Method for producing slag forming agent contg. high calcium and low silicone by corundum arc furnace

An electric arc furnace and slag-forming agent technology, applied in the field of smelting, can solve the problems of high content of harmful impurities, affecting the production of high-quality steel, unstable performance indicators, etc., and achieve the effects of thorough chemical reaction, stable performance indicators, and strong activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

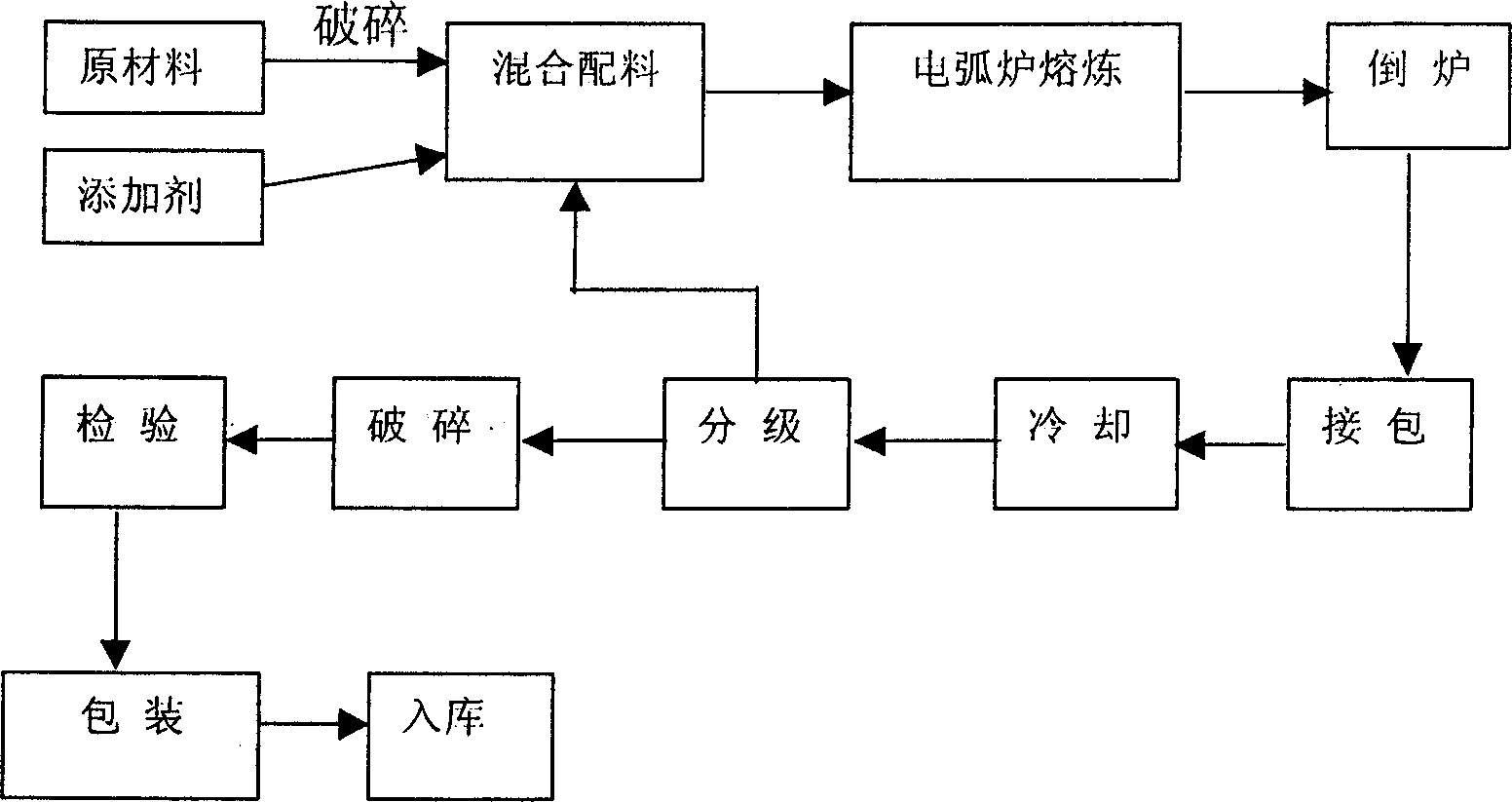

[0014] Referring to accompanying drawing, a kind of method for producing high calcium and low silicon slagging agent with corundum electric arc furnace comprises the following steps:

[0015] (1) Batching: crush the raw materials to 2-15mm, then mix the ingredients according to the following proportions, 4200kg of slaked bauxite, 5300kg of quicklime, 4kg of calcite, and 1kg of coke;

[0016] (2) Melting: The raw material is put into the electric arc furnace with 3000KVA corundum in batches, 1000kg is put into the furnace before the furnace is started, and the remaining material is put into the furnace in 3 times on average. After the current and voltage are stable for 20-30min, put in 3000kg each time, and put into the furnace after feeding. The material layer is completely melted, and the surface of the material turns red and forms a soft cover to stop the furnace;

[0017] (3) Invert the furnace, receive the package, and cool down;

[0018] (4) Classification: Unqualified c...

Embodiment 2

[0021] Referring to accompanying drawing, a kind of method for producing high calcium and low silicon slagging agent with corundum electric arc furnace comprises the following steps:

[0022] (1) Ingredients: crush the raw materials to 2-15mm, then mix the ingredients according to the following proportions, 4300kg of slaked bauxite, 5200kg of quicklime, 3kg of calcite, and 2kg of coke;

[0023] (2) Melting: The raw materials are put into 3000KVA corundum in batches and poured into the electric arc furnace. Before the furnace is started, 2000kg is put into the furnace. The material layer is completely melted, and the surface of the material turns red and forms a soft cover to stop the furnace;

[0024] (3) Invert the furnace, receive the package, and cool down;

[0025] (4) Classification: Unqualified crystallization is broken to 0-15mm and then used (return to mix ingredients with raw materials after reaching a certain amount, and the addition is 10-20% of the total amount of...

Embodiment 3

[0028] Referring to accompanying drawing, a kind of method for producing high calcium and low silicon slagging agent with corundum electric arc furnace comprises the following steps:

[0029] (1) Batching: crush the raw materials to 2-15mm, then mix the ingredients according to the following proportions, 4500kg of slaked bauxite, 5000kg of quicklime, 3kg of calcite, and 2kg of coke;

[0030] (2) Melting: The raw materials are put into 3000KVA corundum in batches and poured into the electric arc furnace. Before starting the furnace, 3000kg is put into the furnace. The remaining material is put into 3 times on average. After the current and voltage are stable for 20-30min, put in 2333kg each time, and put into the furnace after feeding. The material layer is completely melted, and the surface of the material turns red and forms a soft cover to stop the furnace;

[0031] (3) Invert the furnace, receive the package, and cool down;

[0032] (4) Classification: Unqualified crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com