Inclined stirring double-residue discharge biogas digester

A stirring plate and biogas device technology, which is applied in the field of biogas engineering, can solve the problems of cumbersome use and maintenance, low production efficiency, and large floor space, and achieve the effects of enhanced slag discharge, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

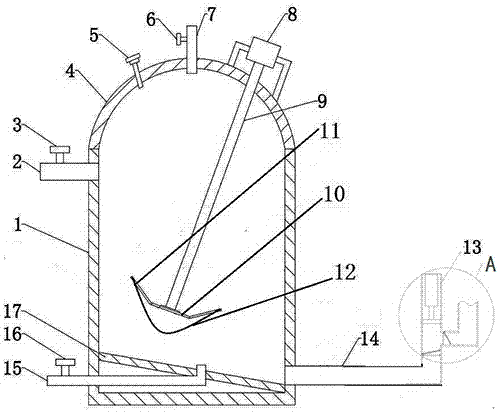

[0018] The specific embodiment of the present invention sees figure 1 , an inclined stirring double slag discharge biogas digester, including a reaction tank 1 with an upper end opening and an arc-shaped cover 4 arranged at the upper end opening of the reaction tank 1,

[0019] The top of the arc-shaped cover 4 is provided with an air outlet pipe 7, and the upper end surface of the arc-shaped cover 4 near the air outlet pipe 7 is fixedly equipped with a stirring motor 8, and the motor shaft of the stirring motor 8 is inclined to be arranged in the reaction tank 1,

[0020] The lower end of the motor shaft is coaxially fixedly connected to the stirring shaft 9, the bottom of the stirring shaft 9 is fixedly provided with a base 10, and the base 10 is uniformly distributed in the circumferential direction and hinged with stirring plates 11, and the stirring plates 11 distributed symmetrically about the center of the base 10 are fixedly installed There are steel chains 12;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com