Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Improve slagging ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

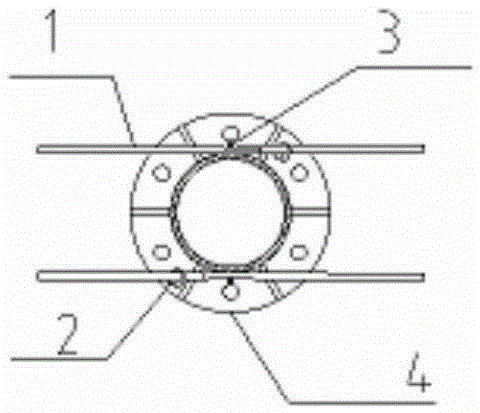

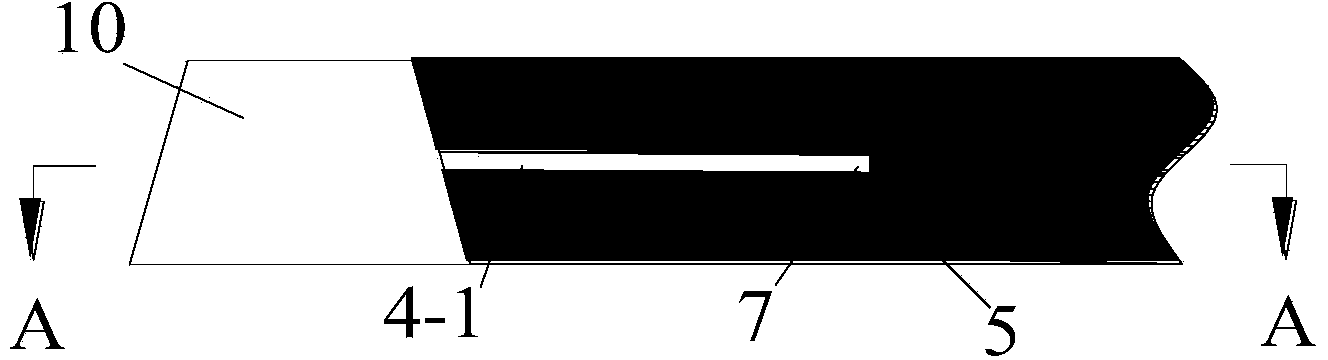

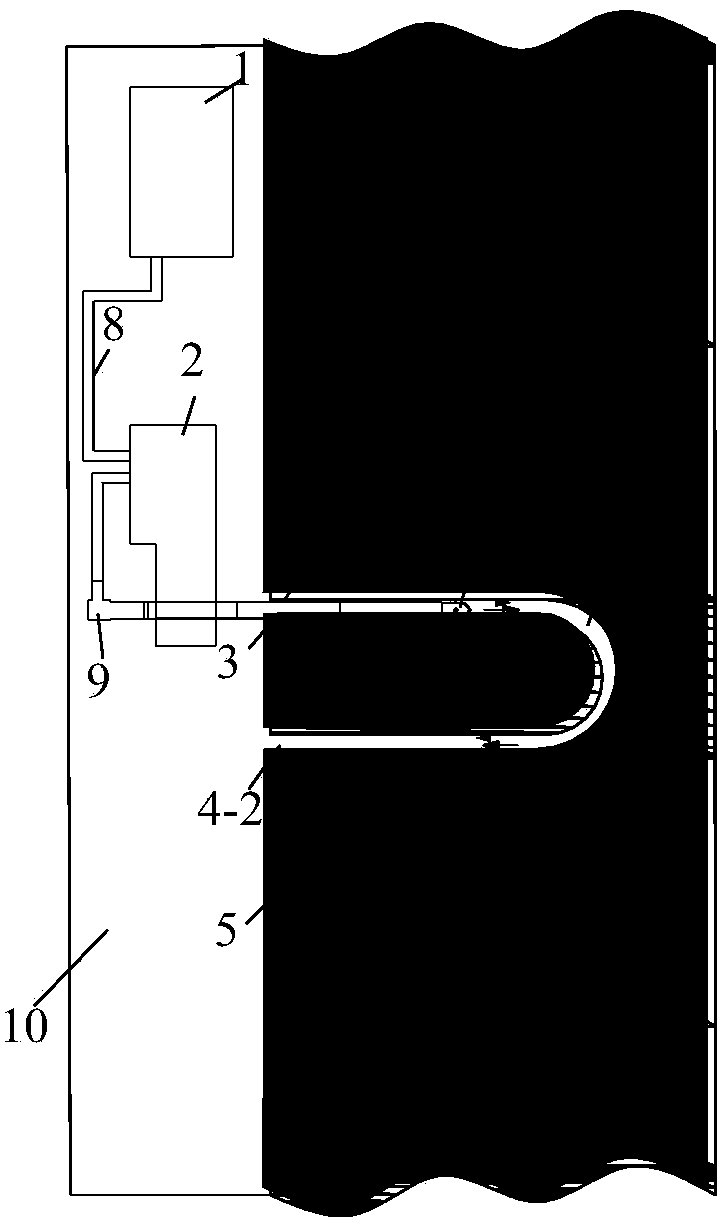

In-hole drilling tool integrating drilling, slotting and punching coal seam and using method thereof

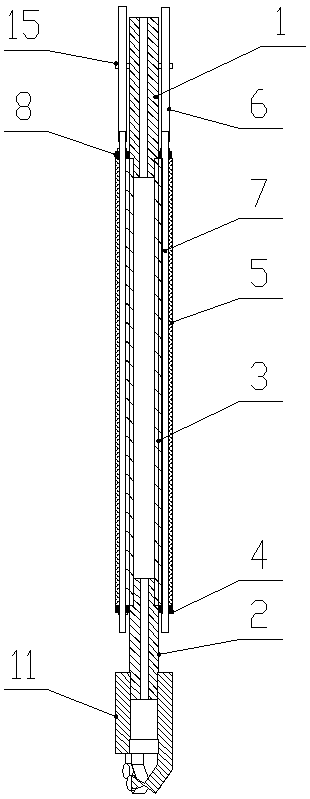

InactiveCN101532391AGuaranteed cleanlinessAvoid enteringDrill bitsLiquid/gas jet drillingHigh pressure waterHigh pressure

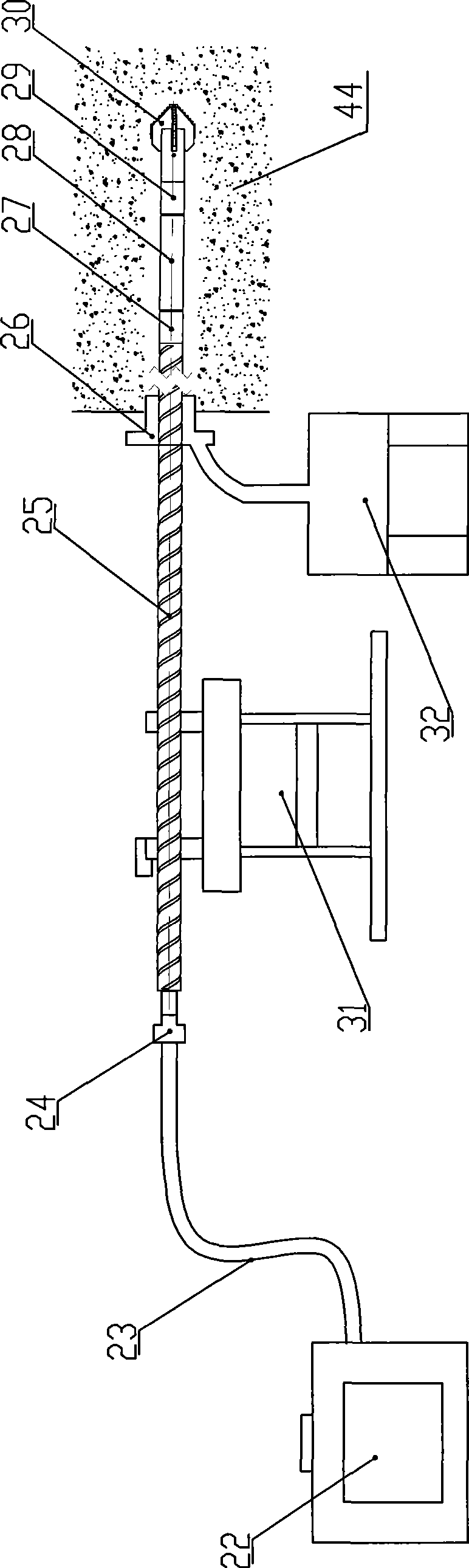

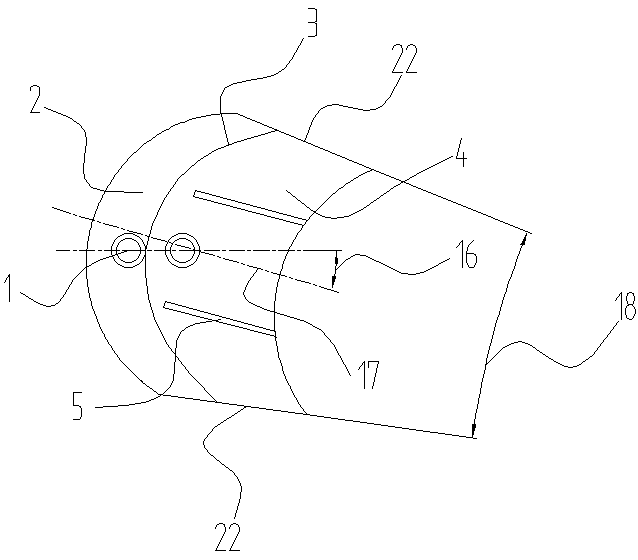

The invention discloses an in-hole drilling tool integrating drilling, slotting and punching a coal seam and a using method thereof. The in-hole drilling tool comprises a water supple device or an air supple device, a high-pressure sealing drill pipe, a slotting and punching valve and a drill bit. The water supply device and the air supply device are connected with the high-pressure sealing drill pipe at an orifice. The slotting and punching valve is installed between the high-pressure sealing drill pipe and the drill bit. The in-hole drilling tool is essentially used for drilling and anti-reflective outburst eliminating after drilling of soft outburst coal seam. The using method is as follows: after the drilling construction is finished, a water supplier with a pressure release valve is used for starting a high-pressure pumping station to improve the pressure and the flux for water supply; high-pressure water current at the pumping station drives the slotting and punching valve to act for closing an axial liquid passage and opening a radial liquid passage; and high-pressure jet current realizes slotting or punching through a cutting nozzle or a punching nozzle. The invention has novel design and easy operation, is safe and reliable, improves the outburst elimination efficiency and realizes the integrated operation of drilling, slotting or punching and outburst eliminating.

Owner:HENAN POLYTECHNIC UNIV

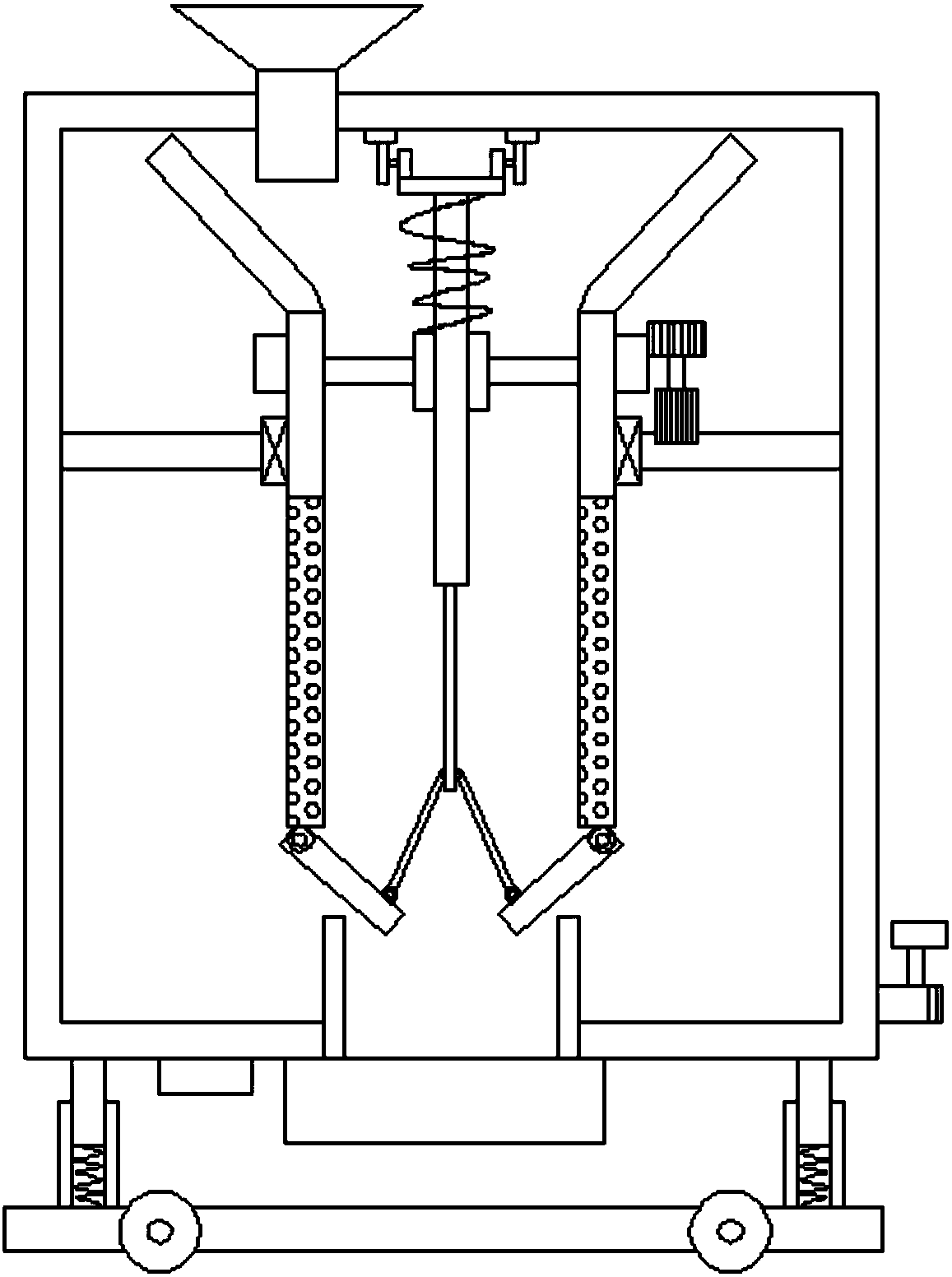

Rotary centrifugal type traditional Chinese medicine solid-liquid separation device

The invention discloses a rotary centrifugal type traditional Chinese medicine solid-liquid separation device, which comprises a base and a processing box. The left and right sides of the base are provided with rollers for convenient transportation of the device, a processing box is arranged above the base, and the lower end of the processing box is symmetrical on both sides. A support rod is provided, the lower end of the support rod is provided with a support sleeve, the lower end of the support sleeve is connected and fixed with the base, and a shock-absorbing spring is arranged inside the support sleeve, and the shock-absorbing spring connects and fixes the support sleeve and the support rod. It helps to improve the anti-seismic performance of the device, thereby making the transportation of the device more stable. A rotating drum is suspended in the middle of the processing box. The structure of the invention is simple and reasonable, and the rapid separation of solid and liquid can be realized through centrifugal screening, which greatly improves the At the same time, the bottom of the screening and separation cylinder is provided with an openable bottom plate to facilitate subsequent slag discharge treatment. In addition, the device also has a vibration mechanism, which helps to improve the slag discharge effect and has strong practicability.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

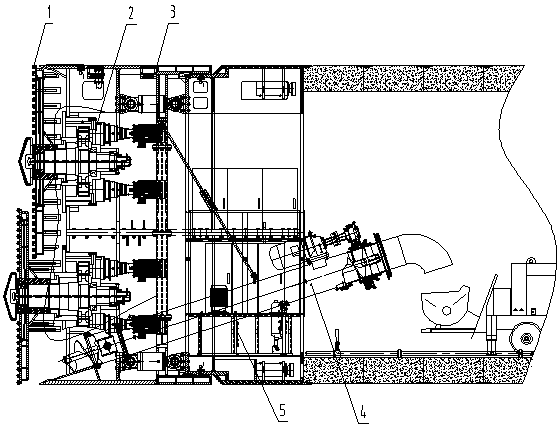

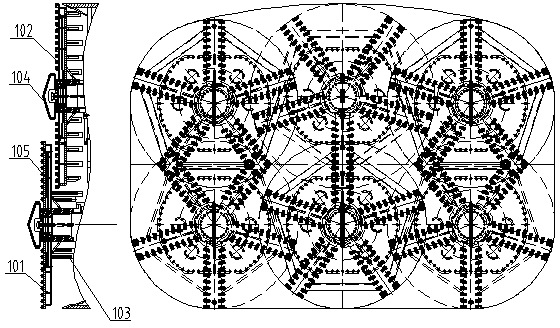

Shield tube push bench with super-large rectangular cross section

ActiveCN104088647AImprove construction efficiencyReduce disturbanceTunnelsEngineeringEarth pressure balance

The invention relates to a shield tube push bench with a super-large rectangular cross section. The tube push bench comprises a cutterhead device, a driving system, a shield structure, a screw conveyer and a back up system, wherein the section of the shield structure is rectangular, and the upper part of the shield structure is in the shape of an arch camber; the shield structure comprises a front shield, error correcting cylinders, a tail shield, adjustable hinged seals and an appearing cylinder; the front shield supporting and driving system is characterized in that the front shield is connected with the tail shield through at least two sets of error correcting cylinders, and the appearing cylinder is arranged at the rear end of the tail shield. In order to further improve the structure of the push bench, the cutterhead device is a combined cutterhead, and can ensure that the earth pressure of the front shield and a tunnelling surface is balanced, and disturbance to an earth layer is small; the driving system is an independent drive system, and a torque can be regulated in a real time manner according to a geological condition. Therefore, the push bench is high in construction efficiency, and small in disturbance to a bottom layer, the ground surface settlement is decreased, the construction reliability is improved, the deslagging efficiency is improved, and the assembling, disassembling, operation and control of the whole tube push bench is convenient and safe; the construction cost of the tube push bench is low, and the tube push bench is economical and practical.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

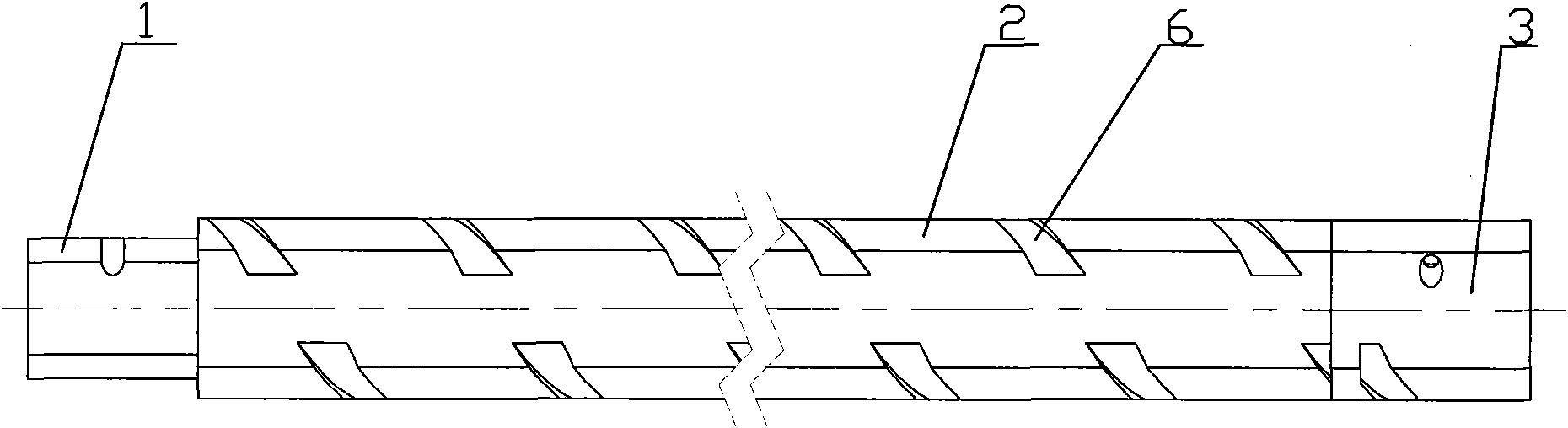

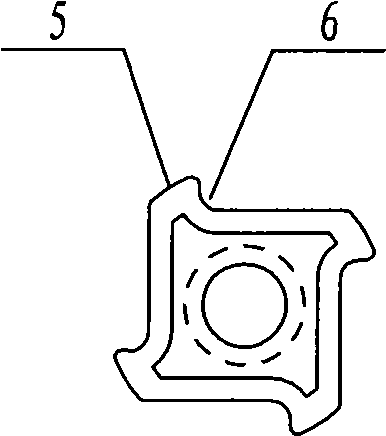

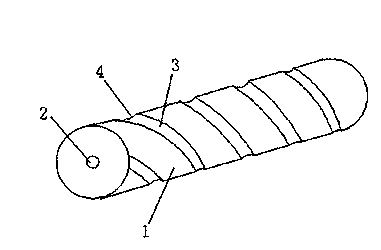

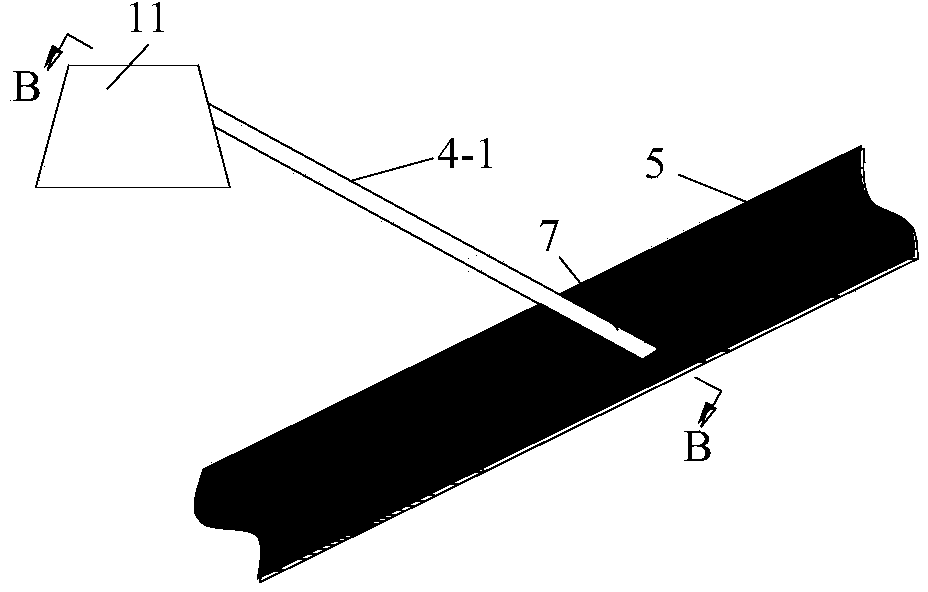

Irregularly shaped multi-land notch groove drill rod

ActiveCN101566049ALow rotational resistanceTake away in timeDrilling rodsDrilling casingsLine segmentHelix

The invention discloses an irregularly shaped multi-arris notch groove drill rod, which consists of a hollow multi-arris rod body and a connecting piece, the section outline of the multi-arris rod body consists of tangential paths and circular arc sections, and incontinuous spiral grooves are distributed on the surface of the rod body simultaneously. The drill rod can cause vortex flow when whirling in loose cinder and raise coal dust deposited on the bottom of a drilling hole in virtue of the arris of the drill rod, and the coal dust in the drilling hole is at a moving status all the time, thus preventing the coal dust from accumulating in the drilling hole and resulting in blockage; simultaneously, the incontinuous spiral grooves distributed on the surface can assist in the outward transmission of the cinder, and when hole collapsing in the drilling hole, the outside of the collapsed hole is unchoked by the hole digging function of the spiral grooves, thus being not easy to have drill absorption and drill blockage. The drill rod has the advantages of reasonable design, simple structure, safety and reliability, thus greatly improving deslagging effect, being beneficial to increasing the depth of the drilling holes, shortening hole drilling time, improving work efficiency and having high hole forming rate. Therefore, the drill rod is worth popularizing and applying in mining enterprises.

Owner:山东益矿钻采科技有限公司

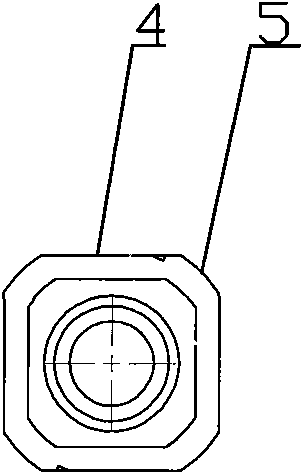

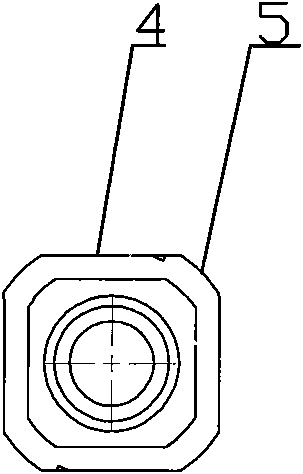

Drilling rod with asymmetric special-shaped cross section

ActiveCN101481999ALow rotational resistanceHigh porosityDrilling rodsDrilling casingsSlagDrilling riser

The invention discloses an asymmetric deformed-section drill pipe which is composed of a hollow pipe body and a connecting piece which are detachably connected; beads which are more than or equal to two and less than or equal to eight are arranged on pipe body along the pipe body, and the outer surface of the bead is an arc surface which takes an axle wire of the pipe body as a circle center, and one side of the bead and the pipe body form a long-strip groove. The drill pipe has reasonable design and simple structure; drill adsorption and drill blocking can not easily happen according to the principle of vortex flow caused by rotation of the deformed-section rigid body in loose coal slag, therefore, the drill pipe is safe and reliable, slag-off effect is greatly improved, thus being beneficial to improving drilling depth, shortening drilling time and improving working efficiency and pore-forming efficiency and being worth of being popularized and applied in coal mine enterprises.

Owner:山东益矿钻采科技有限公司

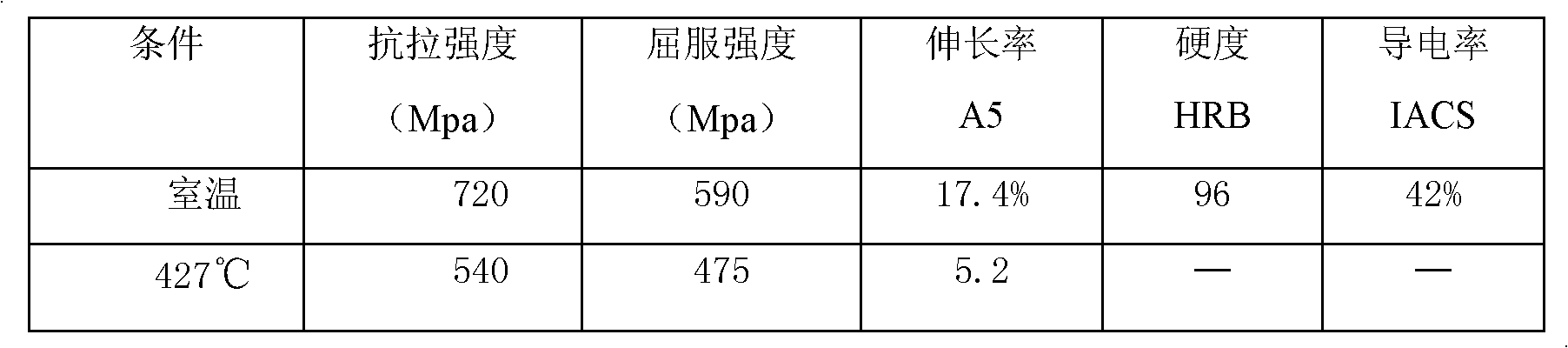

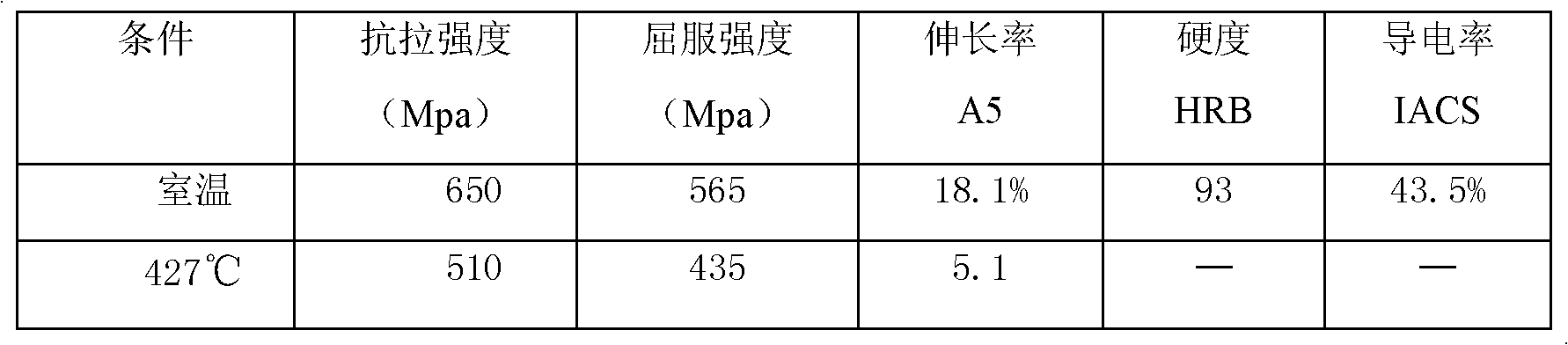

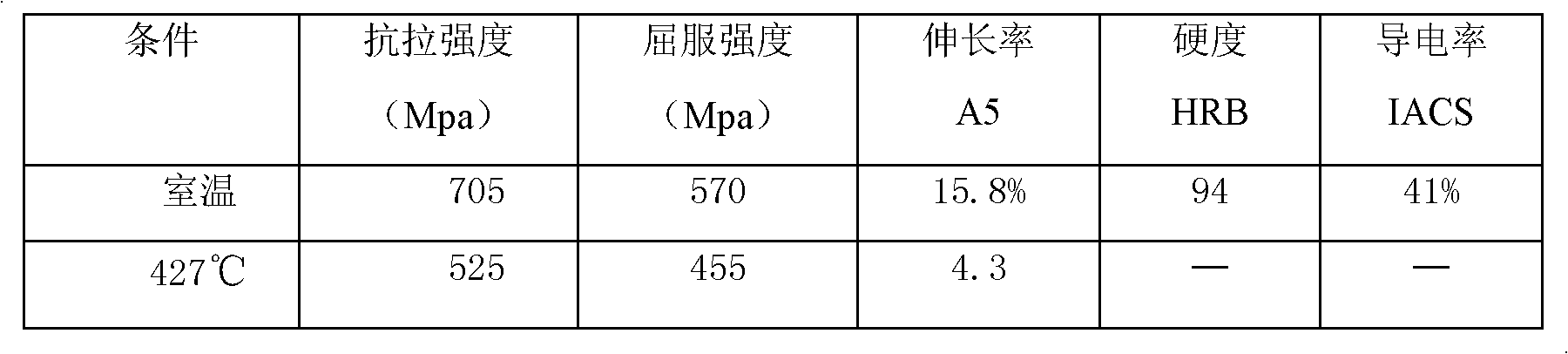

Copper alloy material with high strength and conductivity and manufacturing method of copper alloy material

The invention relates to a copper alloy material with high strength and conductivity and a manufacturing method of the copper alloy material. The copper alloy material with high strength and conductivity comprises the following elements in percentage by weight: 2.30-2.90 percent of Ni, 0.35-0.60 percent of Si, 0.30-0.60 percent of Cr, 0.10-0.3 percent of Al, 0.05-0.10 percent of Be, and Cu and inevitable impurities in balancing amount. According to the invention, the high conducting performance of a Cu-Ni-Si system alloy is utilized, and Cr, Al and a trace amount of Be alloy element are added; and through a proper processing technique, mutual action among the elements is fully played and the requirements on the performances of high strength, high conductivity, heat resistance and high-temperature oxidation resistance are met.

Owner:芜湖金科缘特种材料有限公司

Magnesium alloy rare earth compound flux and its production method

The present invention provides a magnesium alloy rare earth compound flux and its production method. Its composition includes (wt%) 40-55% of magnesium chloride, 15-25% of potassium chloride, 12-25% of sodium chloride, 1-6% of calcium chloride, 5-15% of calcium fluoride, 1-8% of barium chloride and 3-10% of rare earth activator. Said ivnention flux has high activity, proper melting point, density, viscosity and surface tension, and can greatly raise mechanical property of magnesium alloy and corrosion resistance.

Owner:SHANGHAI HAOHUA MOLD

Mg-Gd-Y-Zr magnesium alloy refining flux and producing method thereof

The invention provides an Mg-Gd-Y-Zr magnesium alloy refining flux and a production method thereof. The chemical components of the flux are mixed according to the following mass percentages: potassium chloride of ranging from 30 to 50 percent, barium chloride of ranging from 5 to 20 percent, sodium chloride of ranging from 2 to 10 percent, calcium chloride of ranging from 10 to 20 percent, calcium fluoride of ranging from 2 to 8 percent, cryolite of ranging from 1 to 5 percent, gadolinium compound of ranging from 3 to 8 percent, yttrium compound of ranging from 3 to 8 percent, and zirconium compound of ranging from 2 to 8 percent, wherein, the gadolinium compound is gadolinium chloride, gadolinium carbonate or gadolinium fluoride, the yttrium compound is yttrium chloride, yttrium carbonate or yttrium fluoride, the zirconium compound is zirconium tetrachloride or potassium zirconium fluoride. The flux has good melting point, viscosity, wettability and the slag removing performance which is improved greatly. Because the flux does not contain magnesium chloride or react with the lanthanon such as gadolinium and yttrium, the chemical reaction loss of the lanthanon in the refining process is not caused, thereby being particularly suitable for the refining purifying process of the Mg-Gd-Y-Zr magnesium alloy and improving the refining effect of the magnesium fused mass.

Owner:SHANGHAI JIAO TONG UNIV

Melting agent for refining alloy in rare earth class and fabrication method

This invention provides a Mg rare earth alloy refinery fusing agent and its production method, the sphere of which mass percentage ratio of its chemical components is : 20-40% CaCl, 10-25% KCl, 10-25% NaCl, 15-25% BaCl, 2-5% CaF 3-10% sodium and 3-10% active rare compound which can be: rare earth chloride, rare earth fluoride or rare earth carbonate. This invention regulates the proportion of Cl and F salts and add the slagging constituent sodium and active rare compound, so the fusing agent has a good fusing point, viscosity and humectants and greatly increase its slag eliminating ability.

Owner:SHANGHAI JIAO TONG UNIV

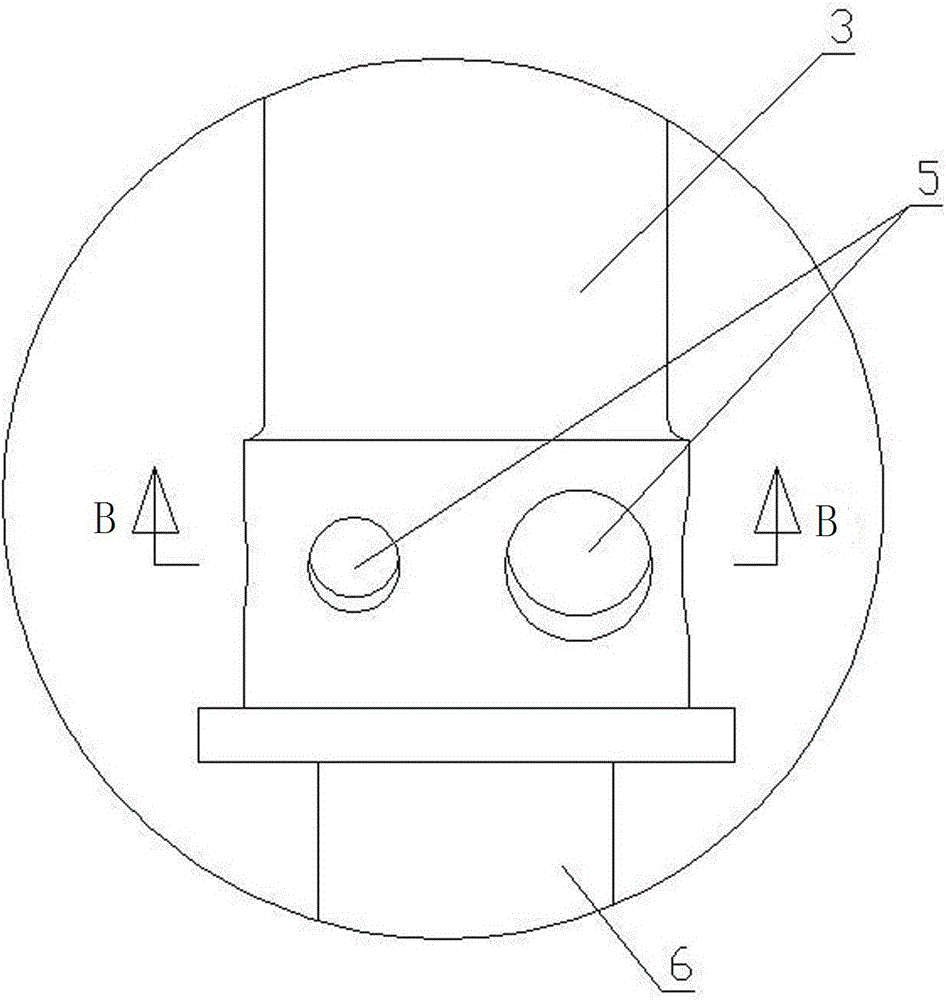

Slagging promoting device for ultra-thick clay layer positive-cycle cast-in-place pile and construction method of slagging promoting device

ActiveCN105297732AReduce deposition thicknessReduce construction costsBulkheads/pilesDrilling machinesWire rope

The invention relates to a slagging promoting device for an ultra-thick clay layer positive-cycle and a construction method of the slagging promoting device. The device comprises crushing steel wire rope bundles, steel wire rope clamps, a fixing pressing bar and a drill rod. The crushing steel wire rope bundles are composed of a plurality of steel wire ropes. Each steel wire rope is connected to be in a ring shape through the corresponding steel wire rope. The crushing steel wire rope bundles are fixed to the drill rod in sequence through the fixing pressing bar. The steel wire rope bundles are symmetrically arranged along the drill pipe in two rows. The construction method includes the steps that the discharging length of each steel wire rope is calculated according to the diameter of a pile hole; the steel wire rope clamps are used for locking all the steel wire ropes into ring shapes, and the position, on the surface of the drill rod, of each steel wire rope is marked; the fixing pressing bar is used for fixing the steel wire rope bundles to the drill rod in sequence according to the sizes of diffusion diameters; a common positive-cycle drilling machine is used for drilling to the position close to a clay layer; and a first section of a common drill pipe is replaced with the drill pipe manufactured in the step, and subsequent drilling construction work is conducted. According to the slagging promoting device, the slagging capability and the drilling efficiency of the positive-cycle construction technology in drilling in the ultra-thick clay layer are effectively improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

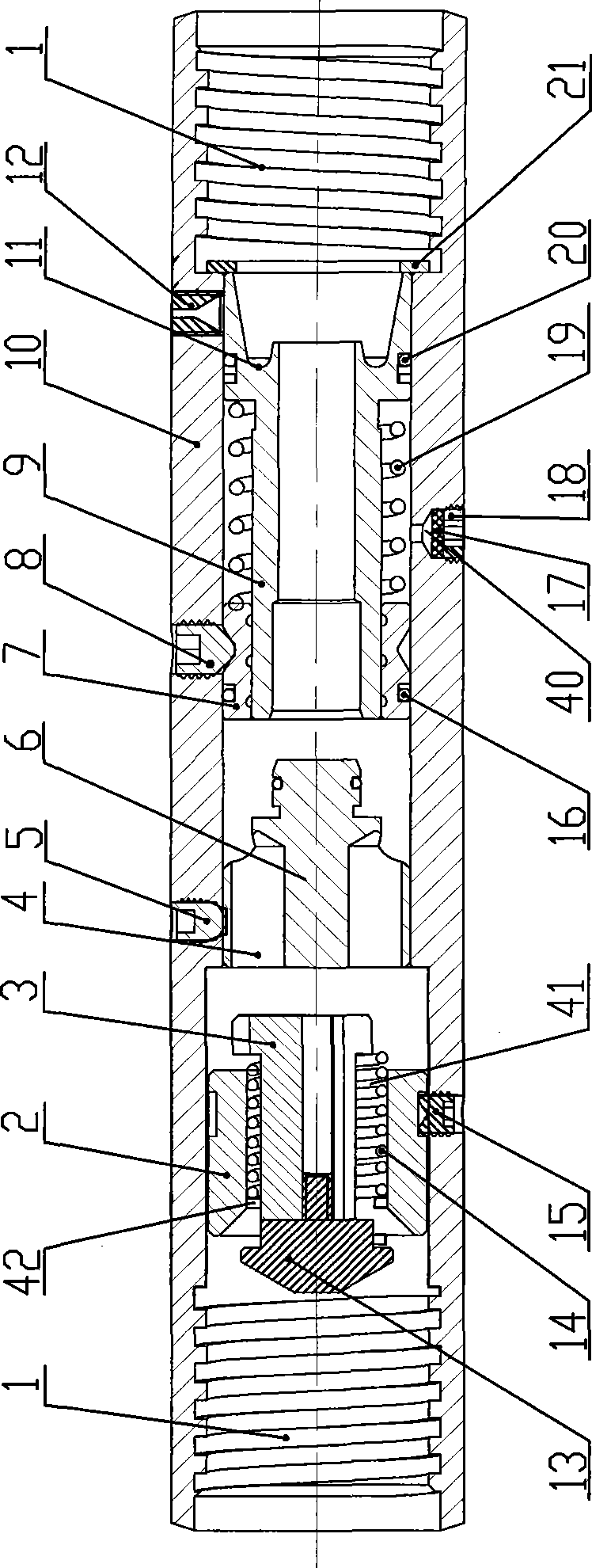

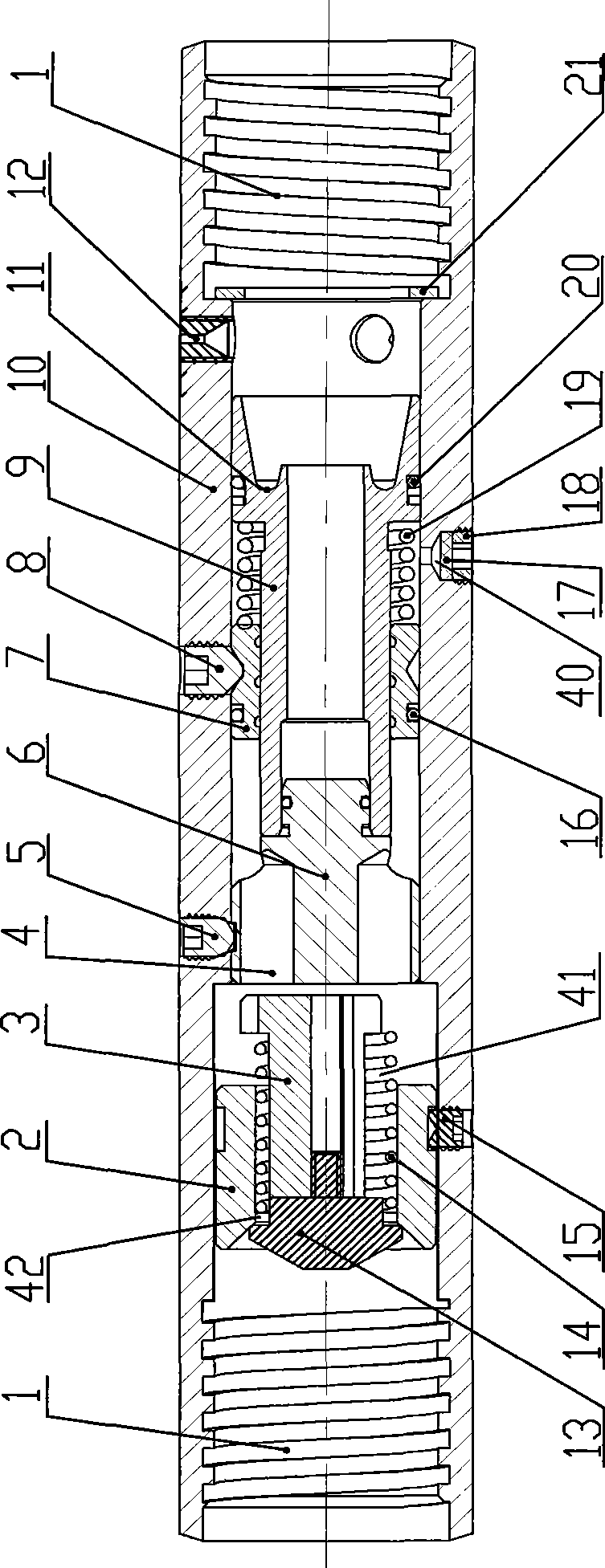

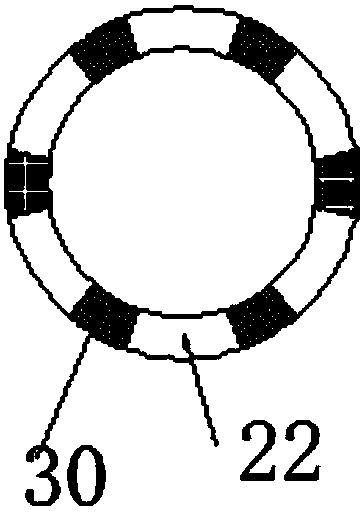

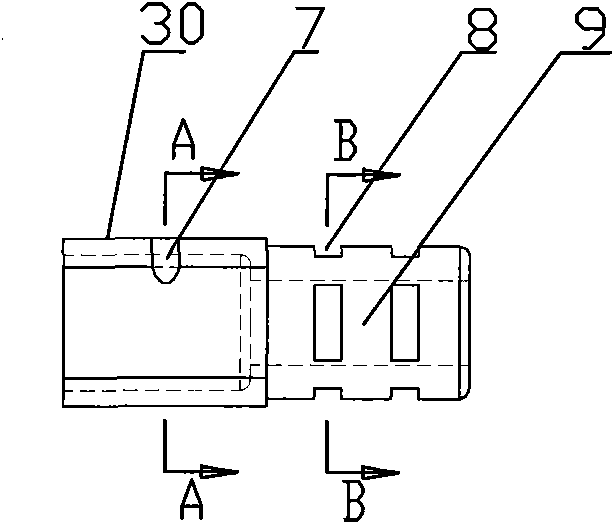

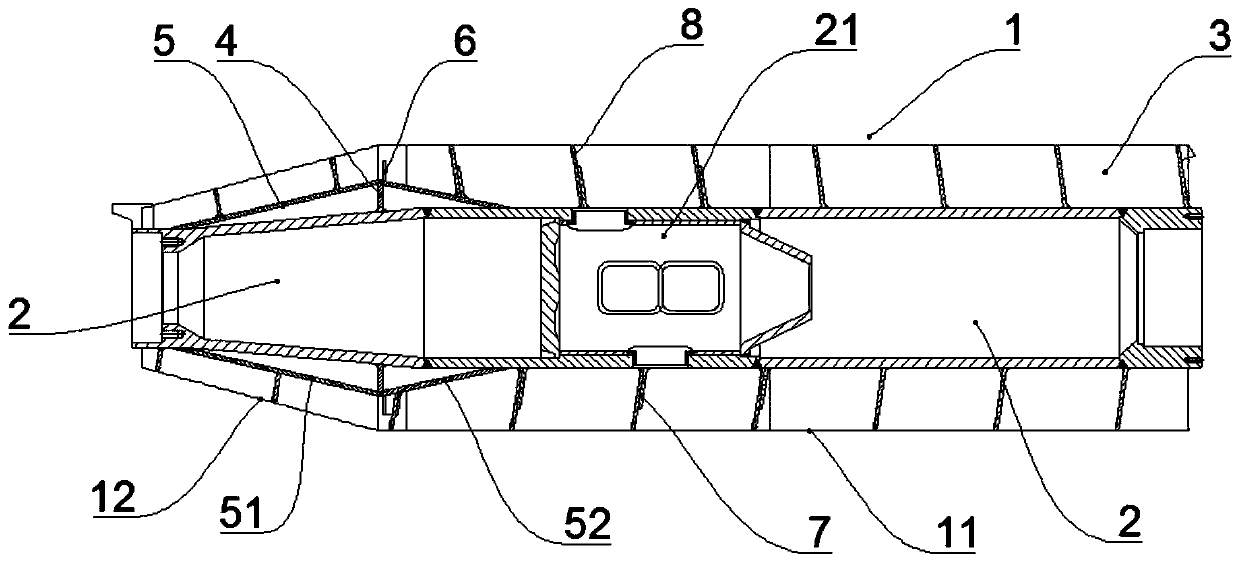

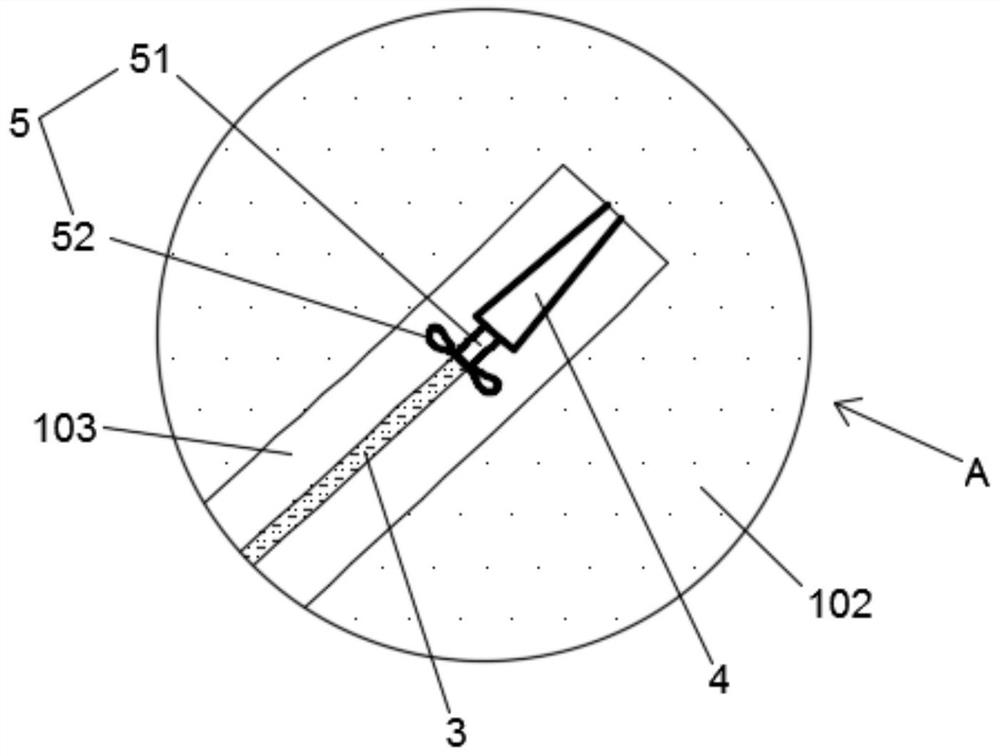

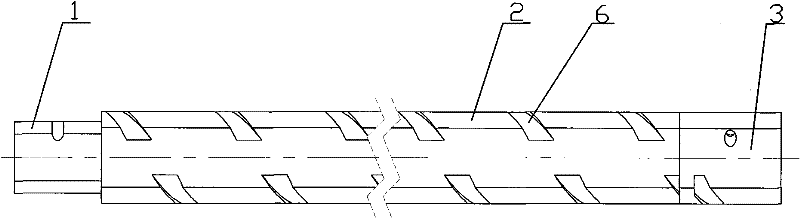

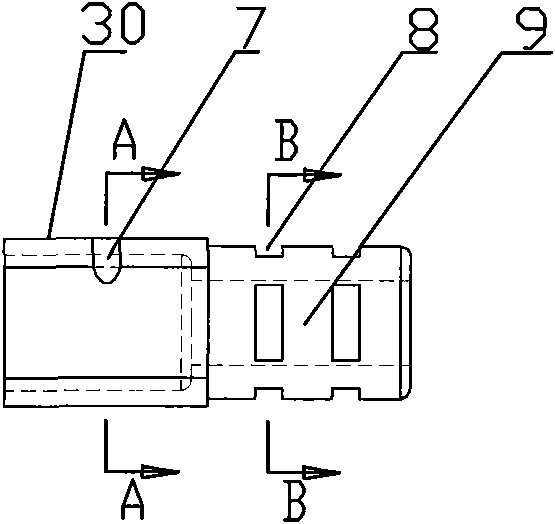

Multistage cuttings discharge air-screw motor for underground coal mine drilling

ActiveCN107217982AImprove slagging abilityEnables directional drillingConstructionsDirectional drillingTransmitted powerDrive shaft

A multistage cuttings discharge air-screw motor for underground coal mine drilling comprises a connector, a motor assembly, a universal shaft assembly, and a transmission shaft assembly; the motor assembly inputs compressed air for rotation driving, the universal shaft assembly and the transmission shaft assembly transmit power, a single-bend outer pipe of the universal shaft assembly can provide directional drilling, and the motor assembly is provided with a continuous right-handed spiral groove; when rotating, the screw motor stirs depositing cuttings, assisting air in discharging the cuttings out of a borehole; multistage cuttings discharge is achieved by adding two sets of reverse bypass holes, and it is ensured that the motor can still normally rotate to discharge powder when a bit blocks at the bottom of the borehole or cuttings accumulate at the bottom; by providing a one-way valve, high-pressure gas is avoided carrying the cuttings reversely into the motor, causing damage to the motor. The multistage cuttings discharge air-screw motor is used with an underground while-drilling measuring system in the construction of long boreholes along an underground coal mine broken-soft coalbed, cuttings discharge effect can be improved, intra-borehole resistance is decreased, construction safety is ensured, and construction depth of boreholes along underground coal mine broken-soft coalbeds and coalbed drilling catching ratio are increased.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

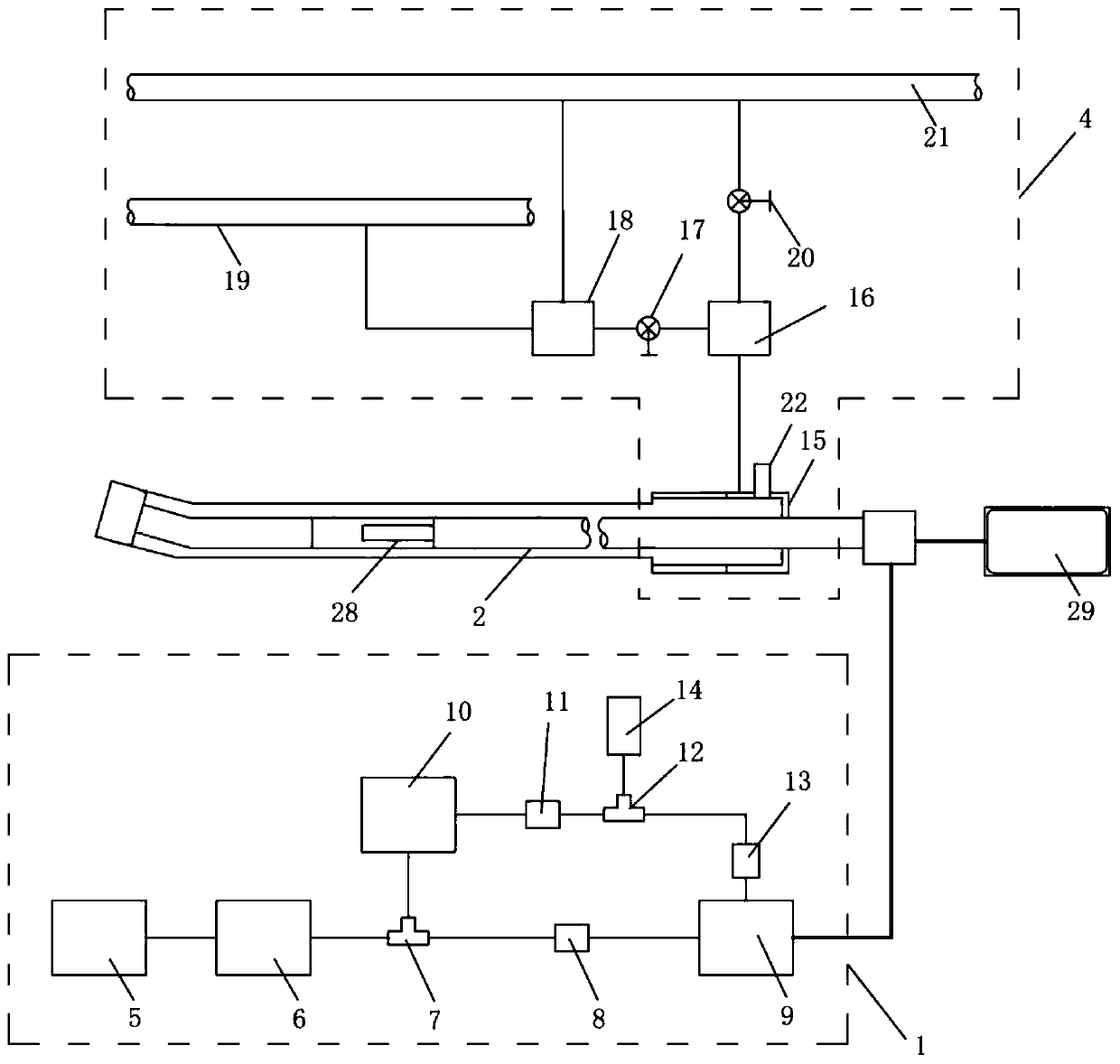

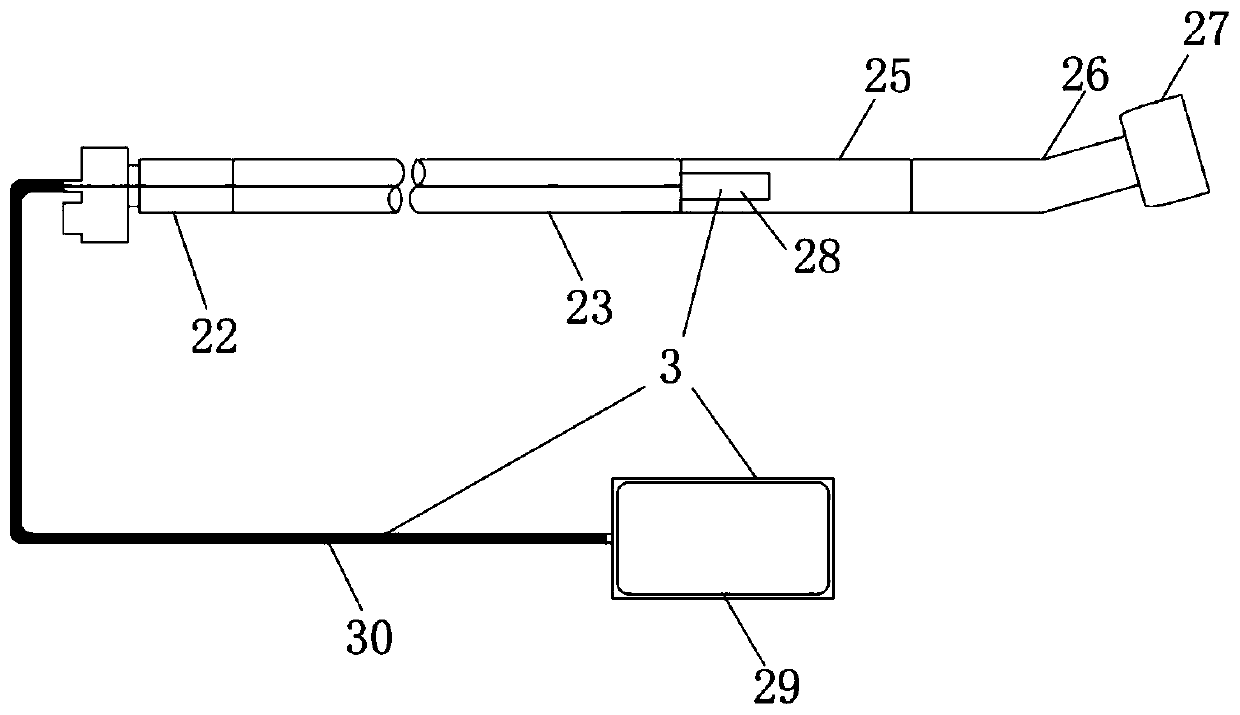

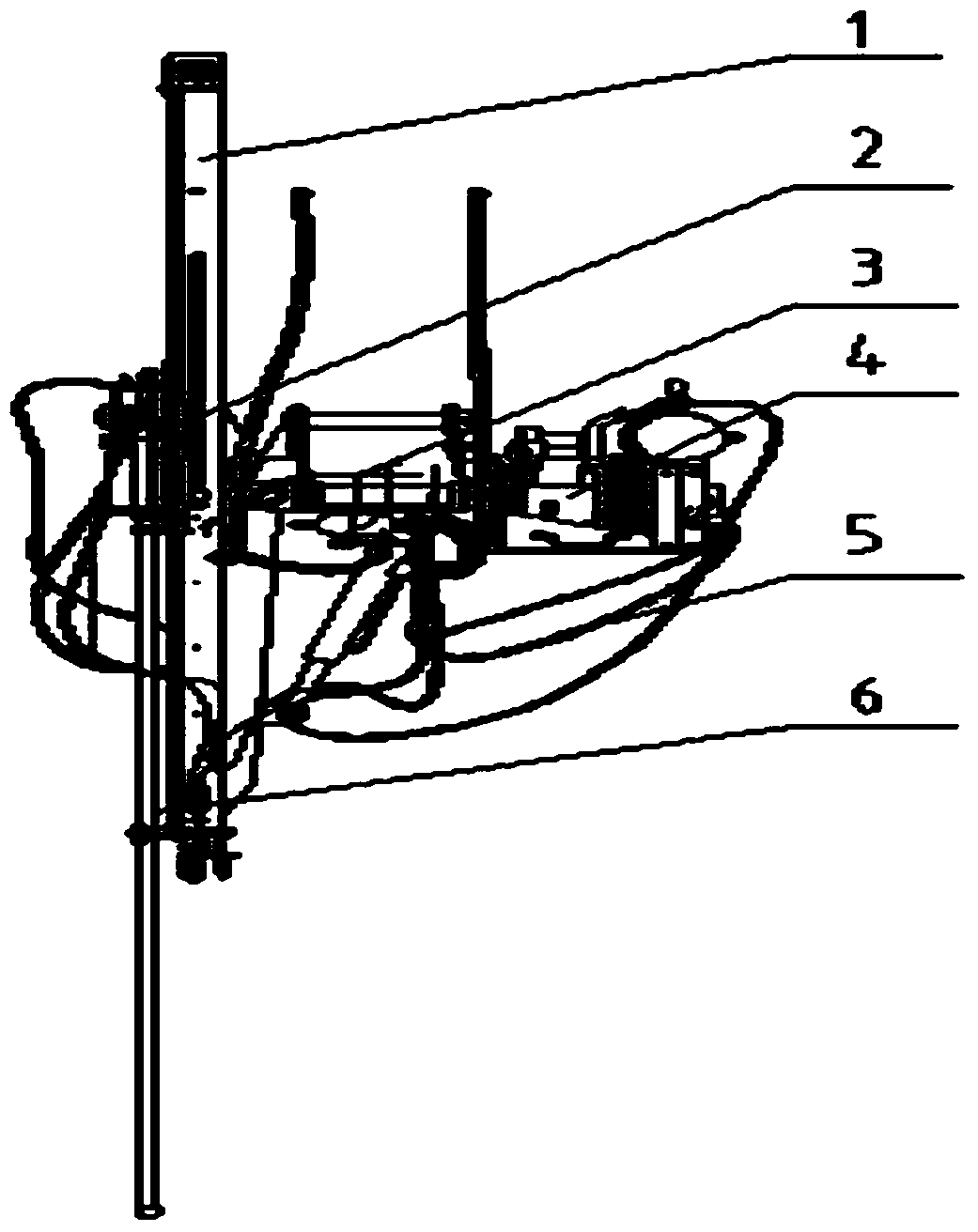

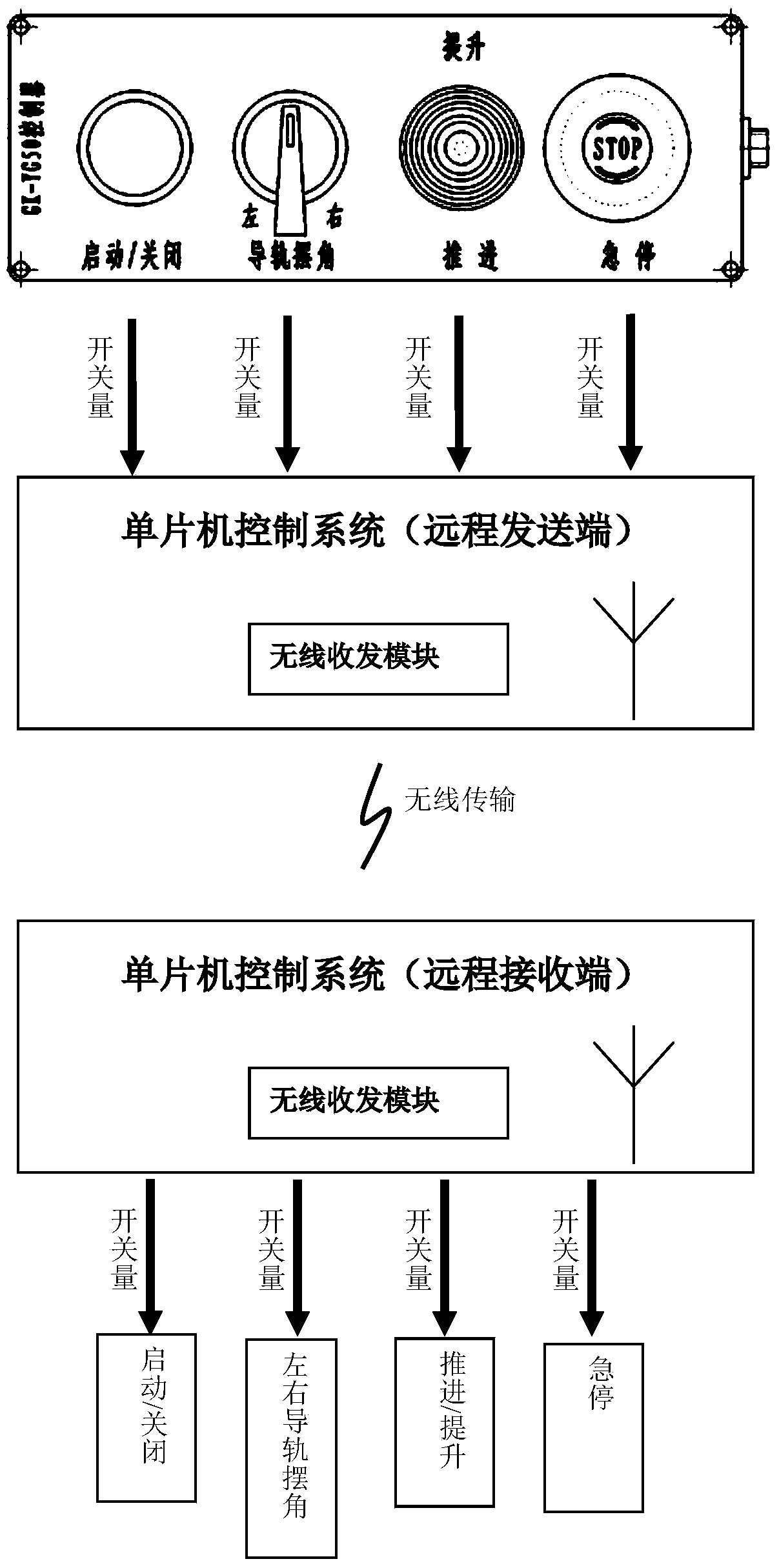

Adjustable gas directional drilling equipment and method for crushed soft coal seam in underground coal mine

ActiveCN110242215AImprove securityAvoid fire in holeConstructionsDirectional drillingSoft CoalsRock breaking

The invention relates to adjustable gas directional drilling equipment and method for a crushed soft coal seam in an underground coal mine. The equipment is composed of an orifice mixed gas supply system, a mine wired measurement while drilling device, a directional drilling tool assembly, an orifice waste gas treatment system and the like, two optional gas of pressurized air and nitrogen are supplied to a borehole by using the orifice mixed gas supply system, and the directional drilling tool assembly is driven for hole bottom high-efficiency rock breaking and drilling cutting discharging; borehole track while drilling real-time measurement and high-efficiency transmission are conducted by using the mine wired measurement while drilling device; measurement while drilling signal transmission and borehole track precise control are conducted by using the directional drilling tool assembly; and the orifice waste gas treatment system is used for removing boring mud and ensuring safe emission of the nitrogen and high-efficiency extraction of gas. The safety of drilling using the gas, the signal transmission efficiency and the slagging efficiency are overall improved, and potential safety hazards such as fire catching in the hole during gas drilling are avoided.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

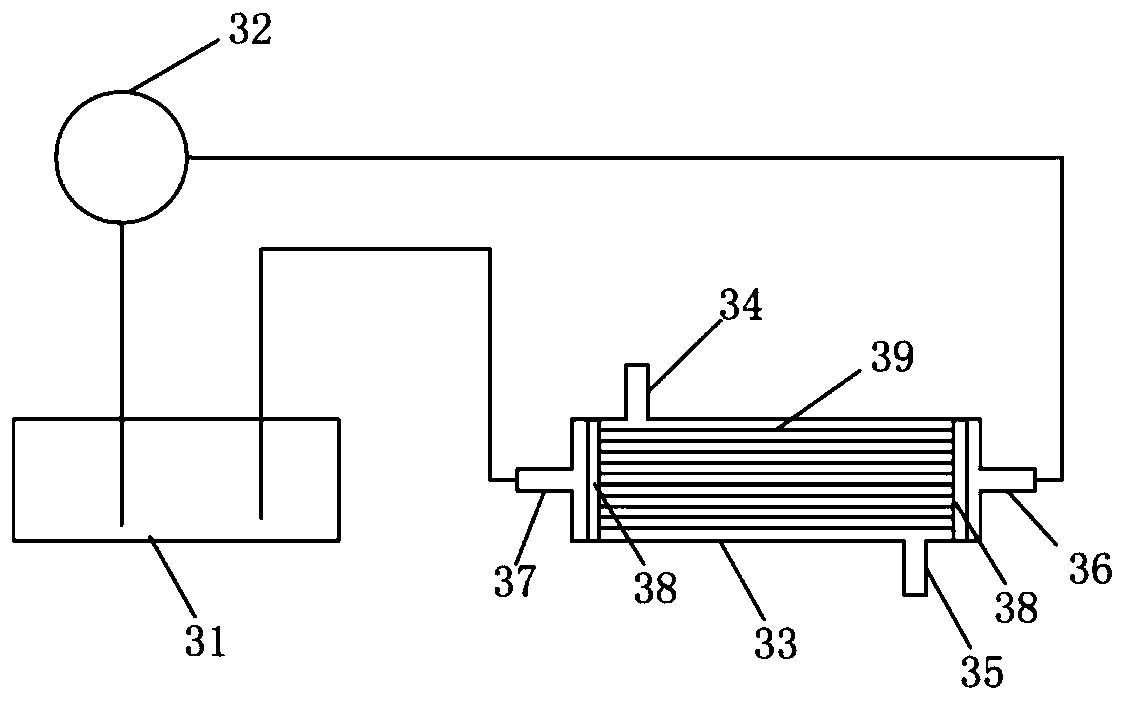

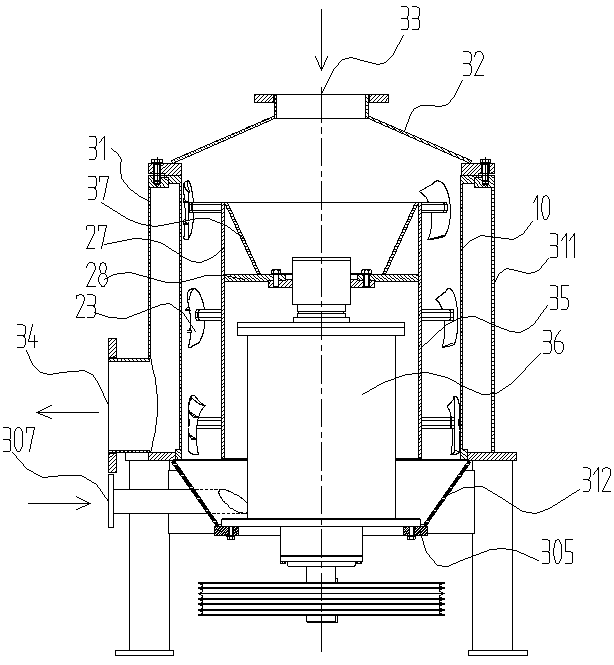

Horizontal spiral unloading sedimentation centrifuge of squeezing baffle plate structure

PendingCN110773330AImprove slagging abilityReduce dead angleRotary centrifugesSpiral bladeStructural engineering

The invention provides a horizontal spiral unloading sedimentation centrifuge of a squeezing baffle plate structure. The horizontal spiral unloading sedimentation centrifuge of the squeezing baffle plate structure comprises a cylinder; a spiral main shaft is arranged in the cylinder; the cylinder consists of a straight cylinder and a conical cylinder; the spiral main shaft consists of a straight section shaft and a conical section shaft; the intersection of the straight section shaft and the conical section shaft is arranged in the straight cylinder; the conical section shaft is welded with aconnecting ring plate; the connecting ring plate is connected with a splashed sleeve; the splashed sleeve consists of a first conical sleeve and a second conical sleeve; one end of the first conical sleeve is welded with the connecting ring plate, and the other end is welded with the conical section shaft; one end of the second conical sleeve is welded with the connecting ring plate, and the otherend is welded with the straight section shaft; spiral blades are welded on the splashed sleeve and the straight section shaft; a spiral channel is formed between the cylinder and the spiral main shaft; and a squeezing baffle plate is welded in the intersection of the first conical sleeve and the second conical sleeve. The slag discharge capacity of the centrifuge is improved; and the blockage cleaning period is prolonged.

Owner:JUNENG MACHINERY CHINA +1

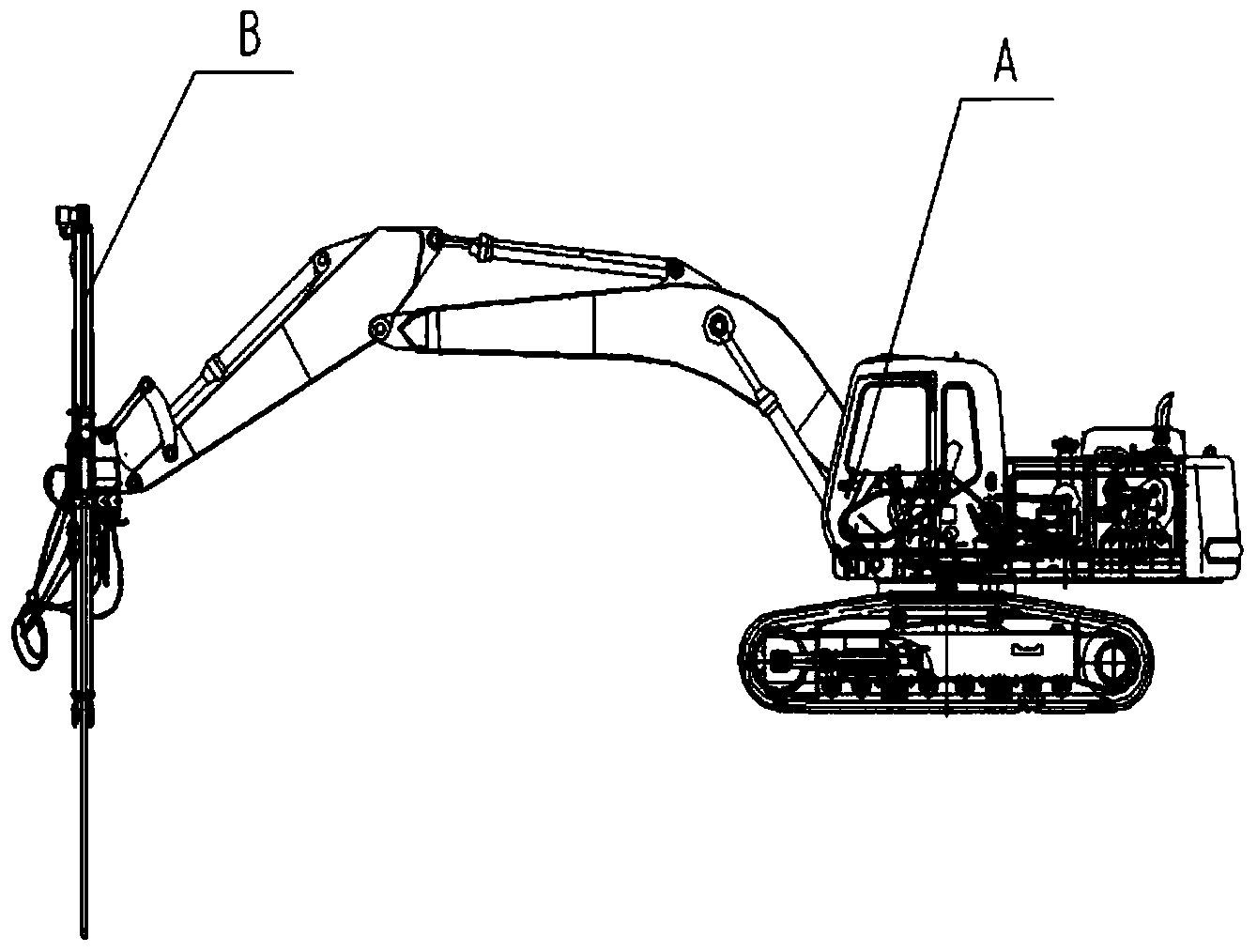

Hydraulic rock drilling machine

ActiveCN103670275AEasy to installEasy to disassembleDrilling machines and methodsAutomatic control for drillingEngineeringAir compressor

The invention relates to engineering machines, in particular to a hydraulic rock drilling machine. The hydraulic rock drilling machine is composed of a hydraulic carrier machine A and a drilling machine B. The hydraulic carrier machine A is an excavator, or a loader or a forklift, and according to the hydraulic rock drilling machine, a working device at the front end of the hydraulic carrier machine A serves as a machine base. Hydraulic oil provided by a hydraulic system of the hydraulic carrier machine and a selectively matched air compressor are used as power sources, and the drilling machine B is installed at the front end of the working section of the hydraulic carrier machine A. The working device at the front end of the excavator, or the loader or the forklift is adopted as the machine base in cooperation with the drilling machine to perform rapid and efficient rock drilling. The hydraulic rock drilling machine is rapid and convenient to install and detach, easy to maintain, low in cost and high in efficiency.

Owner:贵阳矿山机器厂有限公司

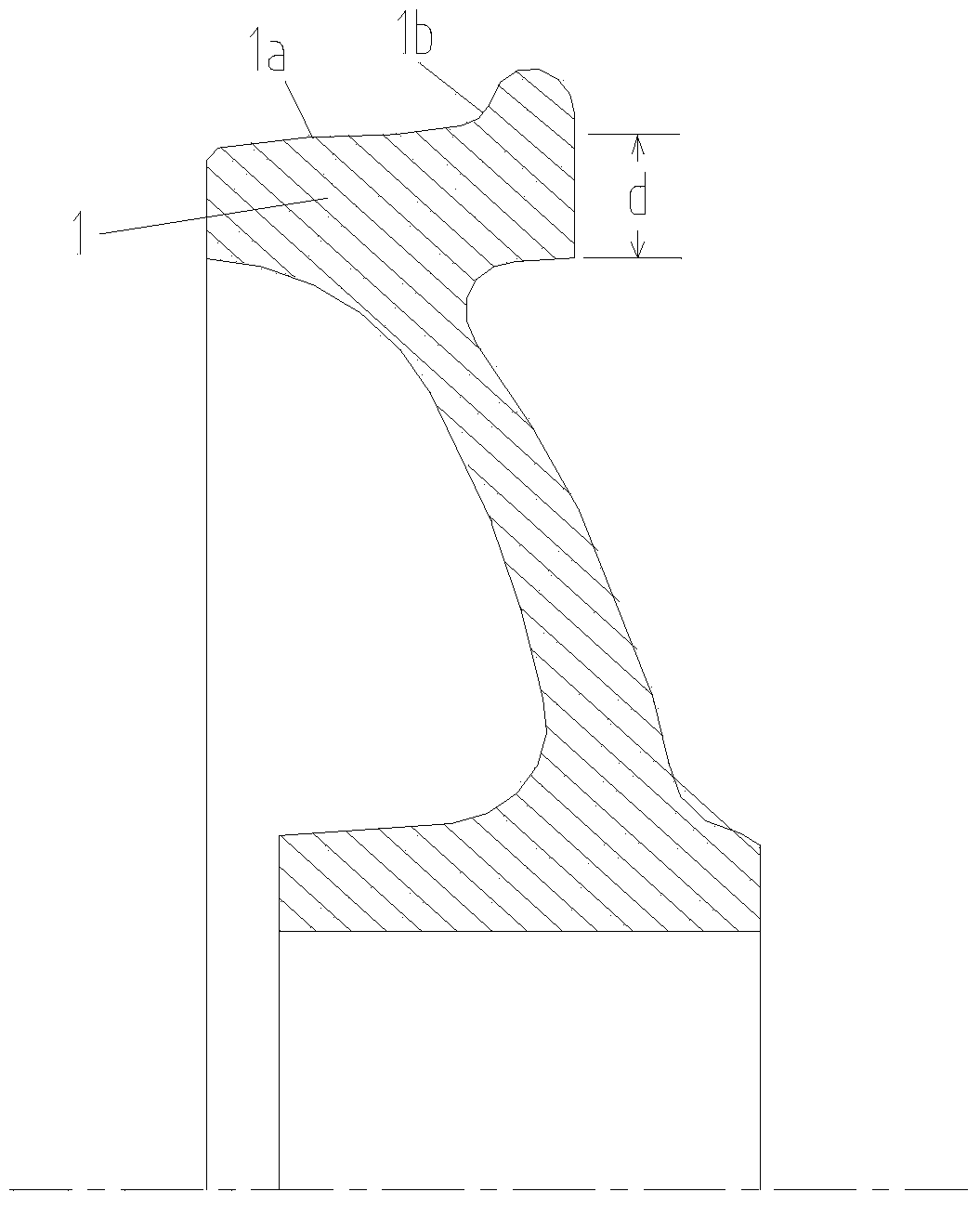

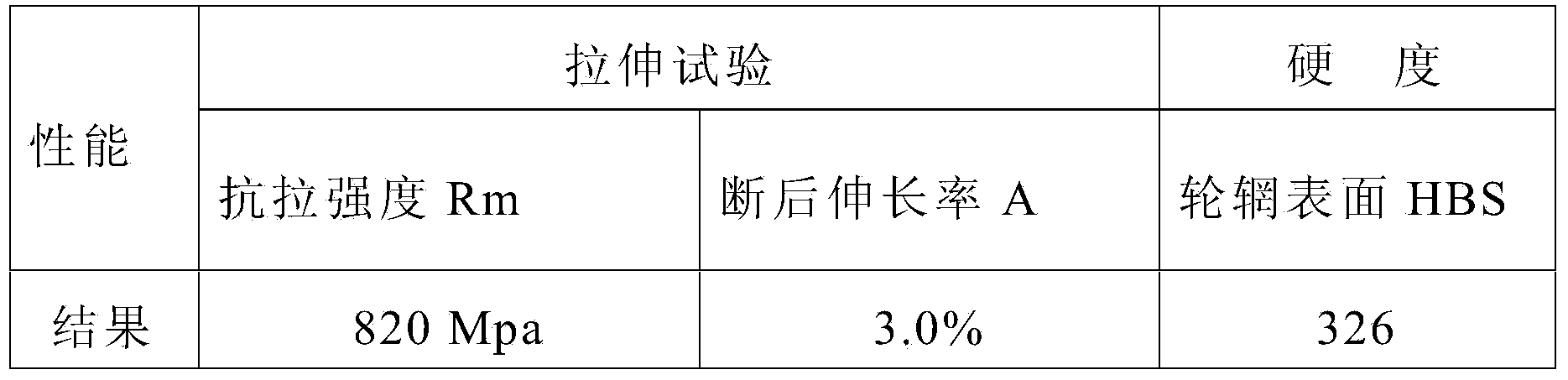

Ferrous alloy spray welding repair material for wagon wheel and repair method thereof

ActiveCN103668035ALow melting pointImprove antioxidant capacityMolten spray coatingRepair materialLimit value

The invention discloses a ferrous alloy spray welding repair material for a wagon wheel and a repair method thereof. The repair material contains the following components by weight: 0.1-0.5% of C, 11-16% of Ni, 12-18% of Cr, 1.0-2.0% of B, 1-5% of Si, and the balance being Fe and inevitable impurities. The repair method comprises the following steps of: (1) inspecting whether thickness of a wheel rim to be repaired is abraded and thinned to be a set limiting value; (2) selecting a wheel to be repaired of which the thickness of the wheel rim is not abraded and thinned to the set limiting value, and cleaning the wheel tread and the internal side of the wheel rim according to a spray welding requirement; (3) using a powder plasma high temperature spray welding technology, and uniformly depositing a ferrous alloy spray welding repair material on the wheel tread and the internal side of the wheel rim; and (4) repairing the wheel tread and the internal side of the wheel rim by machining. Proved by practices, the wheel repaired by the alloy spray welding repair material is matched to combination mechanical properties, and the repair method has advantages of simple operation and low energy consumption.

Owner:CRRC YANGTZE CO LTD

Downward drilling plugging-while-drilling type slag discharging device and method

PendingCN109209283AStable negative pressure slag discharge powerEnsure normal dischargeSealing/packingRubber ringSlag

A downward drilling plugging-while-drilling type slag discharging device includes an upper hollow connecting rod, a lower hollow connecting rod, a sealing bearing, a sealing rubber ring, upper slag discharging ducts and lower slag discharging ducts which are all vertically connected. The upper hollow connecting rod and the lower hollow connecting rod are connected respectively with an upper port and a lower port of the bearing inner ring. The sealing rubber ring is arranged on the outer ring of the sealing bearing. Both the number of the upper slag discharging ducts and the number of the lowerslag discharging ducts are two. The two lower slag discharging ducts are assembled between the sealing rubber ring and the outer ring of the sealing bearing. The upper ends of the two lower slag discharging ducts are coaxially connected with the lower ends of the two upper slag discharging ducts correspondingly. The invention further discloses a slag discharging method of the downward drilling plugging-while-drilling type slag discharging device. According to the invention, the structure is compact, the operation is convenient, the construction method is simple, the method can ensure effective and stable slag discharge power, improve the pore-forming quality for small-diameter and large depth drilling and slag discharging effect and reduce the air pollution, and the method is innovative in small-diameter and deep drilling and slag discharging.

Owner:HENAN POLYTECHNIC UNIV

Attapulgite-containing refining agent for melting of magnesium alloy

A disclosed attapulgite-containing refining agent for melting of magnesium alloy is prepared from the following raw materials in parts by weight: 8-10 parts of attapulgite, 2-4 parts of quartz sand nanometer powder, 12-15 parts of tool steel powder, 3-4 parts of barium oxide, 2-3 parts of boron oxide, 3-4 parts of calcium fluoride, 1-2 parts of manganese chloride, 2-3 parts of magnesium sulfate, 0.3-0.5 part of titanium sponge, 2-3 parts of nanometer silica, 1-2 parts of straw ash, 10-12 parts of sodium nitrate, 1-2 parts of vermiculite powder, 3-4 parts of cryolite, 5-7 parts of charcoal powder, 13-15 parts of hexachloroethane, 7-9 parts of chlorinated rare earth, 5-6 parts of zirconium tetrachloride and 4-6 parts of GaSi. According to the refining agent, titanium sponge, manganese chloride and boron oxide are capable of chemically reacting with element iron in melt for forming compounds, slagging and discharging, so that the content of iron element in magnesium alloy is substantially reduced; cryolite is beneficial for improving the slagging capability of a solvent; zirconium tetrachloride is beneficial for improving inclusion removing rate of alloy and improving the mechanical properties and the corrosion resistance of alloy; and CaSi helps to improve the capability of forming composite inclusions.

Owner:江苏古沙农业科技发展有限公司

Coal bed long-hole drilling deposited coal cinder water-discharging system and cinder discharging method

InactiveCN111980603ALow flow resistanceIncrease the power of slag discharge at the bottom of the holeFlushingDrilling compositionCoal wasteDrill hole

The invention discloses a coal bed long-hole drilling deposited coal cinder water-discharging system and a cinder discharging method. The system comprises a box body, a water pump, a drill rod, a drill bit and a rotational flow device; the inlet of the water pump communicates with the outlet of the box body via a pipeline; a port of the drill rod communicates with the outlet of the water pump viaa pipeline and another end of the drill rod stretches into a drill hole; the tail end of the drill bit communicates with another port of the drill rod; a central hole in the head end of drill bit communicates with the inside of the drill hole; the rotational flow device is fixed at the trail end of the drill bit; a high-density water solution is arranged inside the box body; the high-density watersolution is an inorganic salt solution; and the density of the high-density water solution is larger than the density of coal cinder. According to the system and the method, the high-density water solution is used to increase buoyancy of the coal cinder, so the flowing resistance of the coal cinder is greatly lowered; at the same time, the rotational flow device is installed at the tail end of the drill bit, the rotational flow device rotates synchronously when the drill bit rotates, and the driving force for flowing of the high-density water solution can be increased, so the high-density water solution flows towards the outlet of the drill hole more conveniently, the coal cinder is easy to discharged and drill hole drilling is convenient.

Owner:HUAINAN MINING IND GRP +3

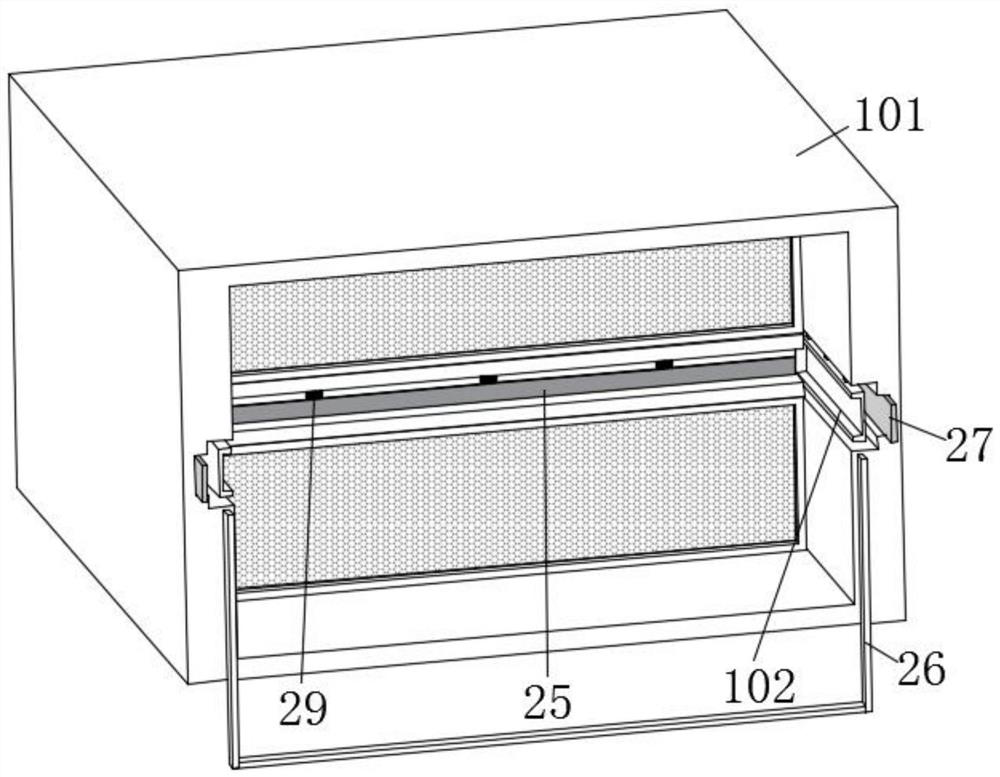

Novel pressure screen

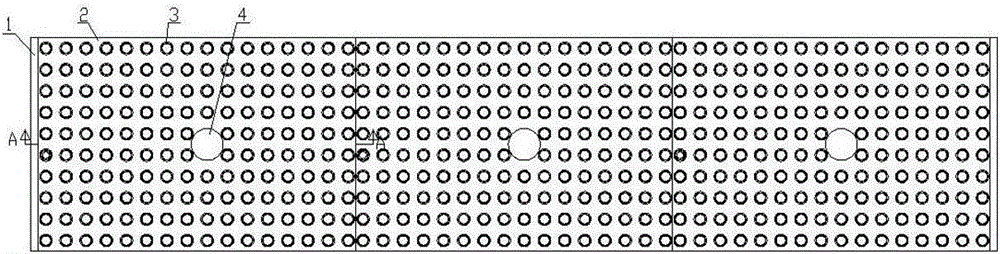

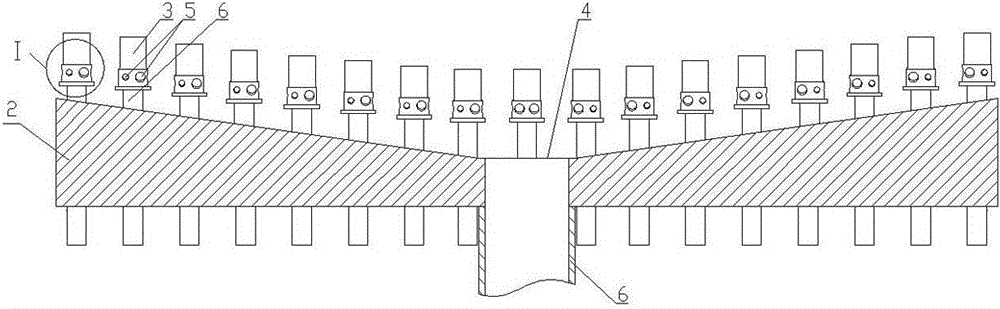

ActiveCN111364274AAvoid destructionImprove slagging abilityPaper material treatmentEngineeringMechanical engineering

The invention discloses a novel pressure screen. The novel pressure screen comprises a pressure screen shell, wherein a screen drum is fixedly arranged in the pressure screen shell; a rotor is arranged at the inner side of the screen drum and comprises a rotor barrel body; a plurality of fin fixing rods are uniformly arranged on the periphery of the rotor barrel body in a layered mode and are divided into a plurality of layers; each layer of the fin fixing rods is uniformly distributed in a circumferential direction; a rotor fin is arranged at the end part of each fin fixing rod and is of a flying wing structure; and every two adjacent layers of rotor fins are overlapped for a distance. According to the invention, through a more streamlined rotor blade structure and arrangement, the powerconsumed by the rotor in the working process is greatly reduced; meanwhile, a good screening effect is achieved.

Owner:ZHENGZHOU LEIZHAN TECH PAPER MACHINERY

Air distribution device for biomass fluidized-bed boiler

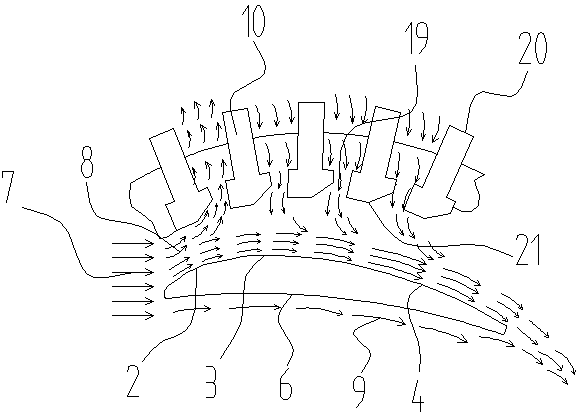

InactiveCN106642093ALoad is not affectedImprove work efficiencyFluidized bed combustionApparatus for fluidised bed combustionFluidized bedSlag

The invention relates to a biomass fluidized-bed boiler assembly, and specifically relates to air distribution device for a biomass fluidized-bed boiler. The air distribution device comprises a support, wherein a horizontally-arranged air distribution plate is arranged on the support; through holes are uniformly distributed in the air distribution plate; an air distribution pipe is arranged in each through hole; the upper end of each air distribution pipe stretches out of the top of the air distribution plate; an air cap sleeves the upper end of each air distribution pipe; and air distribution holes are uniformly distributed in the periphery of each air cap. A slag outlet is formed in the air distribution plate, and a slag outlet pipe is connected to the lower end of the slag outlet. The air distribution device is characterized in that the upper surface of the air distribution plate is gradually descended from the peripheral edge to the periphery of the slag outlet, and thus an air distribution state that the periphery of a bed surface is inclined towards the slag outlet in the middle is formed. The fluidized-bed boiler using the air distribution device is high in working efficiency and low in maintenance cost.

Owner:WUXI DONGMA BOILER

Gas generating composition

ActiveUS20110030858A1Reduce the temperatureReduce generationPedestrian/occupant safety arrangementNon-explosive/non-thermic compositionsMean diameterCombustion

A gas generating composition exhibiting good slag forming ability is provided.The gas generating composition includes a fuel ranging from 10 to 60% by mass, an oxidizing agent ranging from 10 to 70% by mass, and a cooling agent (other than iron oxide) ranging from 1 to 20% by mass. The cooling agent has a volume mean diameter (D50) of 10 to 70 μm and a volume mean diameter at cumulative of 10% (D10) of equal to or greater than 5 μm. The cooling agent acts to decrease the combustion temperature and improve slag forming ability.

Owner:DAICEL CHEM IND LTD

Melting agent for refining alloy in rare earth class and fabrication method

ActiveCN1277940CImprove slagging abilityIncrease the content of active rare earth elementsRare-earth elementSlag

This invention provides a Mg rare earth alloy refinery fusing agent and its production method, the sphere of which mass percentage ratio of its chemical components is : 20-40% CaCl, 10-25% KCl, 10-25% NaCl, 15-25% BaCl, 2-5% CaF 3-10% sodium and 3-10% active rare compound which can be: rare earth chloride, rare earth fluoride or rare earth carbonate. This invention regulates the proportion of Cl and F salts and add the slagging constituent sodium and active rare compound, so the fusing agent has a good fusing point, viscosity and humectants and greatly increase its slag eliminating ability.

Owner:SHANGHAI JIAOTONG UNIV

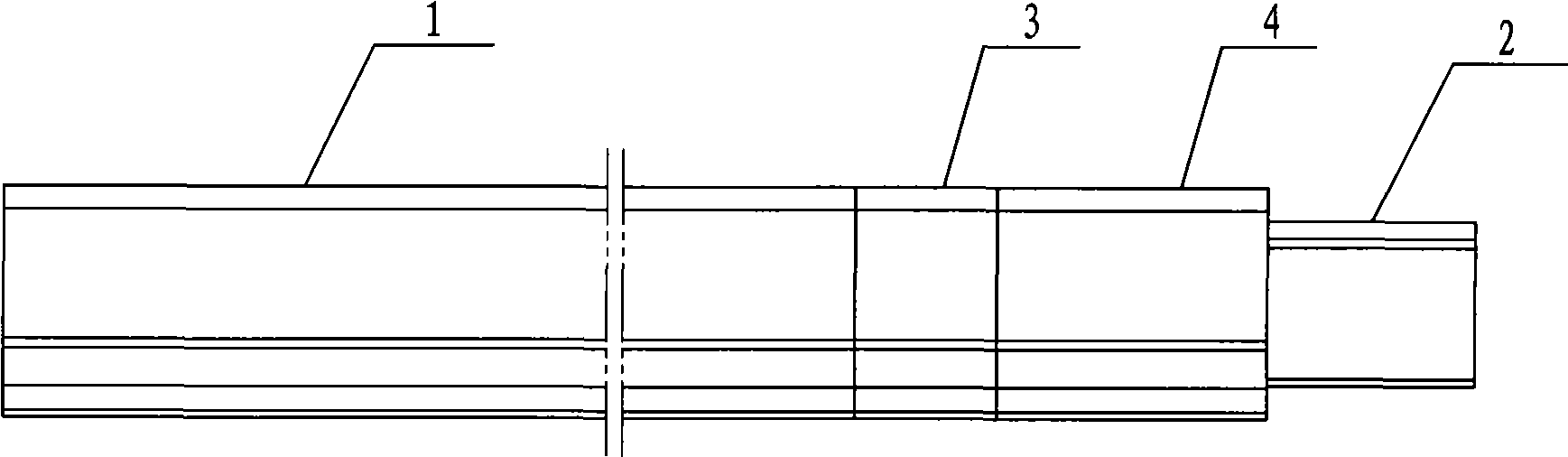

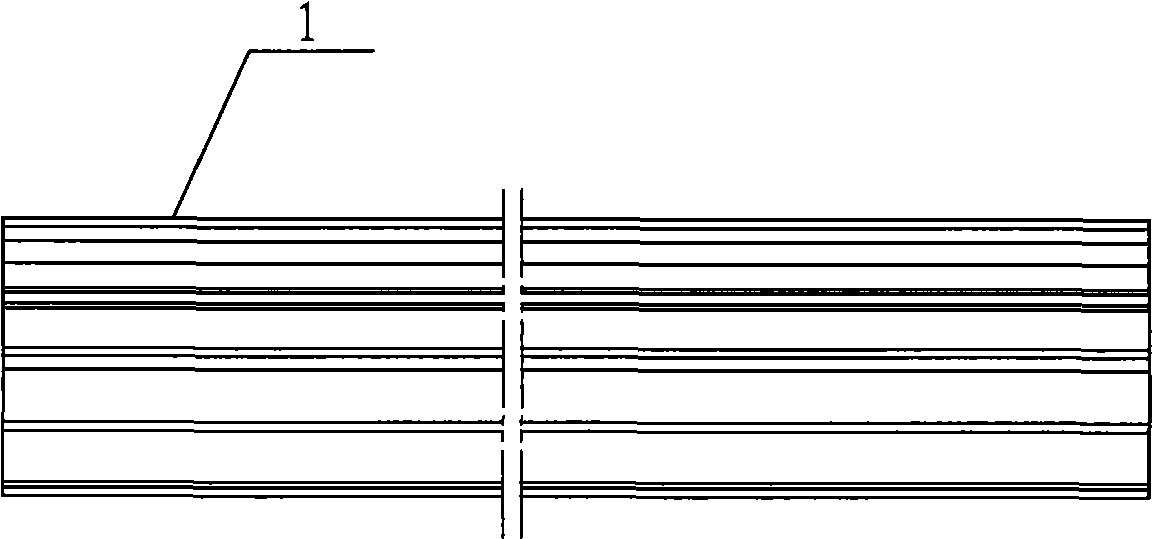

Drill pipe bar material

InactiveCN103510884AHigh strengthExtended service lifeDrilling rodsDrilling casingsPetroleum engineeringCooling speed

The invention relates to a drill pipe bar material. At least one heliciform vent hole is formed in the drill pipe bar material, and a thread structure is also arranged on the outer surface of the drill pipe bar material. The drill pipe bar material can be machined into a drill pipe, when drill pipes of this type are used for drilling, an internal cooling mode is adopted, chipping removal speed and cooling speed are accelerated, the service life of the drill pipes is prolonged greatly, meanwhile, due to the fact that the thread structure is also arranged on the outer surfaces of the drill pipes manufactured by the drill pipe bar material, the drill pipes can generate backward discharging effects on chippings when the drill pipes carry out smash movements on the chippings, chipping removal capacity is improved greatly, and working efficiency is improved.

Owner:张爱平

Magnesium and magnesium alloy composite protection fire-proof covering flux and its production method

A magnesium and magnesium alloy composite protective flame-retardant covering flux and a production method thereof, the chemical components of the flux range in mass percent: 50-70% magnesium chloride, 8-18% potassium chloride, 7-16% sodium chloride, 1 -8% calcium chloride, 1-8% calcium fluoride, 1-7% magnesium oxide, 1-5% slagging agent cryolite, 0.5-6% carbonate foaming agent, 0.5-4% beryllium compound flame retardant. The flux of the present invention has a variety of composite protective and flame-retardant functions during use. The beryllium oxide protective film formed by the beryllium compound sprinkled on the surface of the melt makes the magnesium alloy have good flame-retardant performance, which obviously improves the protective effect and does not As a result, the alloy grains are coarse and the mechanical properties of the alloy are reduced. The inert gas generated during the use of the flux that does not react with magnesium covers the magnesium liquid, which further enhances the protective effect. The cryolite added to the flux is beneficial to improve the flux. Slag ability, and improve the physical properties of the flux.

Owner:SHANGHAI AIERSI LIGHT ALLOY

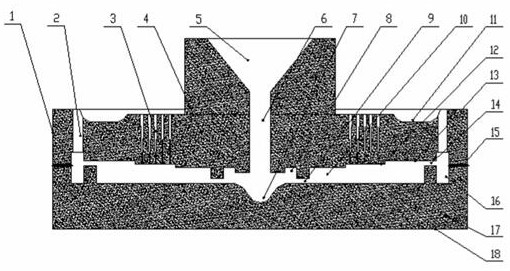

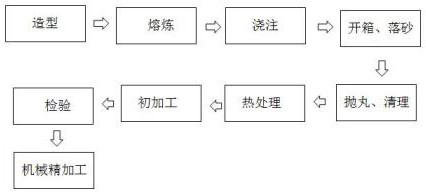

Grinding disc, model for casting grinding disc and casting process of grinding disc

InactiveCN113042684AUniform hardnessCool evenlyFoundry mouldsGrinding devicesMaterials scienceIndustrial engineering

The invention discloses a grinding disc, a model for casting the grinding disc, a casting process of the grinding disc, and optimization design and innovation of the casting process of the grinding disc. According to the casting process of the grinding disc, the product quality and the product qualification rate can be improved, a scientific heat treatment technology is designed according to the technical quality requirement of grinding, the molecular structure is improved, and therefore the grinding disc is good in stability, the product quality is stable in the using and producing process, the work efficiency is improved, and the service life is prolonged.

Owner:扬州振光机械有限公司

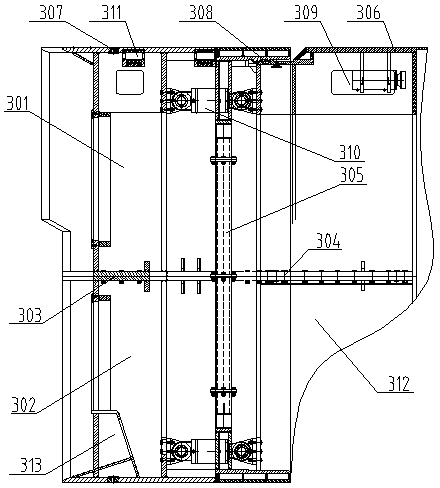

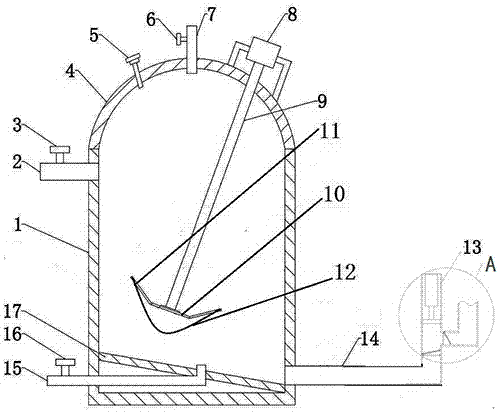

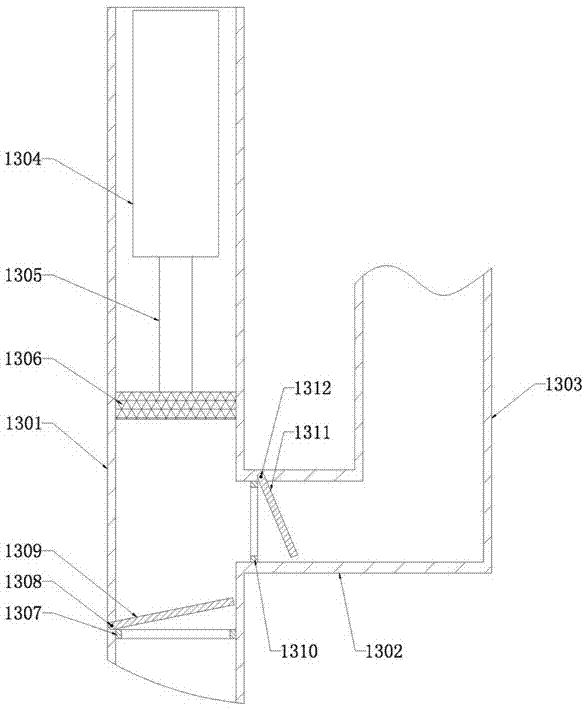

Inclined stirring double-residue discharge biogas digester

InactiveCN106967597AWell mixedImprove filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFermentation

The invention belongs to the technical field of biogas engineering, and mainly relates to an inclined stirring double-residue discharge biogas digester which comprises a reaction tank and an arc-shaped cover, wherein a gas outlet tube is arranged at the top of the arc-shaped cover; a stirring motor is fixedly mounted on the upper end surface of the arc-shaped cover; the motor shaft of the stirring motor is arranged towards the reaction tank in an inclined manner; a stirring shaft is connected with the lower end of the motor shaft; a base is fixedly arranged at the bottom of the stirring shaft; stirring blades are hinged at the periphery of the base in a hinged manner; steel chains are fixedly mounted between stirring blades which are distributed in symmetry about the center of the base; a feeding tube is arranged on a side wall of the reaction tank; a discharge tube is arranged on the side wall of the reaction tank; the discharge tube is connected with a residue discharge device; an inclined support plate is arranged at the bottom of the reaction tank; the lowermost end of the inclined support plate is arranged below the discharge tube. The inclined stirring double-residue discharge biogas digester is capable of turning over and crushing materials, uniformly mixing the materials and improving the fermentation efficiency, and is simple in structure, convenient to use and convenient in residue discharge.

Owner:河南美丽乡村环保科技有限公司

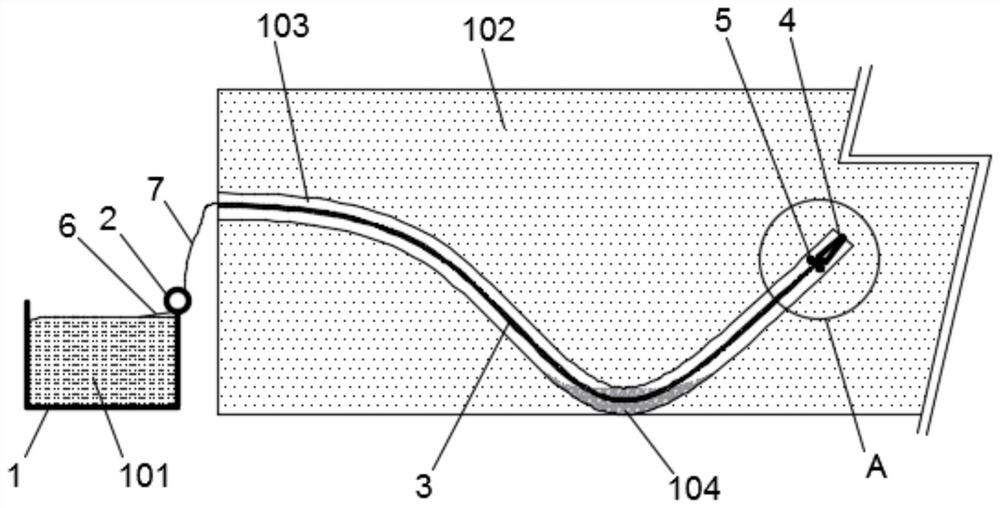

Hydraulic cutting, U-shaped hole slagging and gas treatment method

The invention provides a hydraulic cutting, U-shaped hole slagging and gas treatment method which is applicable to slagging during a process of applying a hydraulic cutting gas technology in drilling of a coal seam bedding, a high-position lane penetrating layer or a low-position lane penetrating layer. A U-shaped drilled hole is pre-constructed in a coal seam by use of a kilo directional drilling machine from the coal seam bedding, the high-position lane penetrating layer or the low-position lane penetrating layer to a target area coal body, and then a hydraulic cutting device is connected with a drill stem and is fed into one hole of the U-shaped drill hole by virtue of the drilling machine; the hydraulic cutting device is started, firstly hydraulic cutting is performed on the coal body in one hole of the U-shaped drilled hole, and draining and slagging is performed by virtue of the other drilled hole of the U-shaped drilled hole; when hydraulic cutting in one drilled hole is finished, hydraulic cutting is performedin the other drilled hole of the U-shaped drilled hole, and the previous drilled hole serves as a slagging hole. The method can be used for solving the problems of difficulty in slagging, hole blockage, hole spraying and the like in hydraulic cutting of the coal seam, further improving the air permeability of the coal seam, and eliminating the concentrated stresses of the coal body and wall rocks; great coal and gas outburst potential energy is released, so that an effective effect of preventing coal and gas outburst is achieved. The method is simple in operation, convenient in use and good in effect.

Owner:CHINA UNIV OF MINING & TECH

Irregularly shaped multi-land notch groove drill rod

ActiveCN101566049BLow rotational resistanceTake away in timeDrilling rodsDrilling casingsLine segmentHelix

The invention discloses an irregularly shaped multi-arris notch groove drill rod, which consists of a hollow multi-arris rod body and a connecting piece, the section outline of the multi-arris rod body consists of tangential paths and circular arc sections, and incontinuous spiral grooves are distributed on the surface of the rod body simultaneously. The drill rod can cause vortex flow when whirling in loose cinder and raise coal dust deposited on the bottom of a drilling hole in virtue of the arris of the drill rod, and the coal dust in the drilling hole is at a moving status all the time, thus preventing the coal dust from accumulating in the drilling hole and resulting in blockage; simultaneously, the incontinuous spiral grooves distributed on the surface can assist in the outward transmission of the cinder, and when hole collapsing in the drilling hole, the outside of the collapsed hole is unchoked by the hole digging function of the spiral grooves, thus being not easy to have drill absorption and drill blockage. The drill rod has the advantages of reasonable design, simple structure, safety and reliability, thus greatly improving deslagging effect, being beneficial to increasing the depth of the drilling holes, shortening hole drilling time, improving work efficiency and having high hole forming rate. Therefore, the drill rod is worth popularizing and applying in mining enterprises.

Owner:山东益矿钻采科技有限公司

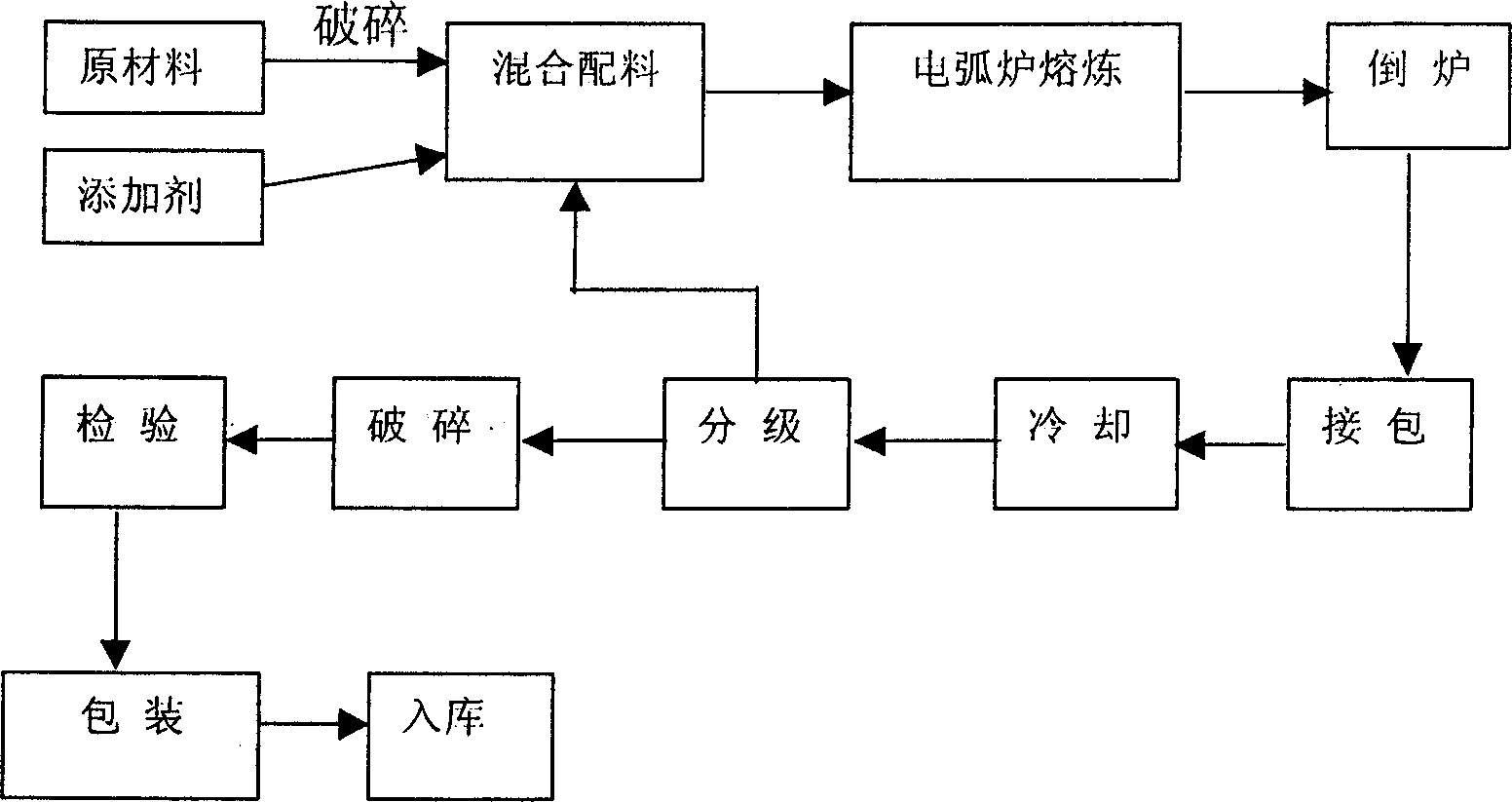

Method for producing slag forming agent contg. high calcium and low silicone by corundum arc furnace

The invention discloses a method to make high calcium low silicon fluxing medium by corundum arc furnace that includes the following steps: mixture that crushing raw material and mixing 42-45% wrought aluminium bauxite, 48%-53% calcium oxide, 3-4% calcite and 1-2% coke; melting that adding the raw material into furnace adding 10-30% of the total quantity before blowing on, and the rest would be added for 3-4 times after current and voltage stabilizing for 20-30min, after the material totally melted, and soft cover is formed, the furnace could be shut down; turning down, fetching, and cooling; classifying; taking crashing, testing, packaging, storing to the qualified product. The invention has good chemical stability, high CaO content, strong activity, good performance.

Owner:GUIZHOU DAZHONG NO 7 GRINDING WHEEL

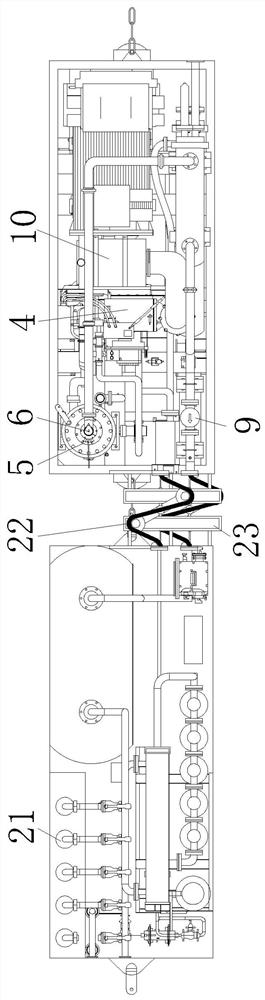

Coal mine underground movable nitrogen making device and process thereof

ActiveCN113521971AImprove slagging abilityMeet the needs of long drillingRotary/oscillating piston combinations for elastic fluidsNitrogen purification/separationAir filtrationNitrogen generator

The invention provides a coal mine underground movable nitrogen making device and a process thereof, and belongs to the technical field of underground nitrogen making. The coal mine underground movable nitrogen making device comprises an air compression mechanism, a membrane separation nitrogen making mechanism and a scaling constraint assembly. According to the coal mine underground movable nitrogen-making device and the process thereof, air is filtered and compressed through the air compression mechanism to obtain high-pressure gas, then high-pressure nitrogen is prepared through the membrane separation nitrogen-making mechanism, the requirement of medium and long drill holes in the coal mine underground can be fully met, meanwhile, pressure loss in the nitrogen conveying process can be made up, the nitrogen deslagging effect in the drilling process is improved, the filter plate can be replaced under the non-stop state, the requirements for the air filtering quality and the air inlet amount in the nitrogen making process can be fully met in time, meanwhile, the problem that unfiltered air directly enters a nitrogen making device to affect the nitrogen purity and flow can be effectively solved, and the stability of the pressure value of the generated nitrogen and the purity and flow of the nitrogen are improved.

Owner:沈阳煤炭科学研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com