Ultrasonic oval vibrating mechanism for assisting diamond cutter in ultra-precision cutting

A diamond tool, elliptical vibration technology, used in the attachment of tool holders, tools for lathes, fluids that utilize vibration, etc. Restrict the quality of the machined surface and other problems, and achieve the effects of good vibration conductivity, no reflection, and large lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

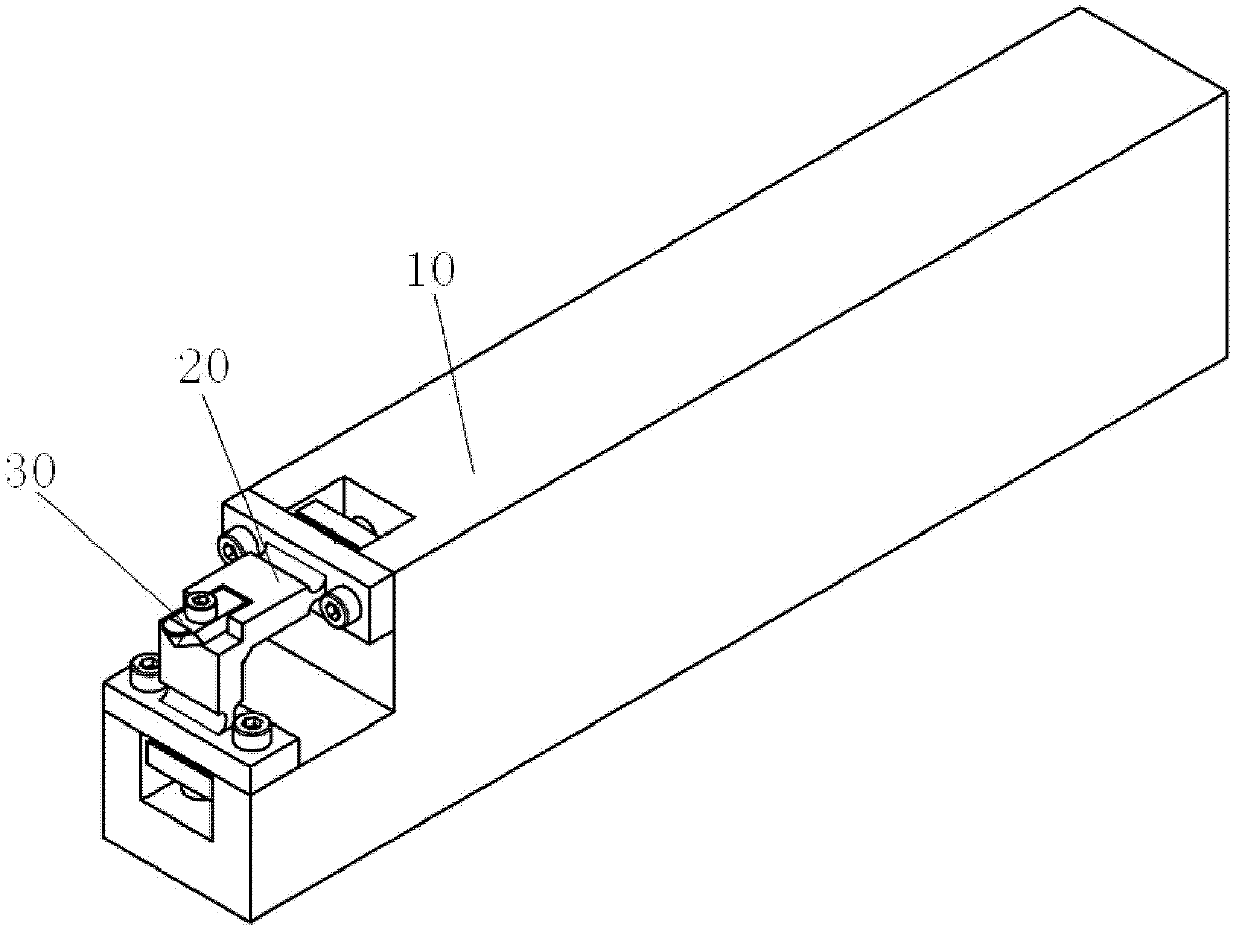

[0018] Such as figure 1 As shown, the present invention mainly includes a handle 10 , a vibration unit 20 and a tool 30 ; the vibration unit 20 is arranged on the handle 10 , and the tool 30 is arranged on the vibration unit 20 .

[0019] Such as figure 2 As shown, one end of the knife handle 10 of the present invention is stepped, and a groove 103 is arranged on the vertical surface 101 and the horizontal surface 102 of the upper step, and a groove is also arranged on the vertical surface 104 and the horizontal surface 105 of the lower step. 106. The size and shape of the tool holder 10 of the present invention are the same as those of conventional cutting, so it can be directly installed on a conventional tool holder.

[0020] Such as image 3 , Figure 4 As shown, the vibrating unit 20 of the present invention mainly includes a vibrating body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com