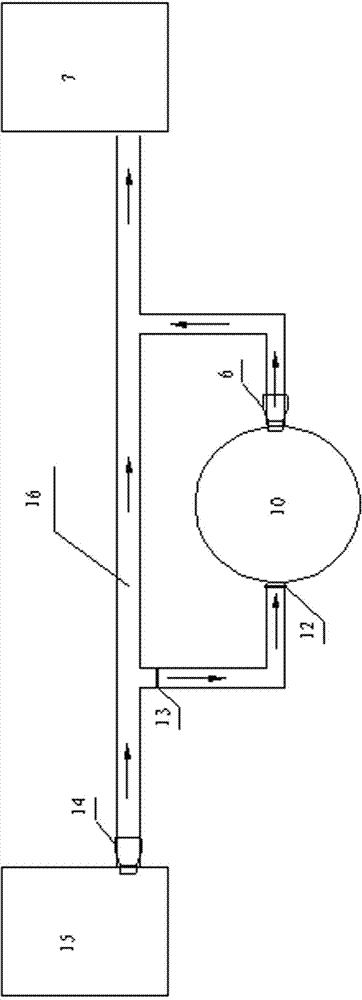

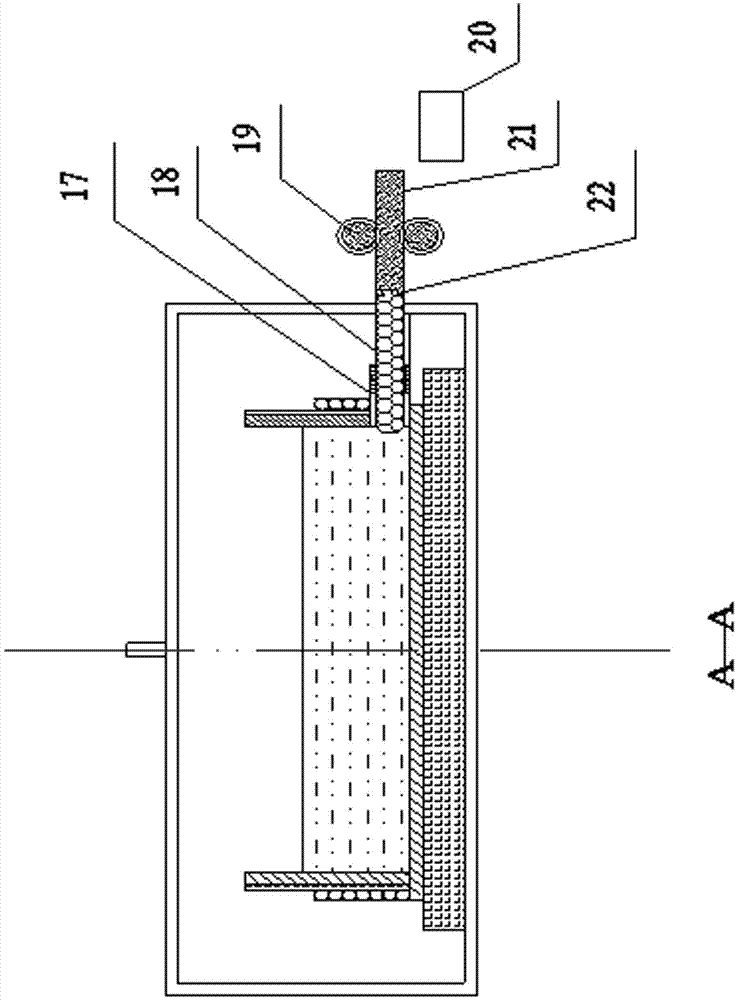

Method and device for purifying refined aluminum and high-purity aluminum through continuous segregation

A high-purity, segregation technology, applied in the field of foundry metallurgy, can solve the problems of inconspicuous purification effect, unstable environmental conditions, and difficult manipulation, so as to avoid impurity accumulation layer, ensure relative stability, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: 99.85Al is melted in the static furnace, and the temperature of the molten aluminum flowing out of the static furnace is 700°C. The temperature of the molten aluminum in the crucible is controlled so that the temperature of the molten aluminum at the crystallizer is controlled within the range of 710°C, and the temperature of the crystallizer is controlled. The cooling speed ensures that the solidification interface of the aluminum liquid is at the entrance of the crystallizer, and then the crystal is drawn at a rate of 200mm / h. After the aluminum crystal grows to a certain length, it is cut and tested. The purity of aluminum can reach 99.95Al.

Embodiment 2

[0037] Example 2: 99.85Al is melted in the static furnace, and the temperature of the molten aluminum flowing out of the static furnace is 695°C. The temperature of the molten aluminum in the crucible is controlled so that the temperature of the molten aluminum at the crystallizer is controlled within the range of 678°C, and the temperature of the crystallizer is controlled. The cooling speed ensures that the liquid aluminum solidification interface is at the entrance of the crystallizer, and then the crystal is drawn at a rate of 100mm / h. After the aluminum crystal grows to a certain length, it is cut and tested. The purity of aluminum can reach 99.98Al.

Embodiment 3

[0038] Example 3: 99.85Al is melted in the static furnace, and the temperature of the molten aluminum flowing out of the static furnace is 695°C. The temperature of the molten aluminum in the crucible is controlled so that the temperature of the molten aluminum at the crystallizer is controlled within the range of 670°C, and the temperature of the crystallizer is controlled. The cooling speed ensures that the liquid aluminum solidification interface is at the entrance of the crystallizer, and then the crystal is pulled at a rate of 10mm / h. After the aluminum crystal grows to a certain length, it is cut and tested. The purity of aluminum can reach 99.995Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com