Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

328results about How to "Take away in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

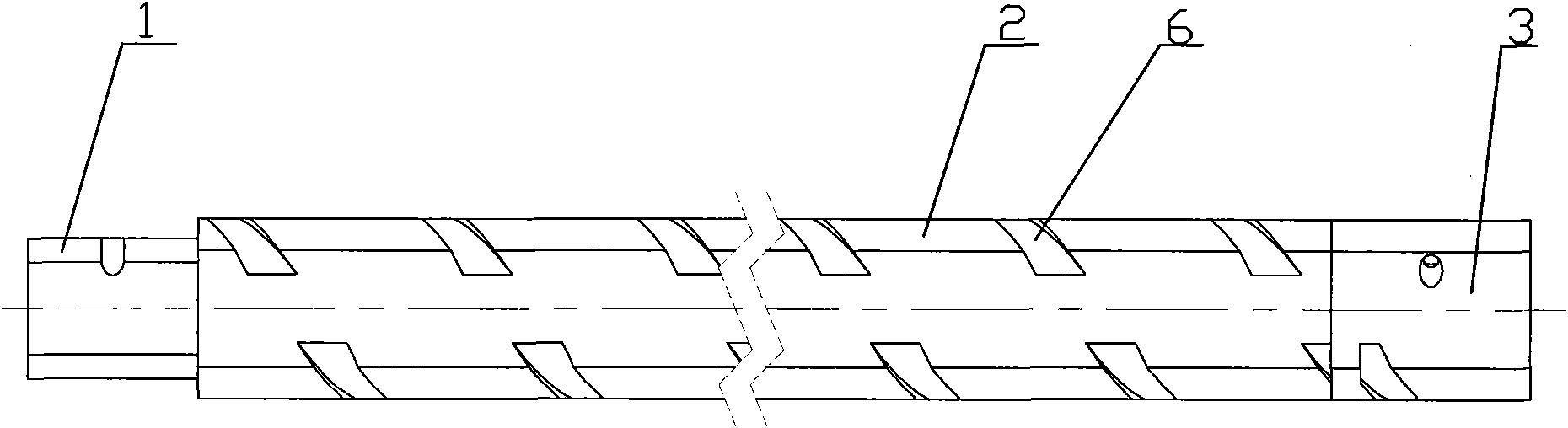

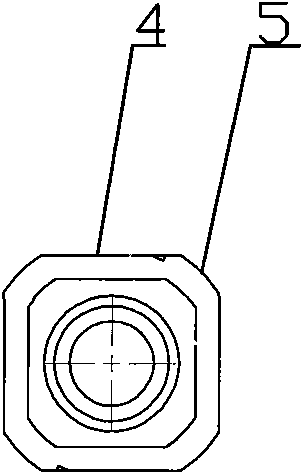

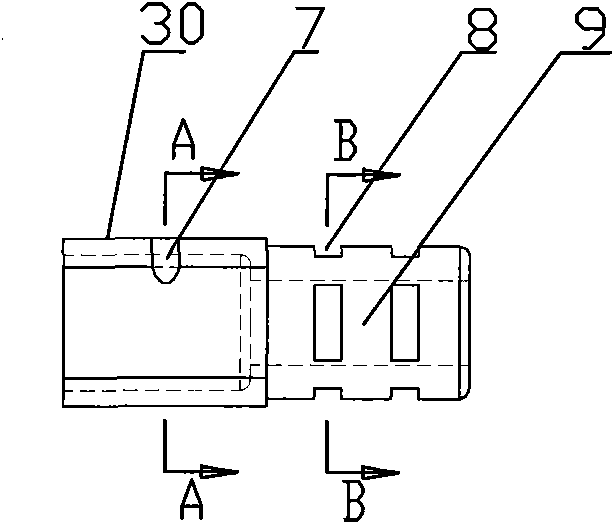

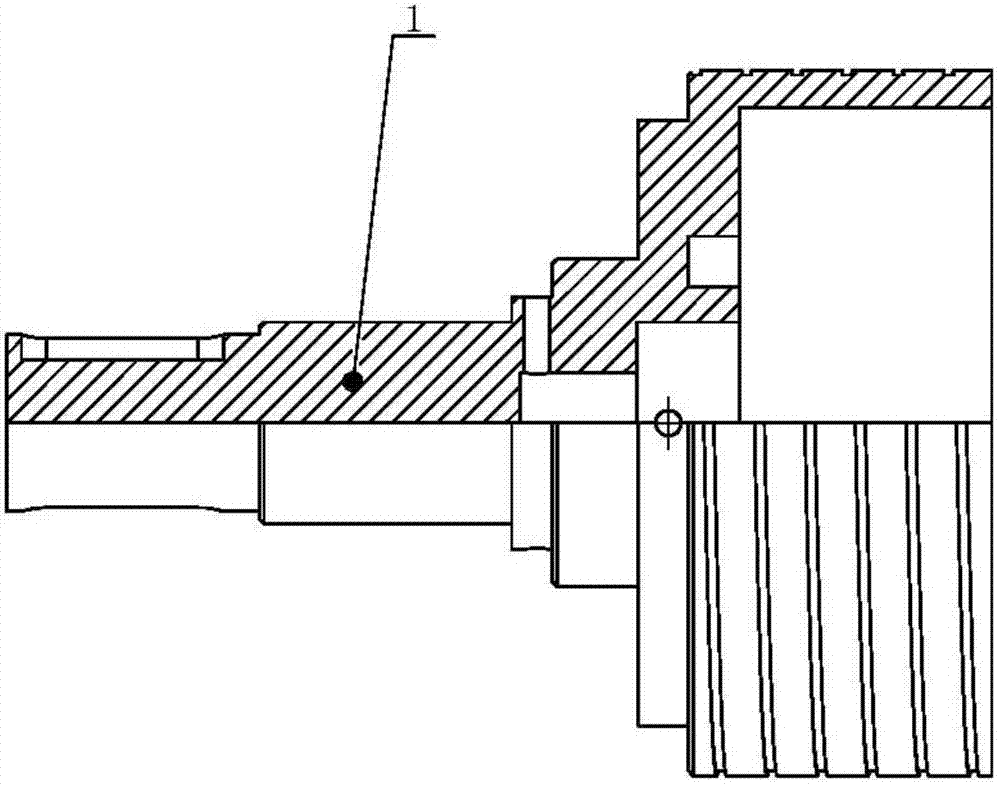

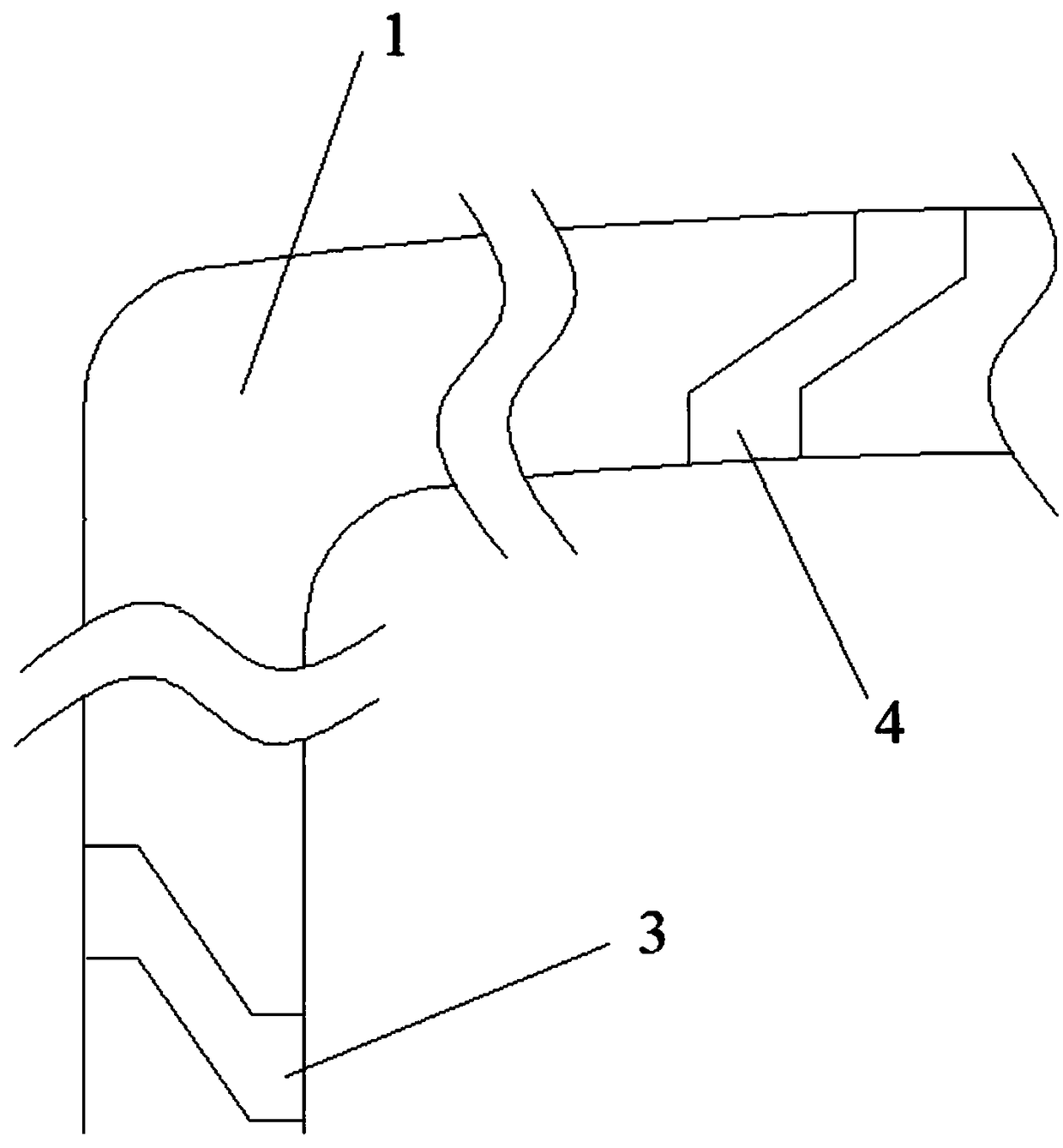

Irregularly shaped multi-land notch groove drill rod

ActiveCN101566049ALow rotational resistanceTake away in timeDrilling rodsDrilling casingsLine segmentHelix

The invention discloses an irregularly shaped multi-arris notch groove drill rod, which consists of a hollow multi-arris rod body and a connecting piece, the section outline of the multi-arris rod body consists of tangential paths and circular arc sections, and incontinuous spiral grooves are distributed on the surface of the rod body simultaneously. The drill rod can cause vortex flow when whirling in loose cinder and raise coal dust deposited on the bottom of a drilling hole in virtue of the arris of the drill rod, and the coal dust in the drilling hole is at a moving status all the time, thus preventing the coal dust from accumulating in the drilling hole and resulting in blockage; simultaneously, the incontinuous spiral grooves distributed on the surface can assist in the outward transmission of the cinder, and when hole collapsing in the drilling hole, the outside of the collapsed hole is unchoked by the hole digging function of the spiral grooves, thus being not easy to have drill absorption and drill blockage. The drill rod has the advantages of reasonable design, simple structure, safety and reliability, thus greatly improving deslagging effect, being beneficial to increasing the depth of the drilling holes, shortening hole drilling time, improving work efficiency and having high hole forming rate. Therefore, the drill rod is worth popularizing and applying in mining enterprises.

Owner:山东益矿钻采科技有限公司

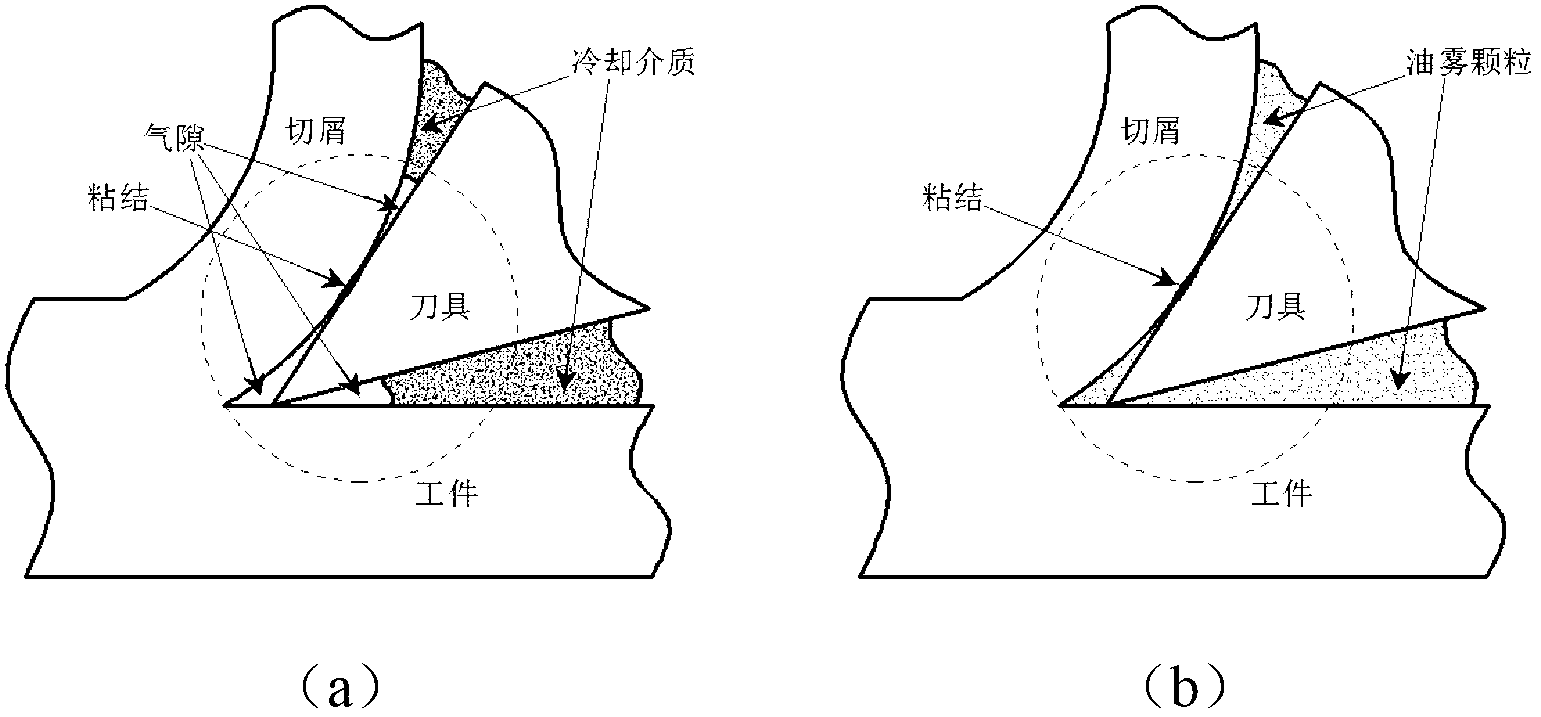

Method and device for forming high-pressure and low-temperature jet flow by cutting coolant

ActiveCN103286629AIncreased durabilityReduce cutting temperatureMaintainance and safety accessoriesJet flowSpray nozzle

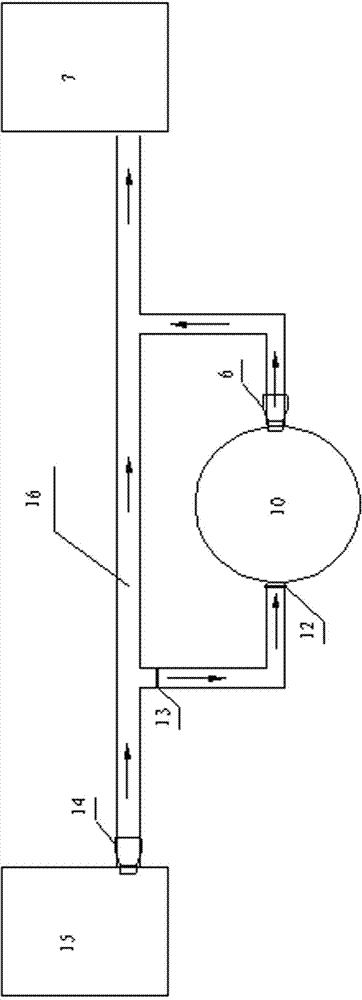

The method discloses a method and device for forming high-pressure and low-temperature jet flow by cutting coolant. The method includes that compressed air stored inside an air storage tank is filtered and dried and connected to a tee joint through a hose to divide an output pipe into two branches, air in one branch is cooled by a cooling device to become low-temperature high-pressure air, and inputted into an air inlet end of a pneumatic spray nozzle after being connected with one or more than one tee joint, the air in the other branch is inputted into a well-sealed cutting fluid storage container after pressure in the air is regulated by a pressure regulating valve, the cutting fluid is pressed out, and connected into liquid inlet ends of a plurality of pneumatic spray nozzles after passing one or more than one tee joint prior through the hose, the air and the liquid are mixed outside a jet nozzle to produce high-speed jet flow. By the method, usage amount of cooling lubricating liquid is reduced, cooling and lubricating functions of fluid medium are fully performed, cutting temperature is greatly lowered, and tool durability is conspicuously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

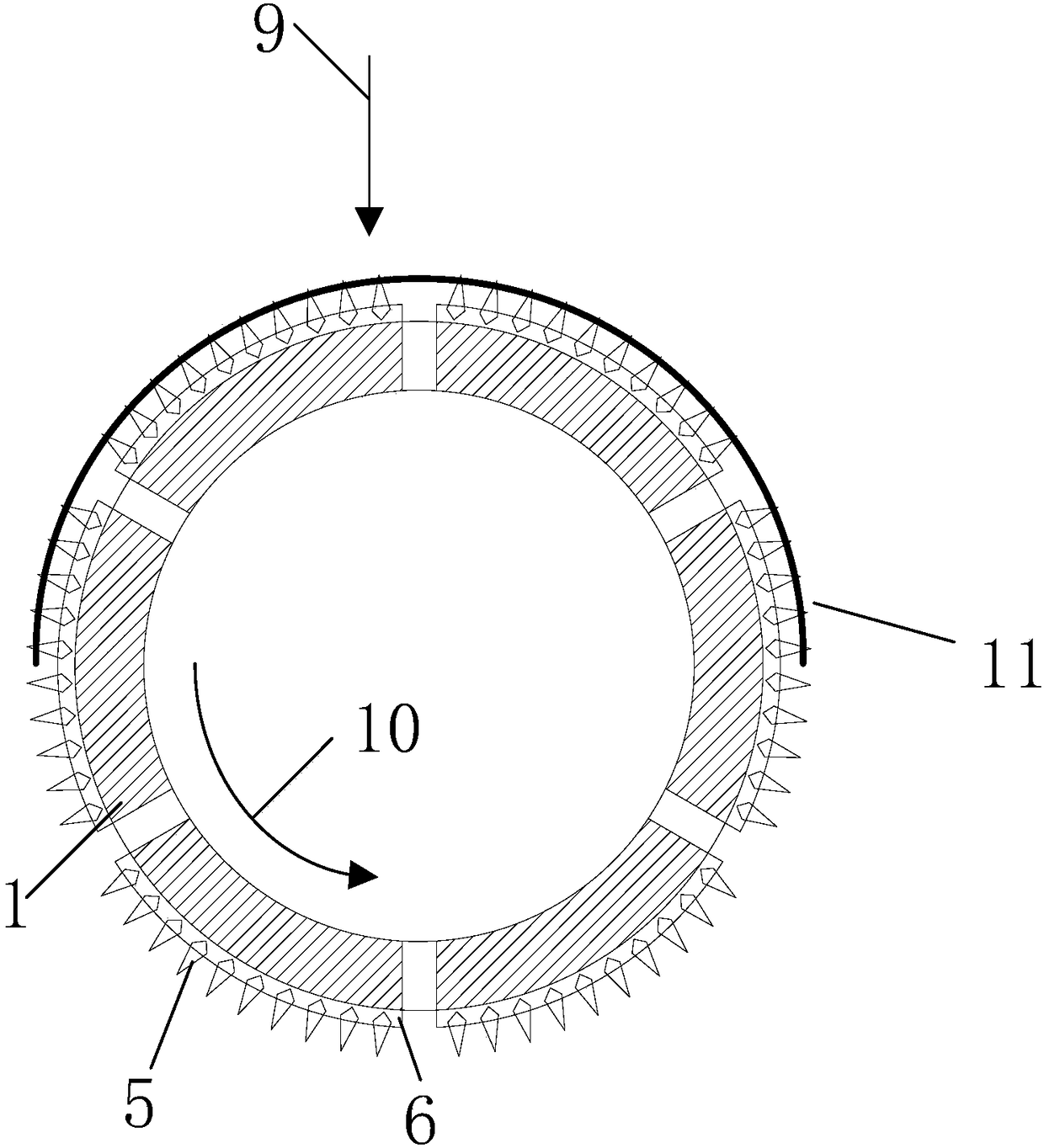

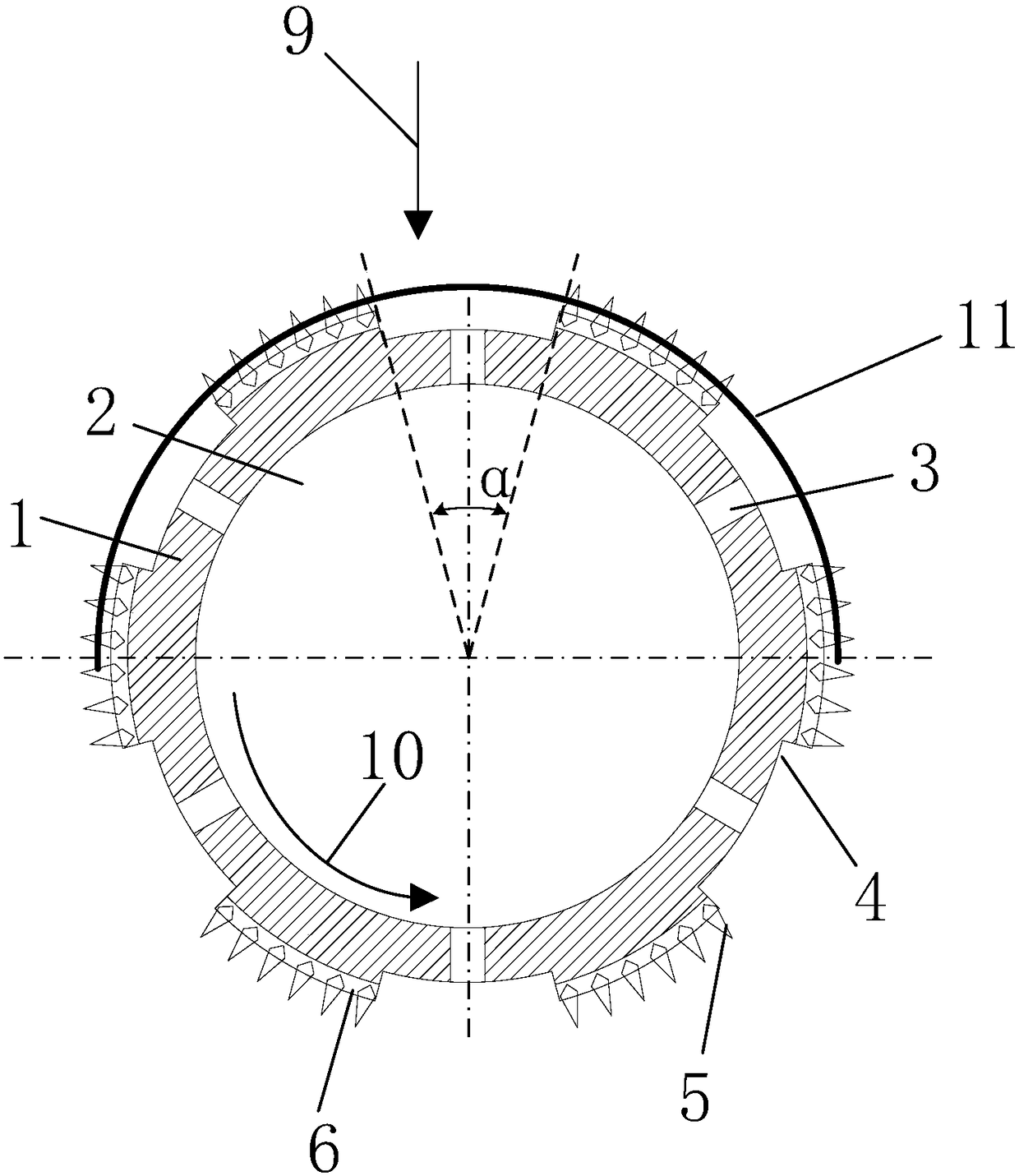

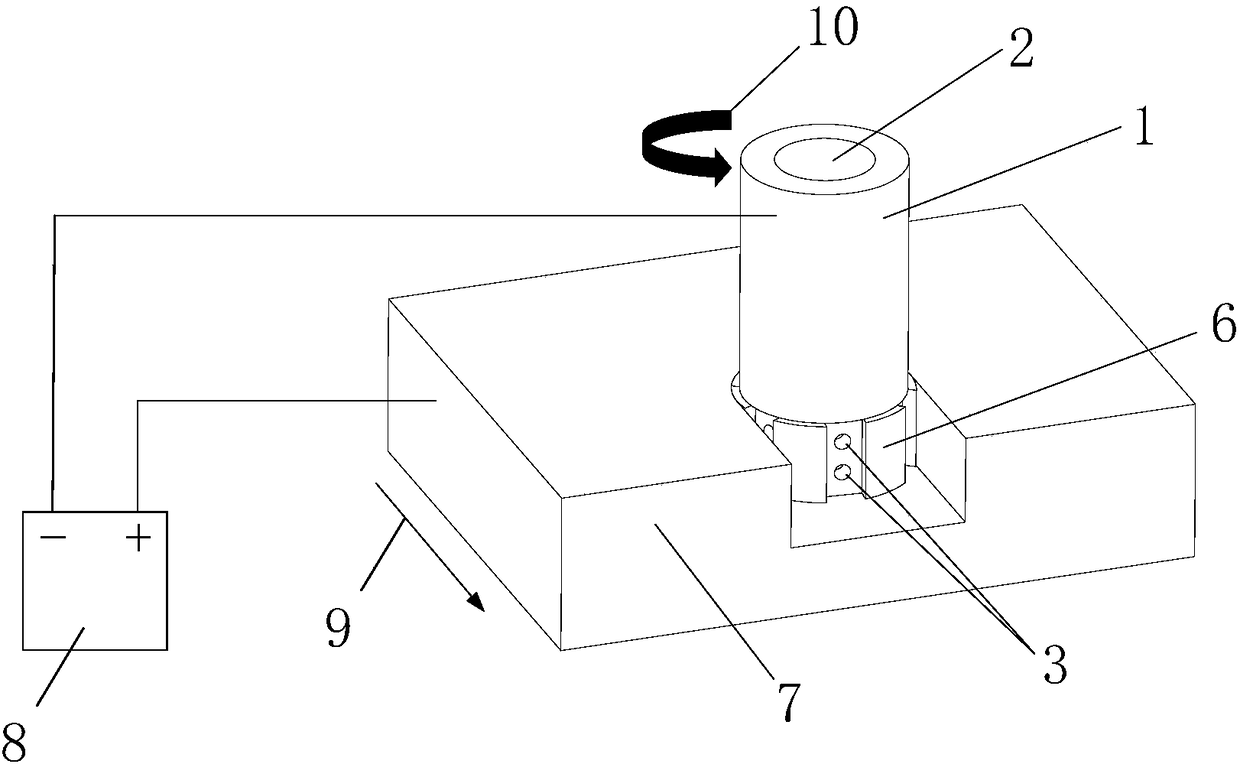

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

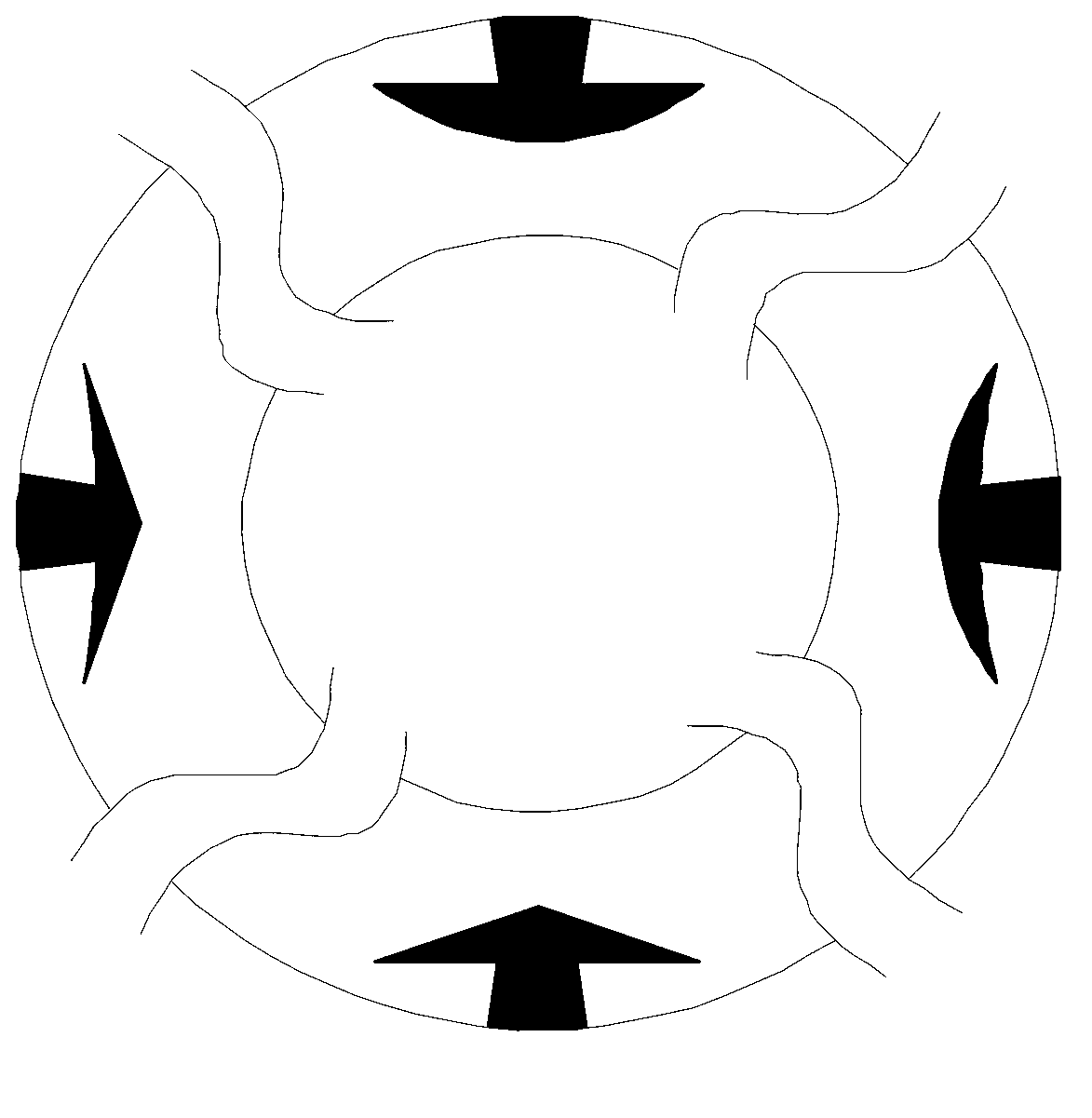

Mushroom-like groove bi-direction rotating fluid dynamic pressure type machine sealing structure

A mushroom-like groove bi-direction rotating fluid dynamic pressure type machine sealing structure comprises two sealing rings of mechanical seal. The two sealing rings refer to a movable ring and a static ring. A plurality of mushroom-like grooves for sealing liquid are evenly distributed on the circumference of the sealing end face of at least one of the movable ring and the static ring. Each mushroom-like groove is composed of a drainage groove and a returning groove. Each drainage groove extends in the radial direction, and the width of each drainage groove gradually becomes narrower from an upper stream (a higher-pressure side) to a lower stream (a lower-pressure side) along the end face in the radial direction. Each returning groove extends in the circumference direction and the radial direction and is in the shape of an arc, an oval arc, a curved arc, or a straight line. The tail end of each drainage groove is connected with each returning groove. Areas which are not provided with grooves and are between the mushroom-like grooves are sealing weirs. A ring belt formed by an area which is not provided with grooves on the circumference of the end face is a sealing dam.

Owner:ZHEJIANG UNIV OF TECH

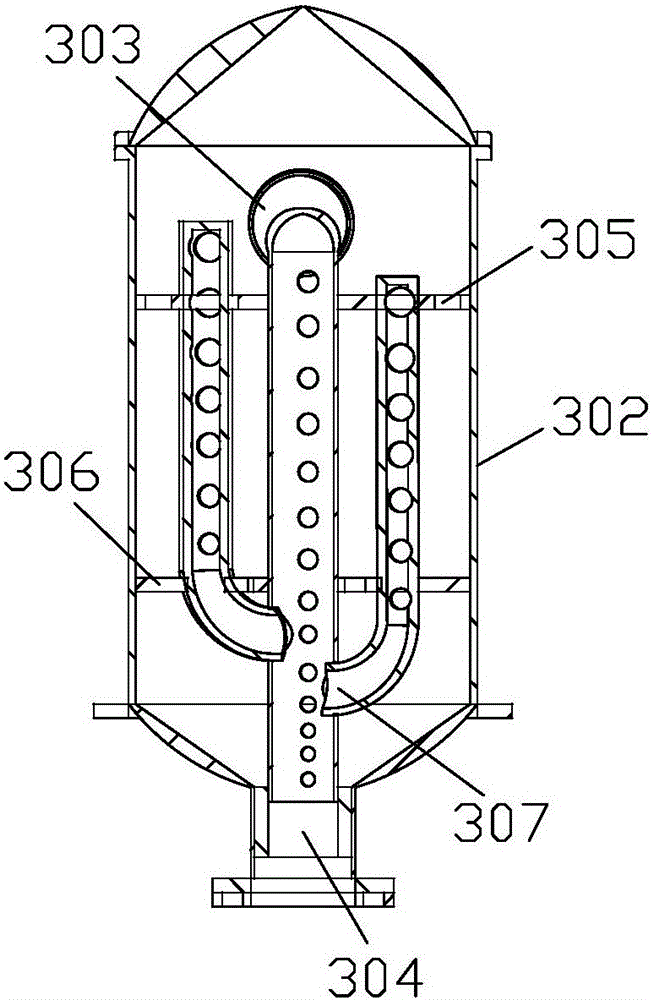

Method and device for purifying refined aluminum and high-purity aluminum through continuous segregation

ActiveCN102864314AGuaranteed stabilityTake away in timeProcess efficiency improvementProduction lineDirectional solidification

The invention relates to a method and a device for purifying refined aluminum and high-purity aluminum through continuous segregation and belongs to the field of casting metallurgy. The method and the device for purifying the refined aluminum and the high-purity aluminum through the continuous segregation are characterized in that crystallization of the refined aluminum and the high-purity aluminum is finished in flowing molten aluminum, the method and the device rely on a liquid supply system of production lines including a continuous casing production line, a continuous rolling production line and the like which need continuous liquid supply, the molten aluminum is from molten aluminum flowing out of a standing furnace, the flowing molten aluminum continuously provides a purification raw material, and continuous high-purity aluminum production is really achieved through the match of the method, the device and a rolling wheel crystal-pulling device. By means of the method, a stirring system is not required in the whole purification process, the energy consumption in the heat preservation process is reduced greatly, purified molten aluminum has no influence on follow-up production activities, the flowing molten aluminum enables the stability of purification raw material components to be ensured, and the uniformity of product components is ensured well under a certain process condition. The method greatly improves the production efficiency and simultaneously reduces the energy consumption, and a directional solidification and purification process is not influenced by the atmosphere environment inside a furnace.

Owner:KUNMING METALLURGY INST

Cable provided with heat shield with heat dissipation holes and wear-resisting layers

InactiveCN104952536ATake away in timeGuaranteed lock disengagementInsulated cablesInsulated conductorsEngineeringCooling fluid

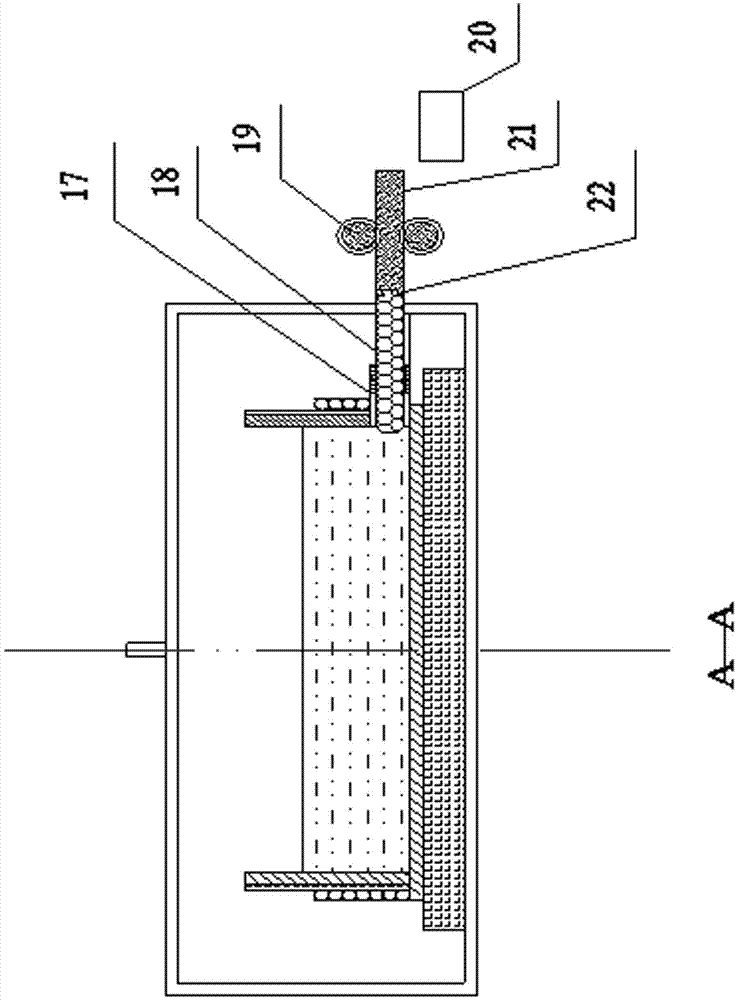

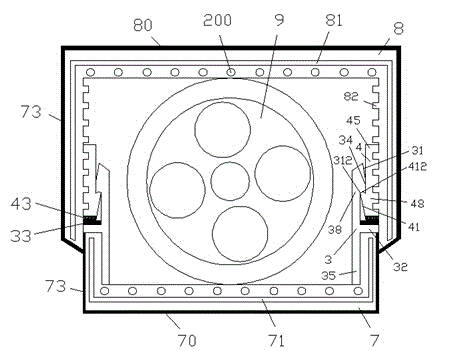

A cable provided with a heat shield with heat dissipation holes and wear-resisting layers comprises a cylindrical cable body (9) arranged in the heat shield and the heat shield including an upper heat shield body (8) and a lower heat shield body (7), wherein shield walls of the upper heat shield body (8) and the lower heat shield body (7) comprise respective bottom walls (80 and 70) and side walls on two sides of each of the bottom walls (80 and 70); the bottom walls (80 and 70) are contacted with two round tops opposite to each other in the diameter direction of the cable body (9) respectively, cooling fluid channels (81 and 71) extending along the shield walls are formed in the shield walls respectively, twenty one or more heat dissipation holes (200) parallel to the cooling fluid channels (81 and 71) are formed in the bottom walls (80 and 70), and the wear-resisting layers (73) are arranged on the outer surfaces of the shield walls of the upper heat shield body (8) and the lower heat shield body (7).

Owner:广东金首诚电线电缆实业有限公司

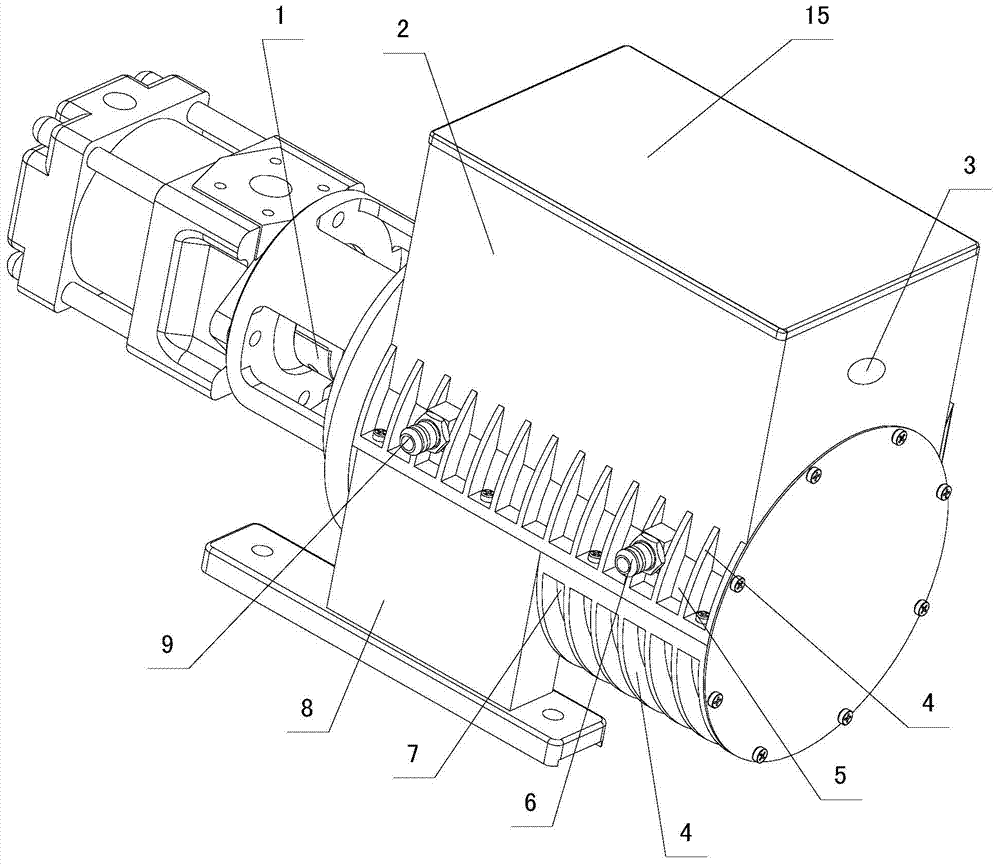

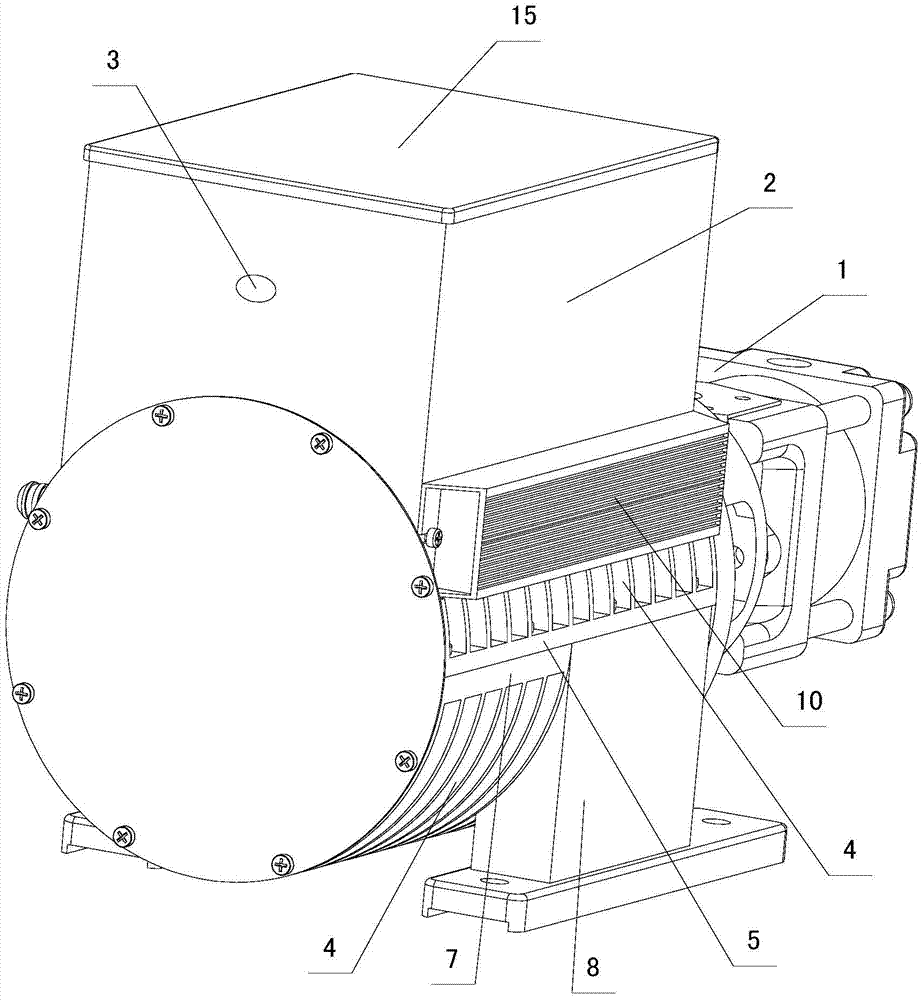

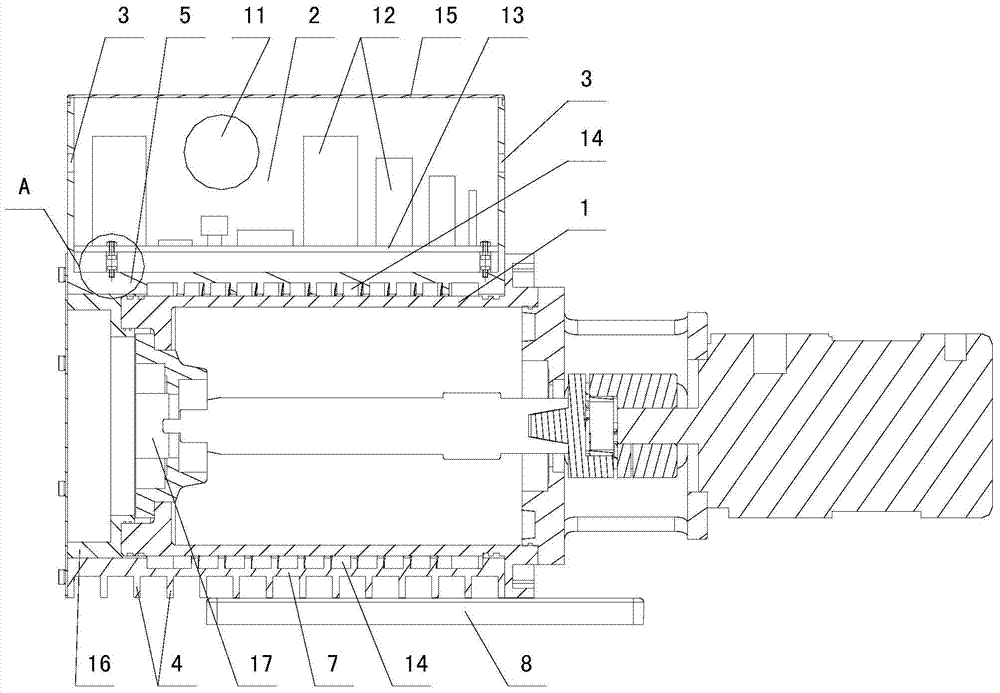

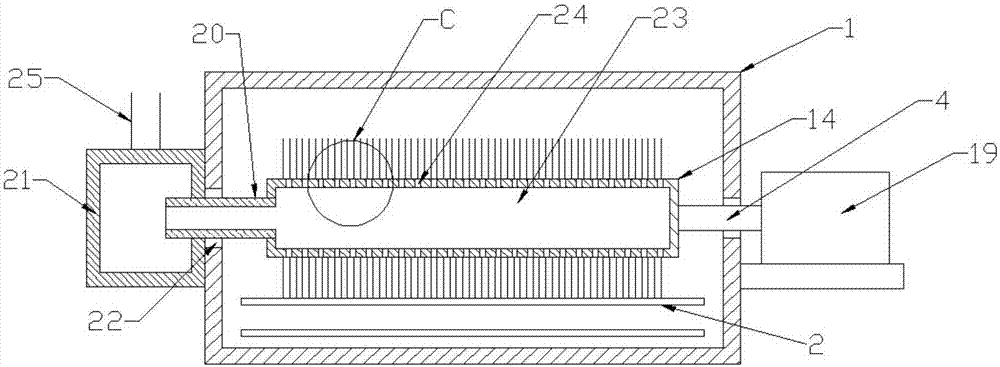

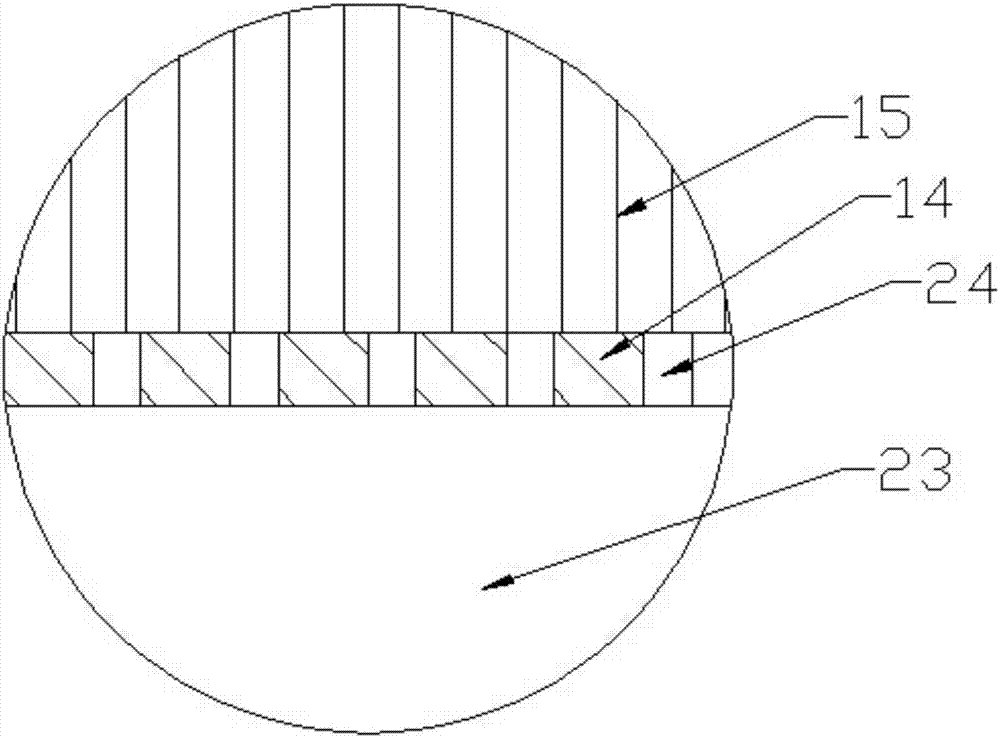

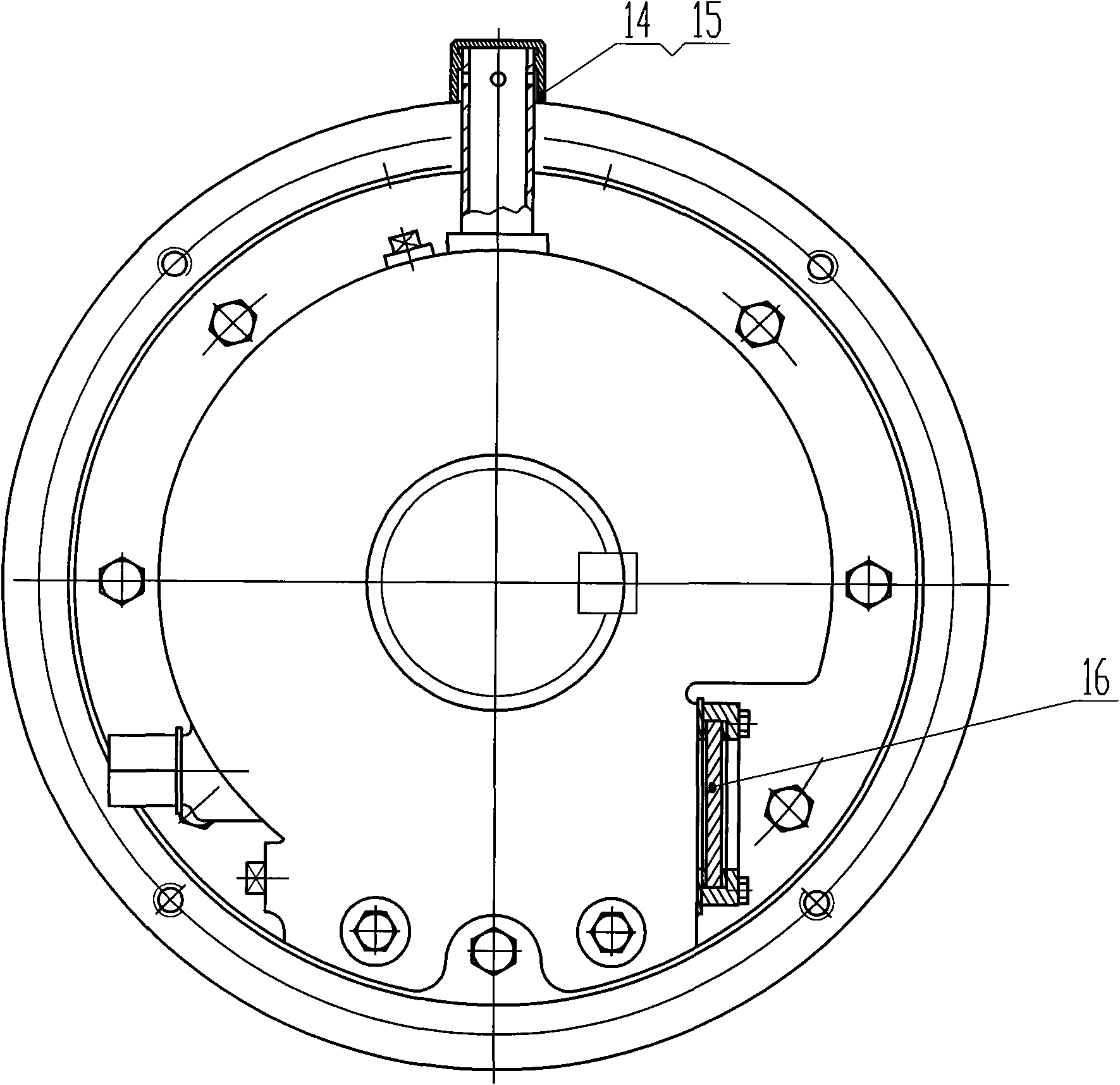

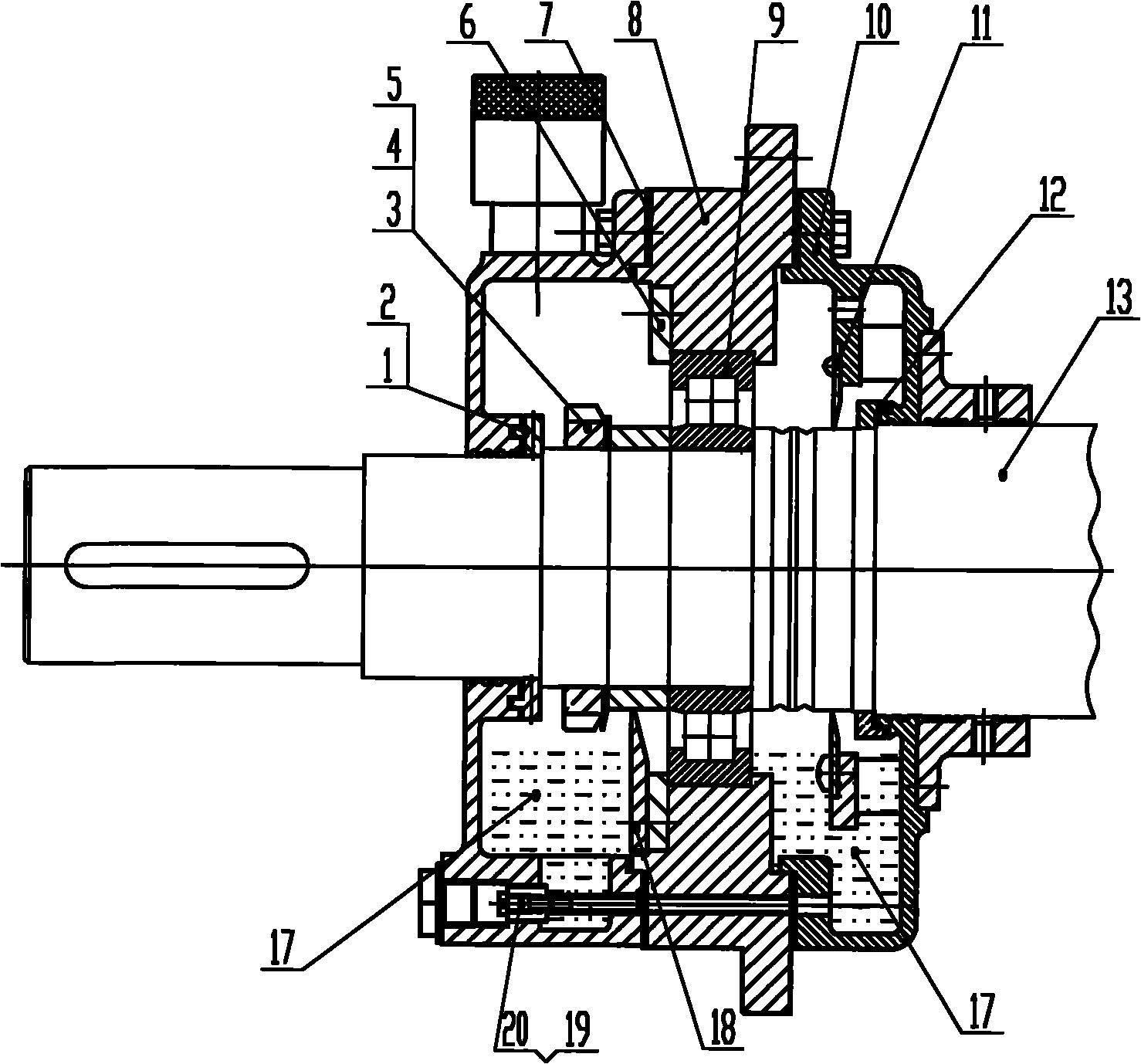

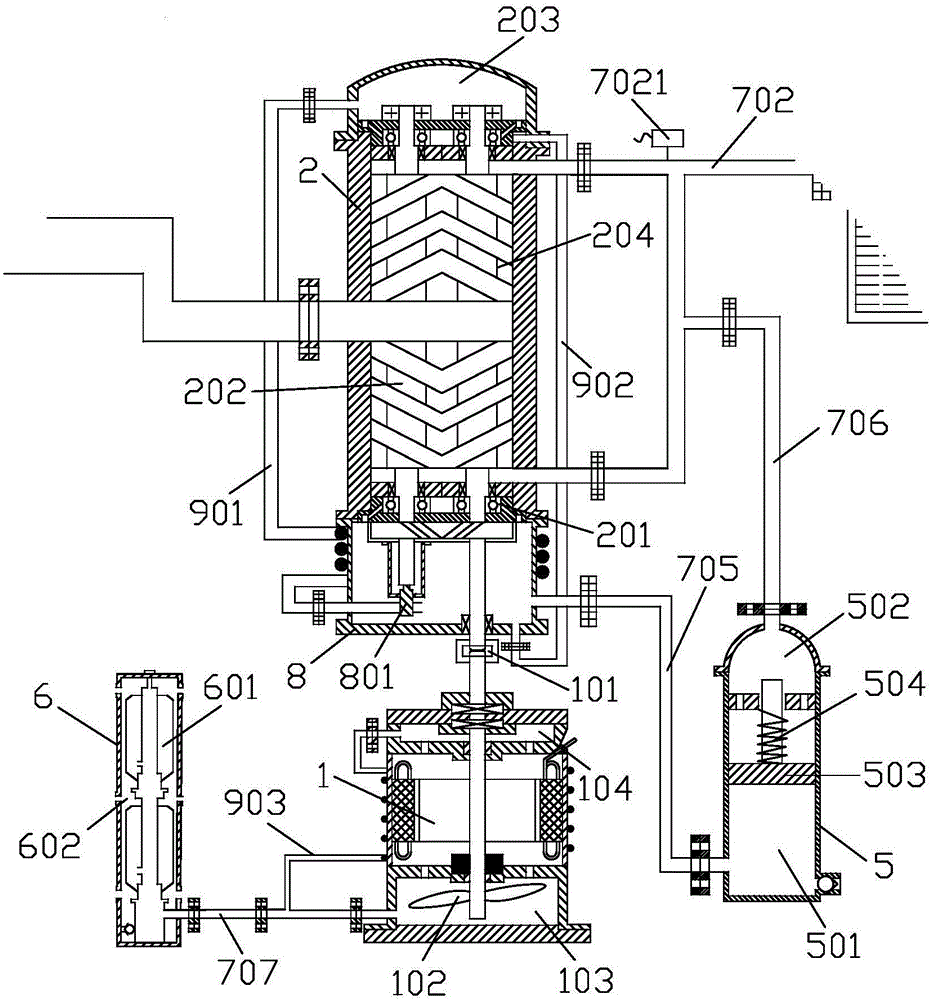

Integrated servo motor

ActiveCN103683685AGood cooling effectGood versatilityAssociation with control/drive circuitsCooling/ventillation arrangementCooling channelClosed cavity

The invention discloses an integrated servo motor. A servo motor body (1) is connected with a servo driver via a cooler, the cooler comprises a cooling jacket which is sleeved on the servo motor body (1), a casing (2) of the servo driver is connected with the cooling jacket, and the wall of the cooling jacket includes cooling channels; the casing (2) of the servo driver internally includes an enclosed cavity and is made of a metal heat-conductive material, and a fan (11) is installed in the casing; an electrical conjunction box (16) is positioned in the cooling jacket, and an encoder (17) is connected with one end, close to the electrical conjunction box (16), of a central shaft of the servo motor body (1); and a vibration-proof device which is used for protecting electronic components (12) in the servo driver is arranged in the servo driver. The integrated servo motor of such structure is good in heat radiation and cooling effects, and is convenient to maintain.

Owner:NINGBO TENGLONG OUTDOOR IMPLEMENT

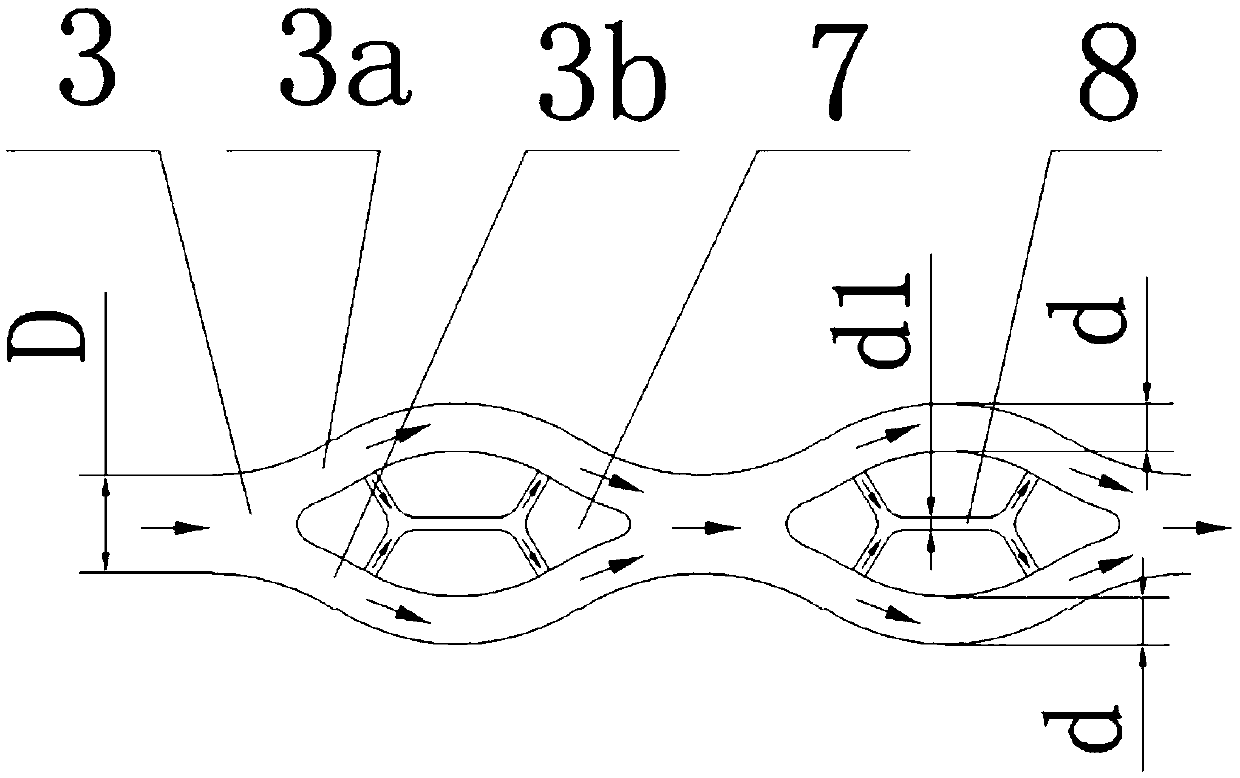

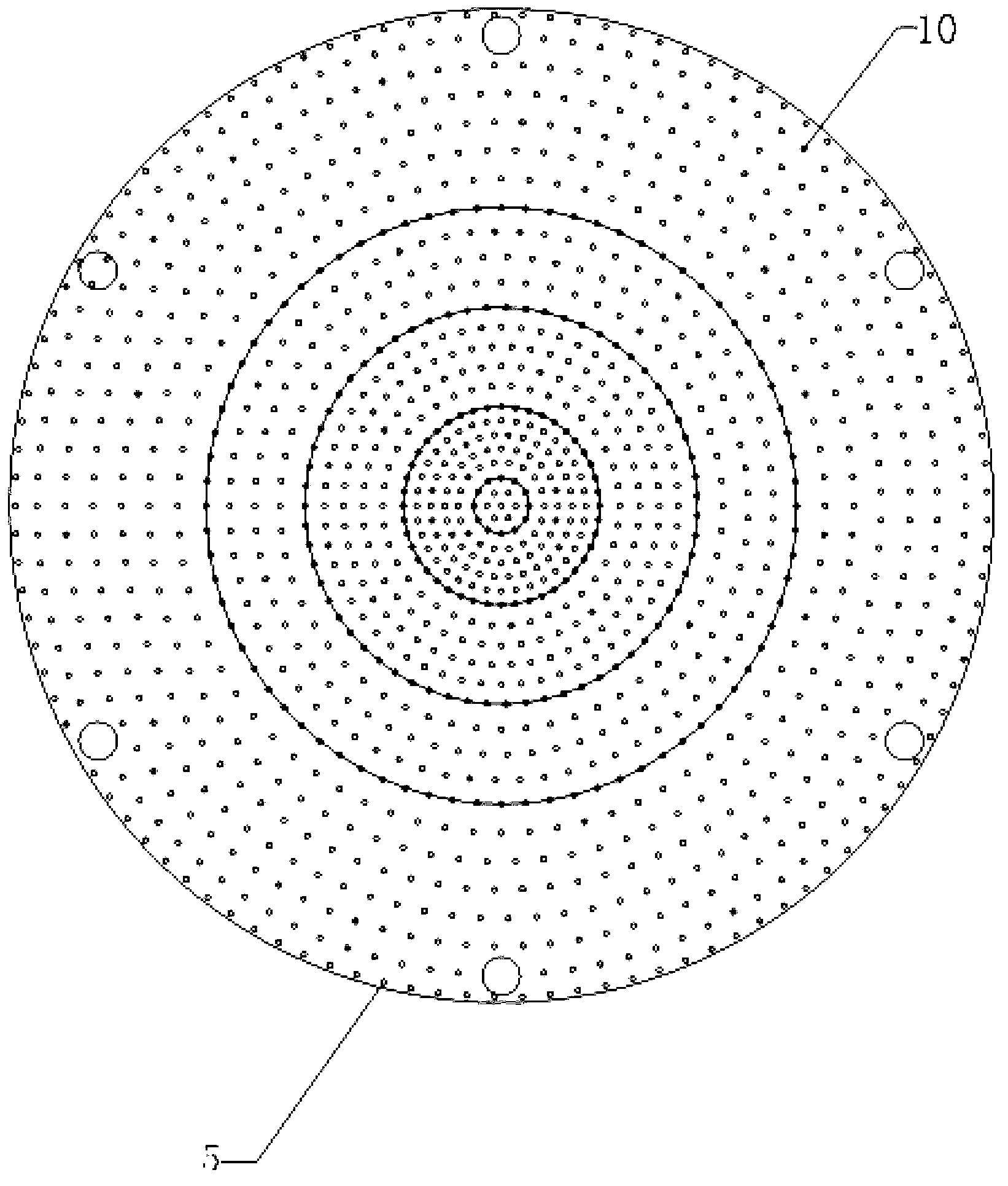

Rotary immersed water treatment ultra-micro-filtering method and device

PendingCN105217734APrevent enrichmentNot easy to blockUltrafiltrationWater/sewage treatment bu osmosis/dialysisRaw waterEngineering

The invention relates to a rotary immersed water treatment ultra-micro-filtering method and a rotary immersed water treatment ultra-micro-filtering device. The two ends of each hollow fibrous membrane wire are cast to an upper membrane wire disk and a lower membrane wire disk respectively; the upper membrane wire disk is connected with a water collecting tank; the lower membrane wire disk and a component base plate are fixed; a cavity of each membrane wire is communicated with a cavity of the water collecting tank; the membrane wires and the water collecting tank are integrated to form a membrane component; the water collecting tank is connected with a hollow shaft; the hollow shaft lifts the membrane component to a bearing seat and is communicated with a negative pressure water outlet pipe; a pin gear fixedly arranged on the water collecting tank, a speed reducer, a transmission shaft and a pinion form a driving device and the driving deice can drive the membrane component to rotate forwardly and reversely, so as to enable the membrane wires to be in a movement state; the negative pressure of a system is achieved in a pumping or siphon manner, raw water is filtered by a membrane, and pure water is drained from a negative-pressure water drainage pipe; due to the movement of the membrane component, the membrane wires and water flow move relatively, dirt attached to the surface of the membrane is taken away in time by the scouring force of the water flow, blocking of the surface of the membrane is effectively prevented, and the filter flow does not attenuate.

Owner:TIANJIN UNIV +1

Vibrating drying device for plate production and processing

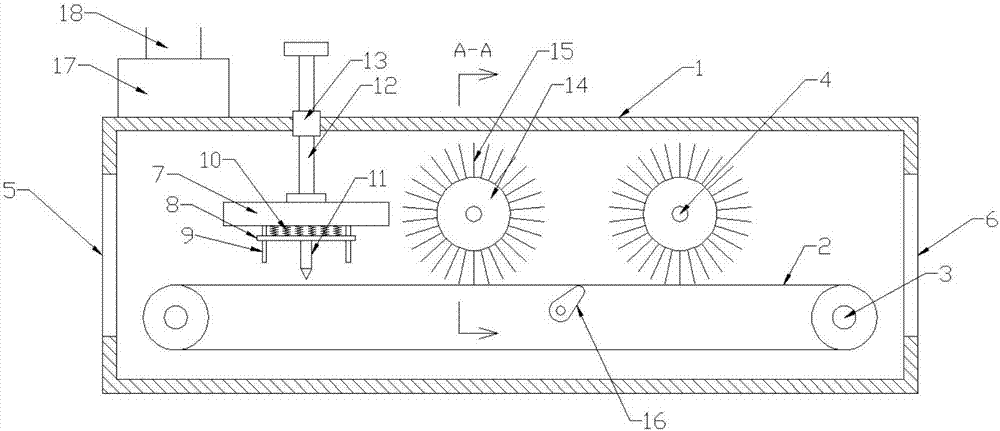

InactiveCN107576182AImprove drying efficiencyShorten drying timeDrying solid materials without heatDrying gas arrangementsBristleEngineering

The invention discloses a vibrating drying device for plate production and processing. The vibrating drying device for plate production and processing comprises a box body, a conveying belt, a transmission wheel and a motor, wherein a plurality of bulges are uniformly distributed on the outer surface of the conveying belt; and a water scraping mechanism is arranged above the conveying belt, a camis installed at the inner side of the conveying belt, horizontal brush rolls are installed above the conveying belt, a hollow shaft is fixed to the other end of the brush roll, a hot-air box is communicated to the tail end of the hollow shaft, a cavity is formed in the brush roll, and bristles are uniformly distributed on the outer wall of the brush roll. According to the vibrating drying device for plate production and processing, hot air is also capable of flowing through the lower surface of a plate through projections arranged on the conveying belt to dry the lower surface of the plate, and the drying dead angles of the lower surface are avoided in combination with the vibration of the cam; and the brush roll absorbs water on the upper surface of the plate into the bristles, and contacts with the hot air during rotation to rapidly evaporate water, and meanwhile, the entering hot air is uniform, and high in flowability.

Owner:邱钱勇

Thin oil-lubricated bearing device for horizontal motor

InactiveCN101924412ALow viscosityGuaranteed lubrication effectBearing componentsSupports/enclosures/casingsFixed bearingRespirator

The invention relates to a thin oil-lubricated bearing device for a horizontal motor. The thin oil-lubricated bearing device for the horizontal motor is characterized in that: a motor shaft is arranged in a bearing bush; a gasket, a respirator, a respiratory tube and an oil duct are arranged on an outer cover of a bearing; a fixed bearing retainer ring, the outer cover of the bearing, an inner cover of a bearing, and a semi-ring are arranged on the bearing bush; a fixed baffle plate is arranged on the inner cover of the bearing; and an outer cover oil throwing disk, a rolling bearing, a round nut, a sleeve and an inner cover oil throwing disk are fixed on the motor shaft sequentially. The thin oil-lubricated bearing device for the horizontal motor has the advantages of completely guaranteeing the lubricating of the bearing of the horizontal motor with heavy load and high rotating speed due to thin oil lubrication and effectively improving the permissible working rotating speed of the motor bearing and prolonging the service life of the motor bearing, along with compact and reasonable structure.

Owner:WUXI ZHONGDA MOTORS

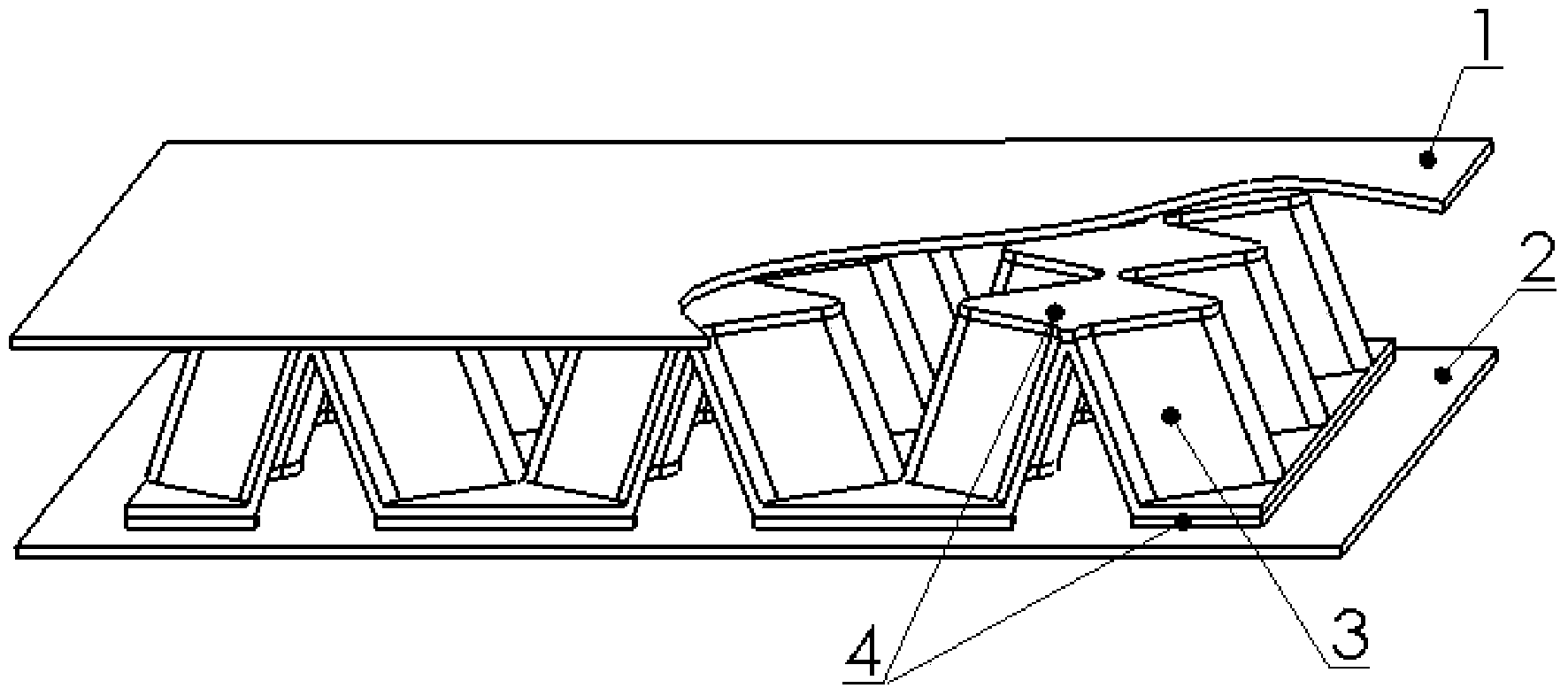

Honeycomb-type composite material laminboard and hot press molding method thereof

InactiveCN104175616AIncrease contact areaGood resistance to buckling deformationLayered productsHoneycombMaterials science

The invention discloses a honeycomb-type composite material laminboard and a hot press molding method thereof, relates to a laminboard and a hot press molding method thereof, and aims at solving the problems that the conventional hexagonal honeycomb laminboard is low in buckling deformation resistance and low in inner shearing and stripping performance, the conventional hexagonal honeycomb laminboard preparation method is complicated in working procedure and the forming quality is not controllable. According to the device, a sandwich layer consists of a plurality of herringbone units; the adjacent herringbone units are transversely and longitudinally interwoven and fixedly connected to form a whole; a space formed between two adjacent columns of the herringbone units is reduced gradually from top to bottom; a space formed in the lower part of each column of the herringbone units is expanded gradually from top to bottom. The method comprises the steps of 1, cleaning a die; 2, assembling the die; 3, heating the die; 4, paving prepregs; 5, folding the prepregs; 6, snapping down a cover plate; 7, solidifying the prepregs; 8, detaching the die. The honeycomb-type composite material laminboard is used in a main bearing structure of an aircraft.

Owner:HARBIN INST OF TECH

Side sucking type range hood and fume sucking control method thereof

ActiveCN107218632AImprove the smoke effectSimple drive controlDomestic stoves or rangesLighting and heating apparatusEngineeringFront panel

The invention discloses a side sucking type range hood and a fume sucking control method thereof. The range hood comprises a fume collecting hood (1) and a front panel (2) movably mounted in front of the fume collecting hood (1); the fume collecting hood (1) is provided with a fume inlet (10), and the front panel (2) can move relative to the fume collecting hood (1) to be switched between an opening state and a closing state; the side sucking type range hood also comprises a movably arranged fume guiding plate (3) which can move to be in an extending state when the front panel (2) is in the opening state; and under the extending state, at least part of the fume guiding plate (3) forms a brim part in front of the front panel (2) to guide cooking fume into the fume inlet (10). Under the condition of larger cooking fume quantity, the fume guiding plate (3) is driven to move to be in the extending state to improve the fume collecting effect of the side sucking type range hood, therefore, the fume sucking effect of the side sucking type range hood is enhanced, and the purposes of timely sucking away the cooking fume and fast purifying a kitchen environment are achieved.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

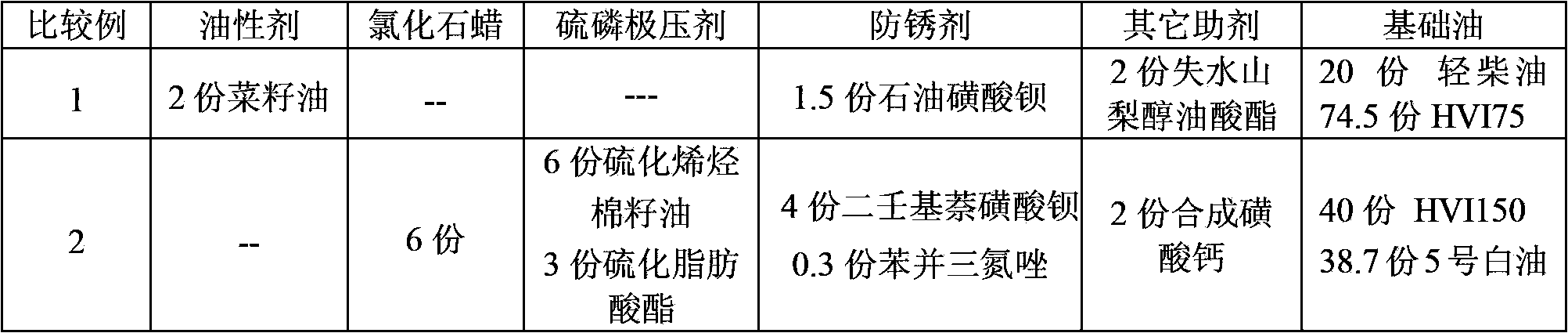

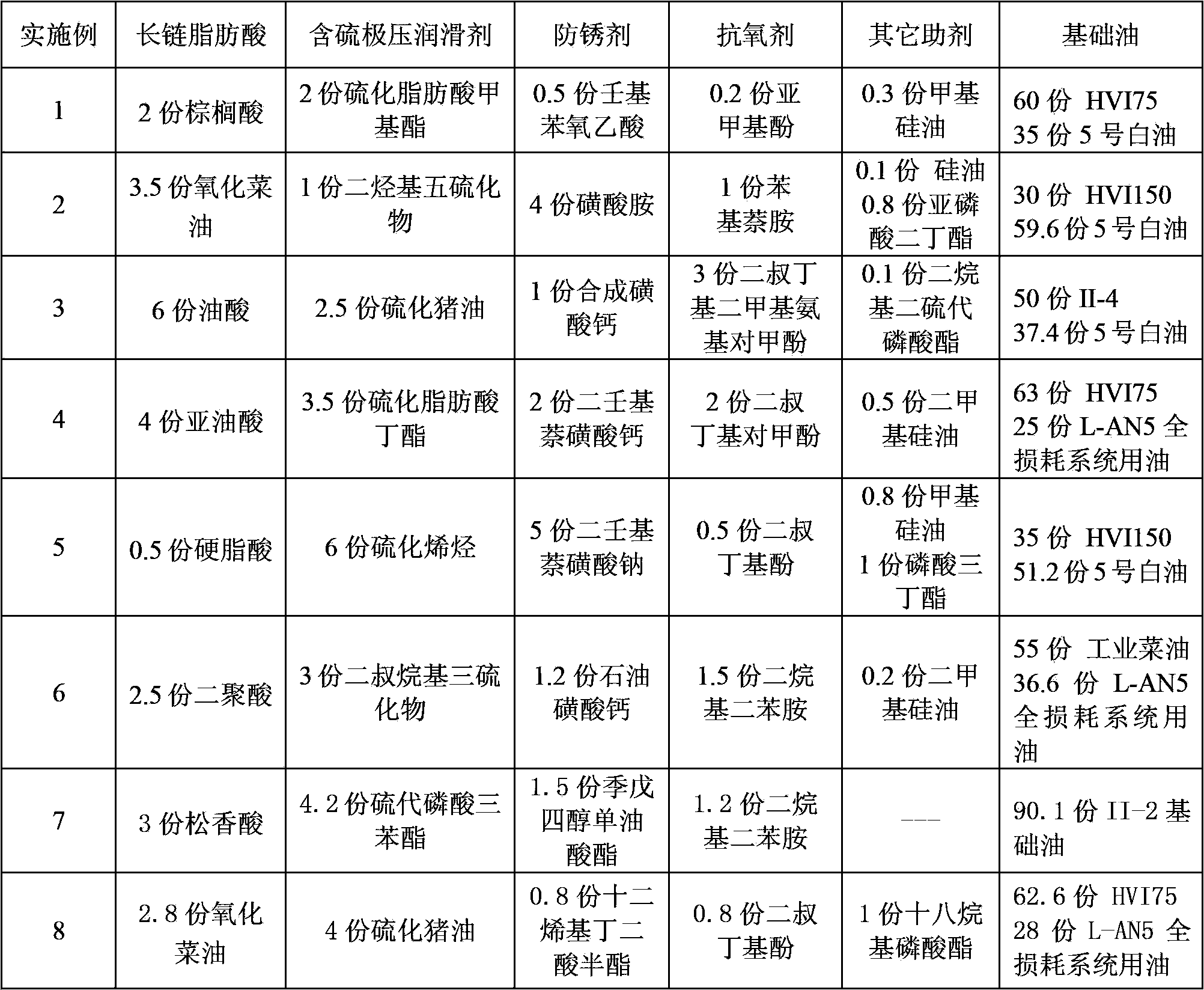

Lubricating oil composition and use thereof

ActiveCN103571590AImprove the finishHigh dimensional accuracyHoning machinesLubricant compositionLong chain fatty acidChemical composition

The invention relates to a lubricating oil composition and use thereof, and is mainly used for solving the problems that the use security is difficult to guarantee since a plurality of lubricating oil compositions for a honing process in the prior art use base oil containing light diesel oil and the like, and a plurality of lubricating oil compositions using chlorinated paraffin extreme-pressure lubricants and barium-containing antirust additives have a certain influence to the environment. The problems are well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 0.5-6 parts of long-chain fatty acid, b) 0.1-4 parts of phosphorus-containing lubricant, c) 0.5-5 parts of antirust agent, d) 0.1-3 parts of antioxidant, and e) 86-96 parts of base oil, wherein the base oil does not contain light diesel oil, and the composition does not contain at least one of the chlorinated paraffin extreme-pressure lubricant or barium-containing antirust additive. The lubricating oil composition can be used for lubricating, cooling and rust prevention in the metal honing process.

Owner:CHINA PETROLEUM & CHEM CORP

Photovoltaic power generation device

PendingCN107483006AEasy to reciprocateReduce power generation efficiencyPhotovoltaic supportsSolar heating energyWater storage tankWater resources

The invention discloses a photovoltaic power generation device, which includes a bottom base, a support base and a mounting plate. The support base is fixedly arranged on the top of the bottom base. A rotary base is installed at the center of the top of the support base. A driving motor is mounted on the top of the rotary base. A support rod is fixedly arranged on a rotary base at one side of the driving motor, and an electric lifting support rod is fixedly arranged on the rotary base at the other side of the driving motor, and the support rod and one end of the electric lifting support rod far away from the rotary base are fixedly connected with the bottom of the mounting plate arranged above the rotary base. One end of the mounting plate is fixedly provided with a rainwater collecting tank, and the other end of the mounting plate is equipped with a recovery funnel. In the invention, rain water is collected by the rainwater collecting groove arranged on one side of the mounting plate and is transported to a water storage tank through a delivery pipe where the rain water is stored to provide cooling water resources for a cooling mechanism. The device of the invention is convenient to use, environment-friendly and pollution-free.

Owner:CHAOHU UNIV

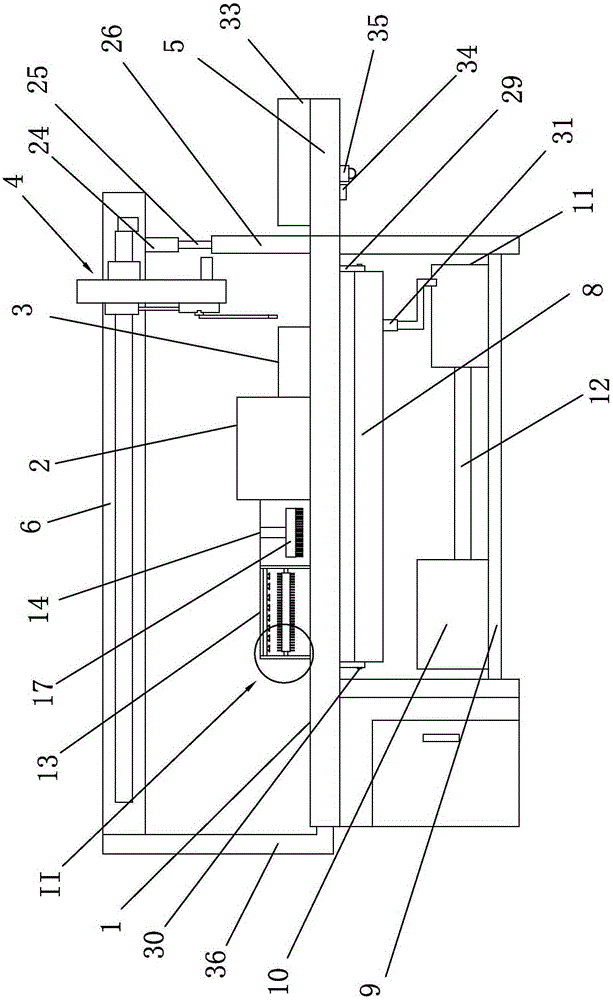

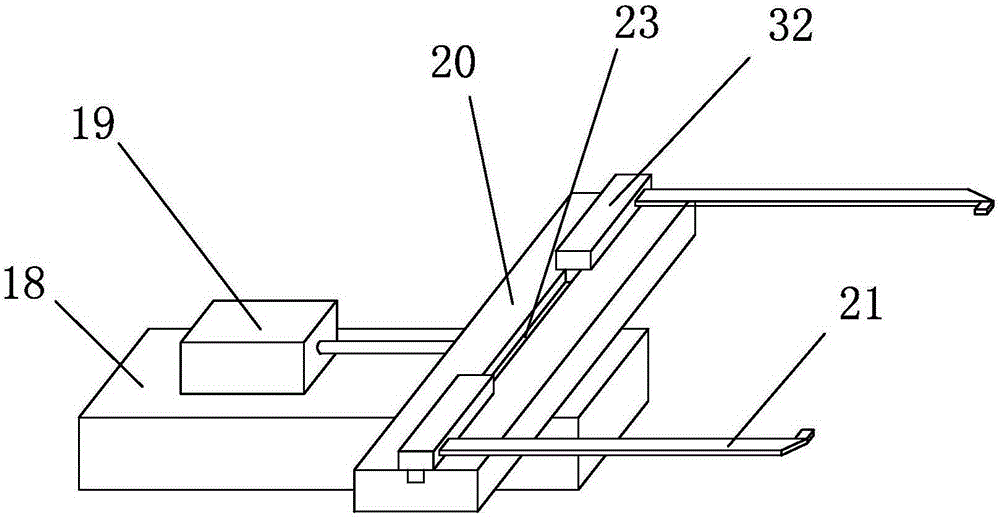

Glass cleaning machine for glass manufacture

The invention discloses a glass cleaning machine for glass manufacture. The glass cleaning machine comprises a working platform, a cleaning room, an air drying room, a detection room, a clamping device and a discharging table, wherein a transverse movement support is arranged above the working platform; a transverse track is arranged on the transverse movement support; the clamping device comprises a support plate, a movable cylinder, a clamping guide rail and clamping claws; a movable sliding block is arranged on the right side of the support plate and limited in the transverse track; a limit slot is formed in the clamping guide rail; and a clamping sliding block is limited in the limit slot. The glass cleaning machine is simple in structure and high in practicability; as the detection room is designed to scientifically detect cleaned glass, compared with the naked-eye observation mode, the glass cleaning machine is more accurate and scientific; together with the designed clamping device, glass can be cleaned more automatically, and the quality of cleaned glass is better; and meanwhile, as a wastewater treatment box is designed, water in the cleaning room can be recycled, accordingly, the water resources are saved, and the comprehensive utilization efficiency is improved.

Owner:佛山市威尔盛科技有限公司

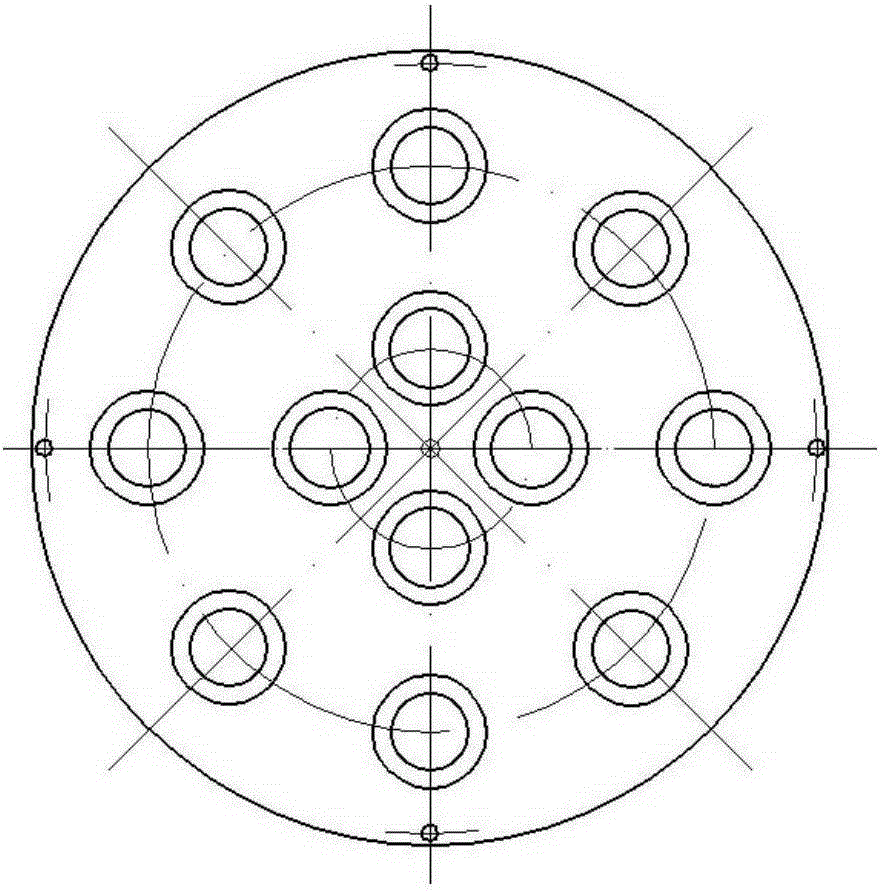

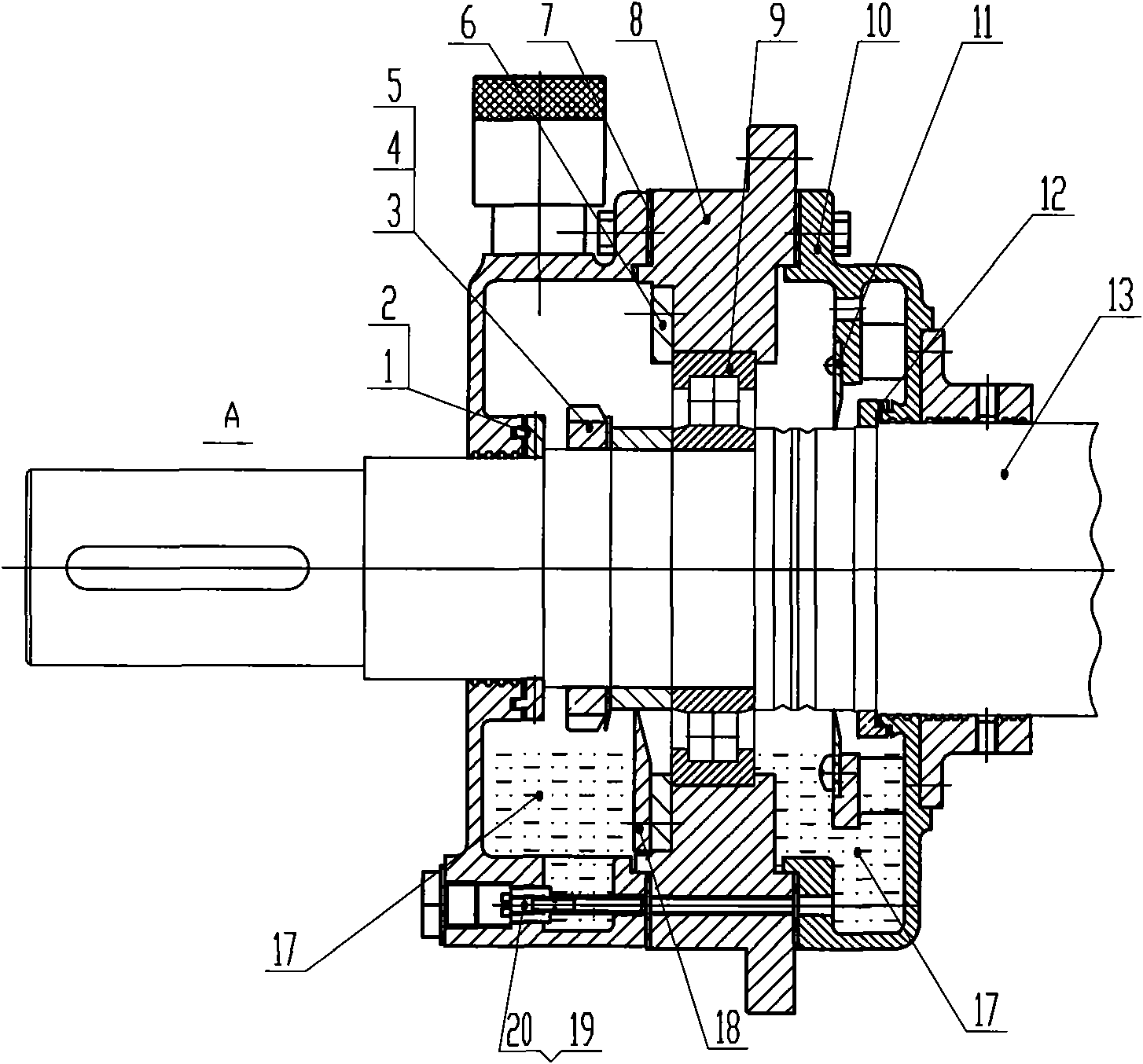

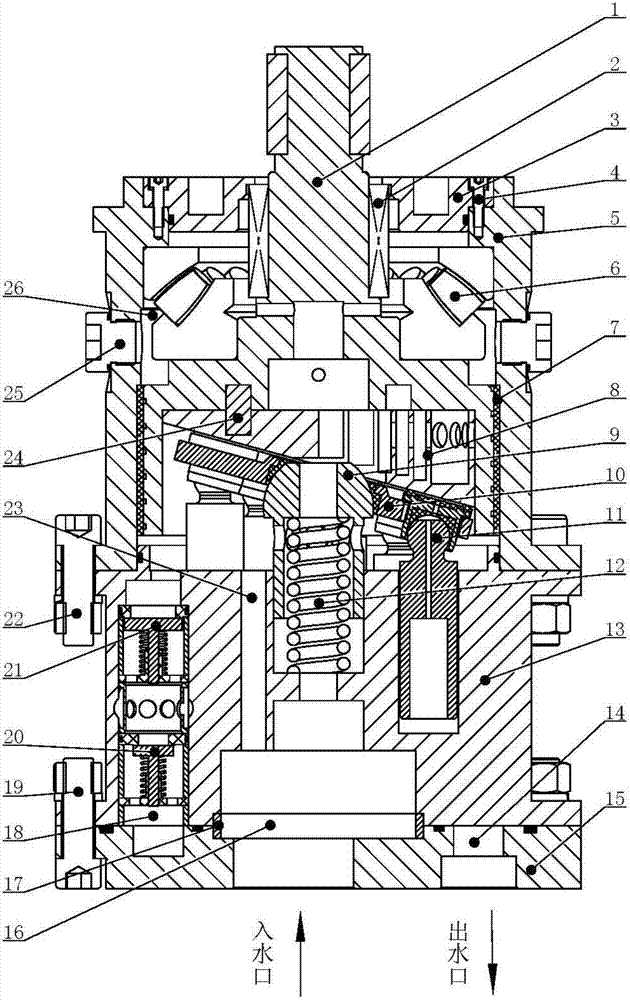

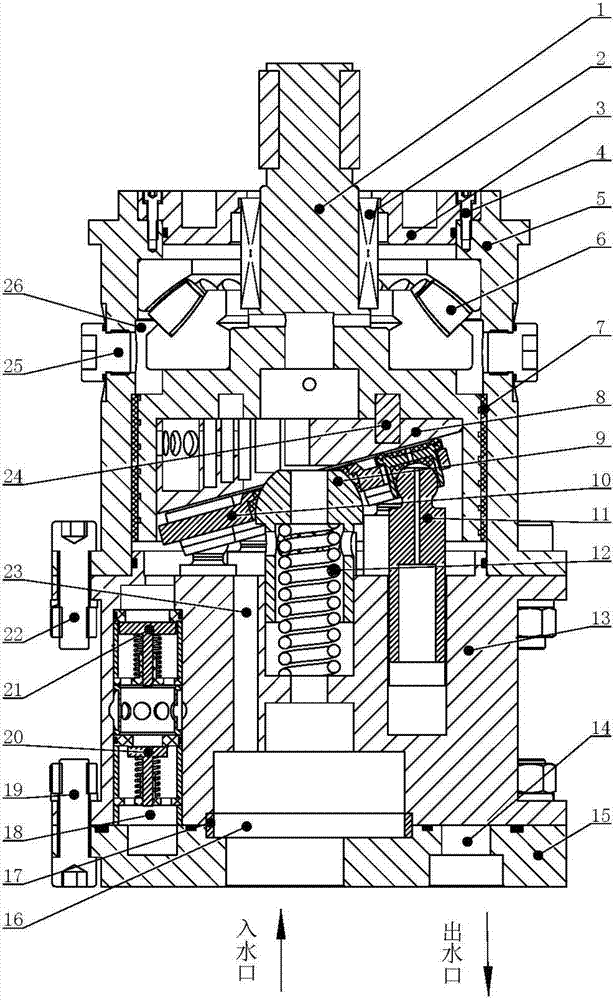

Fully water-lubricated valve distribution plunger pump

ActiveCN102734109AReduce volumeLower thermal equilibrium temperaturePositive displacement pump componentsPositive-displacement liquid enginesHydraulic pumpEngineering

The invention discloses a fully water-lubricated valve distribution plunger pump which comprises a pump main body, a rotary unit, a supporting unit and a plunger distribution unit, wherein the pump main body comprises a cavity, and a water inlet and a water outlet which are communicated with the cavity; the rotary unit comprises a rotation spindle one end of which is arranged in the cavity of the pump main body; the supporting unit consists of an axial supporting unit and a radial supporting unit; the plunger distribution unit consists of a distribution valve assembly and a plunger shoe assembly, the plunger shoe assembly does periodic movement under the rotation of the rotation spindle, thus driving the on and off of valves in the distribution valve assembly, and leading a fluid to flow into the cavity from the water inlet or a fluid in the cavity to be discharged from the water outlet so as to realize flow distribution; a helical groove is arranged on the peripheral surface where the rotation spindle and the radial supporting unit are matched, and the pumping action of the helical groove leads the fluid to circularly flow in the cavity at two end surfaces of the rotation spindle. The fully water-lubricated valve distribution plunger pump fully utilizes the spaces of the shell and the spindle, and the radial sliding bearing design greatly improves the bearing capability of the spindle, and extends the service life of the hydraulic pump.

Owner:WUHAN HUAXI HYDRAULIC +1

Flow guide plate of fuel cell

Owner:氢鑫沃德(上海)新能源发展有限公司

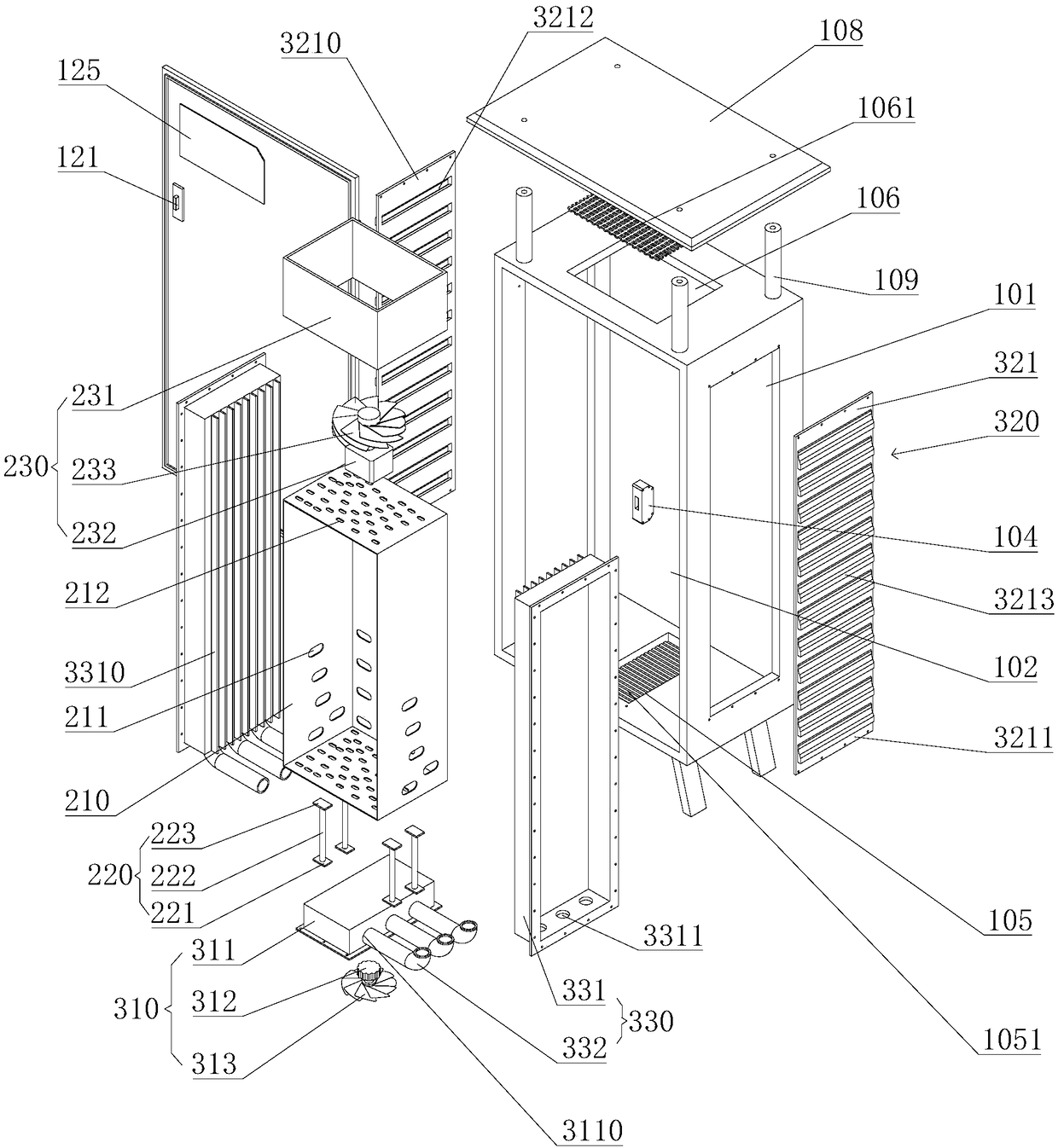

Electrical distribution cabinet

ActiveCN108418128ATake away in timeAvoid damageSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsVentilation ductAir convection

The invention relates to an electrical distribution cabinet, comprising a power distribution cabinet body, an electric appliance fixed mounting frame disposed inside the power distribution cabinet body, and a first heat dissipating device disposed on two sides of the power distribution cabinet body. The power distribution cabinet body has a cubic structure with a mounting cavity inside. The electric appliance fixed mounting frame is disposed in the mounting cavity. The first heat dissipating device includes an air draft mechanism, an air inlet mechanism and a ventilation duct. The power distribution cabinet body is provided with an air inlet in the side wall. The air inlet mechanism is disposed at the side wall of the power distribution cabinet body and is located at the air inlet. One endof the ventilation duct is connected with the air inlet mechanism, and the other end of the ventilation duct is connected with the air draft mechanism. The air draft mechanism performs air draft in the ventilation duct, so as to form air convection inside and outside the power distribution cabinet body to dissipate heat from the electrical distribution cabinet. The electrical distribution cabinetof the invention makes the air flow in the ventilation duct, takes away the heat in the power distribution cabinet, and prevents the external air from directly flowing into the power distribution cabinet and the dust contained in the air from adhering to electrical equipment, which causes damage to the electrical equipment.

Owner:青岛豪源电气有限公司

Sulfur crushing/grading production line

The invention discloses a sulfur crushing / grading production line, belonging to the technical field of solid powder crushing / grading equipment. The sulfur crushing / grading production line mainly comprises a crushing / grading machine, a cyclone collector, a bag-type dust remover and a draught fan which are sequentially connected, wherein a cooling device for reducing the temperatures of a crushing cavity and a grading cavity is arranged in the crushing / grading machine; the crushing / grading machine, the cyclone collector, the bag-type dust remover and the draught fan are respectively provided with an electrostatic grounding device; and the crushing / grading machine, the cyclone collector and the bag-type dust remover are respectively provided with a bursting-port outlet tube (communicated with the outdoor space) at highest micro-sulfur-powder circulation points, and a bursting disc is arranged in each bursting-port outlet tube. According to the invention, the mechanization action of crushing / grading of flammable and explosive substances is realized, and the production efficiency is improved; and the sulfur crushing / grading production line is widely applied to the crushing / grading of flammable and explosive solid particles.

Owner:山东惟远新材料装备有限公司

Fin, stirring shaft and tubular reactor

InactiveCN110694575AImprove the mixing effectHigh purityChemical/physical/physico-chemical stationary reactorsEngineeringMixing effect

The invention relates to a fin, which comprises a T-like fin body with a liquid facing surface and a liquid backing surface, wherein the T-like fin body comprises a root part and an end part, and theend part comprises an expanding part expanding from the connecting position of the end part and the root part to the two sides. According to the invention, the fin can fully refine materials during stirring, and enhance mixing effect; and the invention further provides a stirring shaft with the fin, and a tubular reactor with the stirring shaft.

Owner:HIMILE MECHANICAL MFG

Preparation method of prevulcanization type catalyst

ActiveCN103100444ANo self-heatingNo flammability issuesCatalyst activation/preparationSimple Organic CompoundsVulcanization

The invention discloses a preparation method of a prevulcanization type catalyst. The method consists of: taking an oxidation state catalyst, adding an organic solvent and elemental sulfur, conducting heat treatment, then using an appropriate organic assistant to perform aftertreatment on the catalyst, thus obtaining the final prevulcanization type catalyst. The method enables the organic assistant and sulfur to form an organic compound, which does not decompose at low temperature, thus avoiding untimely contact of hydrogen and sulfur during startup activation, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. After high pressure air sealing, the compound of sulfur and the organic assistant decomposes. Hydrogen and sulfur react, the formed hydrogen sulfide and an active metal undergo catalyst activation in the pores of the catalyst, thus raising the initial temperature of vulcanization. After high pressure air sealing, activation oil is introduced to take away the heat generated by activation timely, thus avoiding temperature runaway of the catalyst bed and ensuring a smooth startup process. The catalyst prepared by the method involved in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

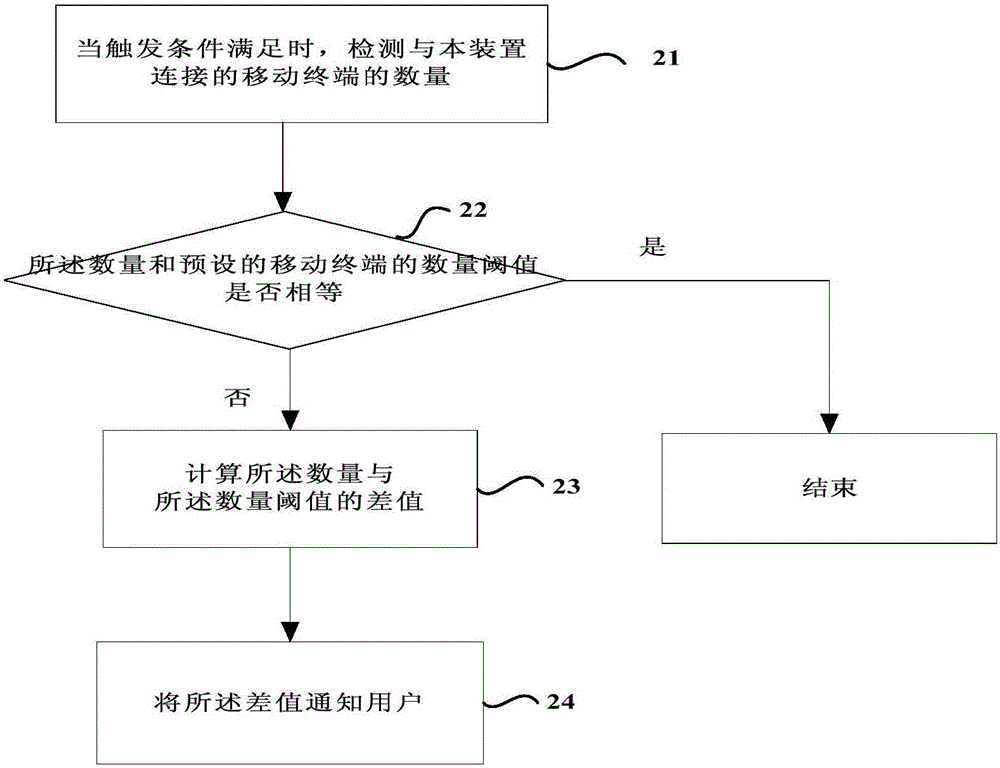

Mobile terminal forgetting reminding method and device

Owner:BOE TECH GRP CO LTD

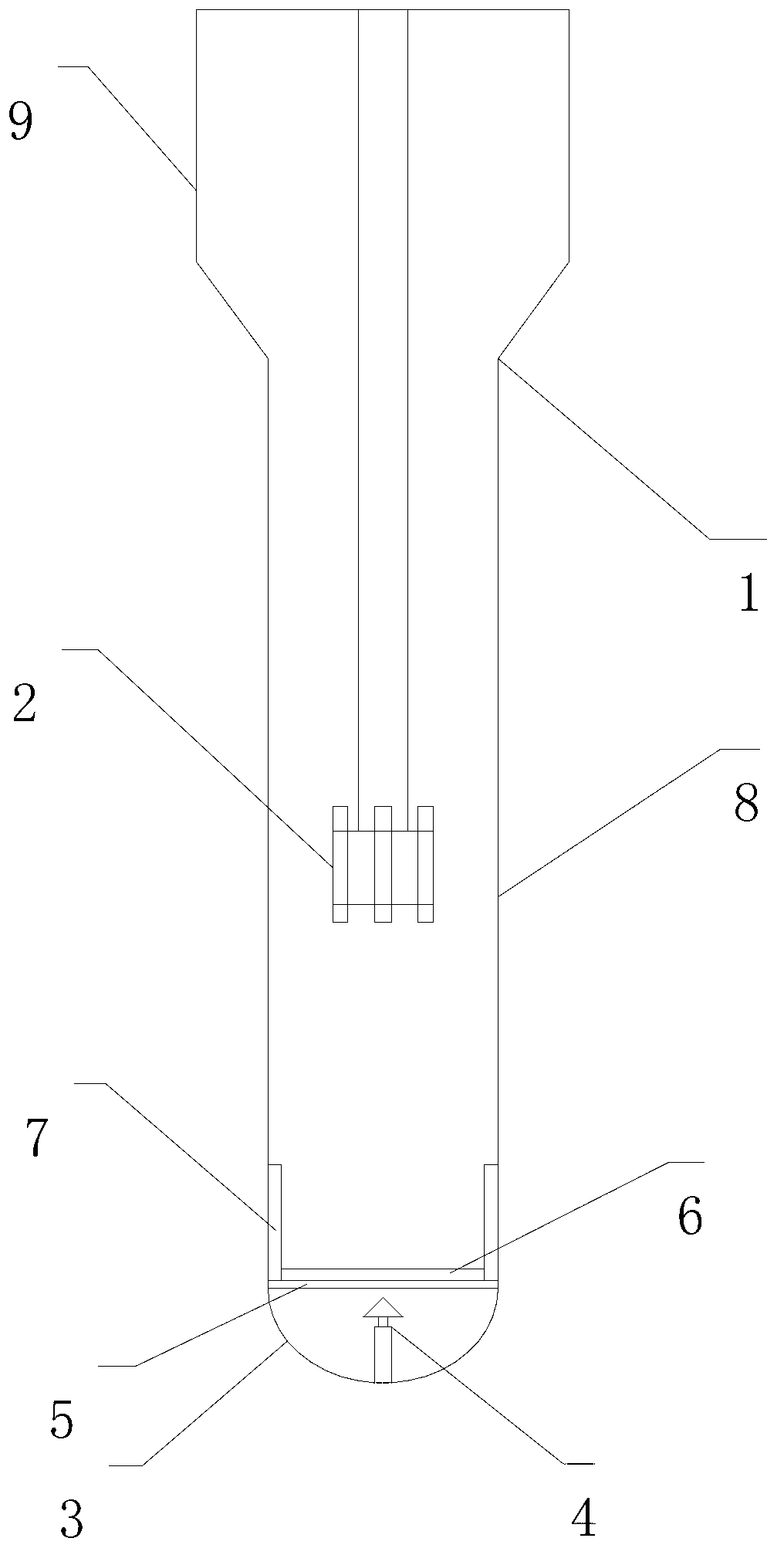

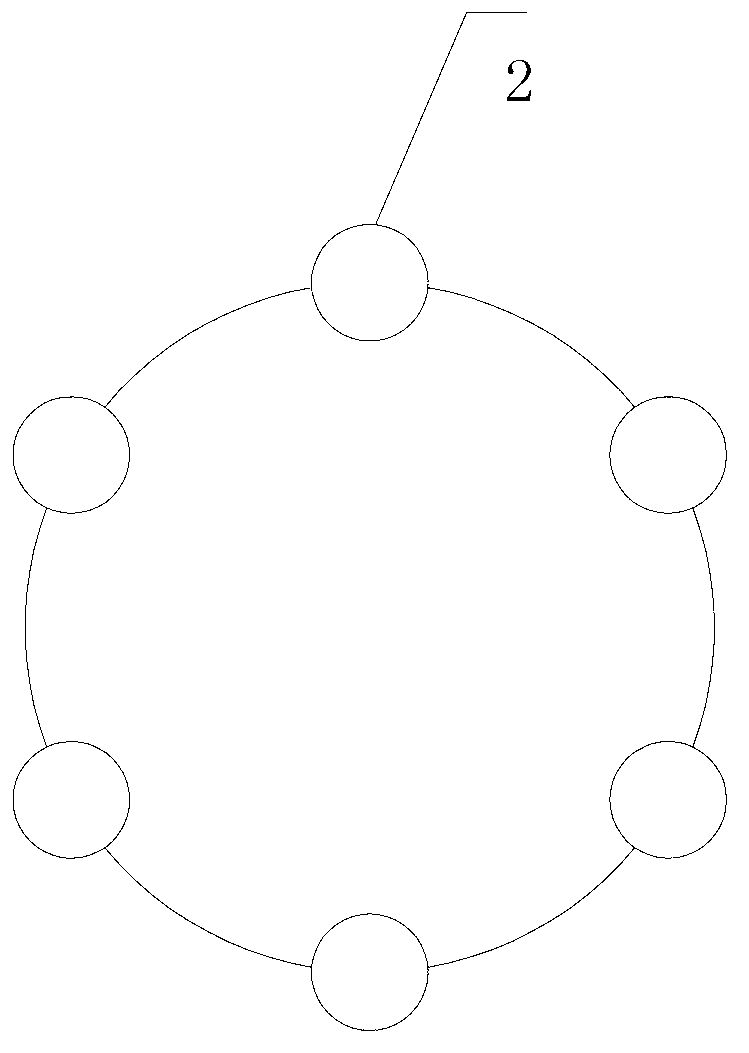

Fluidized bed reactor for preparing chlorosulfonated polyethylene by gas-solid method

InactiveCN102698663AIncrease solids concentrationPrevent subsidenceChemical/physical processesStraight tubeFluidized bed

The invention relates to a fluidized bed reactor for preparing chlorosulfonated polyethylene by a gas-solid method. The fluidized bed reactor comprises a main body of the fluidized bed reactor, wherein the main body of the fluidized bed reactor comprises a straight tube section and a reactor expansion section; the top end of the straight tube section is connected with the bottom end of the reactor expansion section; the inner diameter of the reactor expansion section is larger than that of the straight tube section; a gas premixing chamber is formed at the bottom of the main body of the fluidized bed reactor; a predistribution device is arranged at the bottom of the inner wall of the gas premixing chamber; a plurality of layers of gas distribution plates are arranged between the gas premixing chamber and the main body of the fluidized bed reactor; an ultraviolet lamp glass tube stack formed by annularly arranging a plurality of glass tubes is arranged in the center of the straight tube section, or a plurality of holes are equidistantly and radially formed in the inner wall of the straight tube section along the circumference; and the glass tubes are arranged in the holes. The fluidized bed reactor has the advantages of effectively preventing particles close to the wall surface from being adhered on the wall surface or settled; eliminating dead zones of the whole fluidized bed layer; making reactions more uniform because reaction materials in the bed layer are sufficiently irradiated by ultraviolet.

Owner:刘文潮 +1

Synthetic dual-jet spray cooling device based on ultrasonic atomization

ActiveCN109041523ALarge amount of atomizationFlexible controlCooling/ventilation/heating modificationsControl vectorHeat management

The invention belongs to the field of heat management and spray cooling, and provides a synthetic dual-jet spray cooling device based on ultrasonic atomization. On the basis of the double fluidic exciter which has its own vector control characteristic, A dual-jet actuator and an ultrasonic micro-hole atomizing sheet are combined, the cooling liquid is atomized by an atomizing sheet, and then the spray droplets are ejected by a synthetic double-jet module with the unique property of the synthetic double-jet. The spray speed, spray direction, spray pulse frequency of the spray cooling device ofthe invention can be adjusted by the driving frequency and amplitude of the double-jet exciter and other structural parameters. The spray cooling device is characterized in that Not only the droplet size is small, the atomization quantity is large, but also the spray speed is fast, the direction is adjustable, and the jet impingement cooling and the spray cooling have the advantages of strong heattransfer ability. The spray cooling device has the advantages of compact structure, strong heat dissipation ability, low energy consumption and flexible control, and is expected to solve the heat dissipation cooling problem of micro-miniaturized electronic devices with high heat flux density.

Owner:NAT UNIV OF DEFENSE TECH

Lubricating oil composition and use thereof

ActiveCN103571591AEnvironmentally friendlyEnsure safetyLubricant compositionChemistryLong chain fatty acid

The invention relates to a lubricating oil composition and use thereof, and is mainly used for solving the problems that the use security is difficult to guarantee since a plurality of lubricating oil compositions for a honing process in the prior art use base oil containing light diesel oil and the like, and a plurality of lubricating oil compositions using chlorinated paraffin extreme-pressure lubricants and barium-containing antirust additives have a certain influence to the environment. The problems are well solved by the technical scheme that the lubricating oil composition comprises the following components in parts by weight: a) 0.5-6 parts of long-chain fatty acid, b) 1-6 parts of sulfur-containing extreme-pressure lubricant, c) 0.5-5 parts of antirust agent, d) 0.1-3 parts of antioxidant, and e) 85-95 parts of base oil, wherein the base oil does not contain light diesel oil, and the composition does not contain at least one of the chlorinated paraffin extreme-pressure lubricant or barium-containing antirust additive. The lubricating oil composition can be used for lubricating, cooling and rust prevention in the metal honing process.

Owner:CHINA PETROLEUM & CHEM CORP

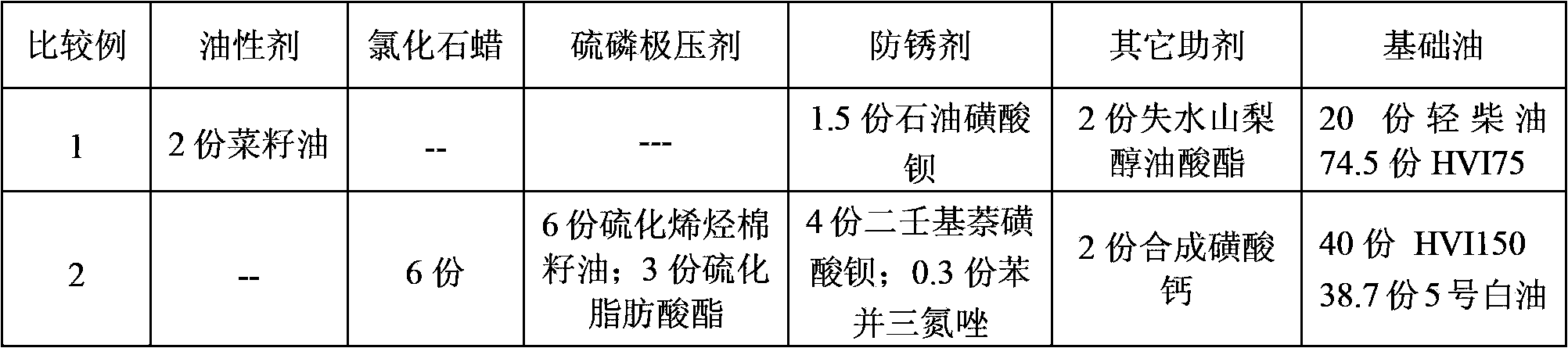

Underwater dual-screw mixed transportation supercharging device

InactiveCN105781500ASafe and reliable workSimplify workFluid removalRotary piston pumpsInternal pressureMarine engineering

The invention relates to an underwater dual-screw mixed transportation supercharging device. The underwater dual-screw mixed transportation supercharging device comprises a deep-water motor, a dual-screw pump, a homogenizer, a liquid storage tank, a piston type pressure compensator and a capsule type pressure compensator, wherein the dual-screw pump is positioned above the deep-water motor; the homogenizer is in butt joint with a wellhead pipeline; the liquid storage tank is in butt joint with a submerged pipeline; independent pressure compensation and cooling-lubricating loops are respectively adopted in the deep-water motor and the dual-screw pump, and work separately; movable seals of the deep-water motor and the dual-screw pump are balanced in internal pressure and external pressure. The underwater dual-screw mixed transportation supercharging device is safe and reliable, and has long service life. Compared with the conventional underwater dual-screw mixed transportation supercharging device, the underwater dual-screw mixed transportation supercharging device has the advantages that the structure is simple, and safety and reliability in work are achieved; heat generated by the dual-screw pump and the deep-water motor can be brought away in time, reliable running of the device is ensured, pressure difference does not exist between the inside and outside of the device, complete pressure compensation is achieved, high economic efficiency is realized, an underwater treatment process is simplified, the platform building cost and running cost are saved, and the supercharging device has remarkable economic benefit and wide application prospect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Cable having fire-proof-layer-contained heat shield

InactiveCN104979045ATake away in timeGuaranteed lock disengagementInsulated cablesInsulated conductorsEngineeringFire prevention

The invention relates to a cable having a fire-proof-layer-contained heat shield. The cable comprises a cylindrical cable body (9) arranged inside a heat shield and the heat shield containing an upper heat shield (8) and a lower heat shield (7). The shield walls of the upper heat shield (8) and the lower heat shield (7) include respective bottom walls (80 and 70) and side walls arranged at the two sides of the bottom walls (80 and 70); and the bottom walls (80 and 70) and two circular top parts opposite to each other at the diameter of the cable body (9) are in contact. Fire-proof layers (72) are arranged at contact surfaces between the bottom walls (80 and 70) and the two circular top parts opposite to each other at the diameter of the cable body (9); and the fire-proof layers (72) are made of fire-proof materials and play a role in fire prevention and heat insulation for the cable body (9). Besides, cooling fluid passageways (81 and 71) extending along the shield walls are respectively arranged in the shield walls.

Owner:余储

Pyrotechnic composition drying system

InactiveCN104807293ATake away in time"Dust" phenomenon to avoidDrying gas arrangementsDrying machines with local agitationPyrotechnic compositionProcess engineering

The invention discloses a pyrotechnic composition drying system. The pyrotechnic composition drying system comprises an air source heat pump and a drying room, wherein an auxiliary evaporator is further arranged between a throttling device of the air source heat pump and a main evaporator; a heat exchanger is arranged between a fresh air supplementing channel and a dehumidification channel; humid and hot air in the dehumidification channel sequentially passes through the heat exchanger and the auxiliary evaporator and then enters a main evaporator chamber; an air inlet of the drying room is formed in the upper part of the drying room, and an air outlet of the drying room is formed in the lower part of the drying room; a top-to-bottom circulation mode of the hot air is formed in the drying room. The pyrotechnic composition drying system serves as a special drying system applicable to firework pyrotechnic compositions and has the advantages of better safety, energy conservation and environmental friendliness.

Owner:CHANGSHA YUEQI ENERGY SAVING ELECTRICAL EQUIP CO LTD

Anti-corrosion cable having thermal-insulation shield with isolating bars

InactiveCN104992771ATake away in timeGuaranteed lock disengagementInsulated cablesInsulated conductorsThermal insulationCorrosion resistant

The invention relates to an anti-corrosion cable having a thermal-insulation shield with isolating bars. The cable comprises a cylindrical cable body (9) arranged in a thermal-insulation shield and the thermal-insulation shield containing an upper thermal-insulation shield (8) and a lower thermal-insulation shield (7). The shield walls of the upper thermal-insulation shield (8) and a lower thermal-insulation shield (7) include respective bottom walls (80 and 70) and side walls arranged at the two sides of the bottom walls (80 and 70); and the bottom walls (80 and 70) are in contact with two circular top parts, opposite at the diameter, of the cylindrical cable body (9). Besides, cooling fluid channels (81 and 71) extending along the shield walls are arranged in the shield walls. The outer surfaces of the walls of the upper thermal-insulation shield (8) and the lower thermal-insulation shield (7) are coated with an anti-corrosion material layer (63); and the anti-corrosion material layer (63) is used for preventing the thermal-insulation shield from being corroded, so that the anti-corrosion protection effect of the cable body (9) can be realized and thus the cable can adapt to different environments.

Owner:周丽娜

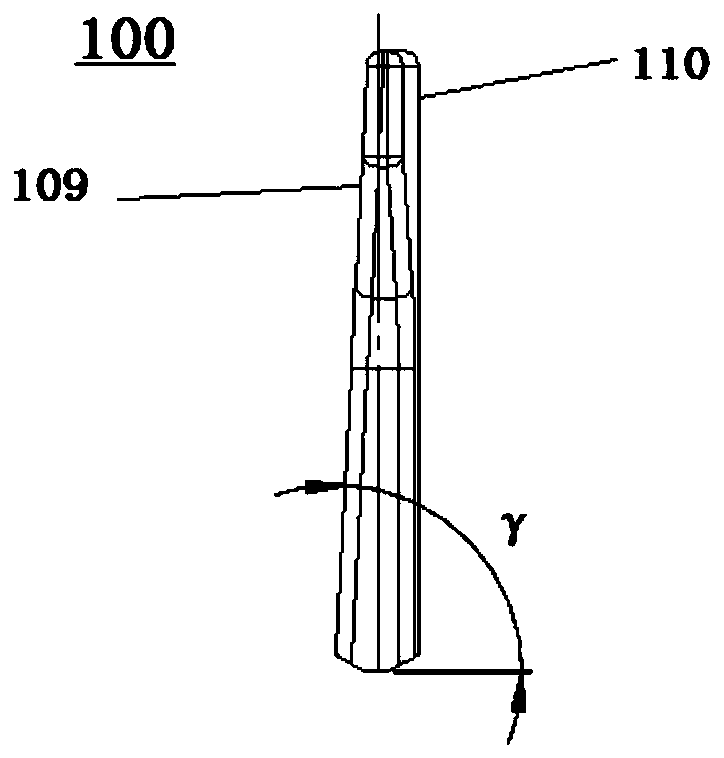

Containment heat guiding device and heat guiding method of nuclear power device

PendingCN109273115AAvoid overheating and overpressure failureEnsure safetyNuclear energy generationCooling arrangementSeawaterNuclear engineering

The invention discloses a containment heat guiding device of a nuclear power device and relates to the technical field of reactors. The containment heat guiding device comprises a shielding layer arranged on the outer side of a containment, a water inlet hole formed in the lower portion of the shielding layer and communicated with the outside of the shielding layer and a gap, and an air outlet hole formed in the top of the shielding layer and communicated with the outside of the shielding layer and the gap, wherein the gap is reserved between the shielding layer and the containment. The invention also discloses a containment heat guiding method of the nuclear power device. By introducing seawater to the gap between the shielding layer and the containment under the extreme severe working condition, the containment is directly cooled, it is avoided that the containment is invalid due to temperature and pressure exceeding, a large number of radioactive substances are prevented from beingleaked to other cabins of the nuclear power device and the atmospheric environment, and the safety of persons and the environment is ensured.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com