Containment heat guiding device and heat guiding method of nuclear power device

A technology of heat export and containment, which is applied in the field of reactors, can solve the problems of not being able to provide sufficient capacity of containment cooling water tanks, and cannot provide air flow channels, etc., so as to avoid over-temperature and over-pressure failure, large specific heat capacity, and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

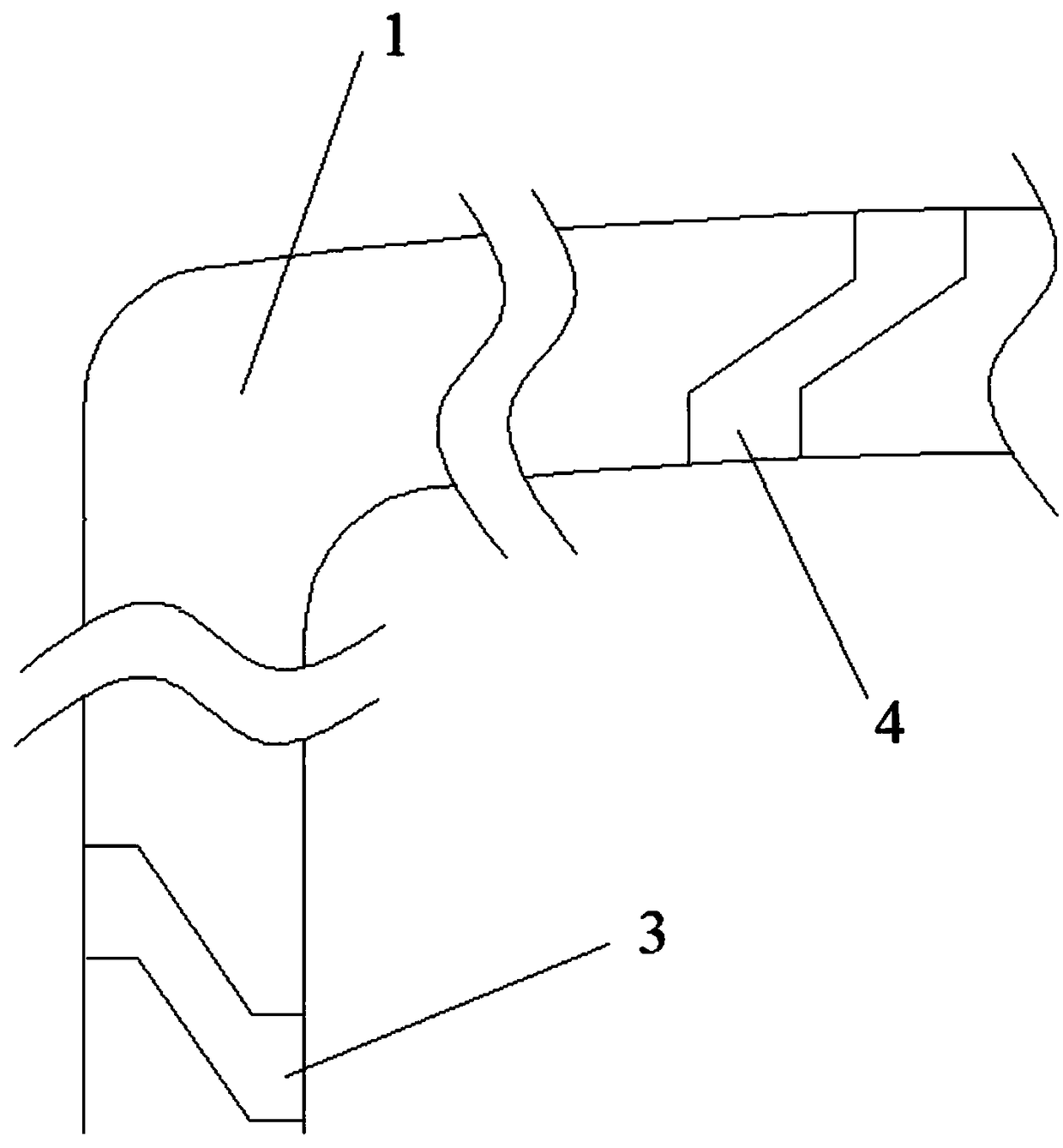

[0026] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a containment heat exporting device, comprising: a shielding layer 1 disposed outside the containment 2, with a gap 13 left between the shielding layer 1 and the containment 2; a water inlet 3 disposed on the In the bottom of the shielding layer 1, the water inlet connects the outside of the shielding layer with the aforementioned gap 13, and the air outlet hole 4 is located on the top of the shielding layer 1, and the air outlet connects the outside of the shielding layer with the aforementioned gap 13.

[0027] Preferably, there are multiple water inlet holes 3 arranged symmetrically with respect to the central axis of the containment vessel 2, and there are multiple air outlet holes 4 arranged symmetrically; the polygon formed by the lines connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com