Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

406results about How to "Reduce backmixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

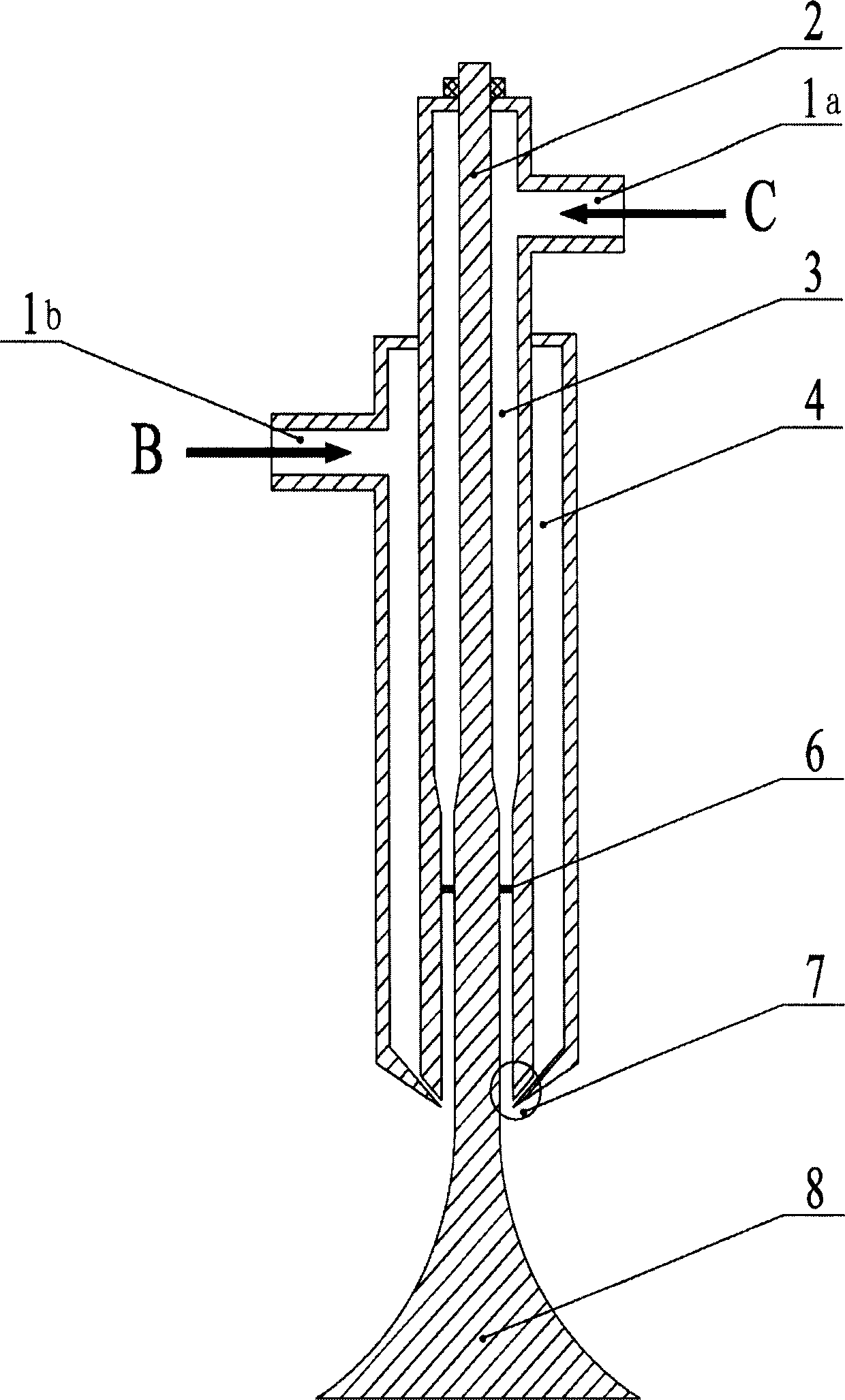

Liquid-solid circulating fluidized bed waste water treatment system for simultaneous carbon, nitrogen and phosphorus removal

InactiveUS20040178132A1Easy to adaptIncrease contactTreatment using aerobic processesIon-exchanger regenerationActivated sludgeOxygen

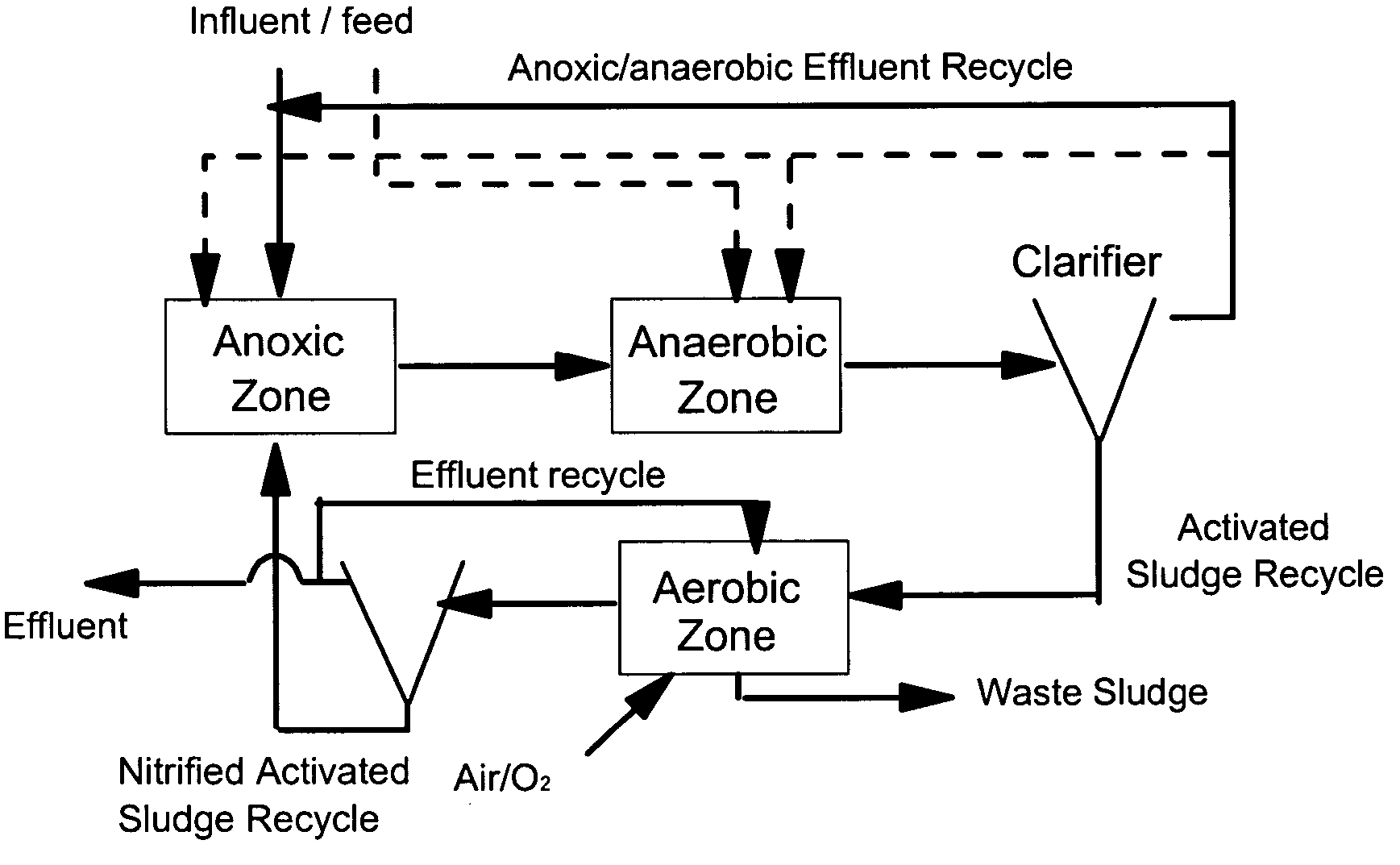

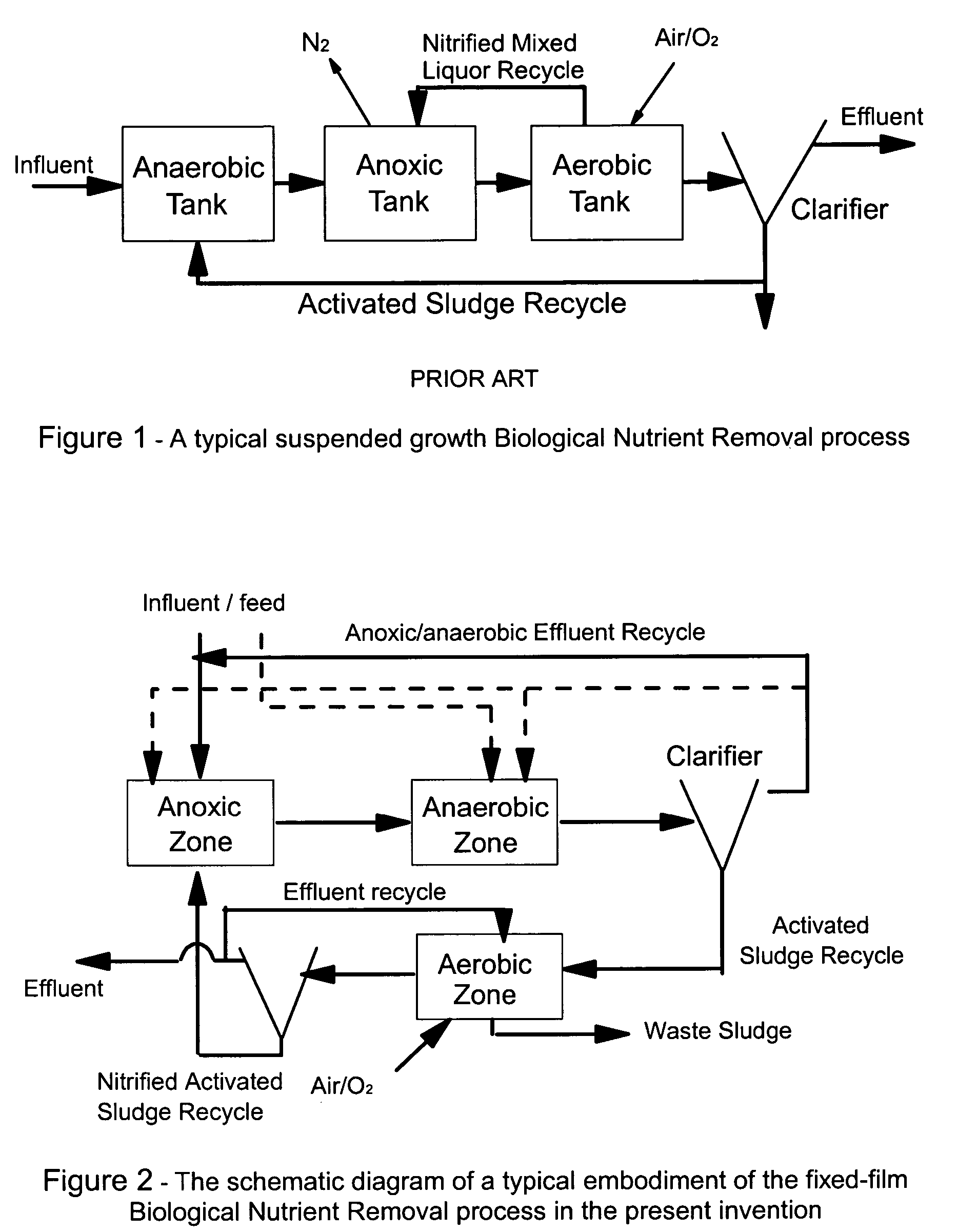

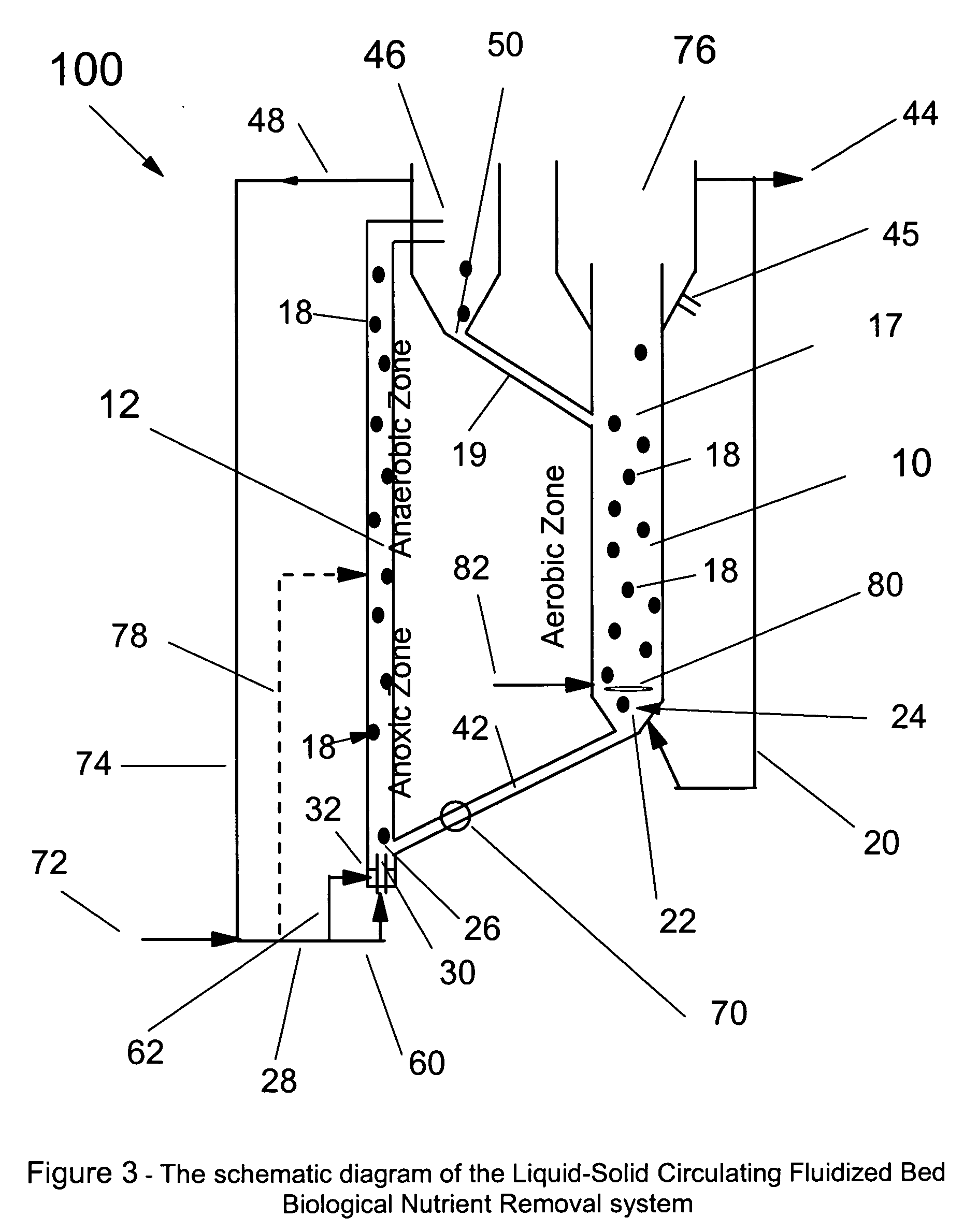

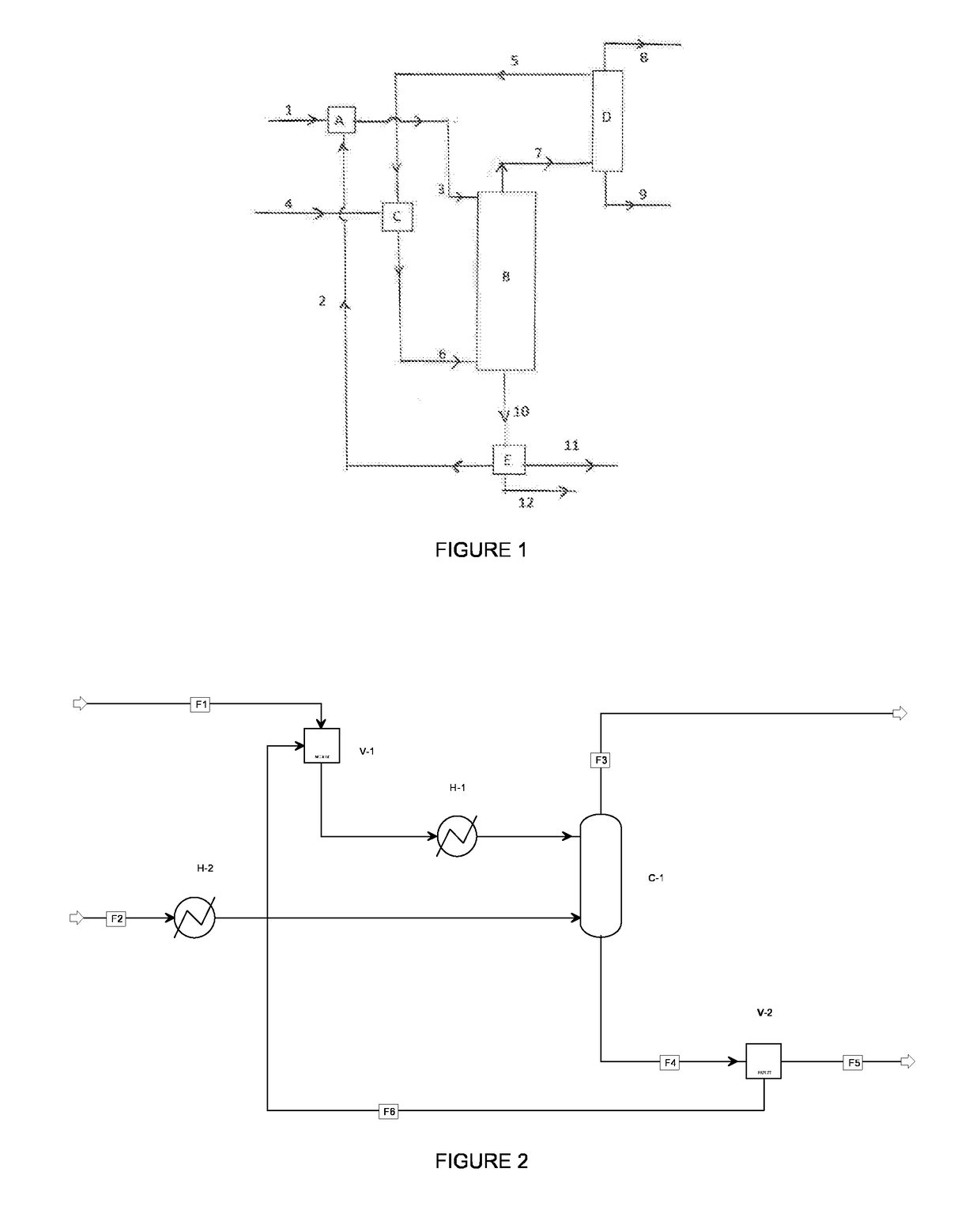

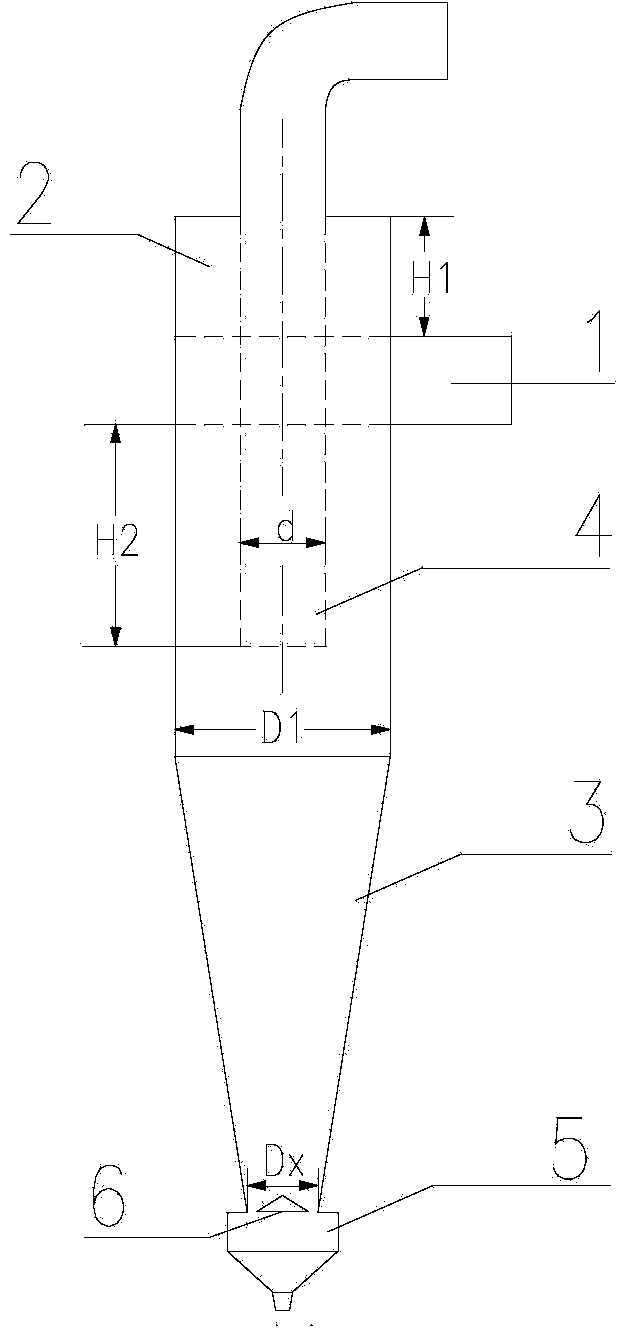

Biological nutrient removal (BNR) in municipal wastewater treatment to remove carbonaceous substrates, nutrients and phosphorus, has recently become increasingly popular worldwide due to increasingly stringent regulations. Biological fluidized bed (BFB) technology, which could be potentially used for BNR processes, can provide some advantages such as high efficiency and compact structure. This present invention incorporates the fixed-film biological fluidized bed technology with the biological nutrient removal in a liquid-solid circulating fluidized bed, which has achieved the simultaneous elimination of organic carbon, nitrogen and phosphorus, in a very efficient manner and with very compact space requirements. The BNR-LSCFB has two fluidized beds, running as anoxic / anaerobic and aerobic processes to accomplish simultaneous nitrification and denitrification and to remove carbonaceous substrates, nutrients and phosphorus, with continuous liquid and solids recirculation through the anoxic / anaerobic bed and the aerobic bed. The new BNR-LSCFB system is not only an excellent alternative for conventional activated sludge type BNR technologies but is also capable of processing much higher loadings and suitable for industrial applications.

Owner:UNIV OF WESTERN ONTARIO

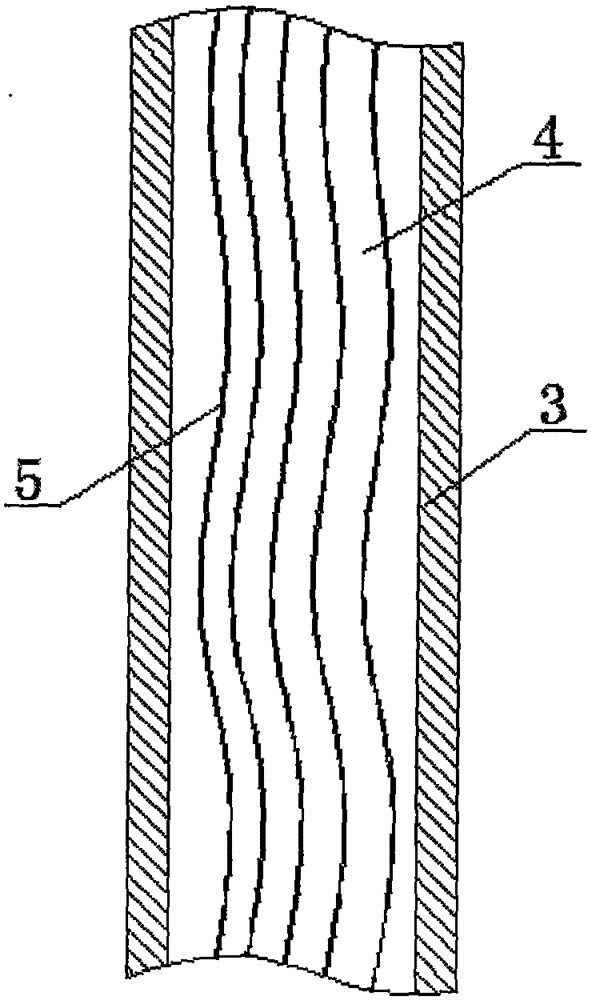

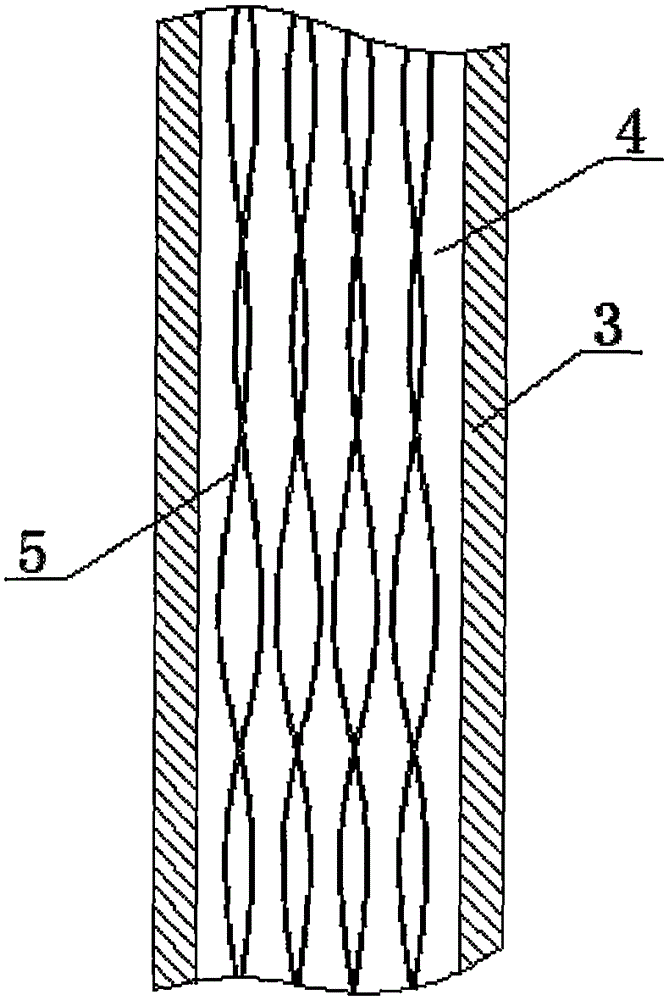

Chemical reactor

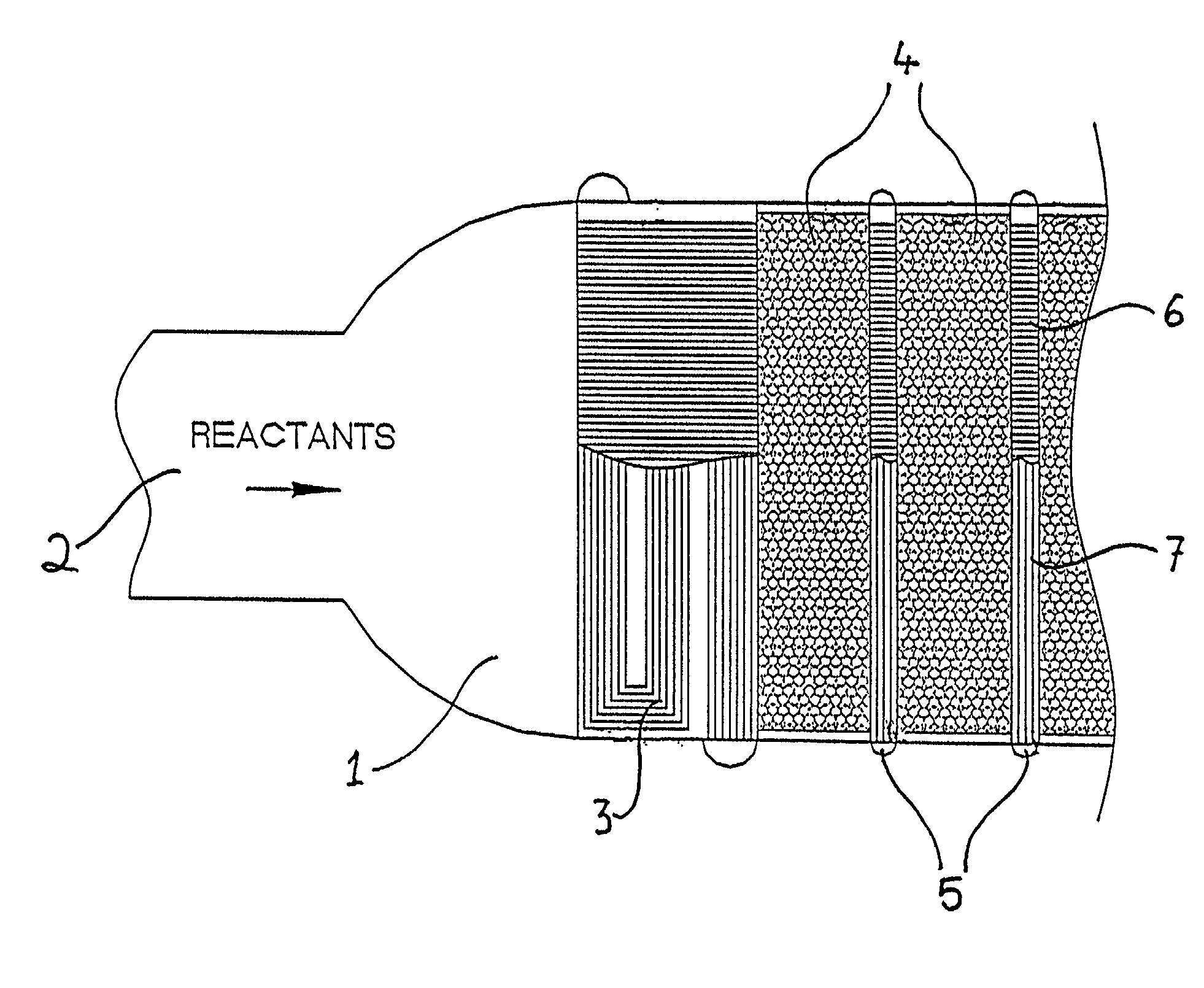

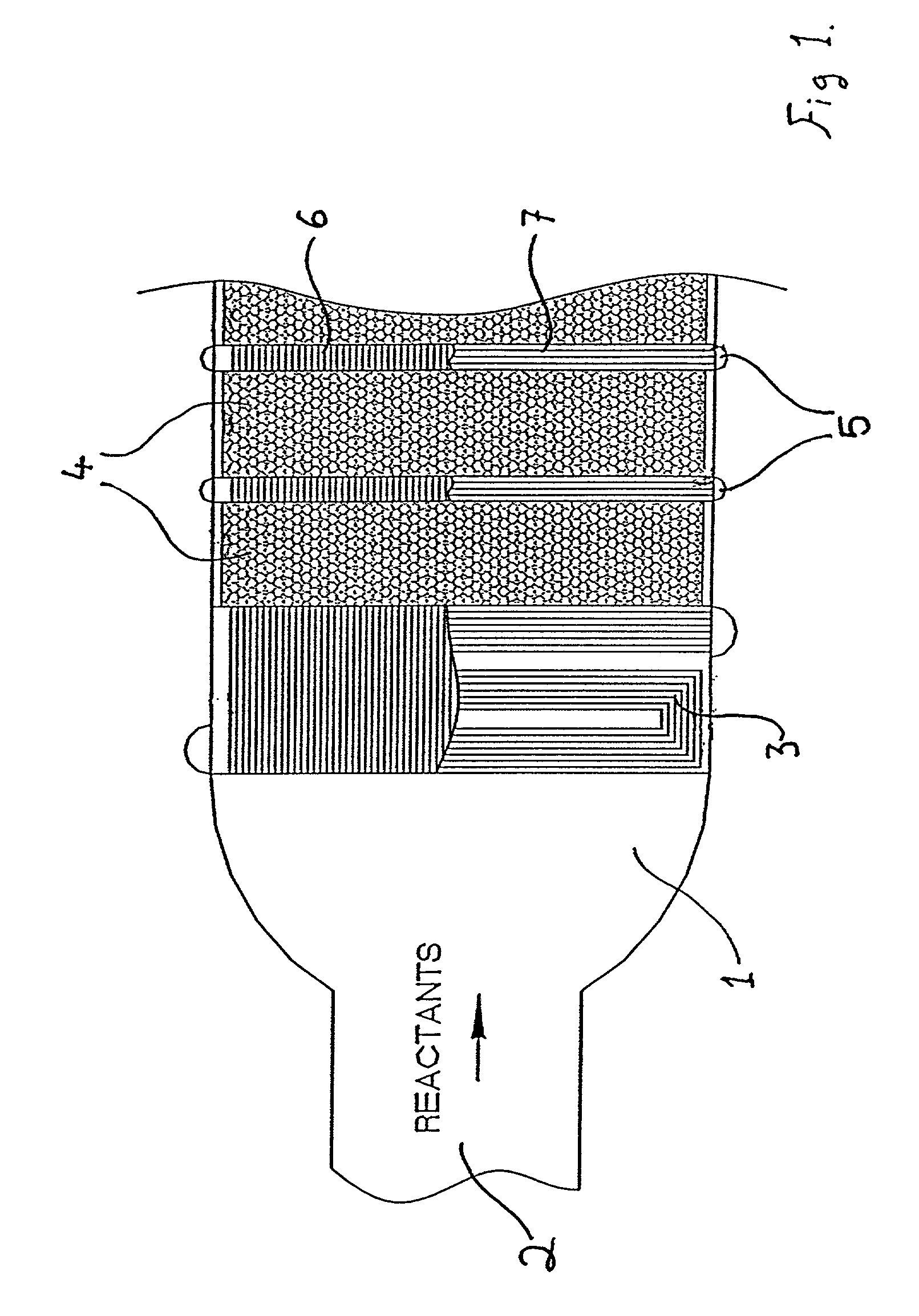

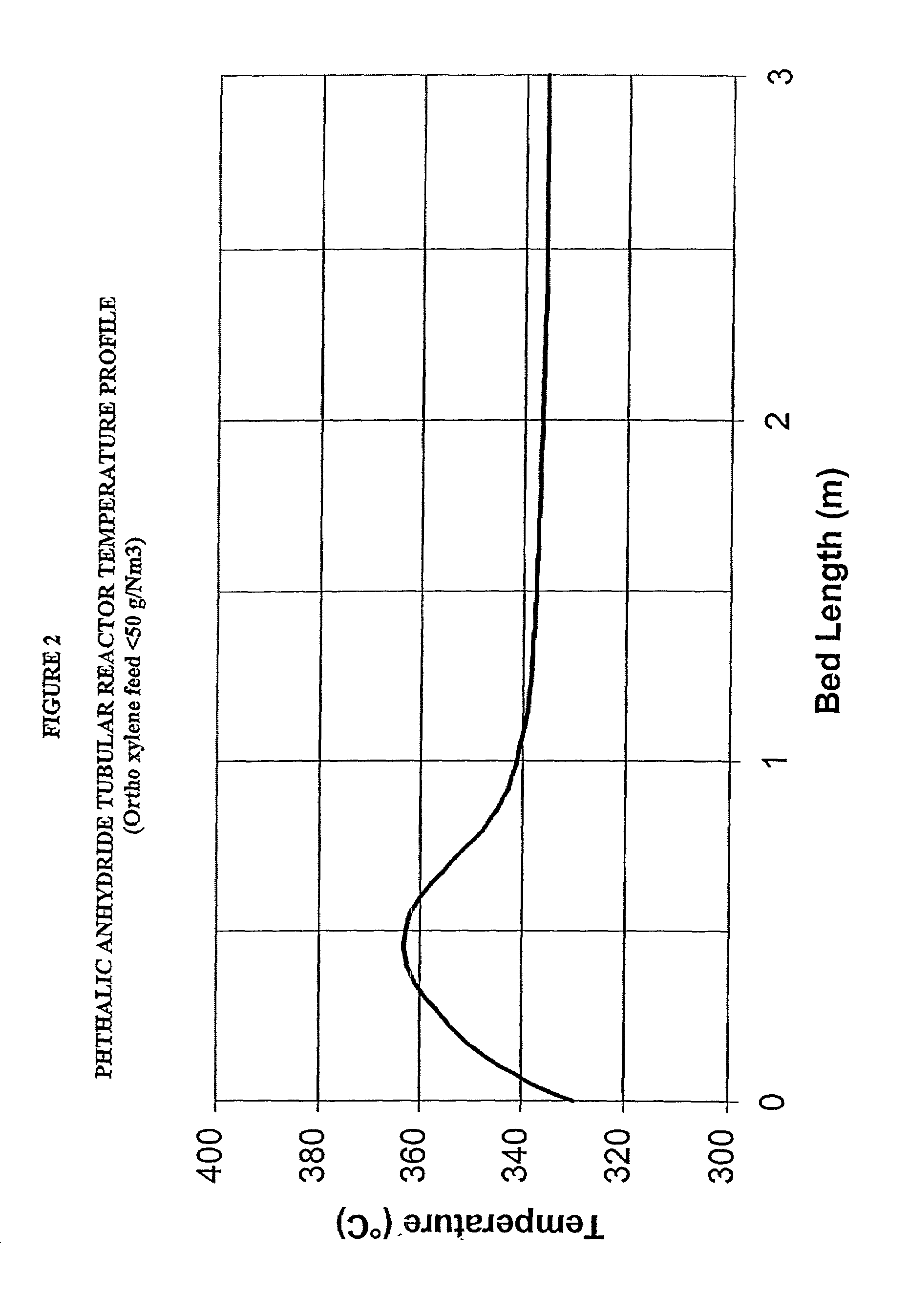

InactiveUS7033553B2Tight controlReduce backmixingPhysical/chemical process catalystsChemical/physical/physico-chemical processesWorking fluidChemical reactor

A reactor comprises a reaction zone, optionally containing a catalyst bed, and heat exchange means inoperative contact with the reaction zone, e.g. embedded in a catalyst bed, and arranged so as to received reactants for heat exchange purposes, wherein the heat exchange means is formed from a plurality of superposed metal plates wherein fluid flow channels have been formed, according t a pre-determined pattern, the channel-bearing plates being aligned during superposition to define discrete heat exchange pathways respectively for reactant and working fluids, and the said plates are diffusion bonded together.

Owner:MEGGIT (UK) LTD

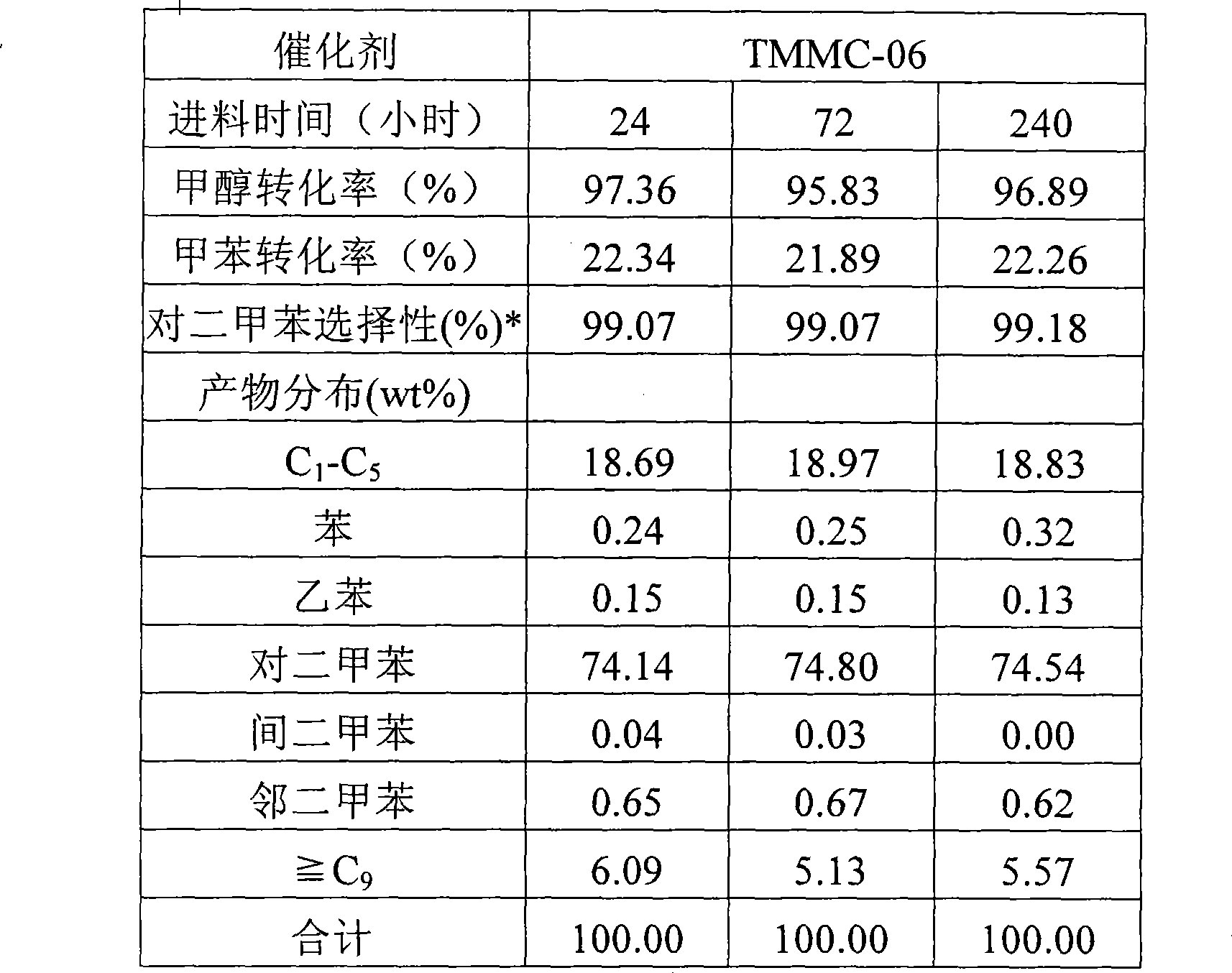

Method for preparing p-xylene and co-producing light olefins by toluene and methylating reagent

InactiveCN101456784AReduce wearHigh activityHydrocarbon by hydrocarbon and non-hydrocarbon condensationChemical recyclingMoving bedResidence time

The invention relates to a method for preparing para-xylene and coproducing low-carbon olefin from toluene and a methylated reagent. The method comprises: a granular catalyst is continuously added from the top of a reactor by moving bed reaction technology, and gradually moved down along with the reaction, continuously flows out from the bottom to a regenerator, and is regenerated; the raw materials, namely the toluene and the methylated reagent, enter a vaporizer for mixing and gasification, enter the reactor, pass through a catalyst bed from the bottom up (or top down), and are subjected to contact reaction with the catalyst; and gaseous mixture products after reaction flow out from the top (or bottom) of the reactor and are separated. The selectivity of the para-xylene in the products in a xylene isomer is more than 99 weight percent, and the selectivity of ethylene and propylene in low-carbon hydrocarbon between C1 and C5 is more than 90 weight percent. The moving bed catalyst has stable activity and can be continuously regenerated; the residence time of solid and fluid in the moving bed reactor can be adjusted; back mixing of materials is small; the conversion rate of the raw materials is improved; and abrasion of the catalyst is small.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

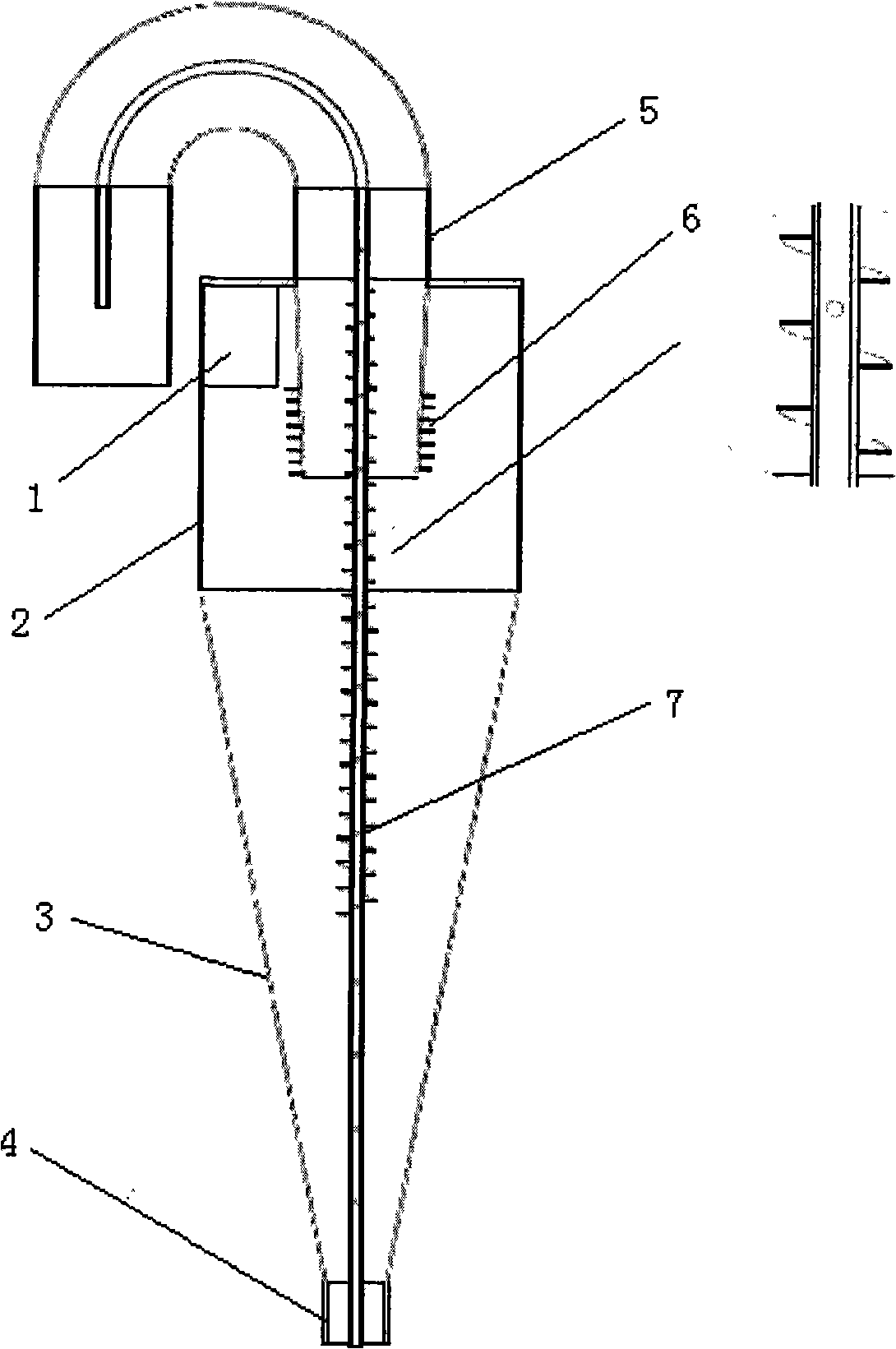

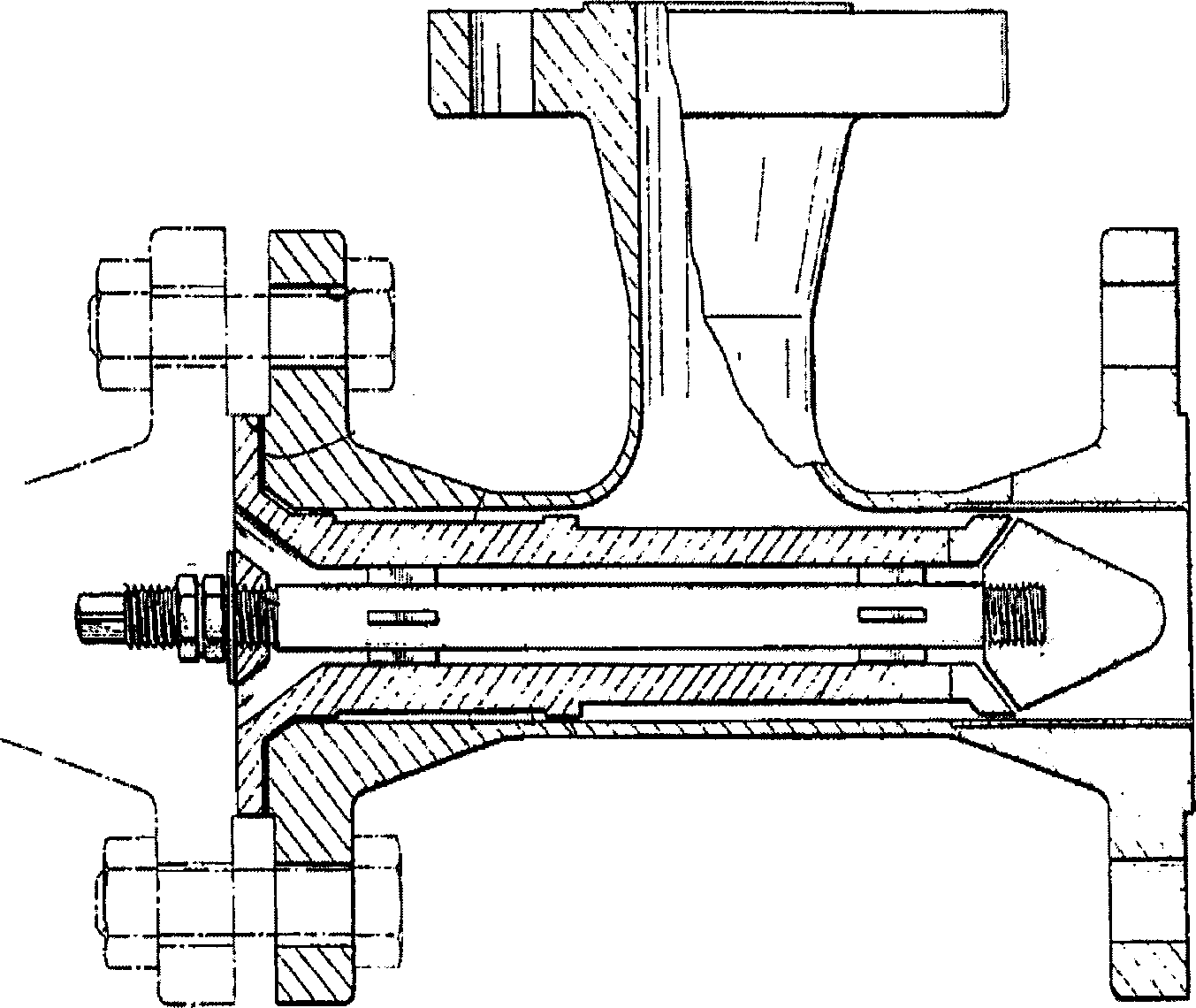

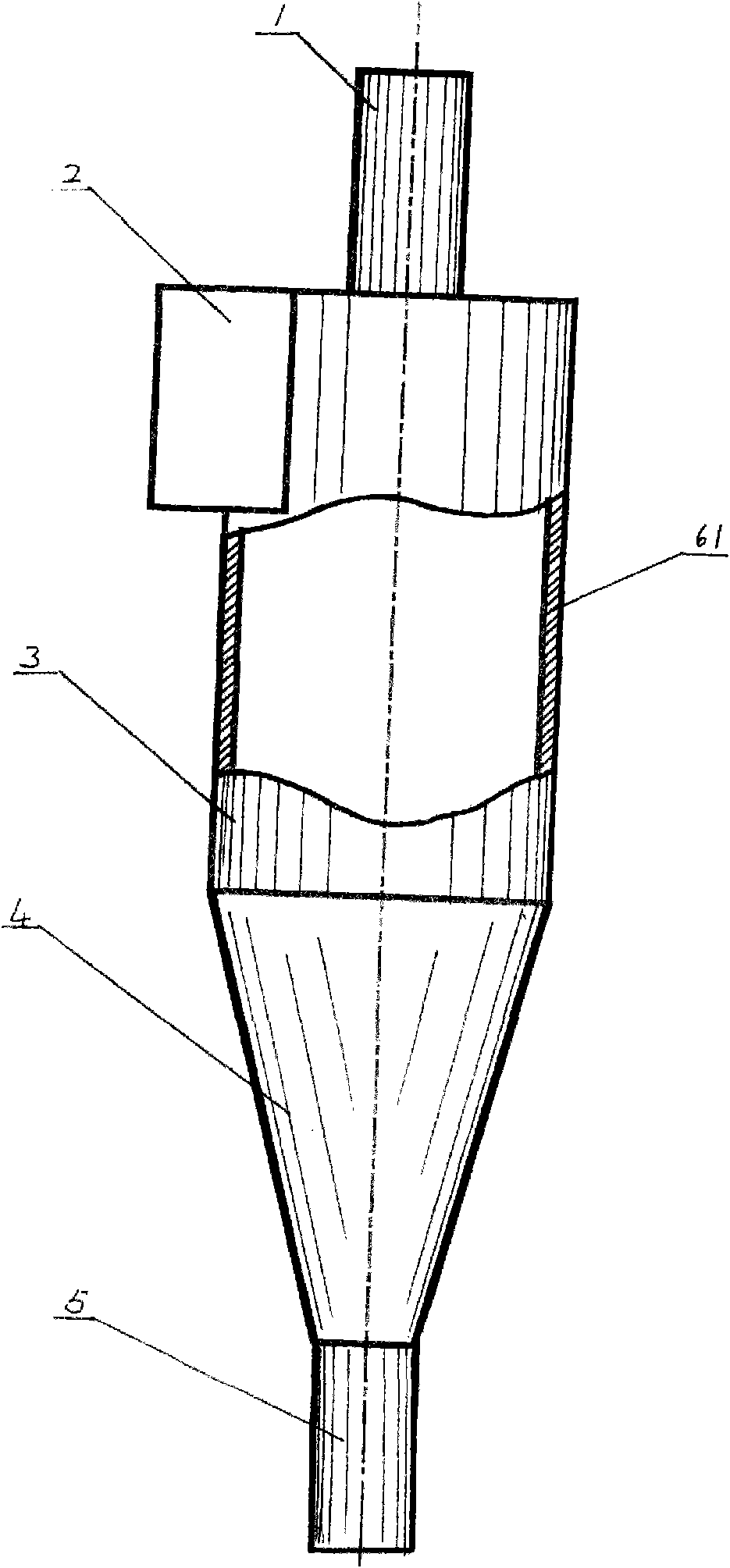

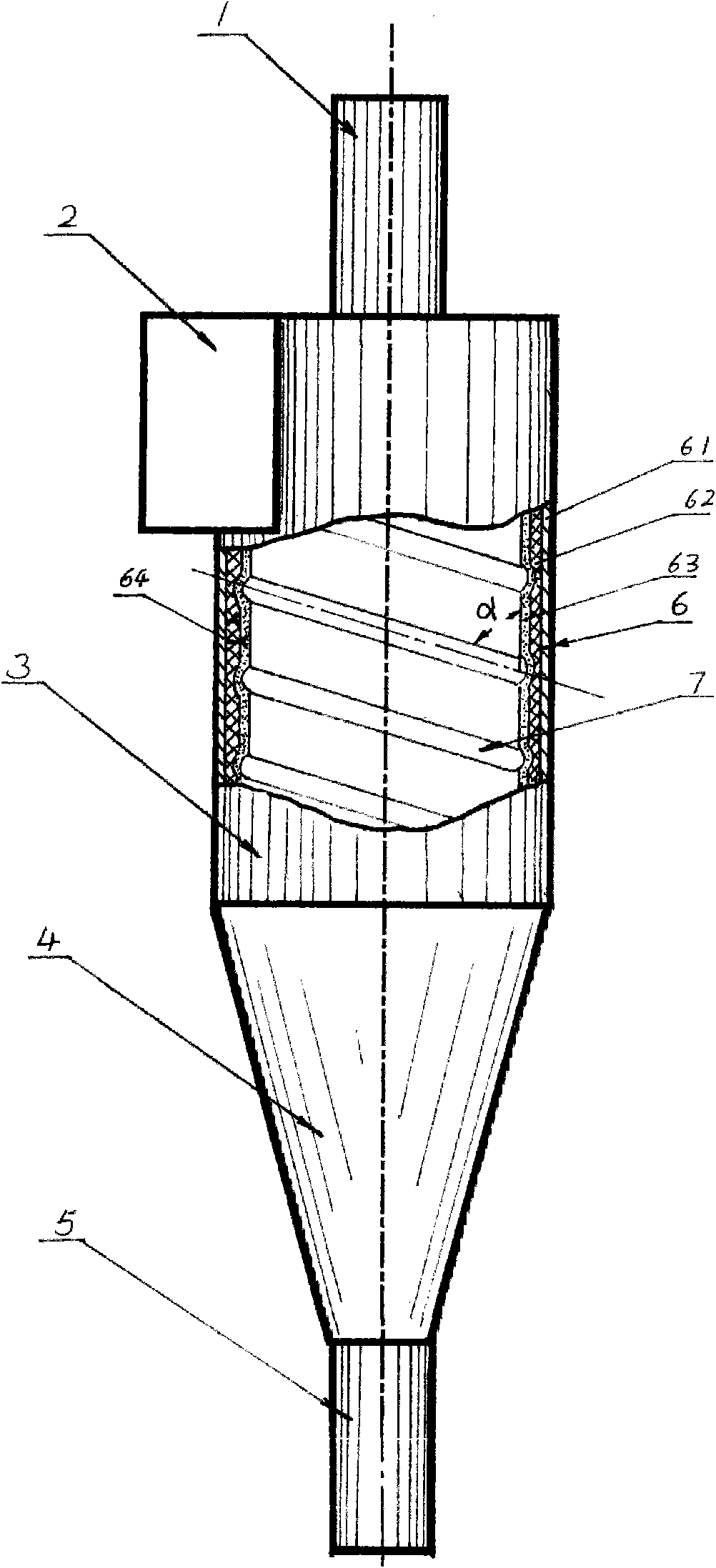

Water cyclone with improved base pipe and overflows structure

InactiveCN101254489ASimple structureReduce energy consumptionReversed direction vortexCycloneEngineering

The invention belongs to a device for solid-liquid separation / classification and non-homogeneous separation, specifically a hydraulic cyclone with improved structure of central post and overflow pipe. The device comprises a feed pipe, a cylindrical section, a coniform section, an overflow pipe and a hollow tubular central post with partial-spiral fins and spiral flow deflectors and provided outside the overflow pipe. The central post is a hollow tube provided thereon with a plurality of holes. The spiral flow deflectors are provided on the outer surface of the central post. The spiral fins are provided on the overflow pipe from the bottom of the overflow pipe to a height below the bottom of an inlet pipe. Compared with the prior art, the separation efficiency of the hydraulic cyclone is increased by 5-10% and the energy consumption is reduced by 20%. The hydraulic cyclone has high stability and reliability in separation efficiency and is suitable for solid-liquid separation in ore dressing, dredging, chemical and petroleum industries.

Owner:EAST CHINA UNIV OF SCI & TECH

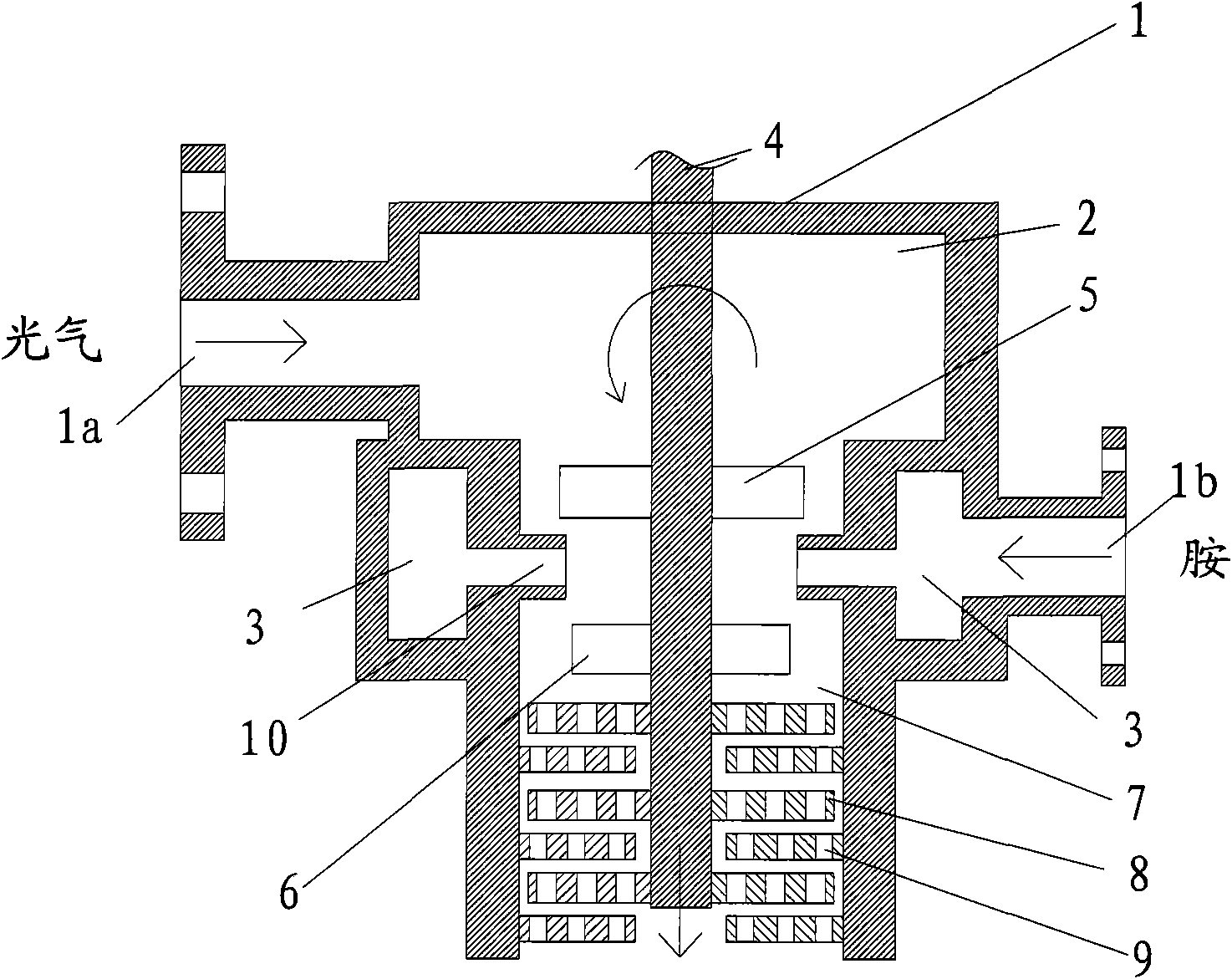

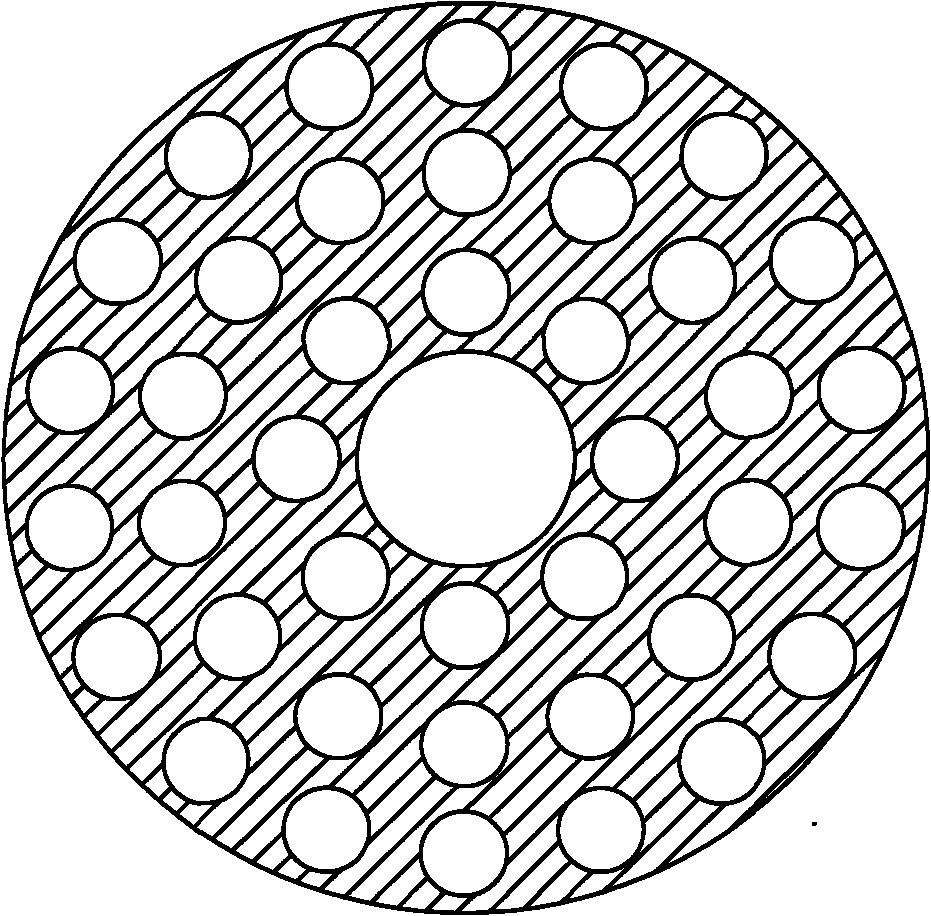

Stirring and grinding reactor and method for preparing isocyanate with same

ActiveCN101811017AIncreased initial mixingRapid responseIsocyanic acid derivatives preparationOrganic compound preparationSolid reactionEngineering

The invention relates to a stirring and grinding integrated reactor and a method for preparing isocyanate by using the reactor. The reactor comprises a reactor shell, a first reactant feeding hole, a first reactant distributing tray, a second reactant main feeding hole, an annular second reactant distributing tray, a stirring shaft, an axial stirring paddle, a radial stirring paddle, a dynamic grinding sheet, a static grinding sheet and at least one second reactant sub feeding hole, wherein the dynamic and static grinding sheets are provided with a plurality of passage holes. Quick mixing and quick reaction between the raw materials are realized by axial and radial strong stirring and a feeding method of a strongest mixing area, and the solid reaction product is further pulverized by hole passage type quick grinding combined through multilayer dynamic and static grinding trays so as to enhance the reaction effect, improve the yield and quality of the isocyanate, reduce the using amount of a solvent and the excess ratio of phosgene, improve the yield of the device, improve the quality of the product and reduce the energy consumption.

Owner:WANHUA CHEM GRP CO LTD +1

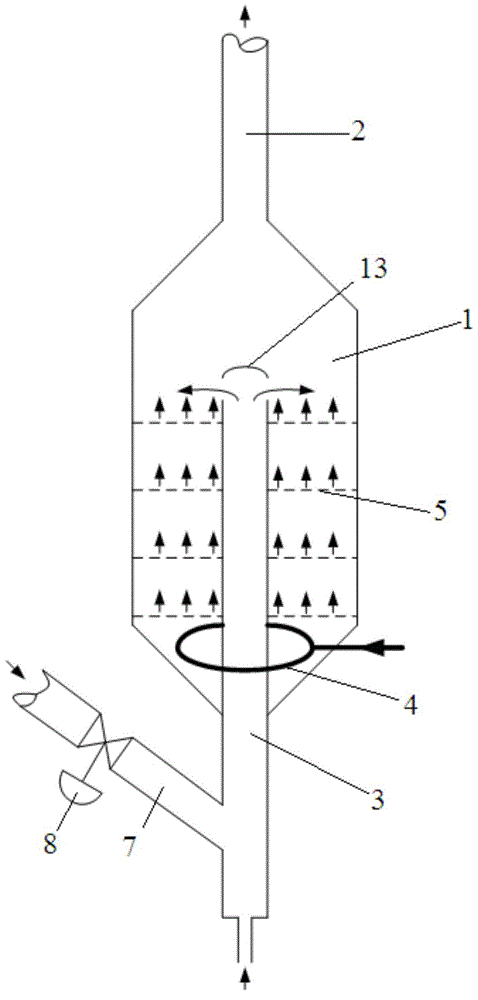

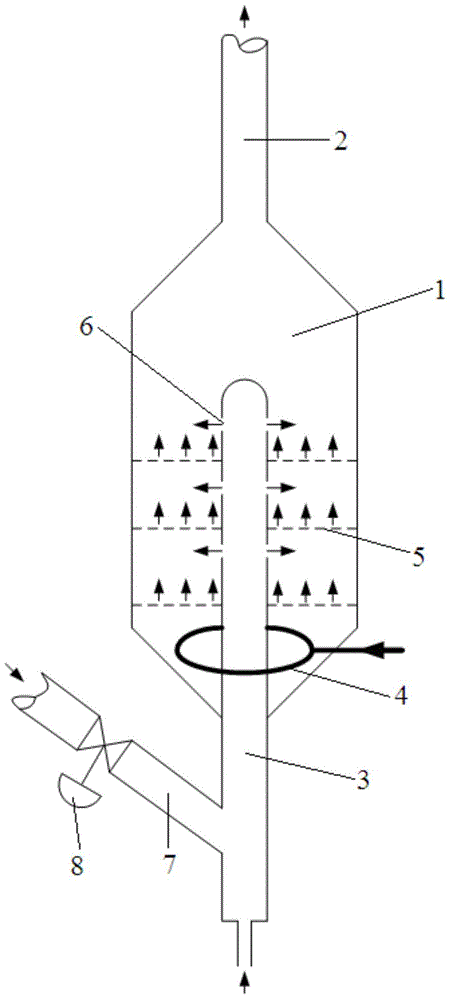

Fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO)

InactiveCN104437274AImprove contact reaction efficiencyHigh selectivityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedAlkene

The invention discloses a fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO), which comprises a reactor and a pre-riser; the reactor comprises a dense phase fluidized bed reactor and a dilute phase conveying reactor which are positioned at same axis, the pre-riser and the dilute phase conveying reactor are respectively positioned at upper part and lower part of the dense phase fluidized bed reactor; diameter of the pre-riser is smaller than diameter of the dense phase fluidized bed reactor, the upper part of the pre-riser extends into the dense phase fluidized bed reactor; an upper end port of the pre-riser in the dense phase fluidized bed reactor is sealed, and a perforate is provided on the tube wall of the pre-riser in the dense phase fluidized bed reactor; or the perforate is provided on the upper end of the pre-riser in the dense phase fluidized bed reactor, and a baffle plate is arranged over the perforate. The reactor is capable of increasing gas-solid contact efficiency, the backmixing degree of oil gas and a catalyst is less, and conversion rate of one way of the light olefin cracking and Methanol To Olefin (MTO) reactions can be greatly improved, and the target product micromolecule olefin selectivity can be greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

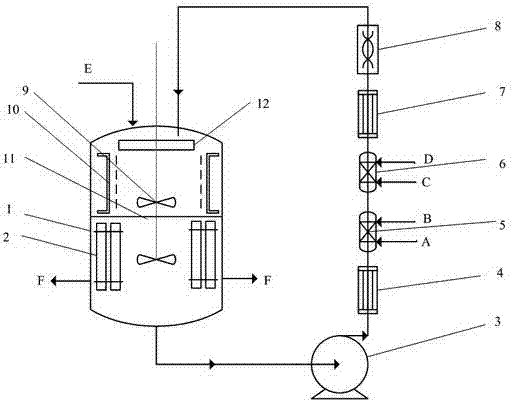

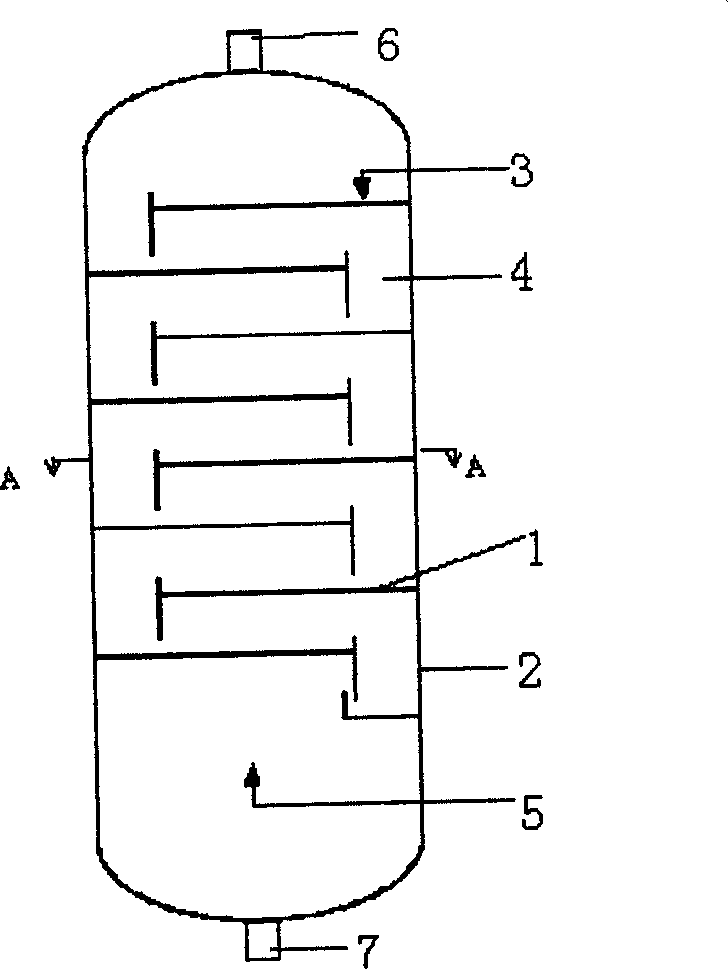

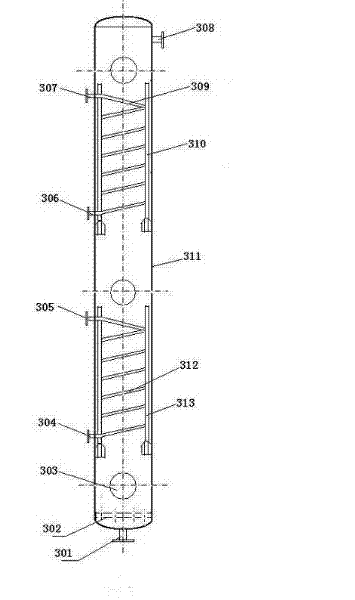

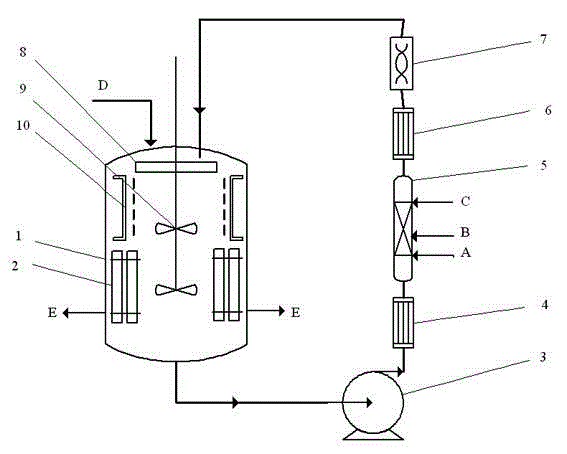

Ammoximation reaction and separation coupling process and device

The invention discloses an ammoximation reaction and separation coupling process which comprises the following steps: continuously adding reaction raw materials and a solvent in different groups outside a reaction kettle into a pipeline reactor for reaction, mixing the components in a mixer, and subsequently feeding the mixture into the reaction kettle for sufficient reaction, wherein the upper part of the reaction kettle is a reaction zone, and the lower part of the reaction kettle is a filtration separation zone; separating a reaction product, namely, cyclohexanone-oxime from a catalyst in the filtration separation zone, feeding the separated cyclohexanone-oxime into a later process, and circulating the catalyst back to the reaction kettle for continuous reaction through equipment such as the pipeline reactor outside the reaction kettle. Backwashing is performed once every 10-300 seconds, so that the continuity of reaction separation is ensured. As the raw materials sufficiently contact the catalyst, the reaction is complete, and the conversion rate of cyclohexanone can be 99.9-100%. The whole set of reaction separation devices is reasonable in arrangement and stable in reaction.

Owner:河北美邦工程科技股份有限公司

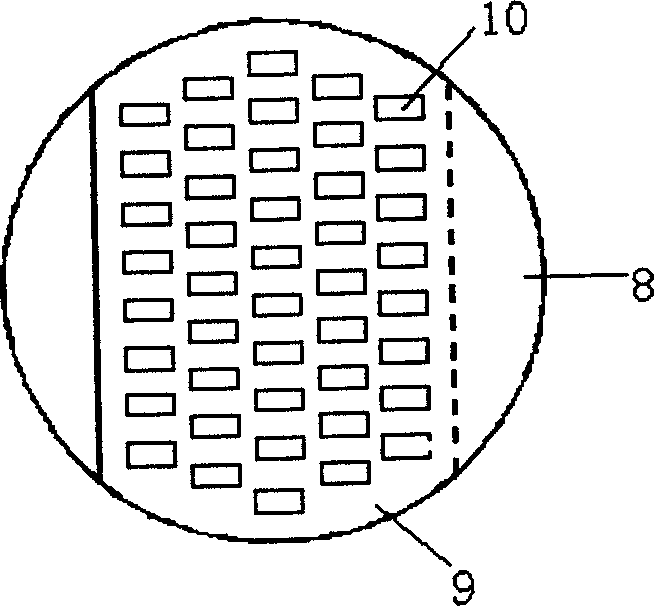

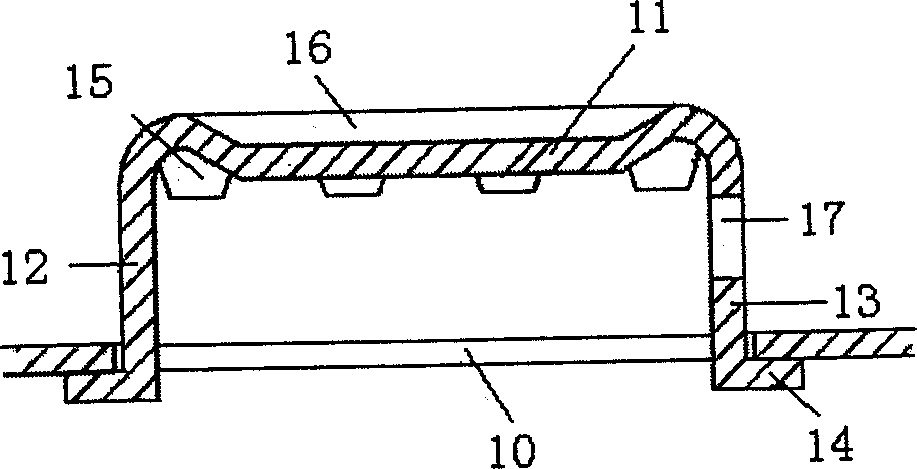

Tooth edge float valve

ActiveCN1683043ASmall bubble diameterIncrease the gas-liquid contact areaDistillation separationAirflowEngineering

The tooth edge float valve includes tabulated valve cover, liquid facing valve leg on one end of the valve cover and in the upstream position, liquid backing valve leg on the other end of the valve cover and in the downstream position, and valve feed fixed separately to the lower ends of the liquid facing valve leg and the liquid backing valve leg. The valve cover has downward bending toothed structures in the sides and the downward bending toothed structures can reduce the bubble diameter, raise the stability of the foam layer and avoid the direct spray of gas and liquid. In addition, the valve cover is provided with wedged slot to avoid the formation of gas flow eddy below the float valve, decrease liquid back mixing and lower the gas resistance of the float valve; and the liquid backing valve leg is provided with liquid guide hole for gas to drive liquid towards the outlet dam so as to reduce the liquid surface fall and decrease liquid back mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

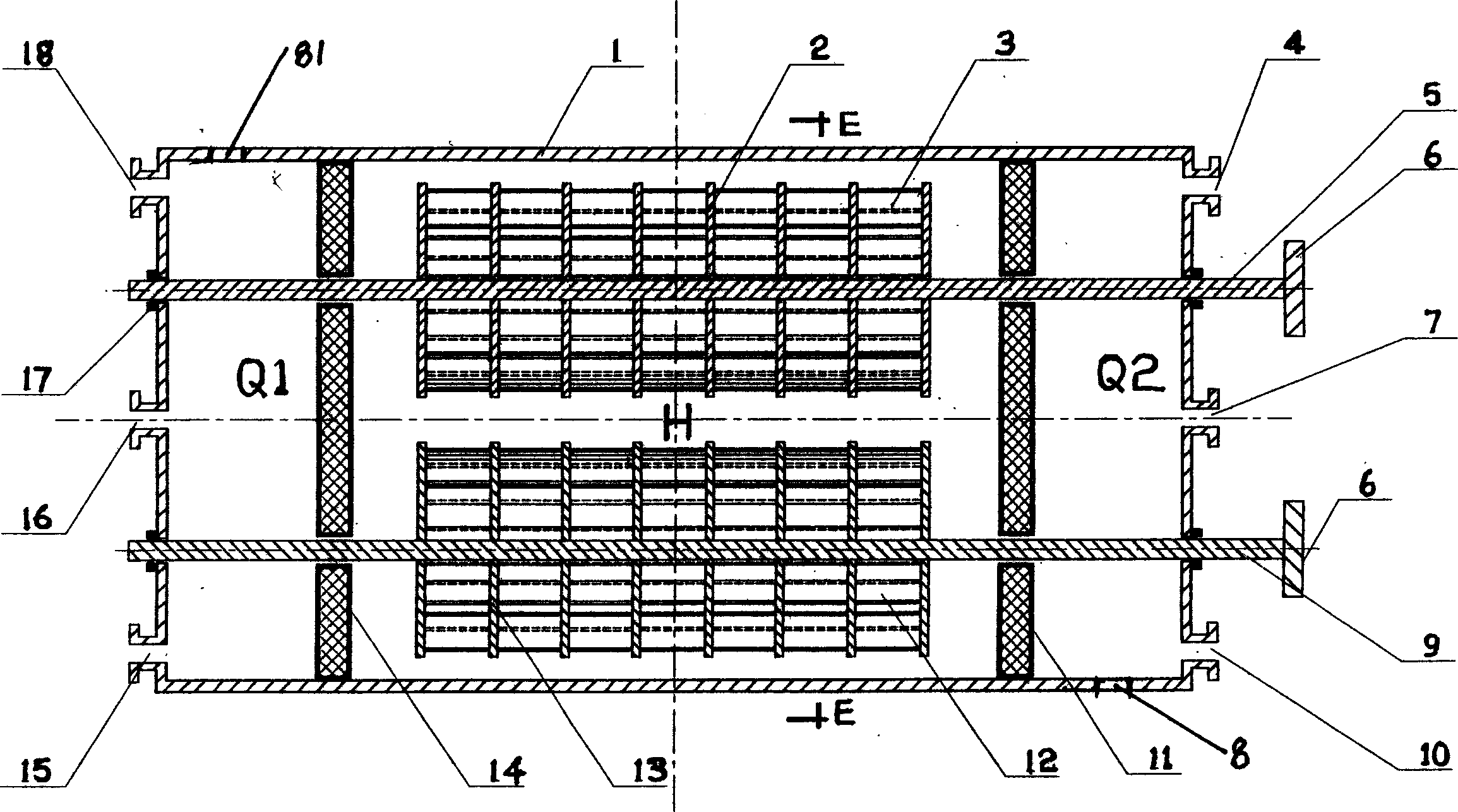

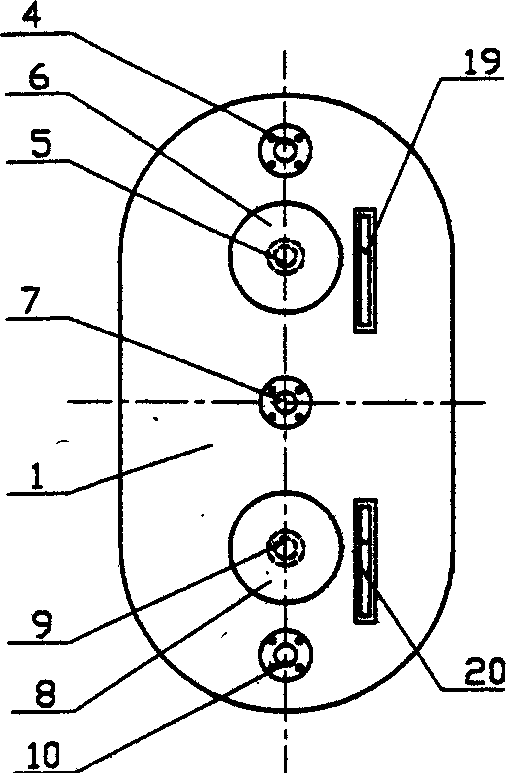

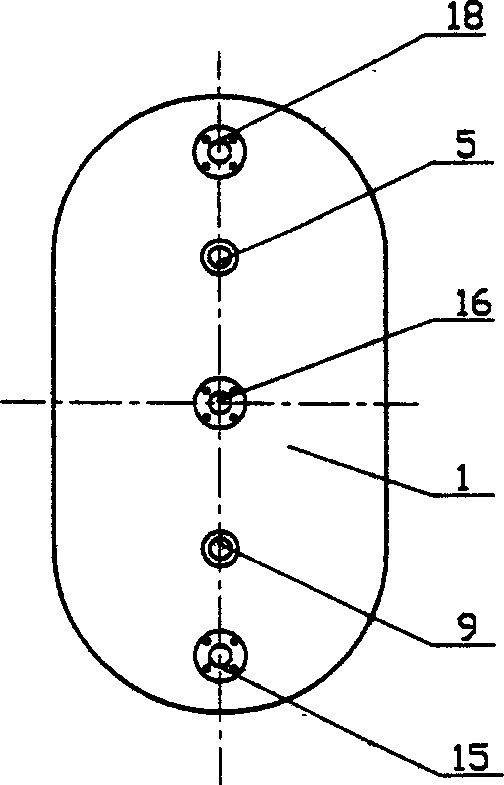

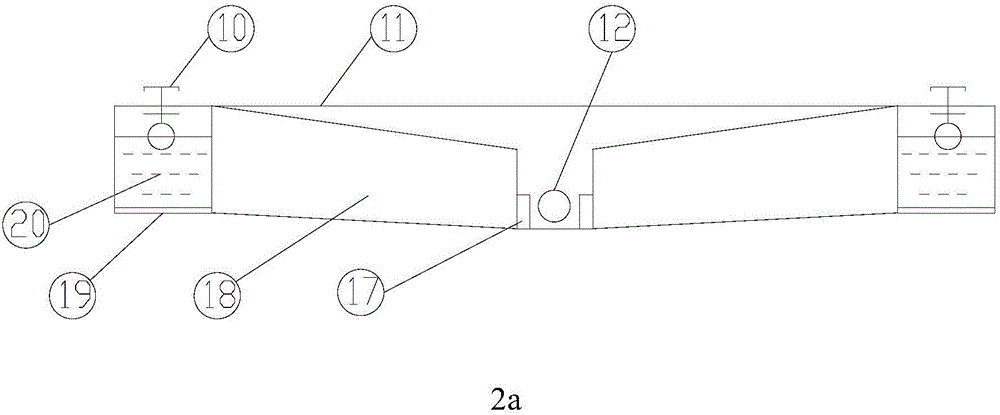

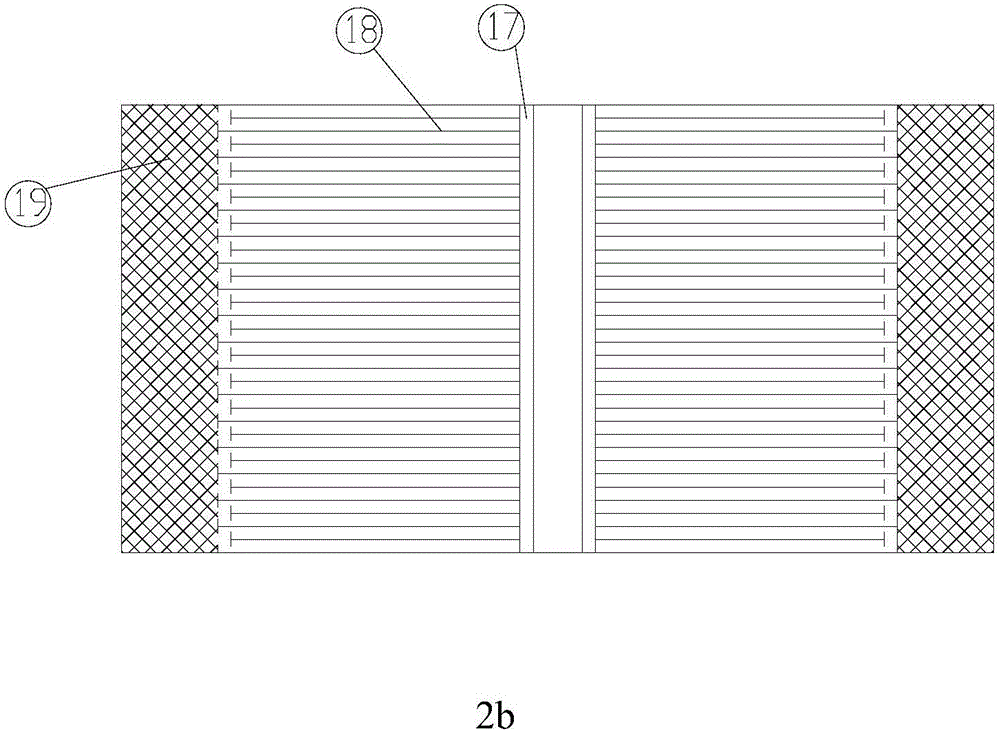

Liquid-liquid-liquid triphase horizontal continuous lifting stirring extraction device

InactiveCN1463782AReduce interfacial tensionReduce backmixingLiquid solutions solvent extractionEngineeringMotor drive

The liquid-liquid-liquid three-phase continuous lifting and stirring extractor includes one horizontal reactor with two stuffing-holding isolating board cases in its two ends; one upper shaft and onelower shaft penetrating the reactor side walls and installed parallelly to the isolating board cases; upper baffle and lower baffle with horizontal arc lift tank in between; light phase outlet, middle phase inlet and heavy phase outlet successively arranged on one side wall of the reactor; light phase inlet, middle phase outlet and heavy phase inlet successively arranged on the opposite side wallof the reactor; and motor driven wheels installed in the ends of the two shafts. With simple structure, low power consumption, flexible operation, no emulsification and less back mixing, the presentinvention is suitable for separating and purifying high-value biochemical product from relevant fermented liquid.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Extraction device and method

ActiveCN106139638AReduce backmixingSolve the problem of strong stirring and mixing extractionLiquid solutions solvent extractionProcess efficiency improvementGas phaseEngineering

The invention provides an extraction device and method. A mixed settler extractor comprises a mixing chamber, an organic liquid film generator, a gas-liquid separation device and a liquid-liquid coalescence separation device. The mixing chamber is provided with a heavy phase input port and a first heavy phase discharge port. The organic liquid film generator is connected with the mixing chamber and provided with a light phase input port and a gas inlet. The gas-liquid separation device is connected with the mixing chamber. The liquid-liquid coalescence separation device is connected with the gas-liquid separation device and provided with a liquid inlet, a first light phase discharge port and a second heavy phase discharge port. The extraction device can be provided with no clarifying chamber, the integrated structure of the mixing chamber and the clarifying chamber is well achieved, the problem of heavy phase liquid distribution uniformity of a mixing chamber and the problem about light phase, heavy phase and gas phase separation of the mixing chamber are solved, the occupied area is small, energy consumption is low, a high-flow water solution containing a to-be-separated target object can be treated, and back-mixing of a high-position extraction tower can be relieved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Subassembly between gas-liquid contacting and in use for knockout tower for mass transfer

InactiveCN1660463AHigh porosityReduced sprayDistillation separationChemical/physical/physico-chemical processesProduct gasEngineering

A gas-liquid contact unit for the mass-transfer separation tower in order to increase the efficiency of tower plate is composed of a cylindrical or truncated conic spray hood with uniformly distributed spray holes, a circular top plate with uniformly distributed guide holes and installed to top edge of said spray hood with a window between them, and 3-4 supporting legs for installing it at the flow-up air hole on tower plate.

Owner:HEBEI UNIV OF TECH

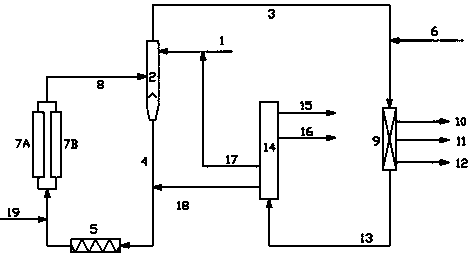

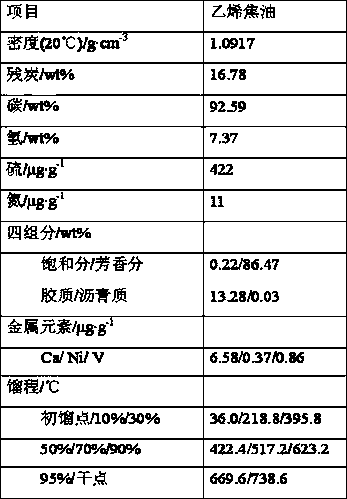

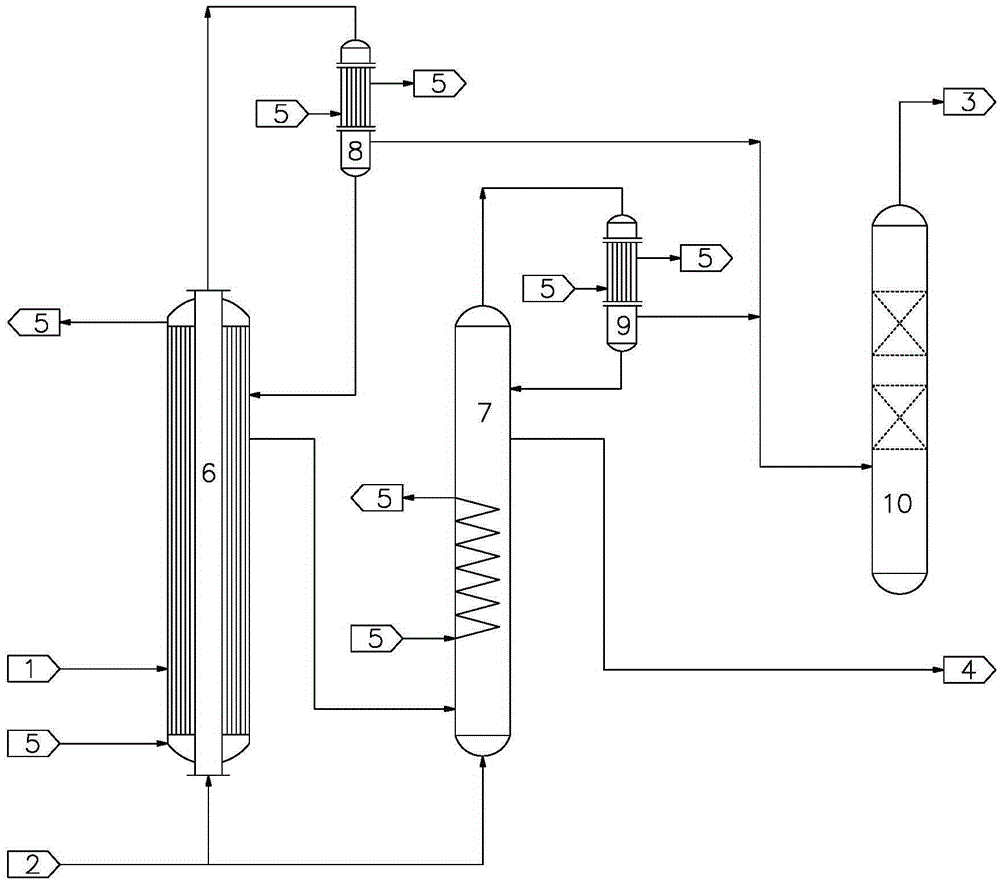

Process and system for treating ethylene tar

ActiveCN109929592APlay a role in strippingRestricted accessTreatment with hydrotreatment processesCracking reactionTreatment system

The invention discloses a process and a system for treating ethylene tar. According to the process, preheated ethylene tar contacts a coking reaction effluent from a delayed coking reaction system ina pretreatment reactor, and a light component and a heavy component are obtained after separation; the heavy component enters the delayed coking reaction system, and the generated coking reaction effluent enters the pretreatment reactor; the light component and hydrogen enter a hydrogenation reaction system, and the reaction effluent is separated to obtain gas, gasoline distillate, diesel oil distillate and heavy oil distillate; and the heavy oil distillate enters a catalytic cracking reaction system, and the catalytic diesel oil obtained after separation enters the pretreatment reaction. Thetreatment system comprises the pretreatment reactor, the coking reaction system, the hydrogenation reaction system, and the catalytic cracking reaction system. With the process and the system of the present invention, the stable long-cycle operation of the whole treatment system can be ensured, and the yield of the light oil product is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

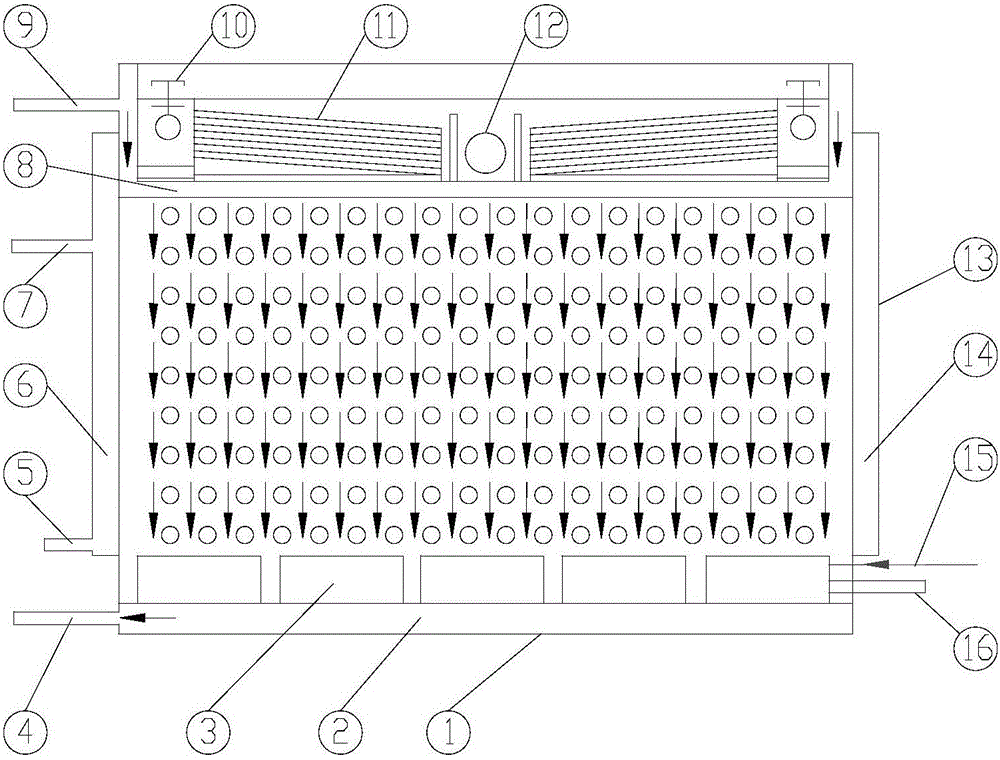

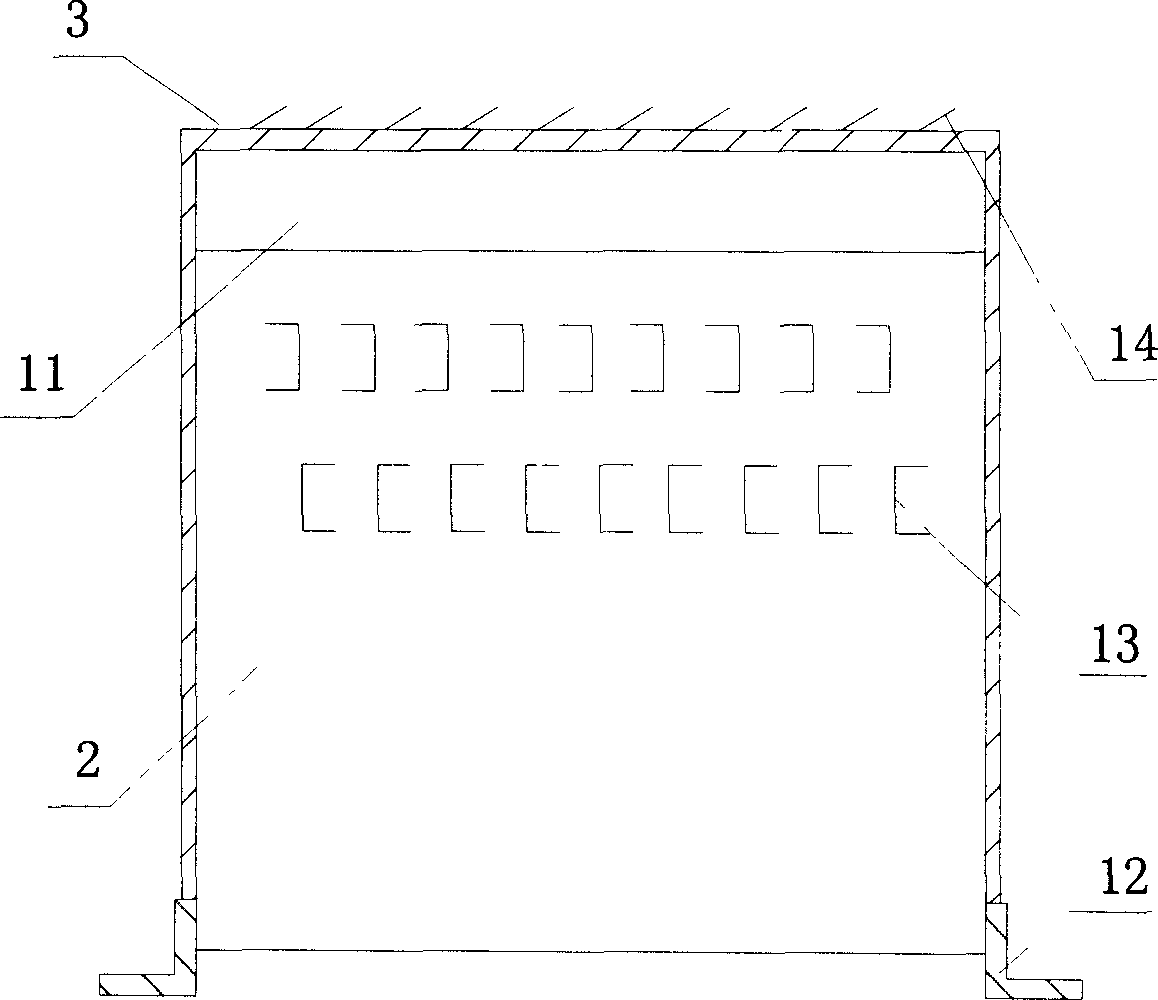

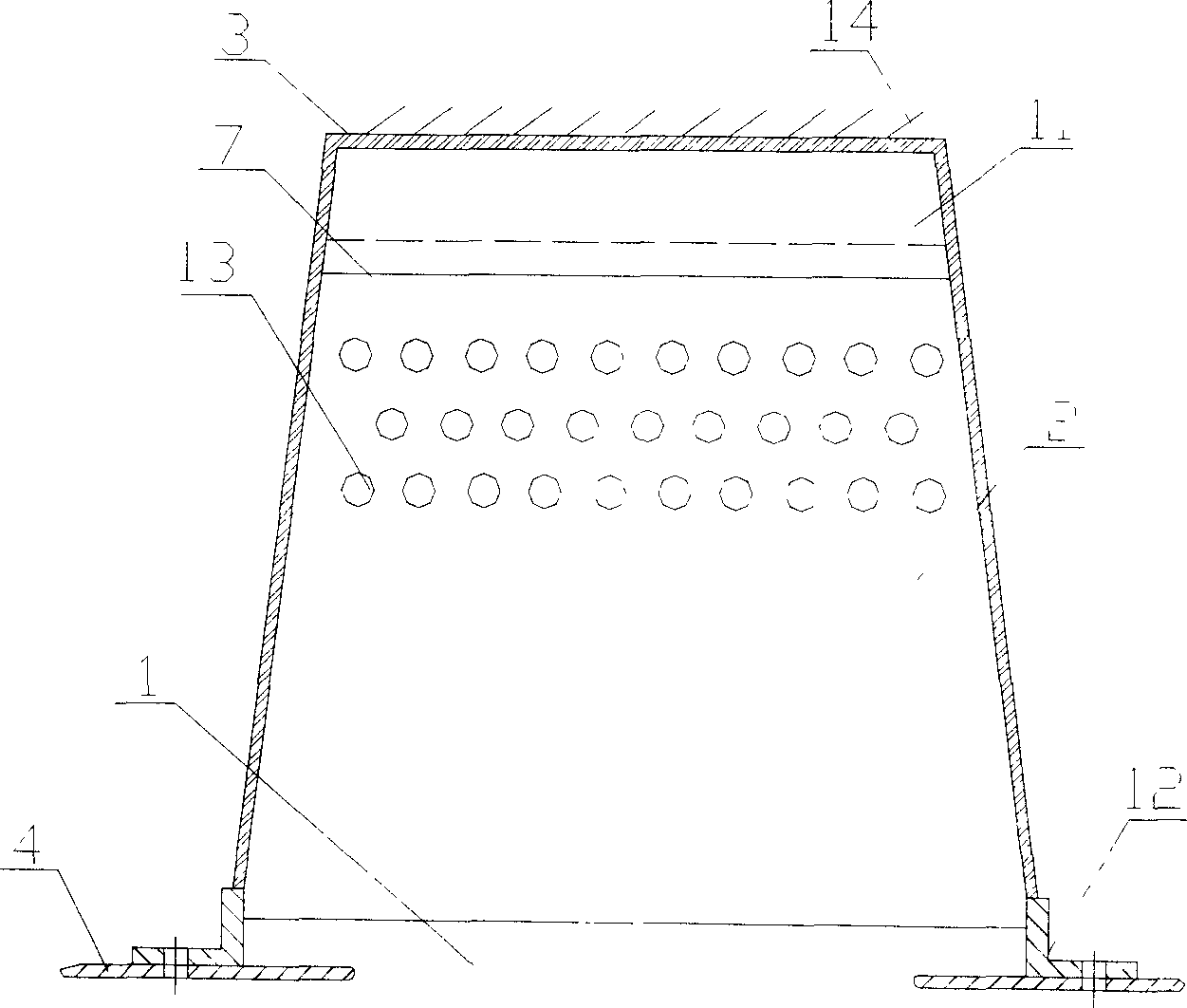

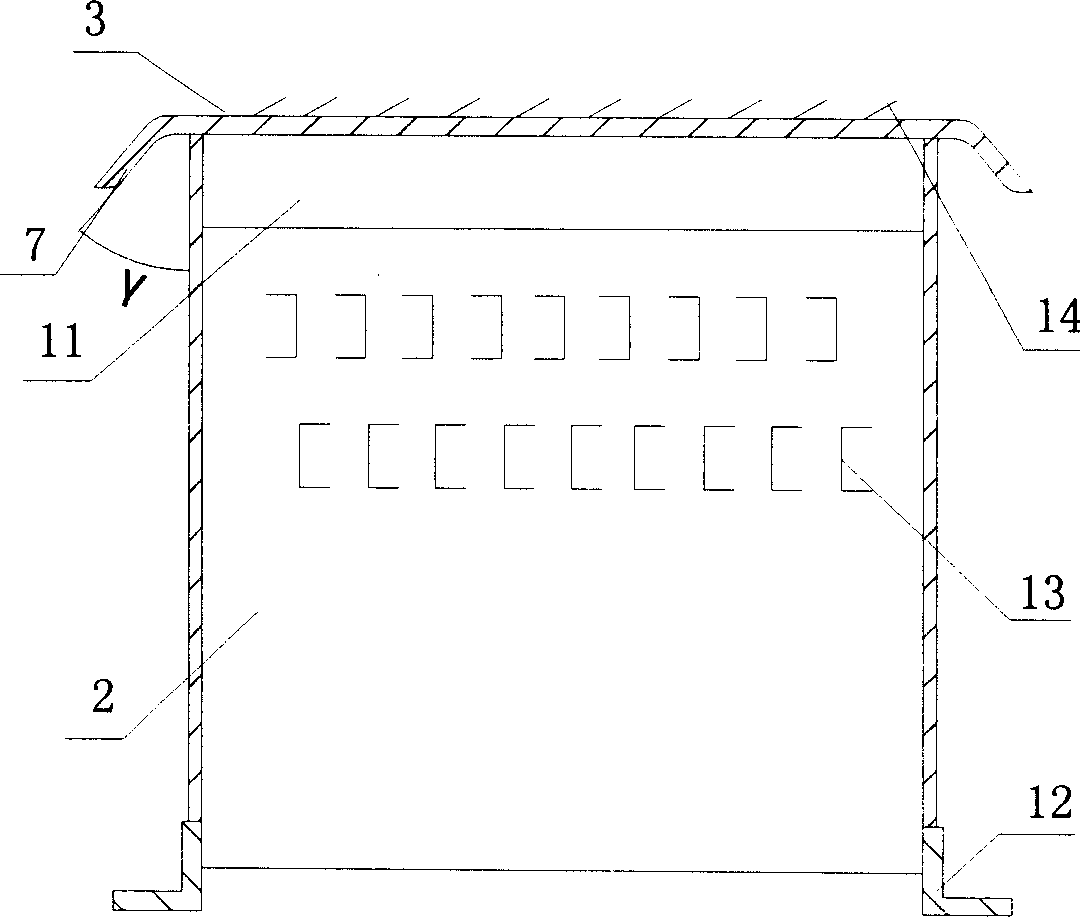

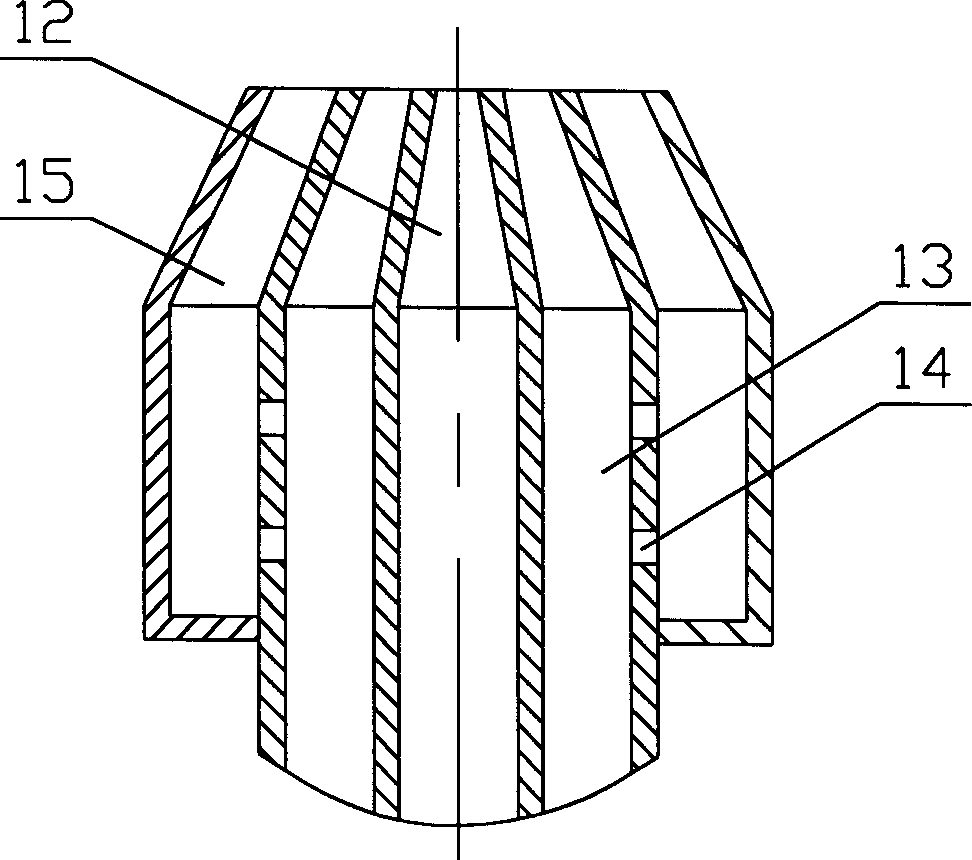

Jet drive fluidized bed pelletizing device with multiple jet drive units

InactiveCN1408469AReduce backmixingPriority dischargeGranulation by powder suspensionFluidized bedEngineering

The present invention discloses one spouted fluidized bed pelletizer with several spouting units. The pelletizer consists of mainly casing, spouted fluidized bed pelletizer with several spouting units comprising vertical partition boards inside the casing. Each spouting unit consists of gas distributing board, self-cleaning pressure jet or self-cleaning double-fluid jet, and guide tube over the jet. The guide tube separates the spouting unit into spouting area and annular area in the area ratio of 0.2-0.5. The ventilating hole in the annular area is inclined hole and that in the spouting area is vertical hole. The present invention has simple structure, less back mixing of the particles and high product homogeneity. The self-cleaning jet without choking and the inclined holes in favor of exhaust of large particles can ensure the continuous production.

Owner:TIANJIN UNIV

Method for synthesizing 2-methyl-5-nitroimidazole-1-ethanol

ActiveCN102321028AImprove solubilityImprove conversion rateOrganic chemistryNitroimidazoleEthylene oxide

The invention provides a method for synthesizing 2-methyl-5-nitroimidazole-1-ethanol, which comprises the following steps: the mixed solution of 2-methyl-5-nitroimidazole, formic acid and sulfuric acid is prepared according to the mole ratio of 1:0.5-0.7:1.2-1.7; ethylene oxide and concentrated sulfuric acid with the mole ratio of 1:0.08-0.3 are alternately added into the mixed solution for 3-4 times; the reaction temperature is 72-108 DEG C, the reaction time is 2.5-5 hours, and after reaction, sodium hydroxide is added to regulate the PH value of the solution to 9.5-10.5, and a finished product is precipitated through crystallization; and a 2-methyl-5-nitroimidazole-1-ethanol finished product is obtained through purification. In the method for synthesizing 2-methyl-5-nitroimidazole-1-ethanol provided by the invention, the mixed solution of formic acid and sulfuric acid is used as a solvent, the conversion rate and the yield are obviously improved, formic acid and sodium hydroxide consumption is less, and the production cost is low.

Owner:HUBEI HONGYUAN PHARMA

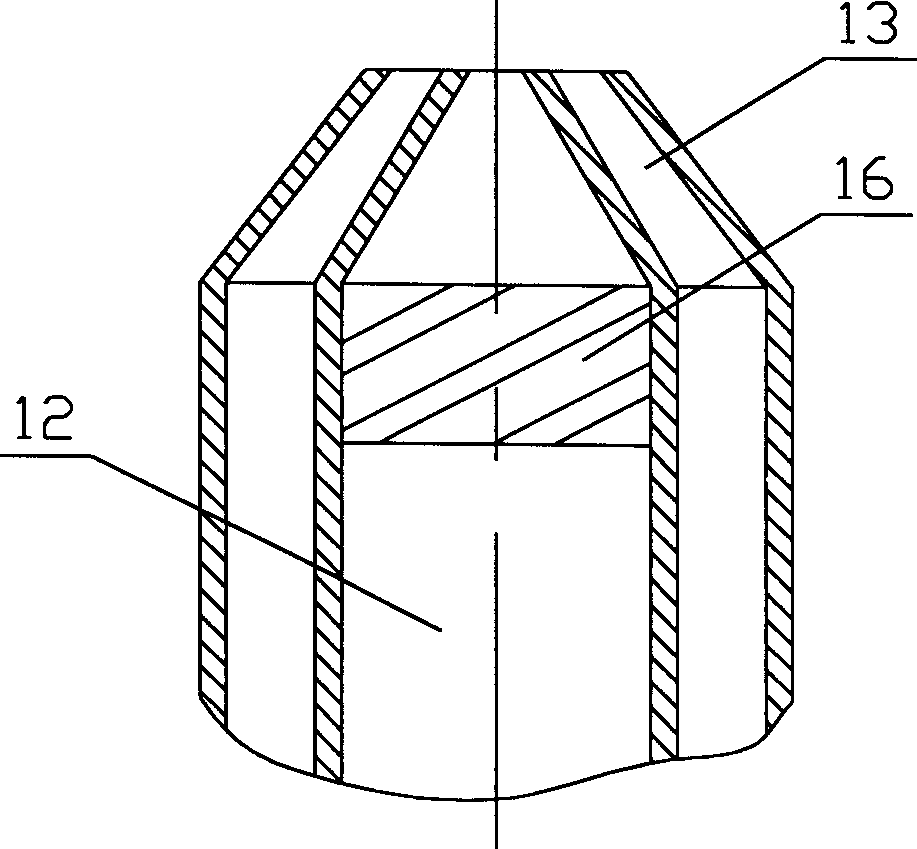

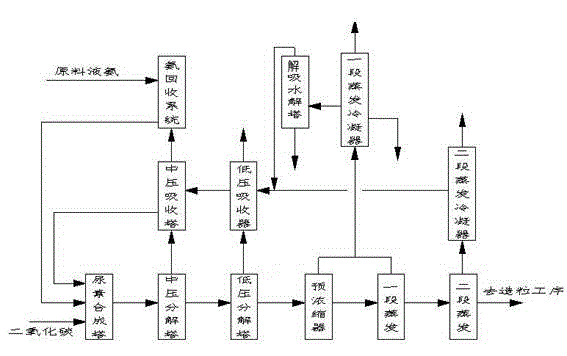

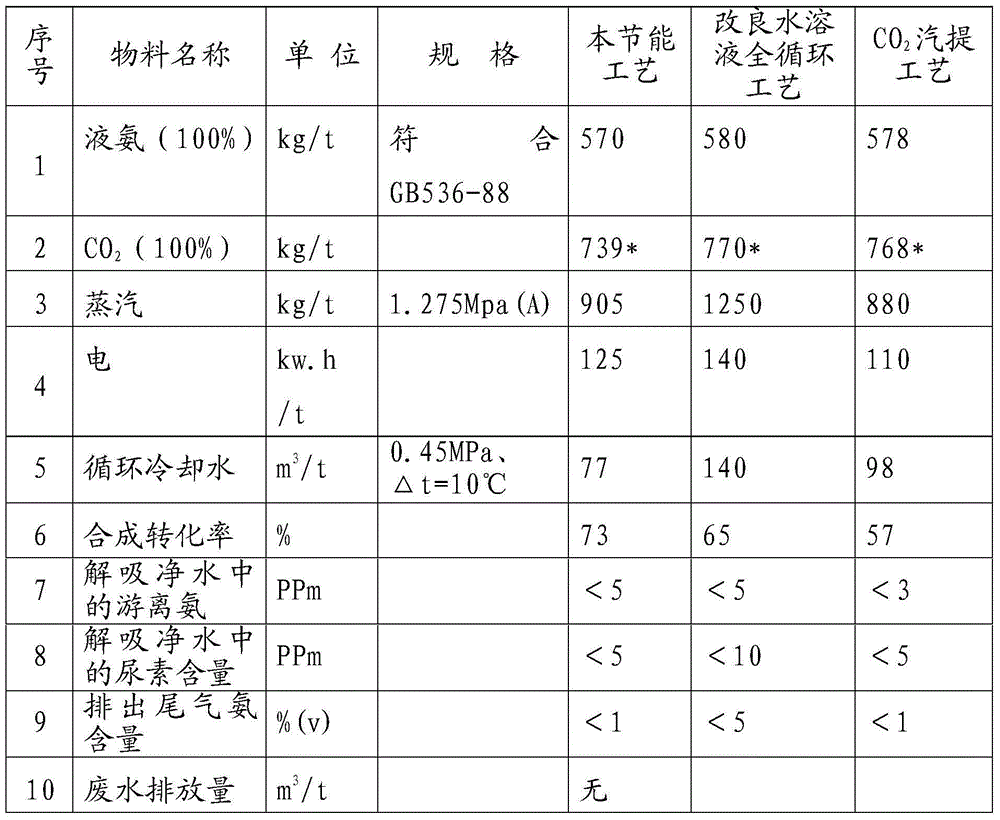

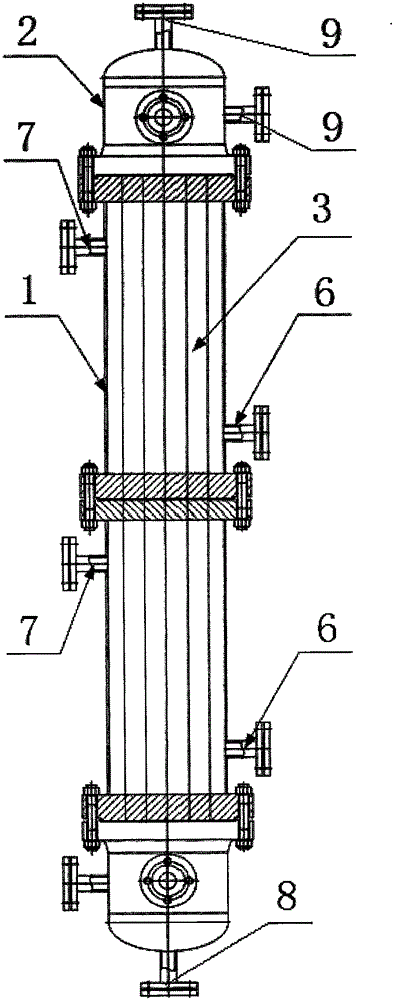

Energy-saving urea production system and production process thereof

ActiveCN104829494AReduce energy consumptionEasy to operateUrea derivatives preparationOrganic compound preparationDesorptionAmmonium carbamate

The invention belongs to the field of urea preparation, and particularly relates to an energy-saving urea production system and a production process thereof. The system comprises a CO2 compressor, an ammonium carbamate pump, a liquid ammonia pump and a urea synthesizer. The system is characterized in that the CO2 compressor is connected with the ammonium carbamate pump and the liquid ammonia pump, the liquid ammonia pump is connected with the urea synthesizer, a falling-film countercurrent medium-pressure decomposing tower and a heater, an ammonium carbamate condenser, an ammonium carbamate separator, a three-stage medium-pressure absorption tower and an evaporative ammonia refrigeration recoverer, a liquid ammonia buffer tank, an inert gas scrubber, a tail-gas ammonia cleaning fine purifier, a low-pressure decomposing tower and a heater, a dimethyl liquid preheater, a horizontal low-pressure absorber, a falling film type pre-evaporator, a one-stage evaporator and a one-stage evaporative condenser, a two-stage evaporator and a two-stage evaporative condenser, and a process wastewater desorption and hydrolysis tower are sequentially connected behind the urea synthesizer in sequence. The energy-saving urea production system has the advantages of low investment, low energy consumption, simple operation, high elasticity and the like, thereby the process technology has considerable economic benefit and social benefit.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

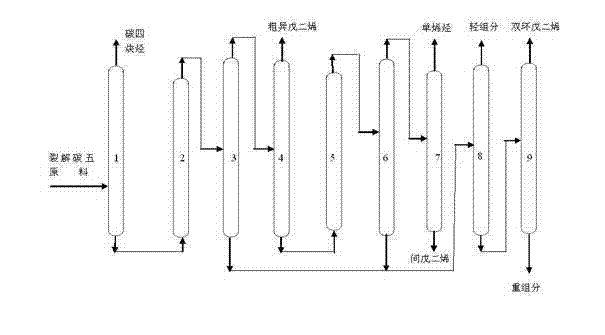

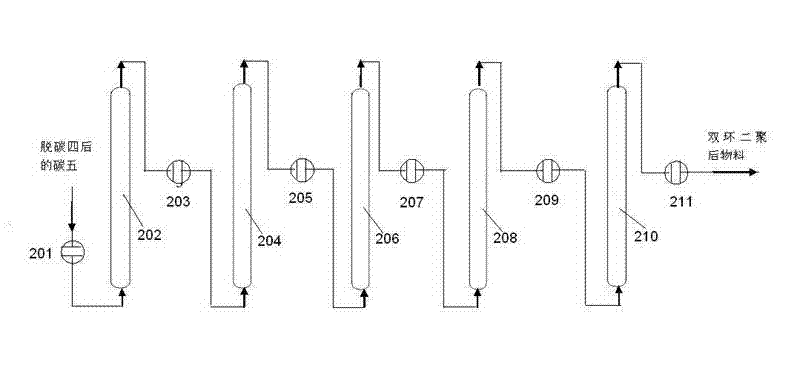

Method and equipment for separating diolefin component in oil cracking ethylene byproduct carbon-5 fraction

ActiveCN102516010ADimerization reaction conditions are mildThe reaction is easy and stable to controlDistillation purification/separationHydrocarbons from unsaturated hydrocarbon additionPiperyleneChemistry

The invention provides a separation method of diolefin in carbon-5 aiming at the problem of high content of cyclopentadiene in isoprene when the diolefin in carbon-5 is separated by utilizing the post-heating dimerization method. The method comprises the following steps of: carrying out thermal dimerization reaction for two times, carrying out heavy removal for two times and removing the cyclopentadiene in the carbon-5 by using a special thermal dipolymer reactor. The content of the cyclopentadiene in the isoprene prepared by adopting the method is below 1 percent (weight), and meanwhile, thecontent of cyclopentadiene in produced piperylene is less than 1 percent (weight); and the content of an isoprene autopolymer or an isoprene copolymer in dicyclopentadiene can reach the level of a post-heating dimerization carbon-5 separation technology. The invention also discloses equipment for implementing the separation method at the same time.

Owner:DAQING HUAKE

Liquid film colliding type jet reactor

ActiveCN1830540AMeet different mixing requirementsMeet mixing requirementsFlow mixersChemical/physical/physico-chemical stationary reactorsEngineering

A liquid film impact type spray reactor for the fast mixing and reaction between two kinds of liquid is composed of material feeding inlets, the coaxially arranged central axle, internal ring tube and middle ring tube, and a mixing head whose lower end is connected with that of central axle.

Owner:WANHUA CHEM GRP CO LTD +1

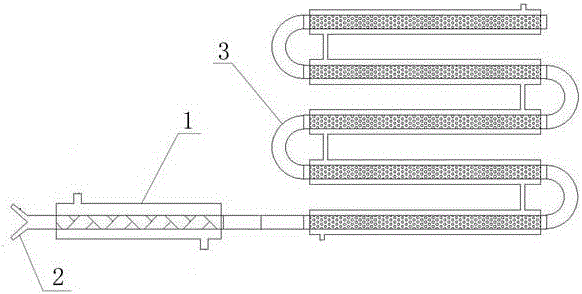

Intelligent industrialized micro-channel flow reactor

ActiveCN105107442AReduce mass transfer resistanceShort reaction timeChemical/physical/physico-chemical processesThermal energyEnvironmental resistance

The invention relates to the technical field of reaction devices for petrochemical engineering, fine chemistry, pharmacy, plastic, synthetic rubber, coating, food processing and the like, in particular to an intelligent industrialized micro-channel flow reactor which greatly improves safety and environment protection performance, greatly saves energy and greatly improves production efficiency. The intelligent industrialized micro-channel flow reactor comprises a shell, a raw material inlet, a product outlet, an end socket and a reaction pipe, and is characterized in that a three-dimensional micro-channel assembly is closely inserted in the reaction pipe, and a plurality of continuous-penetrating micro-channels in the scale of microns or millimeters are formed between the outer surface of the three-dimensional micro-channel assembly and the inner wall face of the reaction pipe. The mass transfer resistance between reaction raw materials is greatly reduced, reaction heat can be rapidly conducted in time, reaction time is shortened, back-mixing and side reaction are reduced, solvent consumption is lowered or eliminated, safety and reliability are high, energy conservation and emission reduction can be greatly achieved, yield is increased, and production efficiency is improved.

Owner:QINGDAO TI TA NB ZR SUCCESSIVE REACTOR CO LTD

Device and method for synthesizing polymethoxy dimethyl ether with medium concentration formaldehyde and methylal

InactiveCN106278836ASmall volumeLarger than surfaceOrganic chemistryOrganic compound preparationHigh energyEngineering

The invention relates to a device and a method for preparing polymethoxy dimethyl ether, particularly relates to a device and a method for synthesizing polymethoxy dimethyl ether with medium concentration formaldehyde and methylal, solves the problems of complicated structure, high operation and maintenance costs, high energy consumption, low yield and not conducive to industrialized continuous production in the prior device, the technical scheme is that the device comprises a static mixer, one end is connected with the input tube, the other end is connected with the pipeline reactor, the other end of the pipeline reactor is connected with a refining separation device. The method comprises the steps of a, filling the reactor with catalyst; b, feeding raw materials into the mixer and mixing well; c, feeding raw materials into the reactor, controlling the temperature, pressure, liquid volume space velocity; d, separation and purification. The device and the method have the advantages of lower energy consumption, high production capacity, suitable for large-scale and continuous production, small back-mixing, sectional temperature control, low wear rate of catalyst, easy separation, no corrosion to device and simple subsequent processing, less pollution, high selectivity, low cost, few high polymer in the product and low separation and purification energy consumption.

Owner:鄂尔多斯市易臻石化科技有限公司

Method of preparing propylene epoxide

ActiveCN104311513AIncrease the effective contact areaImprove conversion rateOrganic chemistryMolecular sieveMixed materials

The invention discloses a method of preparing propylene epoxide. The method comprises the following steps: adding raw materials propylene, hydrogen peroxide, a solvent methanol and a titanium silicalite molecular sieve catalyst into a reaction kettle in proportion, regulating the temperature and the pressure in the reaction kettle, and establishing a cycle; continuously adding the reaction raw materials and the solvent into a pipeline reactor to react from the outside of the reaction kettle, mixing the reaction raw materials and the solvent in a static mixer and then feeding the mixed materials and the solvent into a reaction kettle to react sufficiently to obtain the propylene epoxide. On the lower part of the reaction kettle, the reaction product propylene epoxide and the catalyst are separated under a certain pressure, so that the separated propylene epoxide enters a follow-up process, and the catalyst is fed into the equipment such as the pipeline reactor by virtue of a circulating pump outside the reaction kettle to return to the reaction kettle to continuously react. In the reaction kettle, backwashing is performed once every 10-300s to guarantee the continuity of the separation of the reaction. According to the method disclosed by the invention, the raw materials sufficiently contact with the catalyst, so that the conversion ratio of the hydrogen peroxide is not lower than 96%, and the selectivity of the propylene epoxide is not lower than 95%. The reaction separating device is reasonable in structural arrangement and stable in reaction.

Owner:河北美邦工程科技股份有限公司

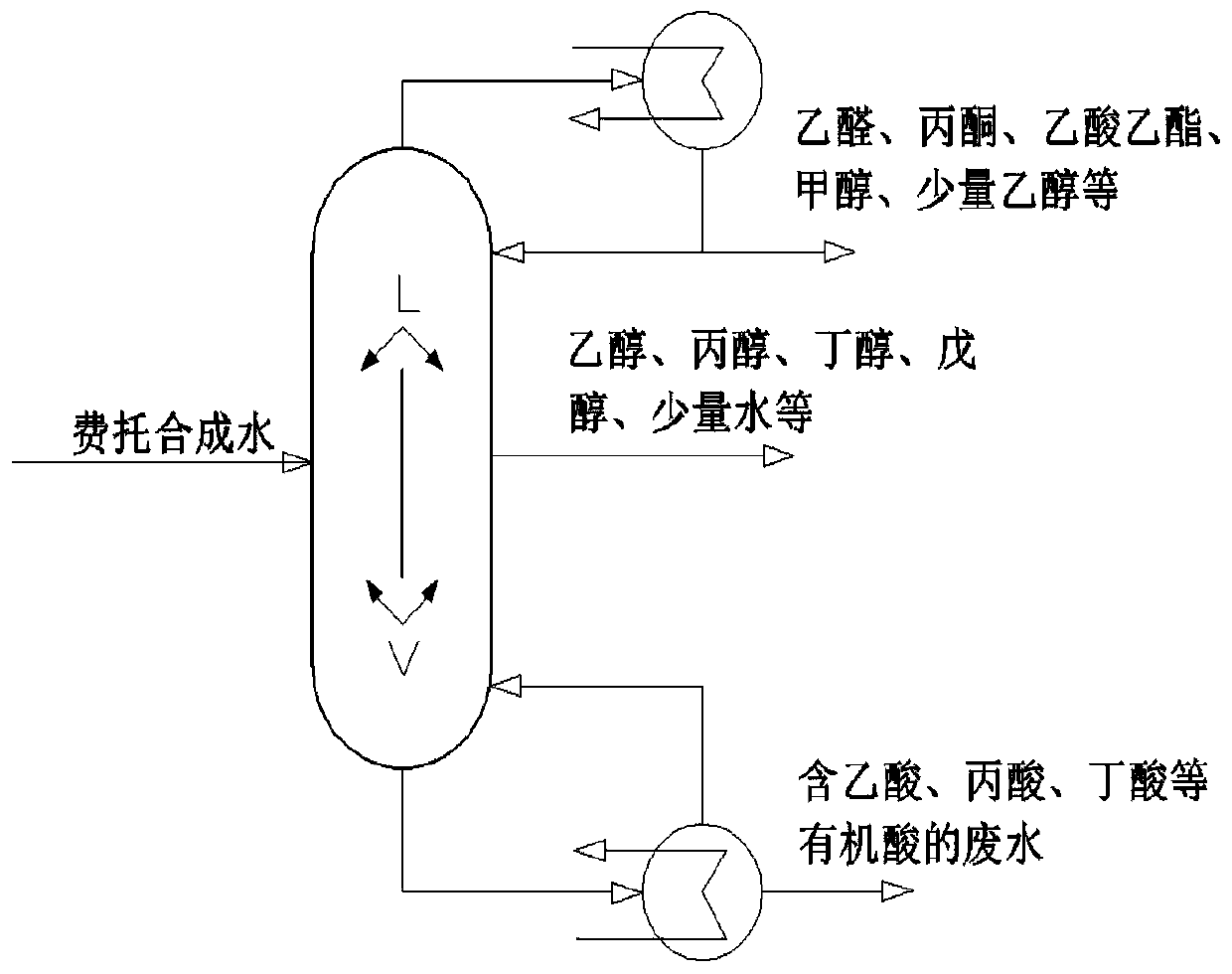

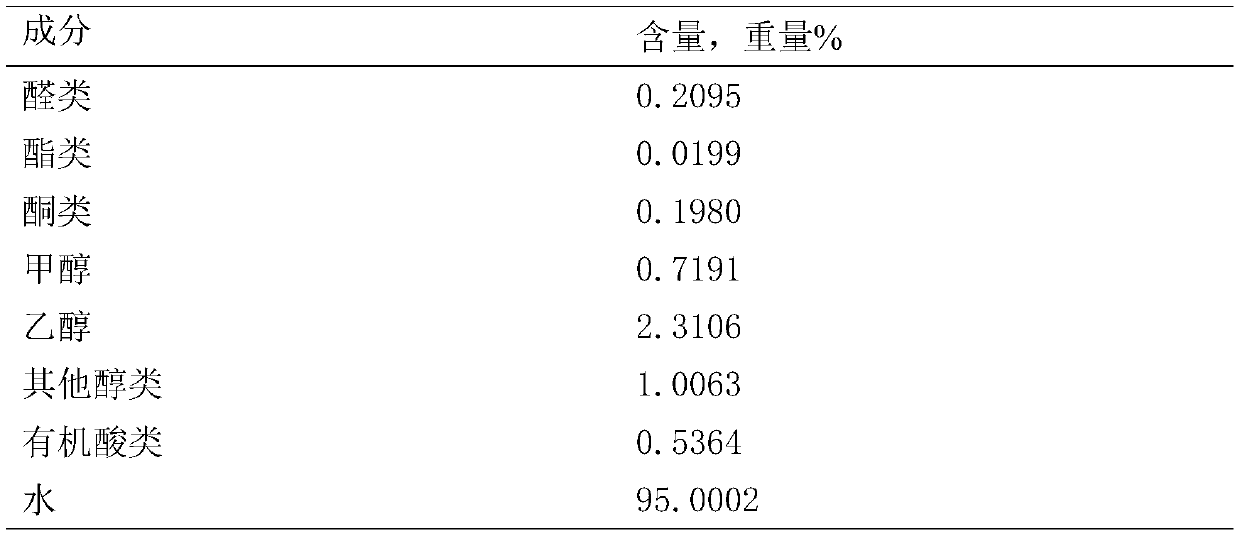

Method for preliminarily separating Fischer-Tropsch synthesized water by dividing-wall distillation column

InactiveCN109796310AIncrease varietySave waterOrganic compound preparationChemical industrySynthesis methodsDistillation

The invention relates to a method for preliminarily separating Fischer-Tropsch synthesized water by a dividing-wall distillation column. The method includes taking the synthesized water obtained fromliquid fuel production based on a Fischer-Tropsch synthesis method as a raw material, separating the synthesized water by the dividing-wall distillation column, adding the synthesized water via a pre-fractionation side feed inlet of the dividing-wall distillation column, obtaining a mixture of low-boiling-point oxygen-containing organics containing a trace amount of water at the top of the column,obtaining a dilute acid water solution mainly containing high-boiling-point organic acids at the bottom of the column, and extracting an oxygen-containing organic mixture mainly comprising mixed alcohols containing a small amount of water from the lateral line of a main column of the dividing-wall distillation column, wherein the operating conditions of the dividing-wall distillation column includes that the temperatures of the top, the bottom and the lateral line of the column are 30-80 DEG C, 70-160 DEG C and 50-130 DEG C respectively, the reflux ratio is 5-35, the gas phase distribution ratio is 0.5-20, and the liquid phase distribution ratio is 0.1-2. The method has the advantages that the dividing-column column distillation technology is fully utilized in the preliminary separation stage of the Fischer-Tropsch synthesized water in terms of energy conservation, and accordingly, energy consumption during treatment of the Fischer-Tropsch synthesized water is greatly reduced.

Owner:HEBEI UNIV OF TECH

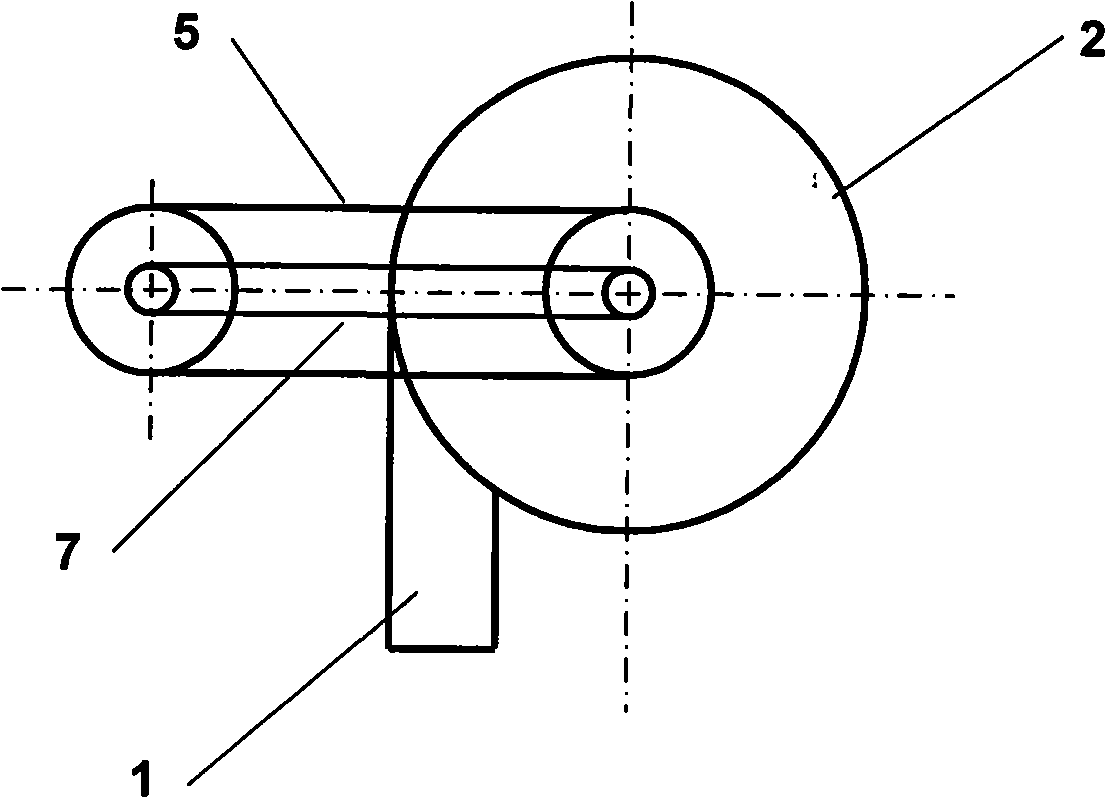

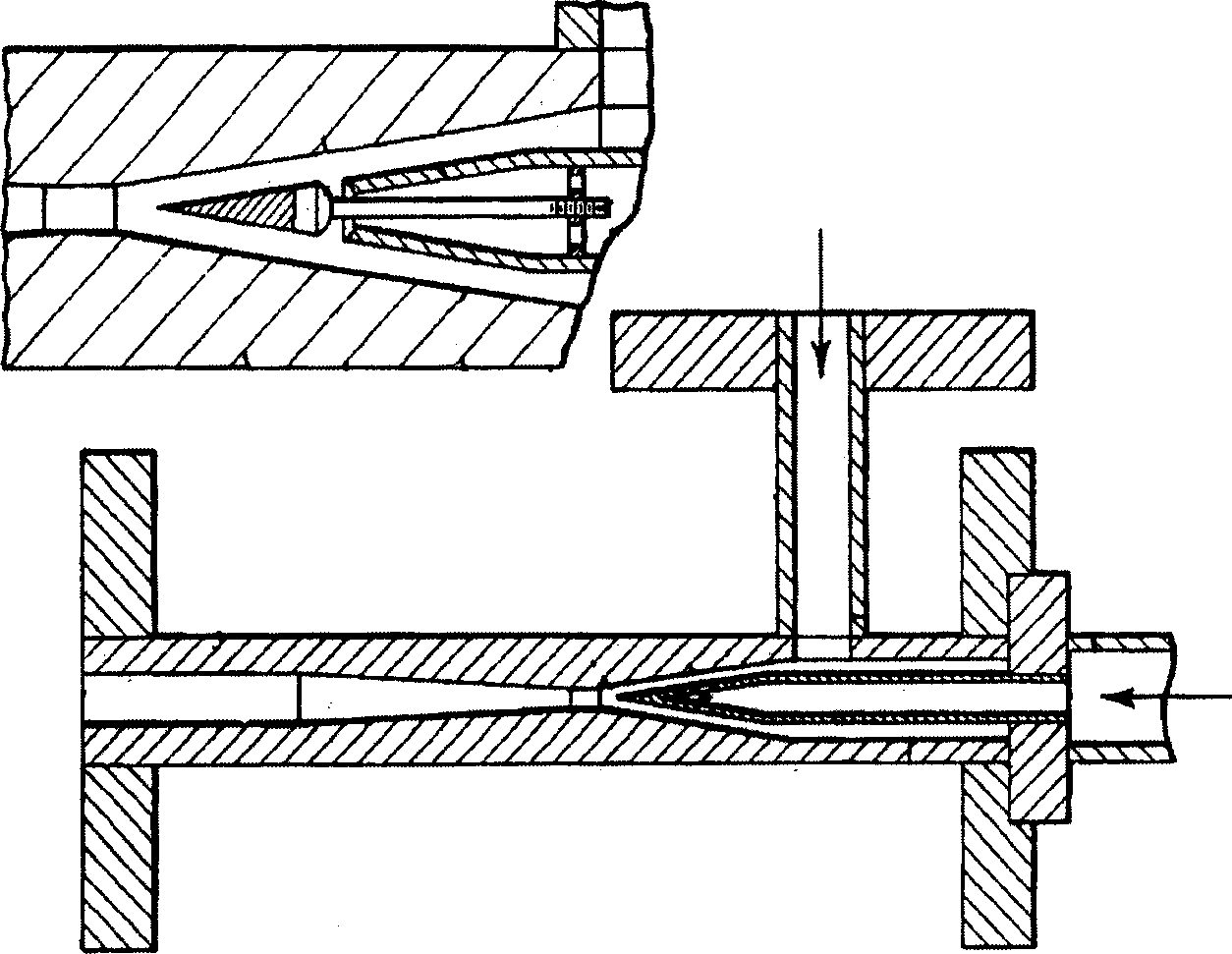

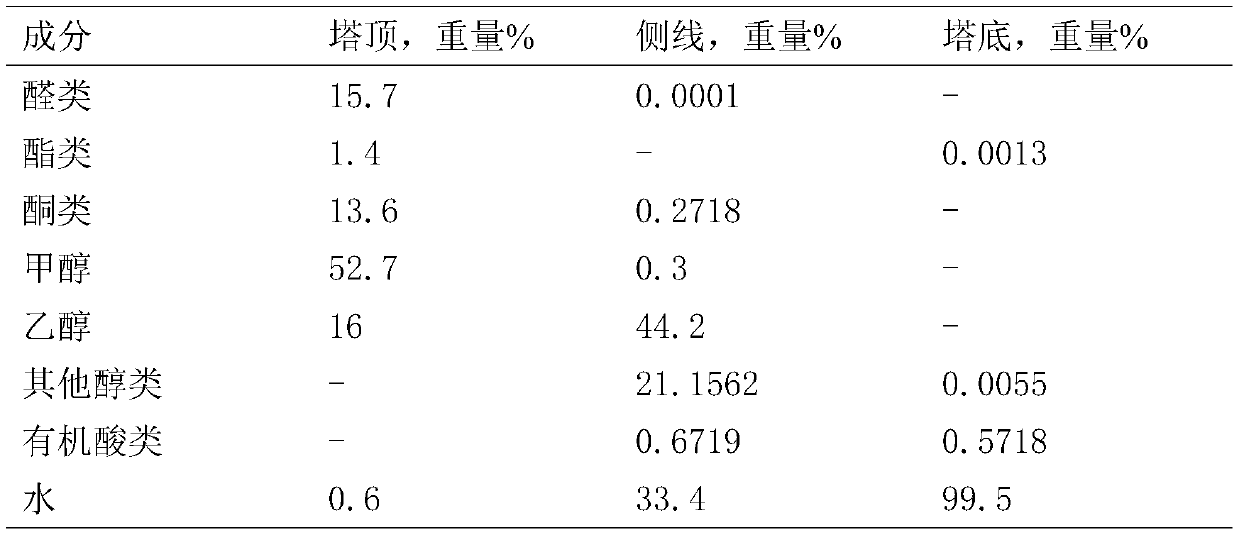

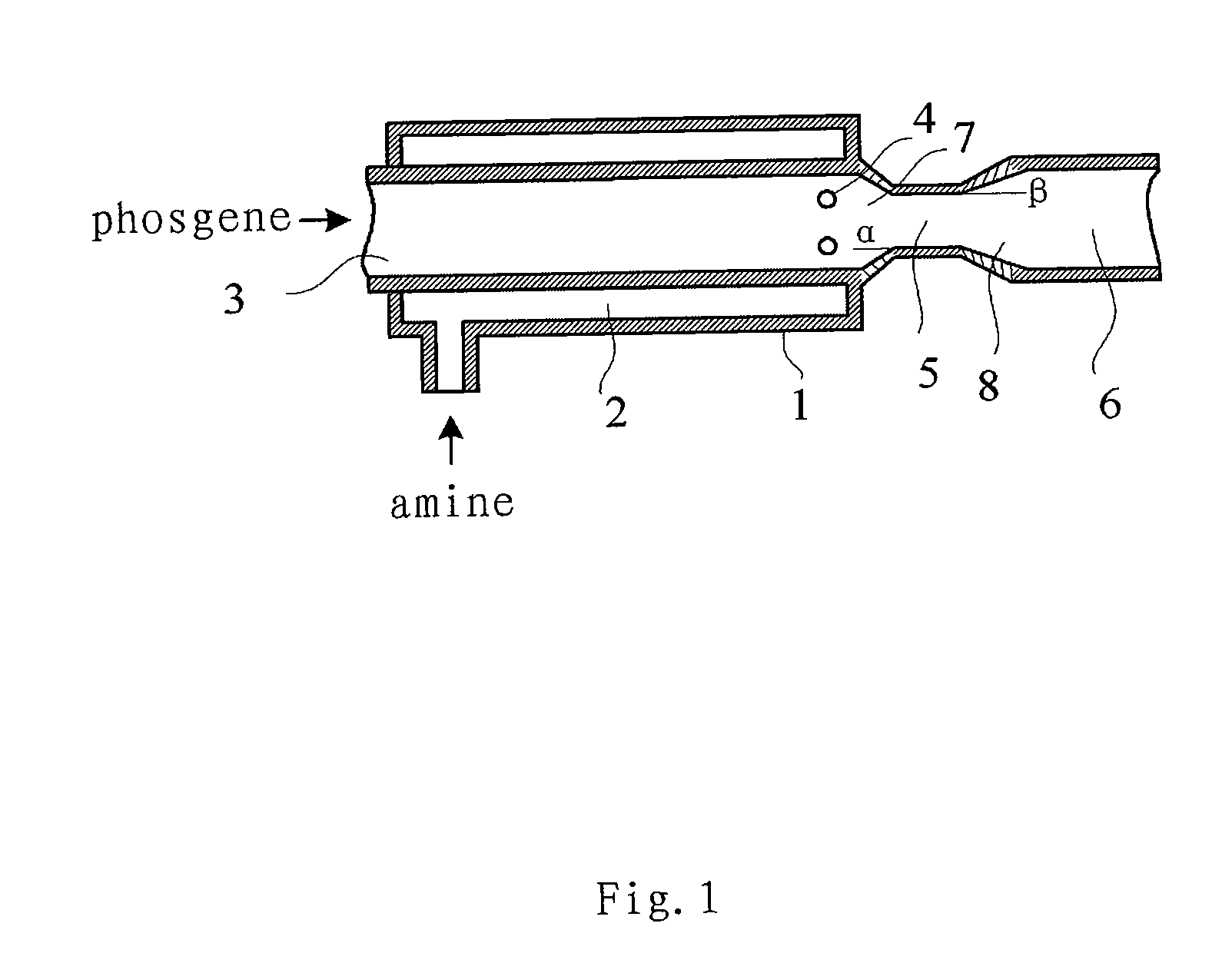

Hole jet reactor and a process for the preparation of an isocyanate using the reactor

ActiveUS20100137634A1Improve the mixing effectIncrease gas velocityFlow mixersUsing liquid separation agentGas phaseReagent

The present invention relates to a hole-jetting type reactor and its applications, in particular to a process for the production of isocyanates by the phosgenation of aliphatic or aromatic diamines or triamines in the gas phase using this reactor. The present invention achieves a good mixing and reacting result of the gas-phase phosgenation reaction at a high temperature by improving the mixing of reactants in the reactor to reduce the possibility of forming swirls and eliminate negative pressure produced at a local jet area, which can finally reduce back-mixing and formation of solid by-products.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

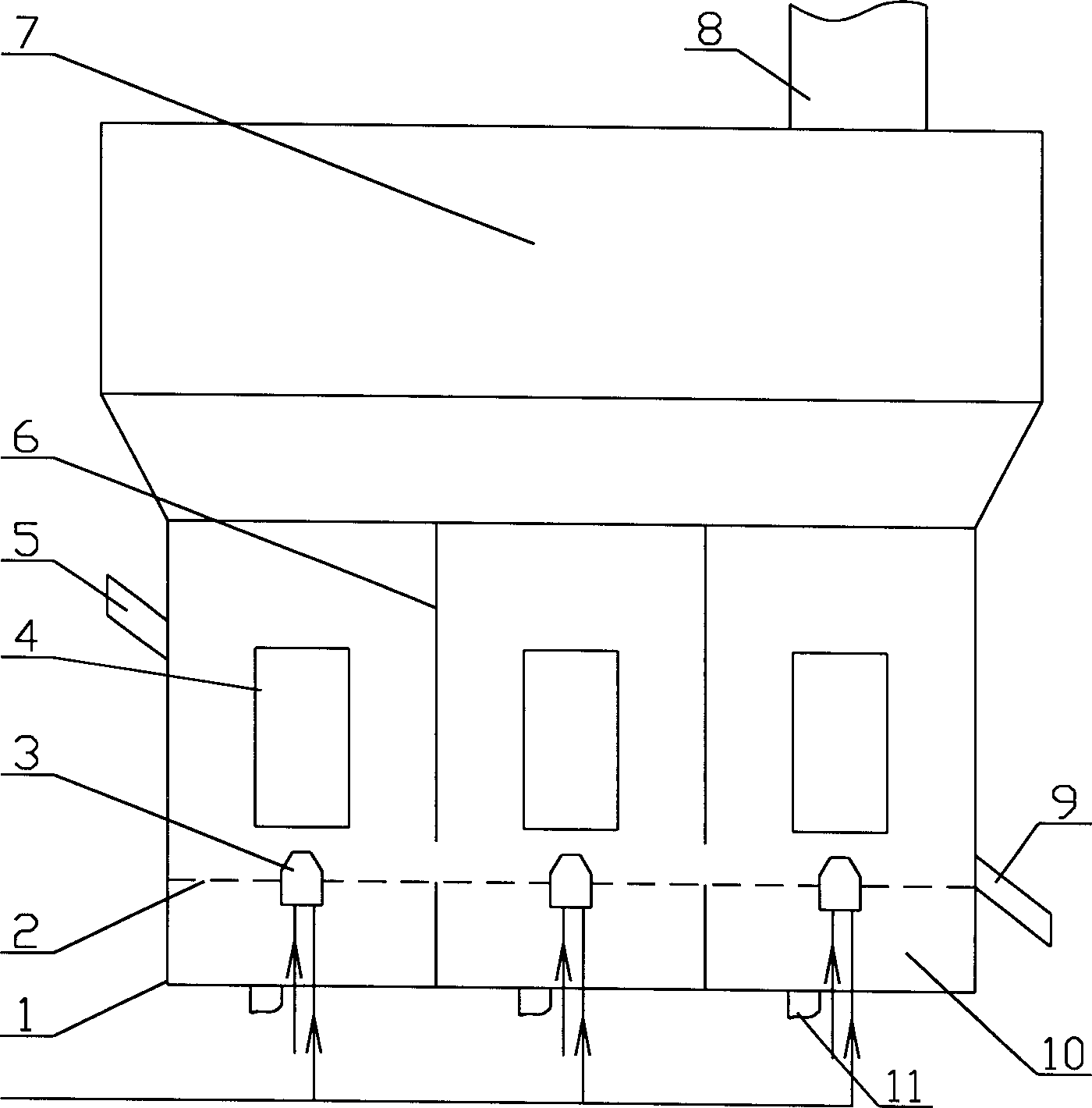

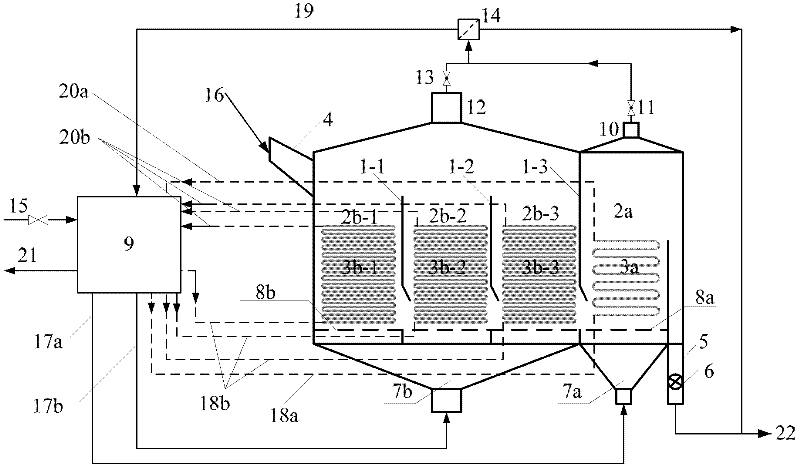

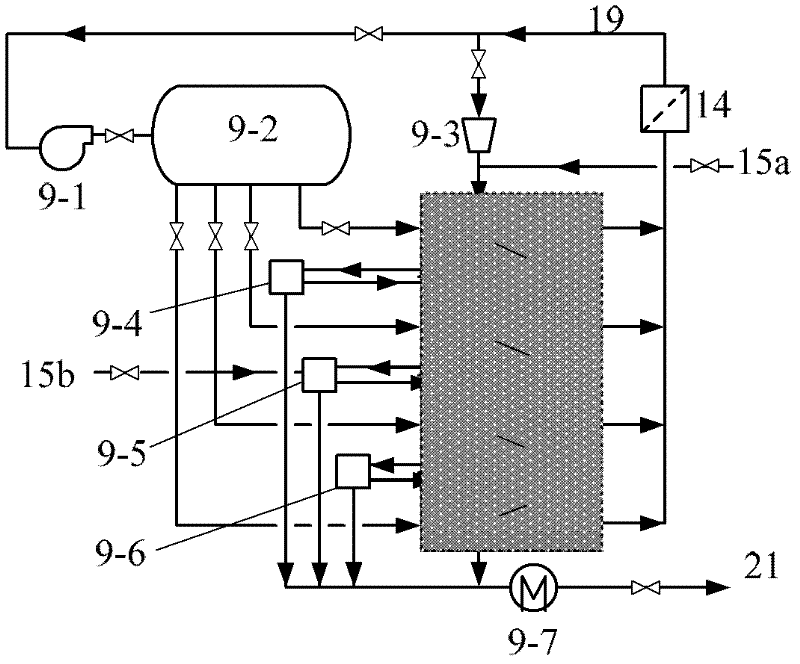

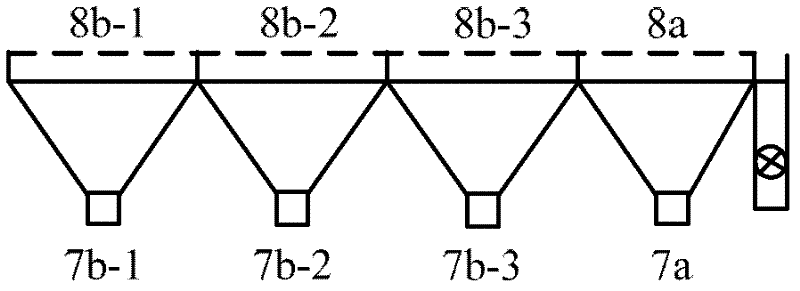

Multi-level solid fuel drying system

ActiveCN102519224AReduce backmixingReduce lossesDrying solid materials with heatDrying gas arrangementsThermal energyFluidized bed drying

The invention relates to a multi-level solid fuel drying system. The multi-level solid fuel drying system comprises a horizontal fluidized bed, a filter and a heating box, wherein the horizontal fluidized bed, the filter and the heating box are connected with one another; the horizontal fluidized bed is divided into fluidizing chambers of different sections by baffles; a heat exchanger is arranged in each fluidizing chamber; the horizontal fluidized bed takes overheat steam as fluidized gas and is used for carrying moisture, and takes multi-level saturated or nearly saturated steam with 105-300 DEG C as heating steam; moisture-containing fuel flows through the fluidizing chambers in sequence under a fluidizing state and is heated by the heat exchangers immersed in bed particles for layered drying or temperature adjustment, and meanwhile, the heating steam passing through the heat exchangers of different sections and the overheat steam passing through the fluidized bed are enabled to pass through the heating box for heat integration; and the step utilization of heat energy in a drying process is realized while the integrated heat is recovered and the overheat steam is recycled. Compared with the prior art, the multi-level solid fuel drying system provided by the invention has the advantages of returning and mixing of smaller fluidized bed drying particles and step utilization of drying heat source and the like.

Owner:WISON ENG

Preparation of dialkyl esters of 2,5-furandicarboxylic acid

ActiveUS20170313670A1Easy to separateKeep energy smallOrganic chemistryReaction zoneEsterification reaction

Dialkyl esters of 2,5-furandicarboxylic acid are prepared from a 2,5-furandicarboxylic acid-containing starting material in a process, which includes: contacting a vaporous stream of an alkanol countercurrently with the at least partially liquid starting material having the 2,5-furandicarboxylic acid, in a reaction zone to conduct an esterification reaction to yield the dialkyl ester of 2,5-furandicarboxylic acid and water; withdrawing a reaction vapor comprising the alkanol and water from the reaction zone; and discharging a liquid phase having at least the dialkyl ester of 2,5-furandicarboxylic acid, from the bottom part of the reaction zone, to obtain the dialkyl ester of 2,5-furandicarboxylic acid.

Owner:FURANIX TECH BV

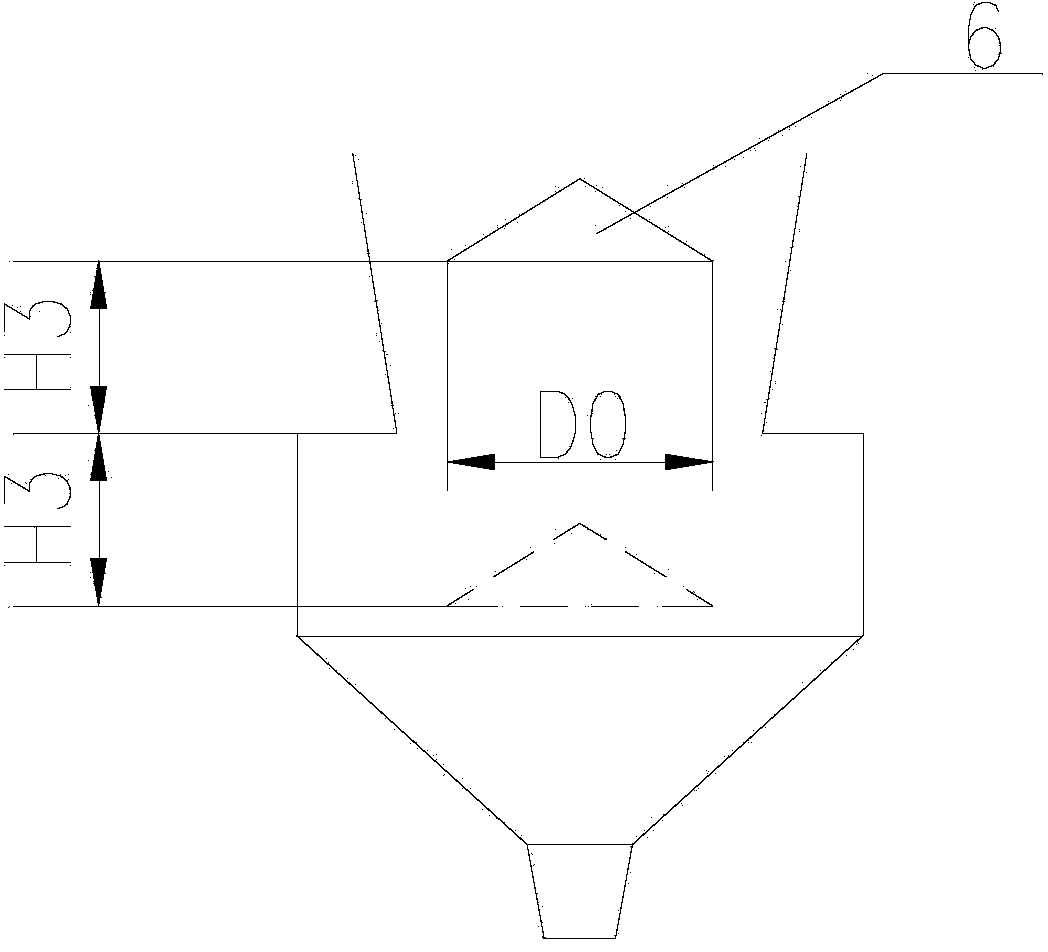

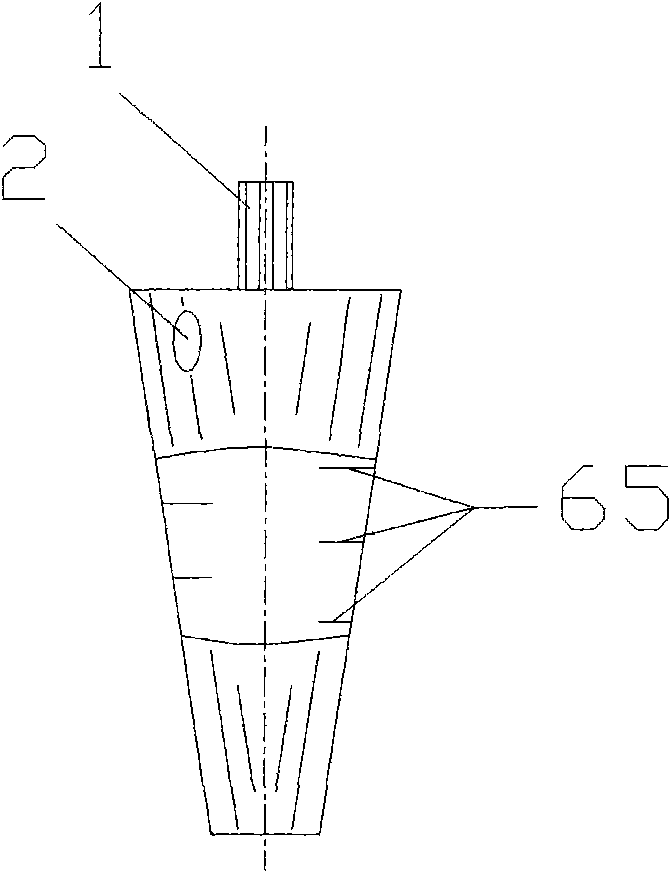

Finely-pulverized coal separator for warehouse type pulverizing system of 100-1,500MW coal-fired power plant boiler

InactiveCN103433157ASolve the entrainment problemImprove combustion effectReversed direction vortexPulp and paper industryExhaust pipe

The invention discloses a finely-pulverized coal separator for a warehouse type pulverizing system of a 100-1,500MW coal-fired power plant boiler. The finely-pulverized coal separator comprises a tangential inlet (1) of the separator, a cylindrical shell (2) of the separator, a lower part cone (3) of the separator, an exhaust pipe (4) and a lower part hopper (5) of the separator, wherein the tangential inlet (1) of the separator is formed in the upper part of the cylindrical shell (2) of the separator; the lower part cone (3) of the separator is arranged at the bottom of the cylindrical shell (2) of the separator; the exhaust pipe (4) is arranged on the top of the cylindrical shell (2) of the separator; the lower part hopper (5) of the separator is arranged at the bottom of the lower part cone (3) of the separator; an inlet of the lower part hopper (5) of the separator is provided with a mixing prevention cone device (6) of the separator; the diameter of an outlet in the bottom of the lower part cone (3) of the separator is not less than the inner diameter of the exhaust pipe (4). The finely-pulverized coal separator solves the problem of powder entrainment in the separator, thus greatly reducing the back-mixing of pulverized coal, being beneficial to the separation of particles, greatly improving the efficiency of the separator and reducing the operation pressure drop.

Owner:彭维明

Cyclone separator with grooved wall surface

InactiveCN101898175AImprove separation efficiencyParticle cutting particle size reductionReversed direction vortexCycloneVolumetric Mass Density

The invention relates to a cyclone separator with a grooved wall surface for heterogeneous system separation, which mainly and sequentially comprises a riser (1), a system inlet (2), a cylinder body (3), a cone body (4) and a tail pipe (5) from top to bottom, wherein a groove channel (7) is arranged on an inner wall (6) according to a medium flowing direction with larger system density, the groove channel (7) forms an alpha angle with a fluid flowing direction, and the cross section of the groove channel (7) is in a semicircular shape, an arc shape, a triangular shape or other geometrical shapes. The invention has the advantages of simple structure, convenient construction and large operation elasticity, is easy to reform the original structure, can obviously reduce cutting grain diameter sizes and greatly increases heterogeneous separation efficiency.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

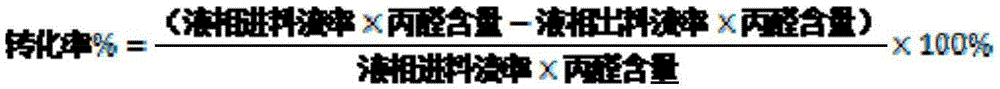

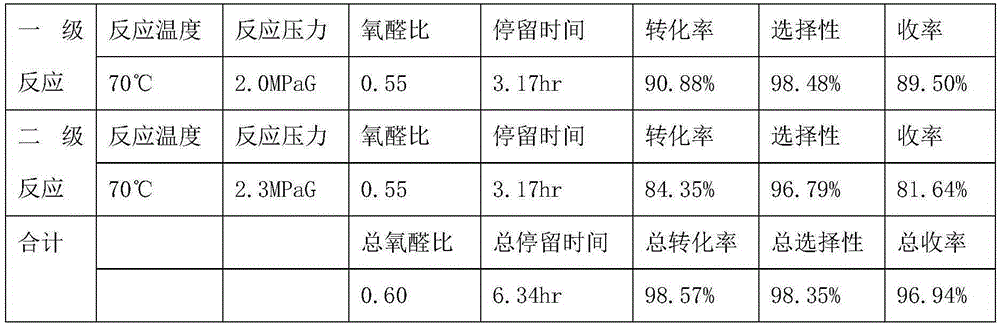

Continuous production method and device for preparing propionic acid through air oxidation of propionaldehyde

InactiveCN105254484AReduce pollutionSimple processOrganic compound preparationCarboxylic compound preparationPropanoic acidGas phase

The invention relates to a continuous production method and device for preparing propionic acid through air oxidation of propionaldehyde. The method comprises the steps that propionaldehyde enters a reactor through a liquid phase inlet in the bottom of a first-order oxidation reactor and makes contact with and is mixed with some compressed air, a majority of propionaldehyde in the raw material is converted into propionic acid through an oxidation reactor, a first-order oxidation product containing a small amount of propionaldehyde continuously enters a second-order or multi-order oxidation reactor and is continuously subjected to the oxidation reaction with the compressed air, and finally the propionic acid with the high-purity is generated. The device comprises two or more oxidation reactors connected in series, a condenser is arranged on the top of each oxidation reactor, and gas phase pipelines and backflow pipelines are arranged between the oxidation reactors for connection. A tail gas processing device is arranged behind each oxidation reactor. A gas phase pipeline is arranged between each condenser and the corresponding tail gas processing device for connection. The reaction conditions are mild, the product yield is high, the product quality is good, the propionaldehyde conversion rate is larger than 98.5%, the selectivity of the propionic acid is larger than 97.5%, and the product purity is larger than 99.5%.

Owner:TIANJIN UNIV

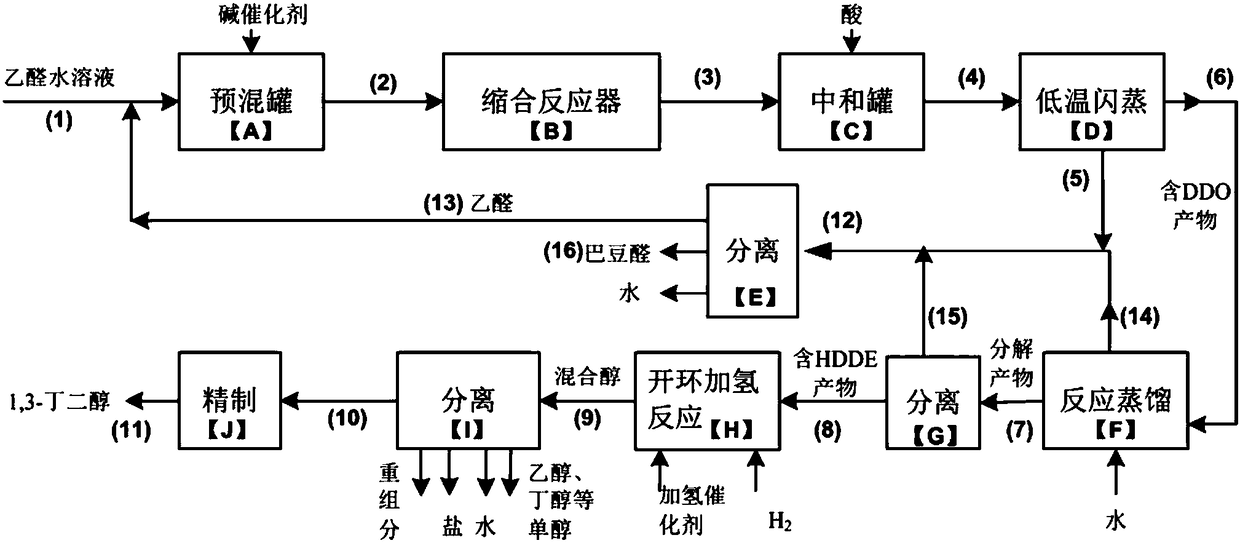

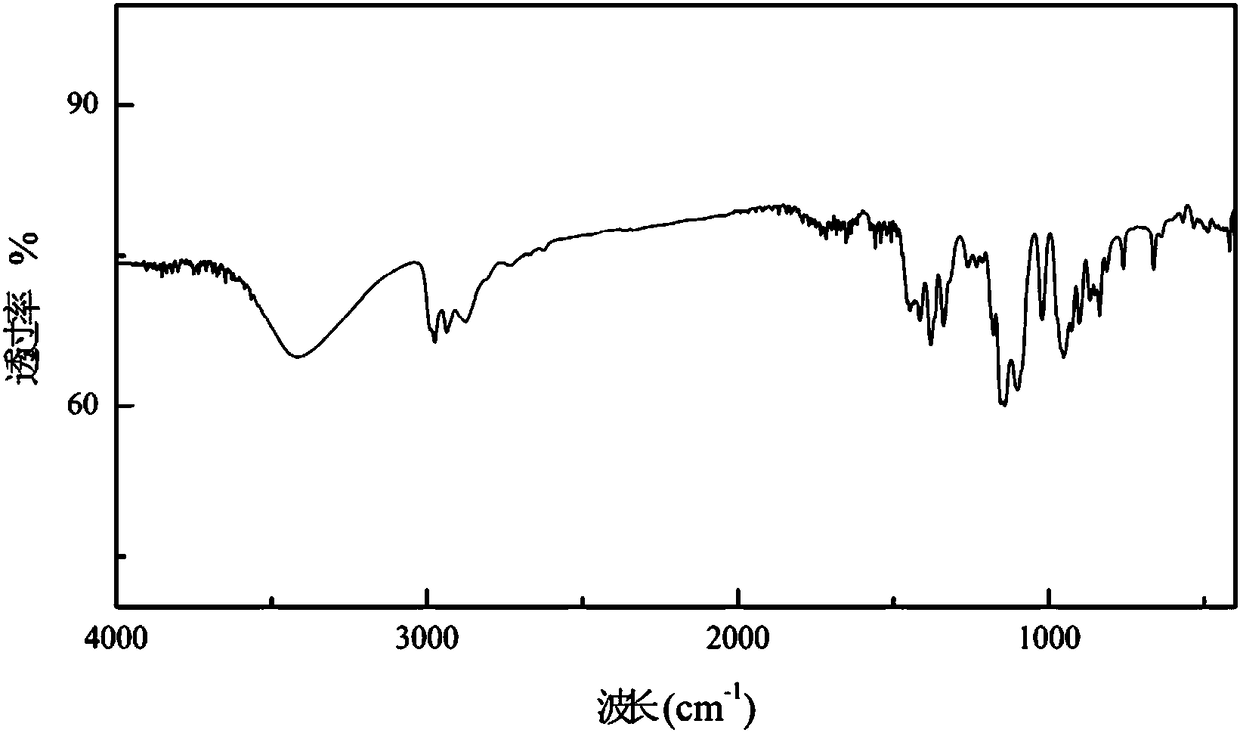

1,3-butanediol synthesis method and system

ActiveCN108383684AImprove stabilityReduce generationOrganic compound preparationHydroxy compound separation/purificationCrotonaldehydeDistillation

The invention discloses a 1,3-butanediol synthesis method and system. For the synthesis method, 1,3-butanediol is produced from acetaldehyde by a 2,6-dimethyl-1,3-dioxane-4-alcohol route; the stability of the intermediate product is improved; the selectivity of the 1,3-butanediol is improved; the generation of harmful, easy-color-developing and smelly crotonaldehyde and derivatives is reduced. Meanwhile, a tubular reactor with a built-in component is used as a condensation reactor; the heat can be effectively removed; the low-temperature cooling load is reduced; the reaction controllability isimproved; the unnecessary backmixing is reduced; the generation of by-products is reduced. The 2,6-dimethyl-1,3-dioxane-4-alcohol pyrolysis is performed in a mode of firstly performing low-temperature flash evaporation and then performing catalytic reaction distillation; the acetaldehyde is recovered; the raw material utilization rate is effectively improved; the yield of the final product is improved; the chromaticity and the odor can meet the requirements of most high-level application.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

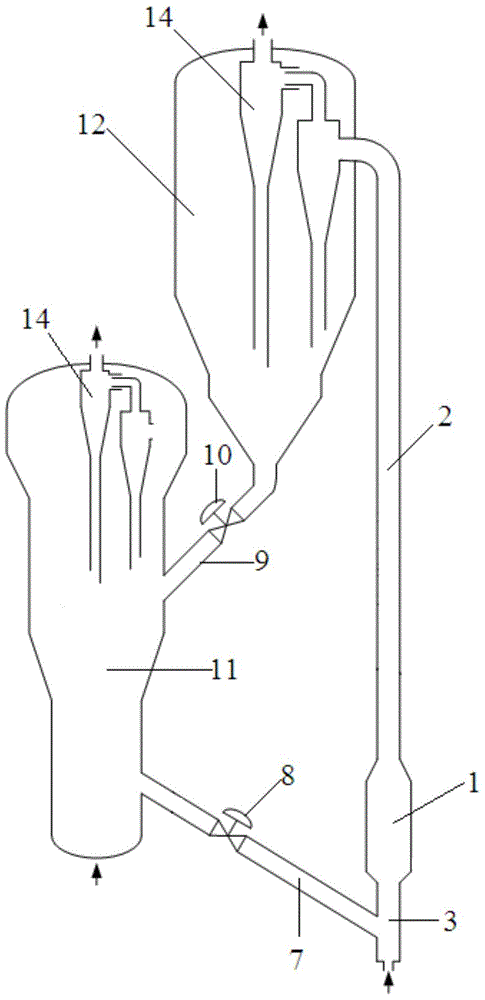

Double-CFB (circulating fluidized bed) reaction-regeneration system and method to prepare arenes with synthetic gas

ActiveCN108654527AReduce design difficultyReduce backmixingLiquid hydrocarbon mixture productionBio-feedstockFluidized bedAromatization

A double-CFB (circulating fluidized bed) reaction-regeneration system and method to prepare arenes with synthetic gas are provided. The system herein comprises an aromatization reactor and a catalystregeneration reactor which are connected with each other through a pipeline; the aromatization reactor comprises a first catalyst filling area and a second catalyst filling area; the catalyst regeneration reactor includes a fourth catalyst filling area and a third catalyst filling area; the aromatization reactor is filled with a hydrocarbon synthetic catalyst and an aromatization catalyst; under the action of a flow of gas, the hydrocarbon synthetic catalyst stays mainly in the area below, and the aromatization catalyst stays mainly in the area above. A regeneration method is also disclosed, including: after the aromatization catalyst is inactive, allowing the aromatization catalyst to enter a low-temperature hypoxic area of the catalyst regeneration reactor and then enter a high-temperature hyperoxic area of the catalyst regeneration reactor. The system and method herein have the advantages that controlling at different temperatures is achieved and catalyst design is less difficult.

Owner:TSINGHUA UNIV

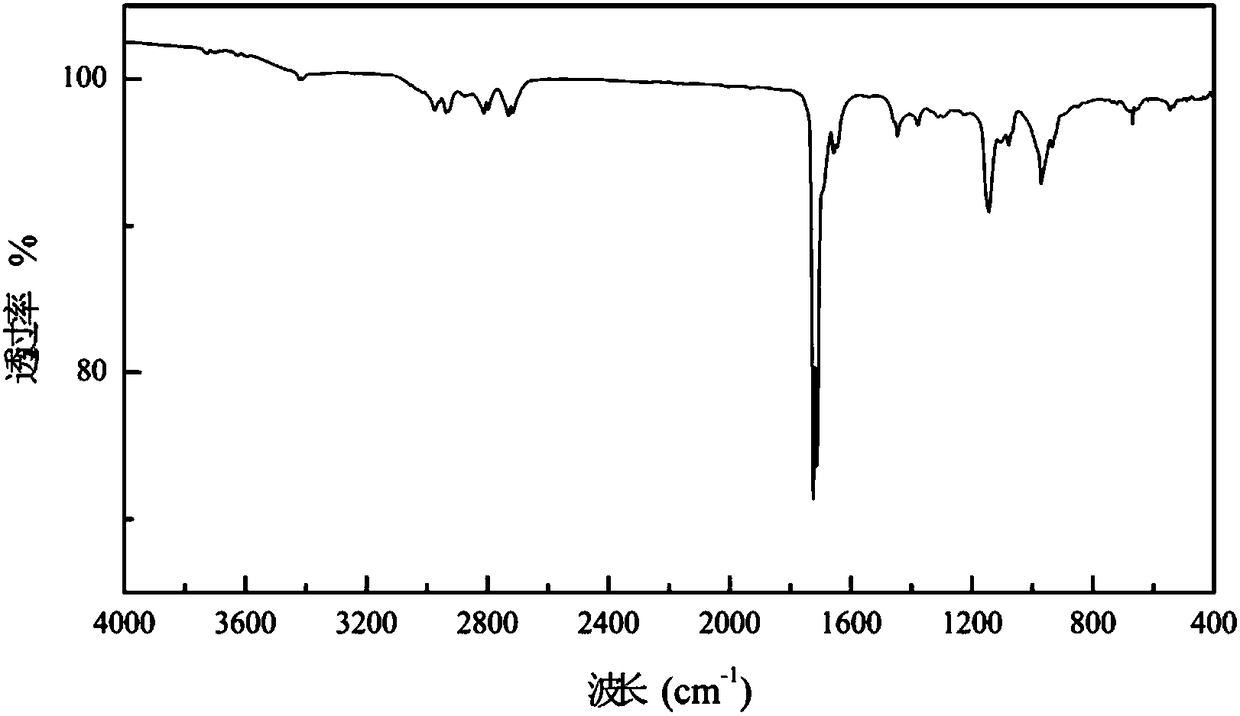

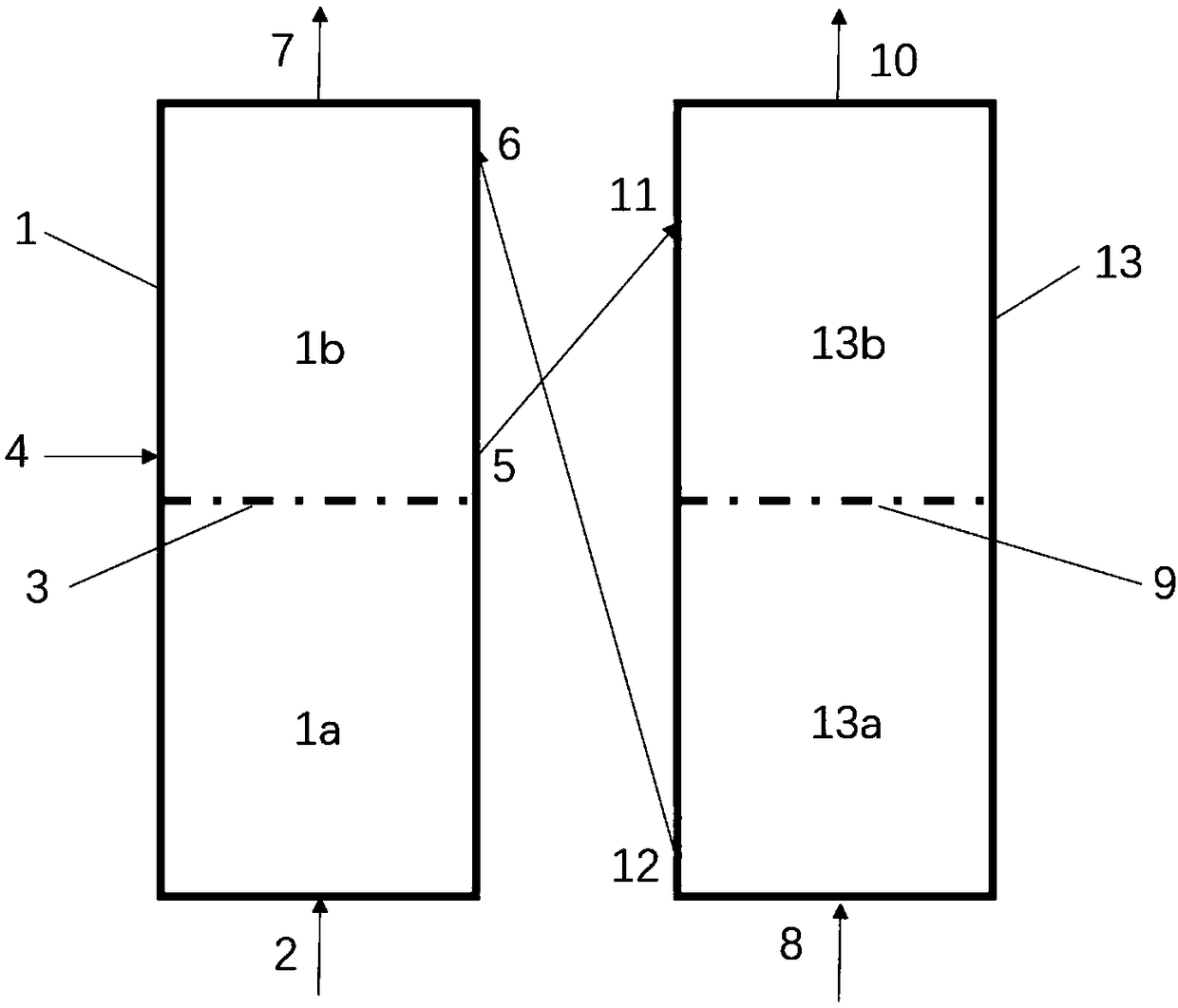

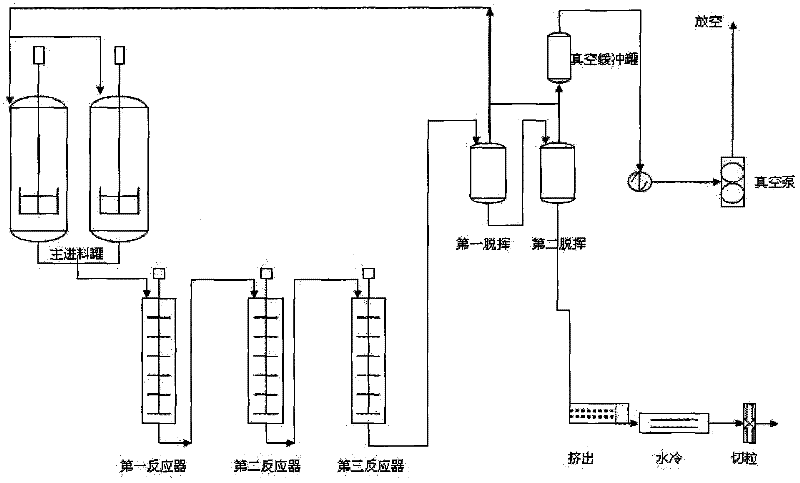

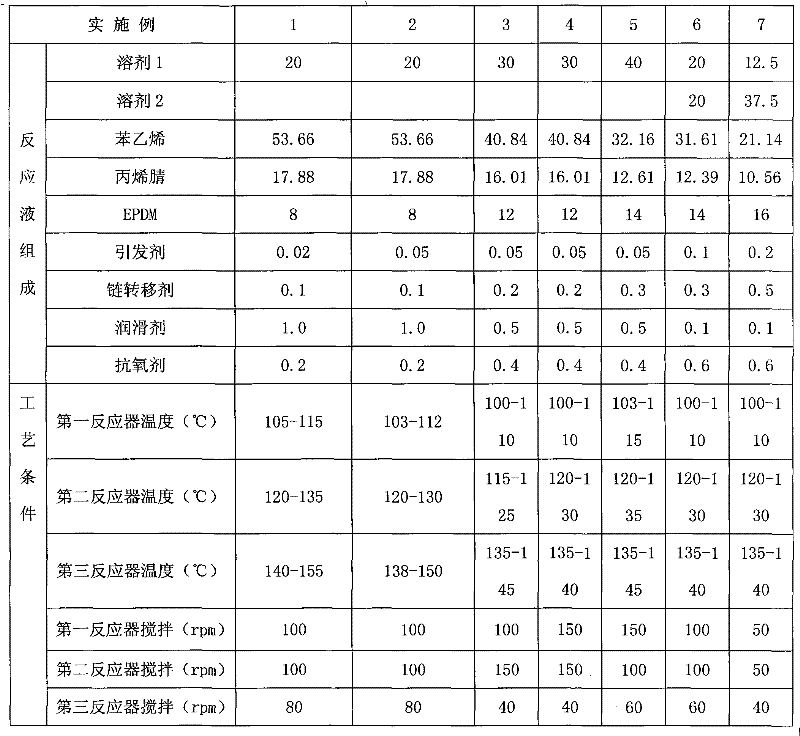

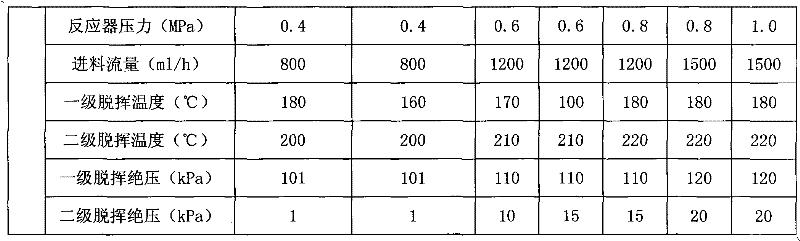

Continuous bulk preparation method of acrylonitrile-ethylene propylene diene monomer (EPDM)-styrene (AES) resin

The invention relates to a continuous bulk preparation method of an acrylonitrile-ethylene propylene diene monomer (EPDM)-styrene (AES) resin. The method comprises the following steps of: adding the EPDM into a solvent to be dissolved completely under heating; mixing the solution, styrene, acrylonitrile, an initiator, a chain transfer agent, an antioxidant and a lubricant to form a rubber solution system; performing graft polymerization reaction sequentially through three series-wound tower reactors; performing aftertreatment through second-level vacuum devolatilization; and preparing the AES resin which is suitable for injection moulding and extrusion processing by controlling the variety of rubber, rubber content and the material feeding ratio. The resin product prepared by the preparation method has high impact strength, excellent weather resistance and notch impact strength retention rate of over 95 percent when an artificial xenon lamp is aged for 1,000 hours, and is applicable in the fields of automobile parts, electron and electricity, building materials, sports equipment and the like.

Owner:ZHEJIANG OCEANKING DEVELOPMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com