Lubricating oil composition and use thereof

A lubricating oil composition and the technology of the composition are applied in the directions of lubricating composition, petroleum industry, etc., can solve the problems of environmental impact, difficult to guarantee use safety, etc., and achieve the effects of good cooling performance, safety guarantee, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

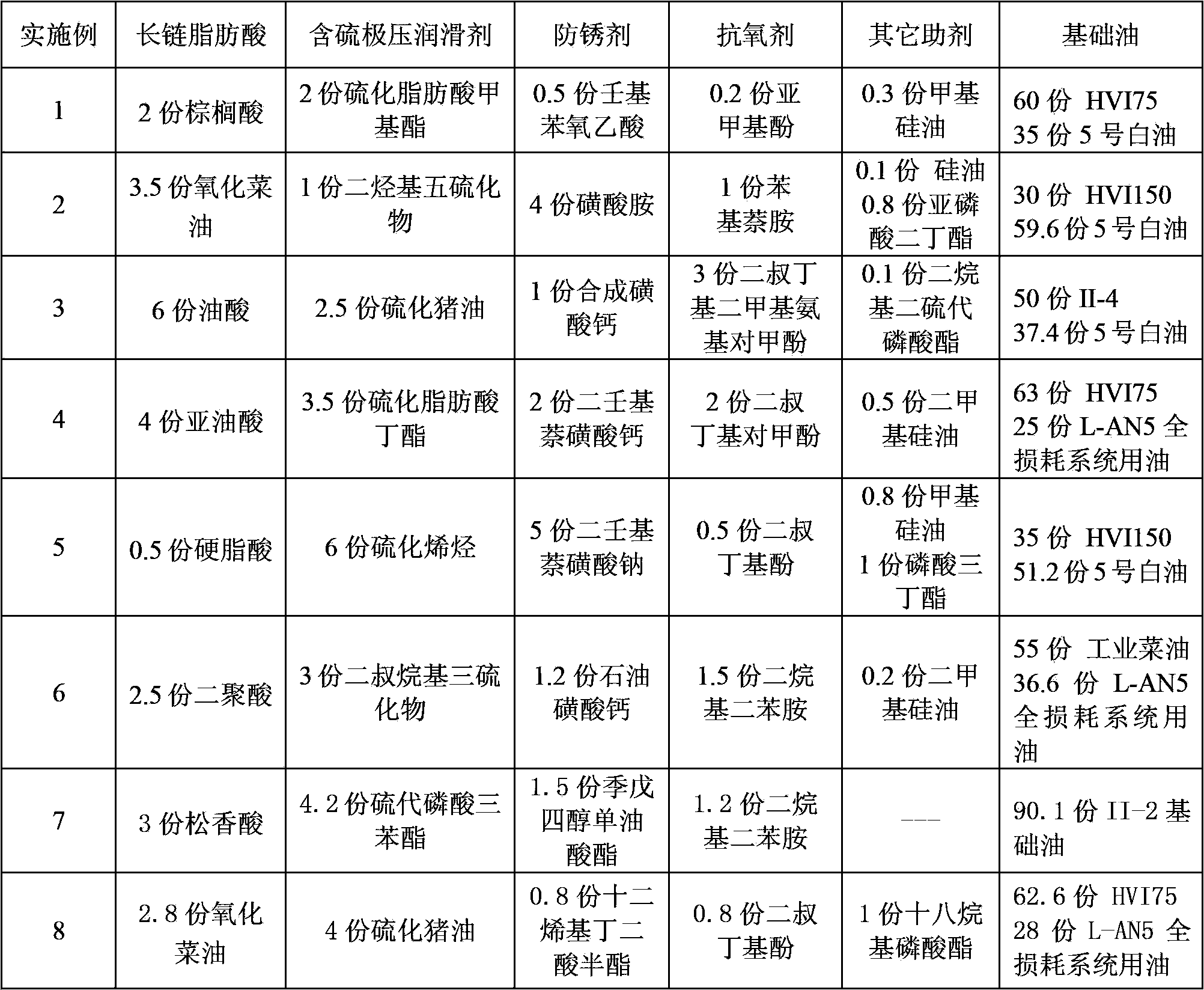

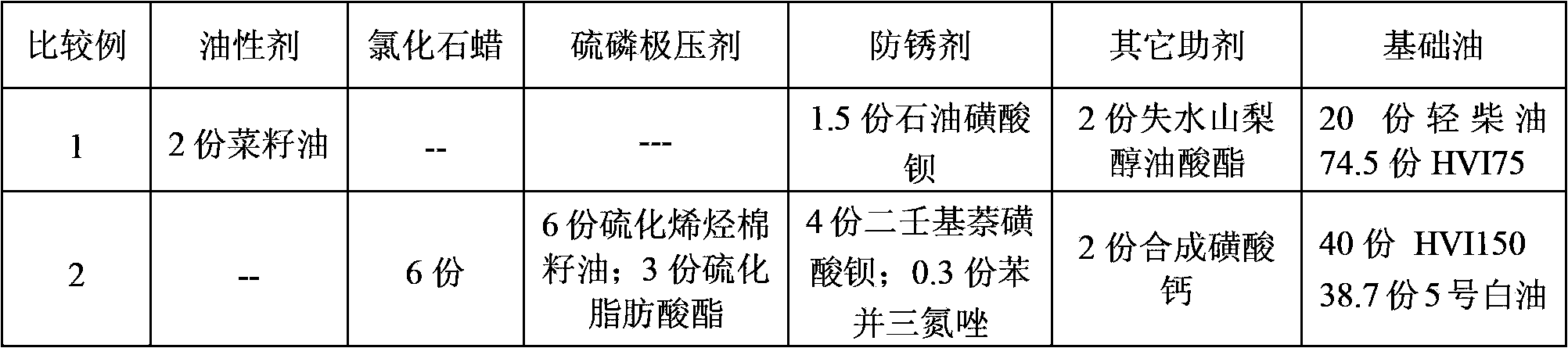

[0024] First add the base oil into the blending tank, start the agitator and the heating switch, and stir while heating. When the temperature of the oil is heated to 45°C, add the rust inhibitor and antioxidant, and stir for 40 minutes; at 40°C Add long-chain fatty acid, sulfur-containing extreme pressure agent and other additives, and stir for 80 minutes to obtain a uniform yellow liquid. Each component and its content are shown in Table 1, and its corresponding performance indicators are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com