Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

285results about How to "Reduce cutting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-lubricating composite soft coating cutter and manufacture method thereof

ActiveCN1927579ARealize self-lubricating functionSelf-lubricating function preventsLayered productsVacuum evaporation coatingManufacturing technologyMiddle frequency

The invention relates to a self-lubricant composite soft coat blade, and relative production. Wherein, said blade uses the MoS2 / Zr / Ti composite coat blade made from middle-frequency magnetic-control multi-arc plating method; the surface of blade is MoS2 layer, between which can base there are Ti, MoS2 / Zr / Ti, and MoS2 / Zr transition layer; when using said blade to cut, the surface of blade can form continuous lubricant layer, to realize self-lubricant function; since the solid lubricant has low shearing strength, the solid lubricant layer will be transferred to the surface of work piece, to form transfer film and the friction in the cutting process will generate inside the solid lubricant layer, to reduce friction, reduce shearing force and reduce shearing temperature.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

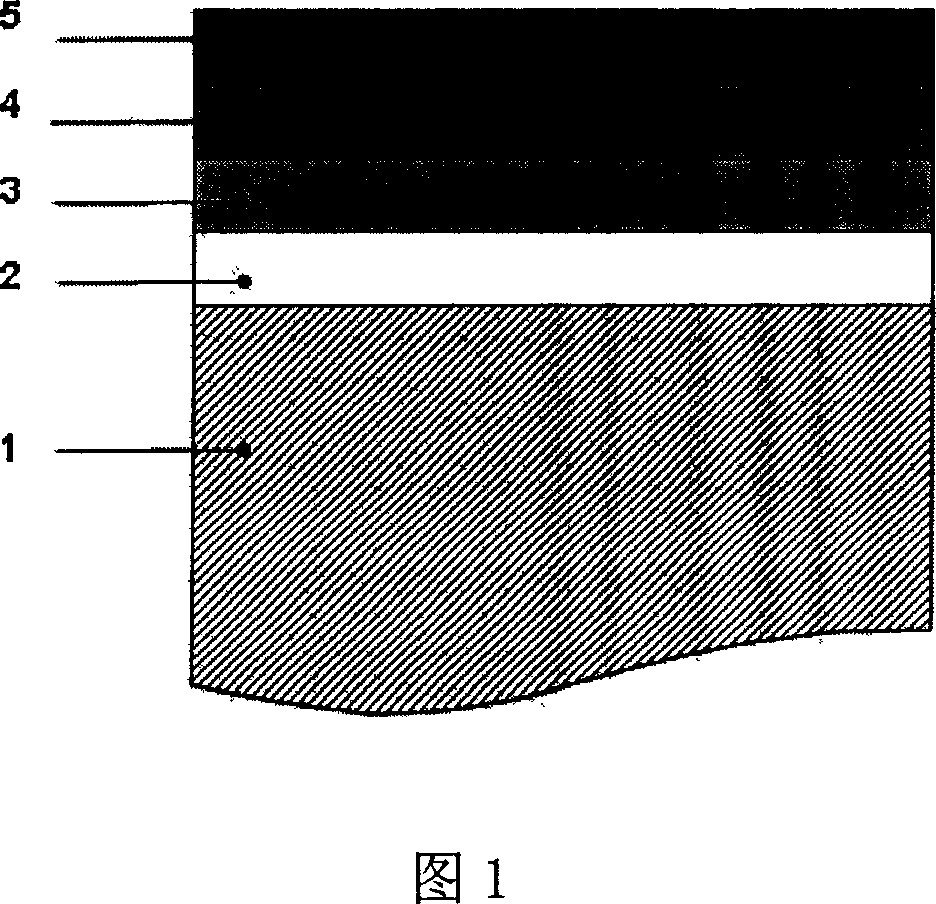

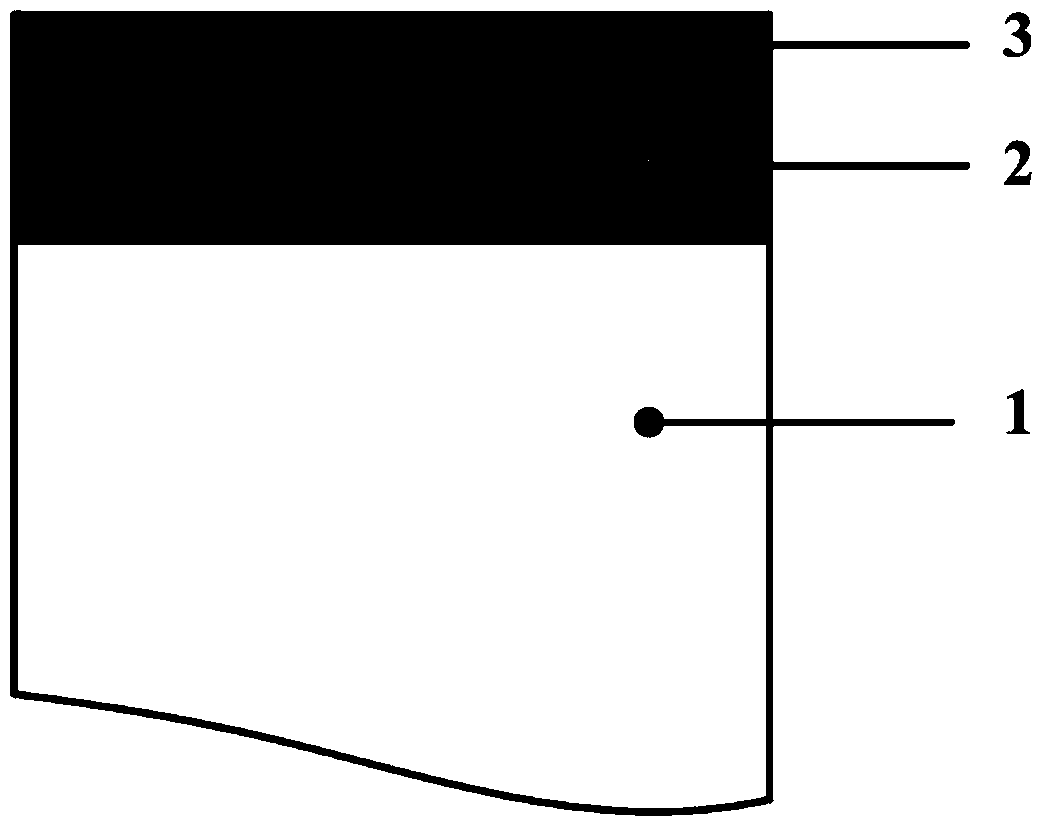

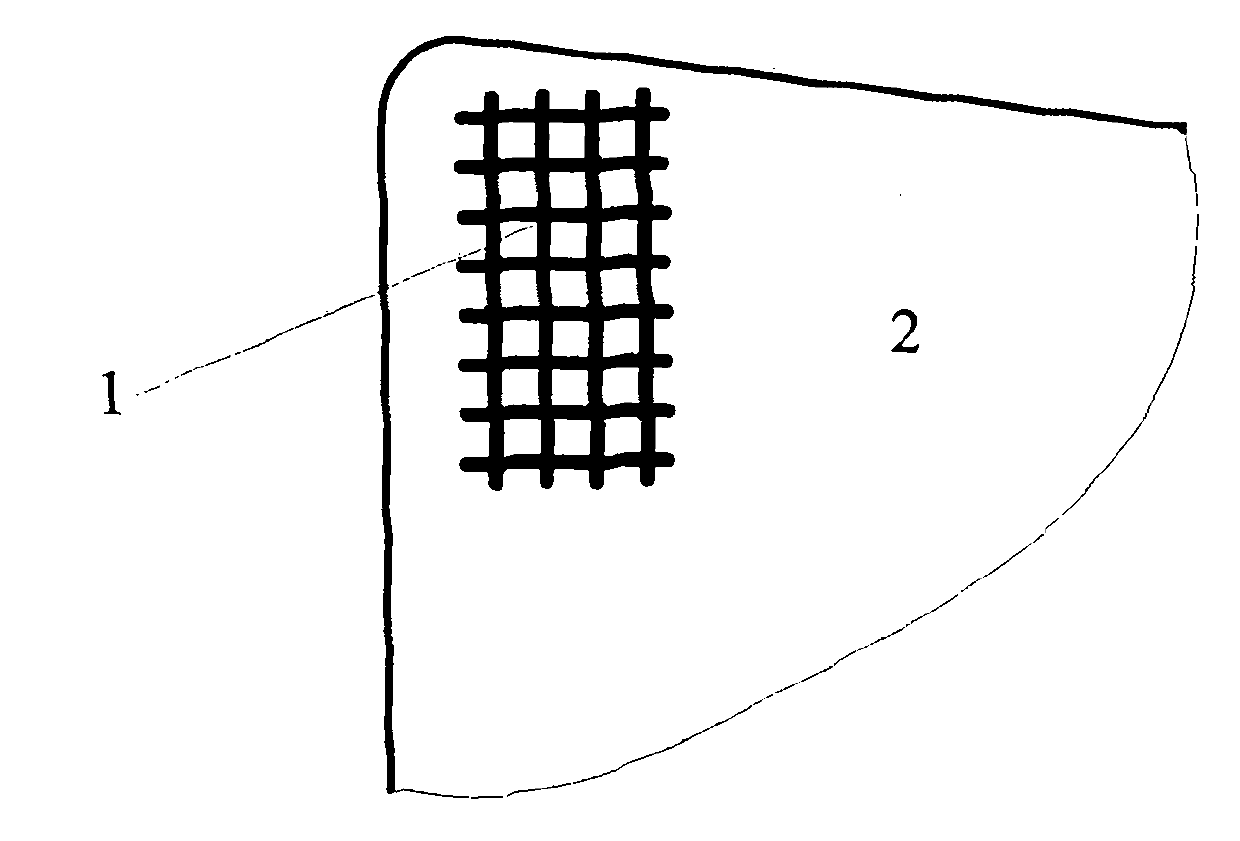

Micro-nano composite texture self-lubricating ceramic tool and manufacture method thereof

InactiveCN103028746AExtended service lifeReduce frictionTurning toolsLaser processingManufacturing technology

The invention belongs to the technical field of manufacture of mechanical cutting tools, and in particular relates to a micro-nano composite texture self-lubricating ceramic tool and a manufacture method thereof. According to the micro-nano composite texture self-lubricating ceramic tool, a micron level texture is processed on a front cutter surface by adopting a laser processing technology, a nano level texture is processed on a negative chamfered edge, a solid lubricating agent is filled in the micron level texture and the nano level texture respectively, during chip dry cutting, the dual functions of the micro-nano composite texture and the solid lubricating agent can realize that the friction is reduced and the cutting force and the cutting temperature are reduced, and thus the purposes of preventing adhesion, reducing friction and abrasion and prolonging the service life of the tool can be achieved. The micro-nano composite texture self-lubricating ceramic tool can be widely applied to high-speed dry cutting and cutting of difficult-to-machine materials, can overcome the environment pollution caused by cutting solution, realizes clean production, and is reduced in cost.

Owner:SHANDONG UNIV

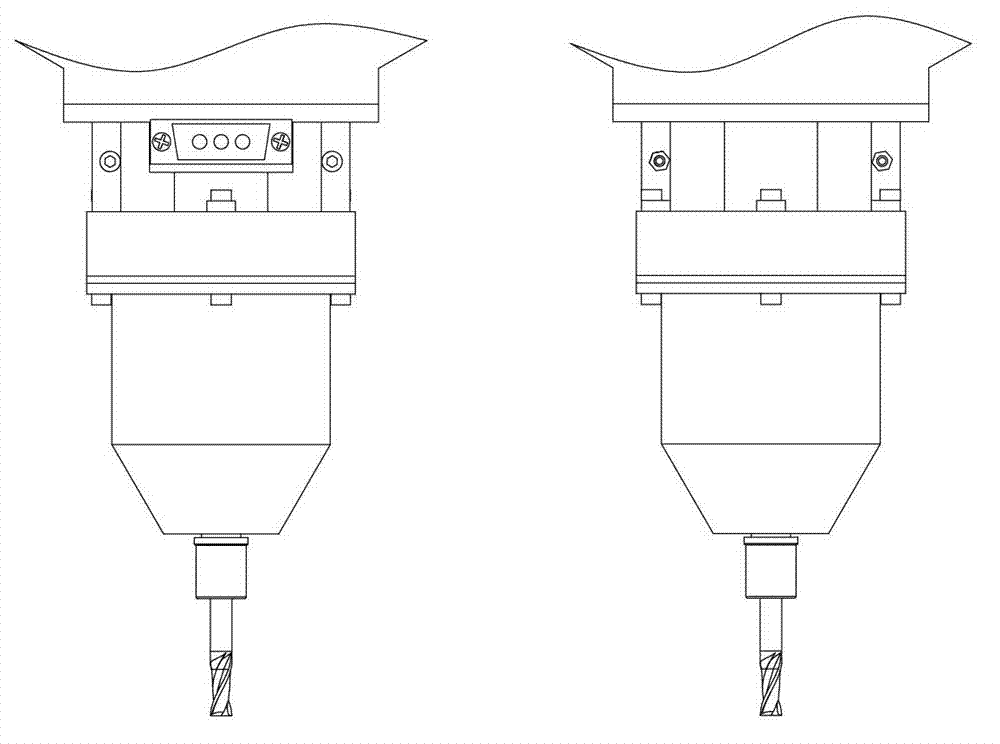

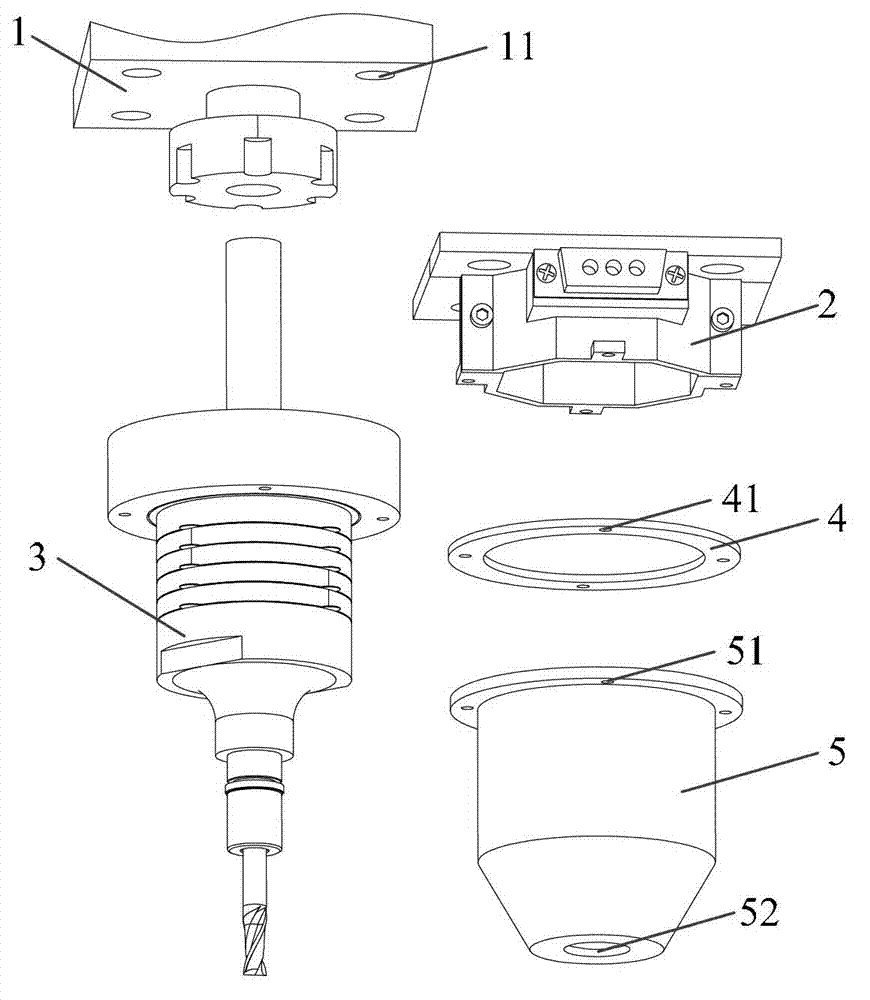

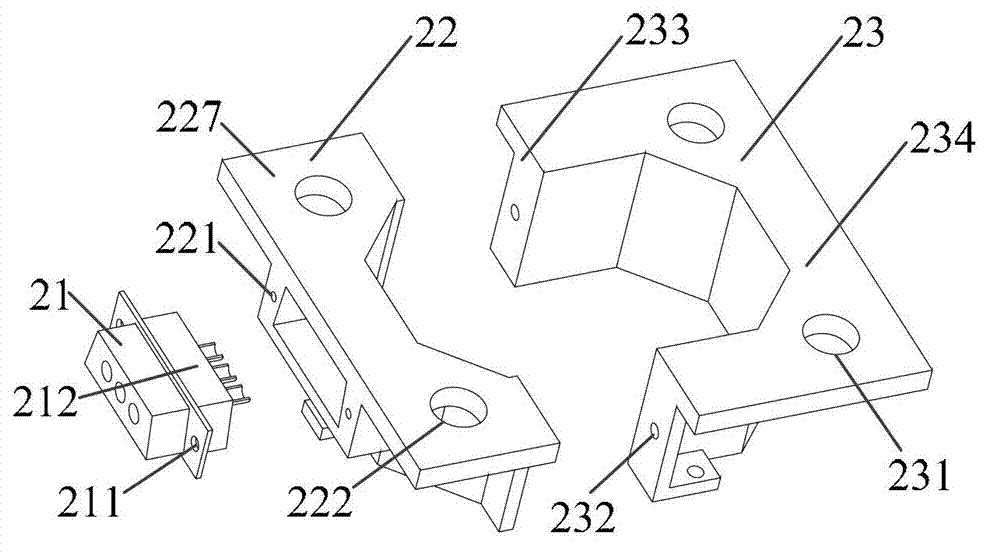

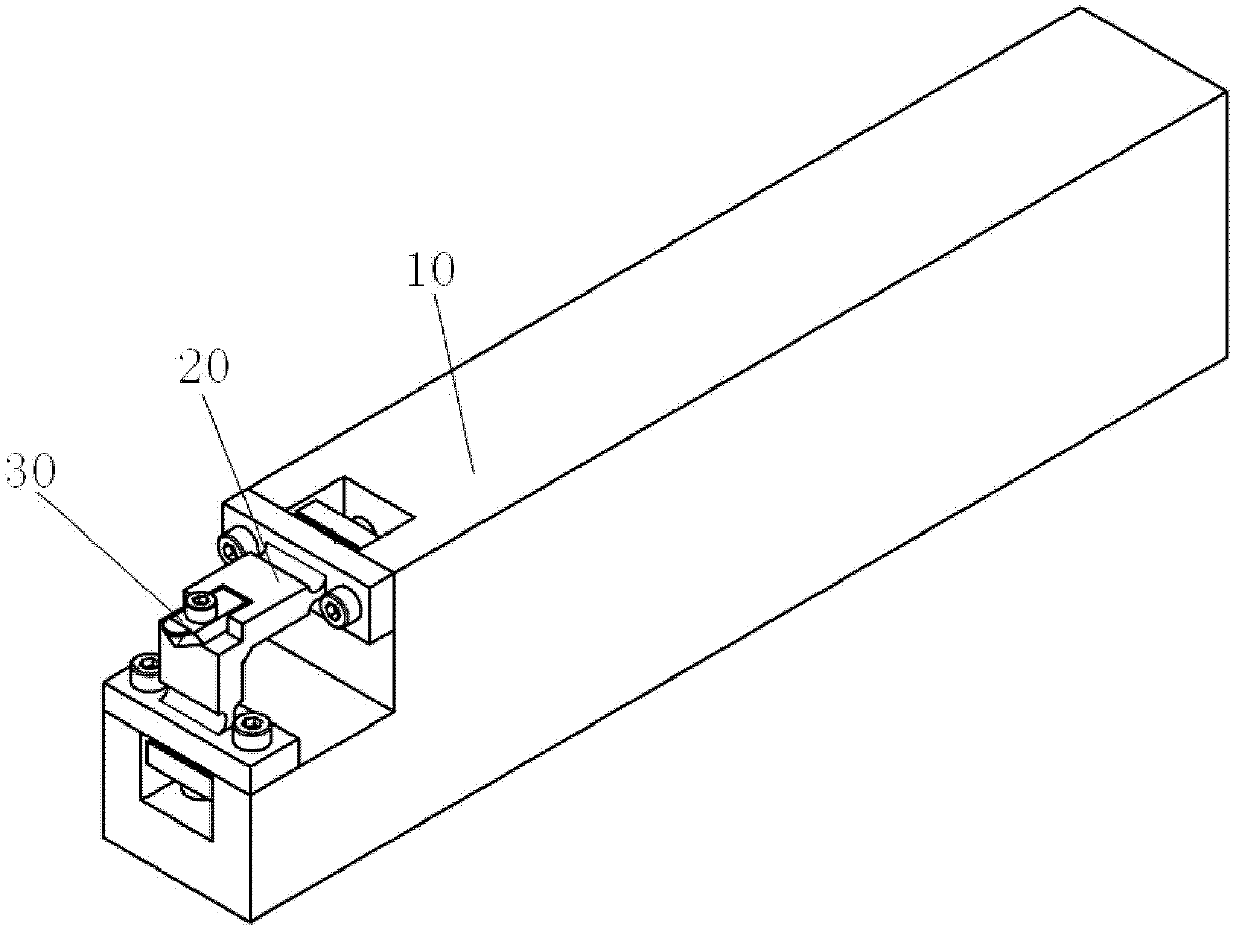

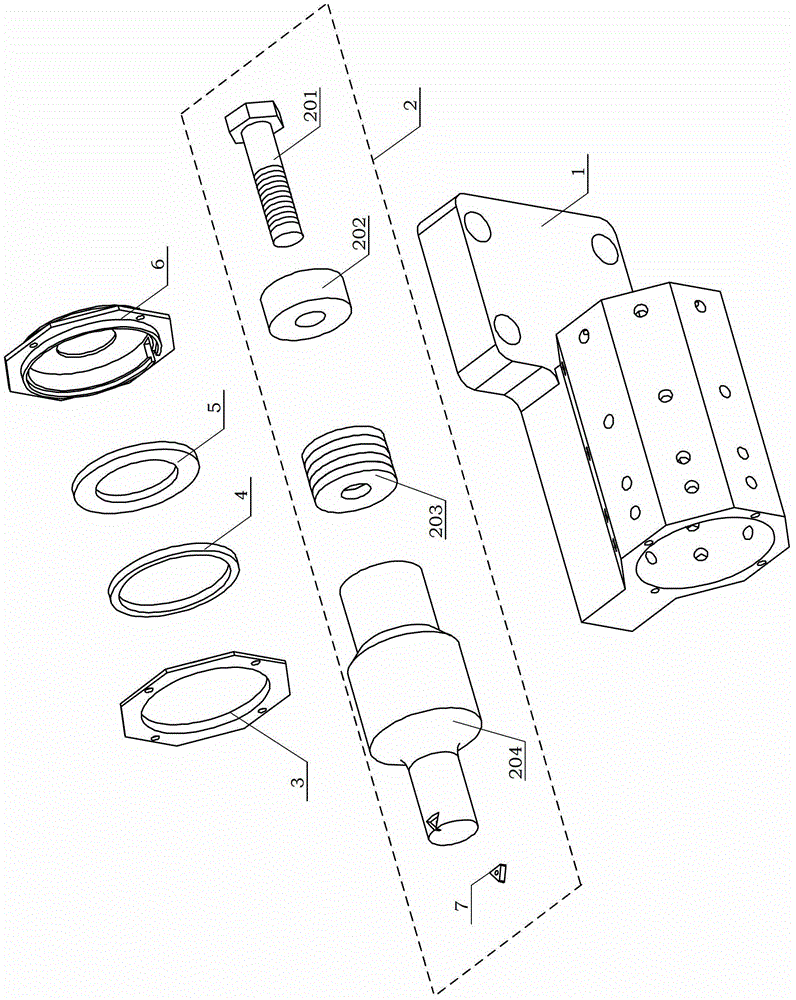

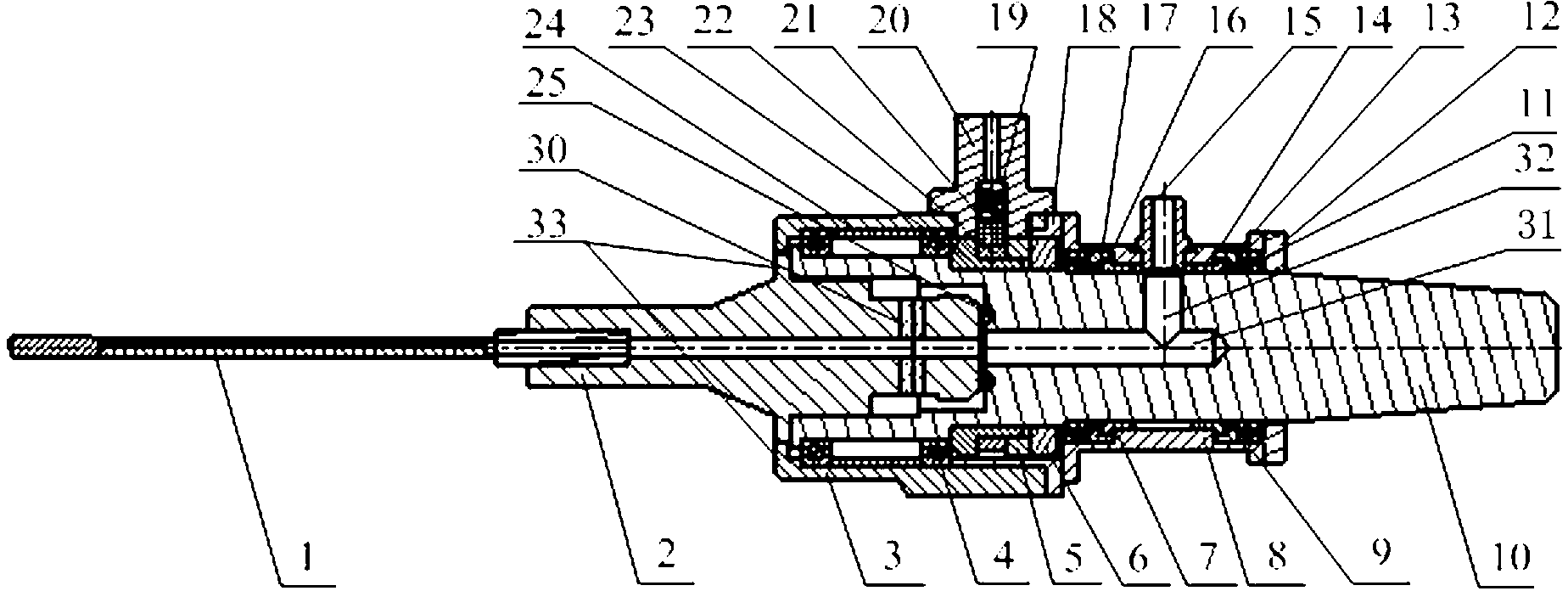

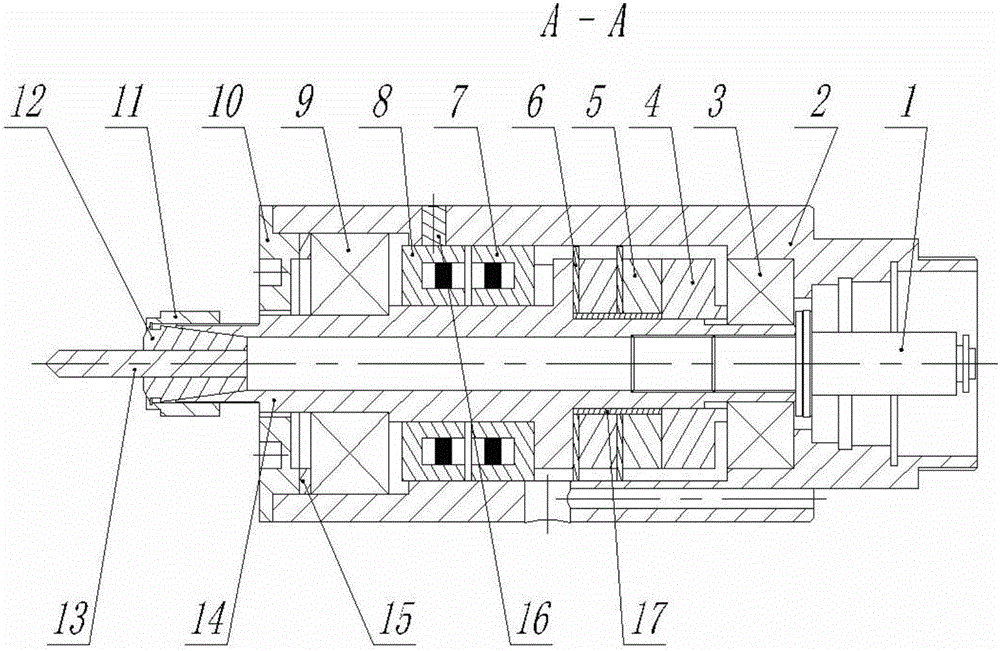

Ultrasound ellipse vibration milling knife handle device

ActiveCN103157593AAvoid rotation errorEasy tool changeMilling cuttersMechanical vibrations separationEllipseTitanium alloy

An ultrasound ellipse vibration milling knife handle device comprises a power supply box, an ultrasound ellipse vibration milling knife handle, a sealing ring and a protective cover. The upper end surface of the power supply box is connected with the lower plane of a cutter disk of a tool through bolts, a small circular shaft of the ultrasound ellipse vibration milling knife handle is connected with the cutting disk through a spring collet, the upper end surface of a large cylinder is connected with the lower end surface of the power supply box in a screw mode, the sealing ring is arranged on the lower end surface of the large cylinder, and the sealing ring is connected with the protective cover through bolts. The ultrasound ellipse vibration milling knife handle device can be flexibly connected with a traditional processing center in a butted mode, high frequency ultrasound ellipse vibration milling is achieved, and the effects of titanium alloy and composite material milling with high accuracy and high efficiency are achieved. The ultrasound ellipse vibration milling knife handle device has a wide application prospect in the technical field of ultrasound vibration processing devices.

Owner:BEIHANG UNIV

Resin grinding wheel and manufacturing method thereof

ActiveCN102363287AStrong grinding forceImprove grinding forceAbrasion apparatusGrinding devicesPyriteEngineering

The invention provides a resin grinding wheel and a manufacturing method thereof, which belong to the field of grinding tools and are used for solving the problem of the production of harmful sulfur dioxide by pyrite serving as a lubricating agent existing in the conventional resin grinding wheel. The resin grinding wheel comprises a grinding body and a reinforcing sheet which is arranged inside the grinding body for enhancing the revolving strength of the grinding body, wherein 90-105 parts by mass of corundum is taken as a grinding material the grinding body; 2-8 parts by mass of phenolic aldehyde resin liquid and 6-25 parts by mass of phenolic aldehyde resin powder are taken as bonding agents; and 1-10 parts by mass of cryolite and 1-5 parts by mass of polytetrafluoroethylene powder are taken as fillers. The invention further provides a manufacturing method of the resin grinding wheel. In the grinding wheel, the polytetrafluoroethylene powder instead of pyrite is taken as a lubricating agent, so that sulfur dioxide is not produced and other pollution is avoided in the using process.

Owner:NINGBO DAHUA GRINDING WHEEL

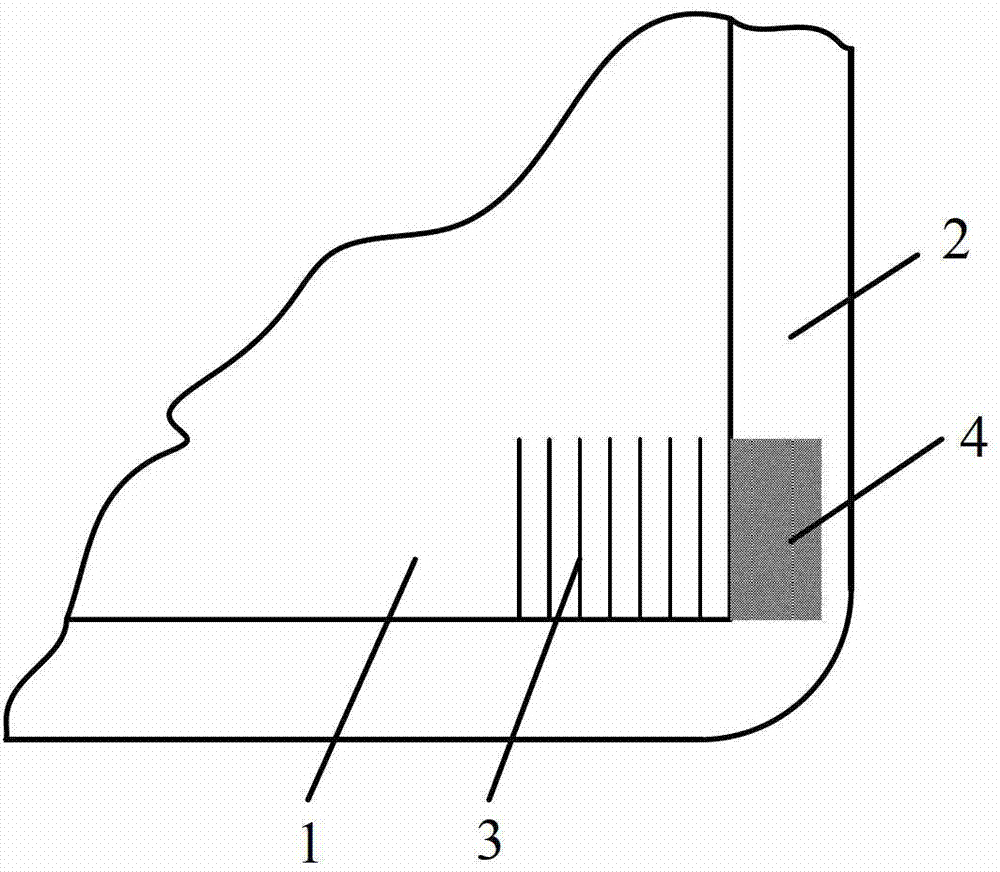

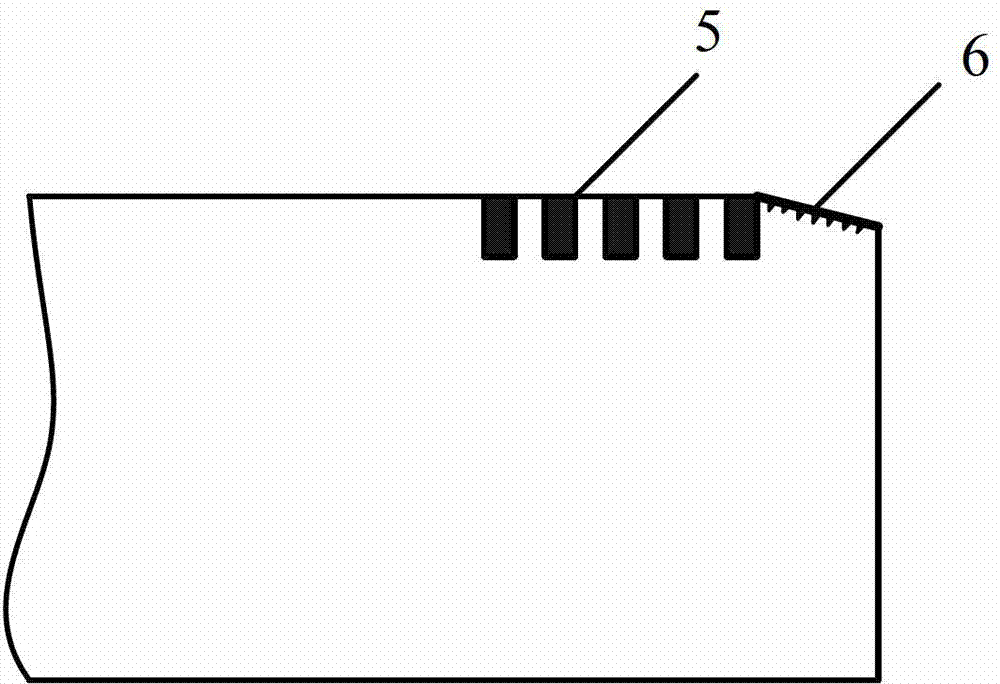

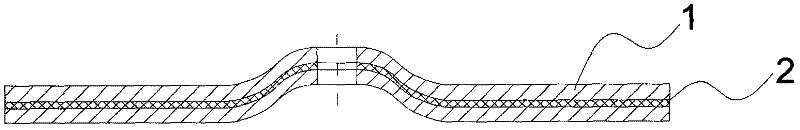

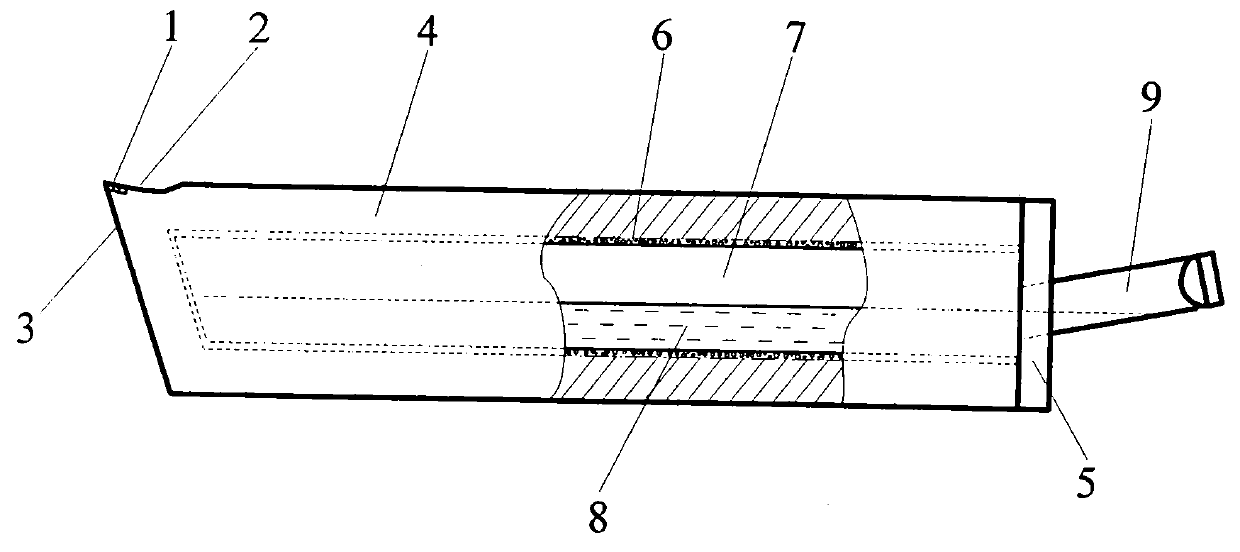

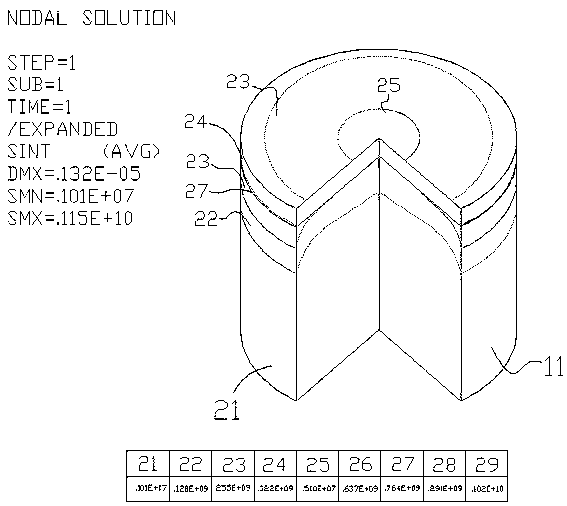

Self-lubricating and self-cooling dry cutter and manufacturing method thereof

InactiveCN102000841ARealize self-lubricating functionAchieve lubricationTurning toolsManufacturing technologyLiquid medium

The invention provides a manufacturing method of self-lubricating and self-cooling dry cutter, belonging to the technical field of mechanical cutter manufacturing. A cutter-scrap contact zone on a front cutter face of the cutter is provided with a plurality of miniature antifriction slots filled with solid lubricants, and the solid lubricants in the antifriction slots are coated on the front cutter face of the cutter in a towing way by the jointed action of cutting heat and scrap extrusion to form a continuous solid lubricating film so that the self-lubricating function of the cutter is realized; and a self-circulation cooling cavity is arranged in a cutter body, during cutting processing, a liquid medium in the cooling cavity absorbs heat transferred from the cutting part of the cutter so that the rapid heat radiation and cooling of the cutting part of the cutter can be effectively enhanced, thereby the self-cooling function of the cutter is realized. The cutter can reduce the frication of the cutting part with a workpiece and also lower the cutting temperature so that the friction of the cutter is reduced, the processing quality of the workpiece and the durability of the cutter are improved, and the cutter can be widely applied to dry cutting and cutting of materials difficult to process and realizes clean production.

Owner:SHANDONG UNIV

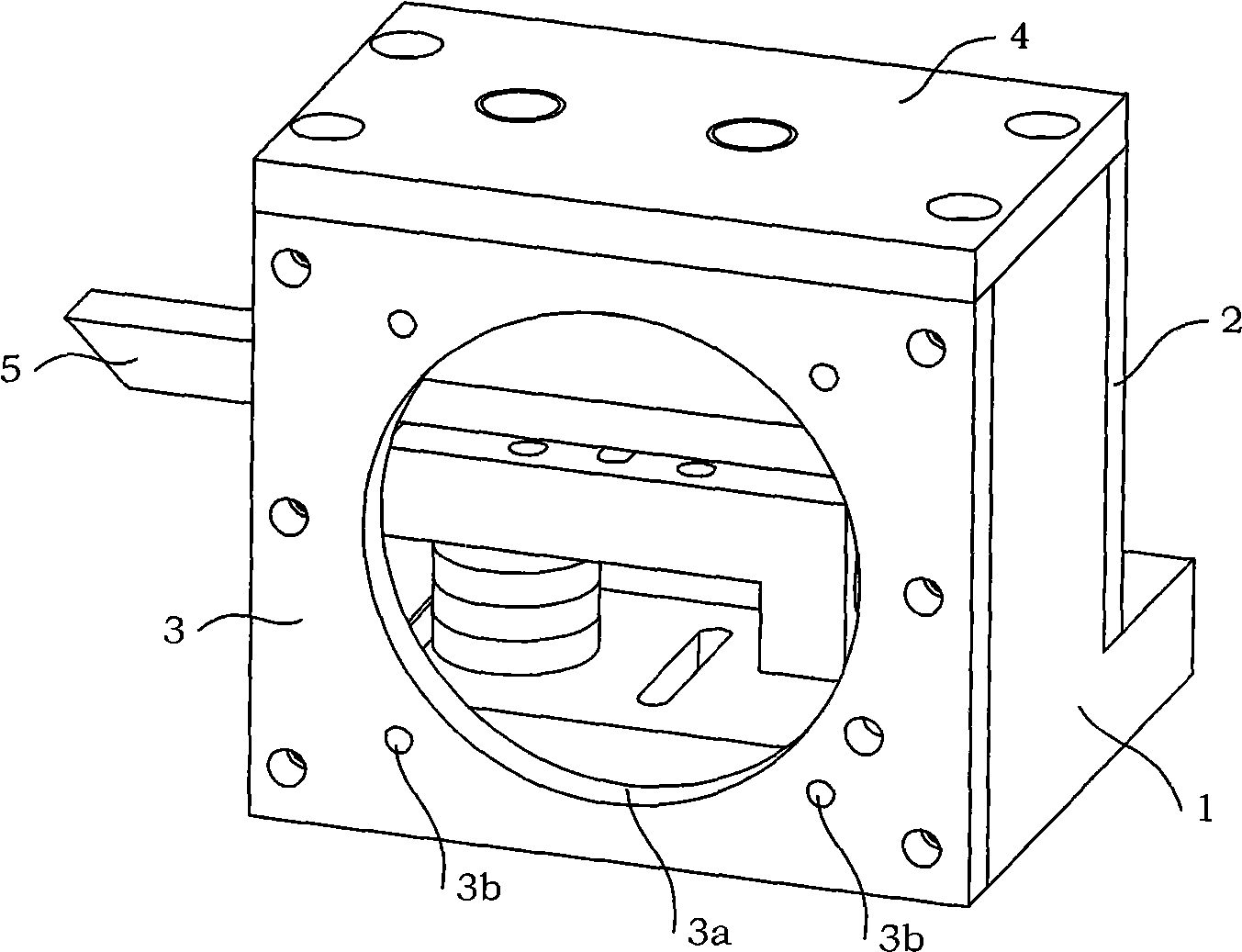

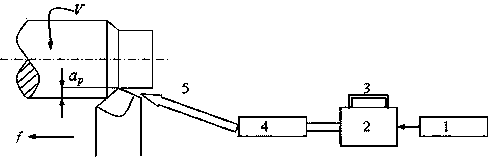

High-frequency ultrasonic elliptical vibration cutting device

InactiveCN101502971AIncrease the critical vibration velocityHigh vibration frequencyAuxillary equipmentMechanical vibrations separationTransformerSurface roughness

The invention discloses a high frequency ultrasound elliptic vibration cutting device which comprises an ultrasound vibration unit and a casing unit. The ultrasound vibration unit is arranged in the casing unit. The casing unit comprises a base, A cover plate, B cover plate and an upper cover plate. The ultrasound vibration unit comprises an amplitude transformer, a vibrating body, A excitation source, B excitation source and C excitation source. The amplitude transformer is installed on the vibrating body. The end part of the amplitude transformer is provided with a cutting tool. The A excitation source and the B excitation source are arranged in parallel way and are adhered on the lateral side of the vibrating body. The C excitation source is installed on the lower part of the vibrating body. The A excitation source and the B excitation source form the driving power in horizontal direction. The C excitation source forms the driving power in vertical direction. The phase separation between two mutually vertical high frequency vibrations is applied for compounding an elliptic vibration at the point of the cutting tool. Thus, the processing surface roughness is lowered effectively. The cutting device works at the high vibration frequency of 100 kHz-200 kHz, so that the vibration chipping critical speed of the cutting tool is improved, and the processing efficiency is improved obviously. The amplitude transformer is adopted to be inserted in the vibration body, so that the installation is easy, and the practicality of the ultrasound elliptic vibration cutting can be promoted.

Owner:BEIHANG UNIV

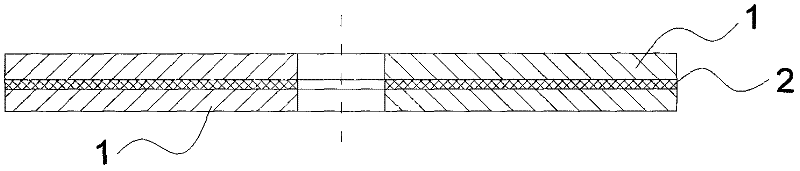

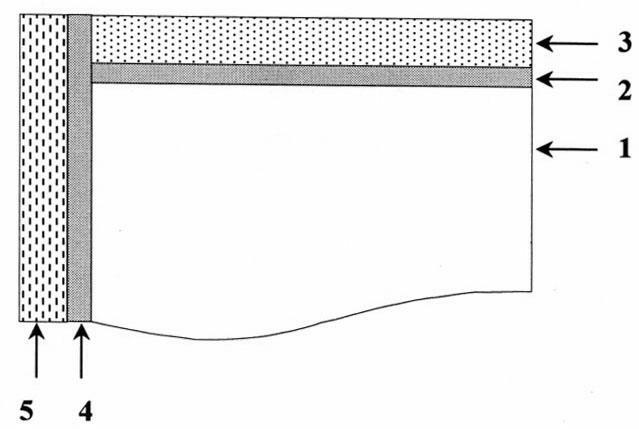

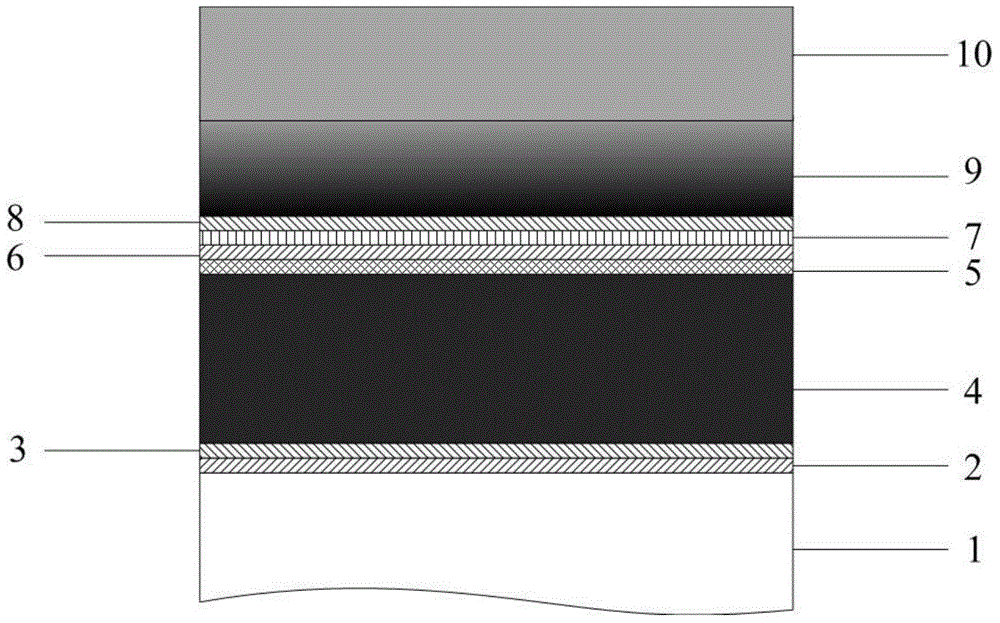

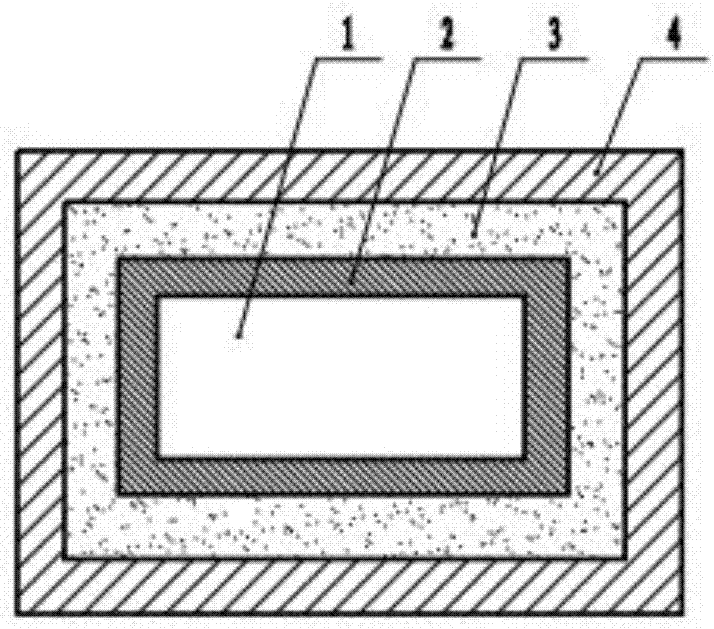

Ti-TiN & Ti-MoS2/Ti double-cutting-surface coated cutting tool and preparation process thereof

ActiveCN102161106AImprove performanceReduce coefficient of frictionVacuum evaporation coatingSputtering coatingHardnessTransition layer

The invention relates to a Ti-TiN & Ti-MoS2 / Ti double-cutting-surface coated cutting tool and a preparation process thereof. The front surface of the cutting tool is an MoS2 / Ti lubricating coating and a Ti front cutting tool surface transition layer is arranged between the MoS2 / Ti lubricating coating and a cutting tool substrate. The rear surface of the cutting tool is a TiN coating with high hardness and a Ti rear cutting tool surface transition layer is arranged between the TiN coating with high hardness and the cutting tool substrate. The preparation process comprises the steps of pre-processing, ion cleaning, depositing the Ti transition layer on the front cutting tool surface, depositing the MoS2 / Ti coating on the front cutting tool surface, sampling, refitting a furnace, ion cleaning, depositing the Ti transition layer on the rear cutting tool surface, depositing the TiN coating on the rear cutting tool surface and post-processing. Advantages of a Ti-TiN coated cutting tool withhigh hardness and a Ti-MoS2 / Ti lubricating coated cutting tool are combined in the present invention of the double-cutting-surface coated cutting tool which has both high hardness and low friction coefficient, so that performance of the coated cutting tool is substantially improved. The preparation process enables the Ti-TiN & Ti-MoS2 / Ti coated cutting tool to be produced conveniently. It is easyto grasp the process and the production process is stable and reliable.

Owner:SHANTUI CONSTR MASCH CO LTD

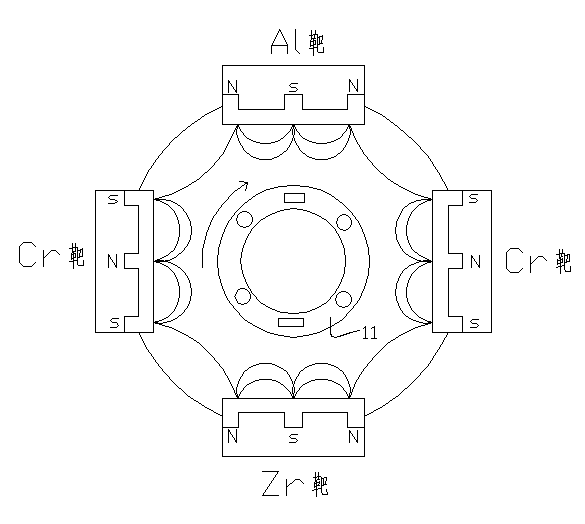

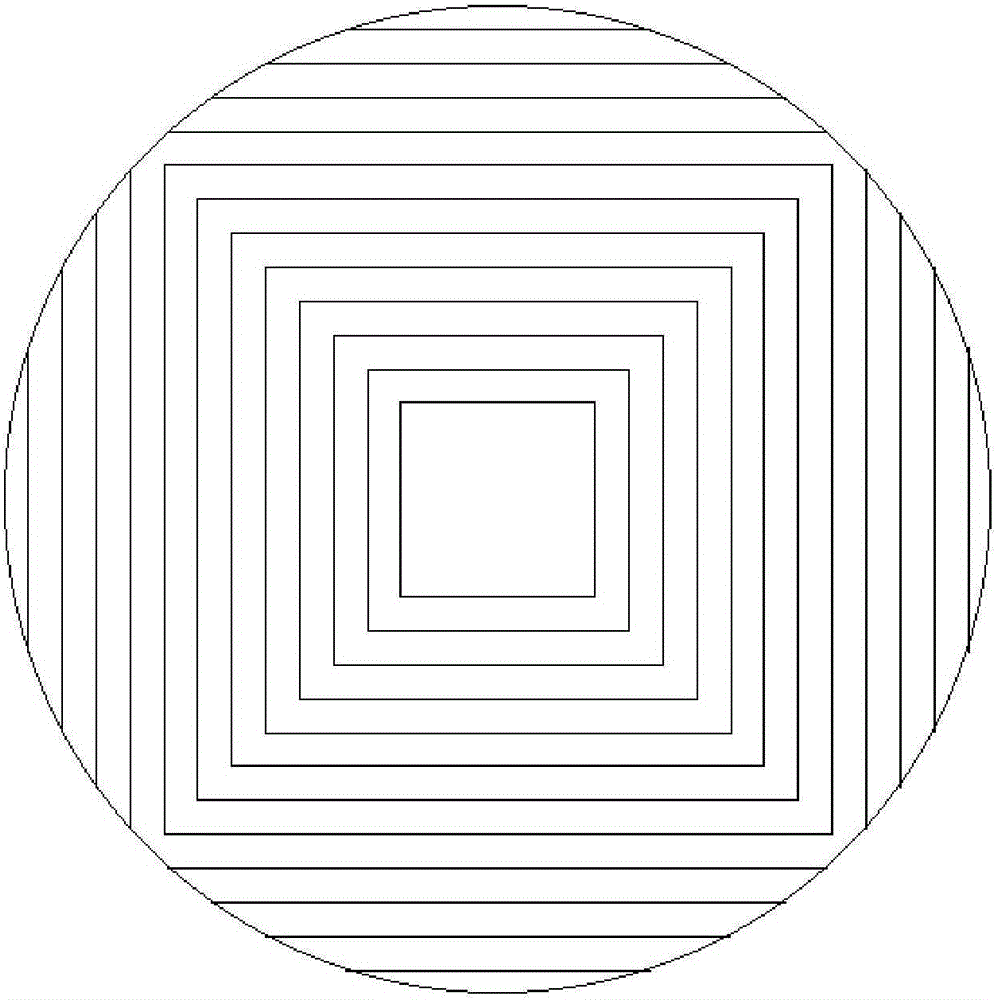

A1ZrCrN composite dual-gradient coating cutting tool and preparation method thereof

ActiveCN103132019AReduce residual thermal stressHigh bonding strengthVacuum evaporation coatingSputtering coatingIon platingComposite coating

The invention relates to an A1ZrCrN composite dual-gradient coating cutting tool and a preparation method thereof. The composite dual-gradient coating cutting tool is prepared by a nonequilibrium closed field magnetron sputtering ion plating manner; and a Cr transition layer, a gradient CrN transition layer, a gradient A1ZrCrN transition layer and an A1ZrCrN layer are sequentially arranged on the coating cutting tool from inside to outside along the a vertical matrix surface direction, so that transition between coatings is smoother, residual thermal stress among all coatings can be obviously lowered in use of the coating cutting tool, and the coating quality of the cutting tool is greatly improved.

Owner:成都史特迪新材料科技有限公司

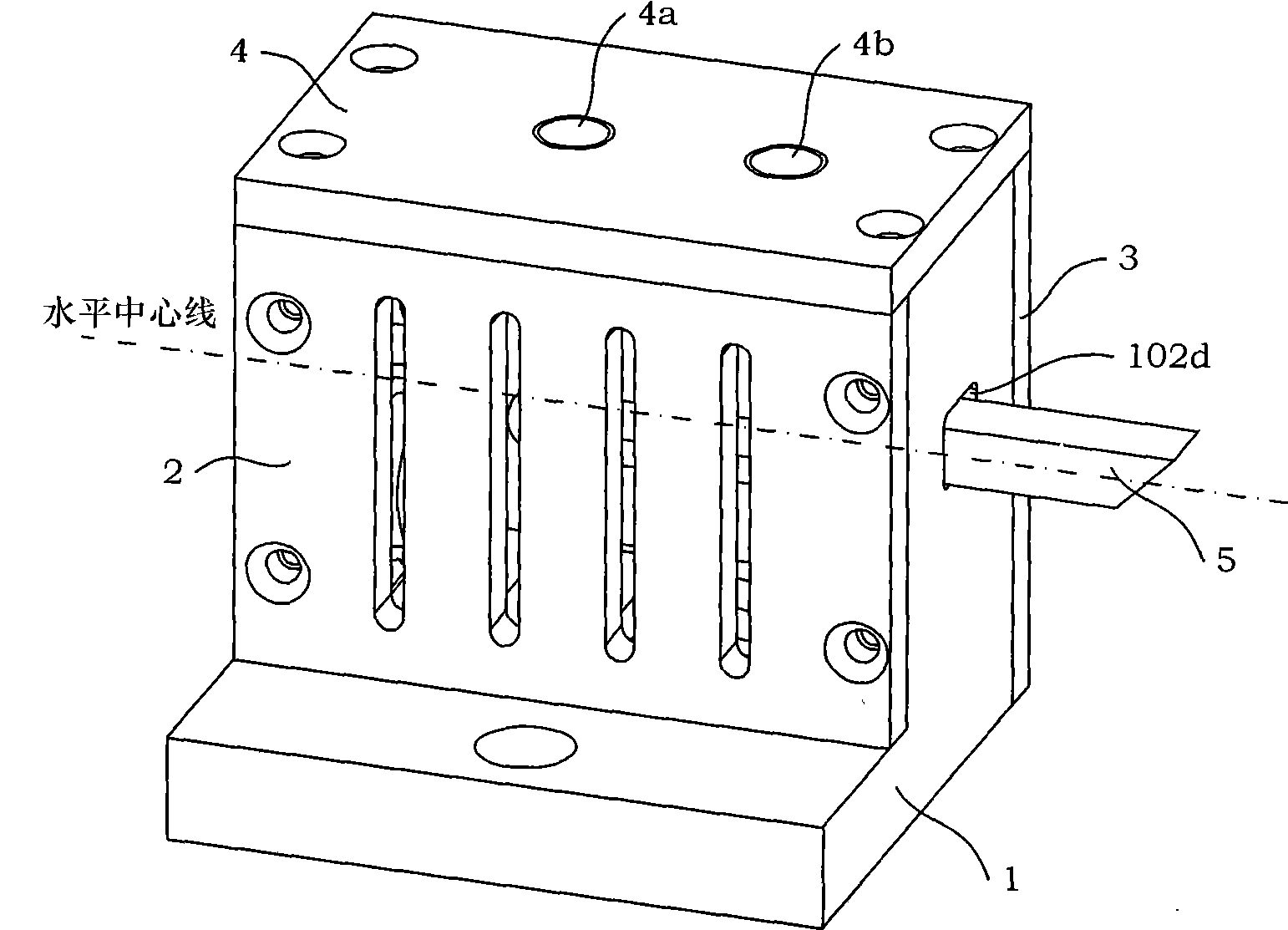

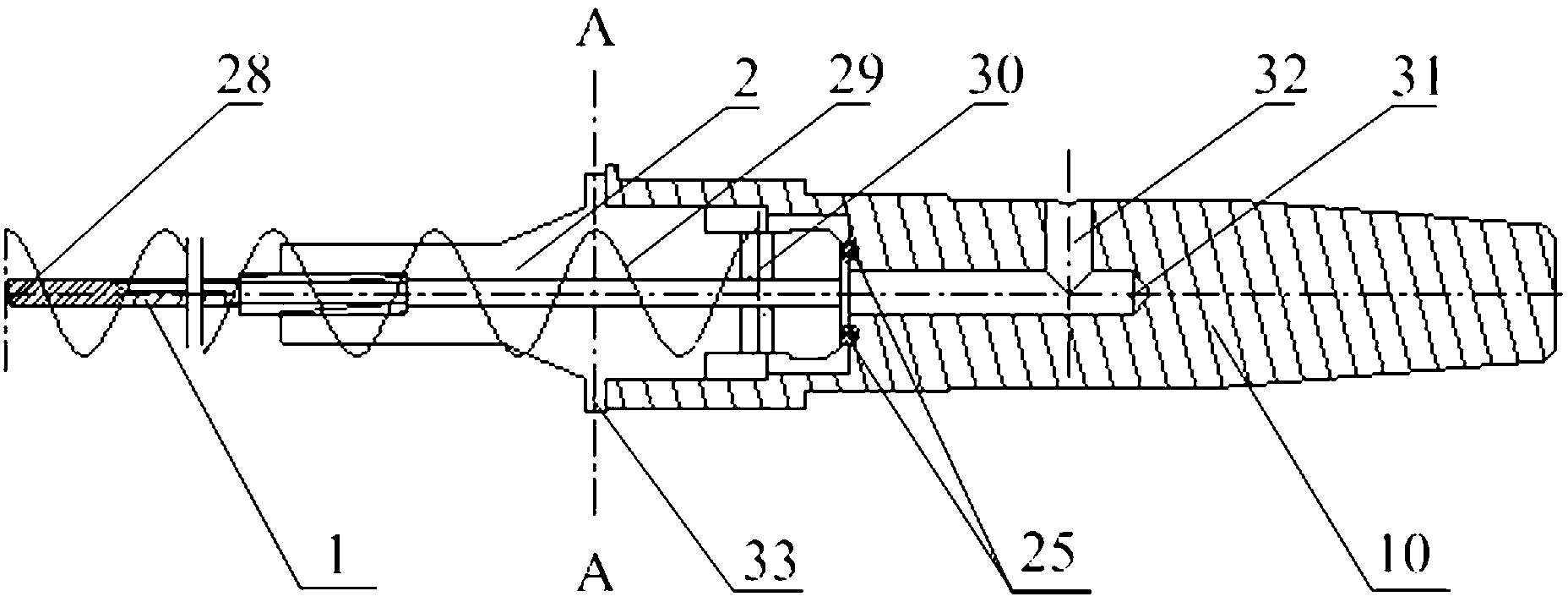

Ultrasonic oval vibrating mechanism for assisting diamond cutter in ultra-precision cutting

InactiveCN102380626AGood vibration conductivityExcellent mechanical propertiesTurning toolsMechanical vibrations separationEngineeringUltra precision

The invention relates to an ultrasonic oval vibrating mechanism for assisting a diamond cutter in ultra-precision cutting. The ultrasonic oval vibrating mechanism is characterized by comprising a cutter handle, a vibrating unit and a cutter, wherein one end of the cutter handle has a step-shaped structure; the vertical surfaces and the horizontal surfaces of an upper layer step and a lower layer step are provided with grooves; the vibrating unit comprises a vibrating body consisting of a transverse vibrating rod and a longitudinal vibrating rod which are vertical to each other; the top surface of the joint of the transverse vibrating rod and the longitudinal vibrating rod is provided with a groove; the end part of the transverse vibrating rod is provided with a transverse end face; the other side of the transverse end face is provided with a transverse excitation source and a transverse cover plate in sequence; the end part of the longitudinal vibrating rod is provided with a longitudinal end face; the other side of the longitudinal end face is provided with a longitudinal excitation source and a longitudinal cover plate in sequence; the transverse end face is formed on the vertical surface of the upper layer step of the cutter handle; the transverse cover plate and the transverse excitation source are positioned in the groove of the upper layer step; the longitudinal end faceis formed on the horizontal surface of the lower layer step of the cutter handle; the longitudinal cover plate and the longitudinal excitation source are positioned in the groove of the lower layer step; and the cutter is arranged in the groove at the joint of the transverse vibrating rod and the longitudinal vibrating rod.

Owner:TSINGHUA UNIV

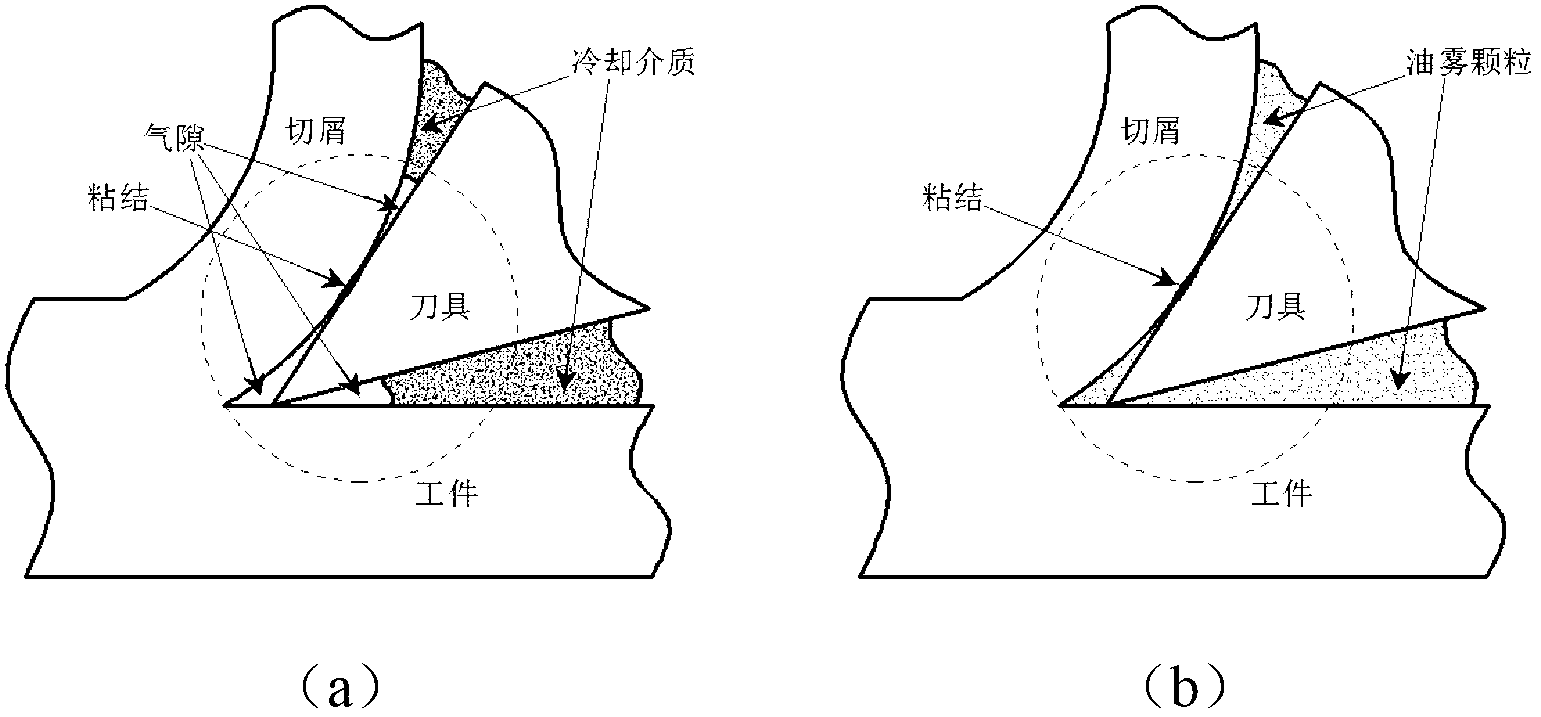

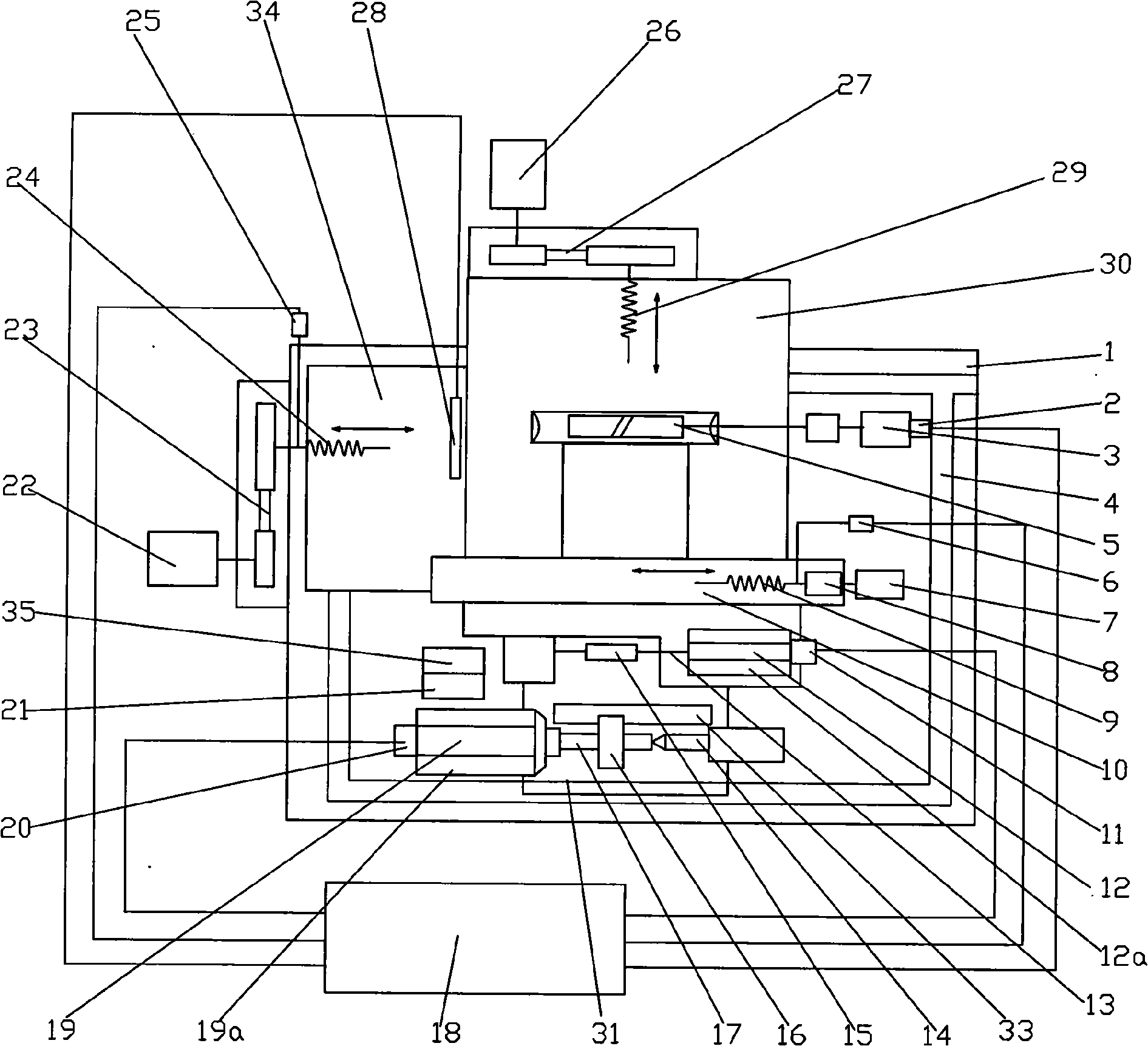

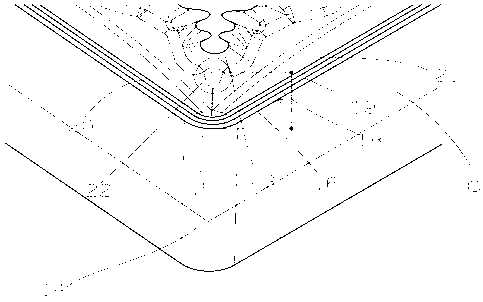

Method and device for forming high-pressure and low-temperature jet flow by cutting coolant

ActiveCN103286629AIncreased durabilityReduce cutting temperatureMaintainance and safety accessoriesJet flowSpray nozzle

The method discloses a method and device for forming high-pressure and low-temperature jet flow by cutting coolant. The method includes that compressed air stored inside an air storage tank is filtered and dried and connected to a tee joint through a hose to divide an output pipe into two branches, air in one branch is cooled by a cooling device to become low-temperature high-pressure air, and inputted into an air inlet end of a pneumatic spray nozzle after being connected with one or more than one tee joint, the air in the other branch is inputted into a well-sealed cutting fluid storage container after pressure in the air is regulated by a pressure regulating valve, the cutting fluid is pressed out, and connected into liquid inlet ends of a plurality of pneumatic spray nozzles after passing one or more than one tee joint prior through the hose, the air and the liquid are mixed outside a jet nozzle to produce high-speed jet flow. By the method, usage amount of cooling lubricating liquid is reduced, cooling and lubricating functions of fluid medium are fully performed, cutting temperature is greatly lowered, and tool durability is conspicuously improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

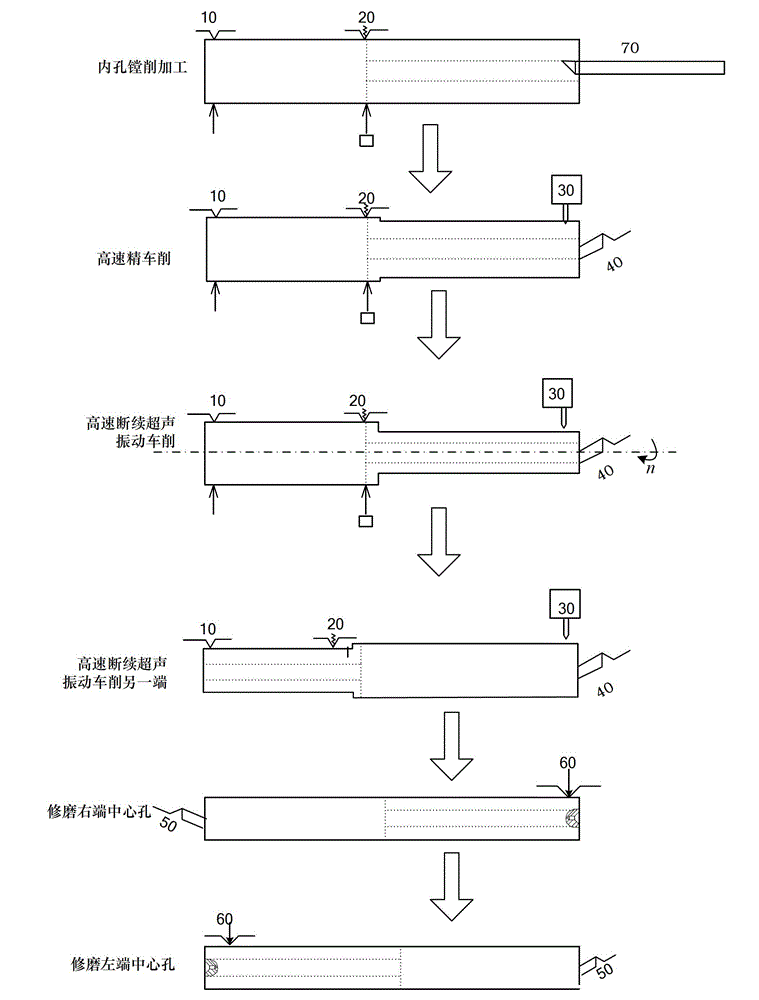

High-speed intermittent ultrasonic vibration cutting method for low-rigidity parts

ActiveCN102717115AEfficient processingReduce surface roughnessUltrasonic vibrationLongitudinal vibration

The invention discloses a high-speed intermittent ultrasonic vibration cutting method for low-rigidity parts. The high-speed intermittent ultrasonic vibration cutting method is a novel machining method for cutting the low-rigidity parts by ultrasonic longitudinal vibration cutting technology. The machining method is implemented by the aid of an ultrasonic longitudinal vibration cutting device, an intermittent cutting process principle is supplemented, accordingly, follow-up working procedures of turning / boring, ageing treatment and grinding in a traditional machining method are omitted, cutting speed is greatly increased, machining time is shortened, machining efficiency is improved, and high-speed, high-efficiency and high-quality machining of the low-rigidity parts which are machined difficultly can be realized by the aid of the machining method.

Owner:BEIHANG UNIV

Resin-based high-strength wear-resistant grinding wheel material and preparation method thereof

InactiveCN107378803AWell mixedImprove performanceBonded abrasive wheelsGrinding devicesBoron nitrideIron disulfide

The invention discloses a resin-based high-strength wear-resistant grinding wheel material. The resin-based high-strength wear-resistant grinding wheel material is prepared from modified phenolic resin, epoxy resin, powder butadiene-acrylonitrile rubber, polyurethane elastomer, polyvinyl butyral, iron disulfide, copper powder, zinc oxide, graphite, hollow ceramic balls, corundum, carborundum, talcum powder, silicon carbide, aluminum oxide, boron oxide, boron nitride, chromic oxide, nanosilicon dioxide, a silane coupling agent, namely KH-550 and wear-resistant auxiliary agents. The invention further provides a preparation method of the resin-based high-strength wear-resistant grinding wheel material. The resin-based high-strength wear-resistant grinding wheel material is excellent in wear resistance, good in bonding performance and high in hardness; heat resistance and hardness of a resin grinding wheel are improved; cracks formed due to rigid grinding are reduced; heat is dissipated fast; a great amount of heat released in the cutting process of the grinding wheel can be dissipated fast and conveniently; and the effect that the cutting temperature is lowered is achieved.

Owner:安徽昌悌进出口贸易有限公司

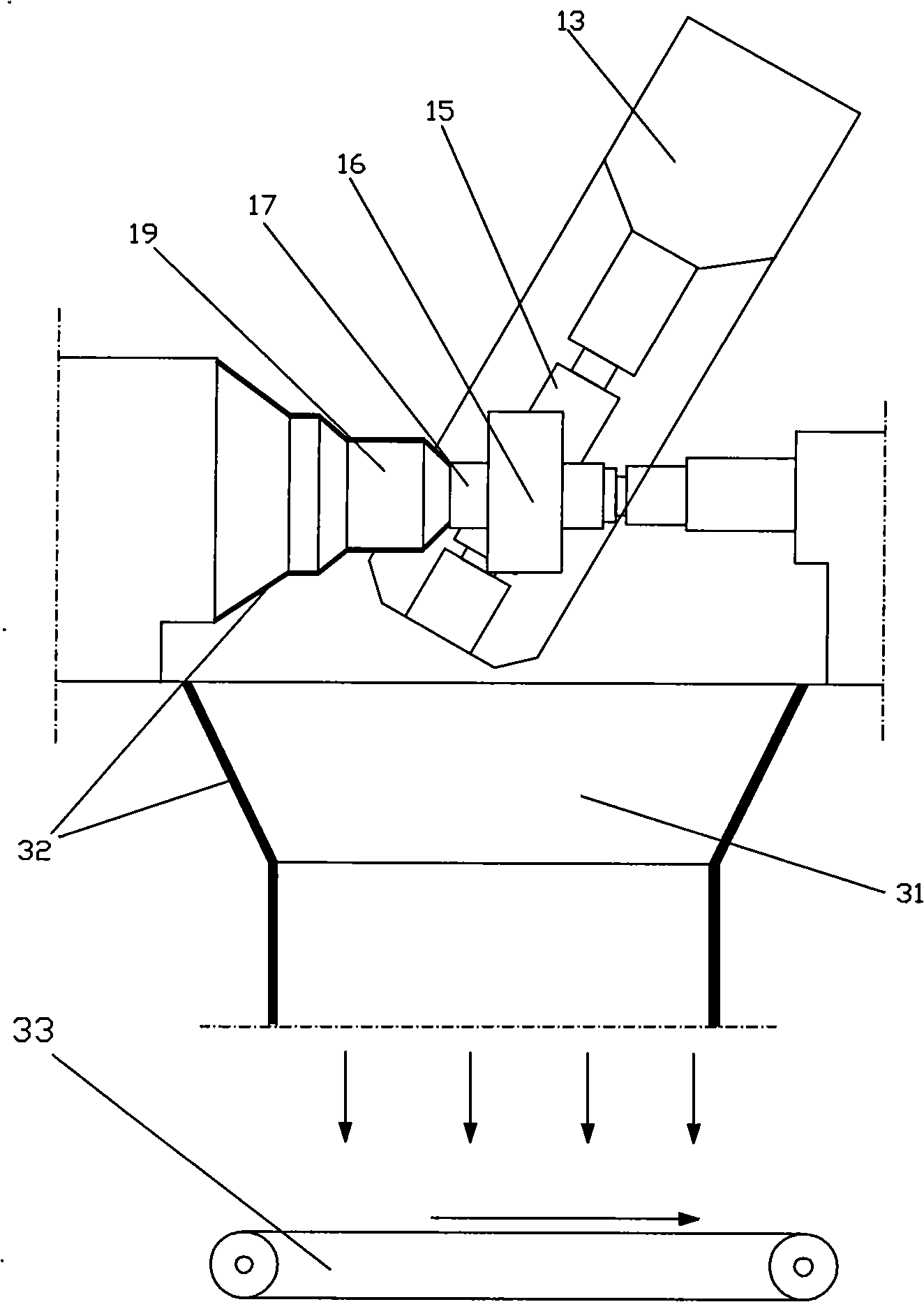

Zero-drive chain digital control gear hobbing machine

InactiveCN101298106AGuaranteed stabilityNo vibrationFeeding apparatusGear-cutting machinesHobbingGear wheel

The invention discloses a numberical control hobbing machine with zero transmission, which comprises a machine body, a main shaft system, a hobbing cutter feeding and angle adjusting system and a control system; the main shaft system comprises a functional part of a hobbing cutter main shaft and a functional part of work-piece main shaft part; the functional part of the hobbing cutter main shaft is an integration of the rotator of the servo motor I and the hobbing cutter main shaft, and the functional part of the work-piece main shaft is an integration of the rotator of the servo motor II and the work-piece main shaft. The numberical control hobbing machine of the invention can remove the manufacturing errors of transmission component of generating motion and the influence on gear process caused by space and assembly error, is able to greatly improve process accuracy and process speed of machine tool. The numberical control hobbing machine of the invention has simple structure, is able to improve overall rigidity of machine tool, solves the wearing problem caused by mechanical transmission chain, improves the retentivity of precision, causes the hobbing speed to be higher than the numberical control hobbing machine with traditional structure, shortens milling time as well as based on which, the hobbing machine is provided with the machine tool conditions required by dry type hobbing through adopting a series of matching technical measures.

Owner:CHONGQING UNIV

Diamond coating cutter, and preparation method and application thereof in high speed graphite processing

ActiveCN105563665AReduce cutting shock and vibrationAvoid breakingChemical vapor deposition coatingStone-like material working toolsHardnessLow friction

The invention discloses a diamond coating cutter, and a preparation method and the application thereof in high speed graphite processing. The diamond coating cutter comprises a cutter tip, a blade and a clamping cutter holder, wherein the clamping cutter holder is made of a hard alloy matrix, the cutter tip and the blade are coated with diamond coatings on matrix materials, the diamond coating cutter is characterized in that the end cutting edge front angle gamma o1 of the blade is 2 to 6 degrees, the end cutting edge rear angle alpha 1 is 5 to 13 degrees, the peripheral cutting edge front angle gamma o2 is 5 to 15 degrees, the peripheral cutting edge rear angle alpha 2 is 10 to 14 degrees, and the helical angle beta is 15 to 45 degrees. The diamond coating cutter provided by the invention has the characteristics of high hardness, wear resistance, low friction coefficient, good heat conduction and the like, is suitable for high speed graphite processing, can effectively overcome frictional wear caused by graphite dust to the surface of the cutter, and is classified as an ideal cutter for cutting graphite.

Owner:GUANGDONG UNIV OF TECH

TiSiN-WS2/Zr-WS2 coated cutting tool and preparation process thereof

InactiveCN104060222AImprove the lubrication effectReduce wearVacuum evaporation coatingSputtering coatingIntermediate frequencyCombined method

The invention relates to a TiSiN-WS2 / Zr-WS2 coated cutting tool and a preparation process thereof. The matrix material of the TiSiN-WS2 / Zr-WS2 coated cutting tool is a hard alloy, and the cutting tool is prepared by adopting a multi-arc ion plating and intermediate-frequency magnetron sputtering combined method; and a coating is of a multilayer structure and sequentially comprises a Ti+TiN transition layer, a TiSiN layer, a TiN+Ti+Ti / Zr+Zr transition layer, a WS2 / Zr layer and a WS2 layer from the matrix to the surface coating of the tool, wherein the content of Zr element in the WS2 / Zr layer is gradually reduced from inside to outside. Due to the gradient change of Zr element in the WS2 / Zr layer, the hardness and the bearing capability of a lubricating layer are increased, a better transition between the TiSiN layer and the WS2 layer is achieved, and thus the lubricating effect is enhanced. The high hardness and high wear resistance of the TiSiN layer and the lubricating property of the WS2 coating are well combined, thereby preventing adhering, reducing a cutting force and a cutting temperature, reducing the abrasion of the tool, and prolonging the service life of the tool. The cutting tool can be widely applied to dry cutting and cutting of a difficult-to-machine material.

Owner:SHANDONG UNIV

Ultrasonic vibration assisted deep hole machining device

The invention relates to a deep hole machining device, in particular to an ultrasonic vibration assisted deep hole machining device. The ultrasonic vibration assisted deep hole machining device solves the technical problems that a tool is abraded severely, the surface quality is poor, and an oil supply device supplies oil inconveniently during the existing deep hole machining. The ultrasonic vibration assisted deep hole machining device comprises a drilling rod internally provided with a hollow structure, a connecting handle internally provided with a cavity, and an integrated amplitude transformer internally provided with a transducer, wherein one end of the connecting handle is opened; a cavity penetrating front and back is arranged in the center of the integrated amplitude transformer; the middle rear part of the integrated amplitude transformer is located in the cavity of the connecting handle and fixedly connected with the connecting handle; the front end of the integrated amplitude transformer is fixedly connected with the rear end of the drilling rod; and the cavity of the drilling rod is communicated with the cavity of the integrated amplitude transformer. The device applies ultrasonic vibration machining into deep hole machining of a gun drill, can effectively reduce a cutting force and cutting temperature and prolong the service life of the tool, reduces the surface roughness, and improves the machining precision.

Owner:ZHONGBEI UNIV

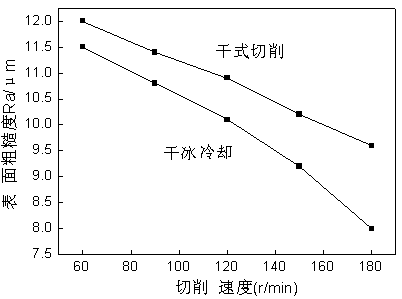

Dry cutting method for dry ice cooling

InactiveCN103801979ANo secondary wasteInhibitionMaintainance and safety accessoriesEconomic benefitsDry ice

The invention relates to the technical field of turning, in particular to a dry cutting method for dry ice cooling. The dry cutting method is characterized in that dry ice is smashed into powder, the powder and compressed air are mixed, and the powder is sprayed on a cutting machining portion of a cutting tool at the same time in the machining process. According to the dry cutting method, the problems of waste of cutting liquid and environmental pollution caused by the cutting liquid in the existing turning process are solved, the temperature of a cutting area is obviously reduced, precision of a machining surface is improved, the service life of a tool is prolonged, and economic benefits in the cutting machining process are improved.

Owner:CHANGZHOU UNIV

High-speed cutting method of thin-walled pod part

InactiveCN105562792AReduce pollutionGuaranteed geometric toleranceMilling equipment detailsEconomic benefitsEngineering

The invention relates to a high-speed cutting method of a thin-walled pod part and relates to the field of machining, in particular to a high-speed cutting method of a thin-walled pod part, comprising the following steps: milling front and back planes as well as a reference edge and a reference hole; rough machining and semi-finishing the front plane; filling a removed material part of the front plane, milling flat and turning over, and aligning the back plane according to the reference edge and the reference hole; rough machining and semi-finishing the back plane; finishing the back plane; removing front filling, filling a removed material part of the back plane, milling flat and turning over, and aligning the front plane according to the reference edge and the reference hole; finishing the front plane in the same finishing manner as the back plane. The method is high in machining efficiency and high in machining precision, low in cutting force, low in cutting temperature and low in environmental pollution, can ensure form and location tolerance of the thin-walled part and can provide higher economic benefit.

Owner:SHAANXI HI-TECH IND CO LTD

Polyvinyl acetal resin grinding wheel and production method thereof

ActiveCN102825557AHigh mechanical strengthImprove heat resistanceAbrasion apparatusGrinding devicesCrazingPolyvinyl alcohol

The invention discloses a polyvinyl acetal resin grinding wheel and a production method thereof. The polyvinyl acetal resin grinding wheel comprises the following materials in weight by parts: 50-60 parts of CBN abrasives, 5-10 parts of zirconia corundum abrasives, 5-10 parts of silicon powders, 5-15 parts of polyvinyl acetal resin powders, 2-6 parts of furfural, 1-2 parts of trioctyl trimellitate, 5-10 parts of cryolite, 5-10 parts of bauxite, 2-5 parts of nanometer siliceous shale powders and 2-5 parts of tool steel powders. The binder polyvinyl acetal resin used by the invention has high mechanical strength and good heat resistance, and the durability of the prepared resin grinding wheel is greatly improved. According to the invention, ceramic materials are added into a filer, thus the polyvinyl acetal resin grinding wheel has good bonding performance, the abrasives do not easily fall off, the heat resistance and the hardness of the resin grinding wheel are improved, cracks formed by rigid grinding are reduced, and the service efficiency and the service life of the resin grinding wheel are improved; and in addition, as the tool steel powders are added, thus the heat dissipation is fast to be beneficial for fast dissipating a large number of head emitted during cutting of the grinding wheel the role of reducing the cutting temperature is played.

Owner:安徽威铭耐磨材料有限公司

AlNbCN multielement gradient composite coating tool and preparing method thereof

ActiveCN107338411AHigh hardnessHigh strengthVacuum evaporation coatingSputtering coatingHeat stabilityCutting force

The invention belongs to the field of machining cutting tools, and relates to an AlNbCN multielement gradient composite coating tool and a preparing method thereof. The coating tool sequentially comprises a tool base body, a Ti transition layer, an AlNbC transition layer and an AlNbCN multielement gradient composite coating with the nitrogen content gradually changing in a gradient manner from interior to exterior, and the coating tool is prepared in a middle-frequency magnetron sputtering and arc plating composite coating method. According to the AlNbCN ultrahard carbohydrates and nitrogenous compound coating, due to the fact that the Al element and the Nb element are added in the coating at the same time, and the content of the nitrogen which is the structure component of the coating gradually changes in a gradient manner, thecutting machining performance of the tool can be improved. The AlNbCN multielement gradient composite coating tool has very high hardness and strength, low surface friction coefficient, good high-temperature oxidization preventing performance and excellent friction abrasion characters. In the cutting process, tool surface friction and cuttings bonding can be reduced through the tool, the cutting force and the cutting temperature can be reduced by 45% or above, the heat stability of the coating tool is improved by 65% or above, the service life of the tool is prolonged by 60% or above, and durability of the tool is improved by 60% or above.

Owner:JINING UNIV

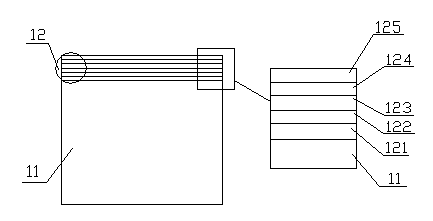

Self-lubricating coated cutting tool prepared based on electric spark deposition and preparation method thereof

InactiveCN103436883ASolve associativitySolve the problem of thin coatingMetallic material coating processesAlloyCutting force

The invention provides a self-lubricating coated cutting tool prepared on the basis of electric spark deposition and a preparation method thereof and belongs to the technical field of manufacturing of a mechanical cutting tool. A base material of the cutting tool is high-speed steel or hard alloy; a soft metal microcapillary electrode or an electrode of which the end face is provided with a microstructure is adopted; the microcapillary electrode or the microstructure of the electrode is full filled with a solid lubricant and then a self-lubricating coating is prepared on the surface of the cutting tool by adopting electric spark deposition. According to the invention, by utilizing the electric spark deposition technology, the cutting tool not only has a self-lubricating effect, but also has high bonding strength in the dry cutting process; due to the result, on one hand, a friction lubricating state of the cutting tool in the dry cutting process can be greatly improved, friction can be reduced, adhesion is prevented, a cutting force and a cutting temperature are reduced and wear of the cutting tool is reduced, and on the other hand, service life of the cutting tool can be prolonged. The self-lubricating coated cutting tool can be widely applied to dry cutting and cutting machining of materials difficult to machine.

Owner:QINGDAO UNIV OF SCI & TECH

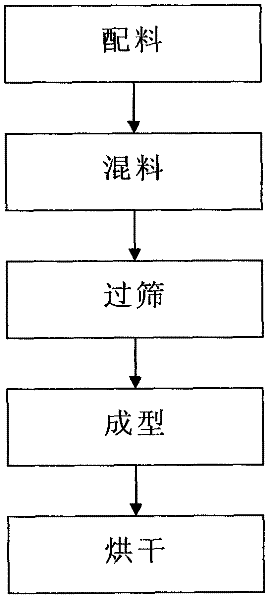

Method for manufacturing metal bonding agent and super-hard abrasive structured arrangement end face grinding wheel through laser cladding process

ActiveCN107520766AImprove liquidityExtended service lifeAbrasion apparatusGrinding devicesLaser processingLaser scanning

The invention discloses a method for manufacturing a metal bonding agent and super-hard abrasive structured arrangement end face grinding wheel through a laser cladding process. The method includes the following steps that metal powder and super-hard abrasives are mixed; ball-milling is performed; screening is performed; a mixture is poured into a laser cladding powder feeder; a metal matrix is polished, oil dirt and impurities on the metal matrix are removed, the surface of the metal matrix is cleaned, and the bright and clean to-be-machined metal matrix is obtained; according to certain laser processing parameters and a laser scanning strategy, the bright and clean to-be-machined metal matrix serves as a substrate for laser cladding processing, laser cladding processing of the super-hard abrasives is performed, and a metal substrate with a cladding layer in a special shape is obtained; and the metal substrate with the cladding layer in the special shape is cut into a disk-shaped metal substrate, and the disk-shaped metal substrate and a machined cutter handle are assembled to form the grinding wheel for end face grinding. The method is flexible and high in manufacturing efficiency, reduces the abnormal failure possibility of the super-hard abrasives, and improves the bonding force and the integrity of the super-hard abrasives in a metal bonding agent.

Owner:NORTHEASTERN UNIV

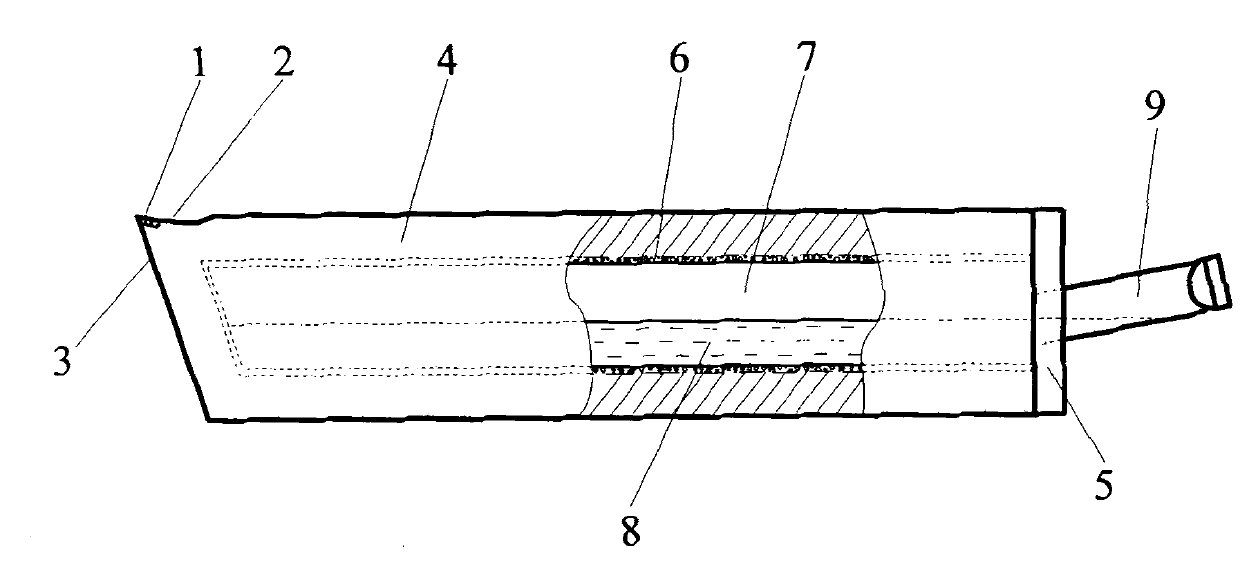

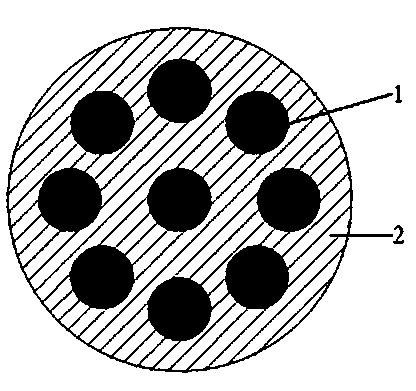

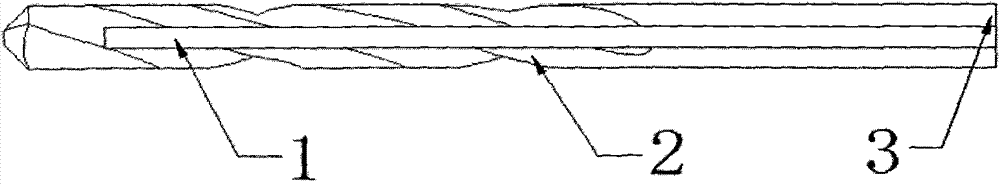

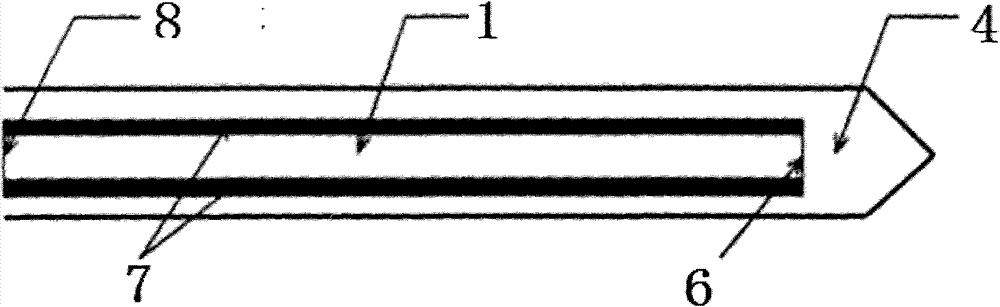

Method for prolonging service life of twist drill based on heat pipe phase changes

InactiveCN103537737AHigh heat transfer efficiencyReduce cutting temperatureTransportation and packagingTwist drillsHeat transfer efficiencyEngineering

The invention discloses an environment-friendly method for prolonging the service life of a twist drill based on heat pipe phase changes, so durability of a standard twist drill with a straight shank can be remarkably improved under a drilling especial for high-speed drilling machining condition. According to the method, a heat pipe theory and technology are brought in, heat pipe phase change heat transfer characteristics are made use of, cutting fluid is not adopted, and the cutting temperature of the main cutting edge and the cutting temperature of the chisel edge part of the twist drill are rapidly lowered with the help of a heat pipe to reduce the abrasion rate of the main cutting edge and the chisel edge part of the twist drill so that the purpose of prolonging the service life of the twist drill is achieved. Heat pipe phase change heat transferring is adopted in the method, so the heat pipe is higher than cutting fluid in heat transfer efficiency; the heat pipe technology is adopted, so the heat pipe is more environment-friendly than cutting fluid, and personal injuries to operation staff do not exist. In addition, the heat pipe adopted in the method is cheaper than the cutting fluid in market price, and therefore manufacturing cost of products of enterprises can be reduced.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Binding-phase-free WC-based hard alloy cutter material and preparation method thereof

The invention discloses a binding-phase-free WC-based hard alloy cutter material and a preparation method thereof. According to the invention, tungsten carbide is used as a base material; nano complexphase ceramic doping is adopted, and the effects of defect reinforced sintering and liquid-phase reinforced sintering are synergistically exerted; meanwhile, two-dimensional graphene nanosheets and one-dimensional carbon nanotubes are hybridized to serve as a synergistic strengthening and toughening phase and a densification phase of the binding-phase-free WC-based hard alloy cutter material; thegraphene is loaded with carbon nanotube, the graphene is supported by the carbon nanotubes; a three-dimensional strengthening and toughening and rapid heat conduction network is constructed; dispersing agents which enable the two components to be mutually dispersed; a contact area of the graphene-carbon nano tube and a cutter material matrix is increased, and a graphene and carbon nano tube synergistic toughening mechanism and a synergistic heat conduction mechanism are formed in the aspect of function, so that the bending strength, Vickers hardness and fracture toughness mechanical properties of the obtained binding-phase-free WC-based hard alloy cutter material are greatly improved. The adopted graphene-carbon nanotube three-dimensional space structure has a high heat conduction coefficient, and the heat dissipation capacity of the cutter is greatly improved.

Owner:XI AN JIAOTONG UNIV

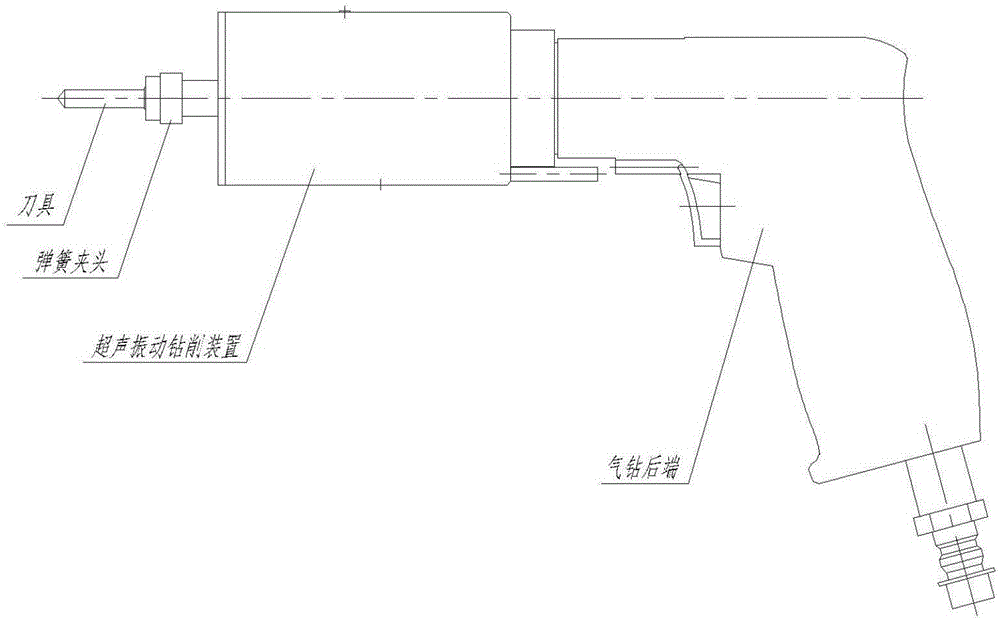

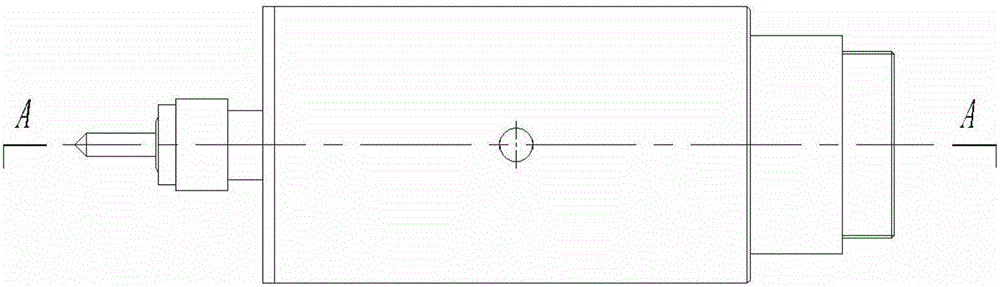

Ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission

InactiveCN106825679AKeep it workingImprove processing qualityCircuit arrangementsPortable drilling machinesElectric power transmissionSmall amplitude

The invention discloses an ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission. The ultrasonic vibration pneumatic drill comprises a rotary wireless electric power transmission assembly, an ultrasonic transduction assembly, an amplitude-change pole, a spring chuck assembly and a connecting assembly, wherein the rotary wireless electric power transmission assembly is used for realizing electric power transmission between two mechanisms rotating oppositely and comprises a wireless electric power transmission primary unit and a wireless electric power transmission secondary unit; the ultrasonic transduction assembly is used for converting ultrasonic-frequency electric signals into ultrasonic-frequency mechanical vibration; the ultrasonic vibration amplitude-change pole is used for amplifying small-amplitude mechanical vibration into large-amplitude mechanical vibration to meet requirements of ultrasonic vibration drilling machining; the spring chuck assembly is used for clamping tools; the connecting assembly is used for connecting ultrasonic vibration drilling parts with the rear end of the pneumatic drill so as to realize power transfer and electric power transmission. Ultrasonic vibration is applied to the traditional drilling machining process, and a combined machining mode of coupling of ultrasonic vibration and traditional drilling motion is formed, so that machining quality is effectively improved and machining efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Indexable cutting insert for rough machining

ActiveCN103009333AImprove impact resistanceGuaranteed impact resistanceMetal-working hand toolsEdge strengthEngineering

The invention discloses an indexable cutting insert for rough machining. An insert body is a polygonal body, the geometrical center is provided with a mounting through hole, a chip breaker body is arranged around the mounting through hole, and cutting units are respectively distributed at the included angle between each two neighboring sides. The indexable cutting insert is characterized in that each cutting unit consists of a main cutting edge and an auxiliary cutting edge; each of the main cutting edge and the auxiliary cutting edge is provided with a chamfer plane and an arris plane, and a first front insert face and a second front insert face are connected with the chip breaker body through concave bottoms; at each cutting unit, the chip breaker body is provided with a boss, the surface of the boss gradually rises to form a first chip breaker and a second chip breaker, a first concave is formed between the ridge of the first chip breaker and the ridge of the second chip breaker, a second concave is formed between the second chip breaker and the chip breaker body, and both the first concaves and the second concaves are smoothly connected with the concave bottoms. Under the premise of guaranteeing the edge strength of the insert, the cutting resistance is decreased, the indexable cutting insert has high chip-breaking ability, and the overall cutting performance is good.

Owner:OKE PRECISION CUTTING TOOLS CO LTD

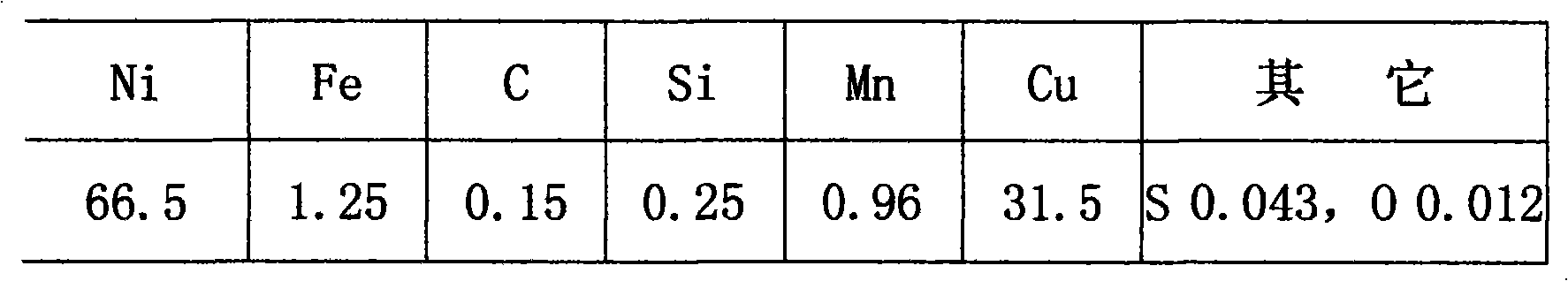

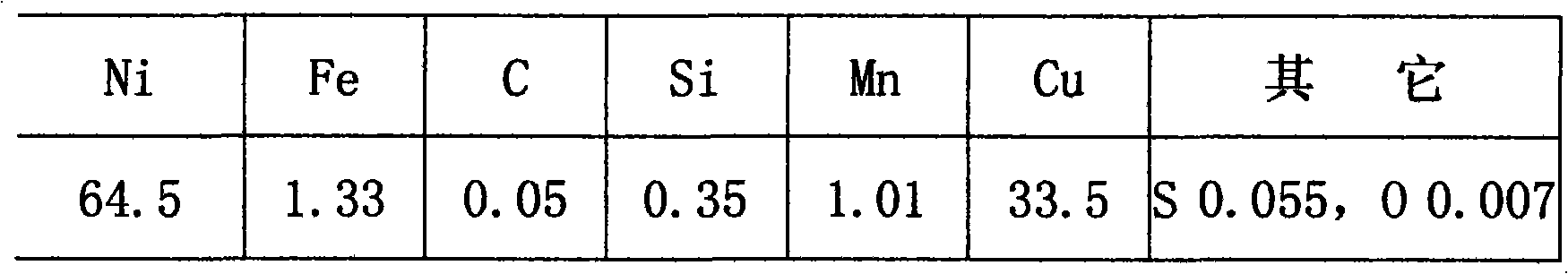

Preparation for free-cutting adnic alloy

A free-cutting nickel-copper alloy is disclosed whose ingredients by percent are that: carbon<=0.3, manganese <=2.0, iron<=2.5, sulphur 0.025-0.060, silicon<=0.5, copper 28.0-34.0, the rests are nickel, the manufacturing method of the free-cutting nickel-copper alloy comprises the steps of: 1, loading and vacuumizing; 2, controlling the temperature within the range from 1500 to 1650 DEG C, refining for 5 to 25 minutes, adding deoxidizer and finally the sulphide to lead the sulphur content in the nickel-copper alloy to be between 0.020% and 0.08%, the optimized sulphur content is 0.040% 0.06%, the sulphide is one of manganese sulphide, iron sulphide, copper sulphide and high nickel matte or mixture thereof, the deoxidizer is one of carbon and nickel-magnesium alloy, calcium-silicon alloy, and copper-zirconium alloy or the mixture thereof; 3, measuring the temperature and casting at the temperature between 1400 and 1500 DEG C for 30 seconds at most, and vacuumizing for at least 10 minutes; the good cutting performance of the steel remarkably improves the cutability of steel, reduces the cutting force and cutting temperature, conspicuously prolonging the life of cutting tool, lessens the surface roughness of working piece and improves the cut-processing performance.

Owner:沈阳金纳新材料股份有限公司

Ultrasonic vibration cutting device

InactiveCN102528102AReduce cutting forceImprove machining accuracyTurning toolsStone-like material working toolsTransducerEngineering

The invention discloses an ultrasonic vibration cutting device, mainly comprising a cutting blade, a cutting tool head, a locking nut I, a variable-amplitude rod, a locking nut II, a shell, a fixed clamping disc, a screw rod, a transducer fan, a rear cover and a digital power control box, wherein the shell is cylindrical; the upper part of the inner diameter of a cylinder is provided with a thread; the lower part of the thread of the inner diameter of the cylinder is provided with a triangular boss; the plane of the triangular boss is upward; the lower part of the inner diameter of the cylinder is also provided with a thread; the upper part of the thread is also provided with a triangular boss; the plane of the triangular boss at the lower part is downward; the middle part outside the cylinder is provided with the fixed clamping disc; and the bottom part of the shell is connected with the rear cover. The ultrasonic vibration cutting device has the advantages that the effect is obvious in the aspects of cutting and processing materials difficult to process, the cutting force is small, and the processing accuracy is high; the processing process is stable, and the flutter can be effectively eliminated; the processed surface is in a pressure state, the fatigue strength, the wear resistance and the corrosion resistance of a part are improved; and a digital power supply is adopted, the frequency can be tracked automatically and the power can be adjusted, so that the working can be continuous for 24 hours and the like.

Owner:河北海拓机电科技有限公司

Ultrasonic vibration workbench and machining technology

ActiveCN109571111ASimple structureEasy to disassembleWorking accessoriesMetal working apparatusEngineeringUltrasonic vibration

The invention relates to the technical field of machining, and discloses an ultrasonic vibration workbench and machining technology. The ultrasonic vibration workbench comprises a base, an ultrasonictransducer, a composite booster and a clamp; the base is provided with a cavity, and the ultrasonic transducer is encapsulated inside the cavity; an input end of the composite booster is detachably connected with the ultrasonic transducer, and an output end of the composite booster is connected with the clamp; and the clamp is used for clamping a workpiece to be machined. According to the ultrasonic vibration workbench, the workpiece performs the ultrasonic vibration so as to be free of limitation from high-speed rotation of a tool, the machining process is more stable and the ultrasonic vibration workbench can be applied to a high-speed cutting environment; the cutting force and the cutting temperature can be effectively reduced, the damage of the tool and the ultrasonic transducer can bereduced, and the machining quality can be improved; and the ultrasonic vibration workbench is simple in structure, convenient to detach, and ready to mount and use.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com