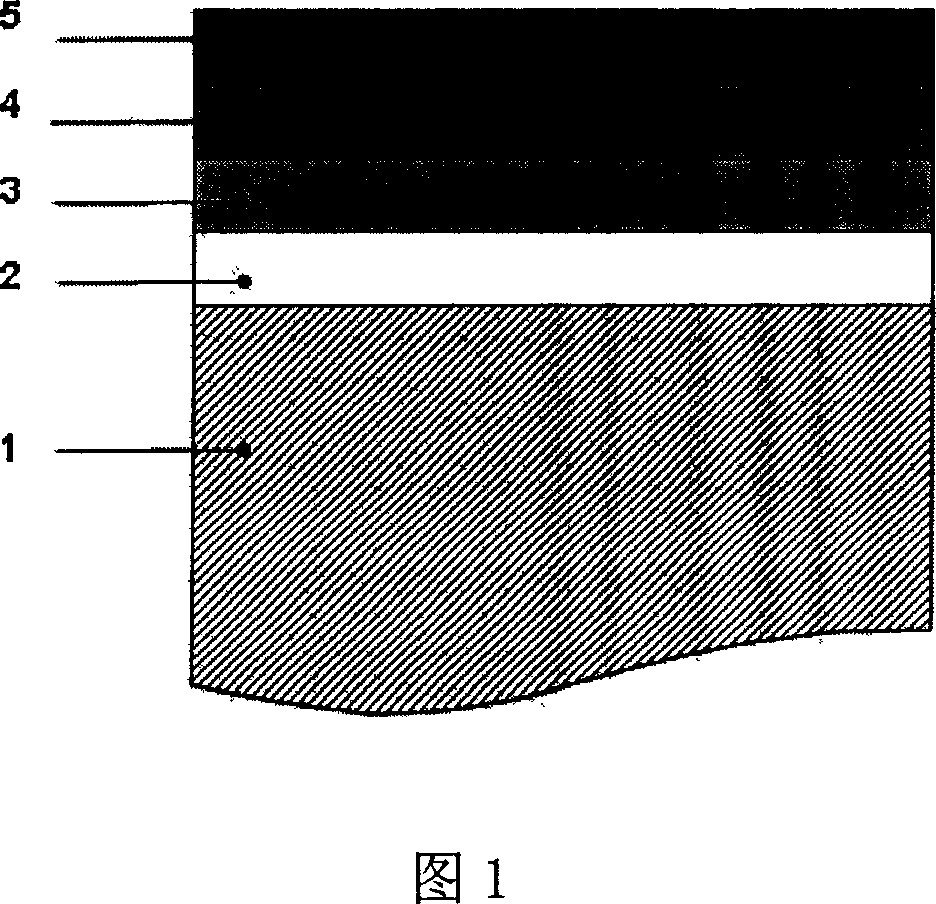

Self-lubricating composite soft coating cutter and manufacture method thereof

A soft coating and self-lubricating technology, applied in coatings, metal material coating processes, layered products, etc., can solve problems such as lack of cutting fluid lubrication and cooling, tool wear, and liquid lubrication performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A self-lubricating composite soft-coated tool and its preparation method. The base material of the tool is: W18Cr4V high-speed steel; the coating material is: Ti, Zr and MoS 2 ; The deposition method is: medium frequency magnetron deposition MoS 2 +Multi-arc plating of Zr and Ti. Its preparation process steps are as follows:

[0021] (1) Pretreatment: Polish the W18Cr4V high-speed steel tool base material to a mirror finish, remove the surface contamination layer, put it into alcohol and acetone for ultrasonic cleaning for 15 minutes each, remove surface sweat stains, oil stains and other dirt, and quickly put it into the vacuum chamber. Vacuum chamber background vacuum 7.0×10 -3 Pa, heated to 160°C and kept for 30 minutes.

[0022] (2) Ion cleaning: Ar gas 0.8Pa, turn on the bias power supply, voltage: 800V, duty cycle: 0.2, glow discharge cleaning for 15 minutes; reduce the bias voltage to 200V / 0.2, turn on the ion source ion cleaning for 15 minutes....

Embodiment 2

[0028] Embodiment 2: A self-lubricating composite soft-coated tool and its preparation method. The base material of the tool is: YT14 cemented carbide; the coating material is: Ti, Zr and MoS 2 ; The deposition method is: medium frequency magnetron deposition MoS 2 +Multi-arc plating of Zr and Ti. Its preparation process steps are as follows:

[0029] (1) Pretreatment: Polish the YT14 cemented carbide tool base material to a mirror finish, remove the surface contamination layer, put it into alcohol and acetone for ultrasonic cleaning for 15 minutes each, remove surface sweat stains, oil stains and other dirt, and put it away quickly after drying fully. into the vacuum chamber. Vacuum chamber background vacuum 7.0×10 -3 Pa, heated to 160°C and kept for 40 minutes.

[0030] (2) Ion cleaning: Ar gas 1.0Pa, turn on the bias power supply, voltage: 900V, duty cycle: 0.2, glow discharge cleaning for 15 minutes; reduce the bias voltage to 200V / 0.2, turn on the ion source ion clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com