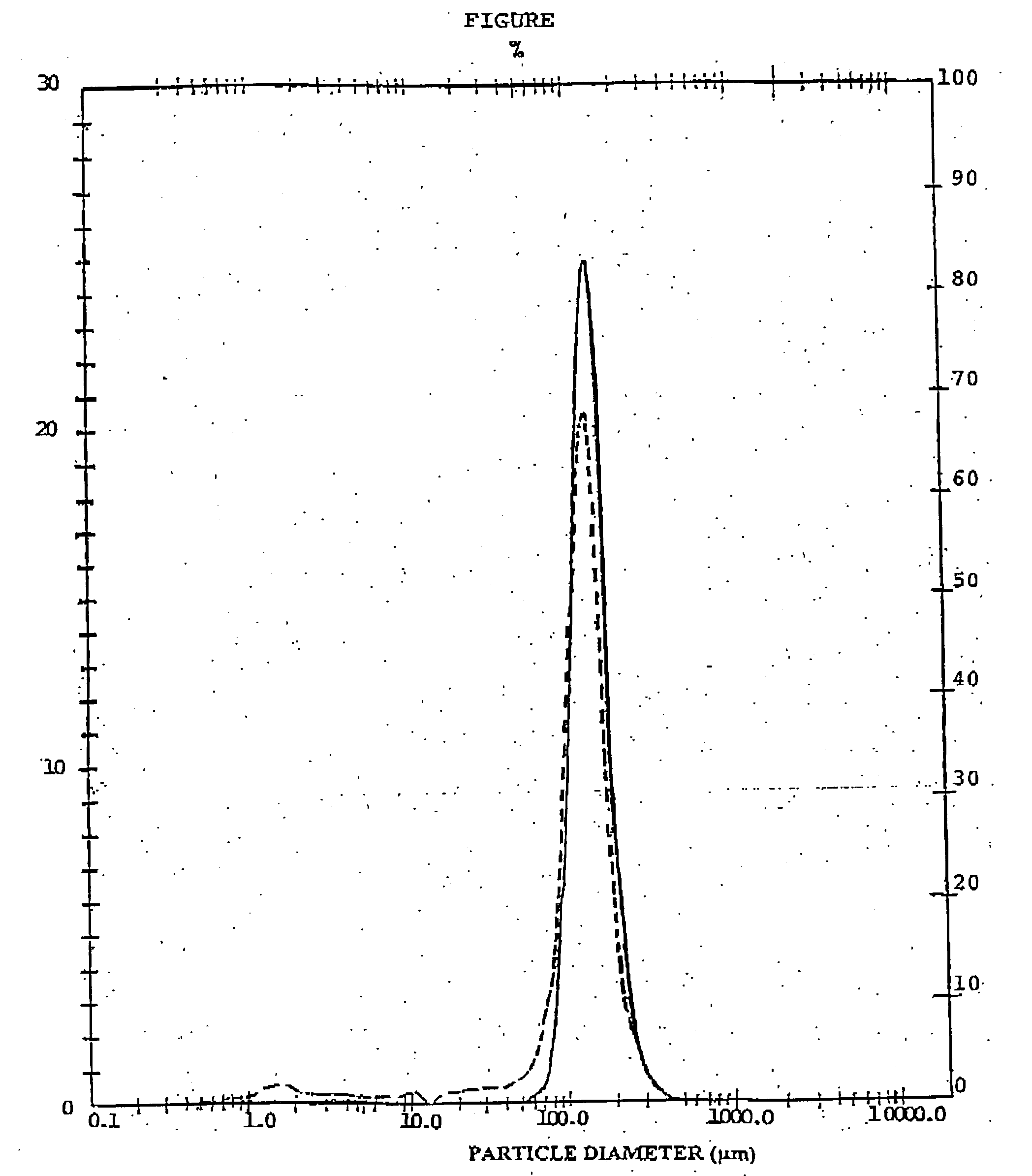

Modified carrier particles for use in dry powder inhalers

InactiveUS20040009127A1Mild conditionsDecrease in flowabilityPowder deliveryMechanical working/deformationMedicineActive particles

Owner:CHIESI FARM SPA

Coating treatment method, computer-readable storage medium, and coating treatment apparatus

ActiveUS8166913B2Improve liquidityReduce thicknessMovable spraying apparatusPhotomechanical apparatusResistLow speed

In the present invention, a substrate is first rotated at a first rotation speed, and a resist solution is applied to the rotated substrate. Subsequently, the rotation of the substrate is decelerated to a second rotation speed lower than the first rotation speed so that the substrate is rotated at the low speed to smooth the resist solution on the substrate. The rotation of the substrate is then accelerated to a third rotation speed higher than the second rotation speed, and a solvent for the coating solution and / or a dry gas are / is supplied to the resist solution on the substrate. In this event, the solvent gas is supplied to a portion of the resist solution on the substrate thicker than a set thickness, and the dry gas is supplied to a portion of the coating solution on the substrate thinner than the set thickness. This thins the thicker portion of the resist solution and thickens the thinner portion to uniform the resist solution.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com