Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Reduce holdup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

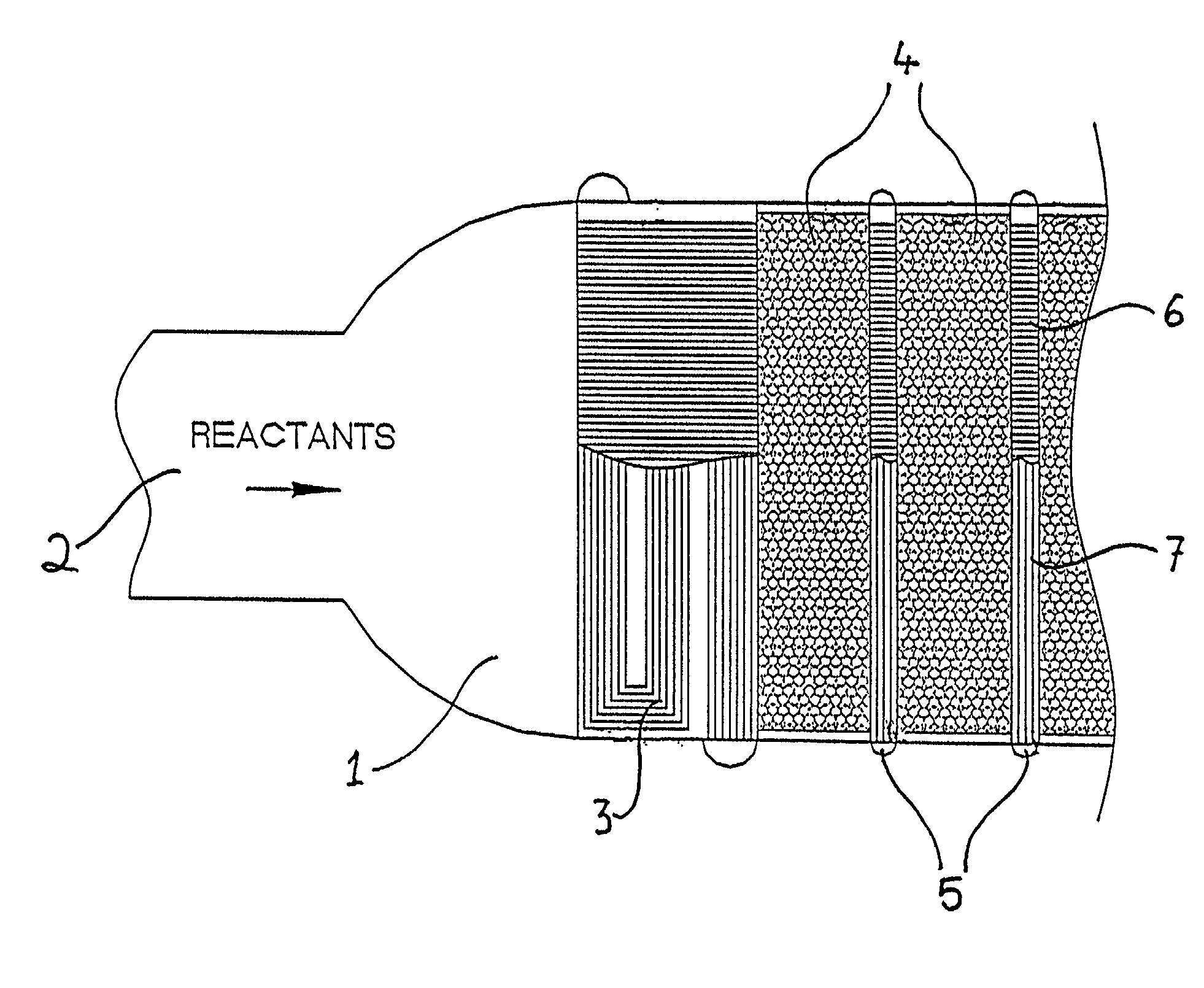

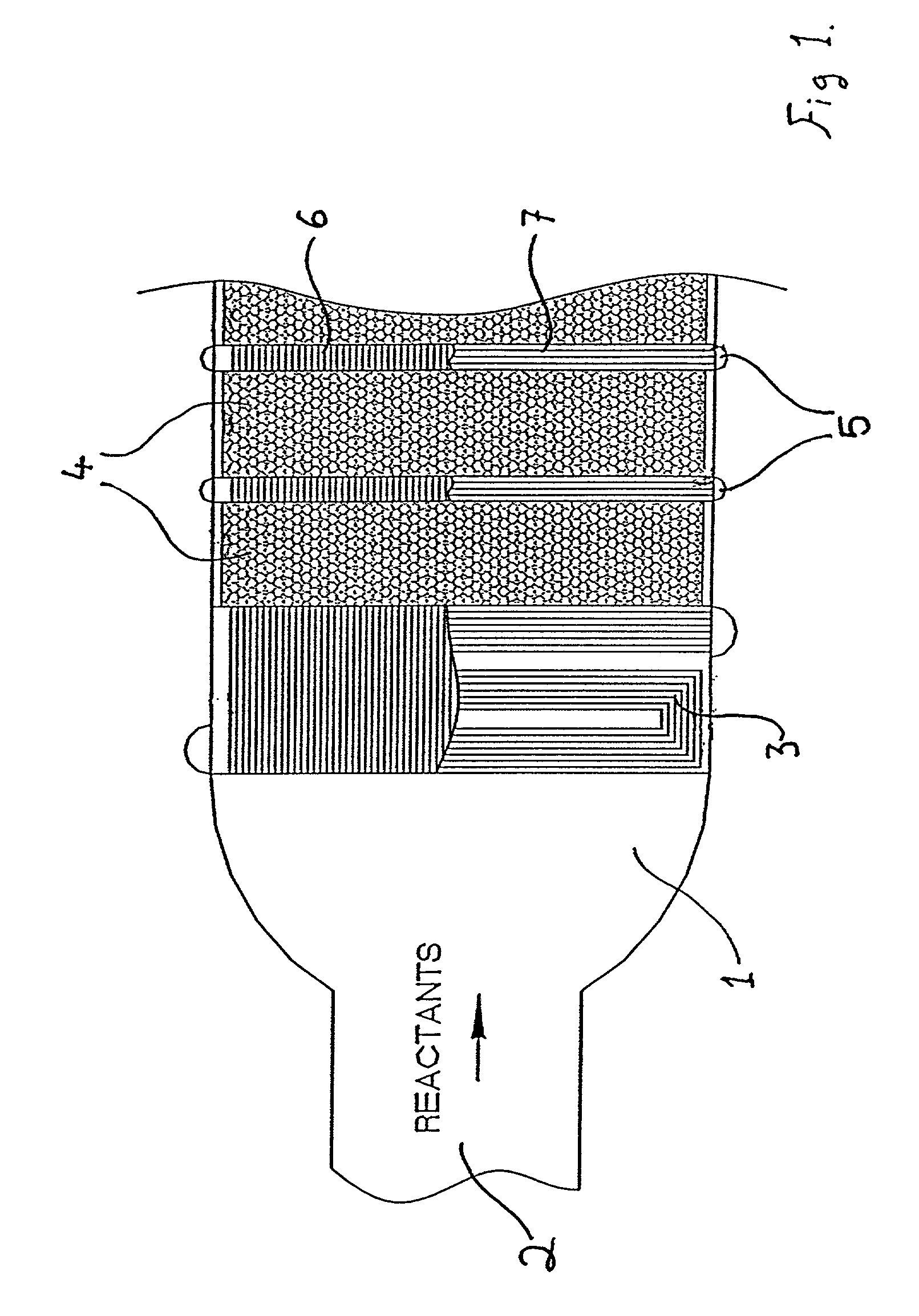

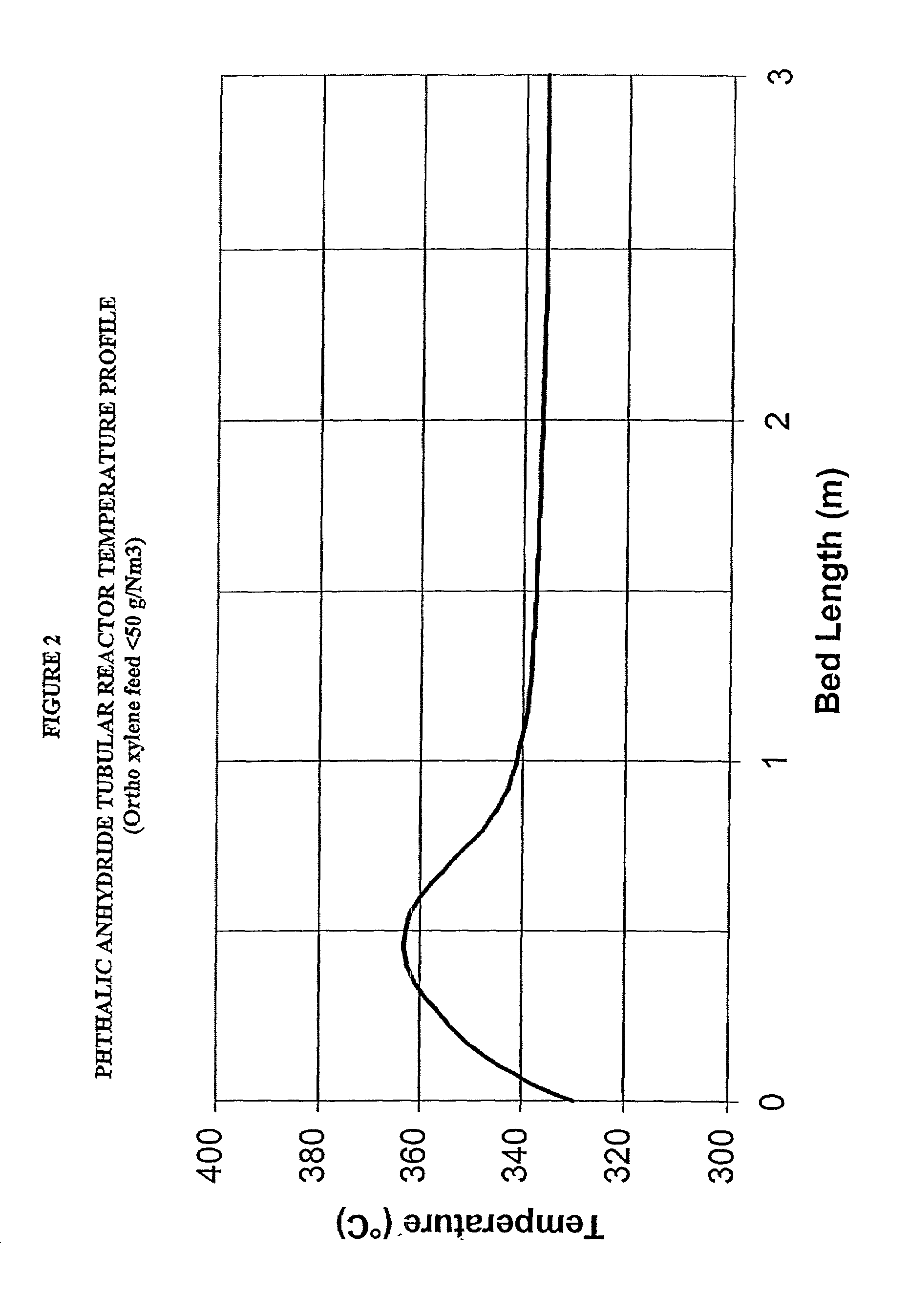

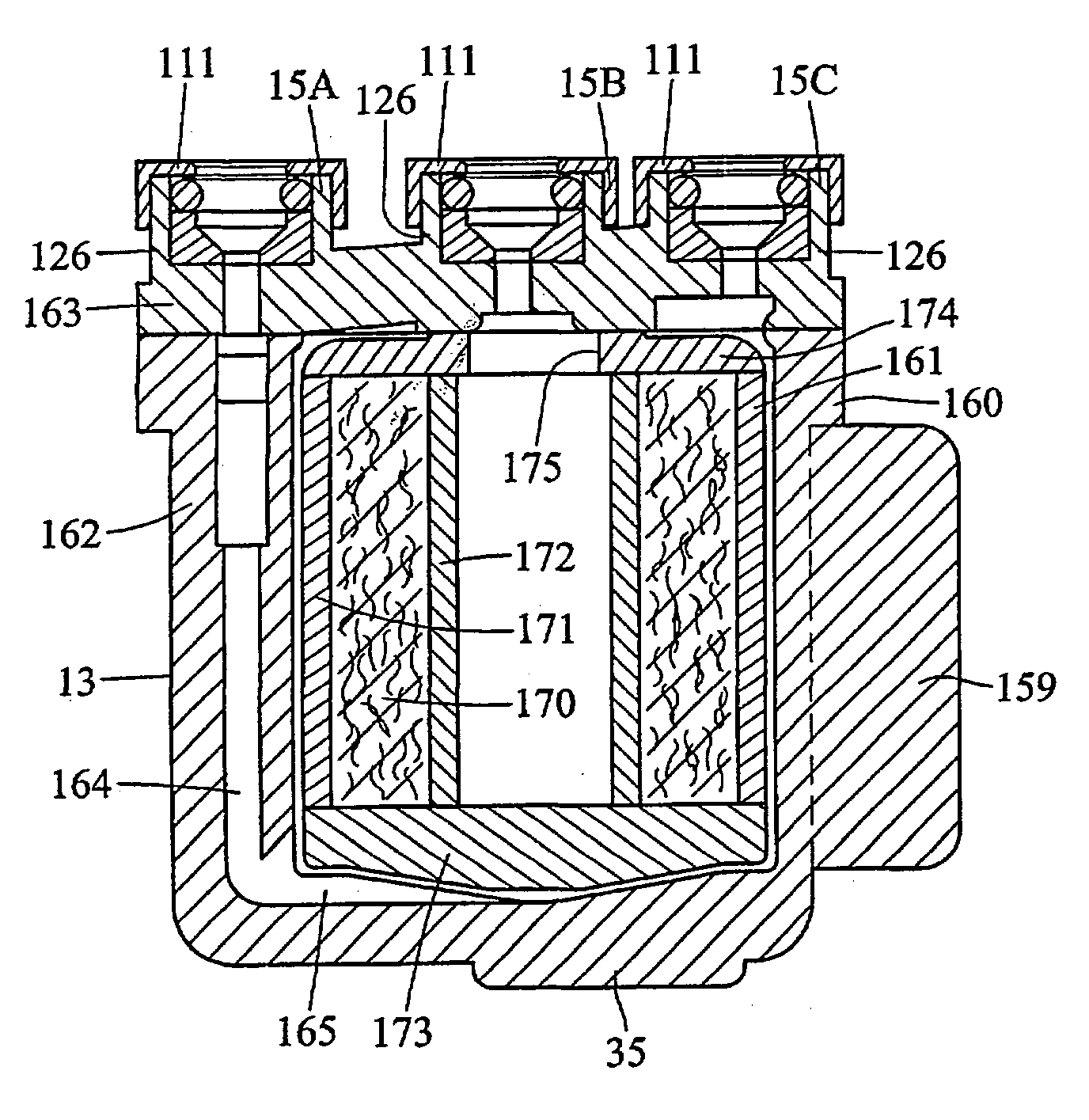

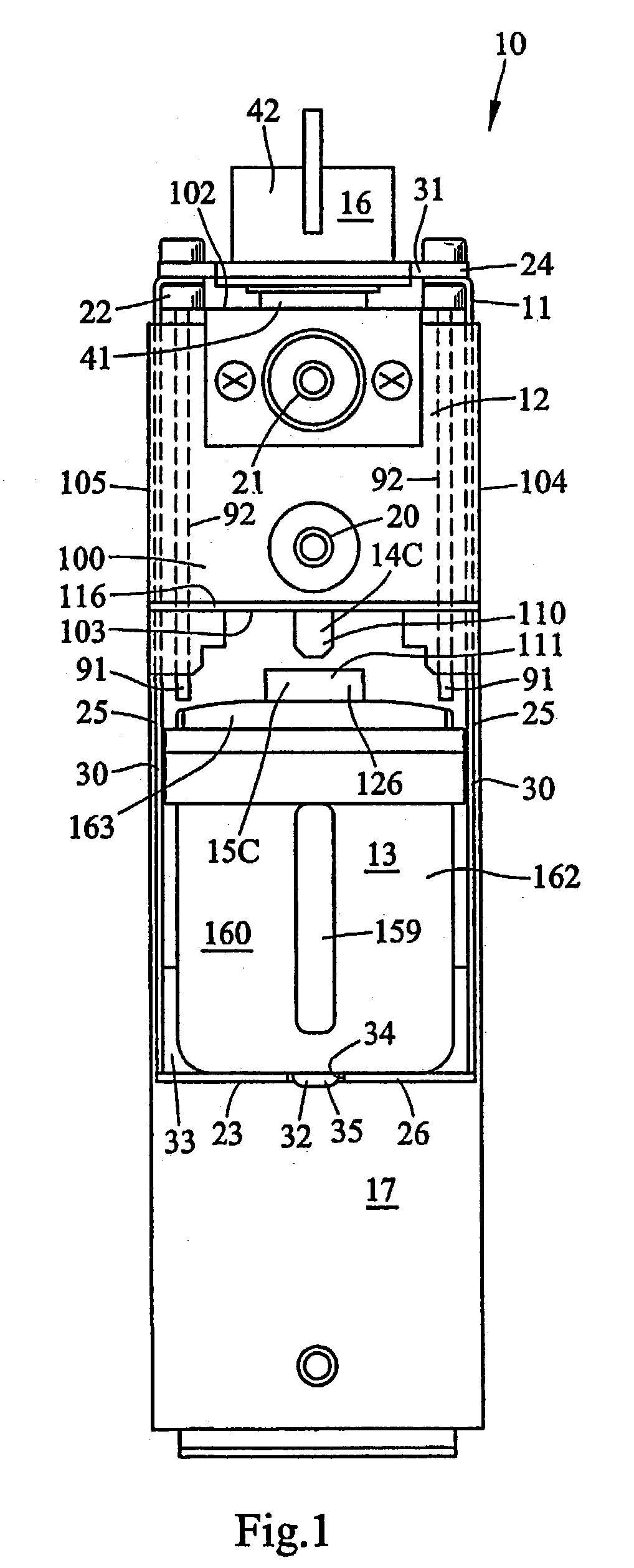

Chemical reactor

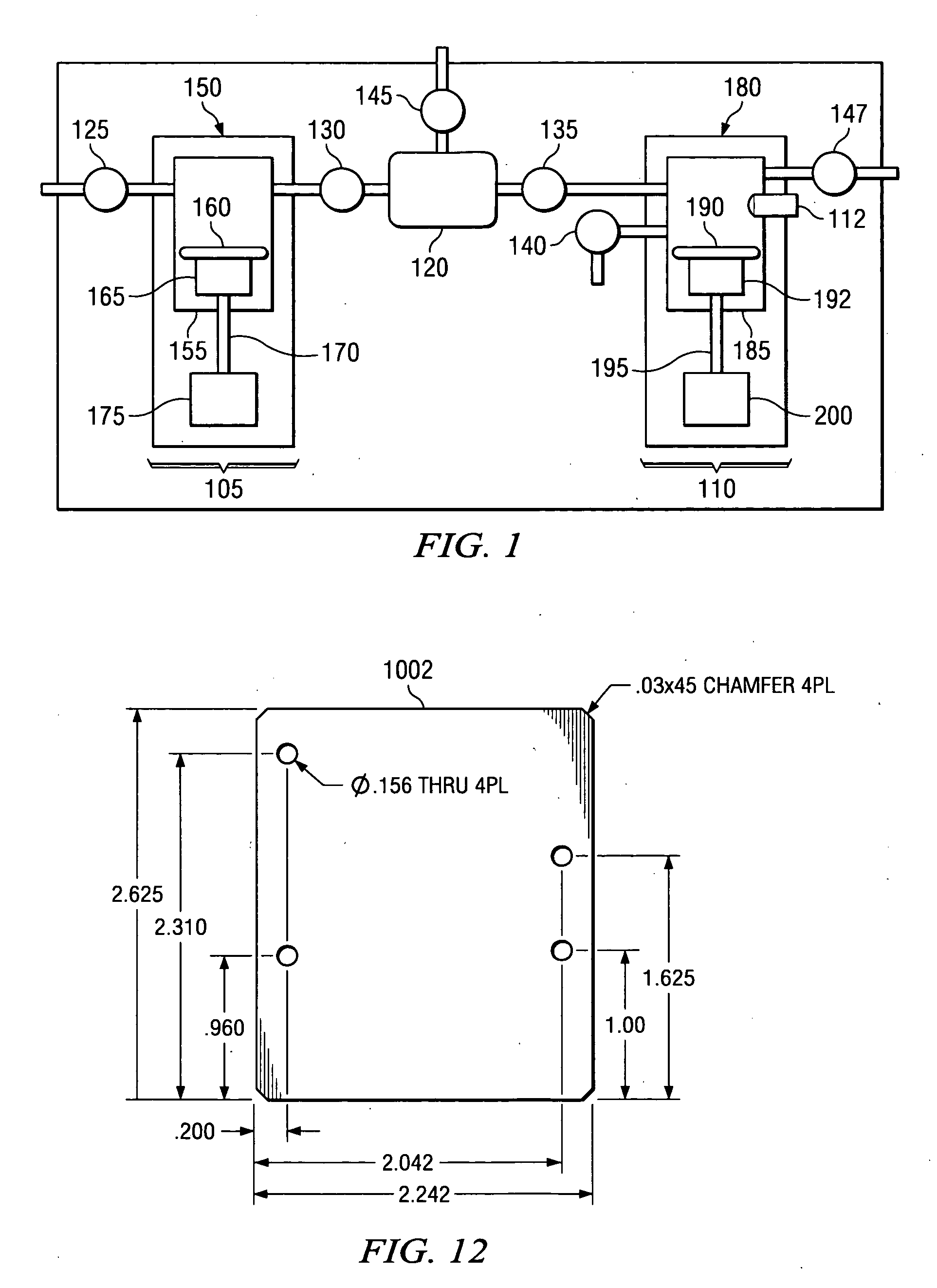

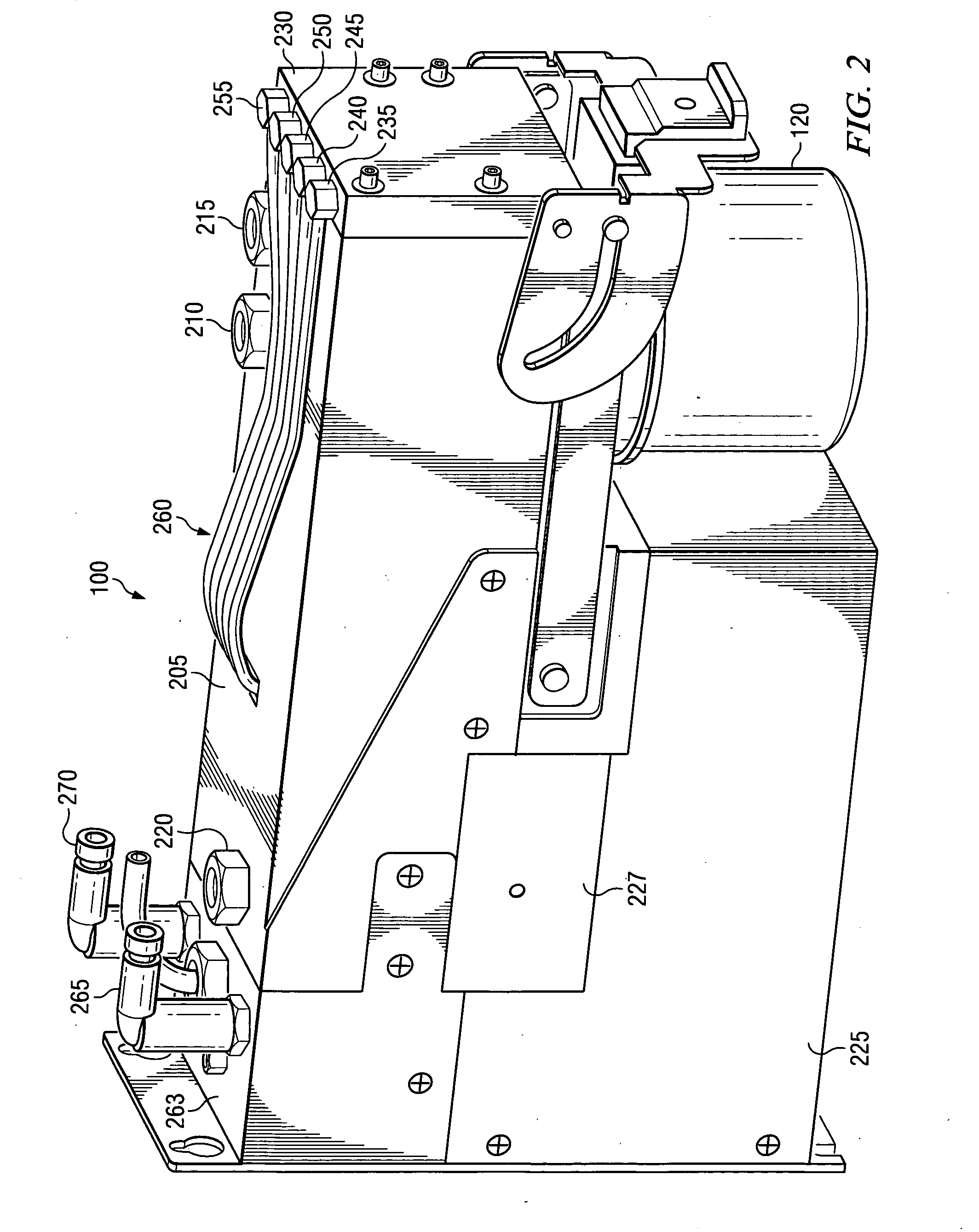

InactiveUS7033553B2Tight controlReduce backmixingPhysical/chemical process catalystsChemical/physical/physico-chemical processesWorking fluidChemical reactor

A reactor comprises a reaction zone, optionally containing a catalyst bed, and heat exchange means inoperative contact with the reaction zone, e.g. embedded in a catalyst bed, and arranged so as to received reactants for heat exchange purposes, wherein the heat exchange means is formed from a plurality of superposed metal plates wherein fluid flow channels have been formed, according t a pre-determined pattern, the channel-bearing plates being aligned during superposition to define discrete heat exchange pathways respectively for reactant and working fluids, and the said plates are diffusion bonded together.

Owner:MEGGIT (UK) LTD

Filters

InactiveUS7195122B2Many problemReduce holdupSettling tanks feed/dischargeMembrane filtersEngineering

A filter comprising a filter cartridge and a housing having at least one fitting and defining a chamber, the filter cartridge being disposed in the chamber, wherein the housing includes a fluid conduit which extends axially from the fitting along the periphery of the filter cartridge, the fluid conduit being isolated from the filter cartridge chamber along a substantial portion of the length of the fluid conduit.

Owner:PALL CORP

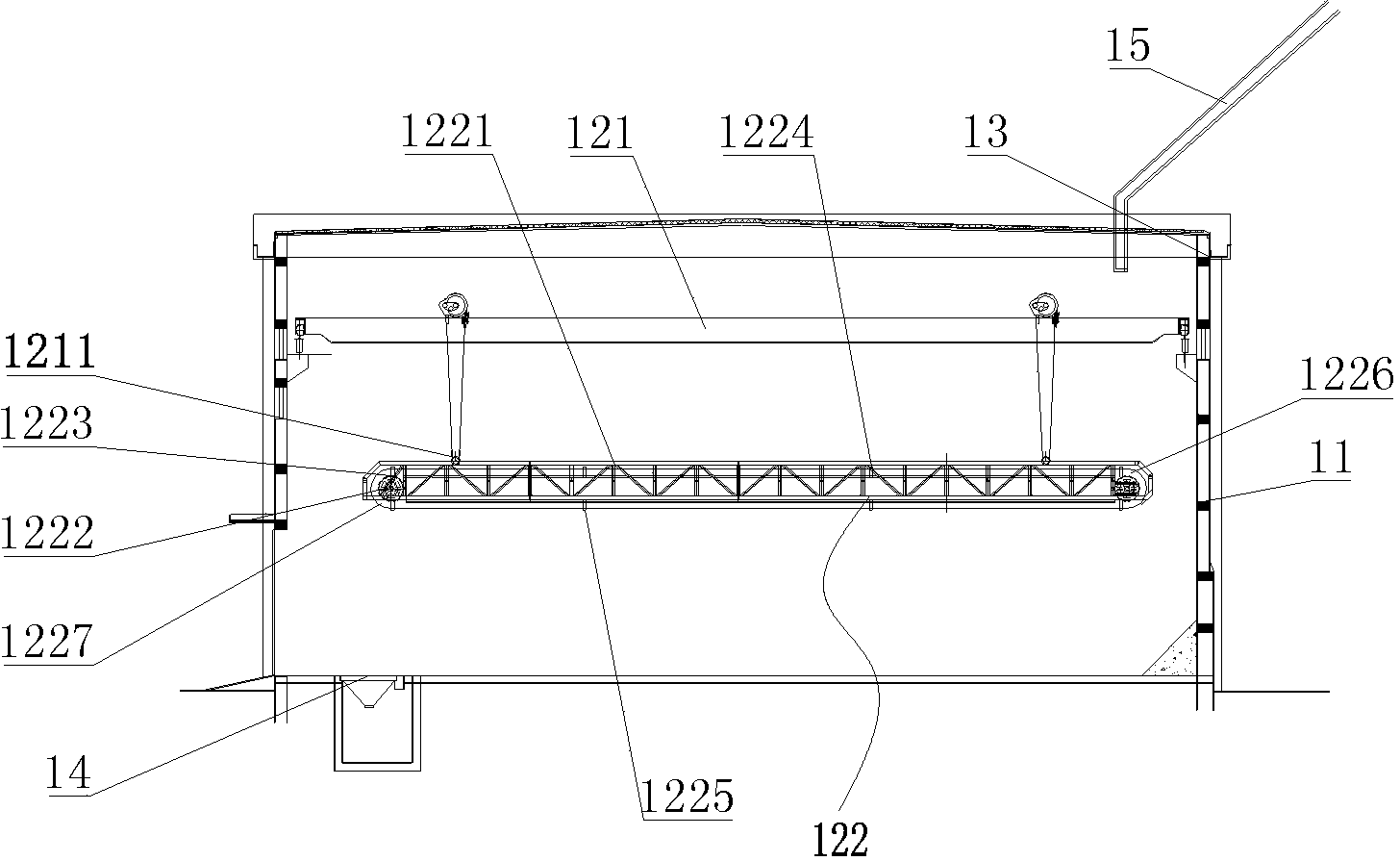

Material bin and bin leveling and unloading device thereof

InactiveCN104340697AReduce holdupIncrease the amount of outboundLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses a material bin and a bin leveling and unloading device thereof. The material bin is characterized in that the bin leveling and unloading device is assembled in a bin chamber; a lifting mechanism for driving a movable bracket to move up and down is arranged on a bridge type crane of the bin leveling and unloading device; a horizontal chain or belt transmission type bin leveling and unloading scraper plate conveying mechanism is assembled on the movable bracket and is provided with an upper scraper plate rotating to the upper side and a lower scraper plate rotating to the lower side; an outward extension part extending out of the lower side of the movable bracket is arranged on the lower side of the lower scraper plate. According to the material bin, the bin leveling operation of the bin chamber is smoothly finished through traveling and lifting of the bin leveling and unloading scraper plate conveying mechanism in the bin chamber, and the bin unloading amount of materials in the bin unloading operation is increased.

Owner:郑州泰和粮油科技有限公司

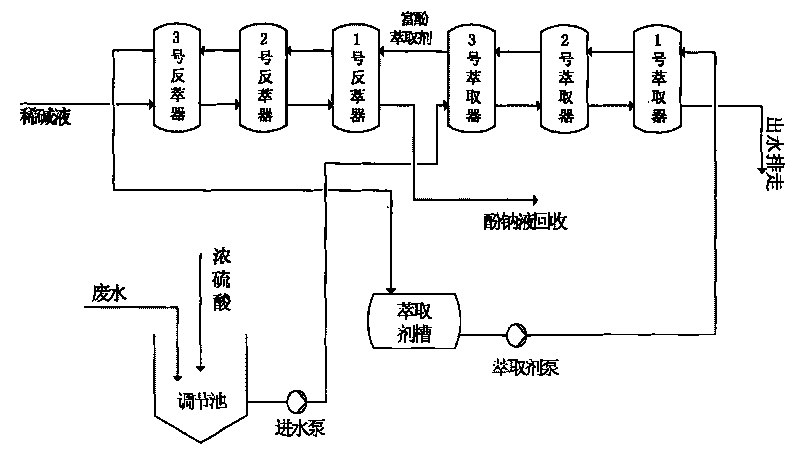

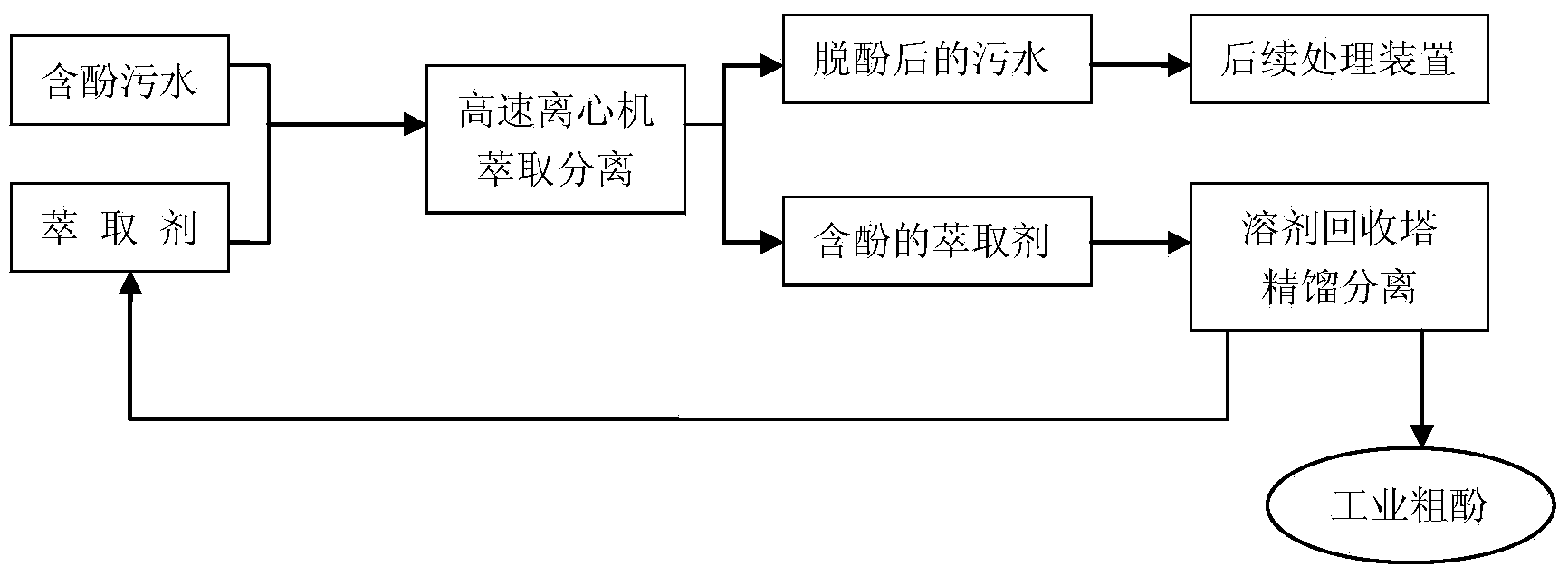

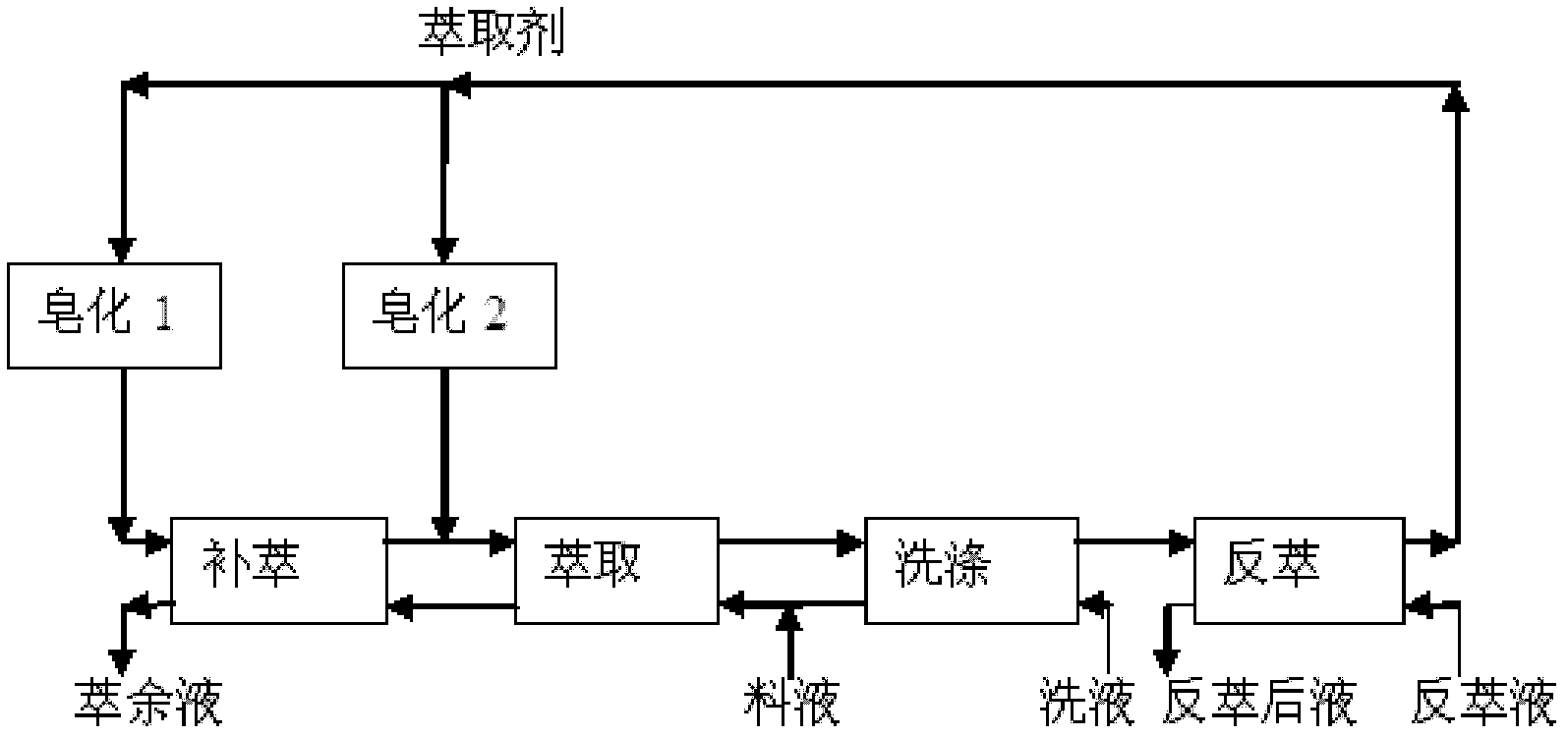

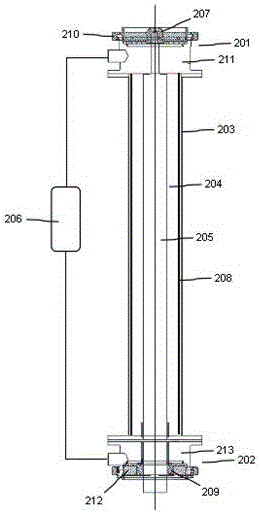

Complexing centrifugal extraction method of high-concentration phenolic wastewater

InactiveCN101723528ALarge extraction and dephenolization coefficientForward and reverse reactions are easyWater contaminantsMultistage water/sewage treatmentHigh concentrationWastewater

The invention provides a complexing centrifugal extraction method of high-concentration phenolic wastewater, which utilizes an efficient extractor and a back wash extractor to process high-concentration phenolic wastewater. The method of the invention comprises the following steps: 1) pretreating the phenolic wastewater; 2) leading the extracting agent to flow to each extractor in turn; 3) leading the phenolic wastewater to flow reversely into each extractor which is flown with extracting agent for extraction reaction; 4) discharging the wastewater from the extractor after dephenolizing; 5) discharging the extracting agent rich in phenol from the extractor which is filled with wastewater firstly; 6) leading the extracting agent rich in phenol to flow reversely to each back wash extractor, leading the thin alkali solution to flow into each back wash extractor which is flown with extracting agent rich in phenol for backextraction reaction; and 7) discharging the phenolate generated in the backextraction reaction from the back wash extractor which is flown with extracting agent rich in phenol firstly, and discharging the extracting agent after backextraction from the back wash extractor which is flown with thin alkali solution. The invention has low cost, small floor area, great flexibility of device operation, low consumption, the phenol content of the processed water is reduced to below 200ppm, the phenol removal rate is above 99%, thus achieving the biochemical treatment water quality standard, recovering the phenol in the waste water in the form of phenolate to return to the system for reuse, and lowering environmental pollution.

Owner:山西焦化股份有限公司

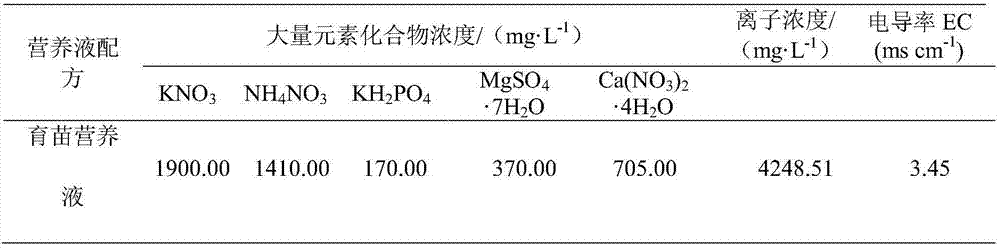

Integrated high propagation method of water planting of virus-free potato seeds and seedlings

InactiveCN107347608APromote circulationReduce holdupAgriculture gas emission reductionCultivating equipmentsNutrient solutionPlant propagation

The invention relates to an integrated high propagation method of water planting of virus-free potato seeds and seedlings. The method comprises the steps that a multiplication technology of the water-planting virus-free seedlings and a water planting production technology of the seedlings and the seeds are integrated, and the concentration of nutrient solution components, the light quality of a supplementary light source, hormone components, seedling cutting times and the like are optimized at the same time. According to the method, the stability and security are high, operation and daily management are simple and convenient, the maintenance and production costs are low, the sound seedling index of water-planting potato plants are significantly improved, the yield and quality of the seedlings and mini-potato are improved, the plant propagation coefficient is enlarged, the production cycle of the mini-potato is shortened, and the method is of great importance in breeding of the potato seeds and seedlings.

Owner:SOUTHWEST UNIVERSITY

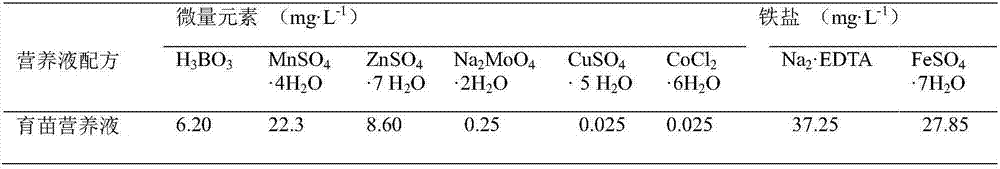

Automatic control system preventing hydropexis deterioration of chamber water and method thereof

InactiveCN105804162AReduce holdupReduce retention and deteriorationService pipe systemsWater mainsAutomatic controlWater quality

The invention discloses an automatic control system preventing hydropexis deterioration of chamber water and a method thereof. A computer for hotel room register is connected with a computer for computing through the OPC protocol, the computer for computing extracts water consumption information to determine water demand through computing, a pressure transmitter, a residual chlorine detector, a water quality detector, a liquid level probe, a highest and lowest liquid level warning device, and an electric valve controlling water input and output of a water tank are all connected with a PLC automatic control system, signals of the pressure transmitter and the residual chlorine detector are taken as input end signals of a PID module, and signal output is achieved after a driving circuit drives a water pump and an automatic chlorinator. Manual control and automatic control can be combined, dynamic supervision is implemented, operability is high, economical efficiency is high, secondary pollution caused by hydropexis deterioration of water in the water tank due to long-time retention can be prevented, and water quality safety is guaranteed.

Owner:NORTHEAST DIANLI UNIVERSITY

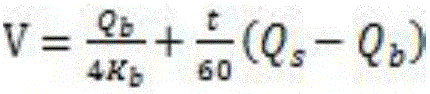

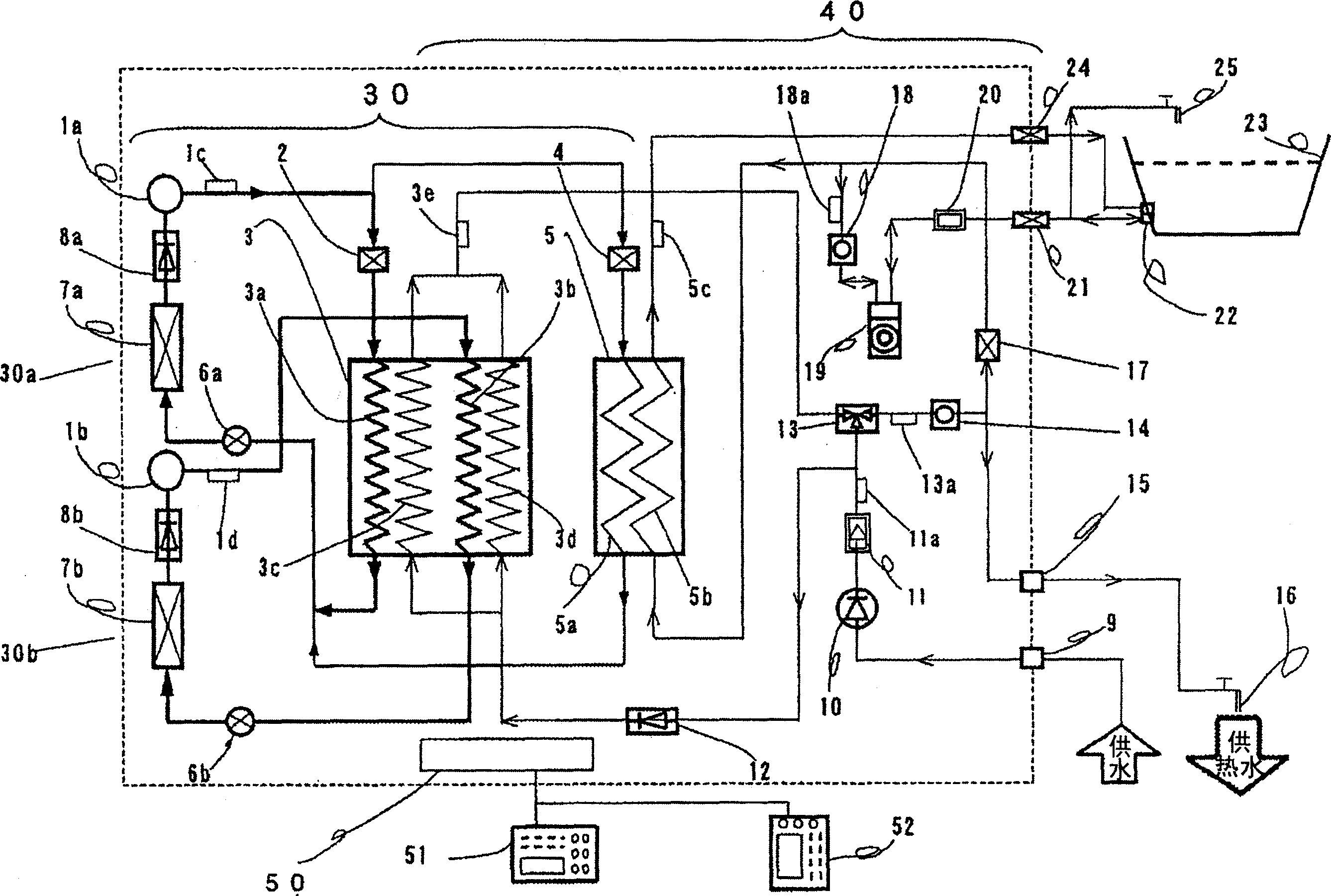

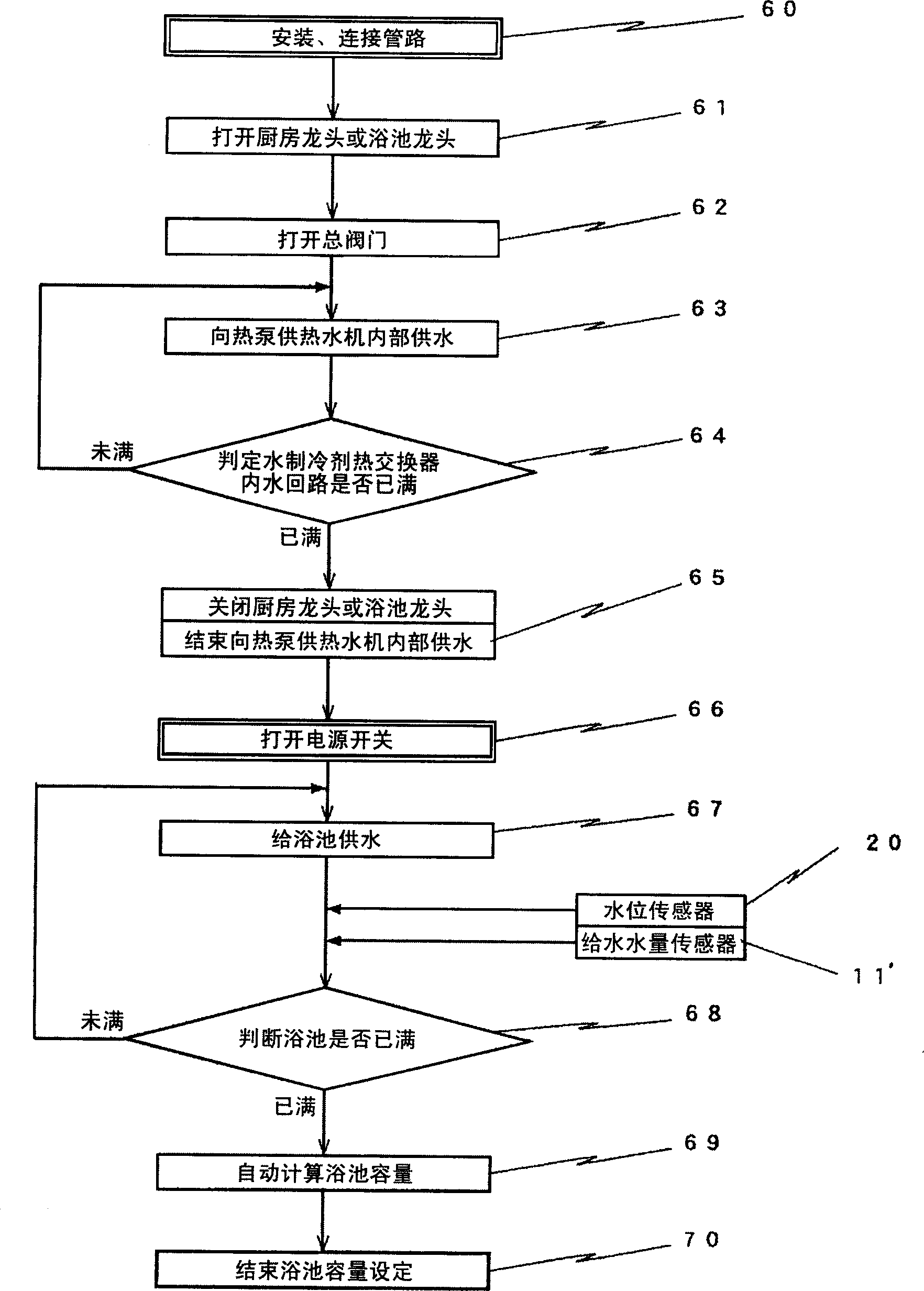

Heat-pump hot water supply apparatus

InactiveCN1837705AAvoid lostReduce holdupHeat pumpsEnergy efficient heating/coolingEngineeringRefrigerant

A heat-pump hot water supply apparatus, for dissolving problems of delaying in heating rise-up time when re-starting, and ill influences upon starting characteristics, due to liquid refrigerant residing in an evaporator when the operation is stepped, within a heat-pump circuit thereof, comprises a heat-pump refrigerant circuit, in which a compressor, a water / refrigerant heat exchanger, a refrigerant adjusting valve, and an evaporator, in series, through refrigerant pipes, a direct hot-water supply circuit, into which is supplied hot water heated, obtained by heating water supplied from an outside via a water pipe by means the water / refrigerant heat exchanger, and a compressor operation controller means for stopping the compressor and also closing the refrigerant adjusting valve when the compressor stops the operation thereof, and for re-starting the compressor after opening the refrigerant adjusting valve when the compressor starts the operation, again, wherein the refrigerant within the evaporator is collected to the compressor side when the operation is stopped, and after stopping, front and back of the evaporator is brought into a sealed condition by means of a refrigerant adjusting valve and a back-flow preventing valve, thereby preventing the refrigerant from residing within the evaporator.

Owner:HITACHI APPLIANCES INC

Concurrent flow heat exchanger

ActiveCN102506523AWell mixedImprove heat transfer efficiencyEvaporators/condensersEngineeringEqualization

The invention discloses a concurrent flow heat exchanger which comprises a lower flow collecting pipe, an upper flow collecting pipe, a plurality of flat pipes arranged between the upper flow collecting pipe and the lower flow collecting pipe and fins arranged between the adjacent flat pipes, wherein the lower flow collecting pipe is internally provided with a flow equalization plate; the width direction of the flow equalization plate is of a convex-concave curved surface or a cambered surface; the part, at which oil is easy to collect, of the flow equalization is provided with a through hole; and the lower flow collecting pipe is divided into a first cavity connected with a refrigerant pipe and a second cavity connected with the flat pipes by the flow equalization plate. According to the invention, the refrigerant enters the larger cavity from the smaller cavity through the through hole on the flow equalization plate, because the flow path of the refrigerant is expanded, refrigerants of gas and liquid phases can be mixed fully, and the heat exchange efficiency of the heat exchanger is improved; when the concurrent flow heat exchanger acts as a condenser, because of the curved surface of the flow equalization plate in width direction, refrigeration oil collected from the flat pipes through condensation is collected to the lower part of the path, and flows back to a refrigerant system through the through hole on the flow equalization plate, thus the flow of the refrigerant is influenced, and the hold-up volume of the refrigeration oil is reduced; and the concurrent flow heat exchanger has the characteristics of simple and reasonable structure, high heat exchange efficiency and wide application range.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

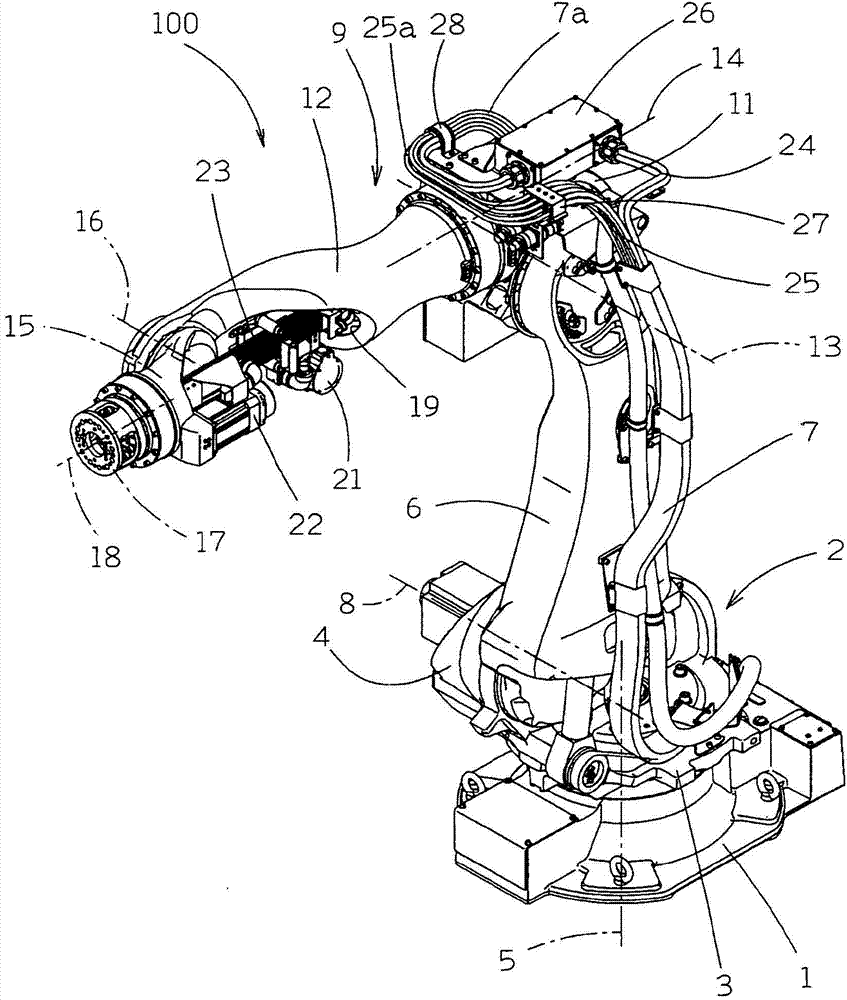

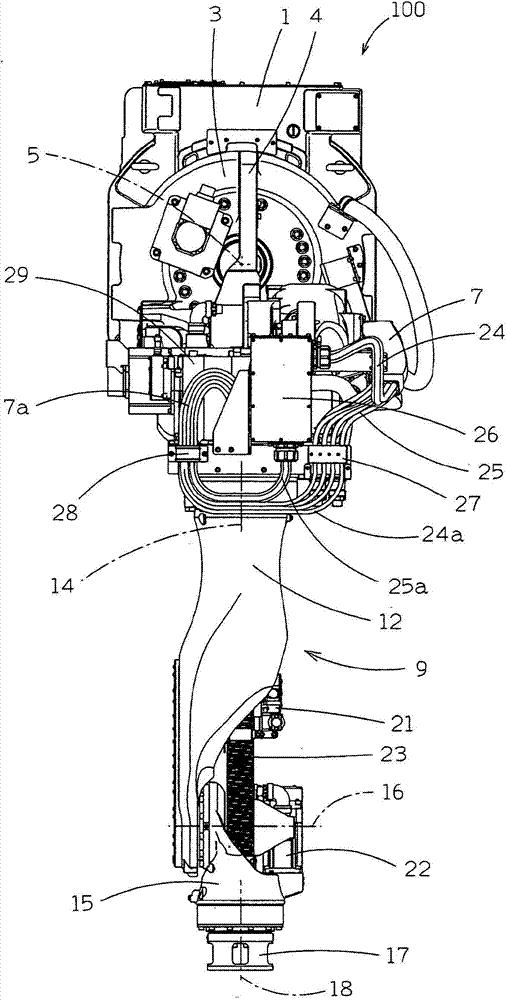

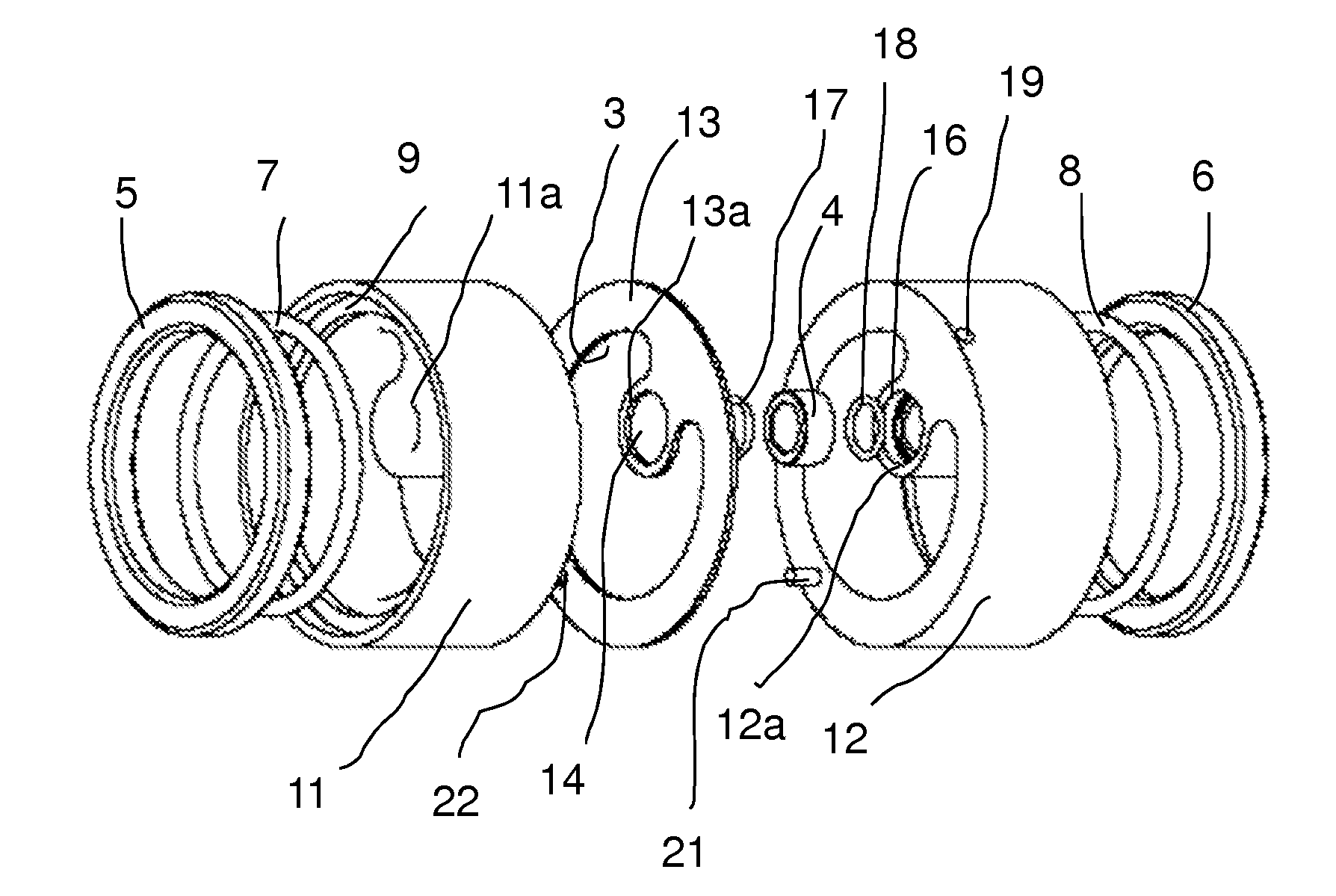

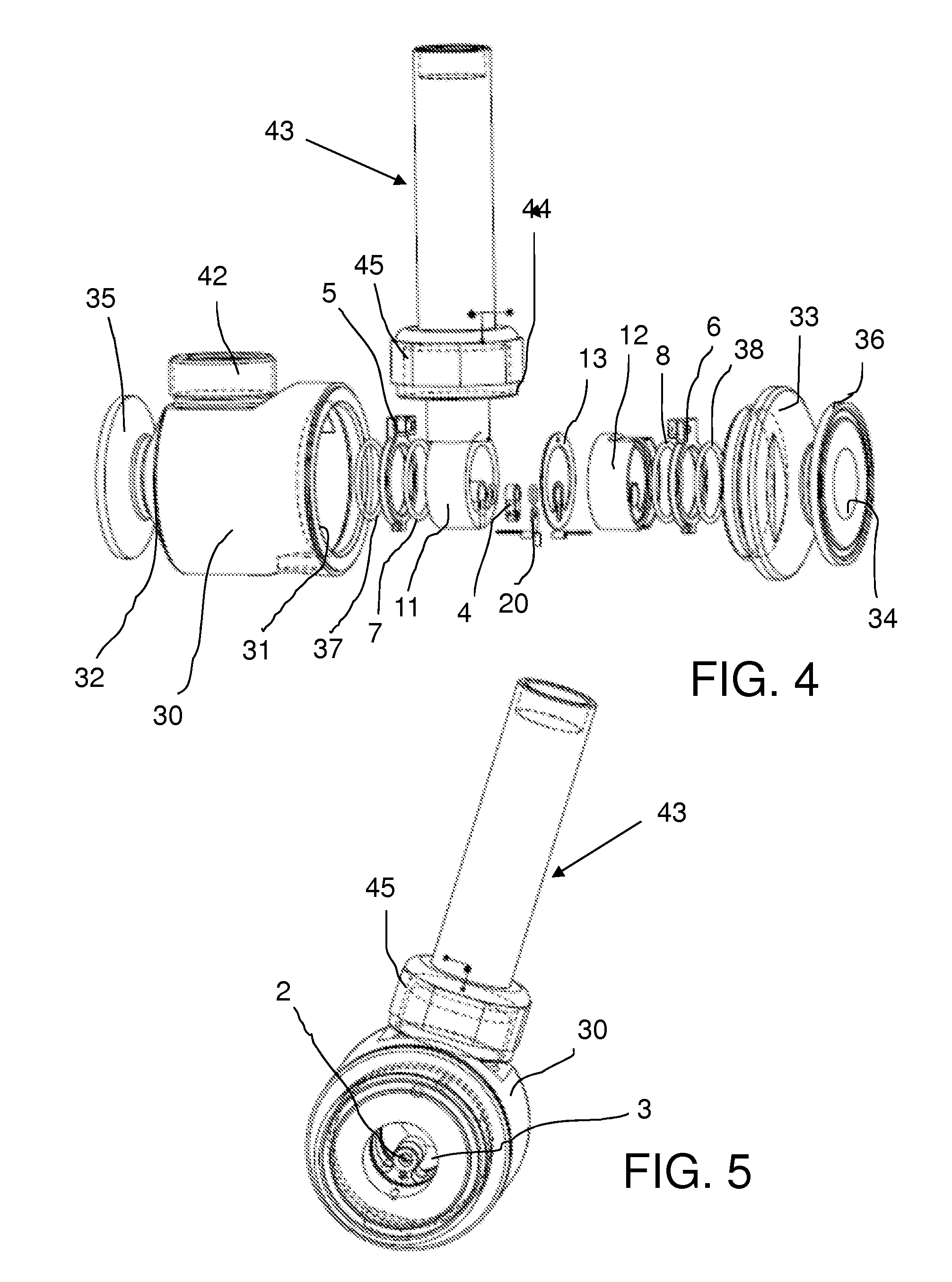

Industrial robot

The invention provides an industrial robot. Cables go through an arm equipped with a wrist and arranged on one side of the industrial robot, so that an unfavorable condition that cables are scattered along with movement of the robot is avoided. An opening part (11a) which allows a cable (7a) to go through is disposed in one end side (11) of a hollow part (12). One end side of the cables (7a) is connected with relay parts (26, 27) on the base of the arm. The cables are provided with a bending part (7a) which bends between the relay parts and the opening part, a restraint member (31) which restrains the cable (7a) of the bending part, and the other end part (7b) which goes through the hollow part towards the wrist (15). The restraint member is larger than the opening of the opening part and can be pressed against the opening part or movably separated from the opening part. The length from the restraint member to the other end part is longer than the necessary length of the cable needed for the motion of the wrist. The restraint member can be detached and assembled in the way of clamping the cable. A guiding member (29) which guides the restraint member is provided so as to allow the central axes of the restraint member and the opening part to be consistent.

Owner:NACHI-FUJIKOSHI

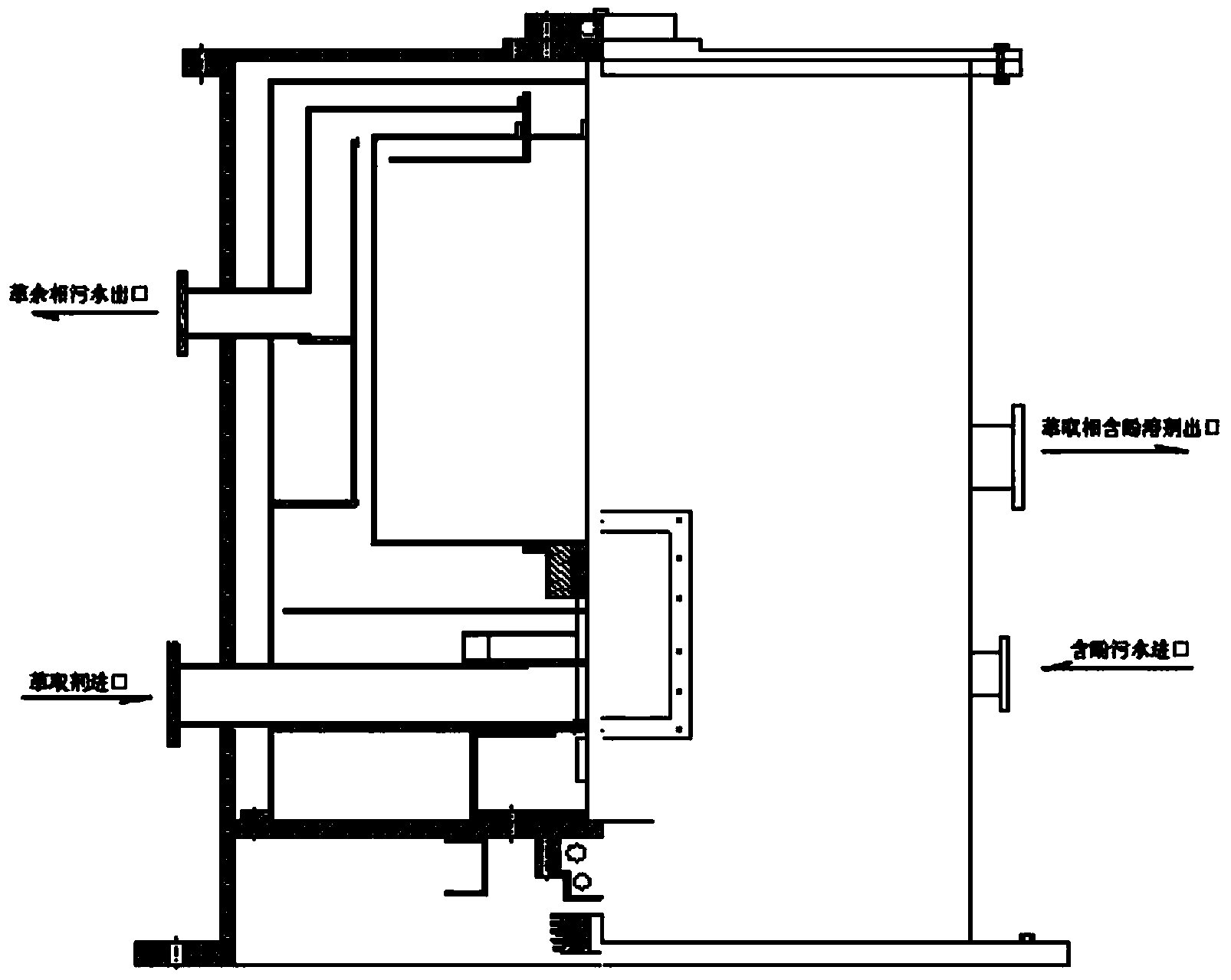

Centrifugal extracting wastewater dephenolization technology

ActiveCN103818982AReduce holdupShort stayWater/sewage treatment by centrifugal separationWater/sewage treatment by extractionWastewaterSmall footprint

The invention relates to a centrifugal extracting wastewater dephenolization technology. A high-speed centrifuge is used as an extraction device to perform centrifugal extraction separation. The technology comprises the steps as follows: phenol wastewater and an extraction agent enter the centrifuge simultaneously for centrifugal extraction separation, an extract phase phenol solvent and extract phase wastewater are produced after separation, the extract phase phenol solvent enters a solvent recovery tower for rectification separation, and a solvent and crude phenol are recovered; the extraction agent extracted at the top of the tower enters the centrifuge again to be recycled, and the crude phenol is recovered at the bottom of the tower. Compared with the prior art, the technology has the benefits as follows: the technology is low in investment, small in occupied area, simple and reliable in technological process, high in dephenolization efficiency and capable of realizing recovery of the industrial crude phenol.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

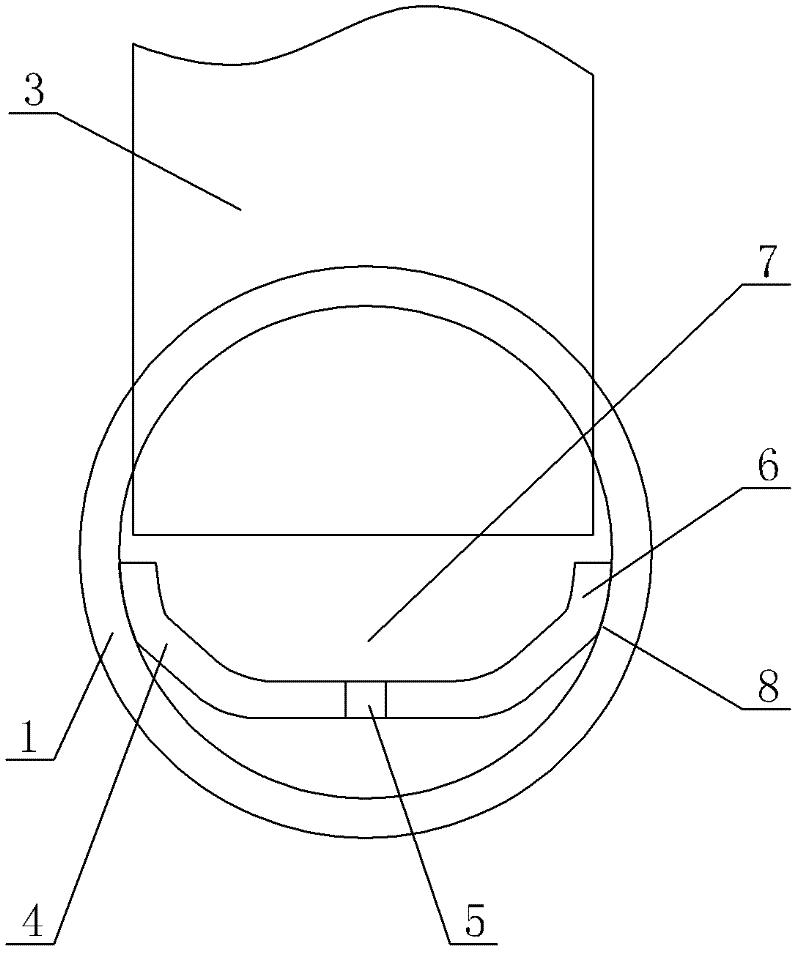

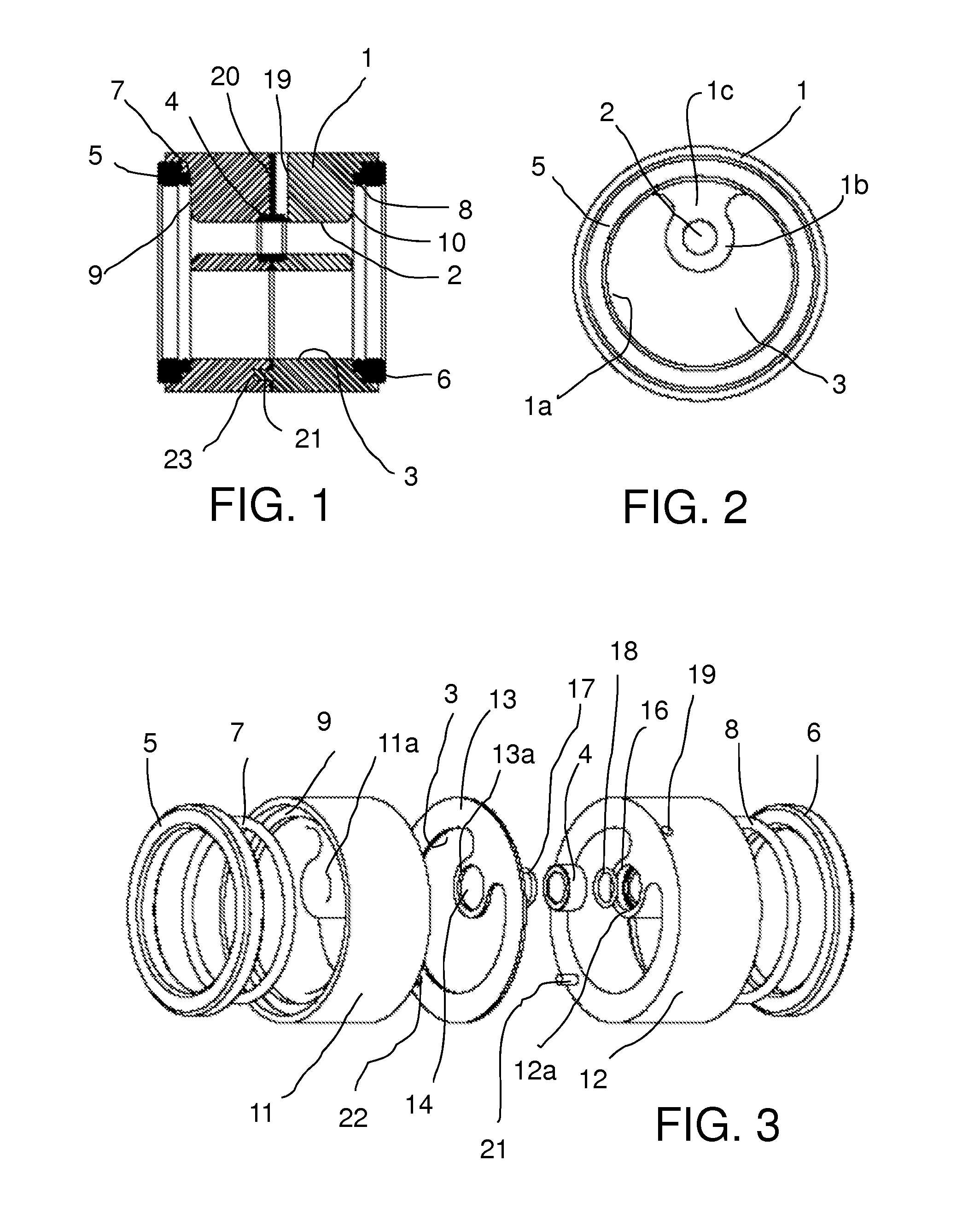

Conductivity sensor assembly

ActiveUS20120256641A1Adding hold-up volumeReduce holdupComponent separationFluid resistance measurementsElectrical resistivity and conductivityMechanical engineering

A flow-through conductivity sensor assembly comprises a housing (4) having a flow passage with an inlet end and an outlet end. The cross section of at least a section of the flow passage extension between the inlet and outlet ends is divided into a conductivity measuring channel (2) and a parallel by-pass channel (3) of larger cross-sectional area than the measuring channel (2).

Owner:CYTIVA SWEDEN AB

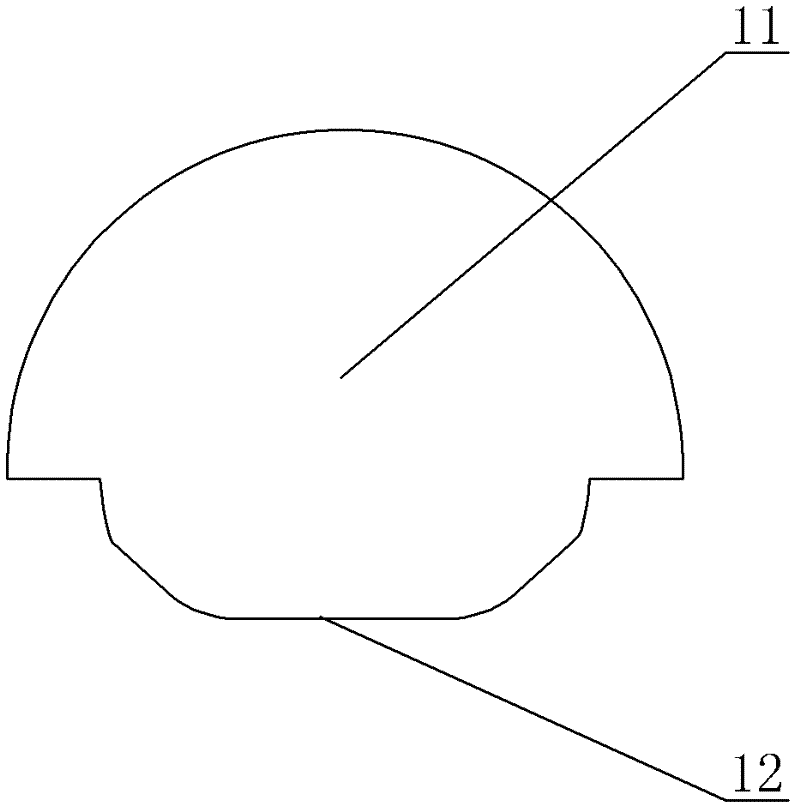

Fixed volume valve system

InactiveUS20070128061A1Eliminating and reducing variabilityReduce the impactPositive displacement pump componentsPiston pumpsEngineeringInlet flow

Embodiments of the present invention provide valves that provide for uniform holdup volume. An embodiment of the present invention provides a valve comprising a valve body (e.g., one or more pieces) that defines a valve chamber having a valve seat, an inlet flow passage, an outlet flow passage and a diaphragm control flow passage intersecting the valve seat. The valve seat is shaped so that the valve has a fixed holdup volume when at least a threshold vacuum is applied to the diaphragm control flow passage. The valve further comprises a diaphragm movable towards and away from the valve seat. According to one embodiment of the present invention, the valve seat can have a semi-hemispherical shape to which the diaphragm conforms when a minimum vacuum is applied to the diaphragm control flow passage.

Owner:ENTEGRIS INC

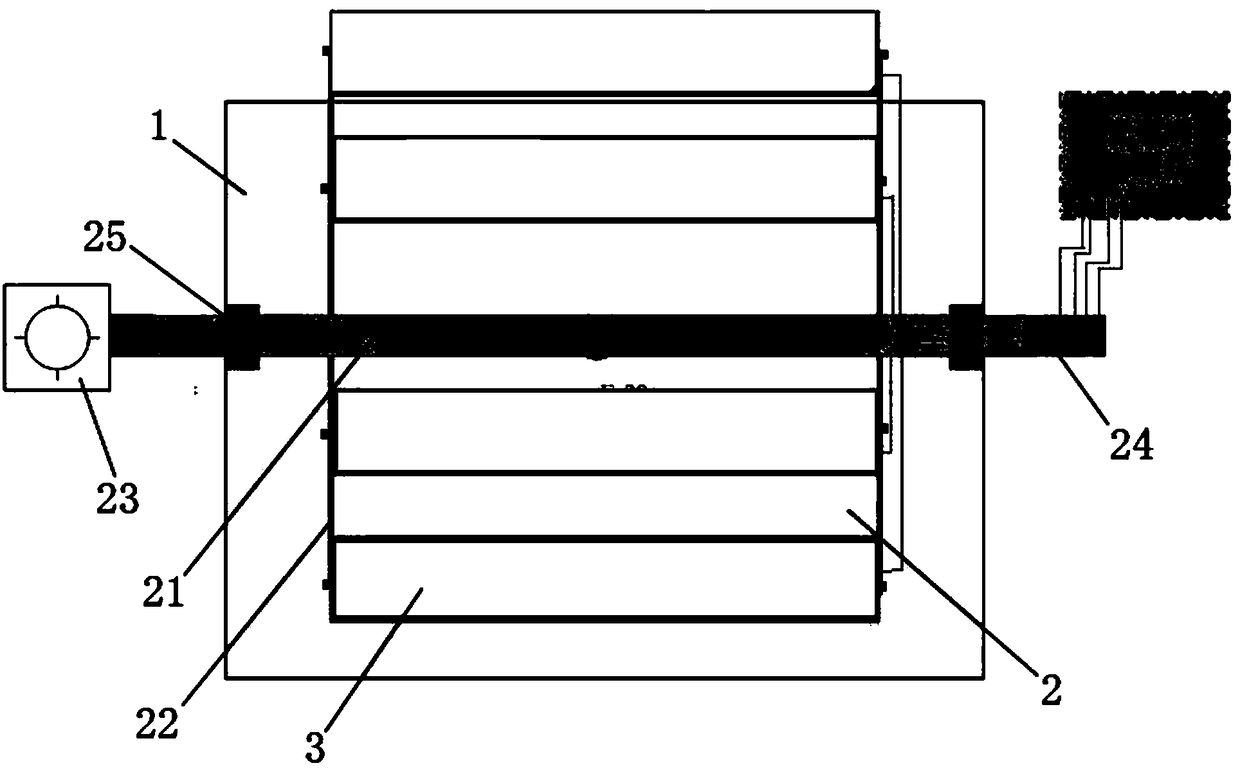

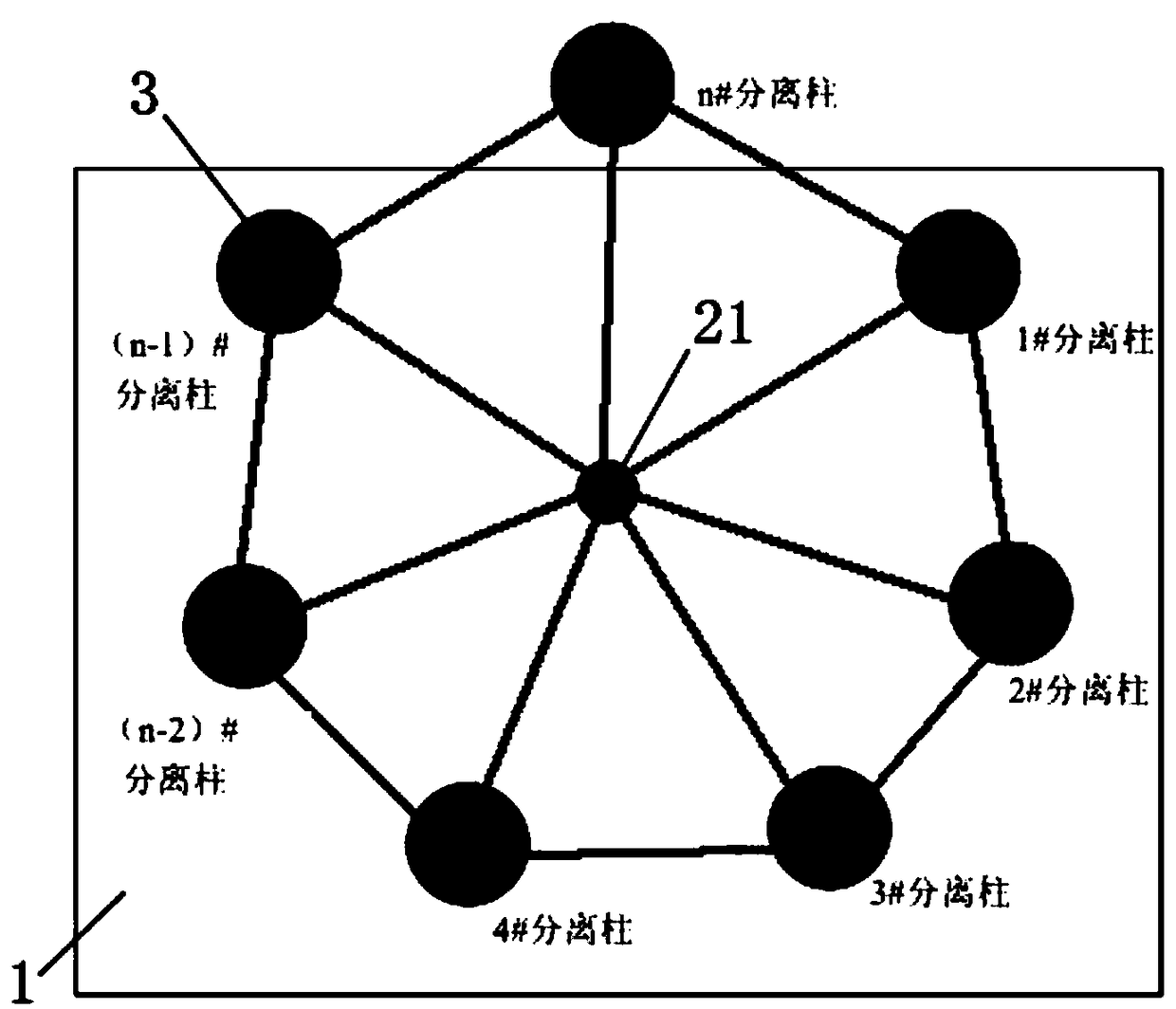

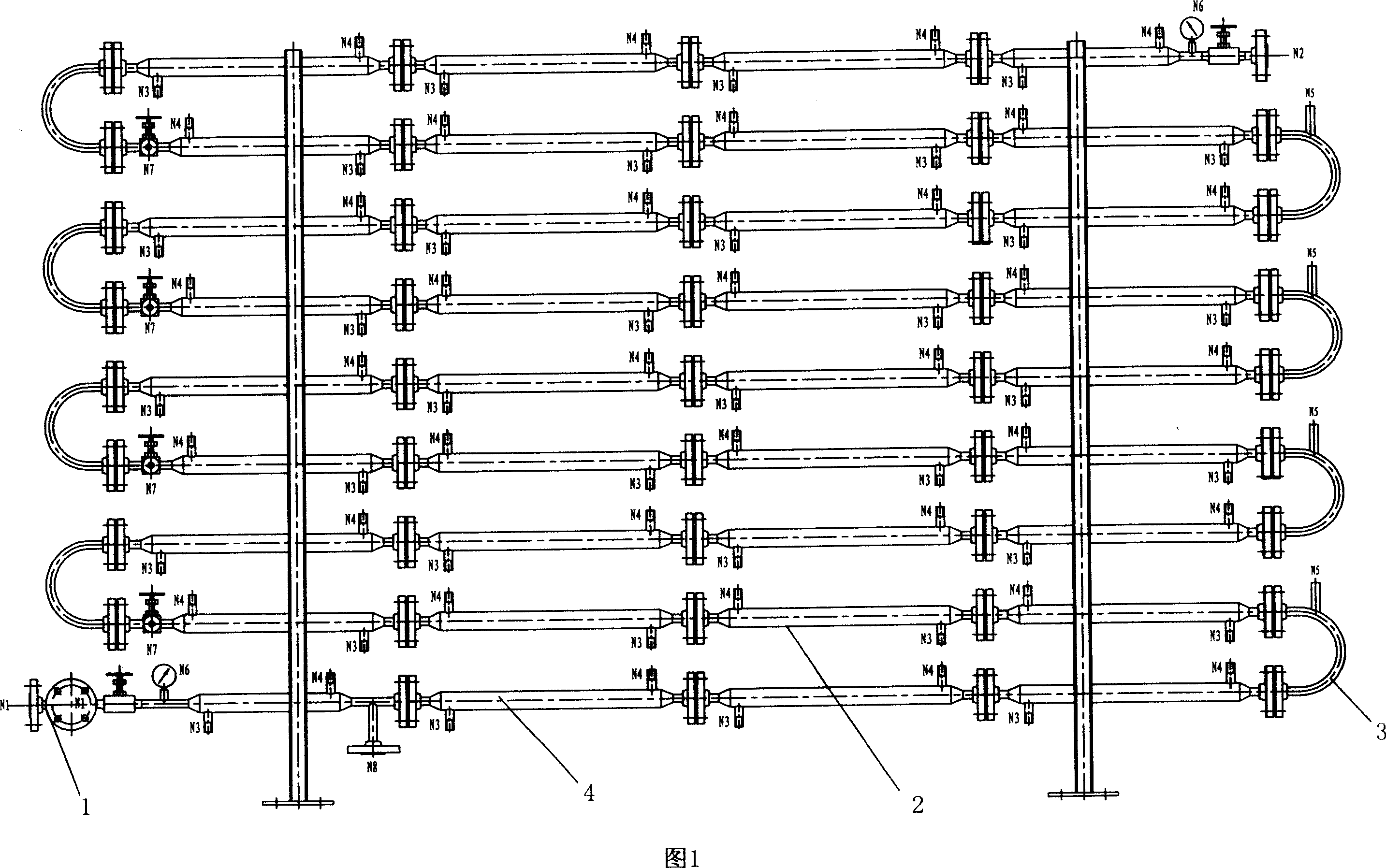

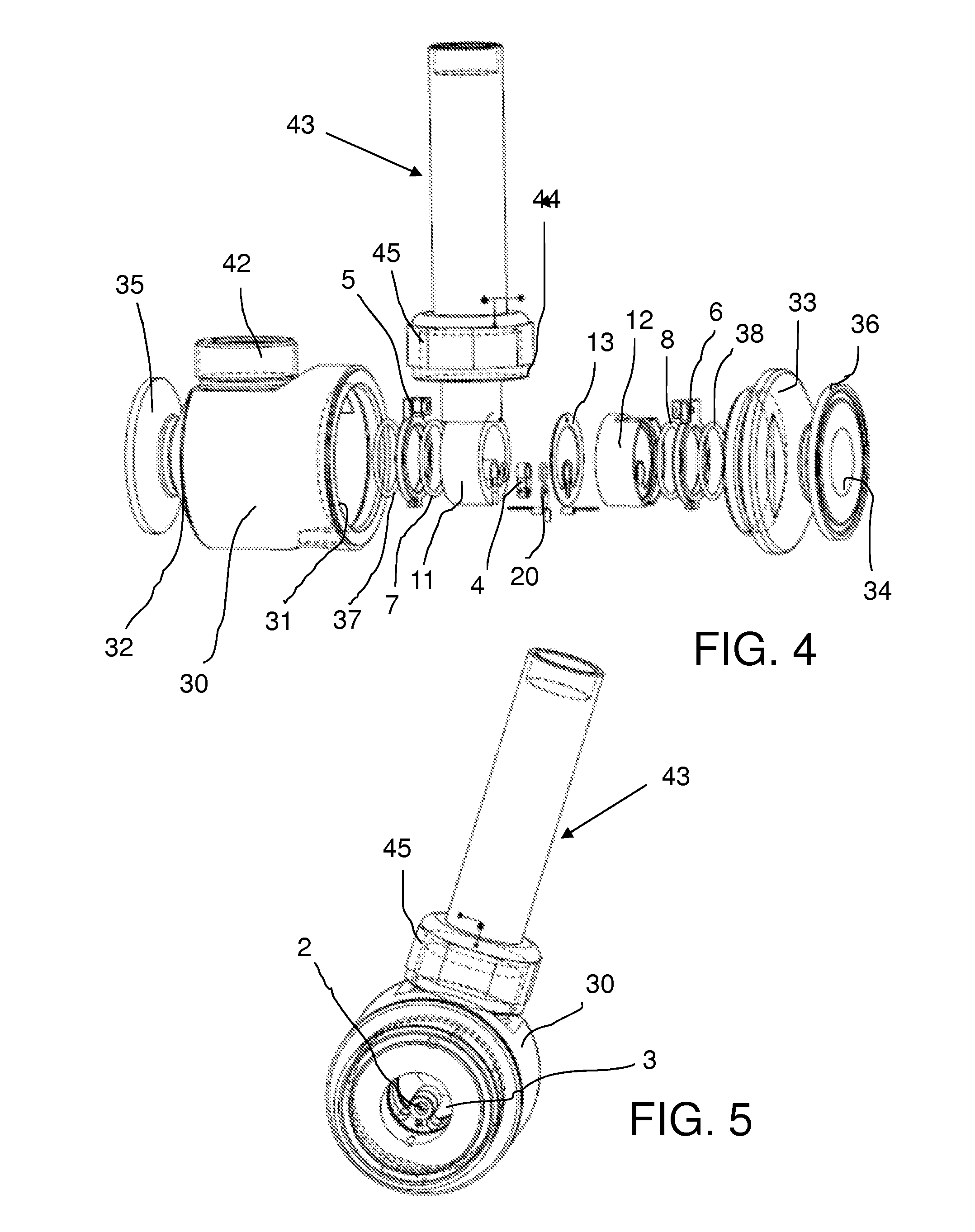

Rotary low-temperature hydrogen isotope separation system and separation method thereof

The invention discloses a rotary low-temperature hydrogen isotope separation system and a separation method thereof, which solve the complicated construction, complicated parameter control, and high operation cost, or helium gas supply requirement, hydrogen and helium separation, and complex separation column regeneration treatment, or high cost of palladium displacement chromatogram filling material and easy failure in the prior art. The separation system includes a cryogenic tank, a reversing frame, a separation column, a raw material hydrogen-storage tank, a light isotope storage tank, a heavy isotope storage tank, a vacuum pump, and an exhaust gas storage tank. The separation method is characterized in that a separation column absorbing the raw material hydrogen to gradually separate the liquid nitrogen liquid level to desorb the hydrogen isotope to complete rearrangement of hydrogen isotope in other separation columns; and the light and heavy isotopes can be finally collected respectively from the far and near ends of the loop. The system creatively utilizes the technical principle of a simulated moving bed, the hydrogen isotope can continuously circulate in the closed loop separation loop, the heavy isotope concentration gradually decreases from the near end to the far end where the desorption occurs in the separation loop, and the concentration gradient of the heavy isotope is continuously increased with the adsorption / desorption frequency.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

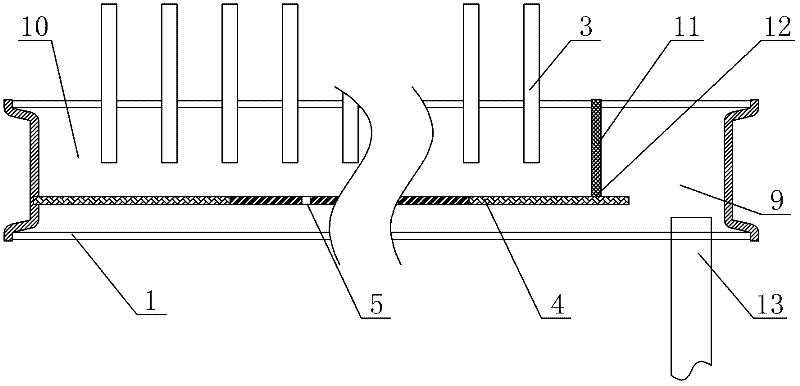

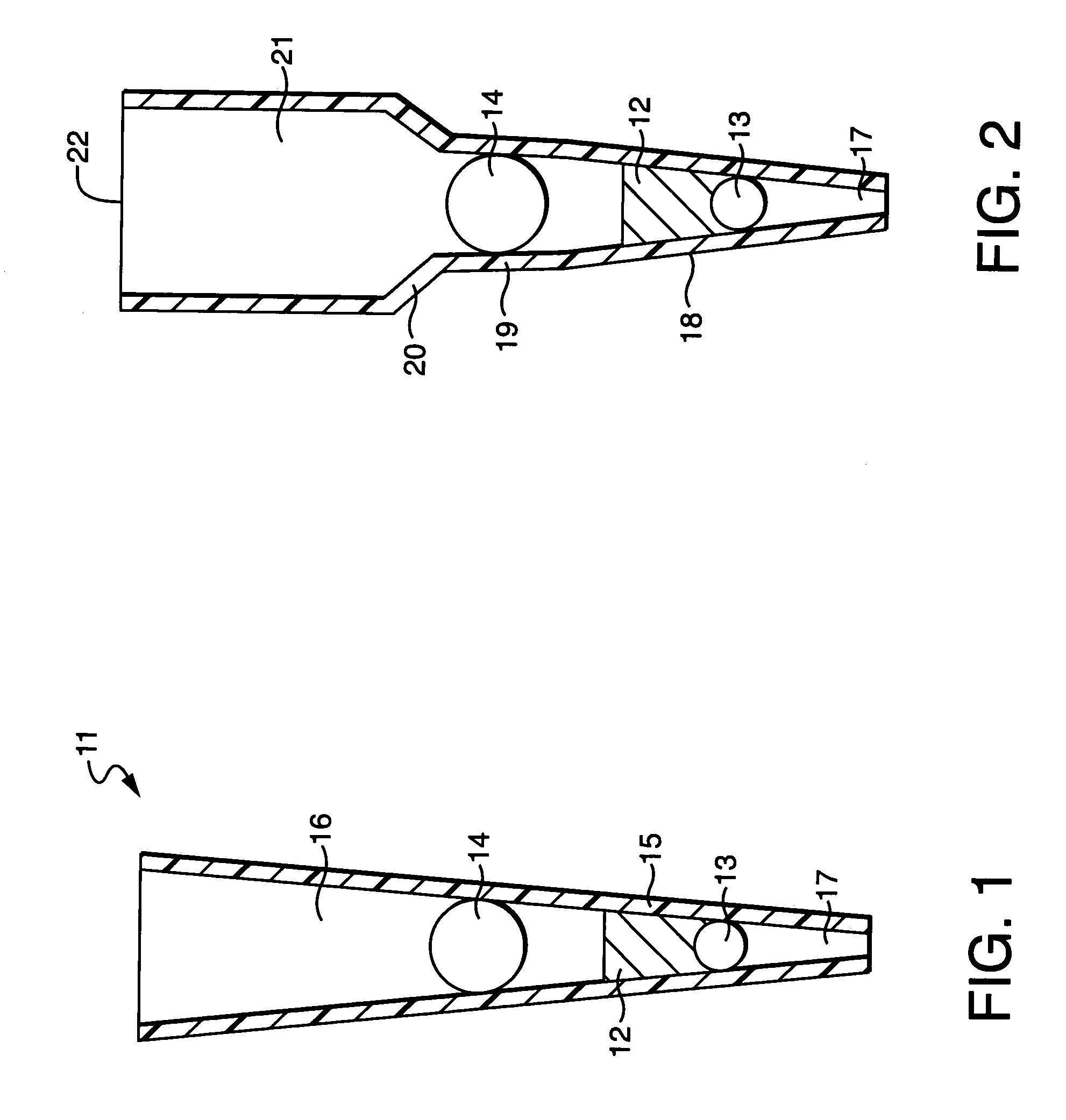

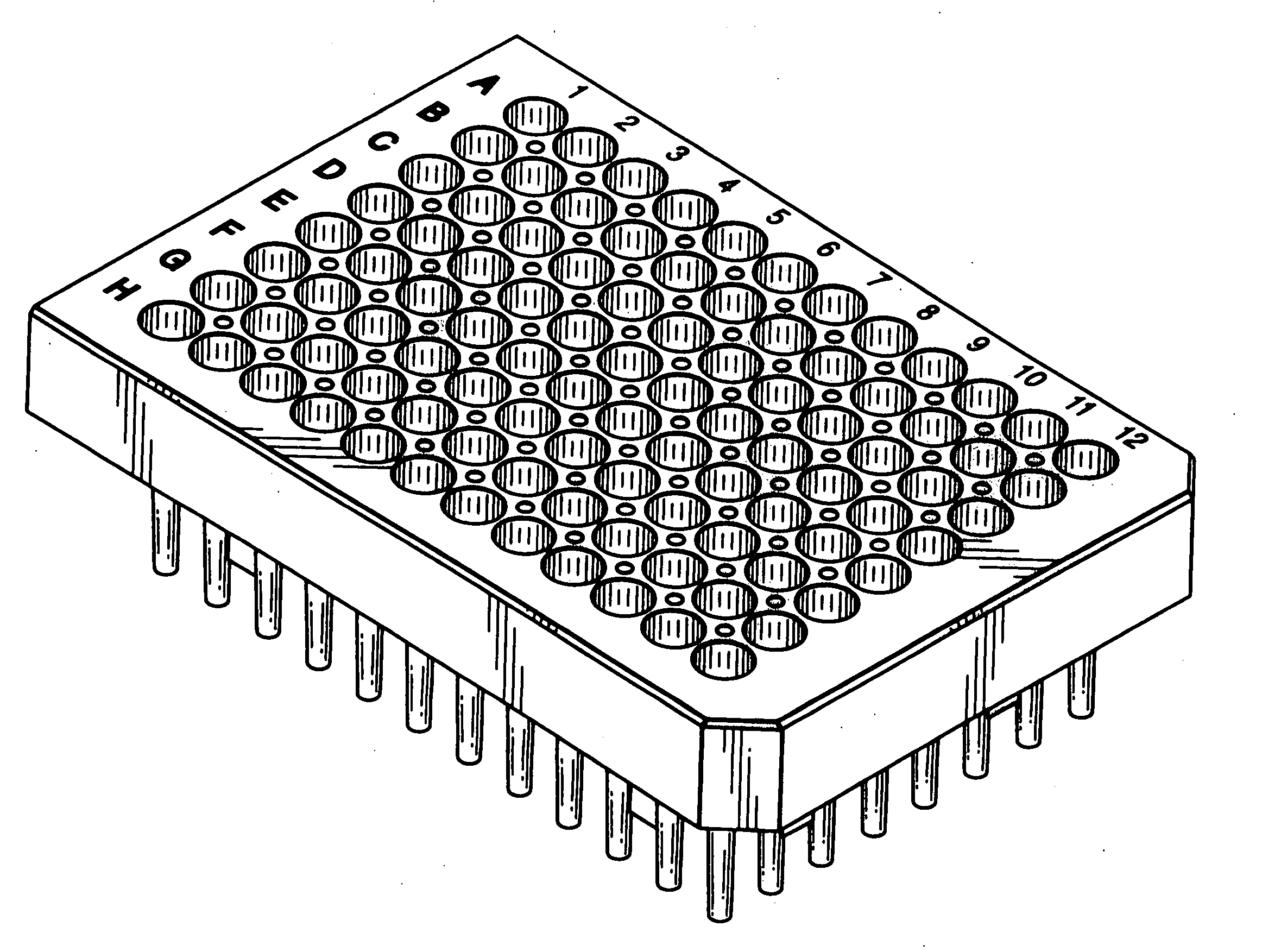

Device for solid phase extraction and method for purifying samples prior to analysis

InactiveUS7052611B2Highly efficient retentionEffective compoundIon-exchange process apparatusOther chemical processesSorbentSolid phase extraction

A solid phase extraction (SPE) device having a reservoir with an opening; a well comprising an internally tapered wall, the well having a wider interior diameter at an end closest to the opening than at an exit spout; a first filter within the well; a bed of sorbent particles within the well below the first filter; and a second filter having a diameter smaller than the first filter within the well below the bed of sorbent particles and above the exit spout is provided. A method of performing SPE using the device is also provided.

Owner:WATERS TECH CORP

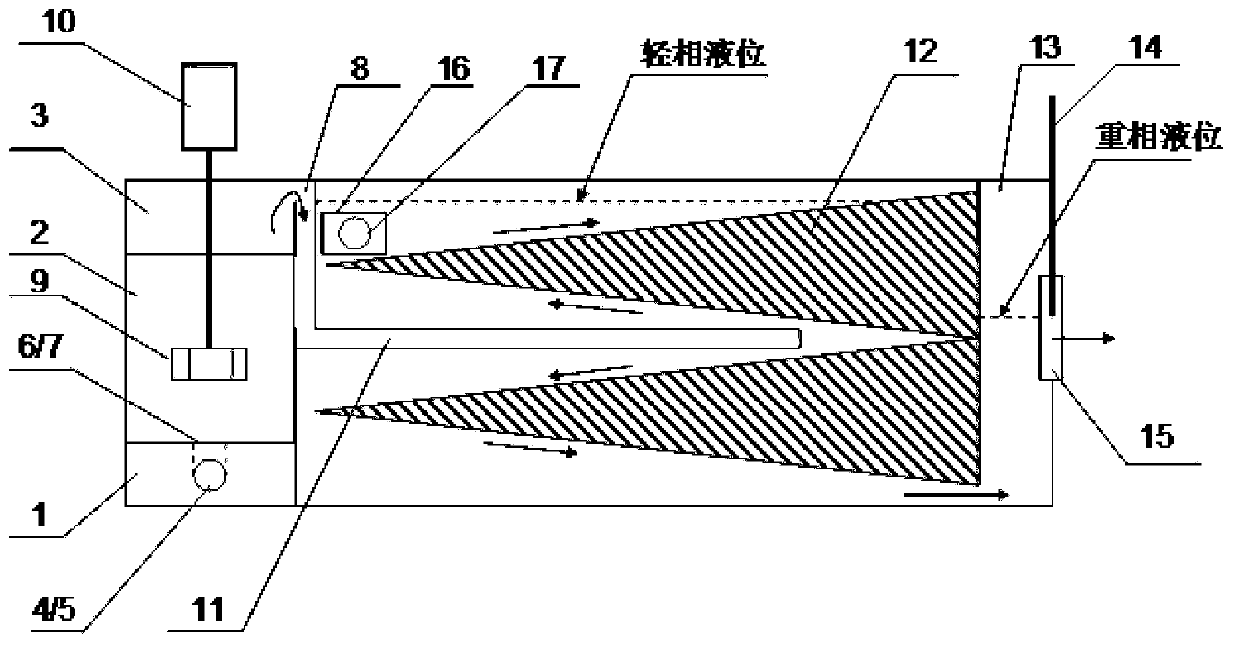

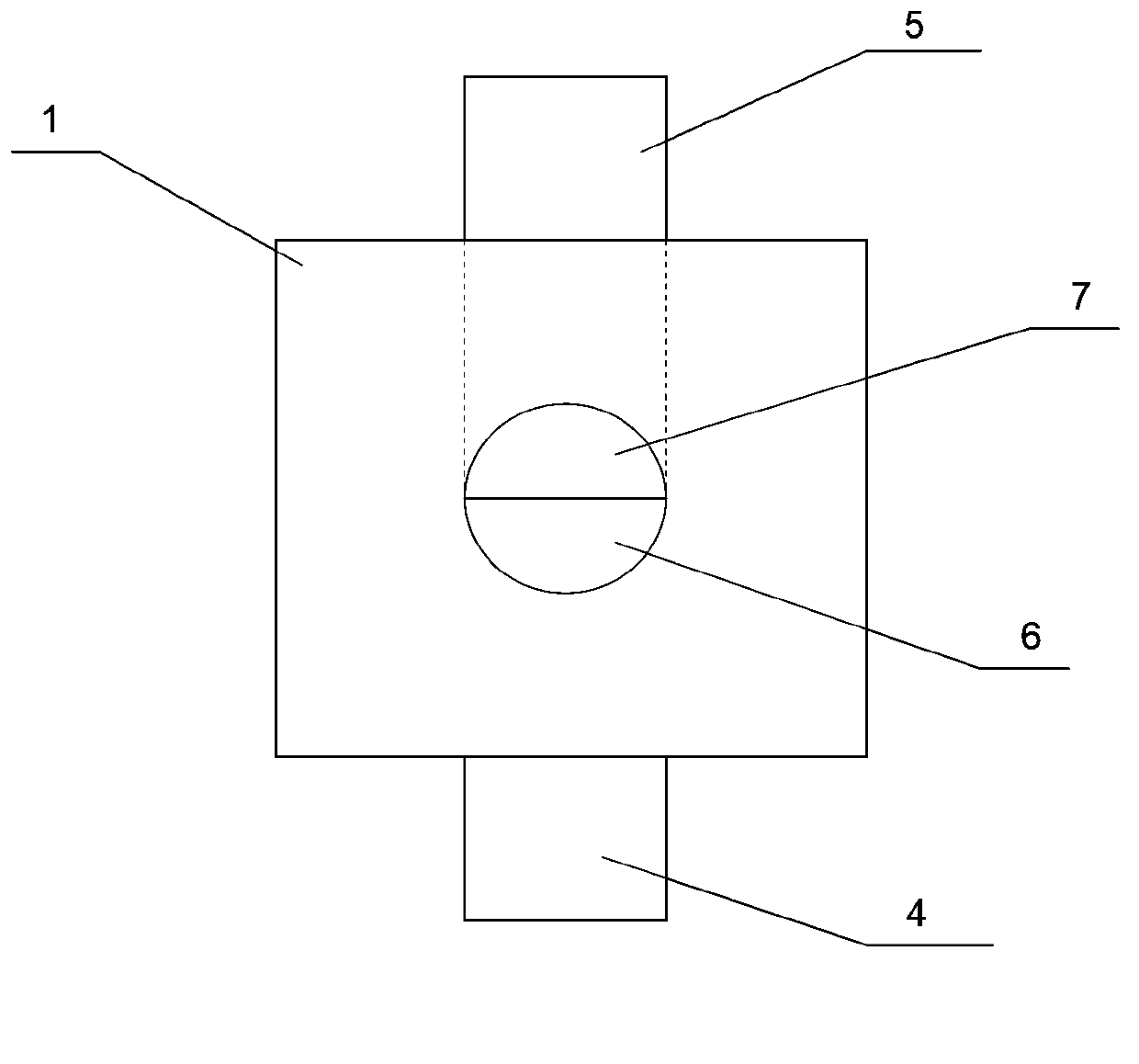

Liquid-liquid extraction mixer-settler and extraction method and application thereof

InactiveCN103120863AIncrease the settlement areaReduce holdupLiquid solutions solvent extractionSingle stagePhase splitting

The invention relates to a liquid-liquid extraction mixer-settler and an extraction method and an application thereof. The mixer-settler comprises a mixing chamber and a clarifying chamber, wherein the side in the clarifying chamber near the mixing chamber is provided with a guide pipe which extends to the tail end of the clarifying chamber from an outlet of the mixing chamber; and at least the upper part or the lower part of the guide pipe in the clarifying chamber is transversely and fixedly provided with a wedge-shaped body. As the upper part and / or the lower part of the guide pipe in the clarifying chamber is fixedly provided with the wedge-shaped body, not only is the storage amount of organic phases in the settling chamber reduced, but also a large light-heavy two-phase settling area is provided so that the clarifying phase-splitting time is prolonged, and the clarifying separation effect is remarkable for an easily-emulsifying system or a system with larger viscosity; and the mixer-settler provided by the invention can be used for single-stage continuous extraction operation or multi-stage series-connected countercurrent continuous extraction operation.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

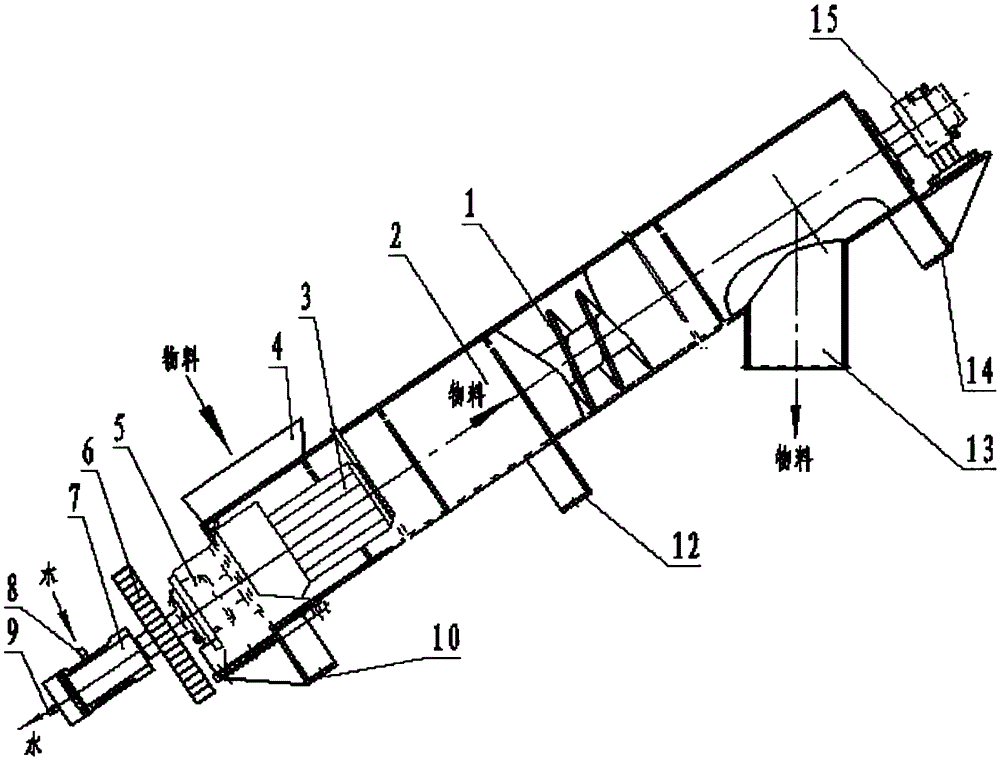

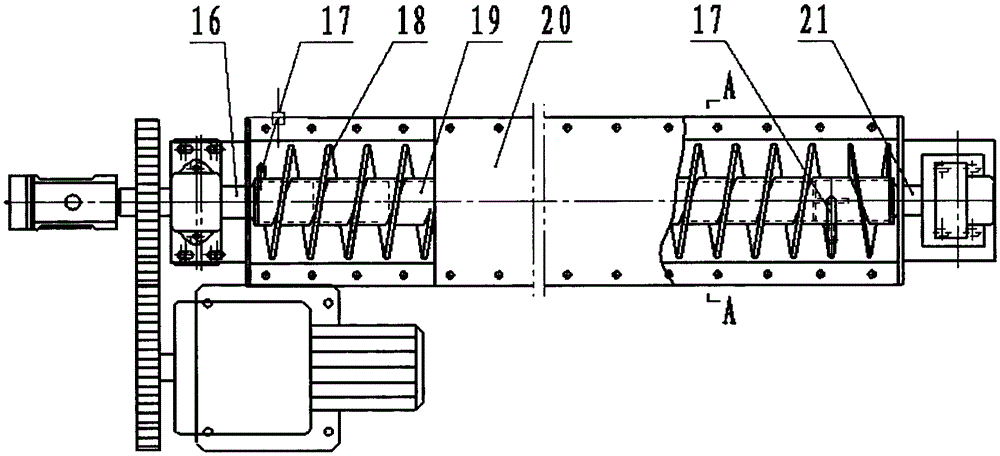

Cooling spiral conveyor for powdery explosives

The invention discloses a cooling spiral conveyor for powdery explosives, and belongs to a powdery explosive production device. The cooling spiral conveyor comprises a spiral body, a spiral groove, a power device, a transmission device, a combined water seal device, a feed device, a discharge device, a sealing cover plate and the like. Spiral blades of the cooling spiral conveyor are designed to be interlayers. A mandrel is in the form of a steel pipe. The spiral groove is also designed to be an interlayer. Inner cavities of the interlayer spiral blades, an inner cavity of the mandrel and an inner cavity of the interlayer spiral groove are communicated to form a cooling liquid circulation channel. When the explosives are conveyed, circulating cooling is conducted by leading in cooling liquid. A spiral is installed at a certain inclination angle. In this way, the explosives are effectively cooled while being conveyed to an inlet of a bundling press, low-temperature explosive charging is achieved, the hygroscopicity of the explosives is greatly reduced, the product quality is improved, and the storage period of the explosives is prolonged.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC

Method of extracting indium from solution by adopting impinging stream-rotating packed bed extractor

InactiveCN104232895AIncrease the areaLow investment costProcess efficiency improvementIndiumChemistry

The invention relates to a method of extracting indium from a solution by adopting an impinging stream-rotating packed bed extractor, and belongs to the technical field of indium smelting. The method comprises the following steps: impinging and mutually mixing an indium-containing solution with an extracting agent in the impinging stream-rotating packed bed extractor to obtain an indium-loaded organic phase in an extracting process; carrying out reverse extraction on the indium-loaded organic phase in the impinging stream-rotating packed bed extractor to obtain an indium product and a no-load organic phase; and returning the load organic phase to the extracting process to be used as an extracting agent. The method can be used for lowering the consumption of the extracting agent in an indium extracting process, improving the production efficiency and the separating efficiency.

Owner:KUNMING UNIV OF SCI & TECH

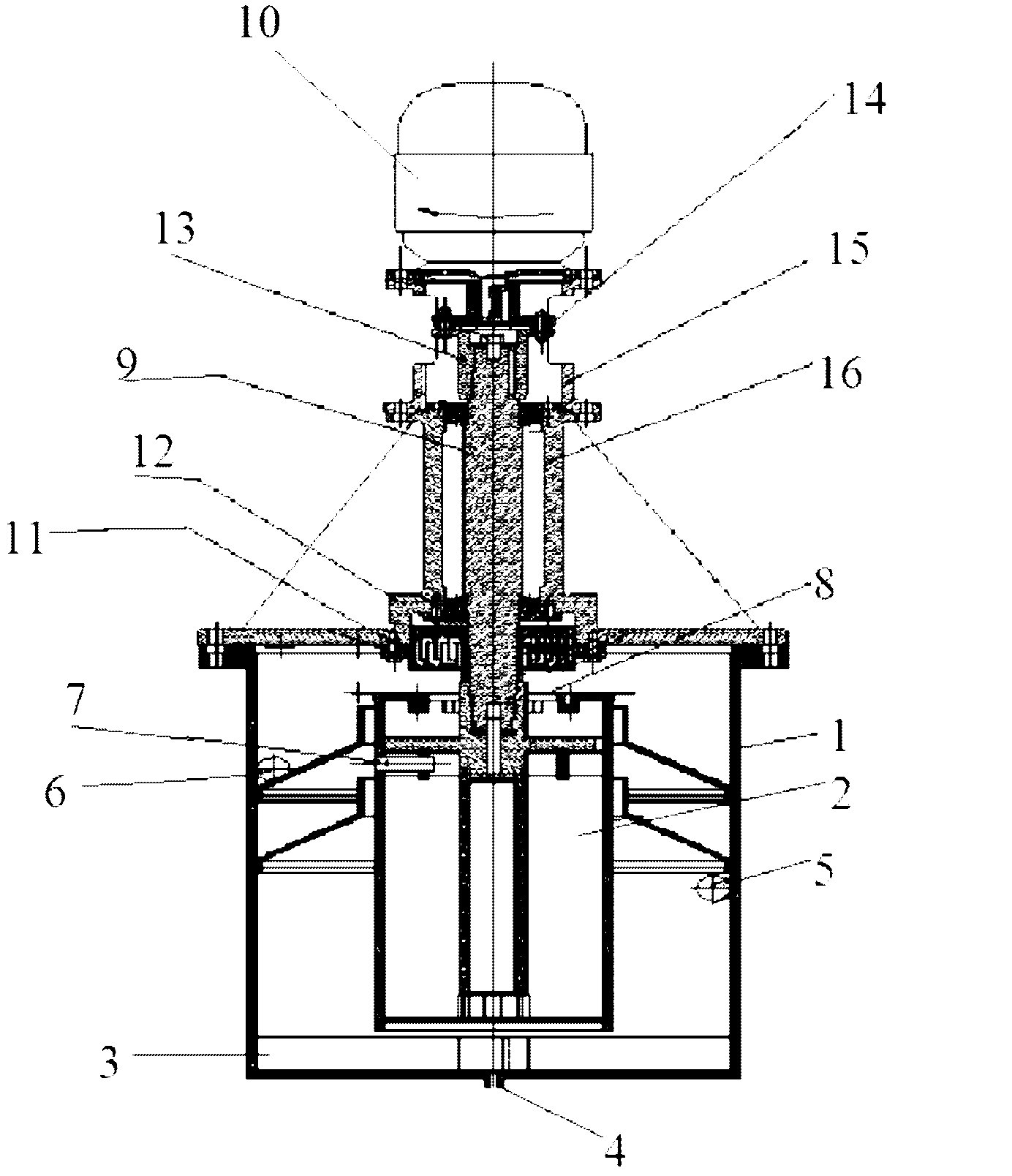

Glass fiber reinforced plastic centrifugal extractor and method for implementing extraction transformation of metal compounds

ActiveCN102505071AImprove efficiencyEasy to separateLiquid solutions solvent extractionProcess efficiency improvementGlass fiberProduction rate

The invention discloses a glass fiber reinforced plastic centrifugal extractor and a method for implementing extraction transformation of metal compounds, falling into the technical field of metallurgy. The glass fiber reinforced plastic centrifugal extractor is adopted in extraction transformation of metal compounds, which can increase service efficiency of extracting agents, increase productivity of equipment and facilitate separation of impurities during washing process. By virtue of the heat generated during the saponifying process, the temperature of the organic phase is increased and the viscosity is reduced. The centrifugal extractor achieves the phase splitting effect by a centrifugal force, and can be applied to highly-viscous organic phases under the same process conditions. The retention volume of materials in the centrifugal extractor is reduced, and the temperature of the organic phase can be increased under high-speed stirring conditions.

Owner:TSINGHUA UNIV

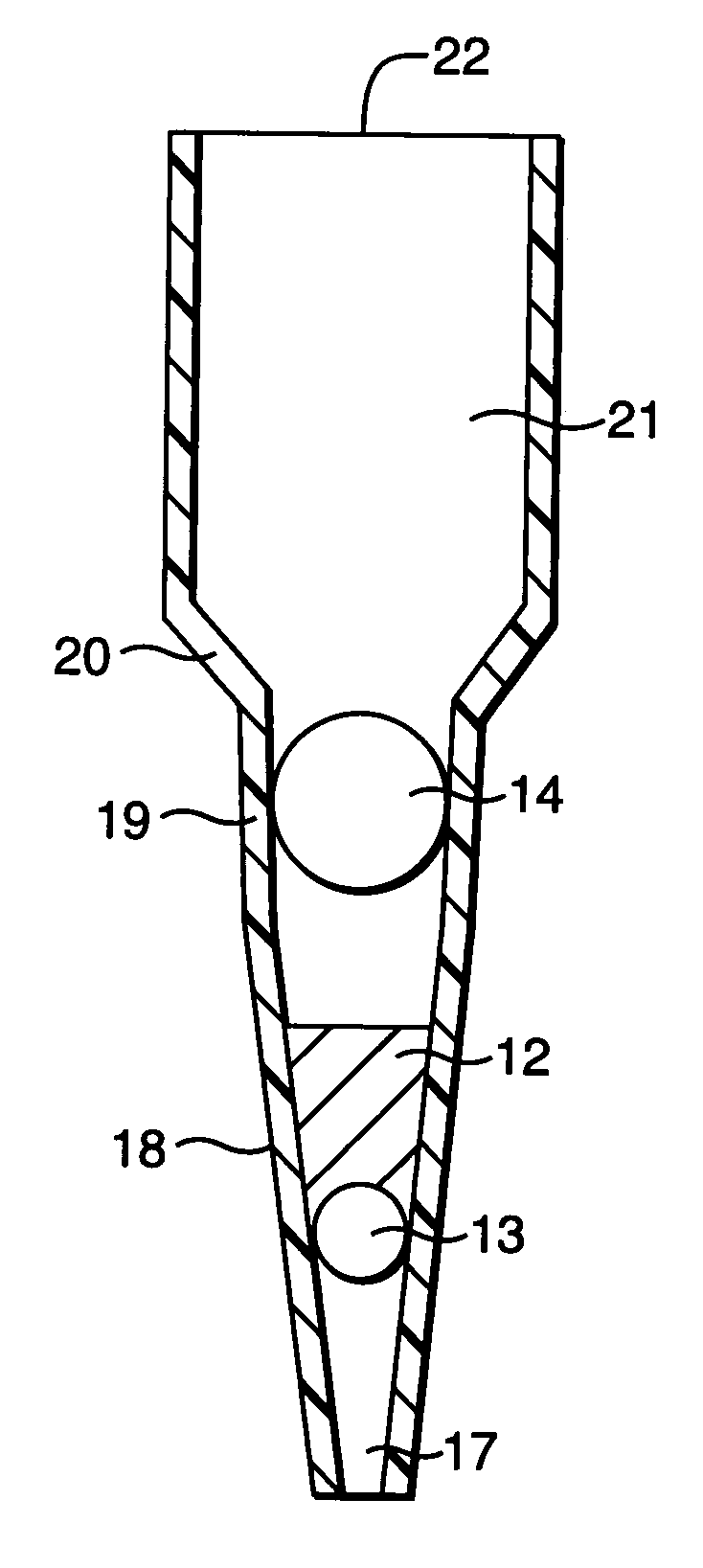

Device for solid phase extraction and method for purifying samples prior to analysis

InactiveUS20060163162A1High retention rateReduce holdupComponent separationIon-exchanger regenerationSorbentSolid phase extraction

A solid phase extraction (SPE) device having a reservoir with an opening; a well comprising an internally tapered wall, the well having a wider interior diameter at an end closest to the opening than at an exit spout; a first filter within the well; a bed of sorbent particles within the well below the first filter; and a second filter having a diameter smaller than the first filter within the well below the bed of sorbent particles and above the exit spout is provided. A method of performing SPE using the device is also provided.

Owner:WATERS TECH CORP

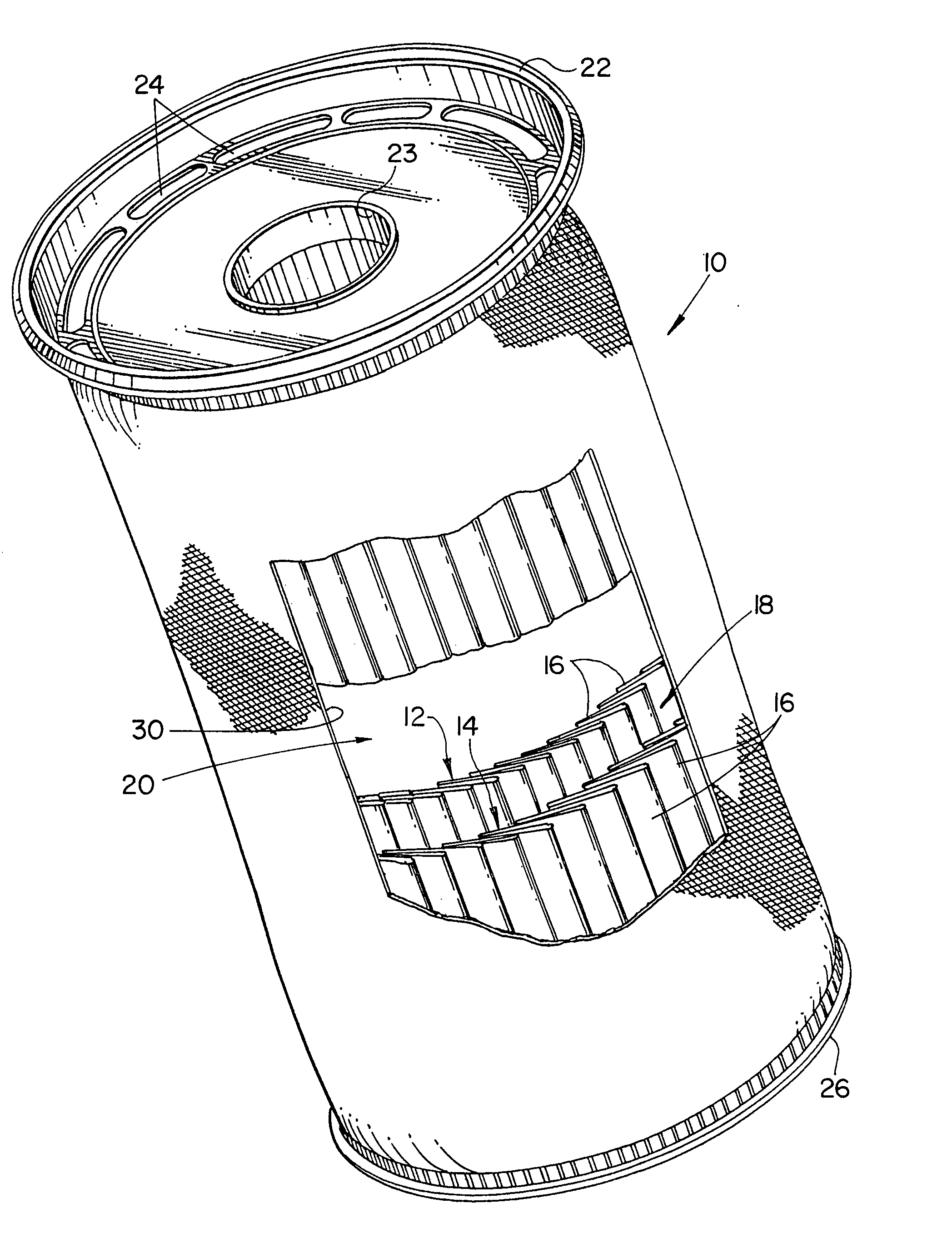

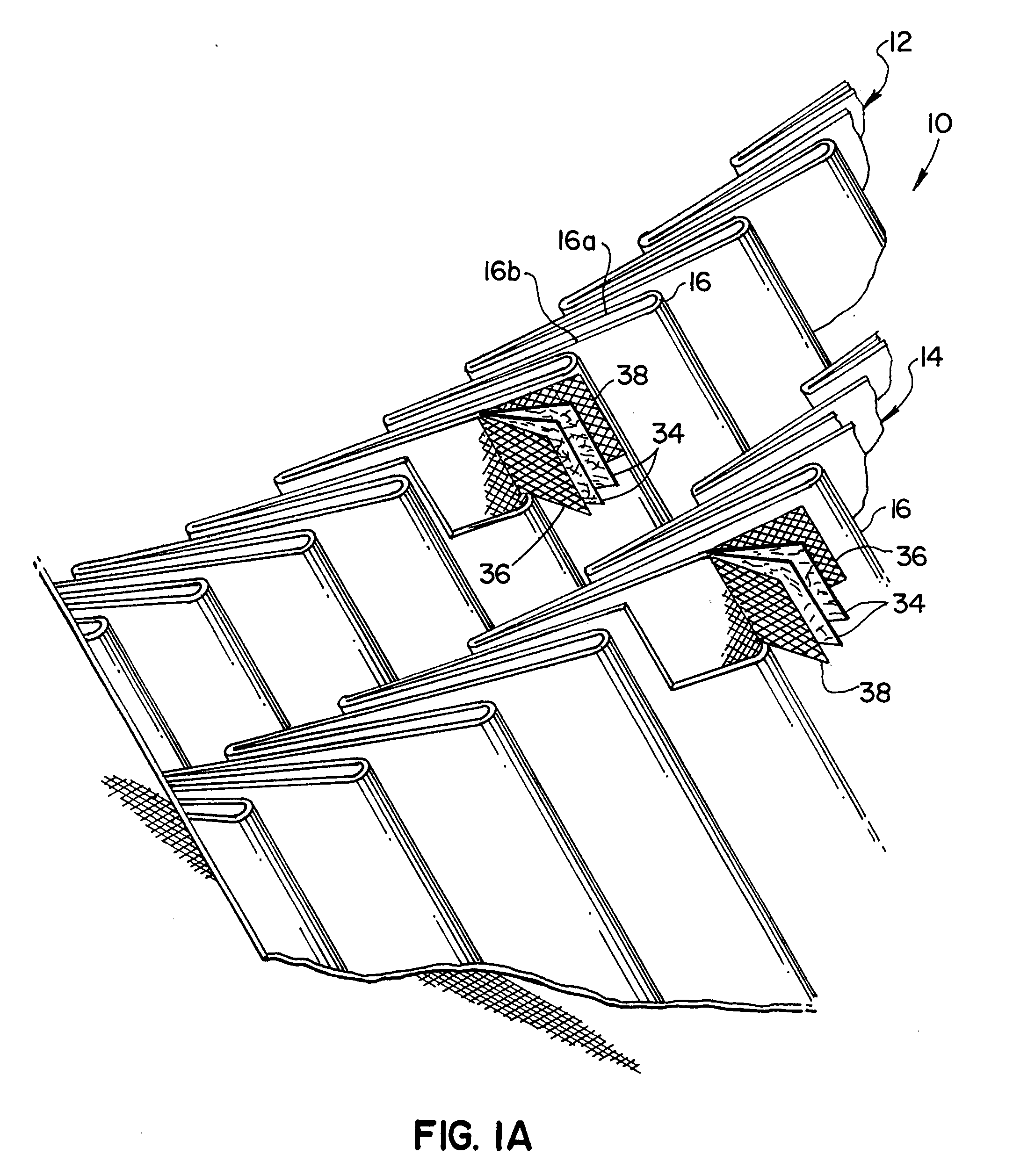

Circumferentially pleated filter assembly and method of forming the same

InactiveUS20070262016A1Increase the effective surface areaExtend filter lifeHaymakersMembrane filtersEngineeringMechanical engineering

A filter assembly is provided which includes an outer filter sleeve formed at least in part by a plurality of pleats, an inner filter sleeve formed at least in part by a plurality of pleats, wherein the inner and outer filter sleeves define a passage therebetween. An inlet cap is secured to a first end of the inner and outer filter sleeves and it has at least one inlet port communicating with the passage, and an end cap is secured to a second end of the inner and outer filter sleeves and it has an end surface closing the passage. Methods of forming such a filter assembly are also provided.

Owner:3M INNOVATIVE PROPERTIES CO

Composite large-area crusher cavity

PendingCN108654751AIncrease the initial velocityImprove crushing effectGrain treatmentsEngineeringCrusher

The invention discloses a composite large-area crusher cavity. The cavity comprises a feeding cavity, an accelerating cavity, a flow guiding cavity, a crushing cavity, finishing cavities and discharging cavities; the accelerating cavity comprises two accelerating rollers; the crushing cavity comprises two crushing rollers; the top of the feeding cavity is provided with a feeding port; the positions below the two accelerating rollers are each provided with a material guiding plate; the position between the two material guiding plates is provided with a material dividing device; first beat-backplates are fixed to the bottom ends of the two material guiding plates; the side walls of the two finishing cavities are each sequentially provided with a second beat-back plate and a third beat-backplate in sequence from top to bottom; a plurality of rows of anti-slip teeth are uniformly arranged on the third beat-back plates; and the discharging cavities with discharging ports are formed belowthe two crushing rollers correspondingly. The composite large-area crusher cavity is simple in structure, can be used for accelerating materials entering a crusher, and guides the materials to a preset path to be subjected to repeated large-area crushing, convenience is brought to crushing and finishing, the quality of crushed materials is increased, the powder amount is reduced, and the crushingefficiency is improved.

Owner:四川皇龙智能破碎技术股份有限公司

Method for synthesizing allylamine using transfer line reactor

InactiveCN1962607AAchieve serializationTake away in timeAmino preparation by functional substitutionReactor systemSolvent

The invention discloses a preparing method of alkylamine through pipe reactor, which comprises the following steps: adopting allyl chloride as raw material; blending catalyst, solvent and ammonia phase evenly; pumping in the pipe reactor through metering pump according to the rate of materials; ammonifying to produce acrylamide, diallylamine and triallylamine; adding sodium hydroxide solution to remove amino to obtain the product; setting the normal pressure in the reactor system at 3.0Mpa under 40-80Deg C for 5-20min; rectifying the product; evaporating the solvent and surplus ammonia; gathering 52-55Deg C fraction as acrylamide; boiling to remove water; gathering 107-111Deg C fraction as diallylamine.

Owner:杭州新成化学有限公司

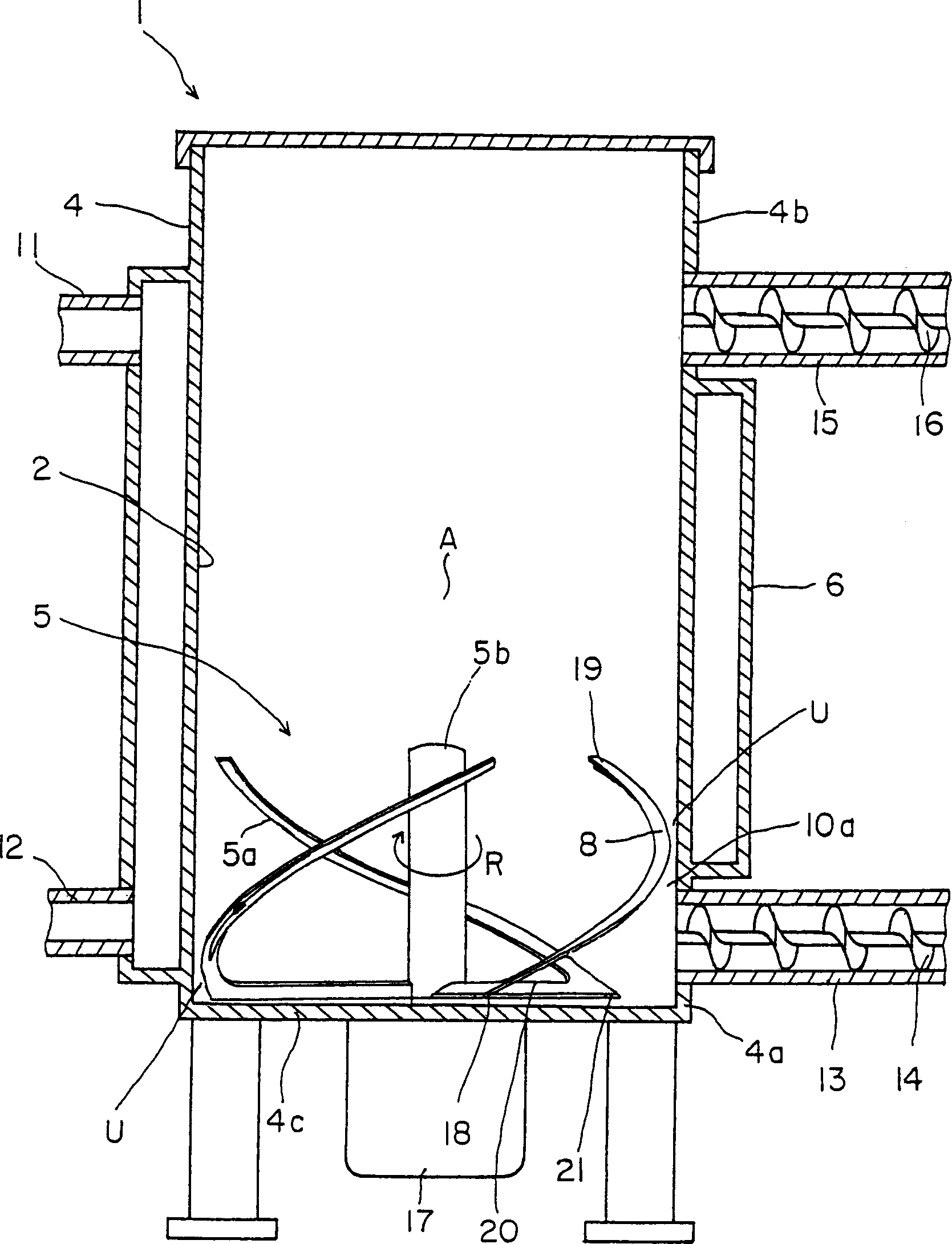

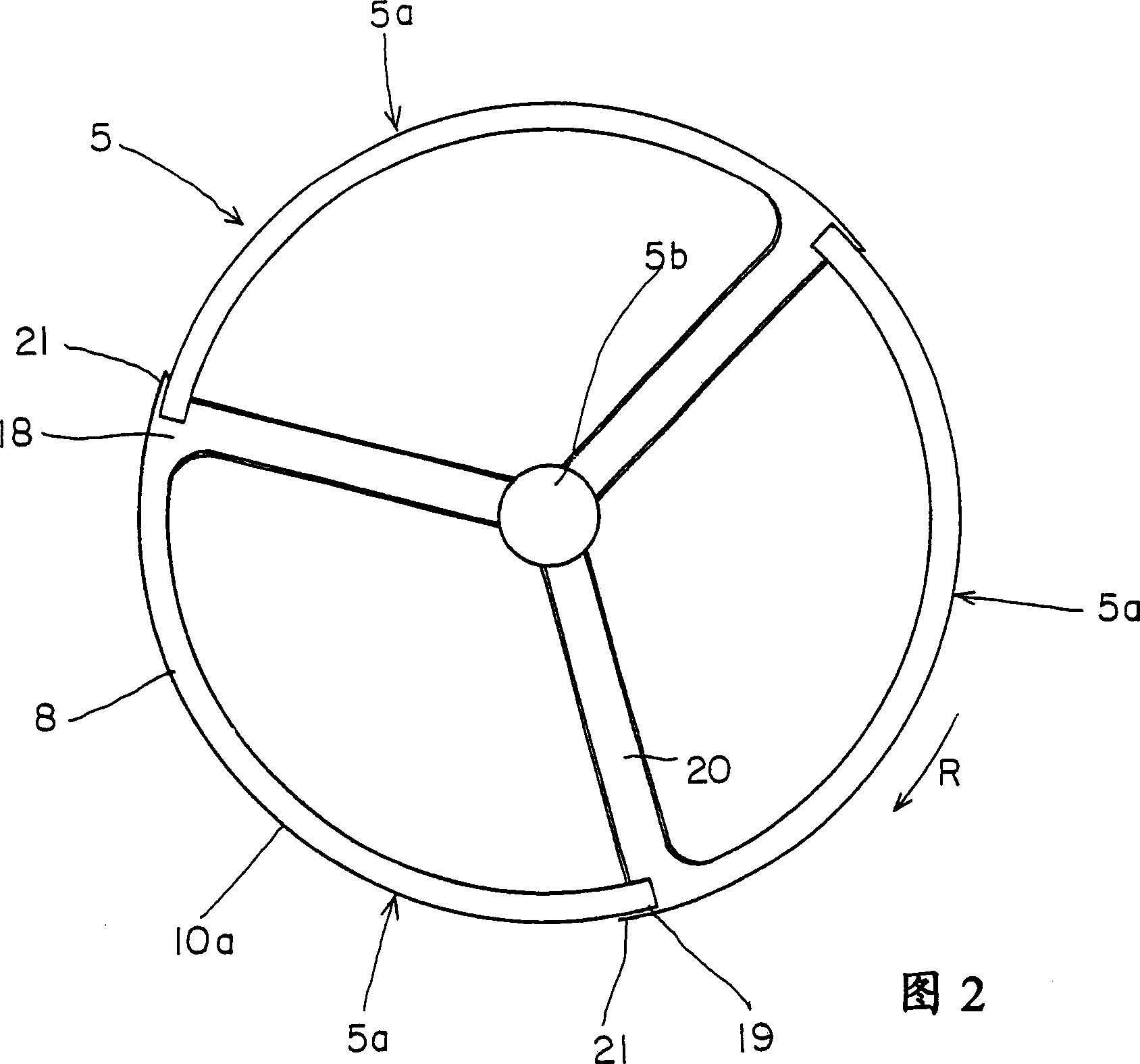

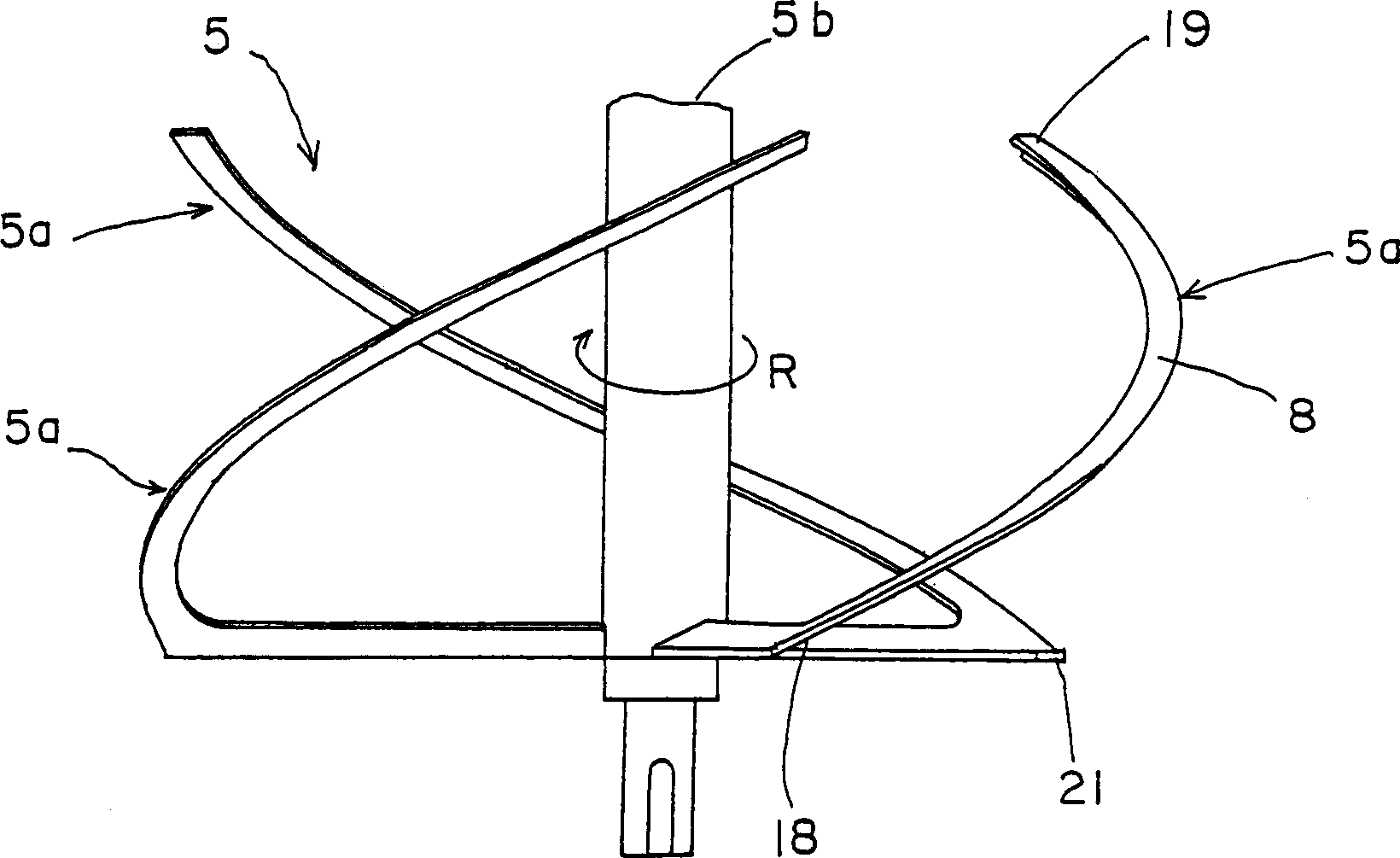

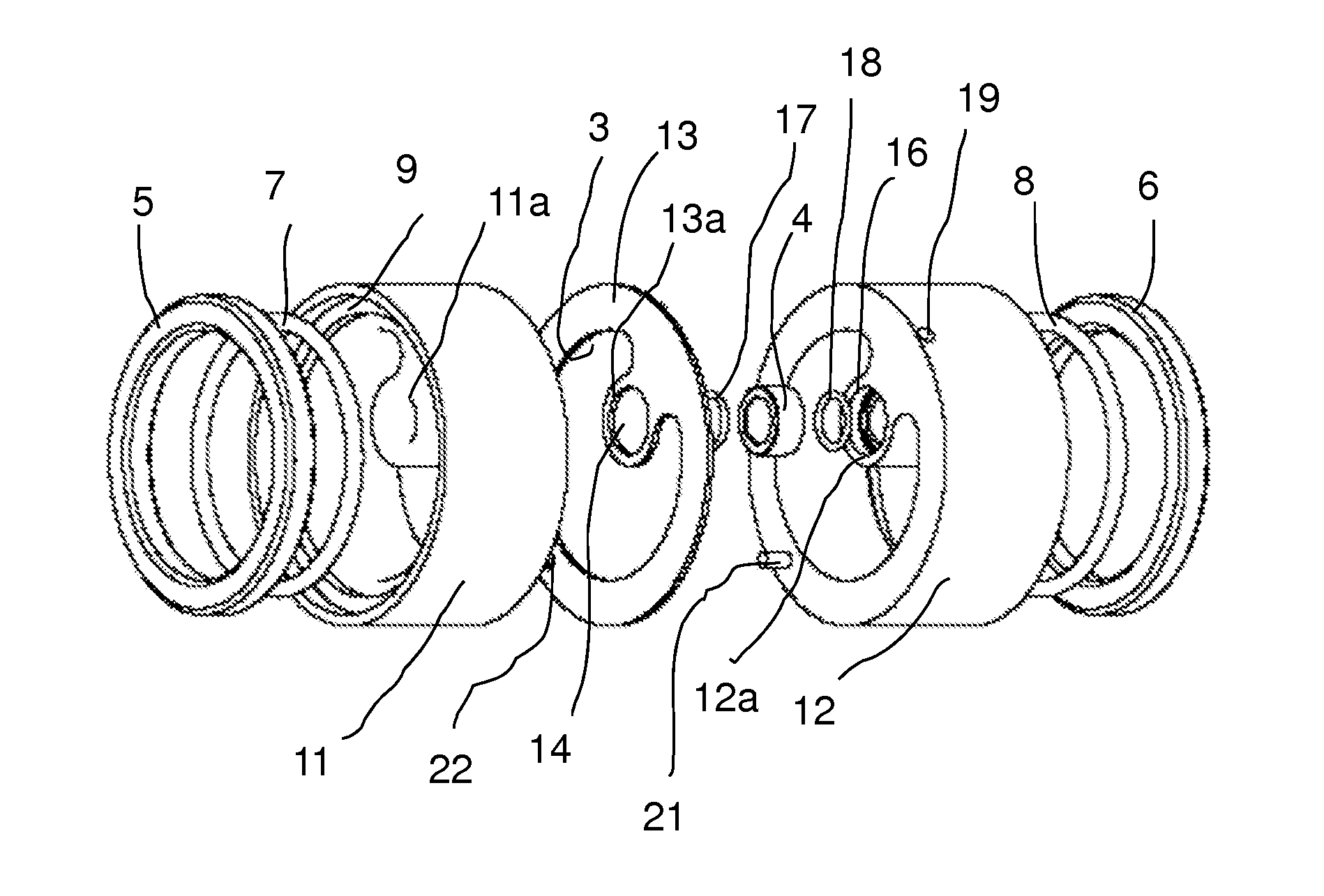

Dryer

InactiveCN1419099AEasy accessIncrease rotation speedSludge treatment by de-watering/drying/thickeningDrying solid materials with heatMechanical engineeringHeat transfer

The present invention provides a drying device of high drying efficiency by effectively using the whole heat transfer face without retention and biting of a dried object. In this drying device (1), a rotary winding blade (5) composed of a plurality of base blades (5a) is installed rotatably around a rotating shaft (5b) in a drying tank (4) formed with a heat transfer face (2). Each base blade (5a) has a flat face (8) of elongate shape extending obliquely upward from one end part (18) toward the other end part (19) in a reverse direction to a rotating direction R, and a clearance U is formed between an outer peripheral end 10a and the heat transfer face (2). The clearance U is formed to be gradually larger in the reverse direction to the rotating direction. One end part (18) of the flat face (8) is continuous with a scraping plate (20), and a projecting part (21) is provided in the rotating direction R from the outermost end part of the scraping plate (20).

Owner:金井 正夫

Conductivity sensor assembly

ActiveUS9035661B2Reduce holdupReduce areaComponent separationFluid resistance measurementsEngineeringMechanical engineering

A flow-through conductivity sensor assembly comprises a housing (4) having a flow passage with an inlet end and an outlet end. The cross section of at least a section of the flow passage extension between the inlet and outlet ends is divided into a conductivity measuring channel (2) and a parallel by-pass channel (3) of larger cross-sectional area than the measuring channel (2).

Owner:CYTIVA SWEDEN AB

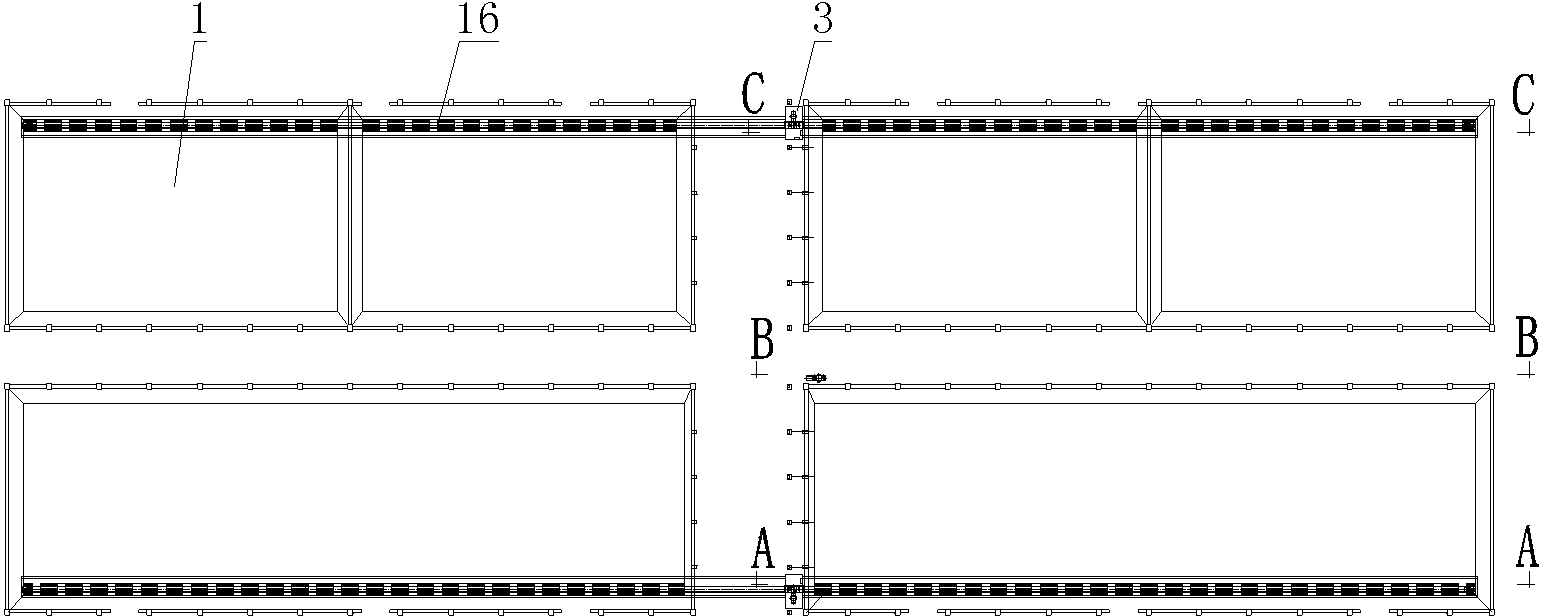

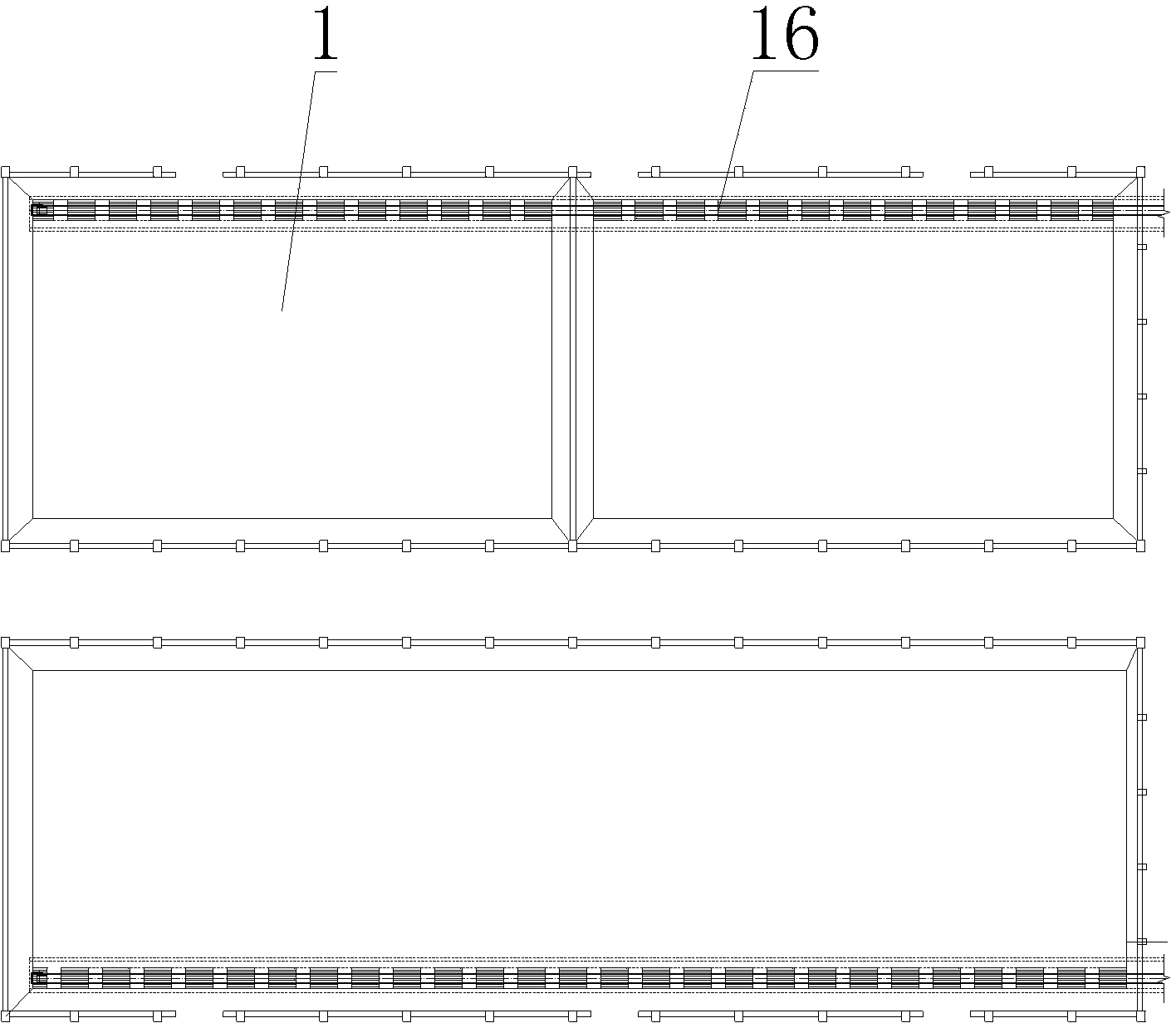

Turbulent electrodeposition method and matching device and modular expansion scheme

InactiveCN106835255AEliminate Concentration PolarizationLess side effectsCellsTanksConcentration polarizationReaction rate

The invention belongs to the technical field of electrodeposition, and especially relates to a turbulent electrodeposition method, the turbulent electrodeposition method is a new type electrodeposition technology, is used for elimination of concentration polarization phenomenon caused by the reason that electro deposition reaction rate is greater than ion diffusion reaction rate by high speed turbulent surging of an electrolyte solution in a limited cathode-anode tubular space, is especially suitable for metallurgy and nonferrous metal resource regeneration industry for recovery of cathode deposition metals from a complex solution containing nonferrous metal ions, the invention also provides a matching device of the turbulent electrodeposition method and a modular expansion scheme of the matching device of the turbulent electrodeposition method, compared with a traditional plate-groove open electrodeposition tank, during a turbulent electrodeposition equipment operation period, side reactions are few, direct current electrical efficiency is high, generated acid gas can be centralizedly collected and processed, modular equipment units are simple to install, solution retention volume in the system is less, process adaptability is strong, with market development, technology promotion and increase of users, the matching device of the turbulent electrodeposition method can ultimately replace traditional electrodeposition equipment, and is a new development direction of the wet aqueous solution metallurgy electrodeposition technology.

Owner:西安互达环保科技有限公司

Novel process for recovering metallic rhenium from copper smelting waste acid

InactiveCN107460320AReduce recycling costsRealize online automatic controlProcess efficiency improvementRheniumAutomatic control

The invention relates to a novel process for recovering metallic rhenium from copper smelting waste acid. The novel process comprises the following steps: through pretreatment, centrifugal extraction, centrifugal washing, centrifugal reverse extraction, concentration, freezing crystallization and recrystallization, so that valuable metallic rhenium in the copper smelting waste acid is recovered, and a high purity ammonium rhenate product is obtained; and meanwhile, the on-line and automatic PLC control is realized in the overall technological process design. With the adoption of the novel process for recovering metallic rhenium from the copper smelting waste acid provided by the technical scheme of the invention, the following benefits are achieved: 1, the technological process is short, the operation is simple and convenient; 2, the equipment floor area is small, the investment cost is low, and the cost can be controlled at RMB1450 Yuan / kg of ammonium rhenate; 3, the degree of automation is high, and the on-line monitoring and controlling are realized; 4, compared with the conventional box-type extraction process, the novel process has the advantages as follows: the extraction efficiency is high, the organic phase retention volume is small, the extraction balance in all time periods is achieved, the real-time start / stop is realized, the treatment capacity is high, the emulsification is eliminated, the on-line cleaning is realized, the recovery rate of valuable metallic rhenium is high, and the separation effect of valuable metallic rhenium from metallic impurities is good; and 5, the sewage quantity is small, the secondary pollution is avoided, and the environmental friendliness is achieved.

Owner:铜陵有色金属集团股份有限公司

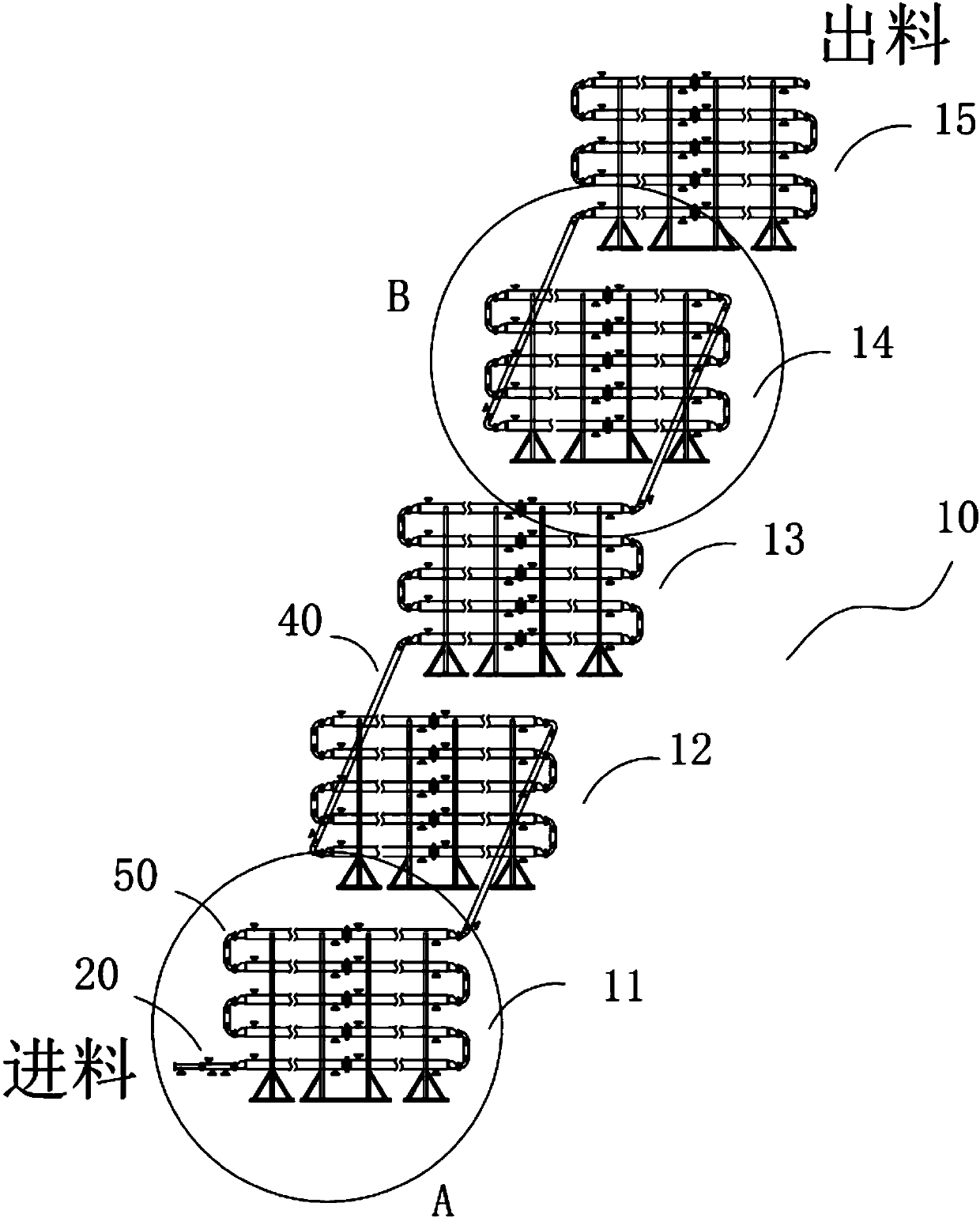

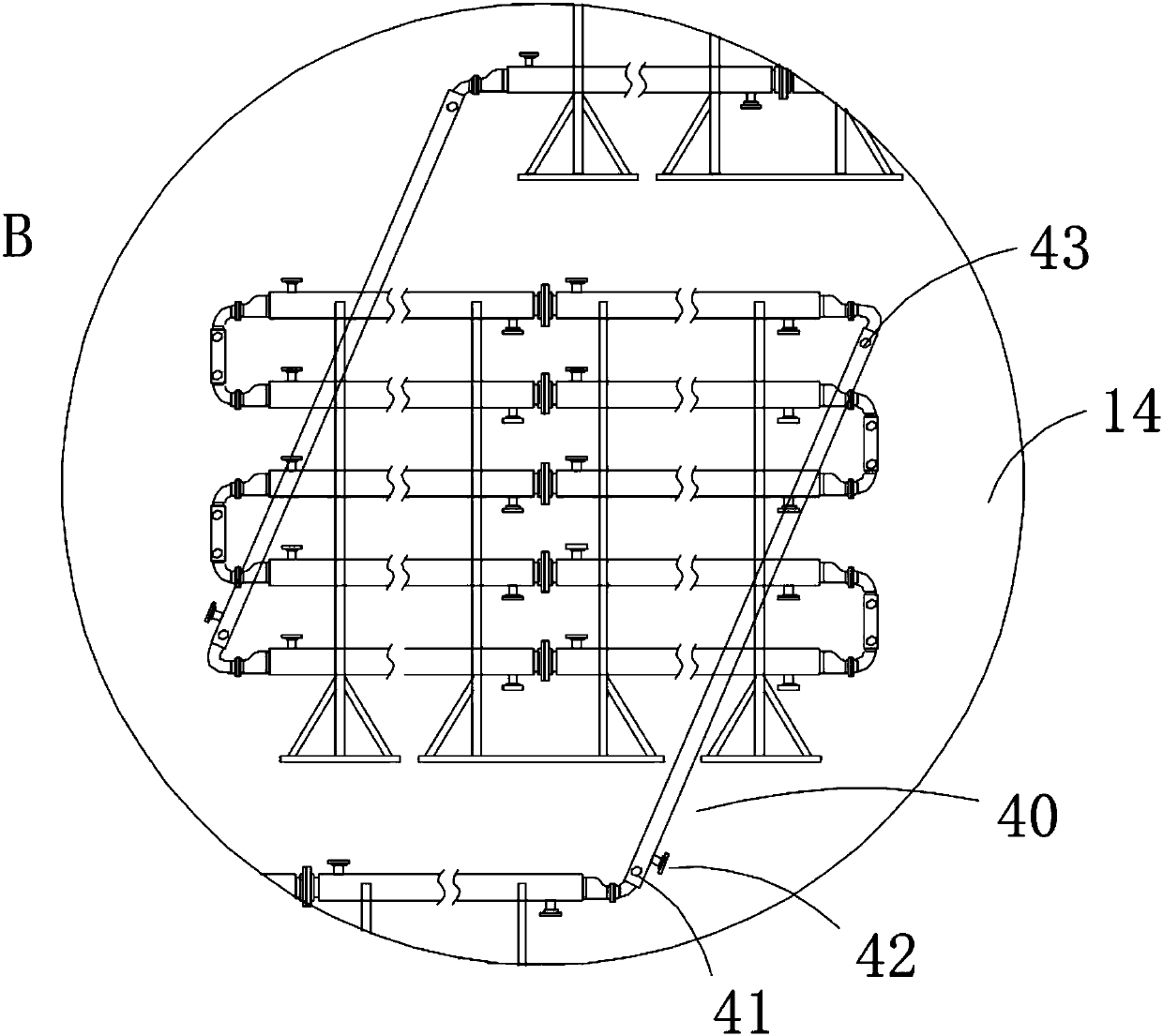

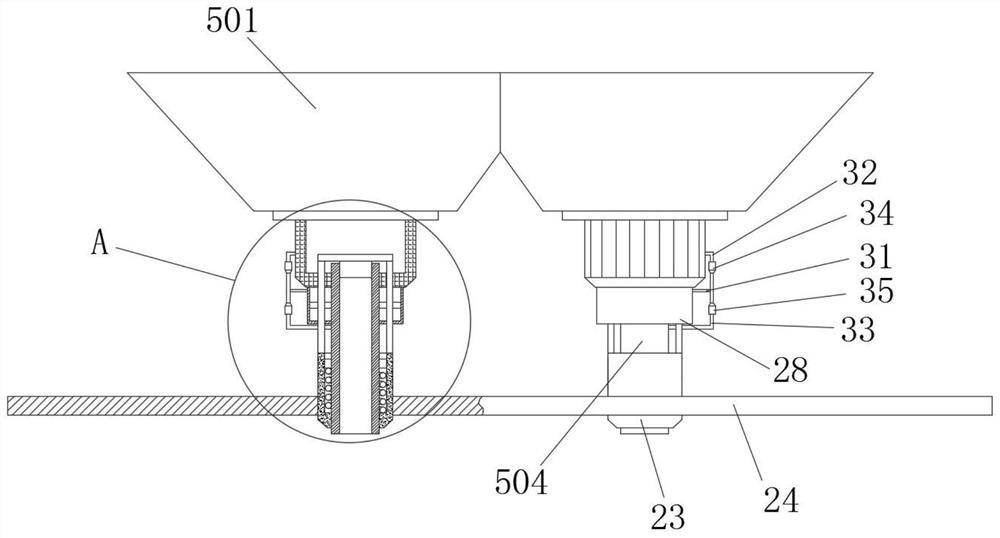

Multi-pipe reaction device for producing epoxidized soybean oil and method

PendingCN107626277AImprove heat transfer coefficientReduce usageFatty acid chemical modificationOrganic chemistryEnhanced heat transferProcess engineering

The invention discloses a multi-pipe reaction device for producing epoxidized soybean oil. The device comprises a pipe reactor unit or at least two pipe reactor units which are sequentially connectedin series and a feed pipe, wherein the pipe reactor unit comprises one or at least two enhanced heat transfer mixing reactor units sequentially connected in series, each enhanced heat transfer mixingreactor unit comprises one or at least two enhanced heat transfer mixing reactors sequentially connected in series, and a cooling water inlet and a cooling water outlet are formed in the enhanced heattransfer mixing reactor; a first feed port for introducing soybean oil, a second feed port for introducing mixed acid and a third feed port for introducing hydrogen peroxide are formed in the feed pipe in the axial direction, and the tail end of the feed pipe is communicated with the enhanced heat transfer mixing reactor. The invention further discloses a method of the multi-pipe reaction devicefor producing epoxidized soybean oil.

Owner:NANTONG HAIERMA TECH CO LTD

Tower type extraction device, tower extraction process method and application

InactiveCN105664524AImprove throughputReduce holdupLithium compoundsRubidium/caesium/francium compoundsEngineeringTower

The invention discloses a tower type extraction device, a tower extraction process method and an application. The tower extraction process method comprises the steps: according to a selected extraction system, determining that an organic phase or an aqueous phase entering the tower is used as a continuous phase or a dispersed phase; when the organic phase entering the tower is the continuous phase and the aqueous phase is the dispersed phase, a two-phase dispersed contact material in the tower is selected from an oleophylic material; and when the aqueous phase entering the tower is the continuous phase and the organic phase is the dispersed phase, the two-phase dispersed contact material in the tower is selected from a hydrophilic material. In the process method, according to the property of the continuous phase in the extraction process, a material has good affinity with the continuous phase is used as the two-phase dispersed contact material, so the two-phase dispersed contact material is infiltrated by the continuous phase preferentially, and the dispersed phase cannot be coagulated and aggregated in the two-phase dispersed contact material. Therefore, the retention amount of the dispersed phase in the tower can be reduced accordingly, the two-phase reverse flow resistance is decreased, the flooding velocity is increased, and thus the tower flux is also increased.

Owner:上海颐润科技有限公司 +1

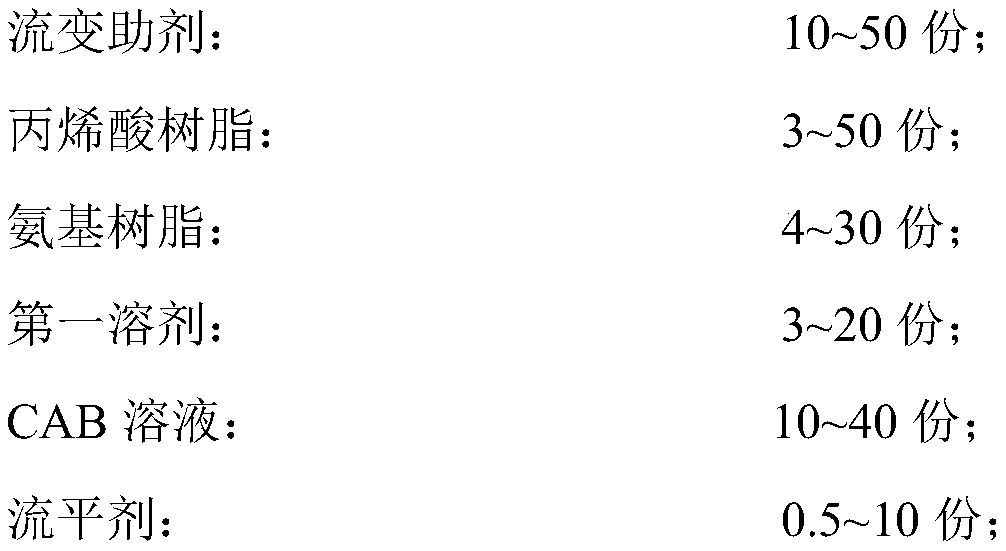

High-adhesive-force and low-temperature refinishing paint composition and preparation method thereof

The invention discloses a high-adhesive-force and low-temperature refinishing paint composition and a preparation method thereof. The refinishing paint composition is prepared from a curing componentand a diluting component, wherein the curing component is prepared from the following components: a rheological auxiliary agent, acrylic resin, amino resin, a first solvent, a CAB (Cellulose Acetate Butyrate) solution and a leveling agent; the diluting component is prepared from the following components: a second solvent, a third solvent, a fourth solvent, a leveling agent, first isocyanate and second isocyanate. The preparation method of the refinishing paint composition comprises preparation of the curing component and preparation of the diluting component. After refinishing paint provided by the invention is subjected to color mixing, requirements on various refinishing paint in the market can be met. In a construction process, the surface of a coated part does not need to be subjectedto polishing treatment in a refinishing or coating process and the refinishing paint is directly sprayed, so that a refinishing procedure is accelerated and the time of a refinishing process is shortened; meanwhile, manual polishing is reduced and the refinishing cost is saved.

Owner:LANGFANG NIPPON PAINT

Anti-leakage aseptic cold filling system for plant extraction concentrated solution

InactiveCN112093749AReduce holdupAvoid polydropsLavatory sanitoryFilling device cleaningAgricultural engineeringStructural engineering

The invention discloses an anti-leakage aseptic cold filling system for a plant extraction concentrated solution. The anti-leakage aseptic cold filling system comprises a box body, bases, a feeding cylinder and a shell, the bases are fixedly connected to the four corners of the bottom end of the box body, a feeding pipe is fixedly connected to the top end of the box body, the feeding cylinder communicates with the box body, the shell communicates with the left side of the box body, and a jacking push rod is installed on the lower portion of the inner cavity of the box body. A placing plate isfixed to the upper end of the jacking push rod, and a filtering mechanism is mounted at the bottom end of the feeding cylinder. Bottle bodies needing to be filled are placed on the placing plate, theplacing plate is lifted through the jacking push rod, a drain pipe can fill the bottle bodies, after filling is completed, a sliding sleeve resets under the action of an extrusion spring, the slidingsleeve moves to drive a jacking column and a piston to integrally move, when the piston moves, the internal space of a cylinder liner changes, so that concentrated solution accumulated in the drain pipe flows back into the cylinder liner through a second connecting pipe, the retention amount of the concentrated solution in the drain pipe is reduced, the concentrated solution is prevented from accumulating drops, and the situation that the filling system is polluted due to leaking of the concentrated solution is avoided.

Owner:康季

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com