Ferrous alloy spray welding repair material for wagon wheel and repair method thereof

A technology of spray welding repair material and railway freight car, which is applied in the direction of metal material coating process, melting spray plating, coating, etc., can solve the problems of high scrapping speed of wheels, re-replacement of wheels, increase in maintenance cost of railway freight cars, etc. The effect of wide control range, enhanced anti-oxidation and slagging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

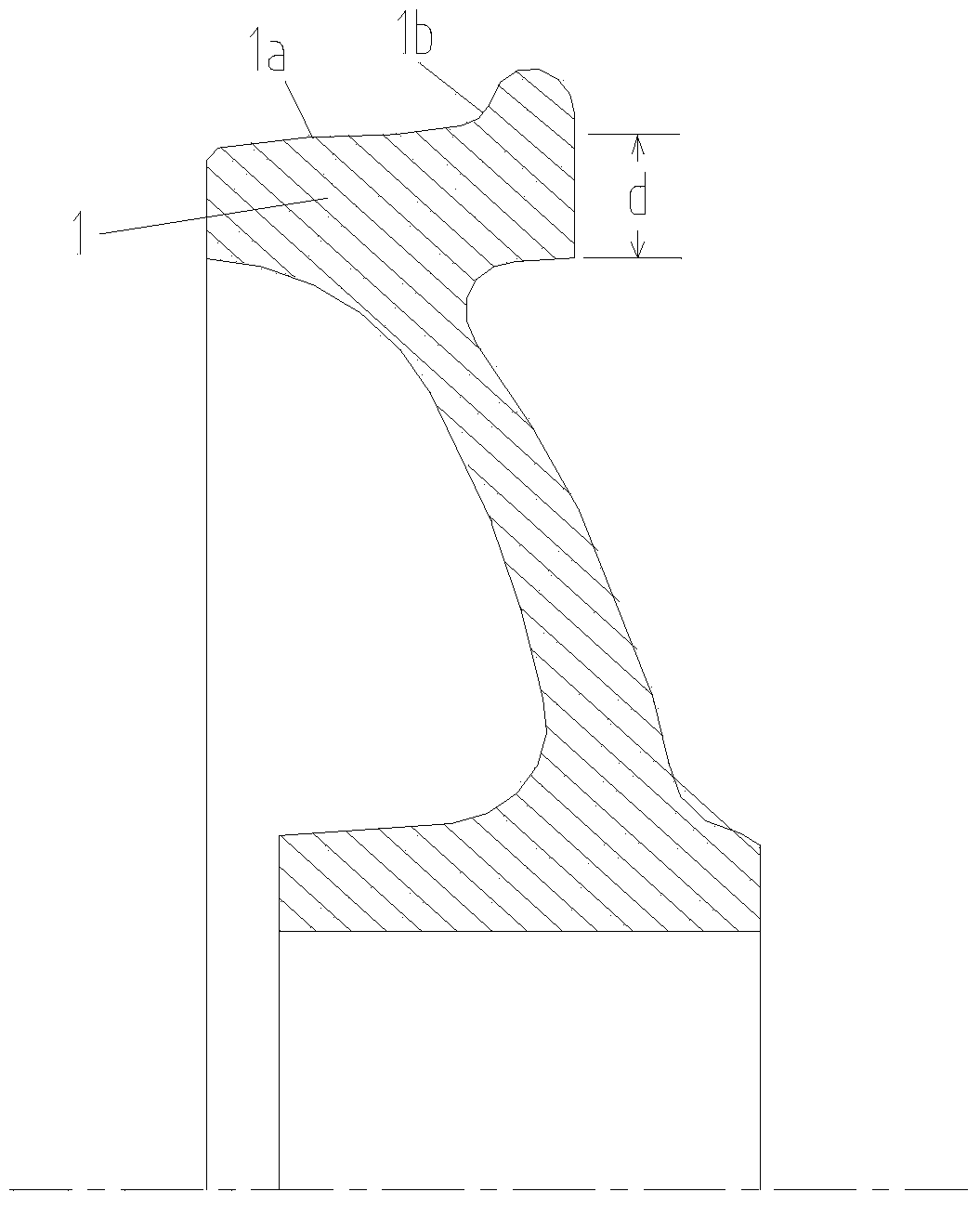

[0024] A railway freight car wheel 1 to be repaired, its structure is as follows figure 1 As shown, its steel grade is ZL-B, and its chemical composition weight percentages are tested as follows: C: 0.57%, Si: 0.16%, Mn: 0.60%, P: 0.035%, S: 0.040%. The components of the iron-based alloy repair material used for railway freight car wheels are calculated by weight percentage: C: 0.3%, Ni: 13.6%, Cr: 15.8%, B: 1.2%, Si: 2.9%, the balance is Fe And inevitable impurities.

[0025] The method for repairing railway freight car wheels using the iron-based alloy spray welding repair material includes the following steps:

[0026] 1) Remove a wheel 1 to be repaired from the railway freight car bogie that has been worn and entered into the maintenance period. Check that the rim thickness d of the wheel 1 to be repaired is 28.5mm, and its thickness has not been worn down to the set value. Limit value

[0027] 2) Clean the wheel tread 1a and the inner side 1b of the wheel flange;

[0028] 3) Us...

Embodiment 2

[0036] A wheel steel grade to be repaired is ZL-B, and its chemical composition weight percentages are: C: 0.67%, Si: 0.20%, Mn: 0.85%, P: 0.03%, S: 0.030%, the selected railway freight car The components of the iron-based alloy repair material for wheels are calculated by weight percentage: C: 0.5%, Ni: 16%, Cr: 18, B: 2.0%, Si: 5%, the balance is Fe and unavoidable impurities;

[0037] Use the above-mentioned iron-based alloy spray-welded repair material on railway freight car wheels (its structure is as figure 1 Shown) The repair method includes the following steps:

[0038] 1) Remove a wheel 1 to be repaired that has entered the overhaul period from the railway freight car bogie, and check that the rim thickness d of the wheel 1 to be repaired is 30mm, and its thickness has not been worn down to the set limit value;

[0039] 2) Clean the wheel tread 1a and the inner side 1b of the wheel flange;

[0040] 3) Using the powder plasma high temperature spray welding process, the above ...

Embodiment 3

[0047] The steel grade of a wheel to be repaired is ZL-B, and its chemical composition weight percentage is: C: 0.60%, Si: 0.21%, Mn: 0.70%, P: 0.02%, S: 0.02%. The railway freight car used The components of the iron-based alloy repair material for wheels are calculated by weight percentage: C: 0.4%, Ni: 14%, Cr: 14, B: 1.5%, Si: 3%, the balance is Fe and inevitable impurities;

[0048] 1) Remove a wheel 1 to be repaired from the railway freight car bogie that has been worn and entered into the maintenance period. Check that the rim thickness d of the wheel 1 to be repaired is 29.6mm, and its thickness has not been worn down to the set value. Limit value

[0049] 2) Clean the wheel tread 1a and the inner side 1b of the wheel flange;

[0050] 3) Using the powder plasma high temperature spray welding process, the above iron-based alloy spray welding repair material is uniformly deposited on the wheel tread 1a and the inner side of the rim 1b, and the thickness of the deposited part re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com