Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Contact depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

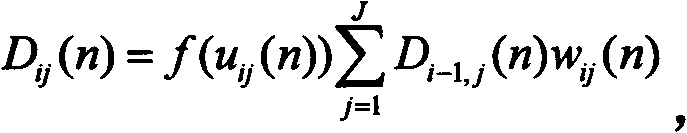

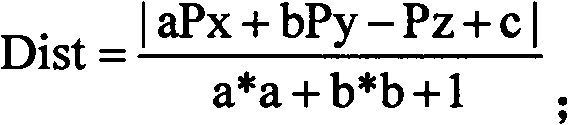

Depth measurement method based on binocular three-dimensional vision

InactiveCN101907448ADifficult to measure directlyEasy to measureUsing optical meansNeural learning methodsNetwork modelContact depth

The invention provides a depth measurement method based on binocular three-dimensional vision, comprising the following steps of: (1) respectively acquiring a left image and a right image of each object through two cameras and acquiring characteristic points of a plurality of objects; (2) establishing a BP (Back Propagation) neural network model; (3) extracting left image coordinates and right image coordinates of the characteristic point on the bottom plane of each object, acquiring three-dimensional world coordinates by BP neural network model training, and establishing a three-dimensional plane function of the bottom surface of each object; (4) extracting left image coordinates and right image coordinates of one characteristic point on the top plane of each object, and acquiring three-dimensional world coordinates by BP neural network model training; and (5) acquiring the depth value of each object according to the three-dimensional plane function of the bottom surface of the object and one characteristic point on the top surface of the object. The invention can realize non-contact depth measurement on the objects and has the advantages of high measurement precision, low cost, and the like.

Owner:SOUTH CHINA UNIV OF TECH

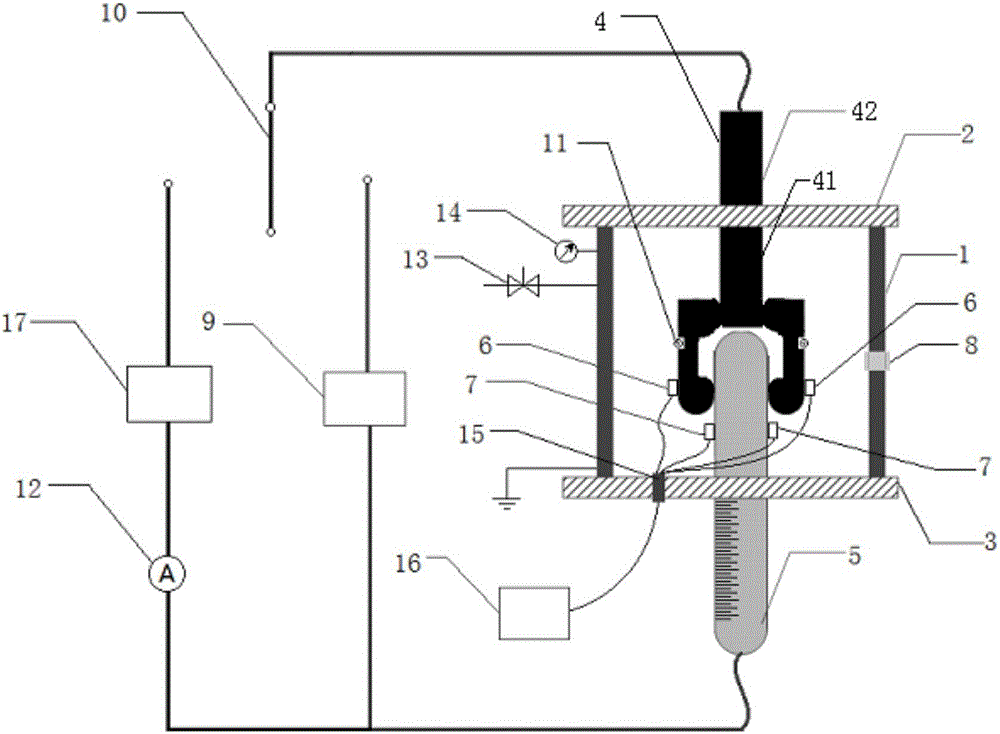

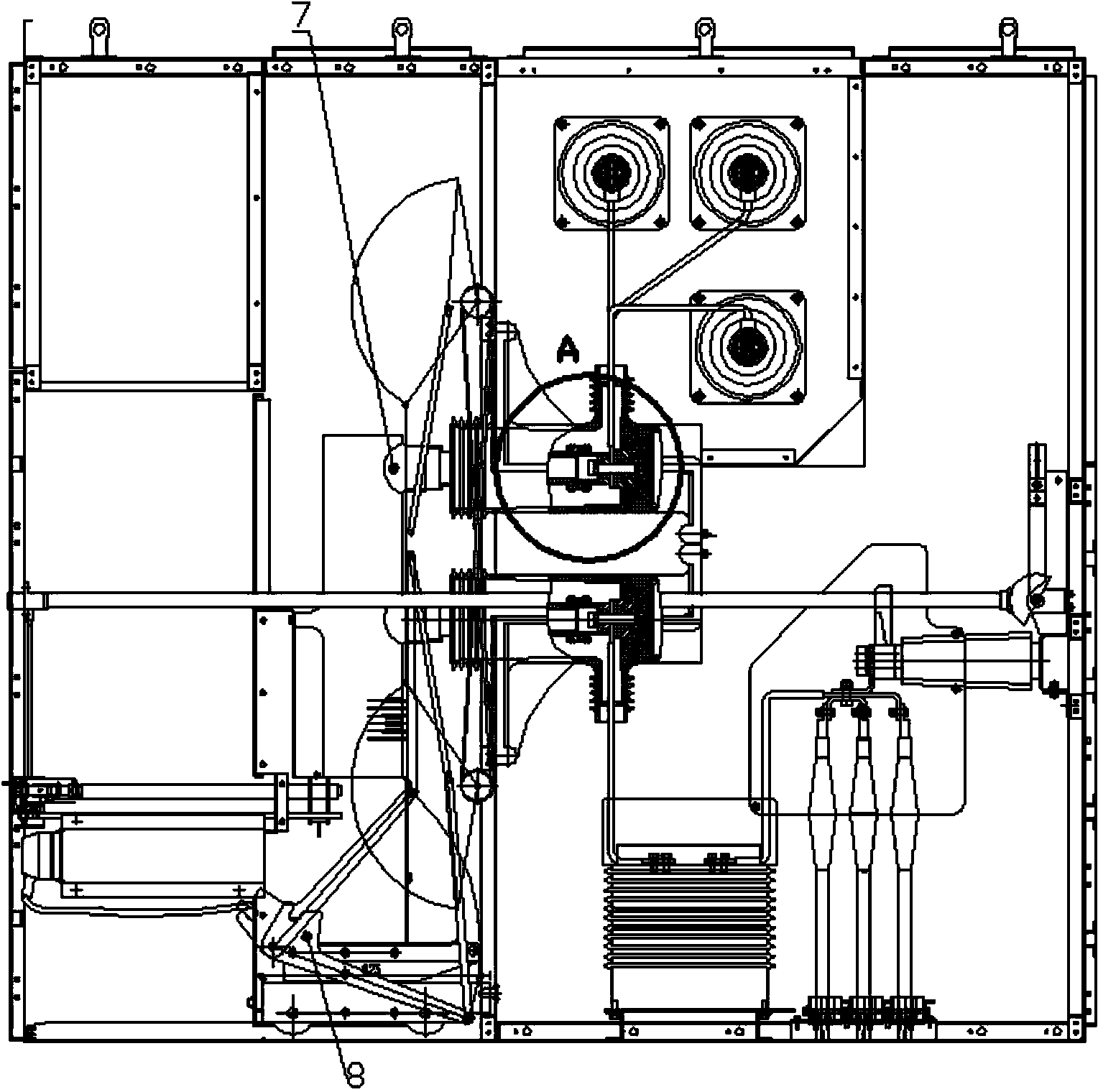

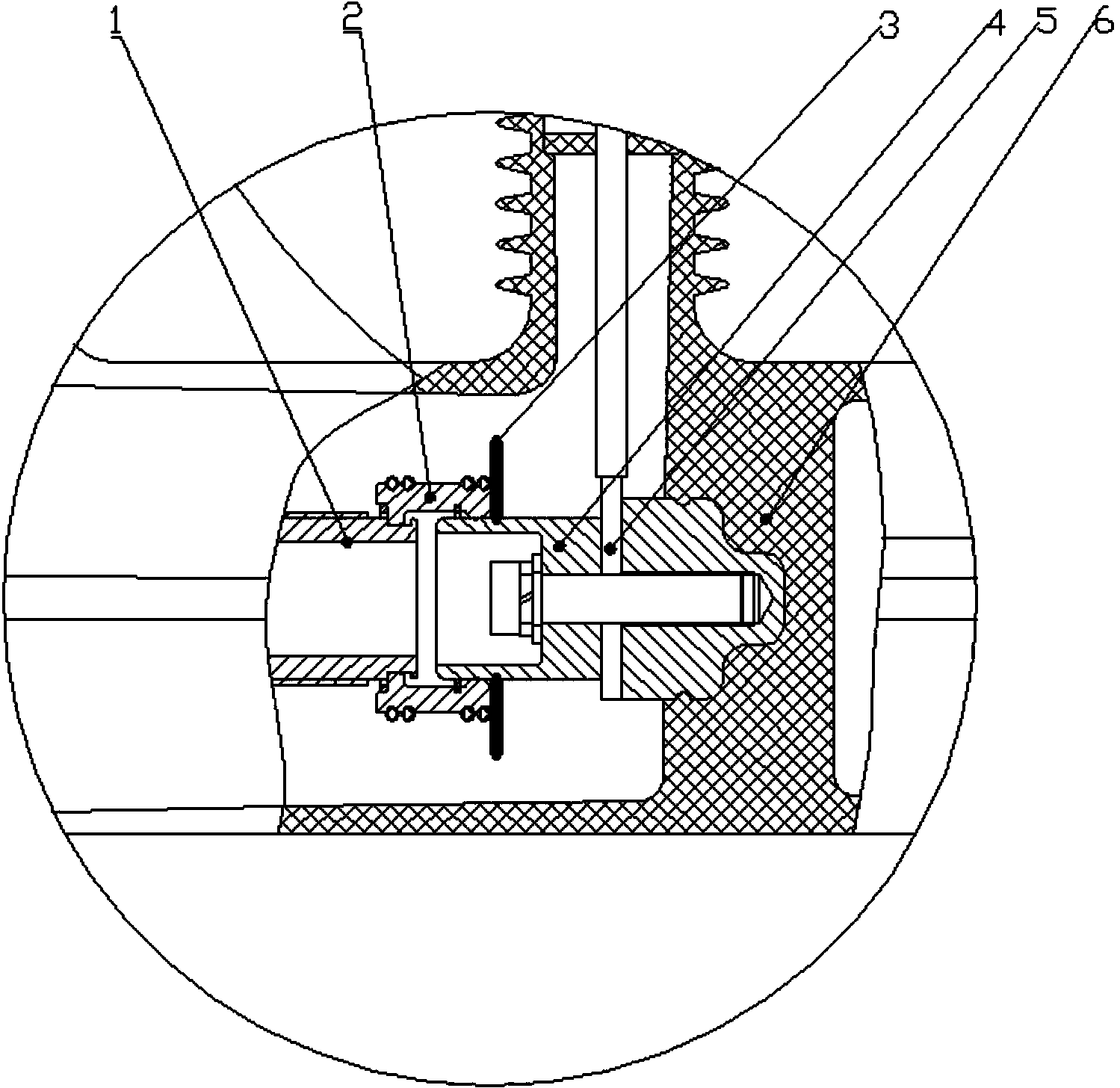

System and method for simulation test of contact state of isolating switch contact in GIS

ActiveCN106226696AQuantitative adjustment of insertion depthEasy to replaceCircuit interrupters testingElectrical resistance and conductanceContact pressure

The invention discloses a system and a method for a simulation test of a contact state of an isolating switch contact in GIS (Geographic Information System). The system comprises a shell, wherein an upper insulating cover plate and a lower insulating cover plate are respectively arranged at upper and lower ends of the shell; a static contact penetrates through the upper insulating cover plate; the static contact and the upper insulating cover plate are statically sealed; a movable contact detachably penetrates through the lower insulating cover plate; the moveable contact and the lower insulating cover plate are movably sealed; the static contact is provided with a groove into which the moveable contact can be inserted. The system provided by the invention can be used for simulating the contact states under the condition of different contact depths, contact materials and contact pressure; voltage and current are applied to the moveable contact and static contact in a test; the contact resistance and the contact temperature under different contact states can be measured practically; the system provided by the invention can be used for researching the relation and change rule of the contact resistance, contact temperature and contact state of the isolating switch contact in GIS and can establish a basis for the detection for the contact state of the isolating switch contact in GIS.

Owner:JIANGSU ELECTRIC POWER RES INST +3

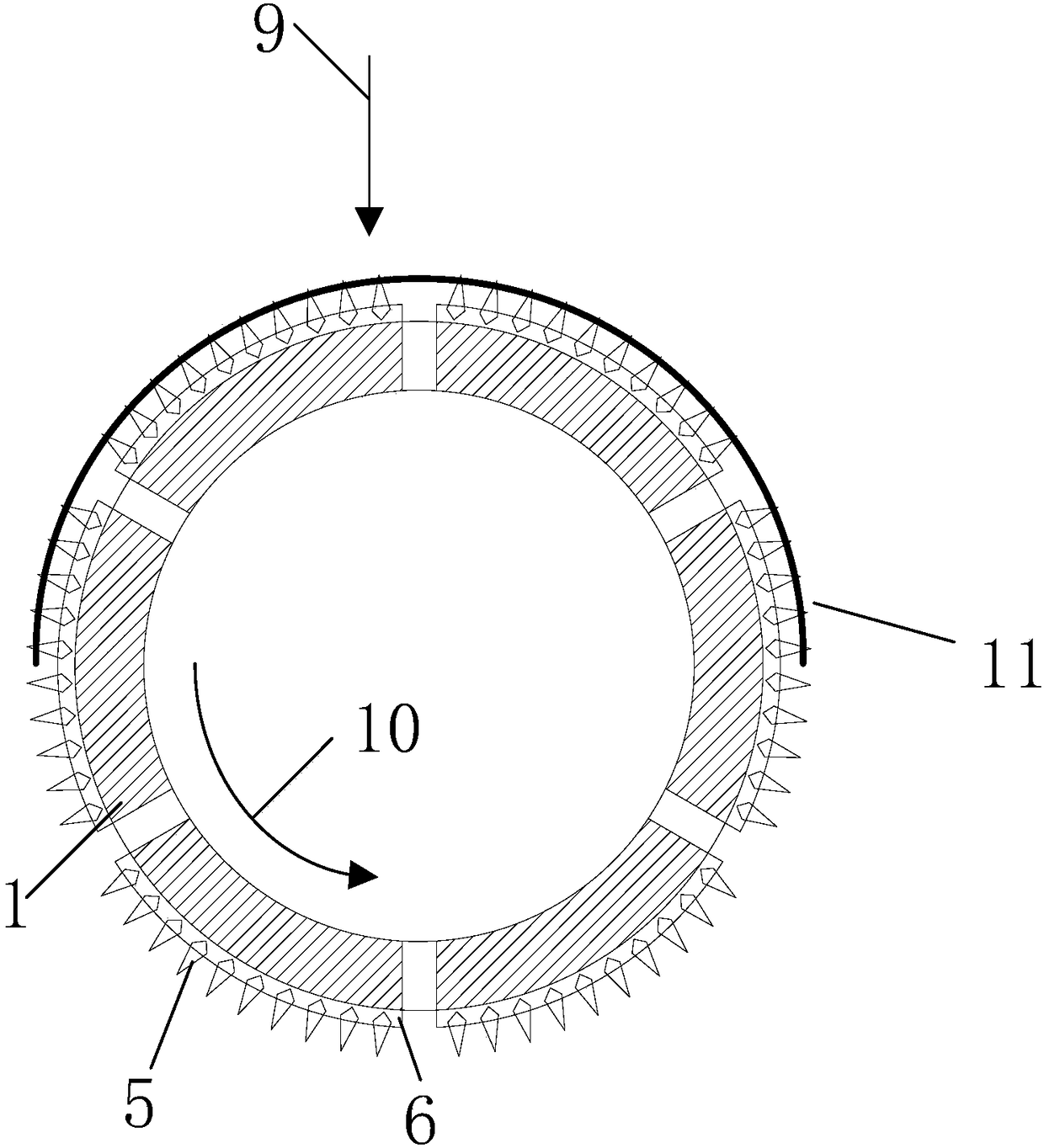

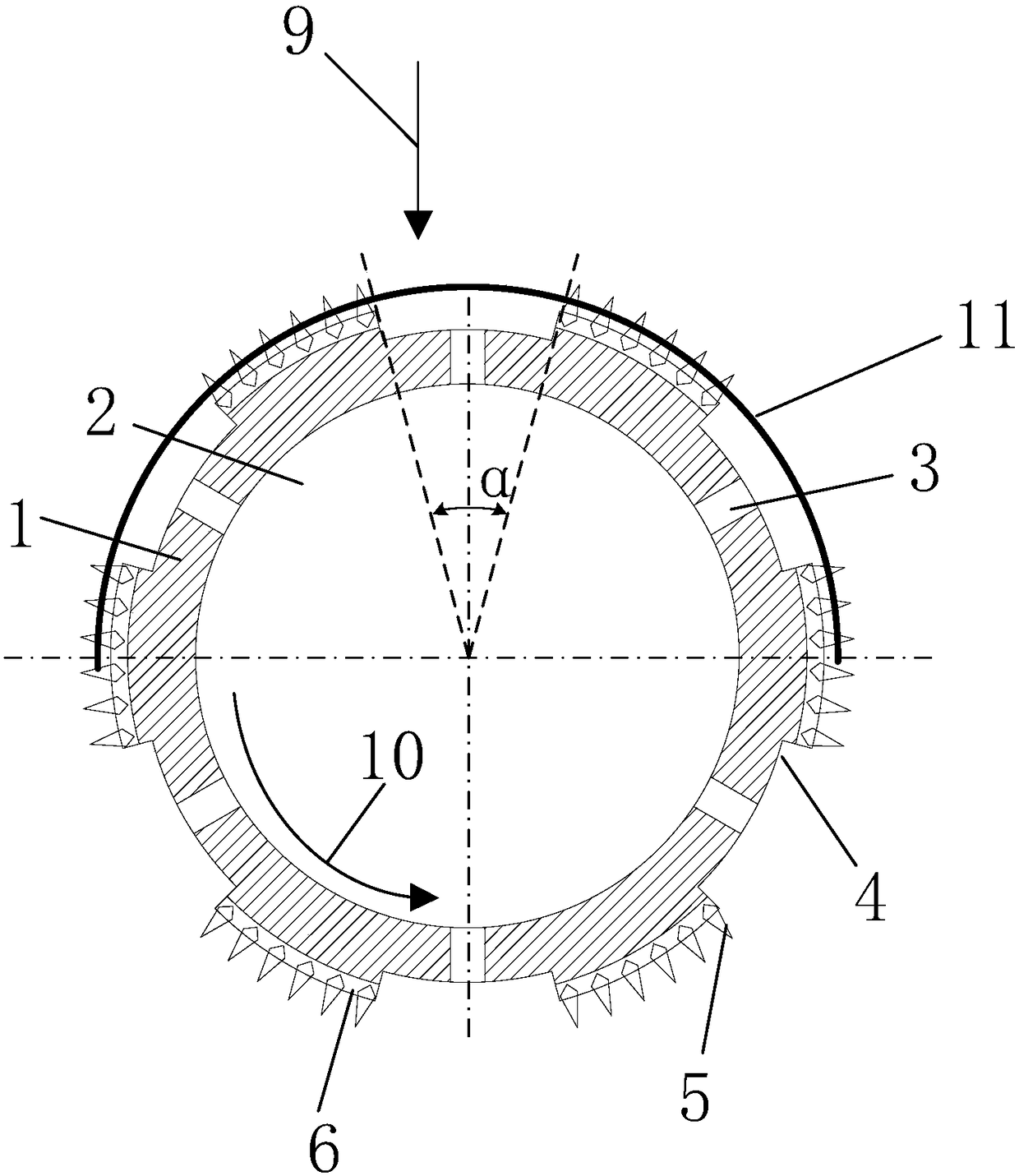

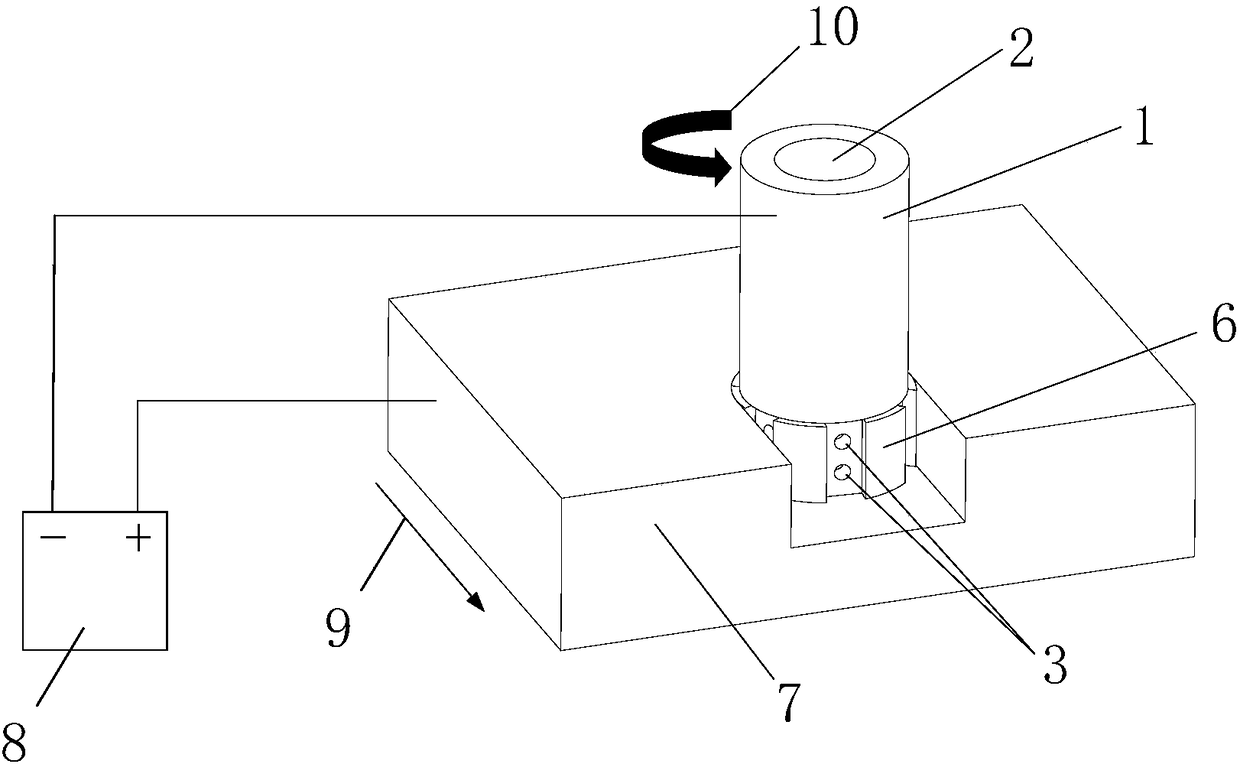

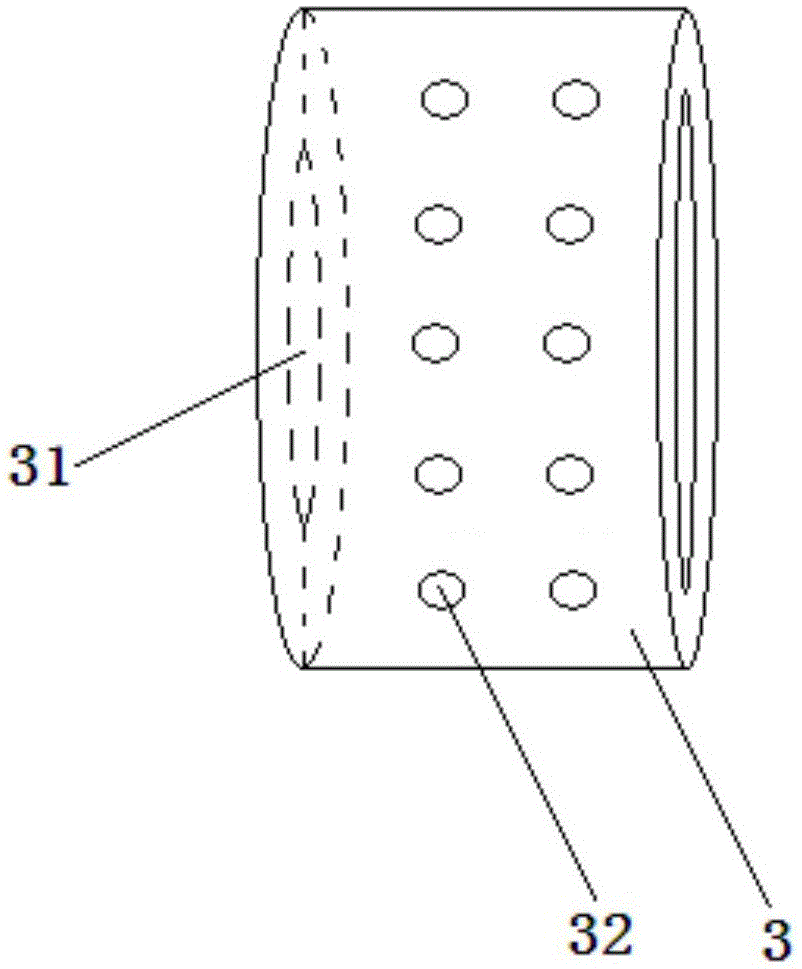

Electrolytic milling-grinding machining tool cathode with efficiency and precision and electrolytic milling-grinding method

The invention relates to an electrolytic milling-grinding machining tool cathode with efficiency and precision and an electrolytic milling-grinding method, and belongs to the field of electrolytic milling-grinding composite machining. According to the electrolytic milling-grinding machining tool cathode and the electrolytic milling-grinding method, a plurality of arc-shaped grooves at equal intervals are formed in the lower end of the side wall of the tool cathode, the side walls of the grooves are insulated, and diamond abrasive particles are inlaid in the wall surfaces of the portions, except for the grooves, of the side wall of a cathode base body through a resin binder, so that electrochemical anodic dissolution only exists in the surfaces of the portions, opposite to the grooves, of aworkpiece, at the moment, the depths of the grooves become a part of a machining gap, accordingly the contact depth between the diamond abrasive particles in the portions, except for the grooves, ofthe side wall of the cathode base body and the machining surface of the workpiece is increased, then the grinding effect of the diamond abrasive particles on the workpiece in the electrolytic milling-grinding process is enhanced, and the precision and the surface quality of the electrolytic milling-grinding machining can be improved; and moreover, compared with the electrolytic milling-grinding finish machining under the low current density in the past, the tool cathode can adopt higher current density, and the machining efficiency can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

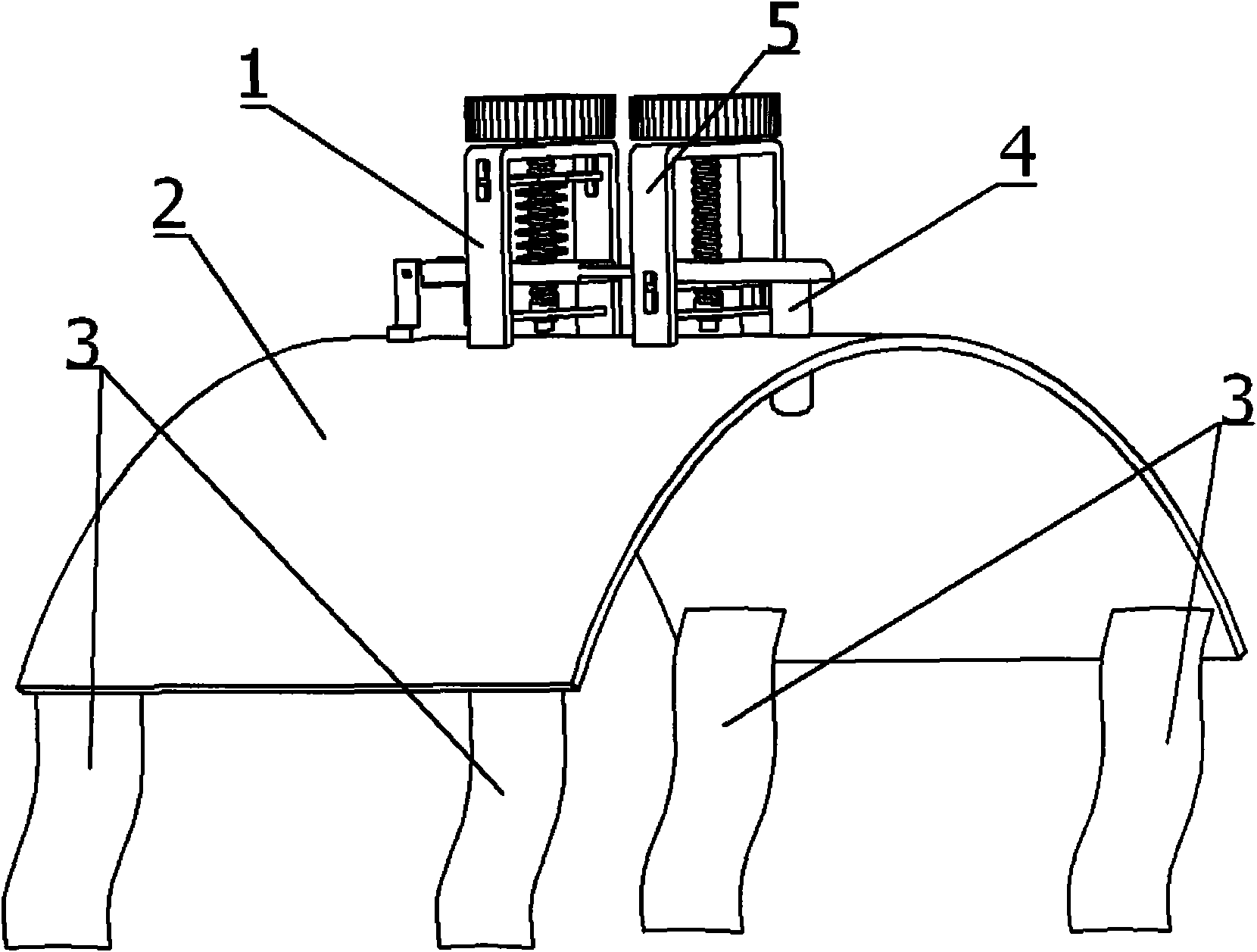

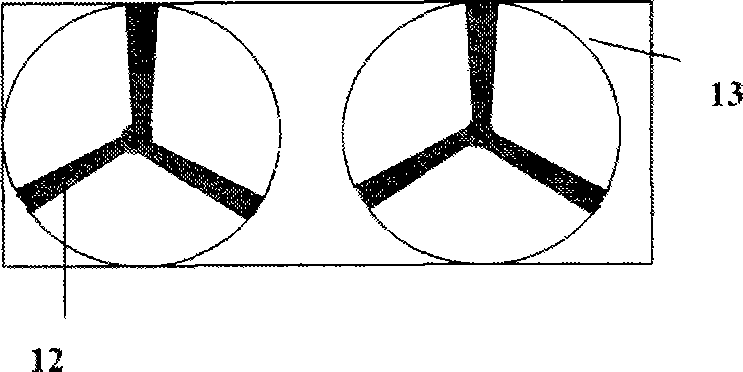

Wheel leg traction type flat curtain cleaning robot

InactiveCN1864940AEfficient and reliable automatic cleaningAdjust posture in real timeCarpet cleanersFloor cleanersEngineeringWindlass

The invention relates to a wheel leg drawing-type plane curtain washing robot. Wherein, three suckers of wheel leg passive adsorb device are independently controlled by the flexible cylinders at two sides of suckers, which can be synchronously or alternatively adsorbed on the wall; the opening of sucker is surrounded by sealing rubber strips; the invention can watch the wall when the gas of sucker leaks little, and clean the water mark along with the downward sliding of sucker; the differential driving wheels at the outer side surfaces of upper and lower suckers form the attitude adjuster; the follow roller at the outer side of middle sucker can limit the contact depth between the rubber strip and the wall, to reduce the abrasion of rubber strip; the washing device comprises a washing rolling brush, a motor and a water recycle device, which are compactly arranged at the middle sucker; the obstacle detector is formed by three groups of mechanical point sensors at the bottom of three suckers, to detect the obstacles protruded from the wall. The invention can move from up to down that drawn by the windlass at the top of building, to effectively clean the plane glass curtain, which can reliably overcome the obstacle.

Owner:SHANGHAI JIAO TONG UNIV

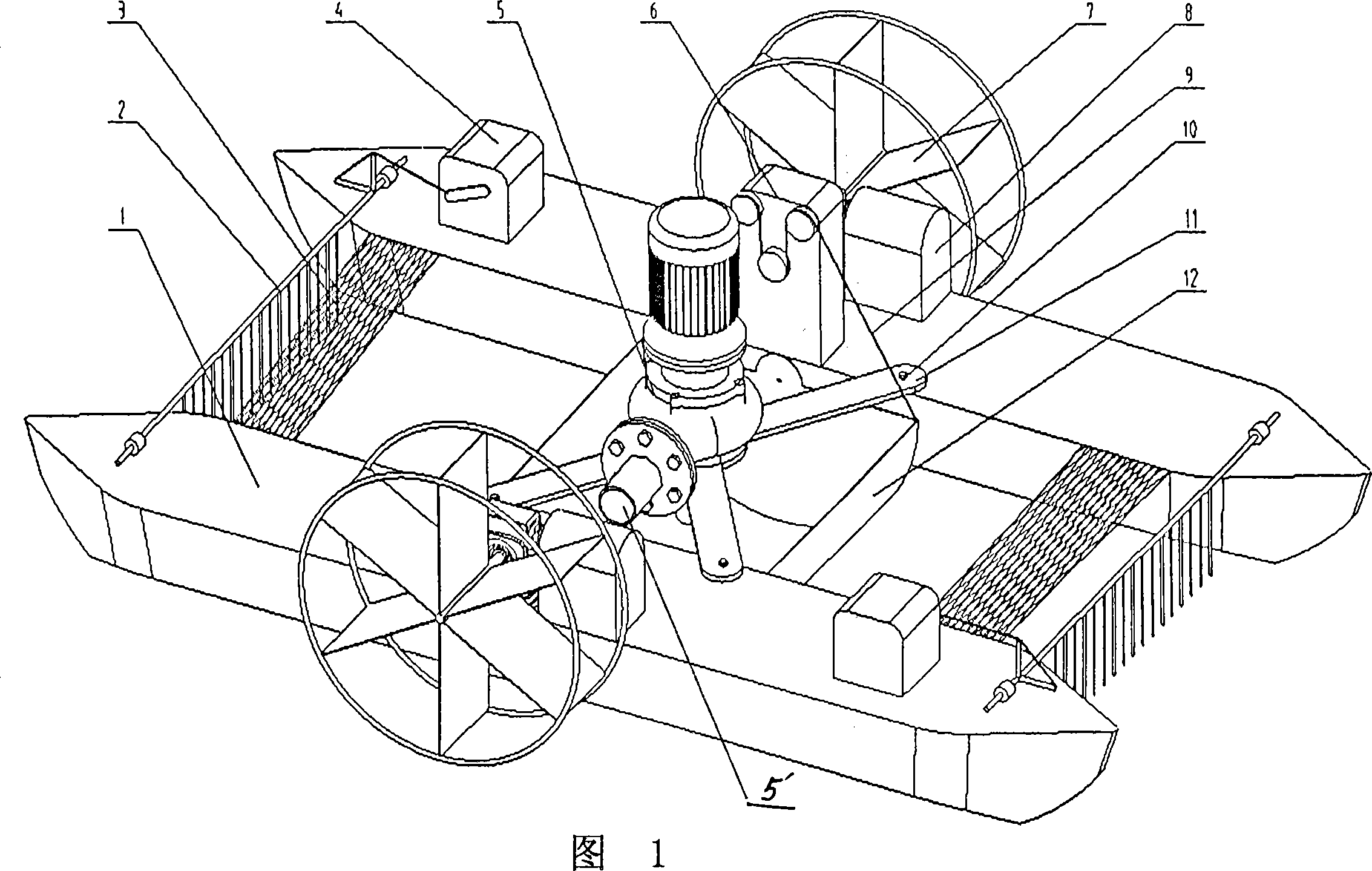

Multifunctional water surface algae removing machine

InactiveCN101078222AAchieve progressAchieve steeringWater cleaningSoil-shifting machines/dredgersPhylum CyanobacteriaDrive wheel

The invention relates to a multi-function water surface algae cleaning machine, comprising double float formed by bracket connection, no-blocking pump set on the bracket, driving device, cyanobacteria collector connected in inner sides of double float and pitch adjusting device for cyanobacteria collector, which are connected and combined. The merit is that driving wheels are set at outer sides of double float; under the driving of motor they can rotate in clockwise and counterclockwise directions or adjust rotation speed of two driving wheels to realize advancing, retreating and turning of algae cleaning machine. Pitch adjustable device is set. The algae cleaning machine moves forwards or backwards for air cleaning work so that as much as possible cyanobacteria is absorbed by the no-blocking pump. Comb-shape division device and miscellany removal device are used to prevent algae absorption pump blocking. The whole algae cleaning machine can operate on bank or on algae storage ship after the algae cleaning machine so that the load of float work of algae cleaning machine, the contacting depth between absorption mouth of pump and algae layer is guaranteed; and two bad conditions of suction and water absorption can be avoided. The invention is provided with reasonable structure distribution, simple operation and good algae cleaning performance.

Owner:SHANGHAI OCEAN UNIV

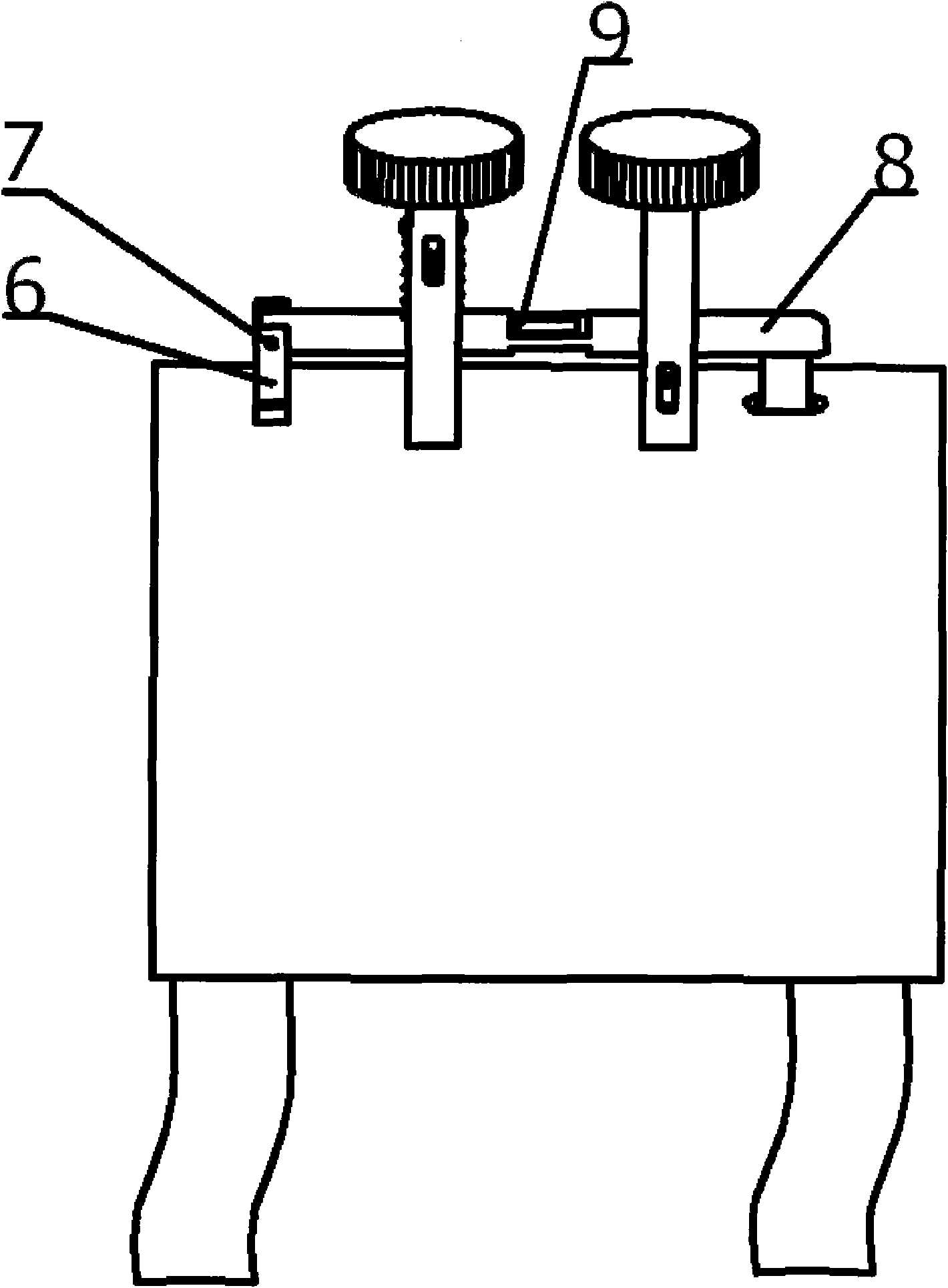

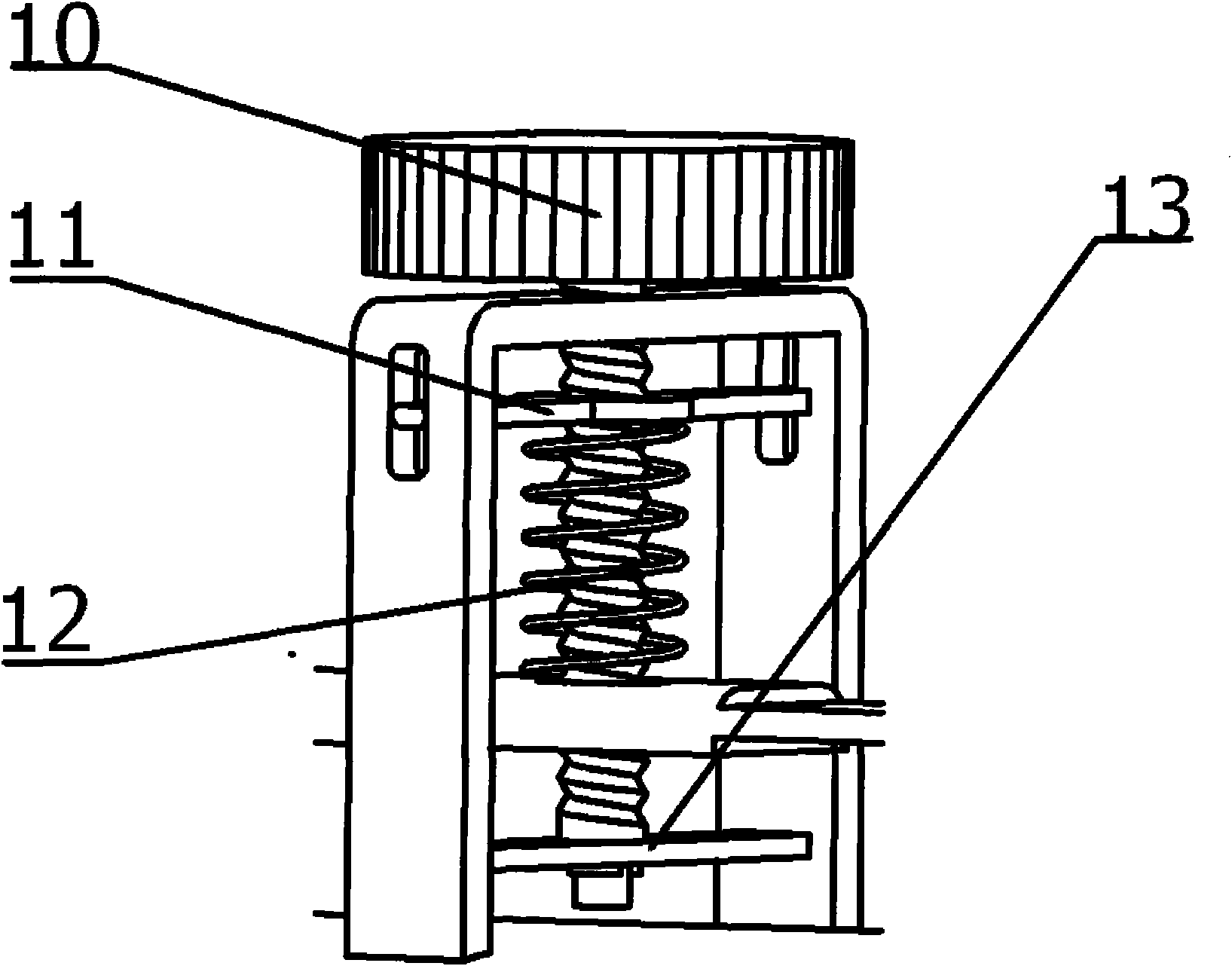

Muscle spasm detection device

The invention provides a muscle spasm detection device, which consists of a shell, a pressure test mechanism, an initial pressure adjusting mechanism, a contact depth adjusting mechanism and a signal processing module, wherein the four angles of the shell are connected with a restraint strap respectively; the pressure test mechanism comprises a support arranged at the shell, a deformed beam, a strain gauge and a movable contact; the initial pressure adjusting mechanism comprises a shell body, an adjusting screw, a strut adapter and a spring; the contact depth adjusting mechanism comprises three shells, two adjusting screws, a strut and a sliding bar; and the signal processing module comprises an amplifier module, a filter module and a module for displaying the elastic modulus of the measured muscle. The device, which detects whether a muscle spasm occurs by measuring the muscle hardness, can perform quantitative analysis. The muscle spasm detection device has the advantages of simple structure, low cost and easy carry, and can be used in the rehabilitation training of the patients.

Owner:HARBIN ENG UNIV

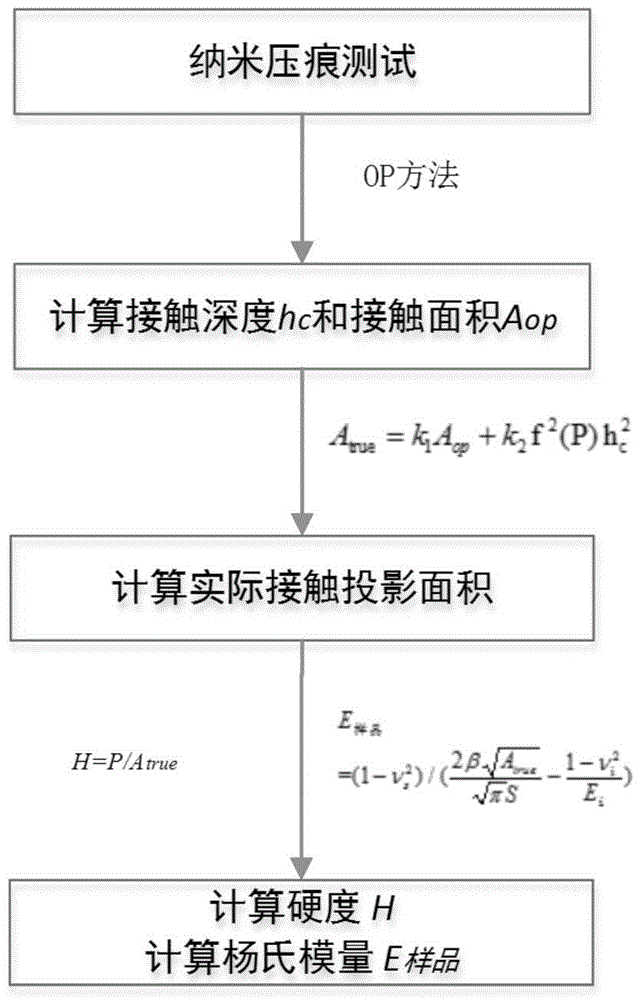

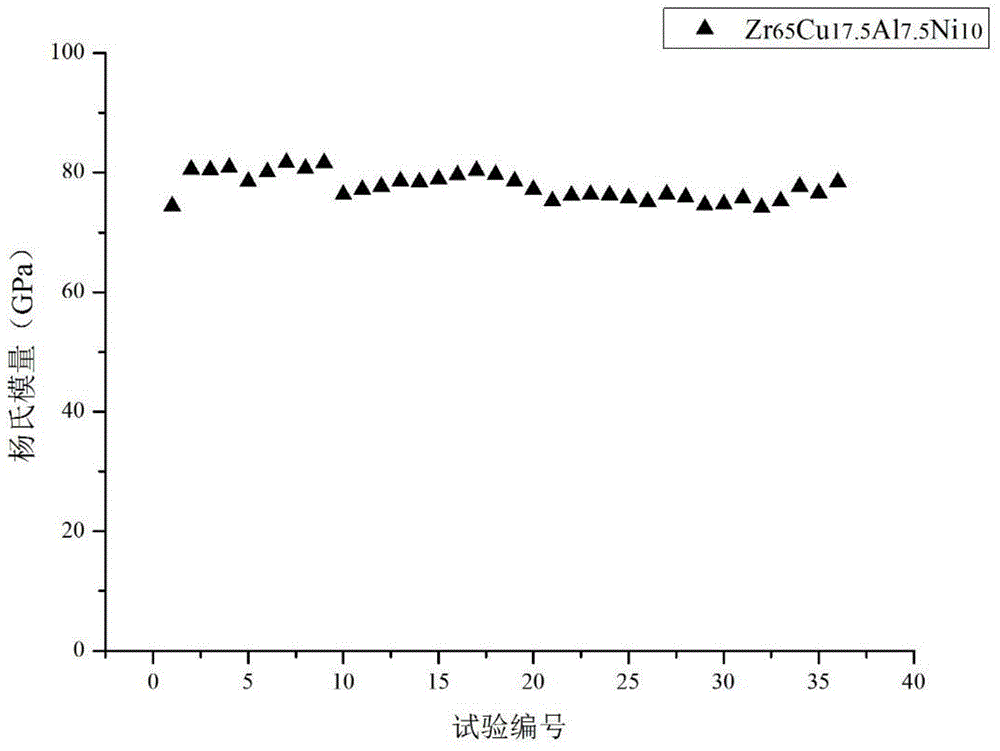

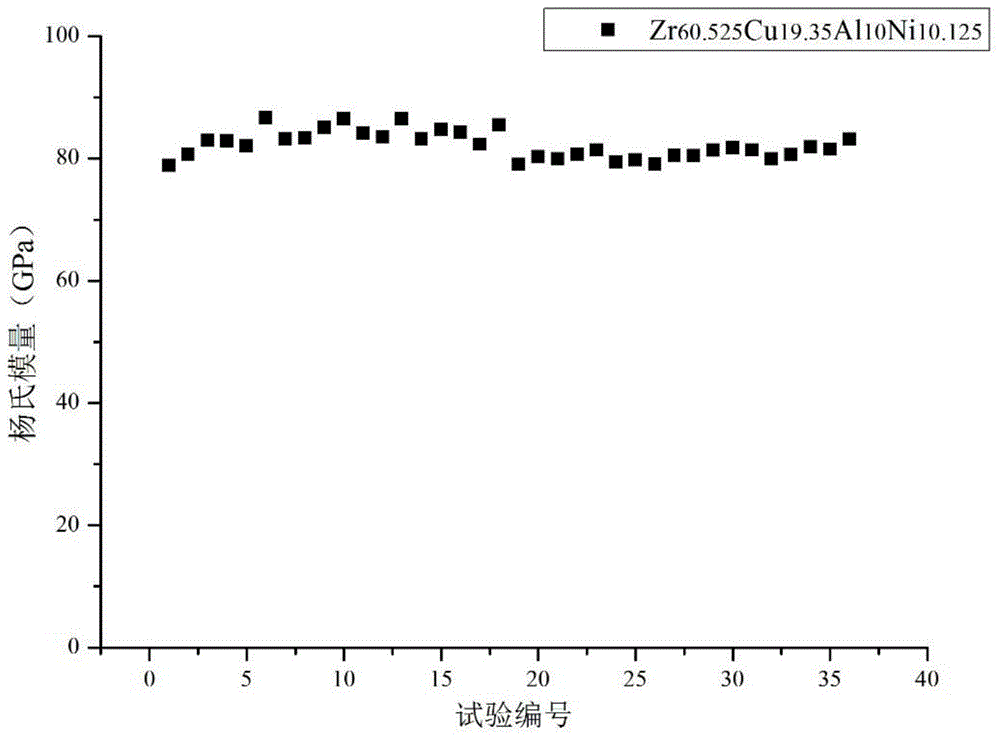

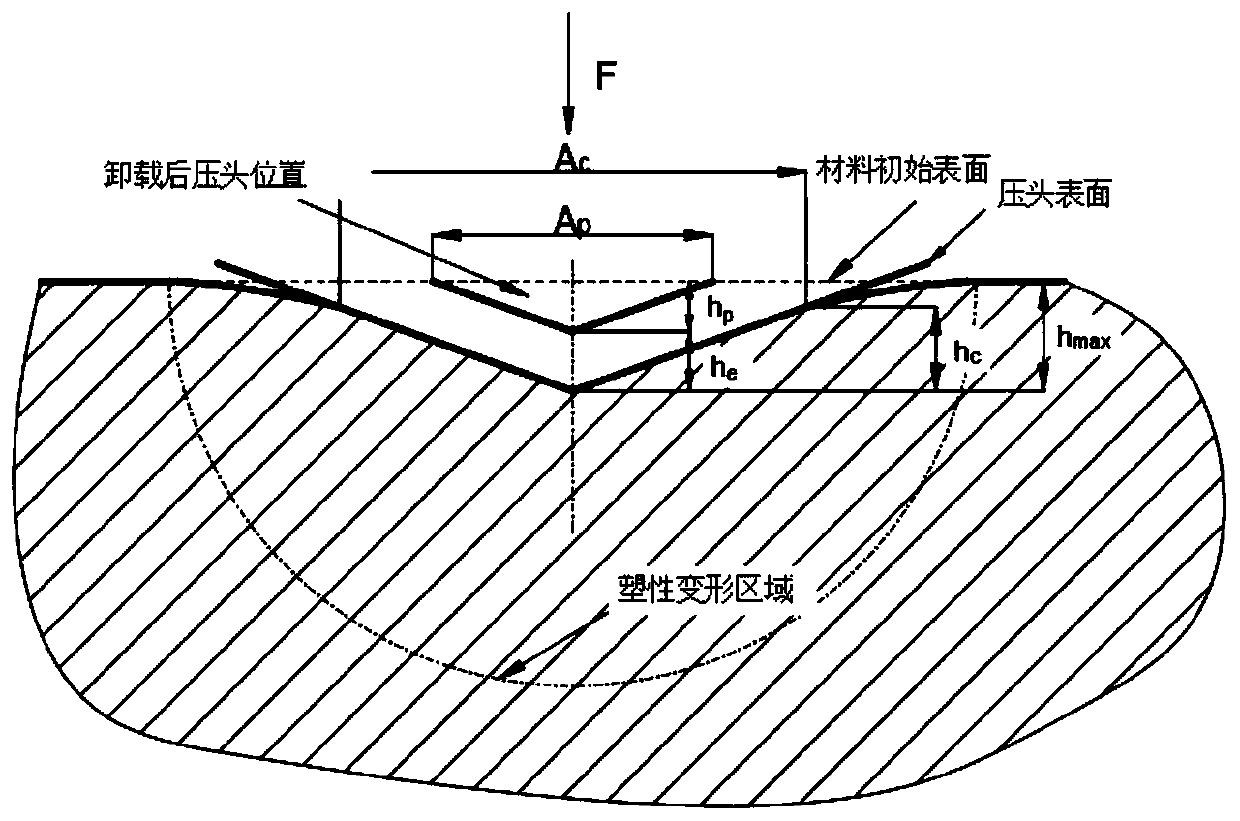

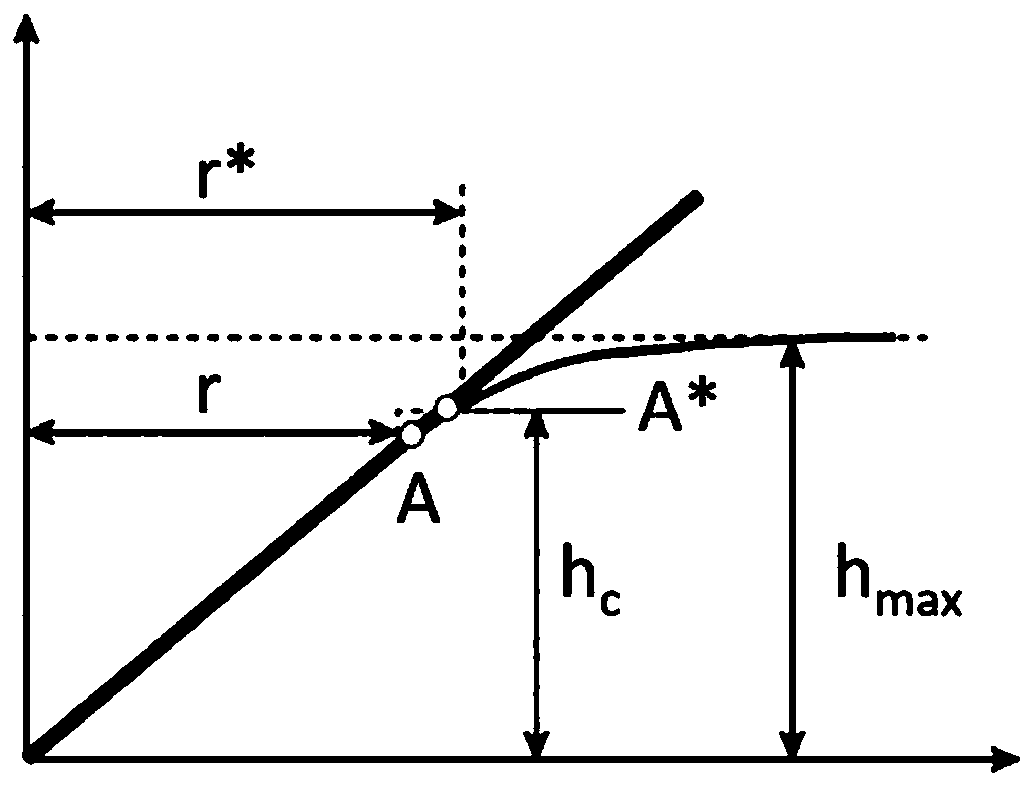

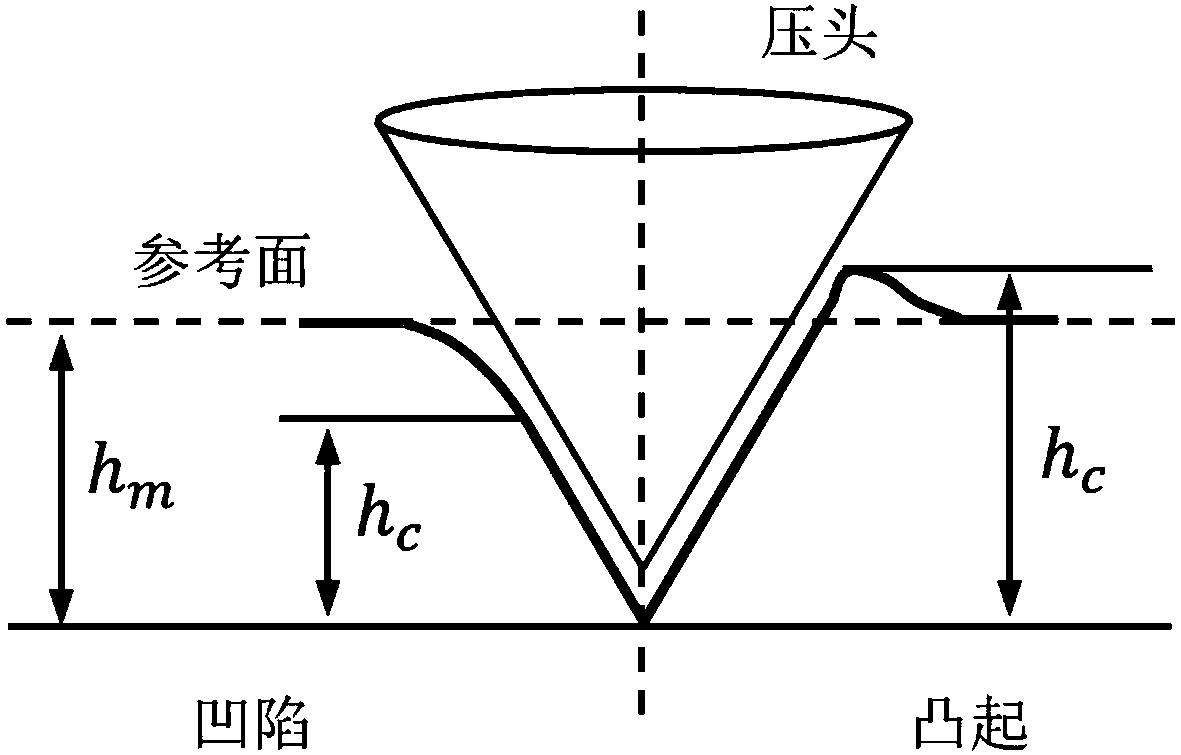

Method for measuring microscopic mechanical property parameter of press-fitting material

ActiveCN106198277AAccurate methodCorrection errorInvestigating material hardnessHardnessComputer science

The invention discloses a method for measuring microscopic mechanical property parameter of a press-fitting material. The method comprises the following steps: S1, executing a nanoindentation test; S2, according to a load-displacement curve obtained by the nanoindentation test, calculating a contact depth hc and a contact area Aop of a pressure head; S3, according to a following formula, calculating the practical contact area Ature of the pressure head, wherein, k1 is the indentation deformation coefficient during an unloading process, k1 is 1.1-1.2, k2 is a deviation factor of the practical pressure head and an ideal pressure head, k2 is 61-62, f(P) is the size effect symptom coefficient during a nanoindentation process, f(P) is 0.30-0.01 P, P is maximum load, and the unit is mN; and S4, calculating young modulus E and hardness H of the press-fitting material based on Ature. The method can accurately and rapidly obtain the practical contact area of the pressure head of the press-fitting material, extra expensive equipment is not required, and the cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

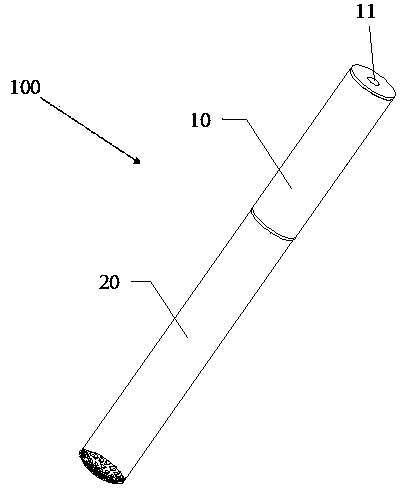

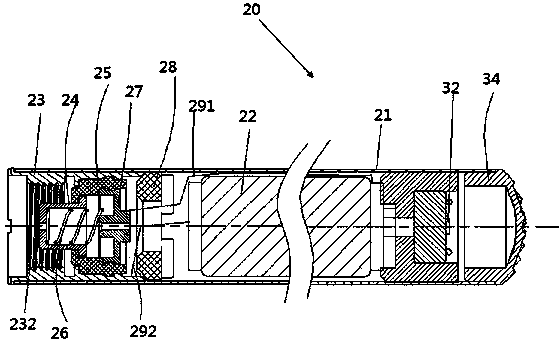

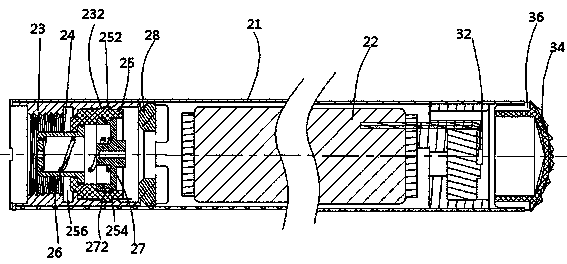

Battery pack for electronic cigarette and electronic cigarette

InactiveCN103349362ADepth can be adjustedFirmly connectedCurrent conducting connectionsMedical devicesElectronic cigaretteEngineering

The invention provides a battery pack for an electronic cigarette, which comprises a battery cover, a battery accommodated in the battery cover, an electrode ring positioned at one end of the battery, an insulating ring and an elastic element, wherein the insulating ring is provided with a through hole in the axial direction of the battery cover; the electrode ring is elastically fixed in the through hole through the elastic element and extends out of the through hole. The invention further provides the electronic cigarette comprising an atomizer and the battery pack. Through the adoption of the elastic element, the contact depth of the atomizer and the electrode ring can be adjusted.

Owner:SHENZHEN FIRST UNION TECH CO LTD

Method for calculating fracture toughness through indentation method

ActiveCN109900554ALow damage fracture toughness valueReduce consumptionMaterial strength using tensile/compressive forcesInvestigating material hardnessState parameterStrain energy

The invention belongs to the technical field of fracture toughness test and provides a method for calculating fracture toughness through an indentation method. The method comprises the following steps: 1) obtaining relationship between depth and load during material pressing-in and unloading stages; 2) obtaining plastic residual depth and contact depth state parameters according to a load-displacement curve during material unloading; 3) predicting a radial displacement correction factor and a Berkovich pressing head non-axisymmetric correction factor of the material under the function of a pressing head by utilizing finite element software; 4) carrying out material uniaxial tension experiment to obtain material elasticity modulus, and obtaining critical hole rate of the material based on the GTN theory with the help of the finite element software; and 5) associating indentation work with fracture energy and carrying out equivalence with strain energy density to obtain a fracture toughness equation characterized by the critical plastic residual depth. The fracture toughness test method can quickly obtain the elastic modulus and the fracture toughness value of the material at low loss through a small-range indentation experiment of the material.

Owner:江苏嘉易安科技有限公司

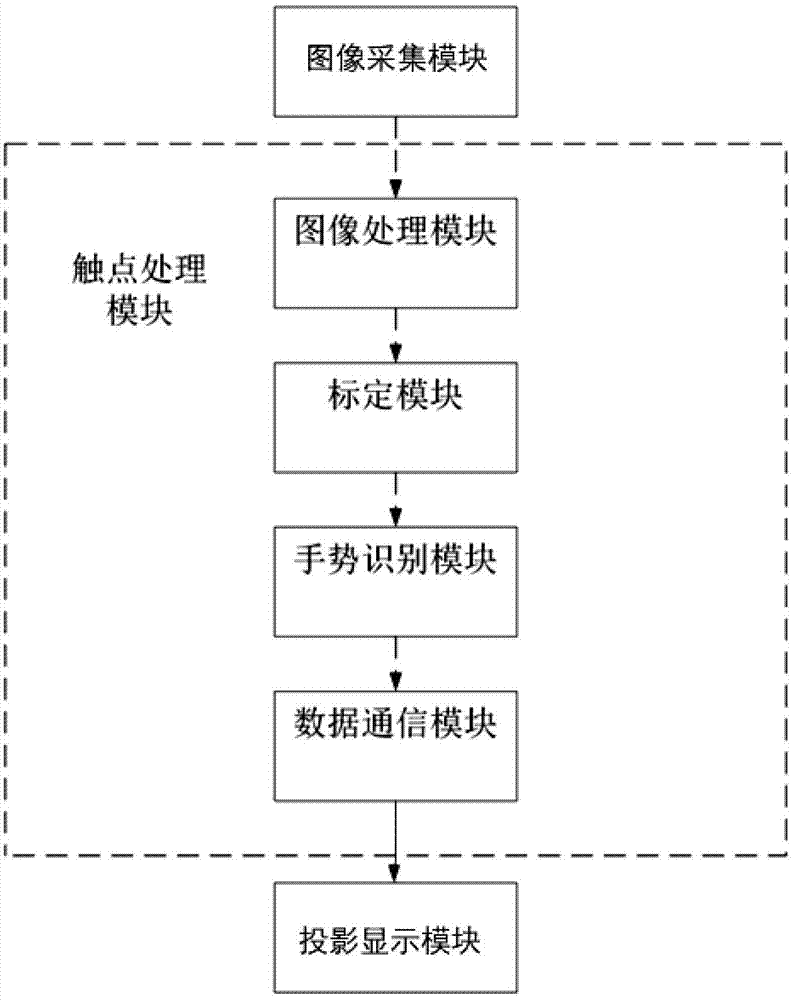

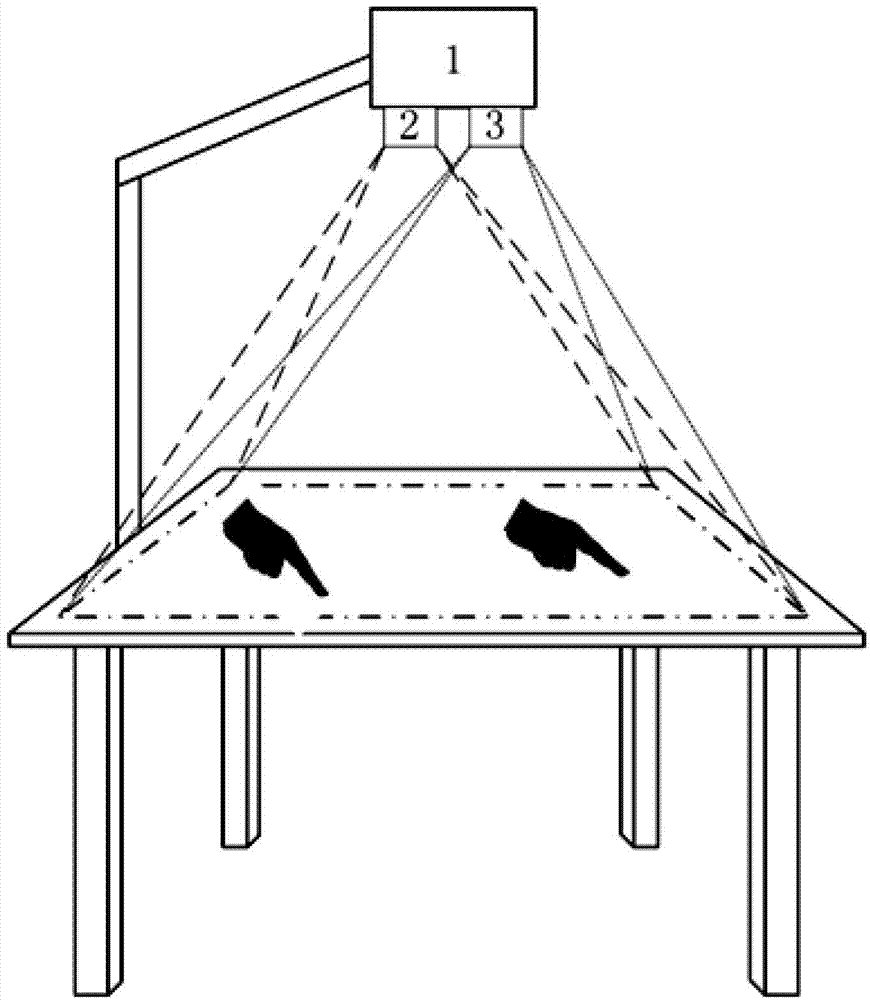

Multi-point touch equipment based on depth camera

InactiveCN102968222AAccurate operationOperation Motion Capture AccurateInput/output processes for data processingColor imageComputer graphics (images)

The invention discloses multi-point touch equipment based on a depth camera. The equipment comprises an image acquisition module, a contact processing module and a projection display module, wherein the image acquisition module is used for acquiring color image information and hand contact depth image information and transmitting the color image information and the hand contact depth image information to the contact processing module; the contact processing module is used for processing the received information to obtain the image information of a projection plane, and further, the contact information of fingers is obtained; contact coordinates on the projection plane are transformed into graphical interface coordinates; the contact information is converted into operating information, and the operating information is transmitted into an application program; and the projection display module is used for projecting the received information onto a specified plane. By adopting the equipment, damage cannot be caused to a human body; the operating dynamics of a user can be accurately captured; and the touch-control reducibility of an image is high. Moreover, the multi-point touch equipment based on the depth camera can be easily carried, and therefore, the interactive experience of the user during an application process is enhanced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

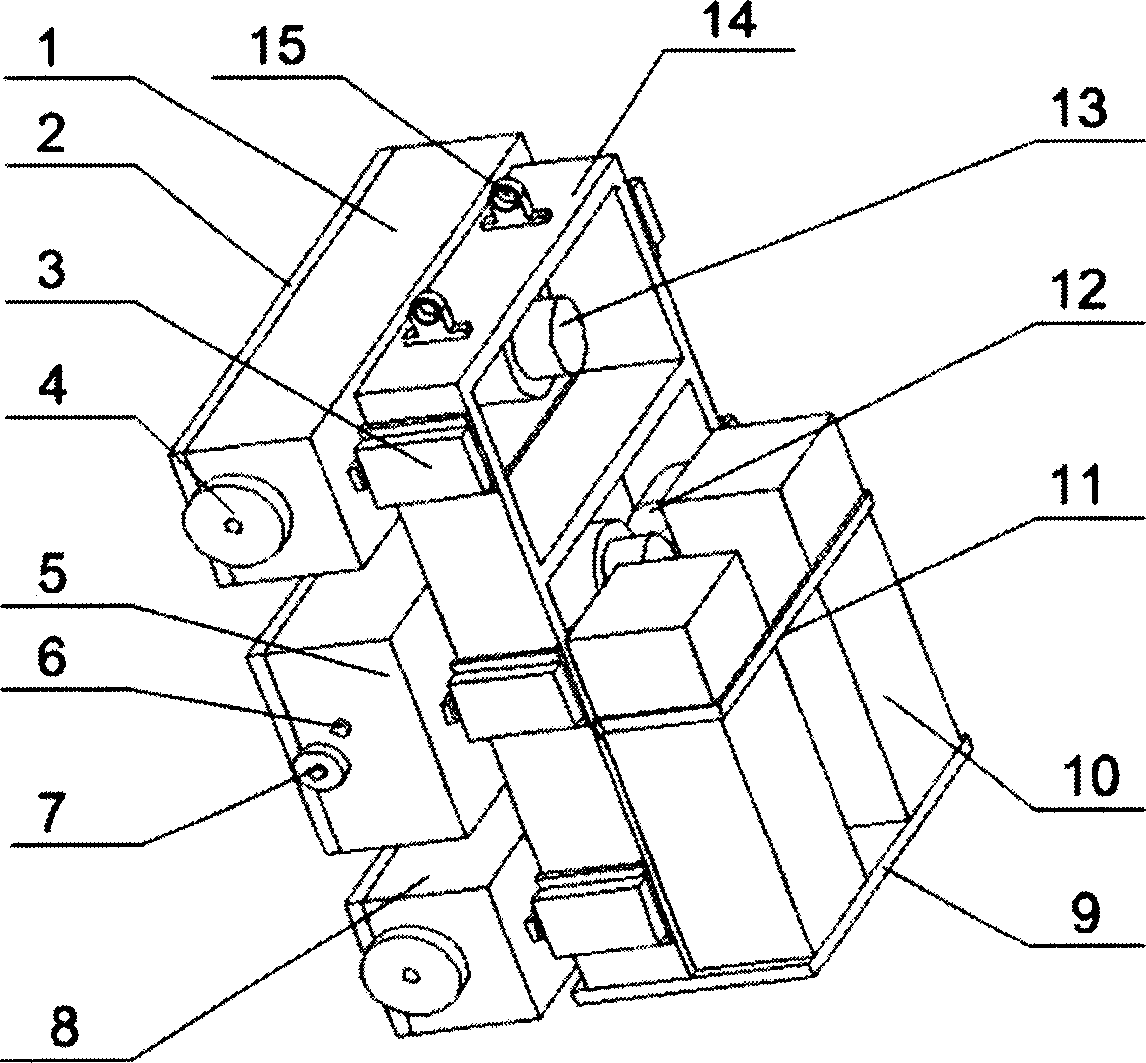

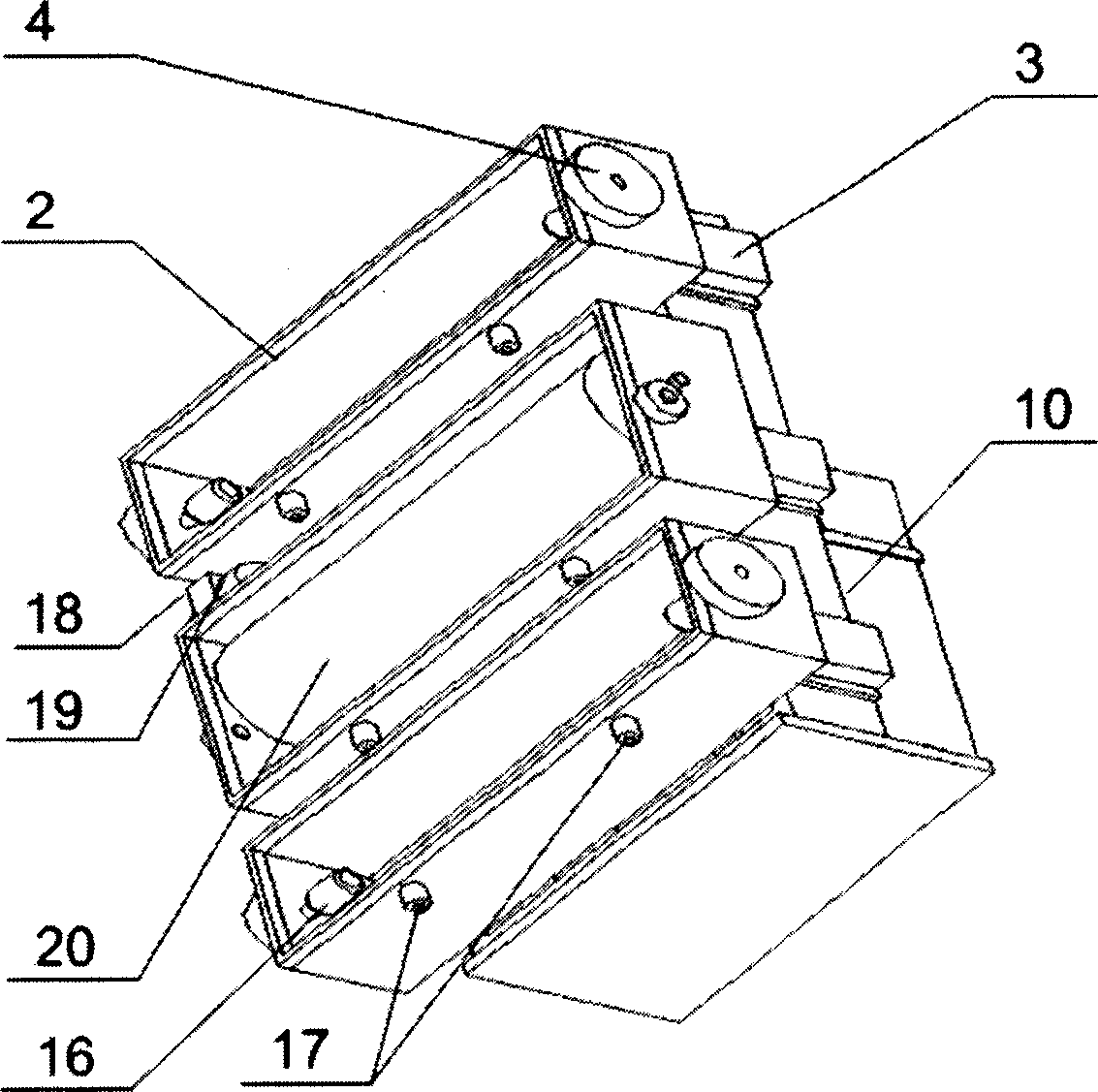

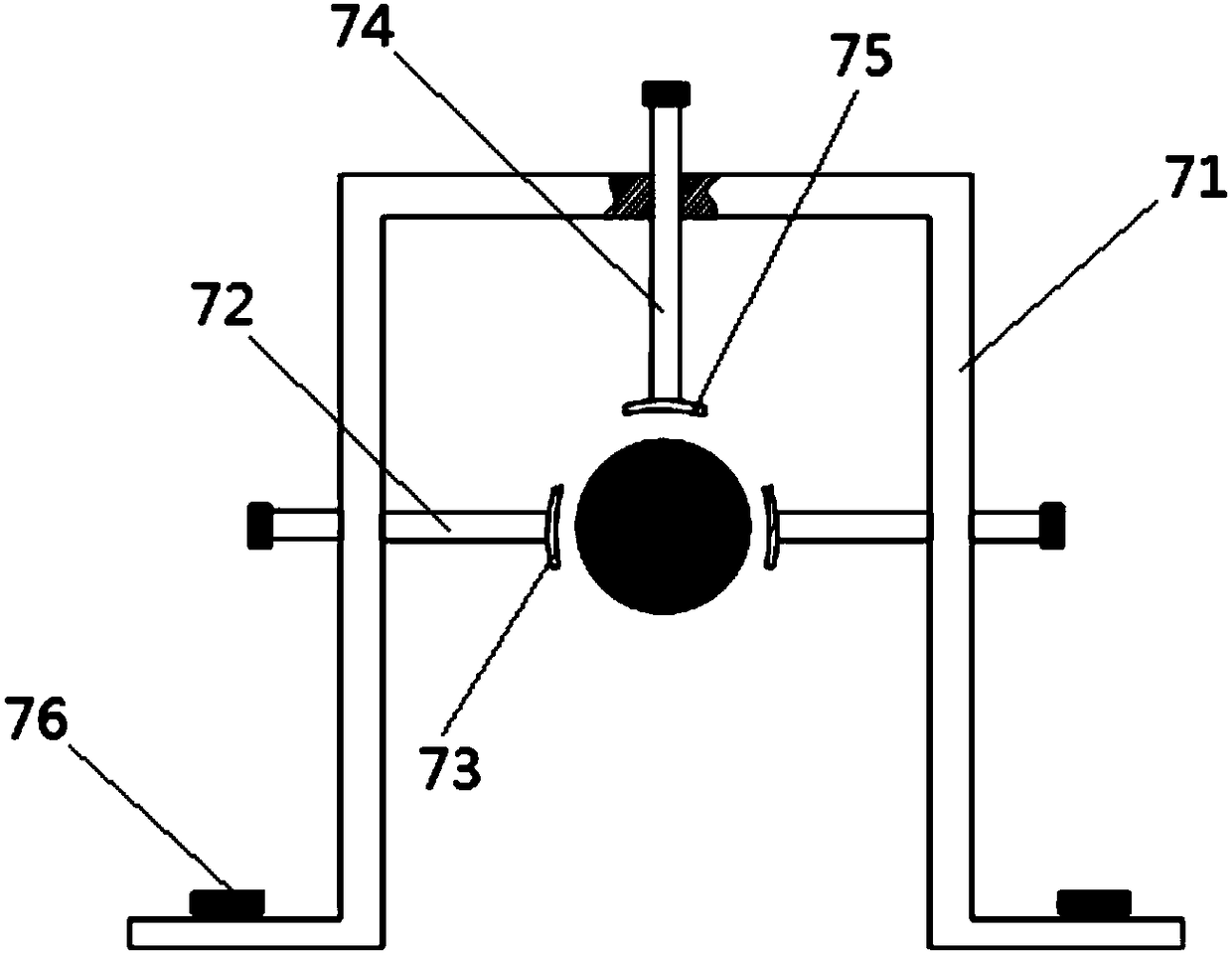

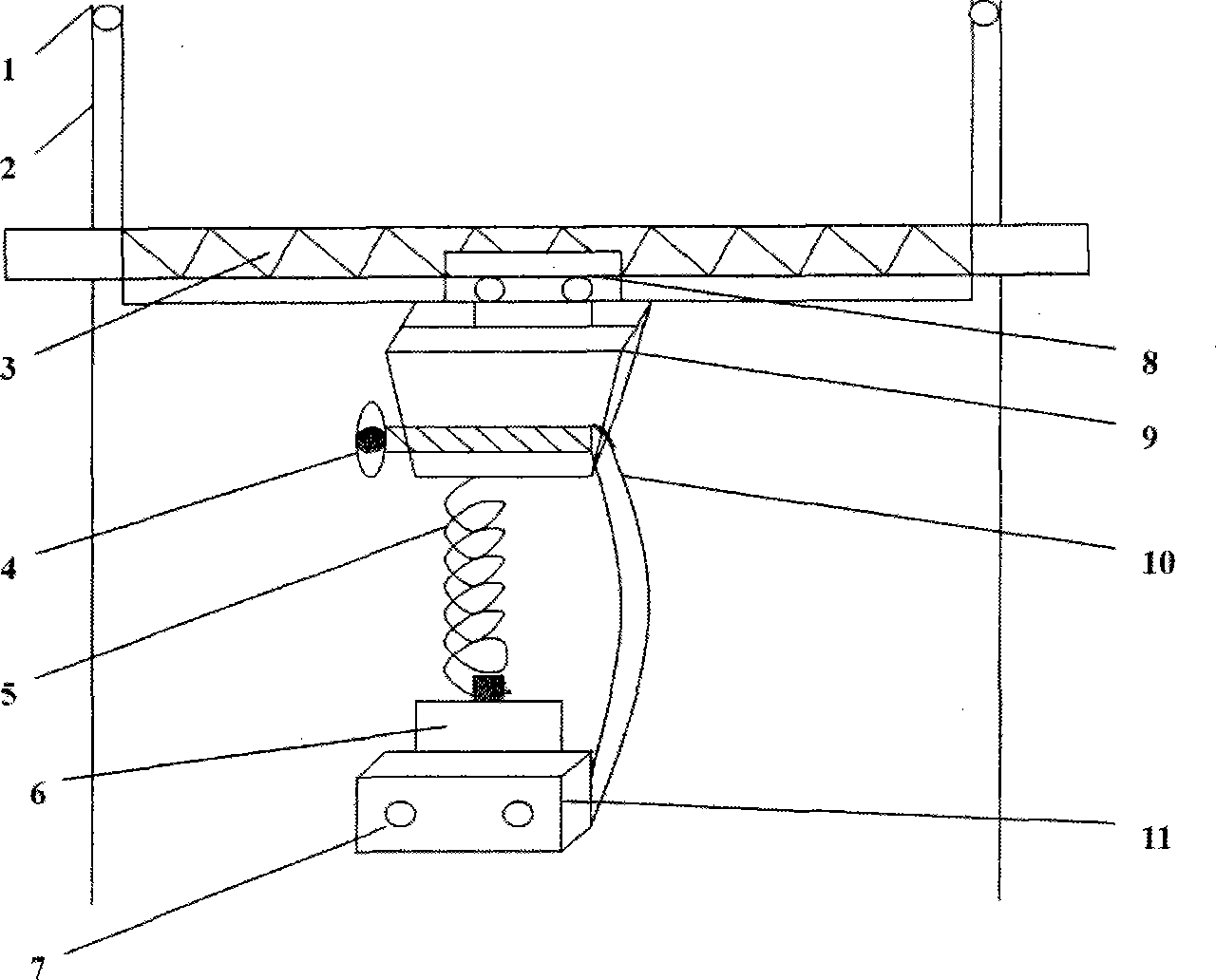

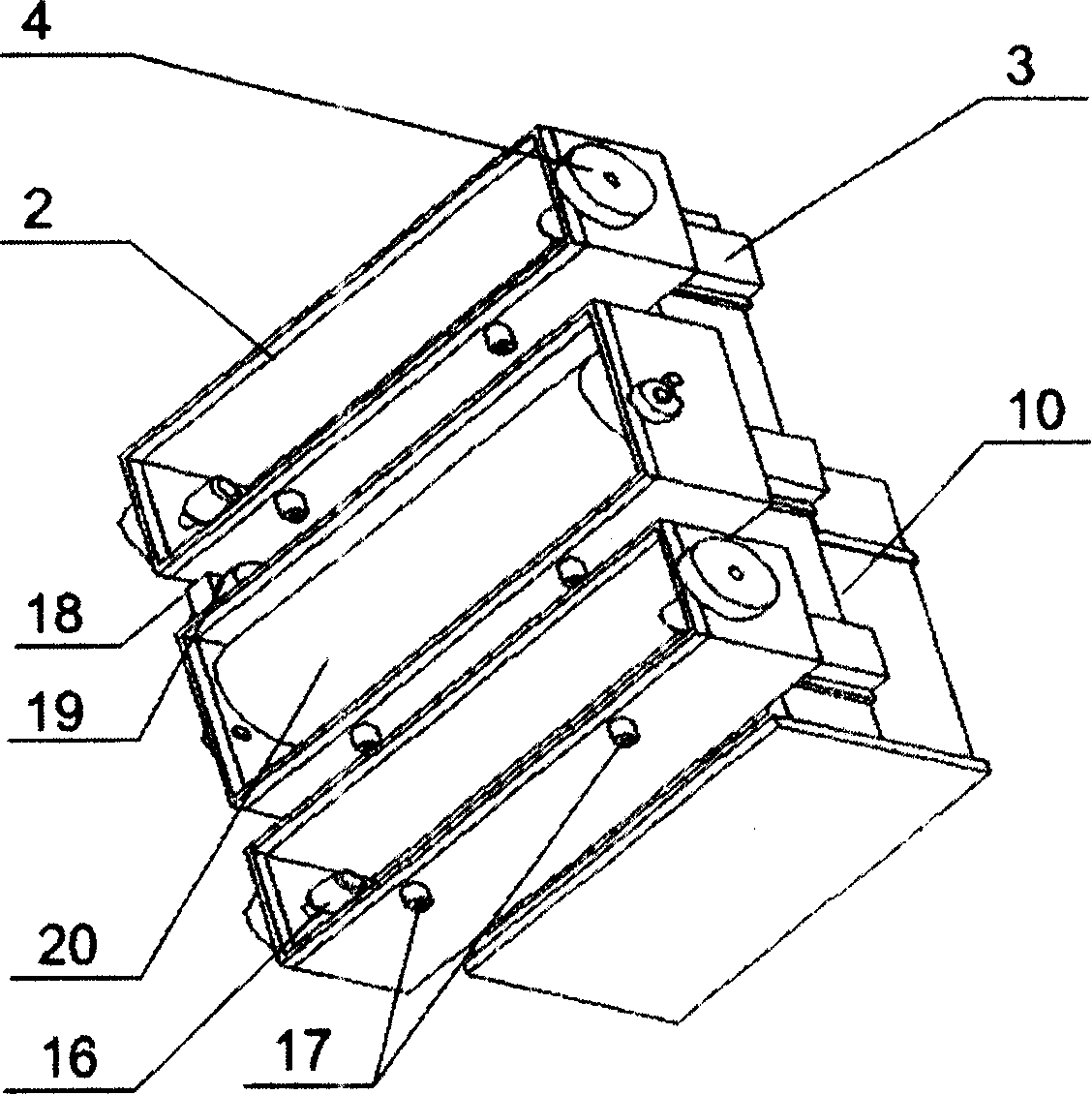

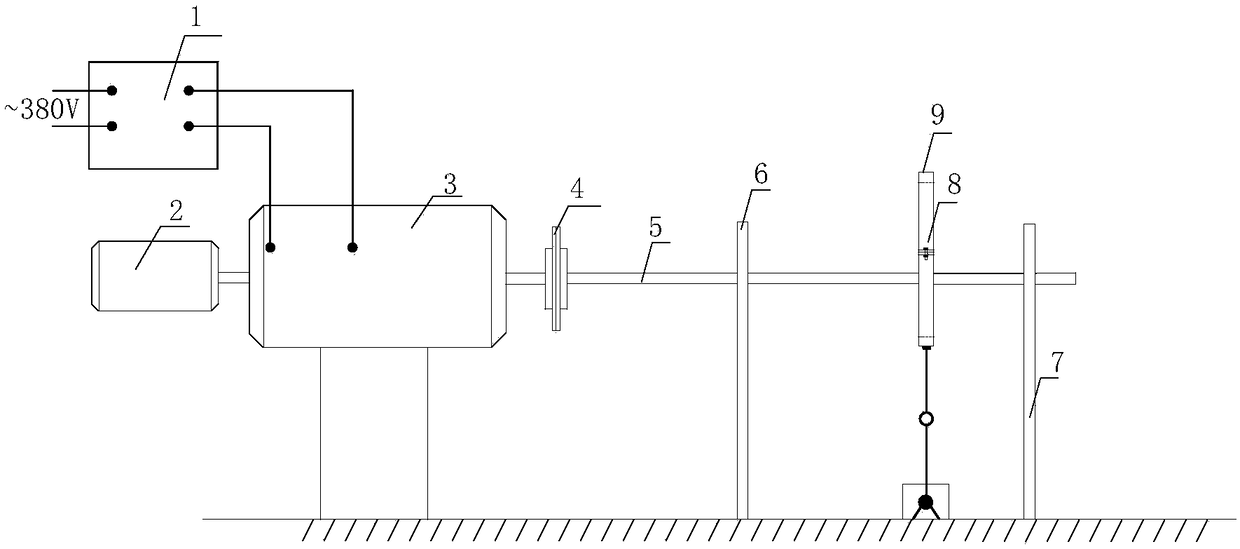

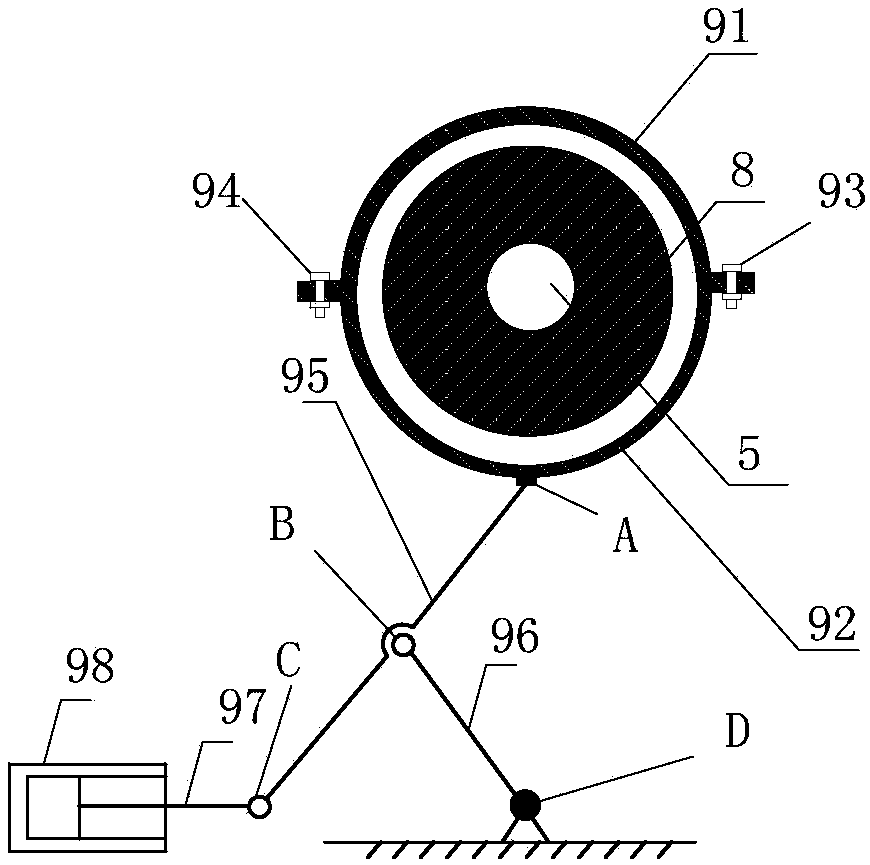

Test device for simulating rotor rubbing fault

The invention relates to a test device for simulating a rotor rubbing fault, belonging to the technical field of rotor rubbing tests. The test device aims to solve the problems that an existing test device cannot adjust the contact depth between a rubbing contact part and a rotor, cannot simulate a rubbing fault weak to be serious and cannot perform one-way simulation of the rubbing fault. A motorand a rubbing device are fixed on a working platform, center lines of the motor and the rubbing device are located on the same straight line, the output end of the motor is connected with one end ofa rotating shaft through a coupler, the other end of the rotating shaft sequentially passes through a first bearing block, the rubbing device, a disc and a second bearing block, and the first bearingblock and the second bearing block are fixedly mounted on the working platform. The test device for simulating the rotor rubbing fault can adjust the rubbing contact part through a plurality of adjusting bolts, so that rotor rubbing faults of different depths in multi-local face contact are simulated precisely.

Owner:HARBIN ELECTRIC CO LTD

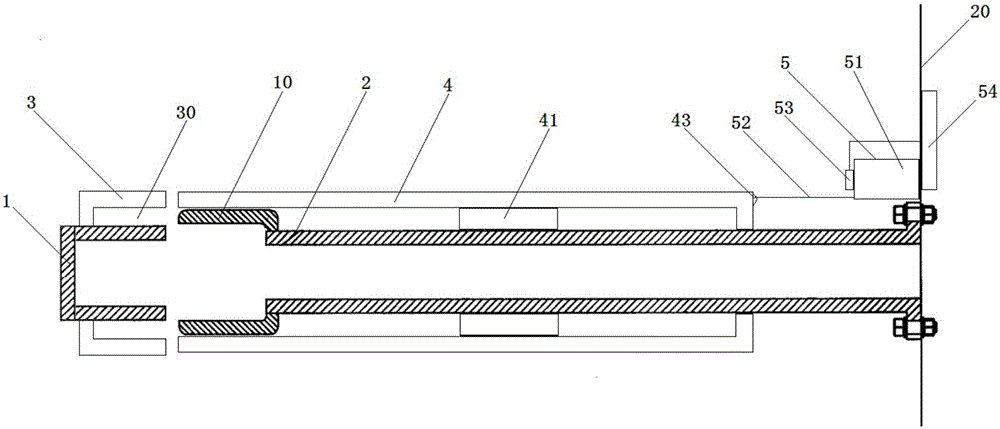

Tool for measuring contact depth of contacts of switch cabinet handcart

InactiveCN105004251AReliable and precise contactGood meshing contactMechanical depth measurementsInsertion depthBarcode

The invention discloses a tool for measuring the contact depth of contacts of a switch cabinet handcart, which comprises a fixed member, a sliding member and a digital display measuring tape, wherein the fixed member is installed at the outer surface of static contact, the sliding member is installed at the outer surface of a moving contact and arranged opposite to the fixed member, and the digital display measuring tape can read automatically. The digital display measuring tape comprises a shell, a measuring tape, a barcode scanner and a display screen, wherein the shell is installed at the inner side of a panel of a switch cabinet handcart body, the measuring tape is arranged in the shell, the barcode scanner is used for carrying out reading on the measuring tape, and the display screen is connected with the barcode scanner and used for displaying the reading; and the measuring tape is provided with a barcode with the adjacent distance being zero. One end of the fixed member is fixed at the tail end of the static contact, the other end of the fixed member is flush with the front end of the static contact, one end of the sliding member is flush with the front end of a plum-blossom-shaped contact, the other end of the sliding contact is connected with an initial end of the measuring tape, the extension length of the measuring tape is at least the axial length of the plum-blossom-shaped contact, and the extension direction of the measuring tape is identical to the axial direction of the sliding member. The tool disclosed by the invention realizes accurate and reliable contact, and the travel of the measuring device can be read, so that the insertion depth of a plum-blossom-shaped contact finger can be judged accurately.

Owner:STATE GRID CORP OF CHINA +2

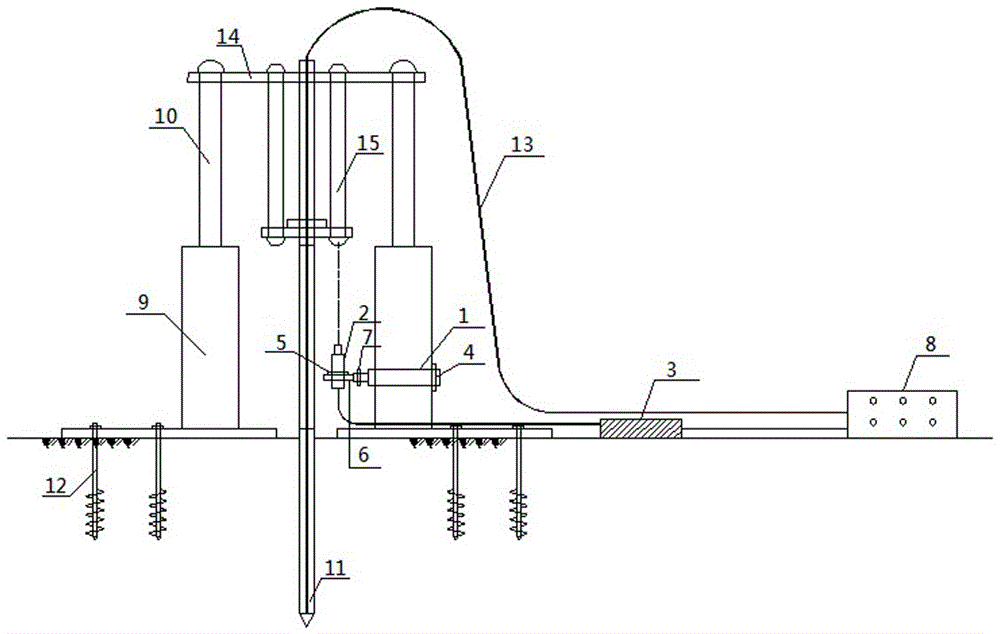

Non-contact depth measurement device for static sounding and application method thereof

InactiveCN105625290AImprove reliabilityHigh precisionIn situ soil foundationMeasurement deviceEngineering

The invention relates to the field of ground exploration, in particular to a non-contact depth measurement device for static sounding and an application method thereof. The non-contact depth measurement device is characterized by at least comprising a distance measurement instrument, a fixed support and a signal processor, wherein the distance measurement instrument is connected and fixed to a static sounding machine through the fixed support, and the signal processor receives and processes distance measurement signals of the distance measurement instrument. The device and the application method thereof have the advantages that the penetration depth of a static sounding probe can be measured in a non-contact mode, the reliability and the accuracy are high, the structure is simple, installation is convenient, the cost is low and popularization is convenient.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

Method for measuring contact depth of movable and stationary contacts of breaker handcart

InactiveCN104390565AReduce measurement errorImprove accuracyMechanical depth measurementsObservational errorMaximum depth

The invention provides a method for measuring contact depth of movable and stationary contacts of a breaker handcart. The method comprises the following steps: preparing a measuring paper board; measuring contact depth of the movable and stationary contacts, sleeving the measuring paper board on the stationary contact so that the distance from the measuring paper board to the end face of the stationary contact is 4mm to 5mm; charging the breaker handcart in a rocking manner so that the breaker handcart reaches a position connected with a valve mechanism, pushing the measuring paper board to move on the stationary contact by using a quincuncial contact so that the measuring paper board can finally reach a maximum depth contact position of the quincuncial contact and the stationary contact; discharging the breaker handcart in a rocking manner, and measuring the size from the left end face of the stationary contact to the measuring paper board by using a millimeter steel plate ruler. The method disclosed by the invention has the effects that by utilizing the normal working position of the handcart, the contact depth can be obtained by just measuring one distance size, the measurement error is + / -0.5mm and reduced, and the measurement accuracy is improved. The measurement can be implemented by operation time of one-step charging and discharging of the breaker handcart in a rocking manner; with addition of the preparation time of the measuring paper board, the total measurement time is only 2 minutes, so the measurement speed is five times the original speed.

Owner:CHUANTIE ELECTRIC TIANJIN GRP

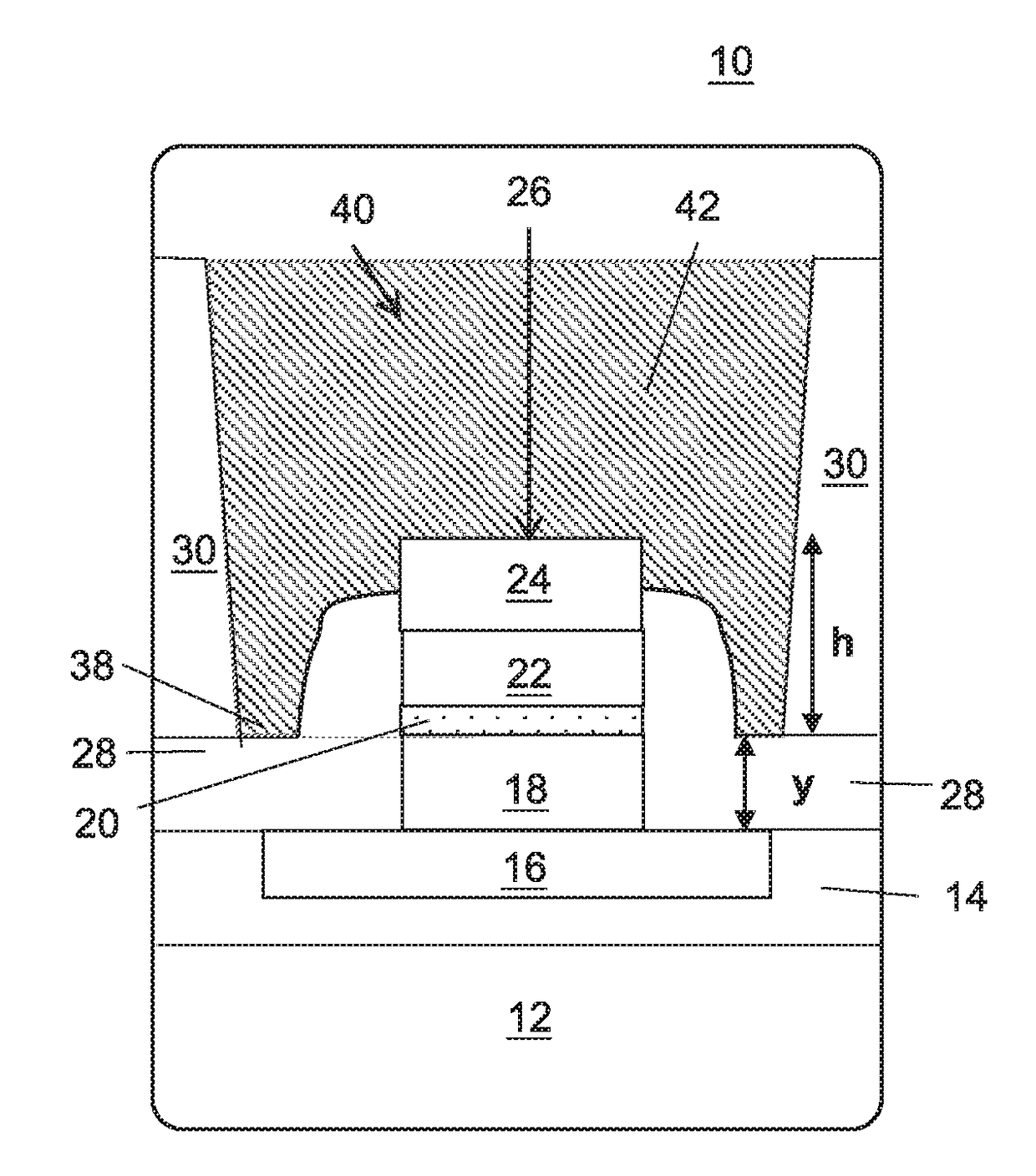

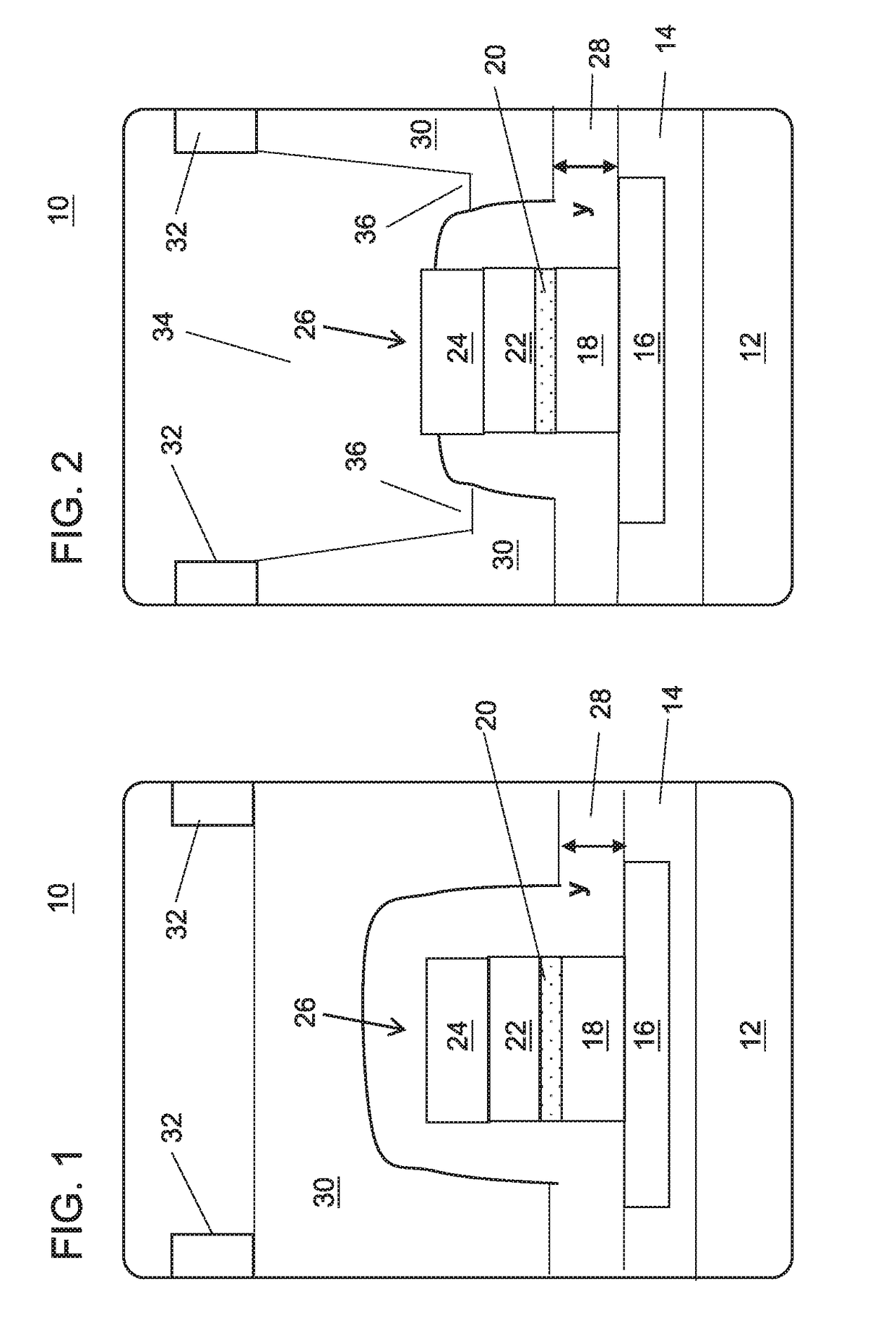

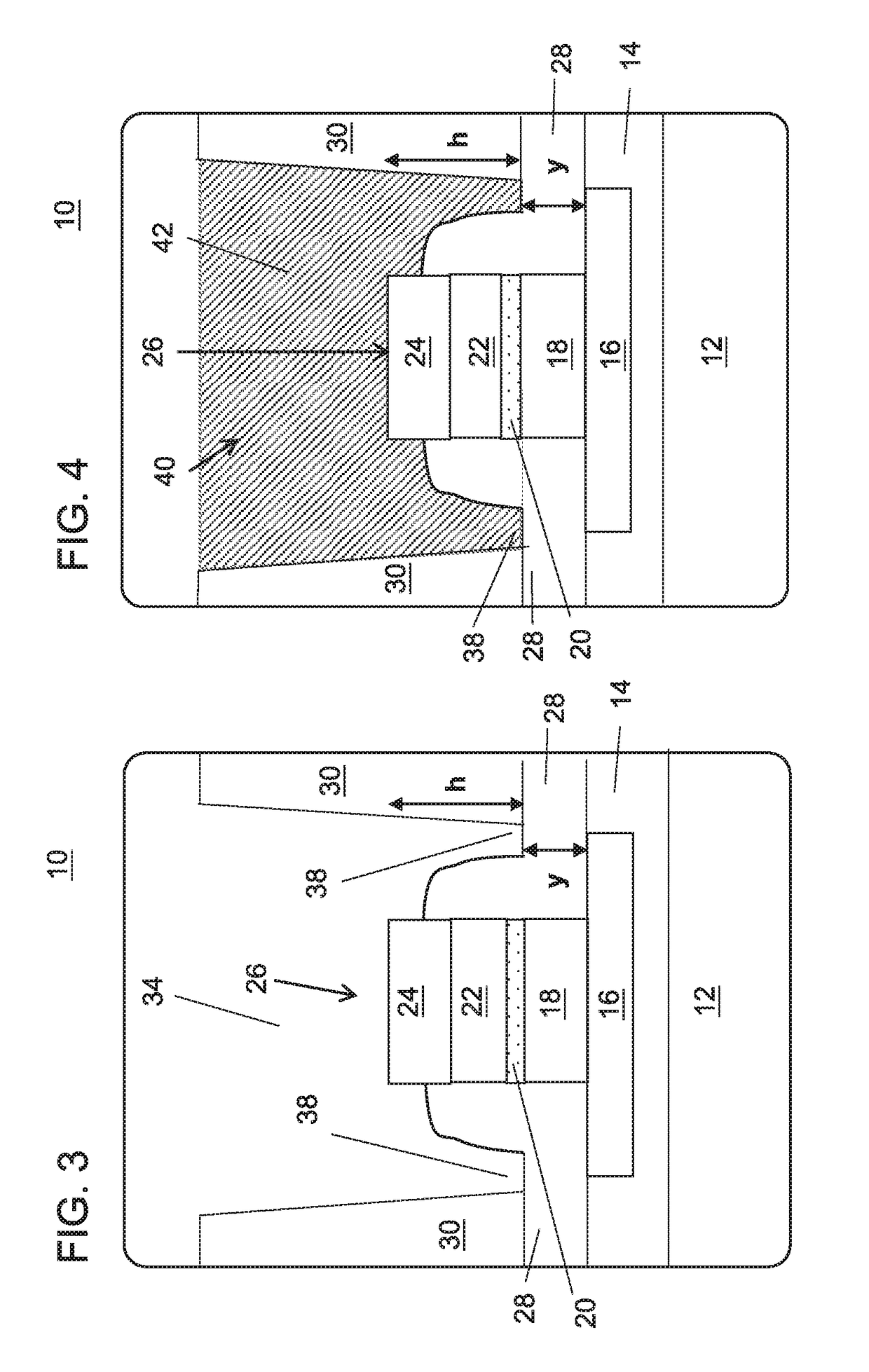

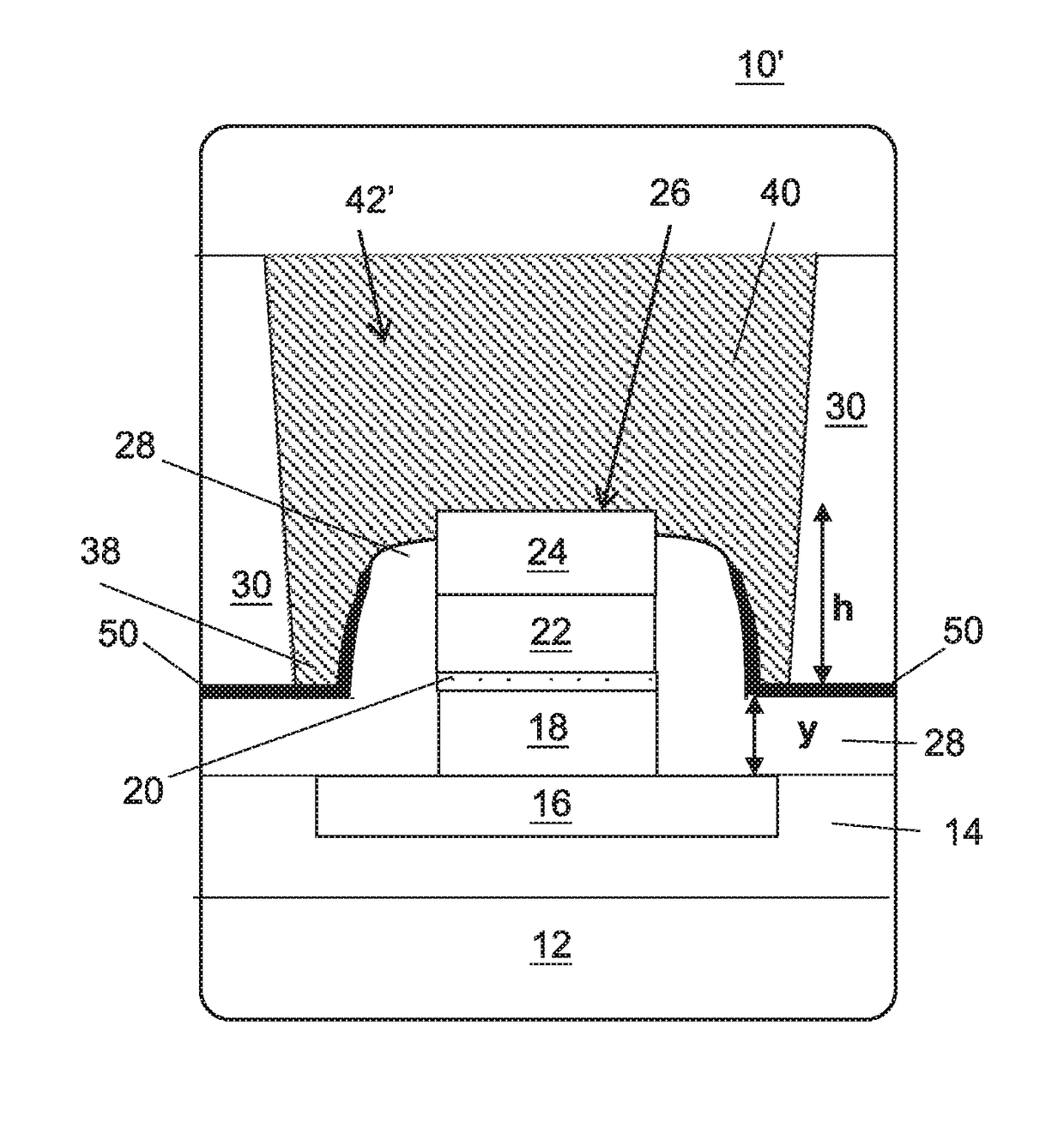

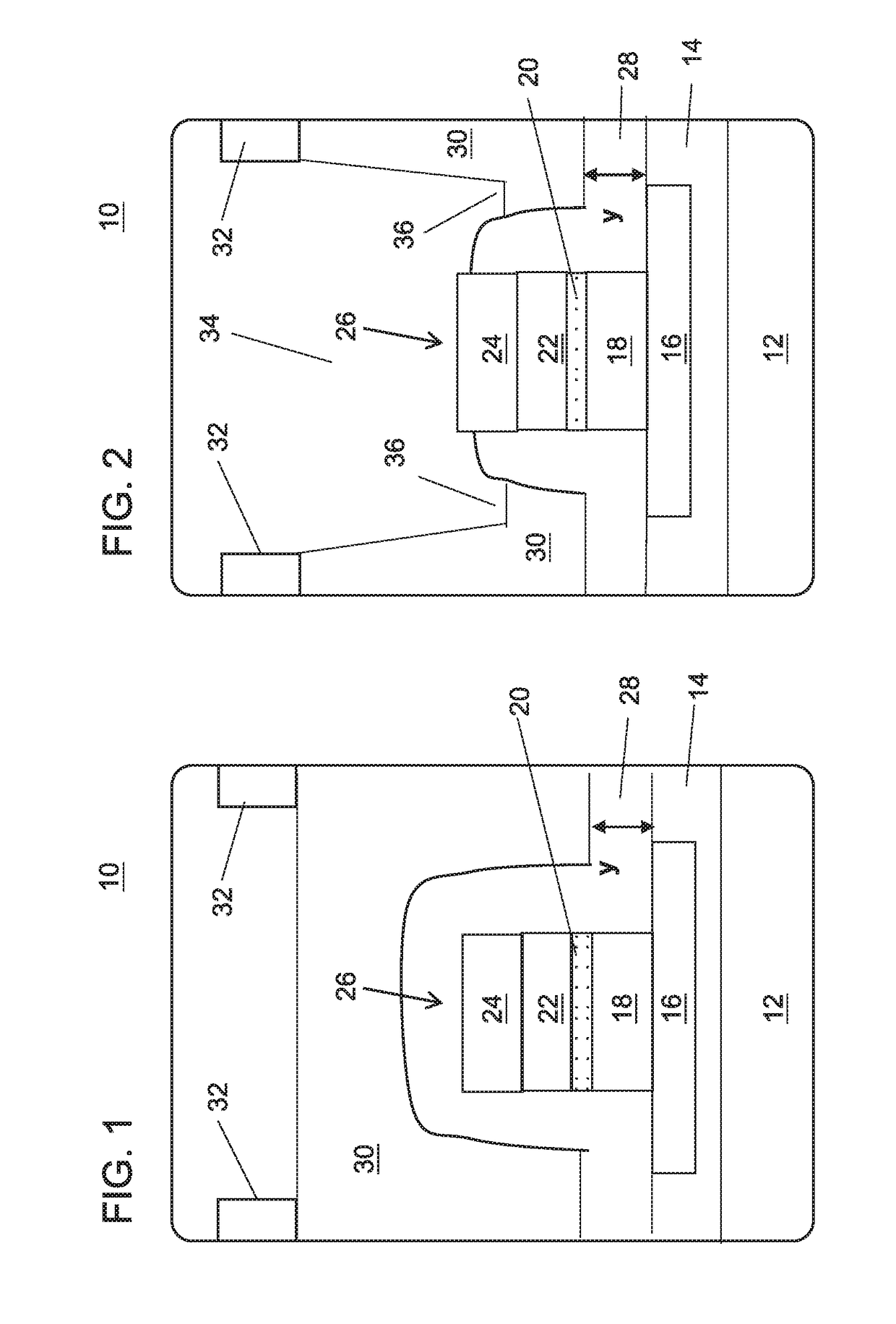

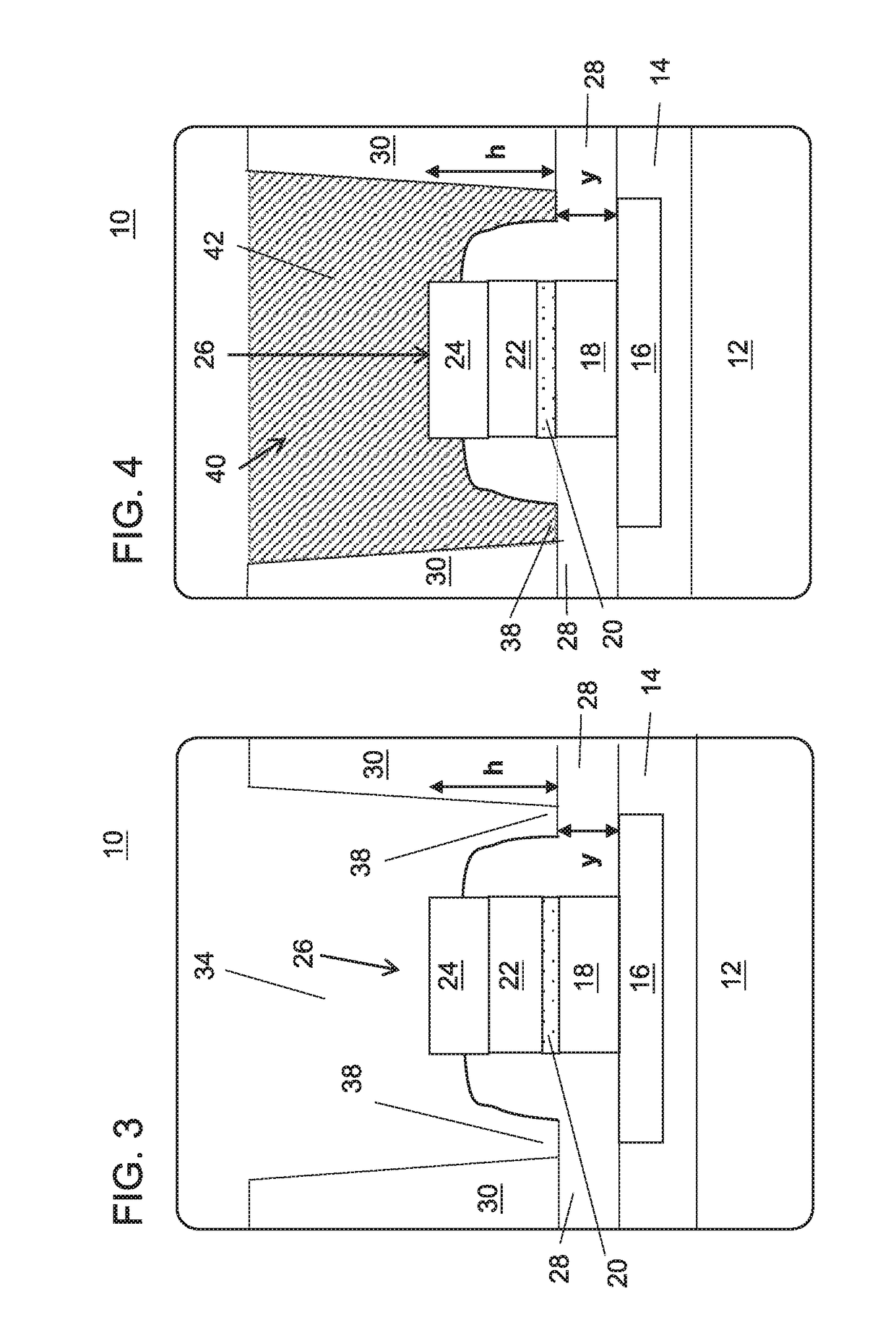

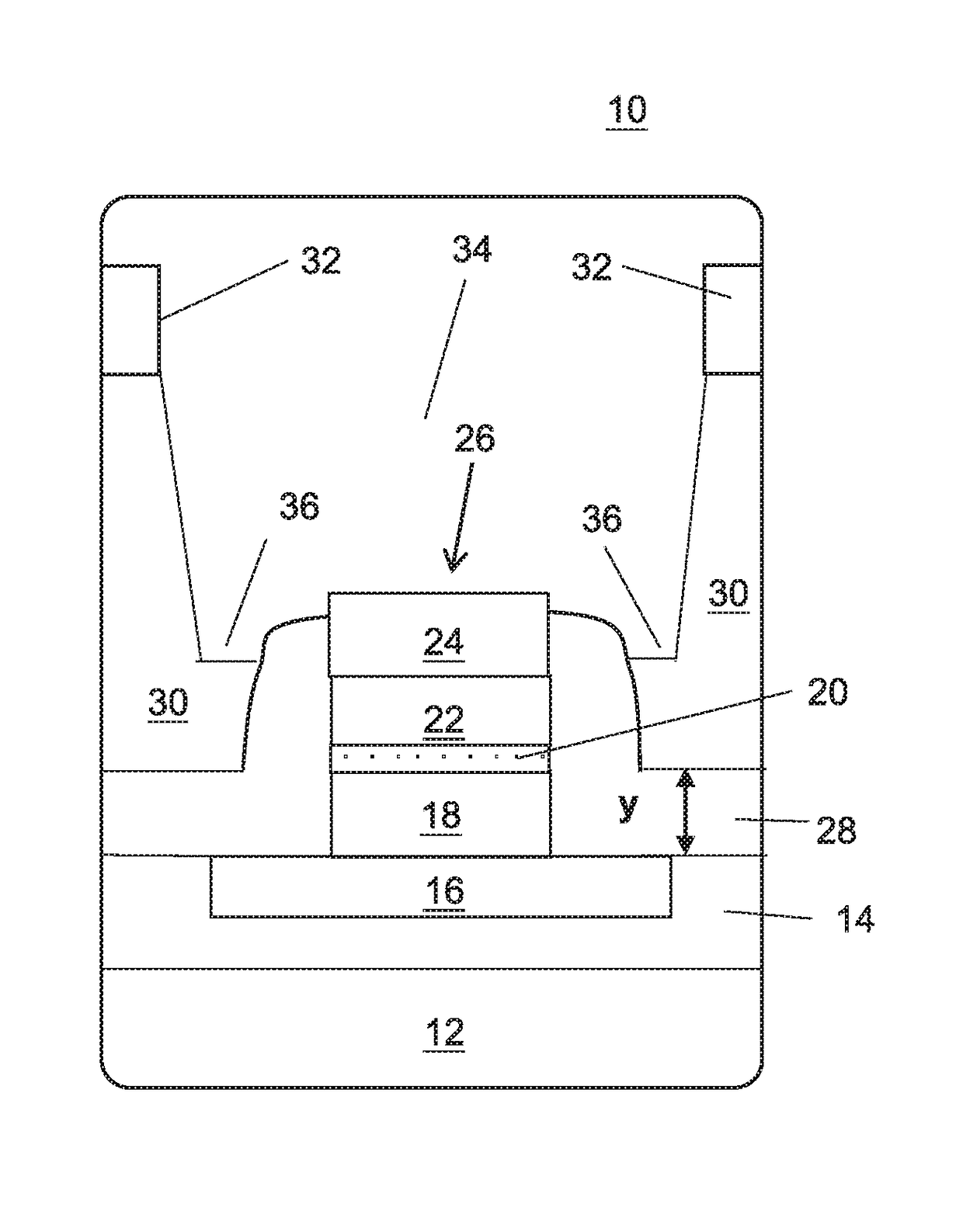

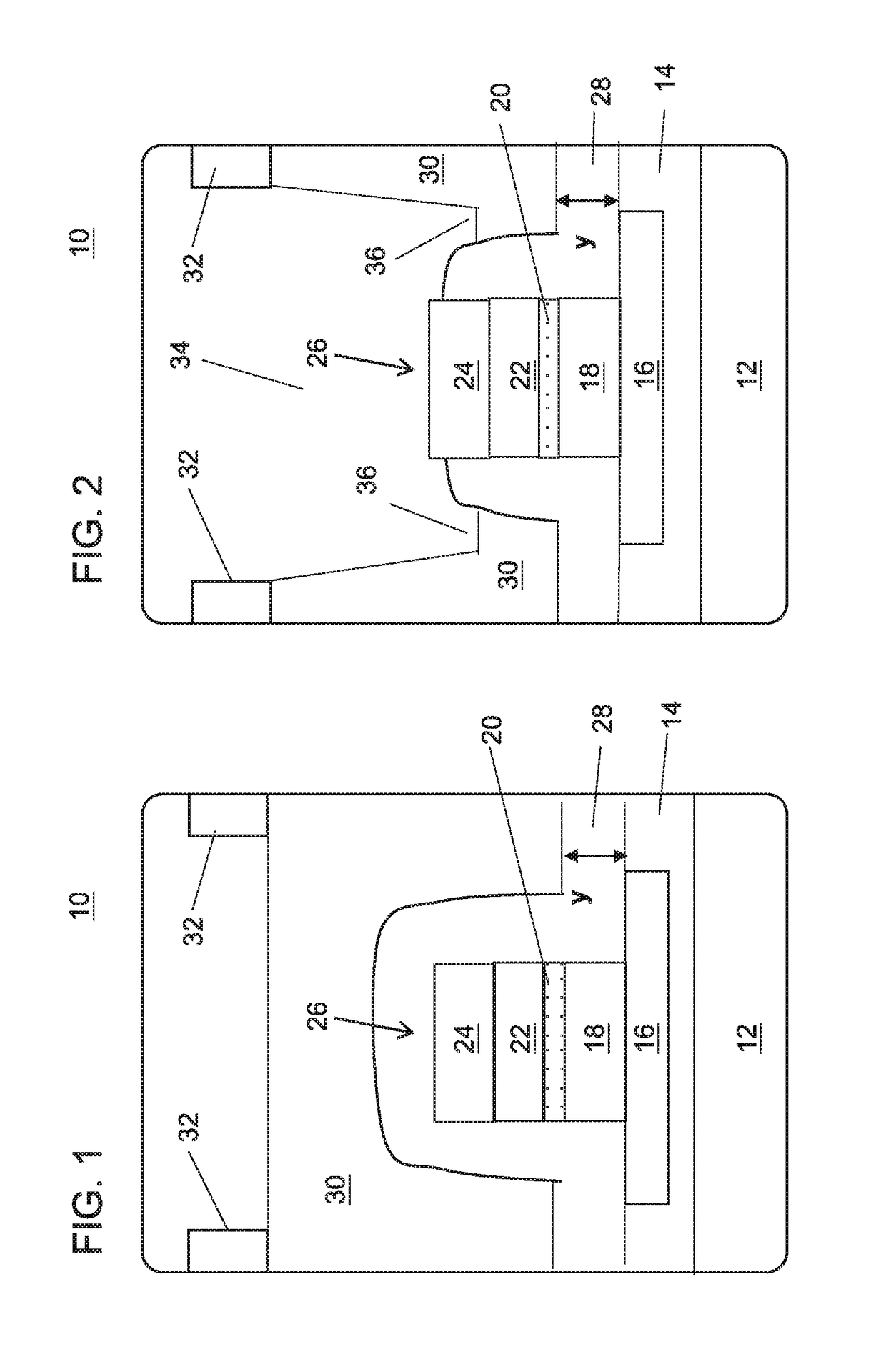

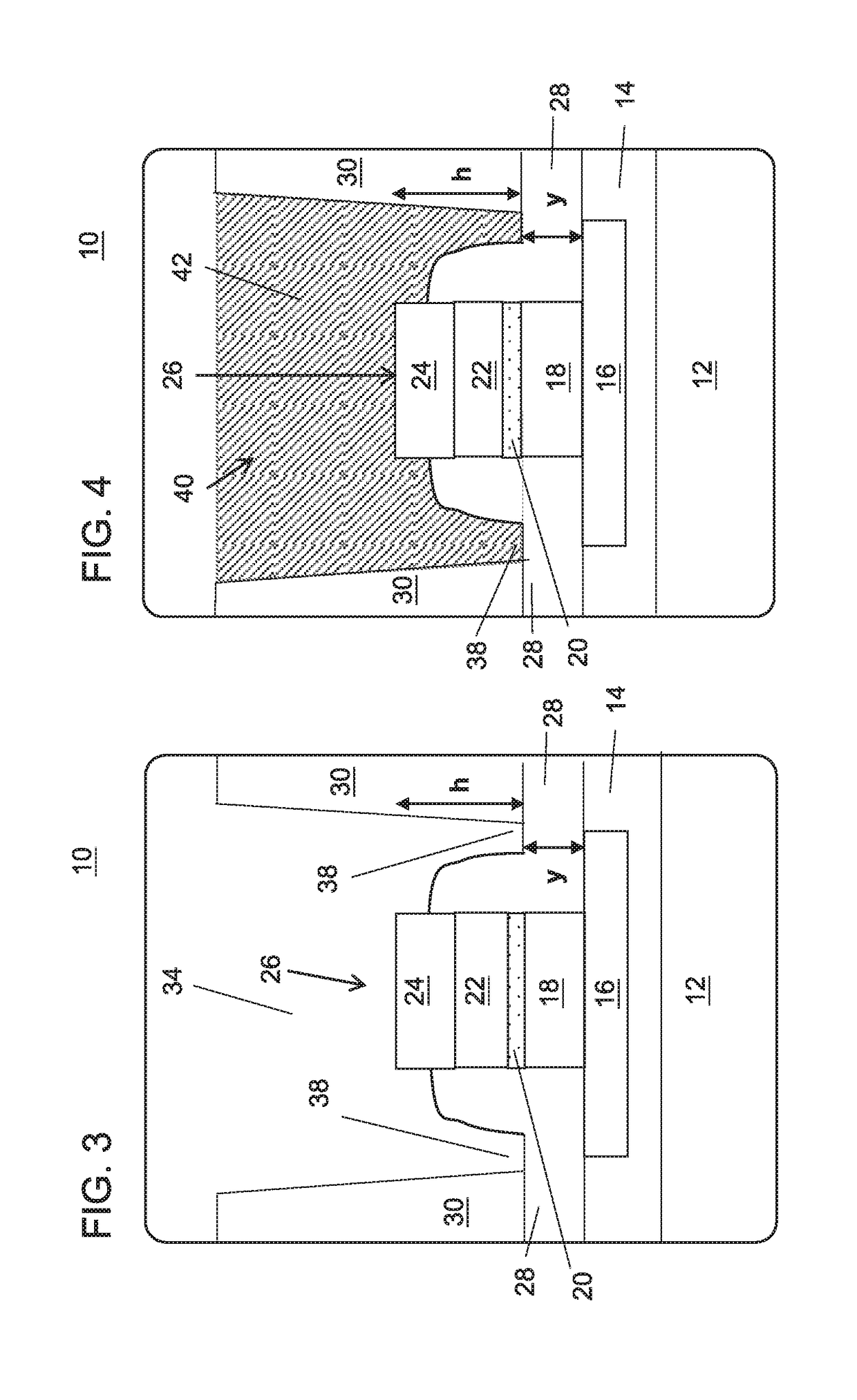

Enhanced coercivity in MTJ devices by contact depth control

A magnetic memory device includes a magnetic memory stack including a bottom electrode and having a hard mask formed thereon. An encapsulation layer is formed over sides of the magnetic memory stack and has a thickness adjacent to the sides formed on the bottom electrode. A dielectric material is formed over the encapsulation layer and is removed from over the hard mask and gapped apart from the encapsulation layer on the sides of the magnetic memory stack to form trenches between the dielectric material and the encapsulation layer at the sides of the magnetic memory stack. A top electrode is formed over the hard mask and in the trenches such that the top electrode is spaced apart from the bottom electrode by at least the thickness.

Owner:IBM CORP

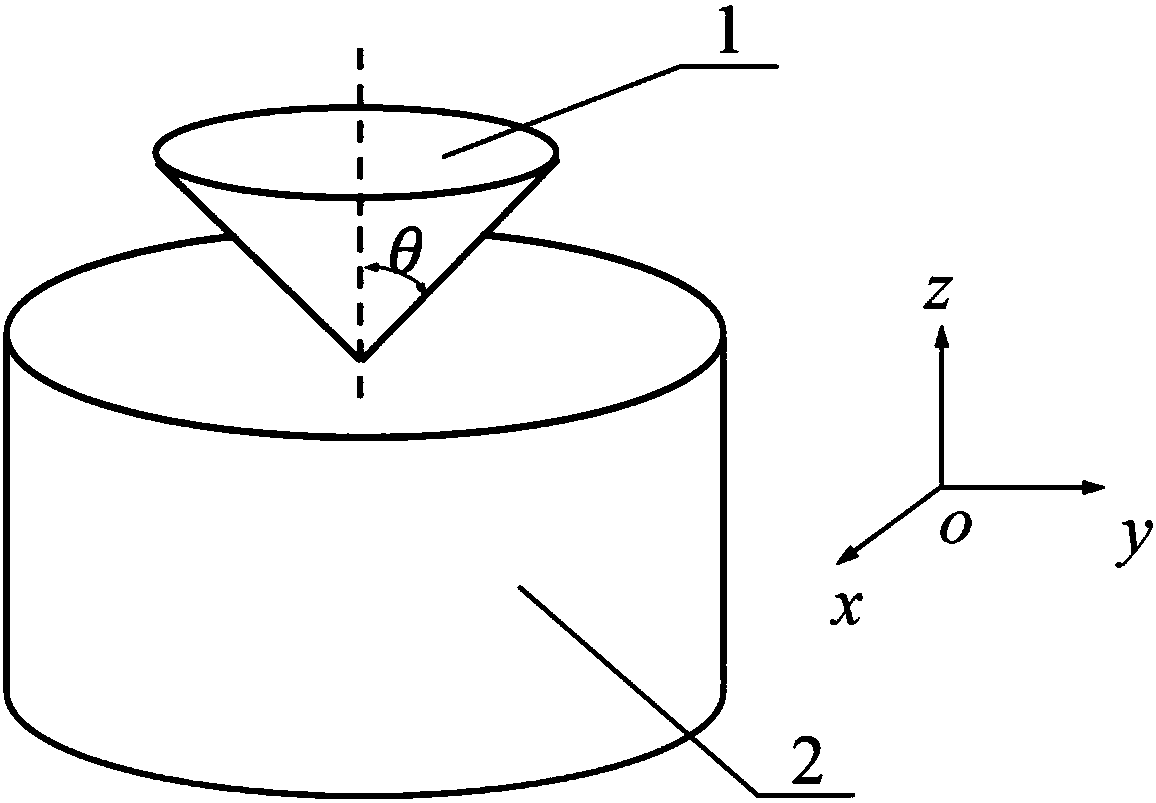

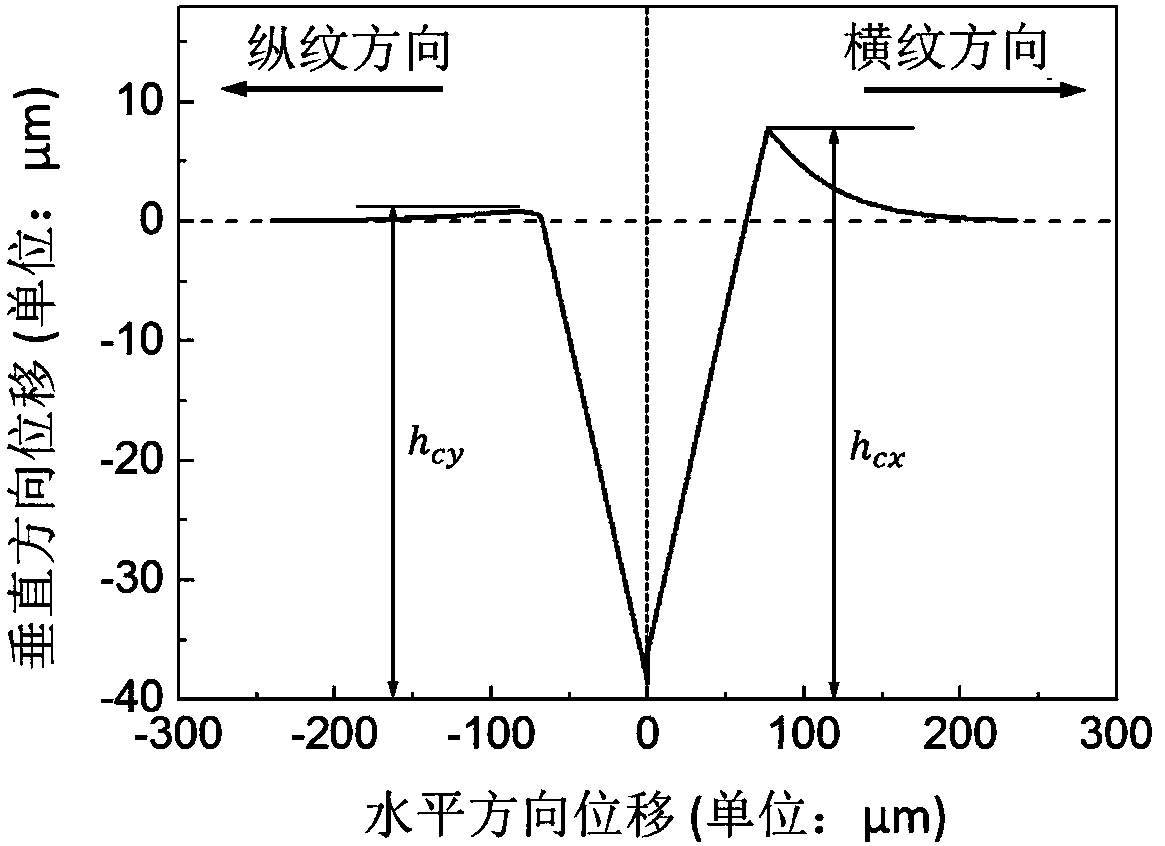

Method for identifying anisotropic plasticity parameters of plate based on single-cone indentation

ActiveCN107631949AConvenient experimentThe experimental results are accurateInvestigating material hardnessAnisotropic plasticityNumerical models

The invention discloses a method for identifying the anisotropic plasticity parameters of a plate based on single-cone indentation, used in the technical field of nondestructive testing and in-situ testing of anisotropic materials. The method comprises the following steps: establishing a numerical model for correlating the indentation response parameters and the plasticity parameters of an anisotropic material by using a dimensionless function; analyzing the material response of a single-cone indentation experiment to obtain the anisotropic plasticity parameters of a metal plate, and obtainingthe load-displacement relation curve of a test piece; testing the unloaded residual indentation morphology by a three-dimensional confocal microscopic device, and extracting the contact depth valuesof the residual indentation contour in two orthogonal directions of transverse and longitudinal lines of the tested material; and substituting the material response information extracted in the indentation experiment into the established dimensionless function model, and carrying out reverse calculation to obtain the anisotropic plastic parameters of the metal plate. The anisotropic plasticity mechanical parameters reversely calculated by the method are unique and have a high accuracy.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Enhanced coercivity in mtj devices by contact depth control

ActiveUS20170222130A1Magnetic-field-controlled resistorsGalvano-magnetic device detailsMagnetic memoryContact depth

A magnetic memory device includes a magnetic memory stack including a bottom electrode and having a hard mask formed thereon. An encapsulation layer is formed over sides of the magnetic memory stack and has a thickness adjacent to the sides formed on the bottom electrode. A dielectric material is formed over the encapsulation layer and is removed from over the hard mask and gapped apart from the encapsulation layer on the sides of the magnetic memory stack to form trenches between the dielectric material and the encapsulation layer at the sides of the magnetic memory stack. A top electrode is formed over the hard mask and in the trenches such that the top electrode is spaced apart from the bottom electrode by at least the thickness.

Owner:IBM CORP

Enhanced coercivity in mtj devices by contact depth control

ActiveUS20170222136A1Magnetic-field-controlled resistorsSolid-state devicesMagnetic memoryDielectric layer

A magnetic memory device includes a magnetic memory stack including a bottom electrode and having a hard mask formed thereon. An encapsulation layer is formed over sides of the magnetic memory stack and has a thickness adjacent to the sides formed on the bottom electrode. A dielectric material is formed over the encapsulation layer and is removed from over the hard mask and gapped apart from the encapsulation layer on the sides of the magnetic memory stack to form trenches between the dielectric material and the encapsulation layer at the sides of the magnetic memory stack. A top electrode is formed over the hard mask and in the trenches such that the top electrode is spaced apart from the bottom electrode by at least the thickness.

Owner:INT BUSINESS MASCH CORP

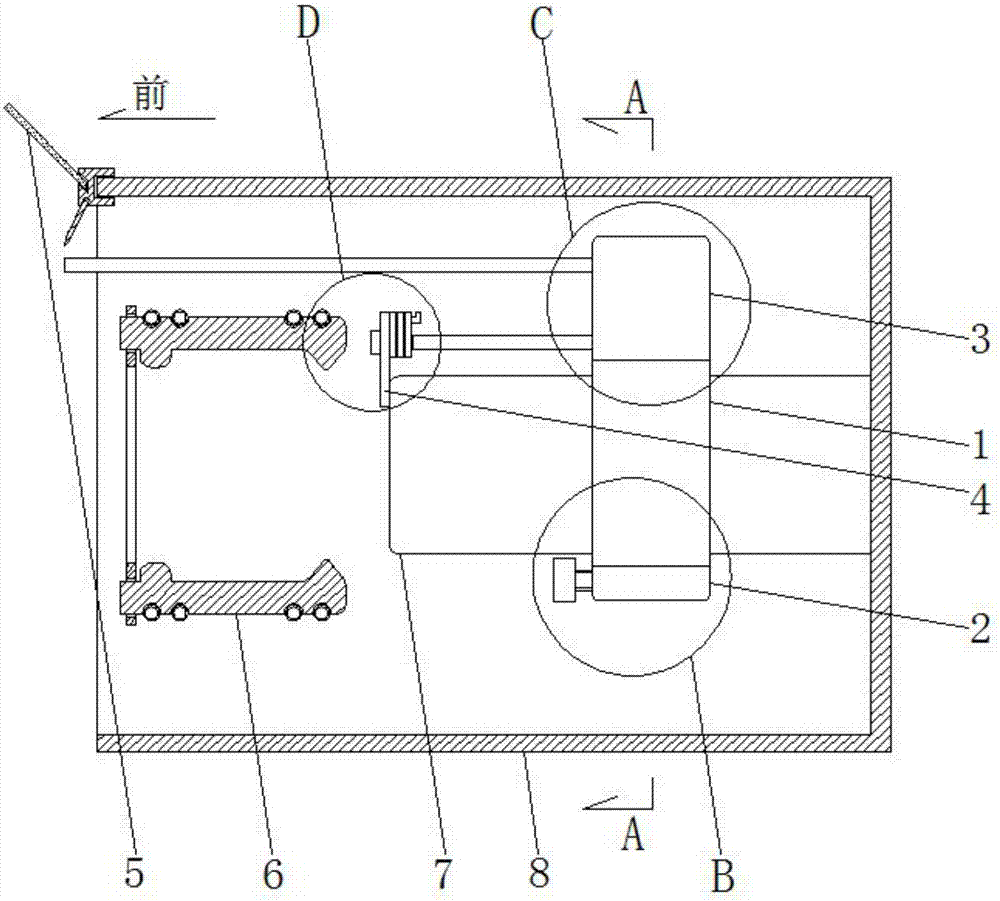

Wall cement mortar plastering and rendering machine

InactiveCN104110121AImprove work efficiencyReduce labor intensityBuilding constructionsCement mortarContact depth

Disclosed is a wall cement mortar plastering and rendering machine. By means of the air pressure energy in an air pump, the impact force can be formed onto the cement mortar in a tube, the cement mortar is sprayed to a wall, a rotary trowel is driven by a motor to rotate, the contacting depth of rotary wings contacting with the surface of the cement mortar is grasped when the rotary trowel contacts with the wall cement mortar under the manual external force, and the surface of the wall cement mortar is floated and compacted to form a plane. The wall cement mortar plastering and rendering machine is a novel one.

Owner:程海 +1

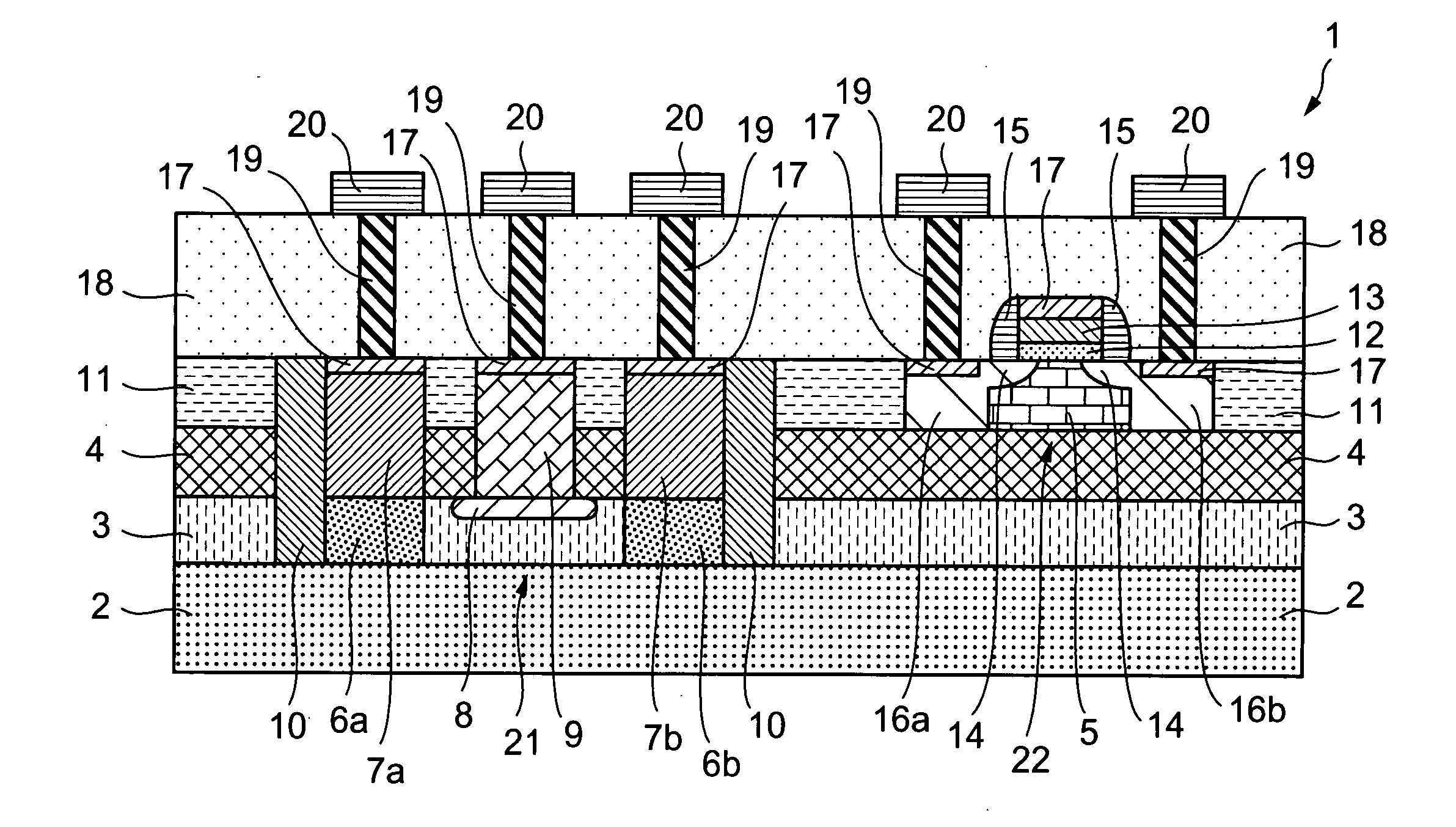

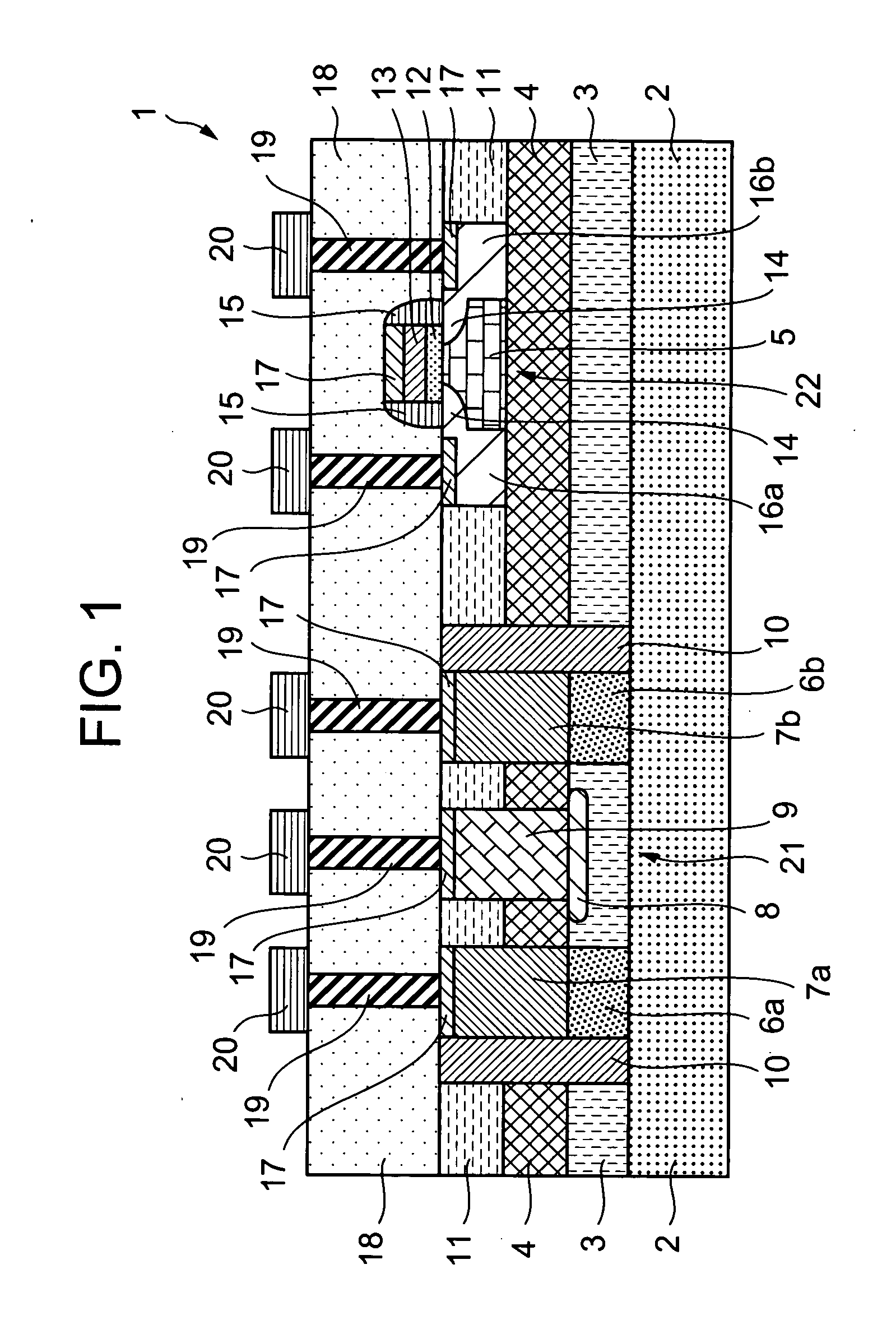

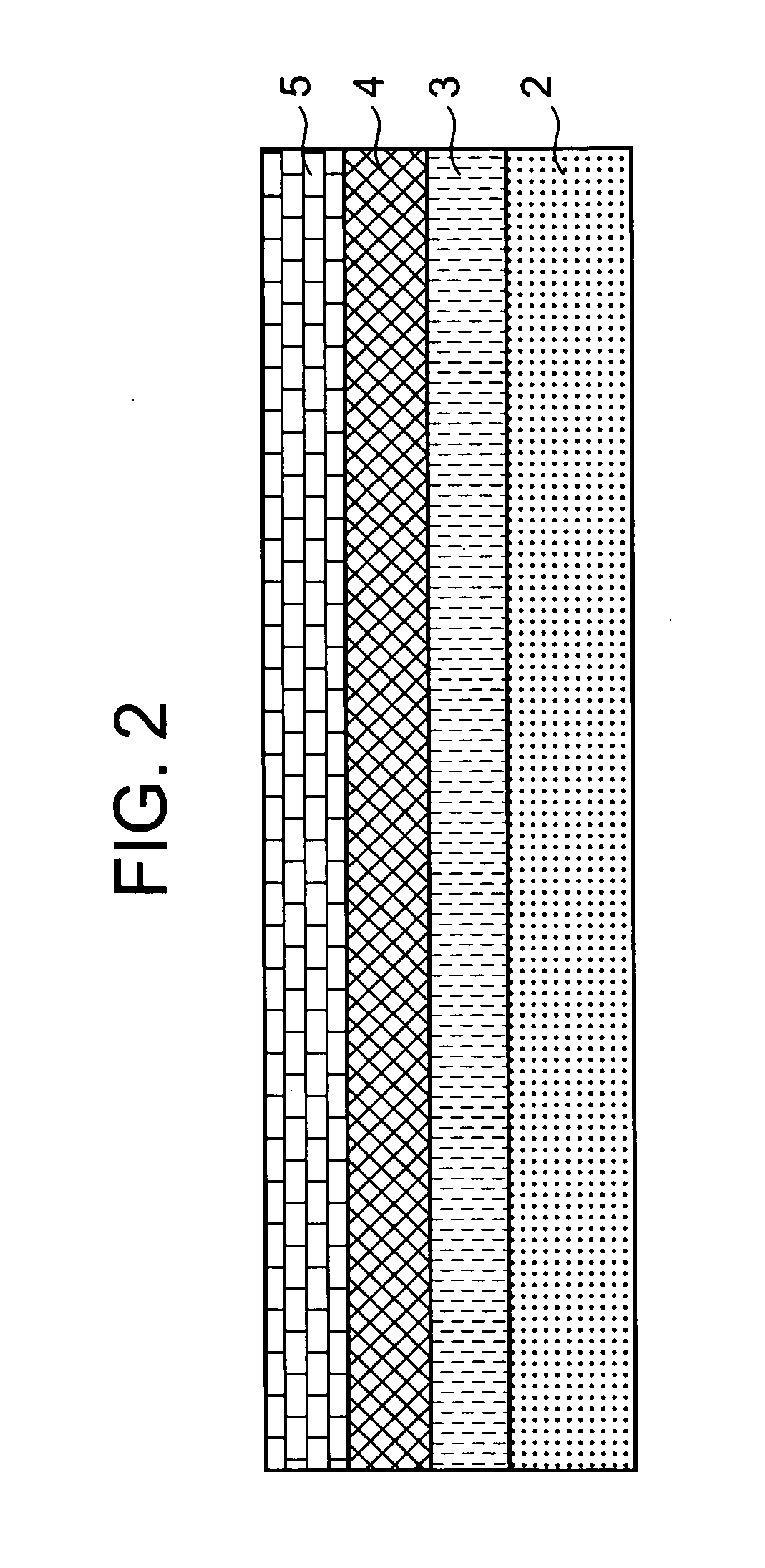

Integrated circuit and corresponding manufacturing method

The present invention provides an integrated circuit including a field effect transistor formed in an active area segment of a semiconductor substrate, the transistor comprising:a first and a second source / drain contact region; anda channel region arranged in a groove formed in the active area segment and extending to a groove depth larger than a lower first contact depth,wherein the second source / drain contact region is arranged at a vertical extension above the extension of the first source / drain contact region and a corresponding manufacturing method.

Owner:POLARIS INNOVATIONS LTD

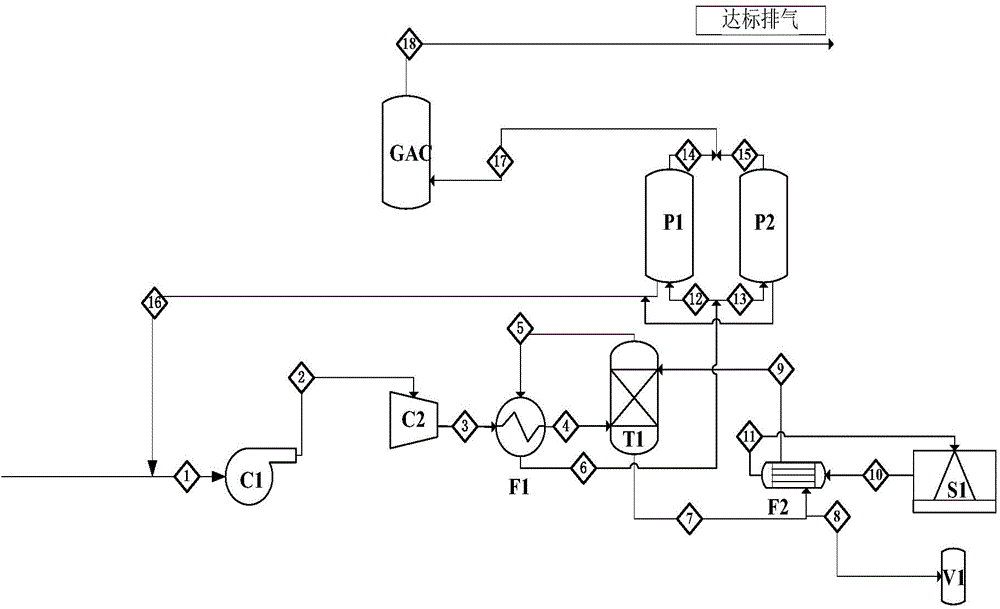

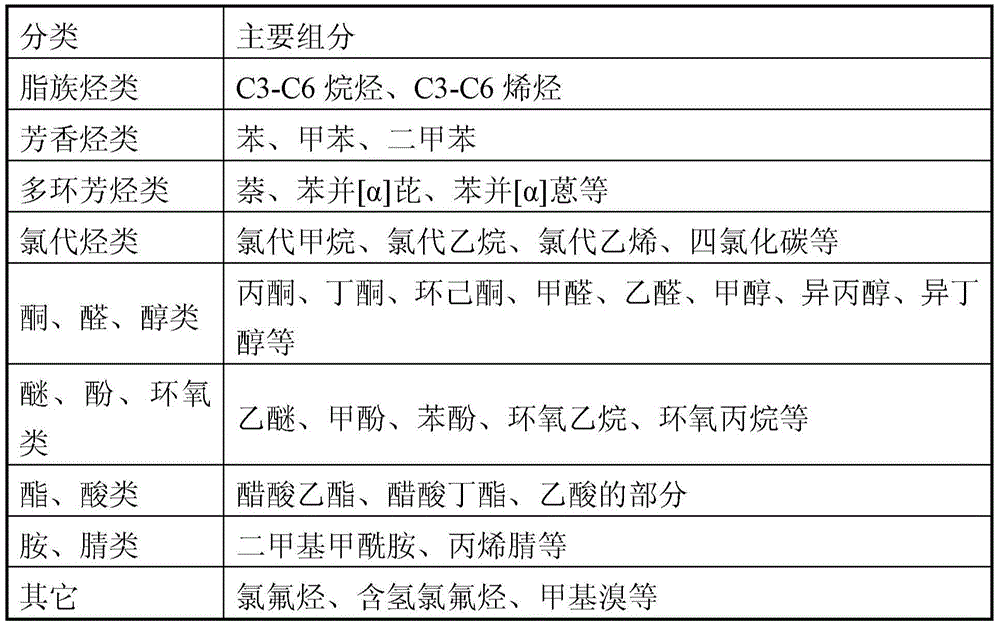

Method and equipment for processing exhaust gases of volatile organic compounds

InactiveCN104436980AFlexible assemblyReduce heat transfer areaDispersed particle separationLiquid wasteCondensation process

The invention provides a method and equipment for processing exhaust gases of volatile organic compounds. In the method, the processes of compression-direct cooling-adsorption are integrated, and the method can be used for processing exhaust gases, with a plurality of concentrations, of the volatile organic compounds. According to the method, a direct-contact depth cooling device adopting gas-liquid direct contact is adopted in the direct cooling condensation process; and cooling liquid waste is utilized as refrigerant liquid, so that the cost is reduced, and the efficiency is improved.

Owner:TIANJIN UNIV +1

Rainwater monitoring device arranged on roof

ActiveCN106483263ARealize acquisitionRealize automatic dischargeTesting waterWater qualityEngineering

The invention discloses a rainwater monitoring device arranged on roof. The rainwater monitoring device comprises a water quality detection platform, water quality detection heads, a plurality of signal receiving emitters and a support; the water quality detection platform is provided with a chamber structure inside, and a plurality of diversion grooves with tilt angles are arranged equidistantly on the outer periphery of the water quality detection platform and around the center of the same; a height adjustment mechanisms are arranged inside the diversion grooves, the water quality detection heads are mounted on the height adjustment mechanisms, and the height adjustment mechanisms can make probes of the water quality detection heads and rainwater to change in contact depth; the signal receiving emitters are equidistantly arranged on the upper end face of the water quality detection platform. The diversion grooves are arranged on the outer side of the water quality detection platform, automatic discharge of the rainwater is realized, influence of substances accumulated in the water quality detection platform in the long term is further reduced, and accuracy in detection data is improved; meanwhile, a protective sleeve is arranged on the outer side of each water quality detection head, damage of the water quality detection heads is avoided, and service life of the water quality detection heads is prolonged.

Owner:宝应县振新农业发展有限公司

Semiconductor device and manufacturing method therefor

InactiveUS20050139907A1Increase freedomEasy to controlTransistorSolid-state devicesResistDevice material

The present invention provides a semiconductor device that permits free setting of characteristics of individual semiconductor elements which are mixedly mounted and have different characteristics, and is free of steps between formed semiconductor elements, and a manufacturing method for the same. In the semiconductor device, an n-type silicon layer is deposited on a p-type silicon substrate by epitaxial growth, and then an SOI layer is deposited thereon through the intermediary of a BOX layer. A junction transistor using a part of the n-type silicon layer as a channel region and a MOS transistor using the SOI layer are produced. The semiconductor device ensures uniform resist, control of contact depths, wire processability, etc., making the semiconductor device ideally suited for microminiaturization.

Owner:LAPIS SEMICON CO LTD

Wheel leg traction type flat curtain cleaning robot

InactiveCN100382933CEfficient and reliable automatic cleaningAdjust posture in real timeCarpet cleanersFloor cleanersEngineeringWindlass

Owner:SHANGHAI JIAOTONG UNIV

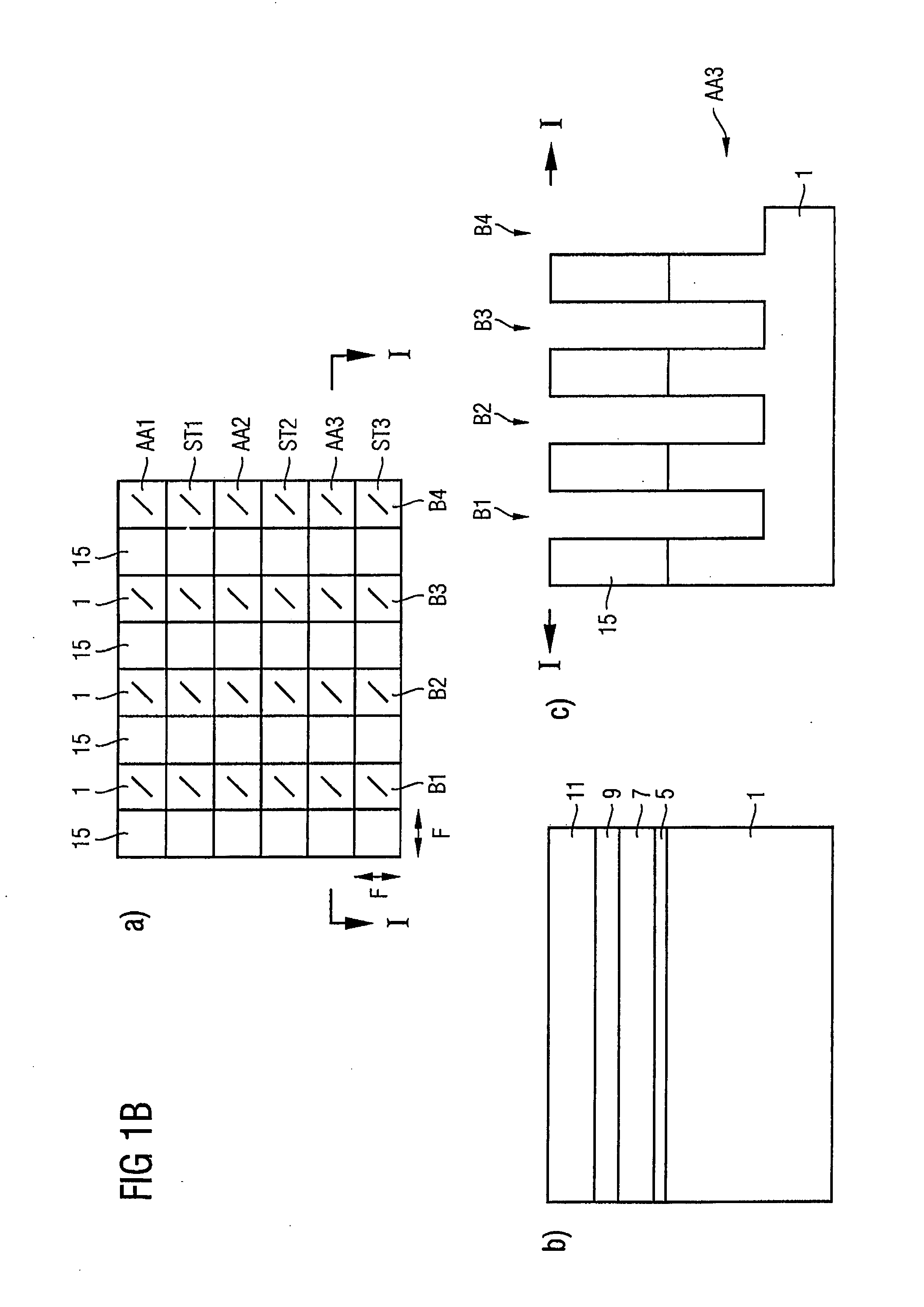

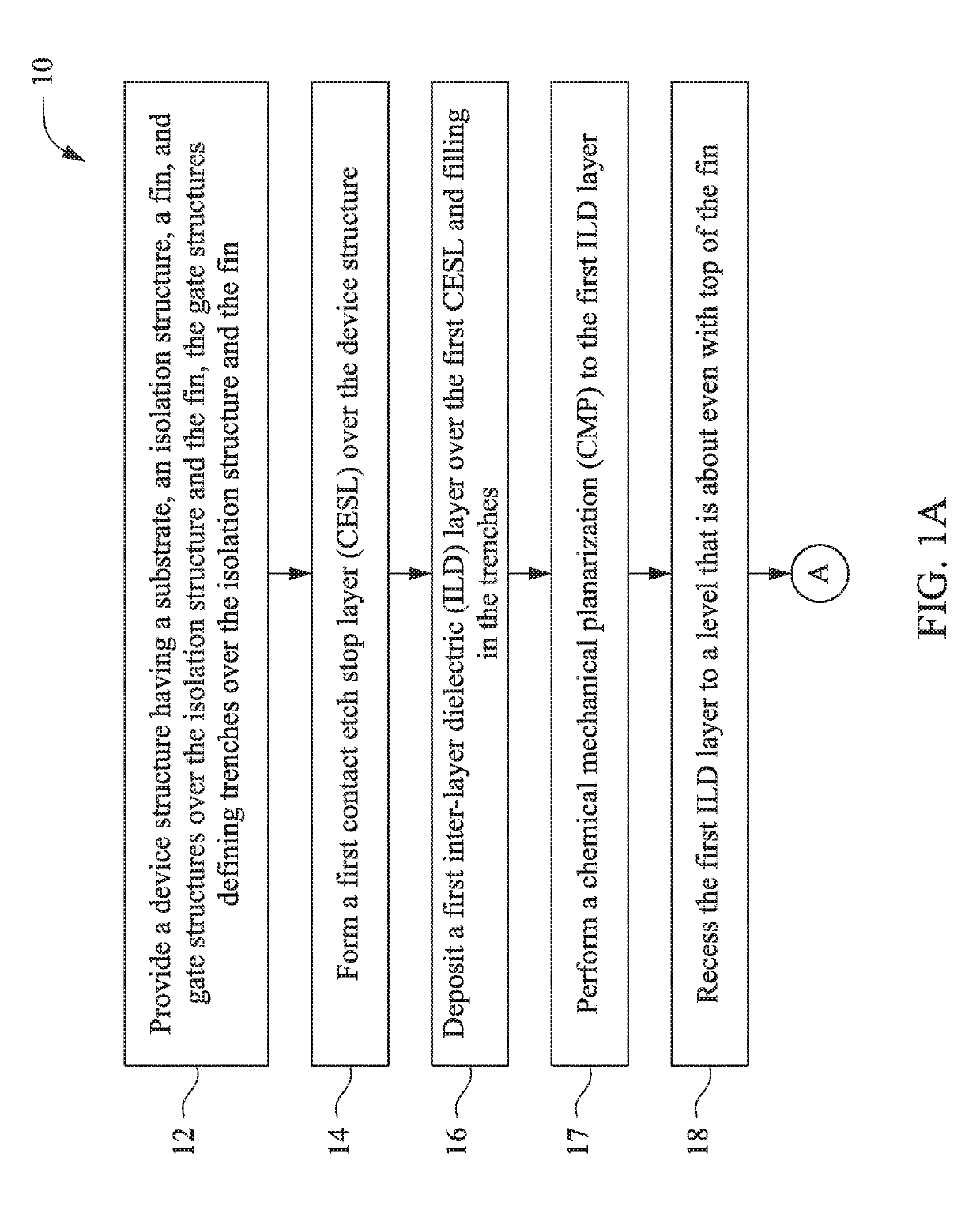

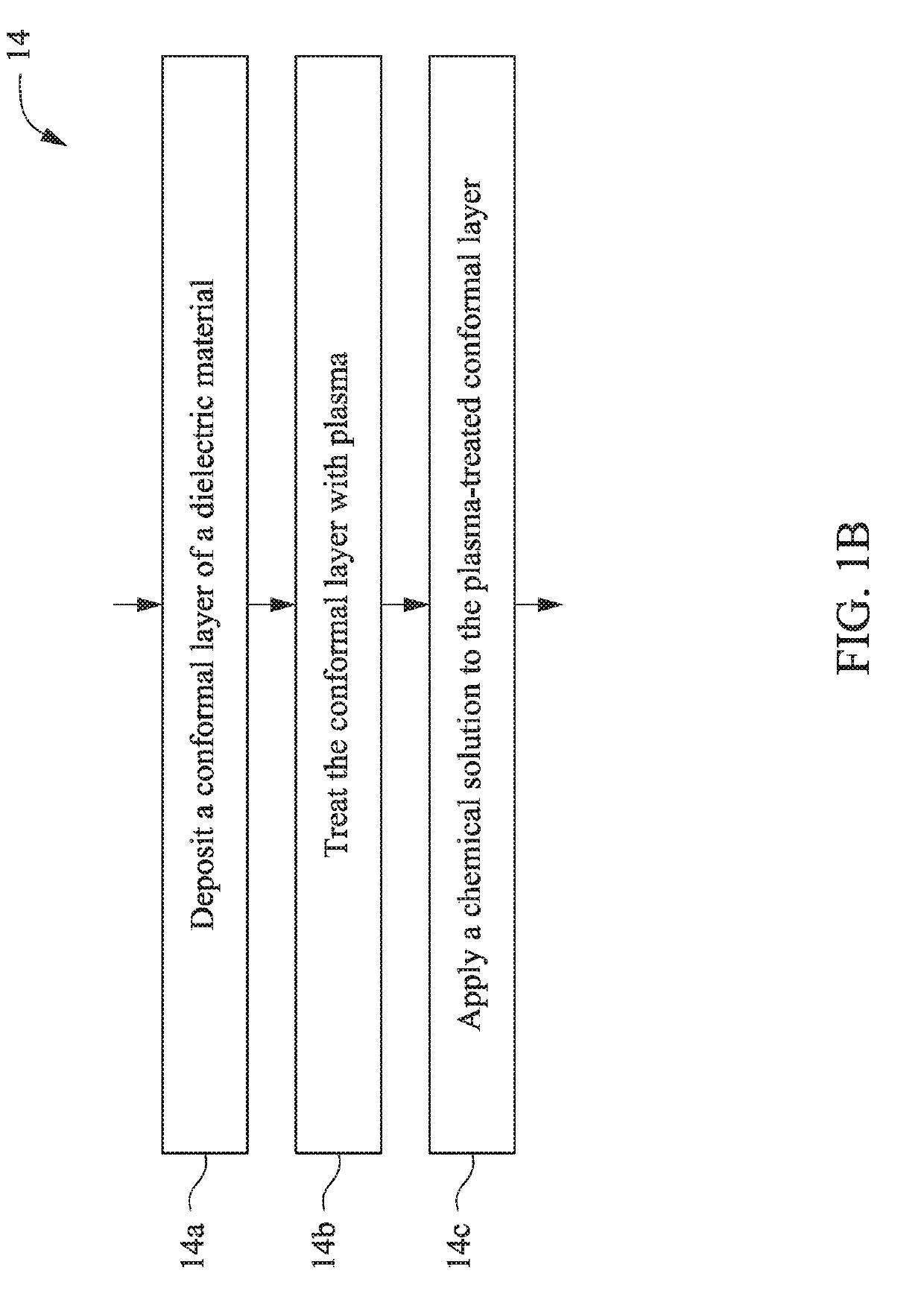

Methods for Reducing Contact Depth Variation in Semiconductor Fabrication

ActiveUS20190096760A1Semiconductor/solid-state device detailsSolid-state devicesDielectricInter layer

A method includes providing a device structure having an isolation structure, a fin adjacent the isolation structure and taller than the isolation structure, and gate structures over the fin and the isolation structure. The isolation structure, the fin, and the gate structures define a first trench over the fin and a second trench over the isolation structure. The method further includes forming a first contact etch stop layer (CESL) over the gate structures, the fin, and the isolation structure; depositing a first inter-layer dielectric (ILD) layer over the first CESL and filling in the first and second trenches; and recessing the first ILD layer such that the first ILD layer in the first trench is removed and the first ILD layer in the second trench is recessed to a level that is about even with a top surface of the fin.

Owner:TAIWAN SEMICON MFG CO LTD

Scab grinding device

The invention relates to a scab grinding device. The scab grinding device consists of an outer shell, a power supply, a water bag, a motor, a connecting mechanism, a protection cover and a scab grinding sand tray. The scab grinding device has the advantages that the scab grinding device is provided with the adjustable protection cover, so that the scab grinding depth can be controlled. The scab grinding device can be powered on or off according to the contact depth between the scab grinding sand tray and the skin of a patient. By arranging the water bag and a water outlet passage, when the scab grinding sand tray begins to work, a switch of the water outlet passage is switched on, and the water outlet volume is controlled by adjusting a grip of the scab grinding device by virtue of a holding force. The outer shell is provided with scales, so that a water level in the water bag can be observed.

Owner:SECOND MILITARY MEDICAL UNIV OF THE PEOPLES LIBERATION ARMY

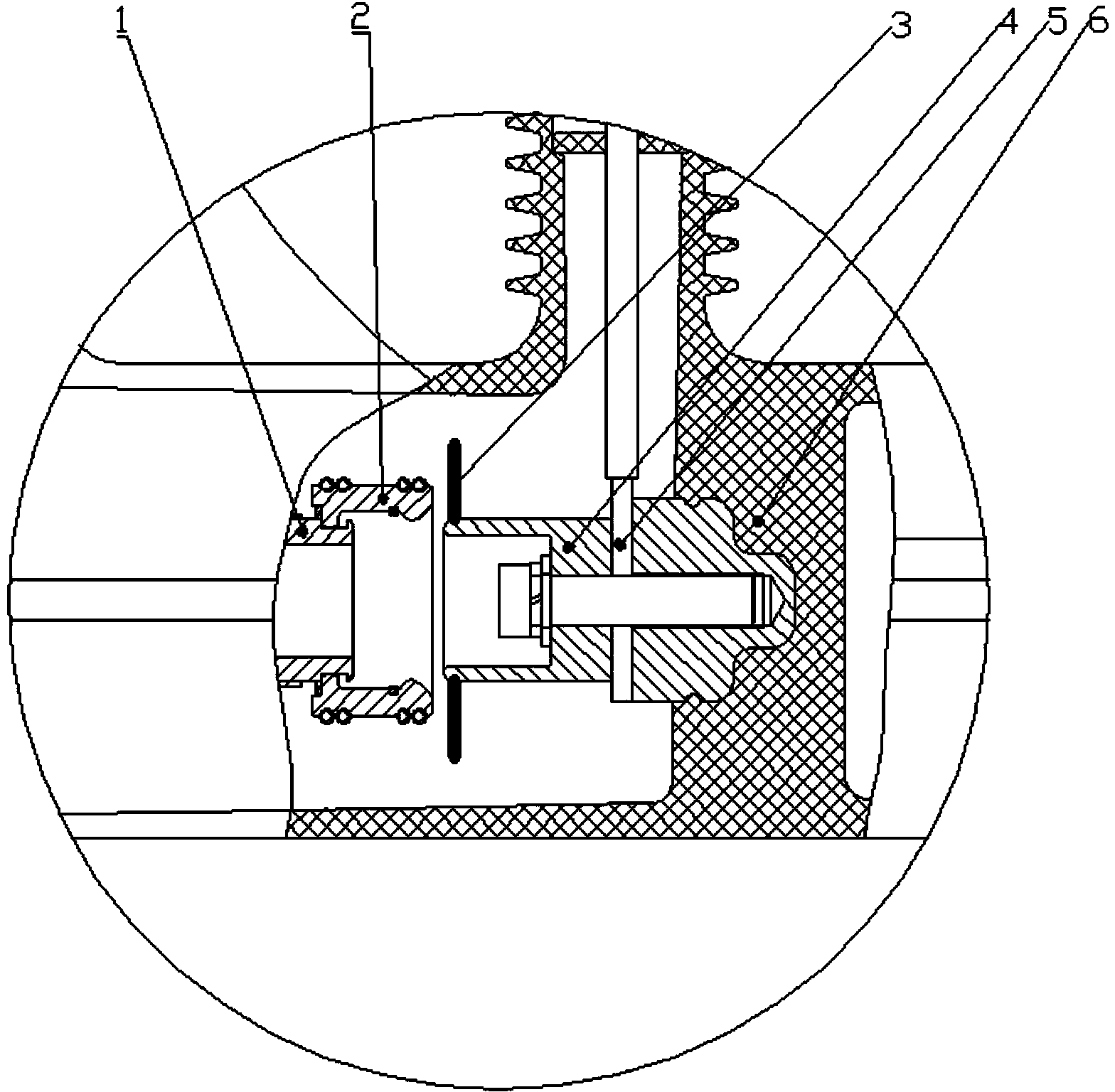

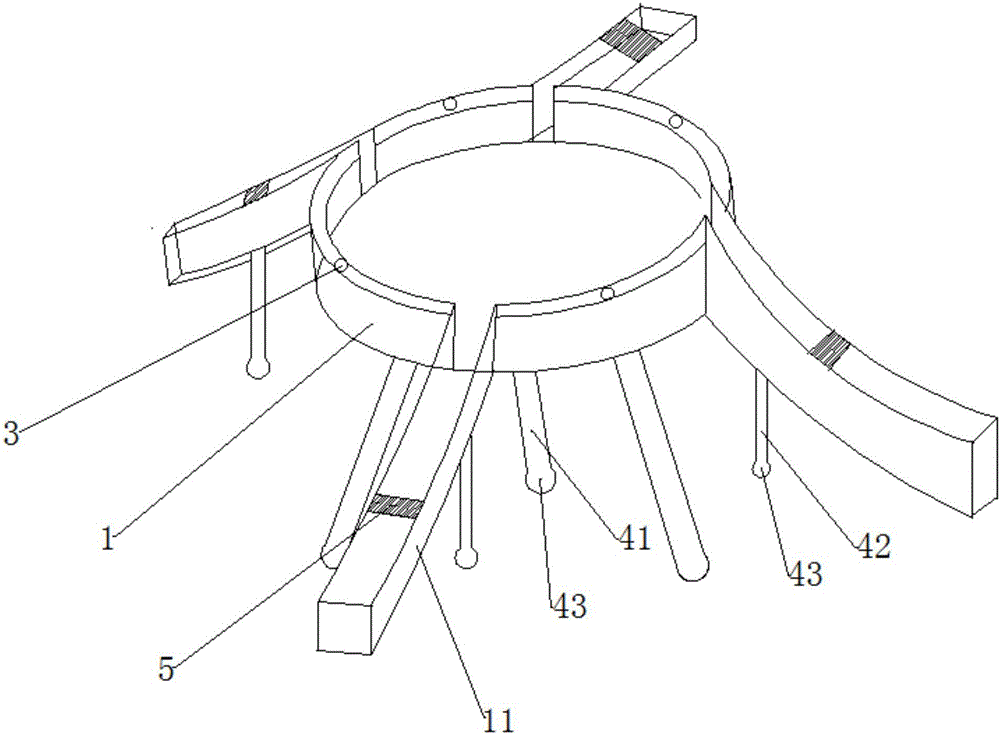

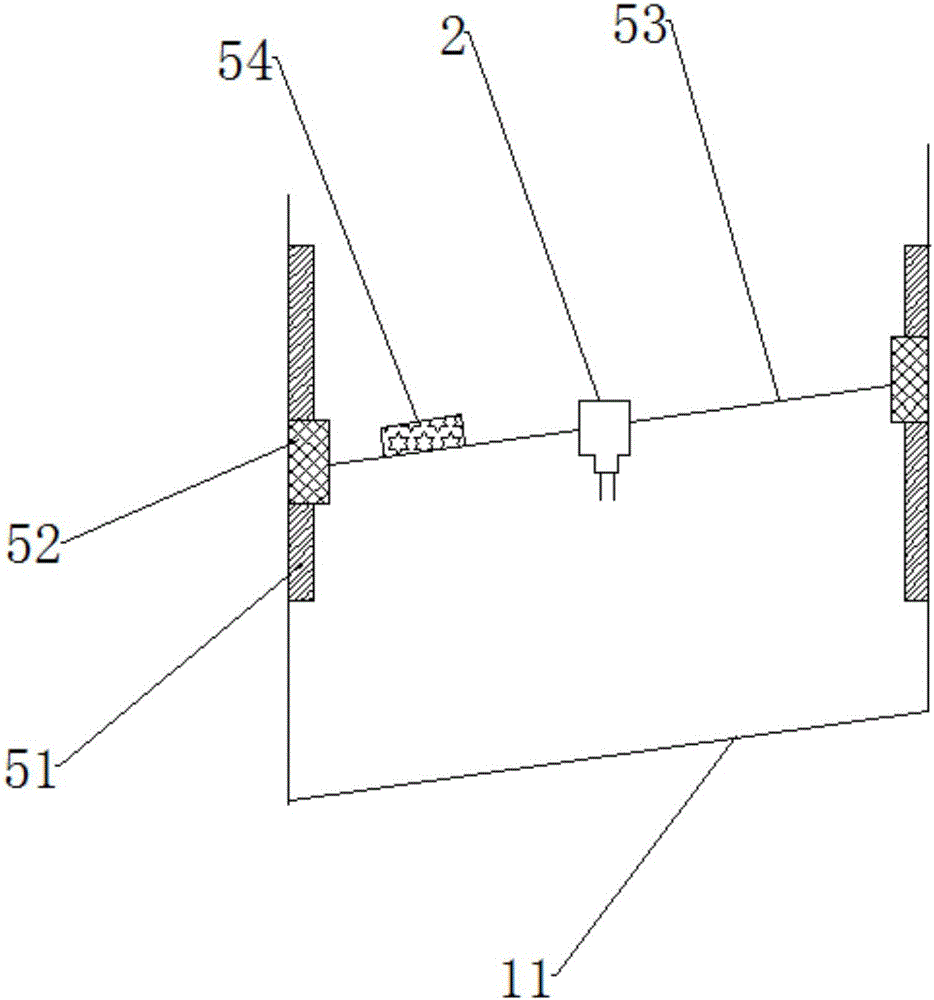

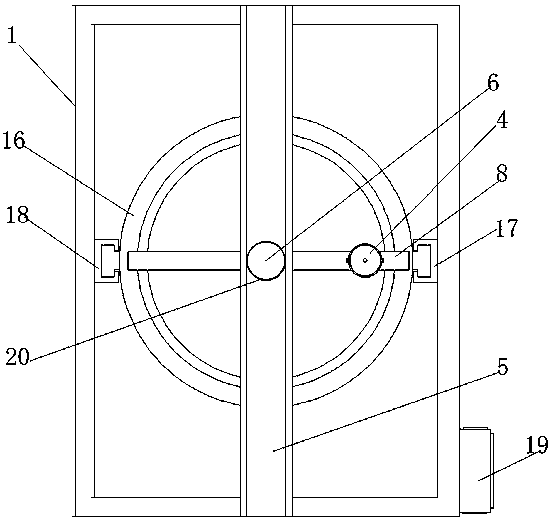

Device and method for measuring contact depth of moving and static contacts of switchgear

InactiveCN106839942BEasy to installReal-time reading of contact depthMechanical depth measurementsEngineeringContact position

The invention discloses a device for measuring the contact depth of switch cabinet movable and static contacts. The device comprises a fixed ring and further comprises a locking device, a reference adjusting device and a reading device. The invention further discloses a method for measuring the contact depth of the switch cabinet movable and static contacts. The method includes the steps that firstly, the device for measuring the contact depth of the switch cabinet movable and static contacts is taken out and installed; secondly, a reading is measured, wherein the first step includes the substeps that the reference adjusting device is installed in advance, the fixed ring is installed and fixed, the reference adjusting device is detached, and the reading device is installed; the second step includes the substeps that the movable contact is pushed to a critical contact position, and the contact depth of the movable and static contacts is read. The device for measuring the contact depth of the switch cabinet movable and static contacts has the advantage of being convenient to install, and the method for measuring the contact depth of the switch cabinet movable and static contacts has the advantages that the contact depth of the movable and static contacts is read in real time and operation is quick and stable.

Owner:国网山东省电力公司乳山市供电公司

Sewage station sewage temperature rise device

InactiveCN108545796AMonitor temperature in real timeIncrease heating rateWater treatment parameter controlTransportation and packagingFixed frameEngineering

The invention discloses a sewage station sewage temperature rise device, which comprises a sewage pool, wherein the whole of the sewage pool is in a cuboid structure; in addition, a first C-shaped rail and a second C-shaped rail are respectively welded to the inner walls of the two opposite sides of the sewage pool; a T-shaped slide block is glidingly connected into each of the slide grooves of the first C-shaped rail and the second C-shaped rail; in addition, the same tapered roller bearing is welded between the outer walls of the two T-shaped slide blocks; an arch-shaped support fixing rod is fixed on the upper surface of the outer ring of the tapered roller bearing through a screw bolt; a fixed clamp ring is welded in the middle of the arch-shaped support fixing rod; a fixing frame is fixed on the upper surface of one end, near the first C-shaped rail, of the arch-shaped fixing rod through a screw bolt; a driving motor is clamped and connected with the middle of the fixing frame. The temperature of sewage to be heated can be monitored in real time, so that the contact depth of sewage and a heat conduction pipe and the heating gear of an electric heater can be regulated accordingto the requirements so as to accelerate the heating speed.

Owner:徐剑霞

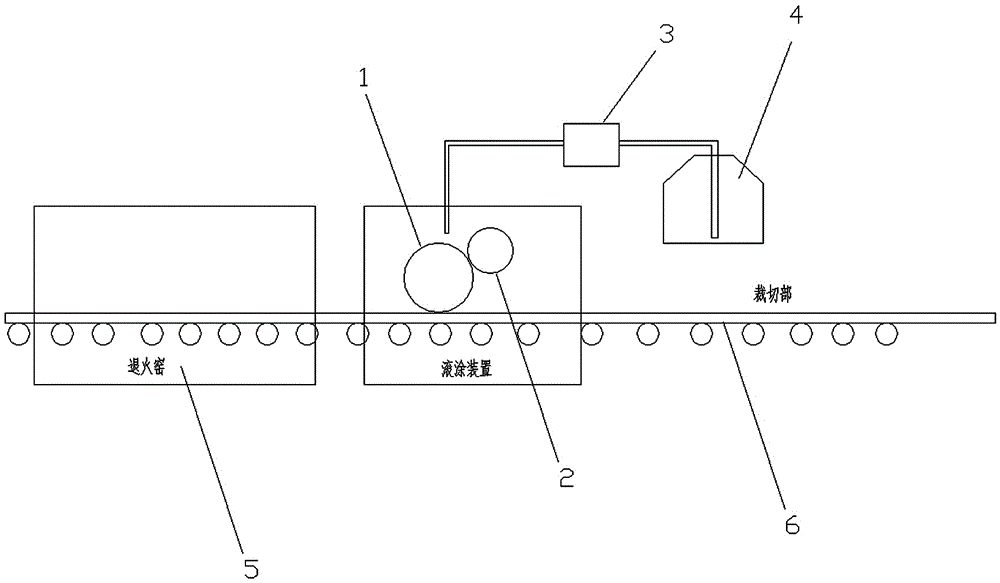

A method for online roll coating of anti-ultraviolet coated glass

The invention relates to a method for roll-painting anti-ultraviolet coated glass online. The method comprises the steps of mounting roll-painting equipment with a coating rubber roller (1), an electric carving stick (2) and a slurry tank (4) between an annealing kiln (5) and a cold-end cutting part (6) of a glass production line, and filling the slurry tank with a sol solution which comprises the following raw materials in percentage by weight: 0.1-3 percent of nano silicon dioxide, 0.5-5 percent of nano titanium dioxide, 0.1-1 percent of nano ferric oxide and the balance being organic solvent, wherein the length of the coating rubber roller is consistent with the width of a glass plate; adjusting the contact depth of the bottommost end of the coating rubber roller and the upper surface of the glass to be 0.1-1mm and the moving speed of a glass substrate to be 9m / min, roll-painting the surface of the float glass at the temperature of 50-100 DEG C with coating slurry, and performing cooling and curing on a film layer under the normal temperature. The method has the advantages of simple technology, stability, reliability, uniform film layer, low cost, high efficiency, suitability for large-scale continuous production, and the like.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Connecting rod experimental device for simulating rotor rub-impact faults

Owner:HARBIN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com