Glass cleaning machine for glass manufacture

A glass cleaning and glass manufacturing technology, applied in the directions of cleaning flexible objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of no detection device, high labor cost, hidden safety hazards, etc., and achieve long service life. , Reduce the loss of energy consumption, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

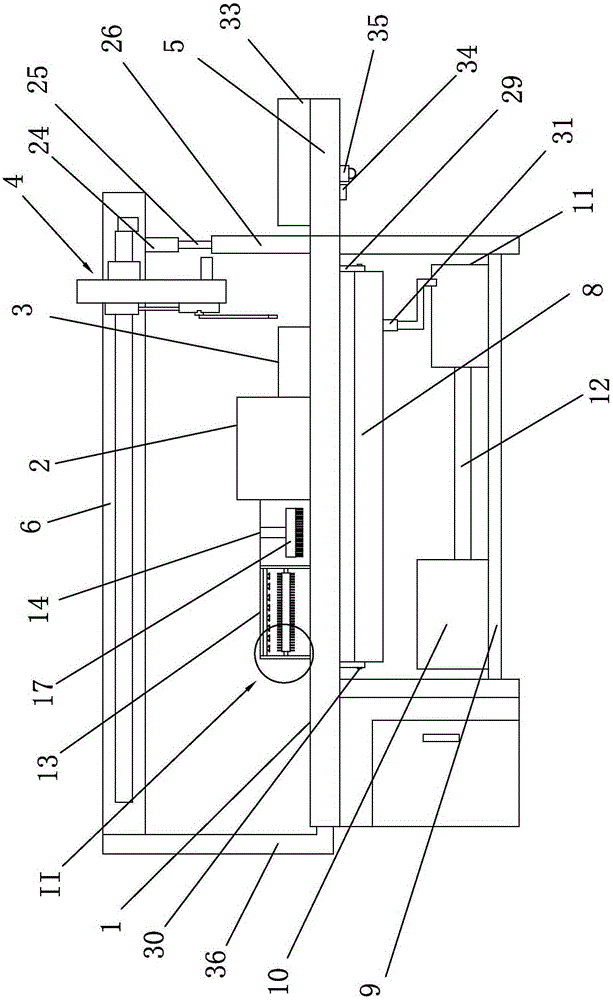

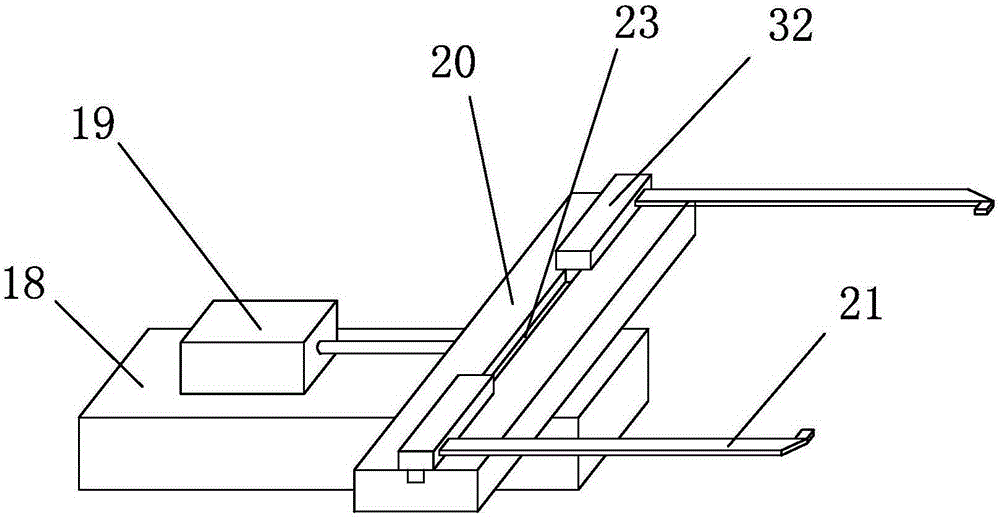

[0032] Such as Figure 1 to Figure 6 Shown is a glass washing machine for glass manufacturing of the present invention, which includes a working platform 1, a cleaning room, an air drying room 2, a detection room 3, a clamping device 4, and a discharging table 5. The working platform 1 is provided with a lateral movement The support 6, the lateral movement support 6 is connected to the left end of the work platform 1 through the support 36, a horizontal drive motor 46 is provided on the lateral movement support 6, and the horizontal drive motor 46 provides power to the moving slide 22, so that the moving slide 22 It can drive the entire clamping device 4 to move left and right. The design of the support frame 36 can facilitate the installation and disassembly of the horizontally movable bracket 6, making the installation of the entire glass washing and drying machine more convenient and simple. The horizontally movable bracket 6 is provided with a horizontal rail 7. The design ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com