Shield tube push bench with super-large rectangular cross section

A technology with a rectangular section and a shield roof, which is applied to mining equipment, earthwork drilling, tunnels, etc., can solve the problems of high precision control of the pipe jacking axis, uneven thrust of the tunneling surface, and difficult control of surface settlement, etc. The effect of surface settlement, high construction efficiency, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

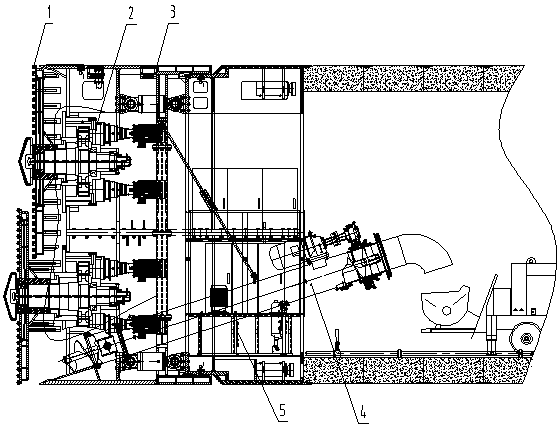

[0023] like figure 1 As shown, the super-large rectangular section shield pipe jacking machine of the present invention includes: a cutter head device 1, an independent drive system 2, a rectangular shield 3 supporting the entire equipment, a screw conveyor 4 and a supporting system 5.

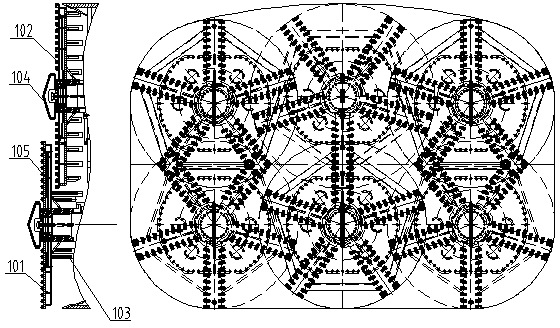

[0024] like figure 2 As shown, the cutterhead device 1 is a combined cutterhead, consisting of six small spoke-type cutterheads, wherein the three spoke-type small cutterheads of the front small cutterhead 101 are distributed on the same front plane in an inverted shape, and the rear small cutterheads The three spoke-type small cutterheads of 102 are distributed on the same rear plane in the shape of genuine products, so that the cutting areas overlap and overlap each other. Each spoke-type small cutter head structure is mainly composed of five main knife beams and a central fishtail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com