Cooling spiral conveyor for powdery explosives

A cooling screw and conveyor technology, applied in packaging and other directions, can solve the problems of soft and deformed waxed paper tubes, reduced explosive power, difficult charge blasting, etc., and achieve the effects of reduced hygroscopicity, low cost, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be further described below in conjunction with an embodiment, but the content of the present invention is not limited to this.

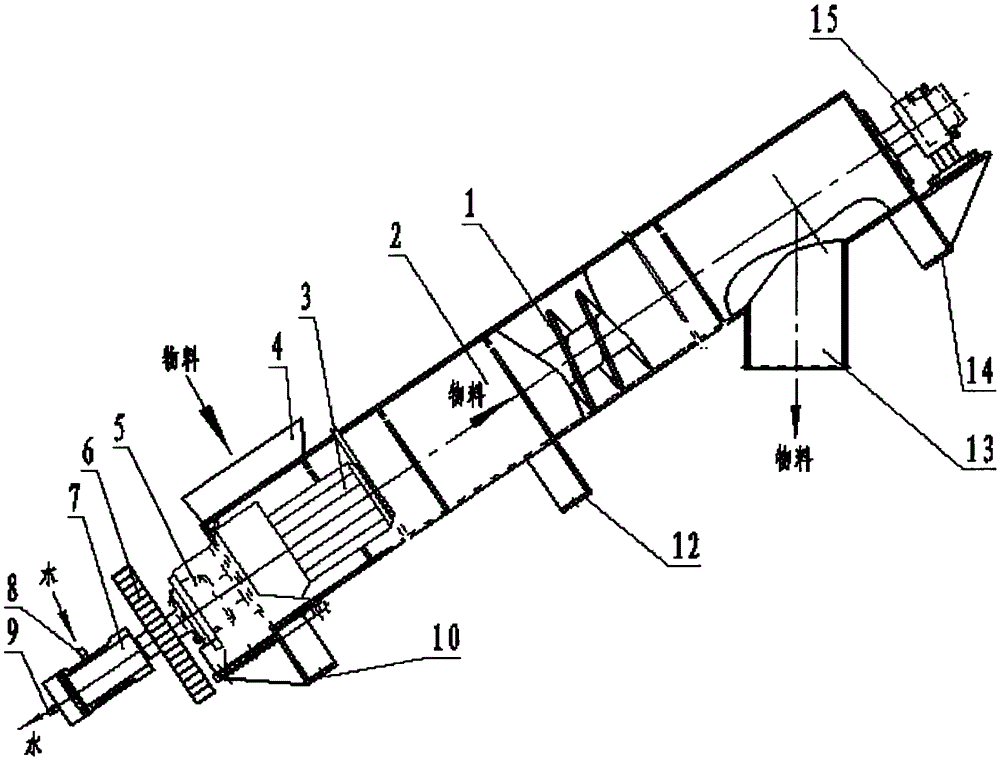

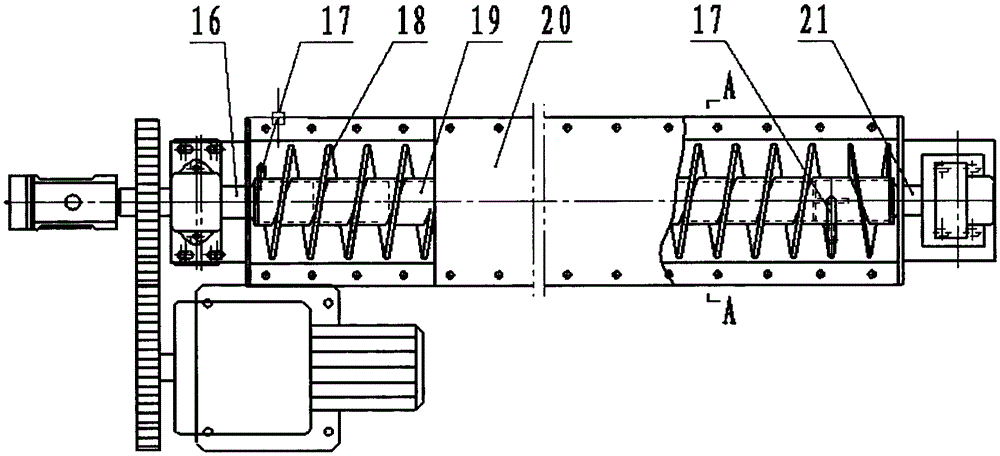

[0029] 1. See image 3 , Figure 5 , Image 6 , Figure 7 The steel pipe mandrel 19 in the spiral body 1 can be made of φ127×10 stainless steel pipe, the upper shaft head 21 and the lower shaft head 16 can be made of 45 steel, and the lower shaft head 16 is drilled with a water inlet and a water outlet. One end of the two long holes Corresponding to the water inlet 8 and the water outlet 9 of the combined water seal device 7, one of the long holes at the other end communicates with the inner cavity of the steel pipe mandrel 19, and the other long hole communicates with the sandwich spiral blade 18 through the elbow 17. The sandwich spiral blade 18 A stainless steel plate with a thickness of 12mm can be used to process a 9mm deep annular groove and then weld a stainless steel plate with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com