Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

158 results about "Centrifugal extractor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A centrifugal extractor—also known as a centrifugal contactor or annular centrifugal contactor—uses the rotation of the rotor inside a centrifuge to mix two immiscible liquids outside the rotor and to separate the liquids in the field of gravity inside the rotor. This way, a centrifugal extractor generates a continuous extraction from one liquid phase (fermentation broth) into another liquid phase (organic solvent).

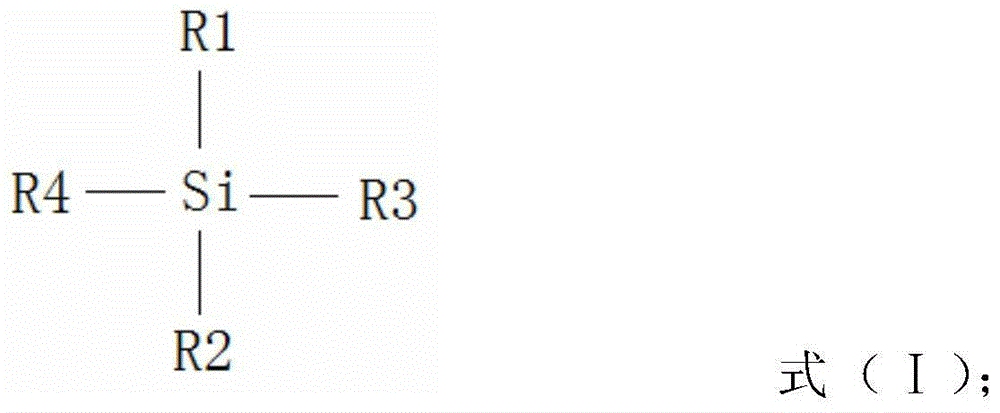

Method for extracting rubidium salt and cesium salt

ActiveCN103787375ASpeed up extractionImprove working environmentLiquid solutions solvent extractionRubidium/caesium/francium compoundsRubidiumSalinity

The invention relates to a method for extracting rubidium salt and cesium salt. The method comprises the steps of 1) regulating a high-salinity solution to obtain an alkaline solution which has a pH value of 11-14; 2) extracting rubidium ions and cesium ions from the alkaline solution obtained from the step 1) in a centrifugal extractor through an organic extracting agent, thus obtaining a loaded organic phase (I) and raffinate; 3) washing the organic phase (I) obtained from the step 2) through washing water to obtain an organic phase (II) and a washing solution; 4) implementing reverse extraction to the loaded organic phase (II) through reverse extraction acid (I) to obtain a rubidium salt reverse extraction solution and an organic phase loaded with cesium ion; and 5) implementing reverse extraction to the organic phase loaded with the cesium salt obtained from the step 4) through reverse extraction acid (II) to obtain a cesium salt reverse extraction solution and a blank organic phase. The extraction method disclosed by the invention is simple and easy to implement, and can be matched with comprehensive development and utilization of a high-salinity medium to produce a rubidium salt and cesium salt product of preset type.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

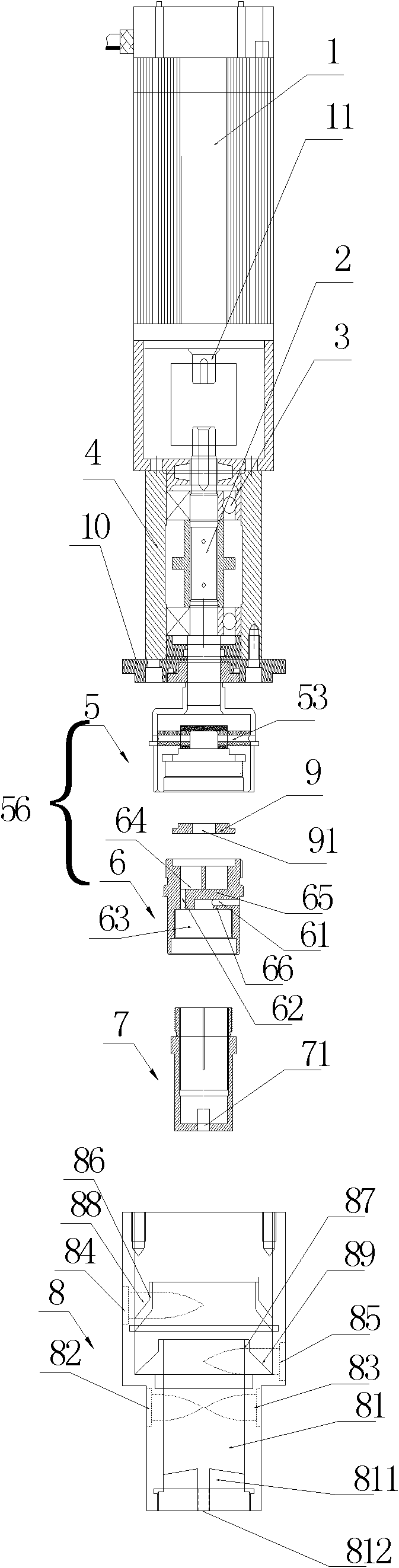

Copper recovery form etching waste liquid of circuit board

InactiveCN101289707AAchieve recyclingReduce energy consumptionProcess efficiency improvementLiquid wasteCopper sulfate

The invention provides a method for recovering copper from circuit board etching solution. The method comprises the following steps: A. according to a certain ratio, the etching solution and organic phase are pumped in a centrifugal extractor for continuous extraction, obtaining organic phase carrying copper and water phase; extracting agent is of aldoxime copper extracting agent, the volume ratio between the organic phase and the water phase is 1 to 5:1, and the number of extraction stages are 3 to 8 stages; B. the organic phase carrying copper undergoes 1 to 3 stages of water washing; C. the organic phase carrying copper undergoing the water washing undergoes sulfuric acid stirring back extraction, and after phase separation, the organic phase and the back extraction water phase are obtained; D. the back extraction water phase is cooled and crystallized, and undergoes centrifugal separation for obtaining copper sulfate products and copper sulfate crystallization mother liquors. The method has the advantages that metallic copper can be recovered from the alkali etching solution by extraction, thereby realizing an aim of cyclic utilization of the treated waste solution, greatly lowering energy consumption, simplifying process, easily being popularized among practical manufacturers and creating excellent benefit and environmental benefit.

Owner:DONGGUAN GUANGHUA CHEM

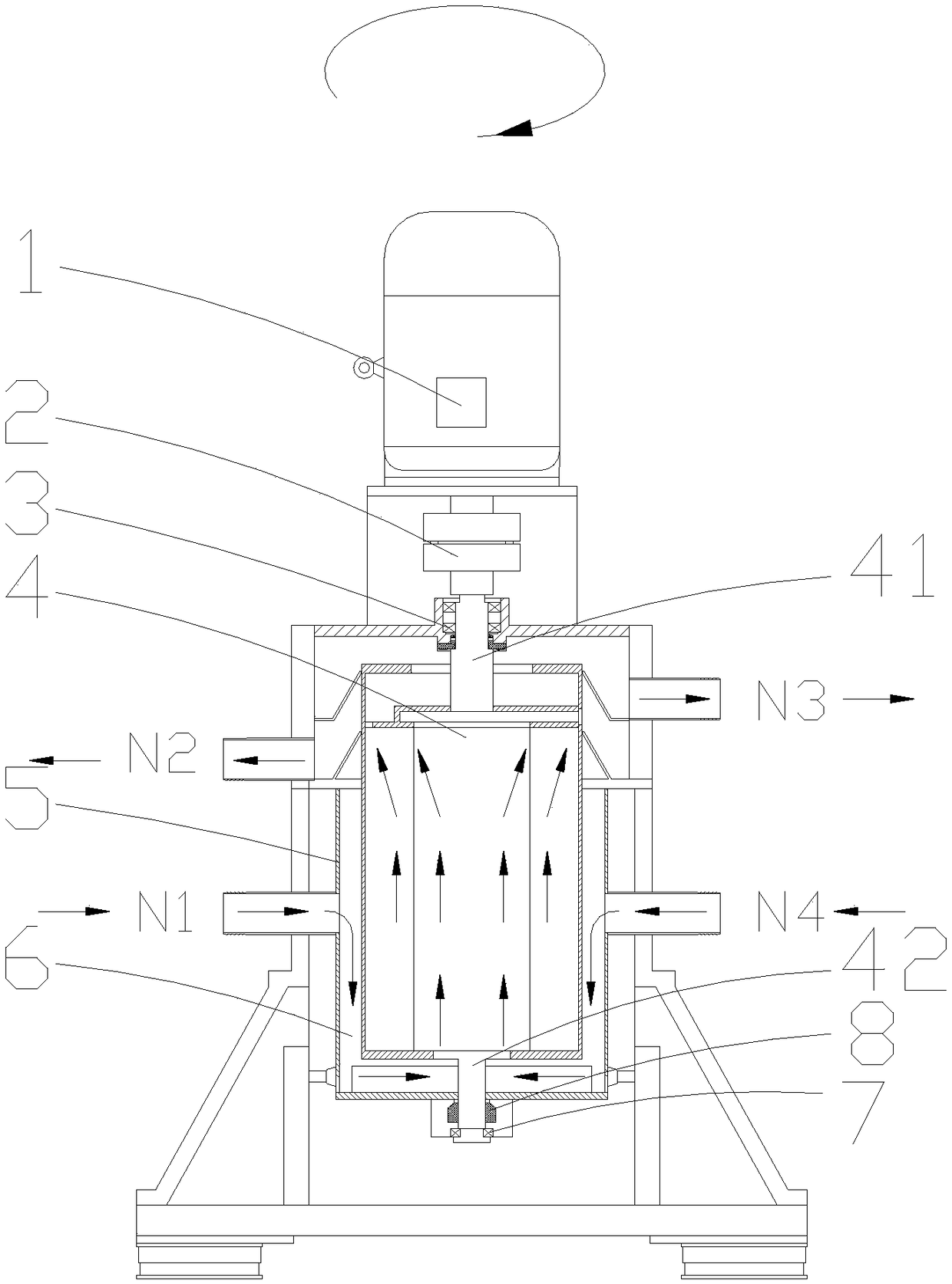

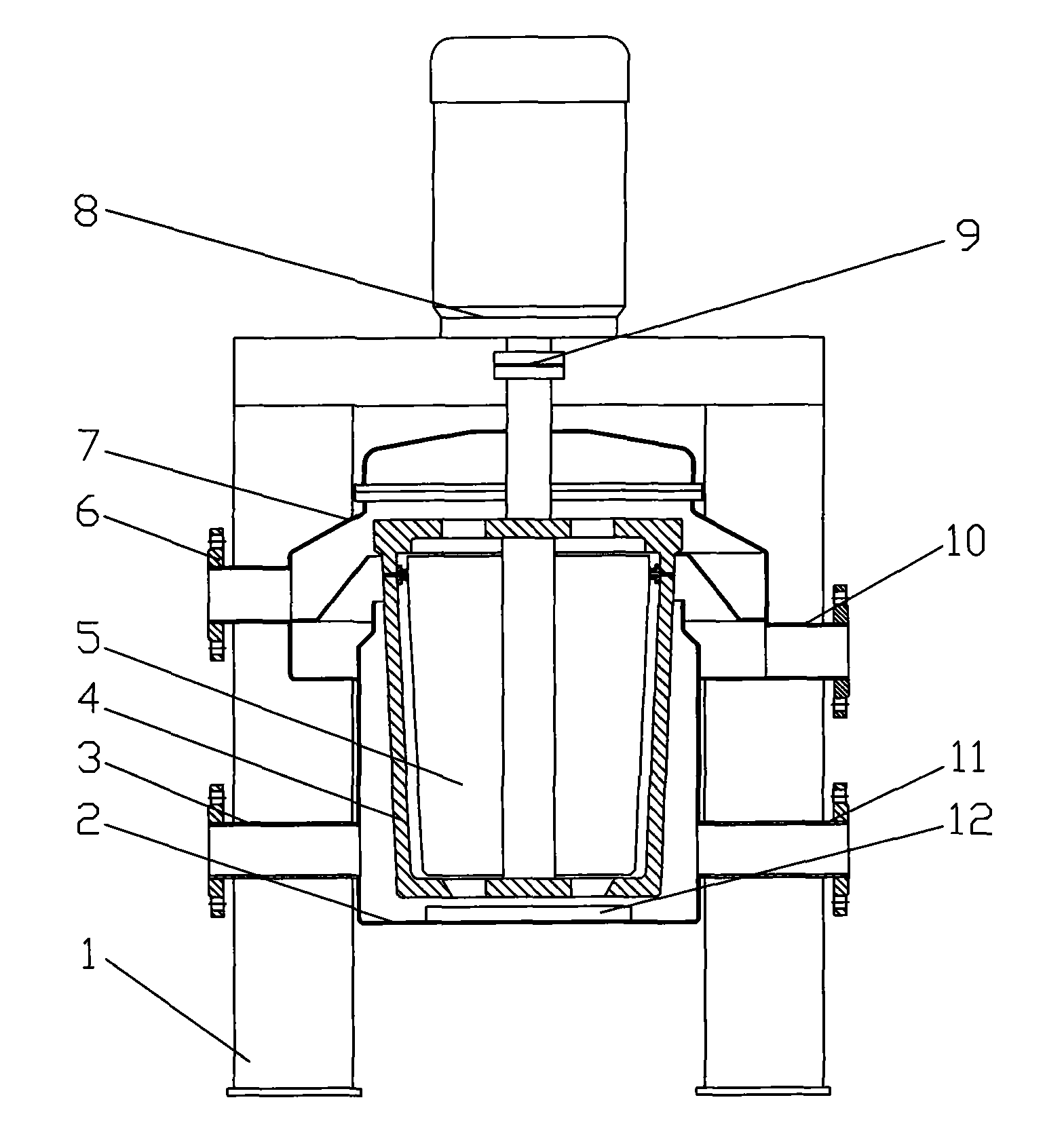

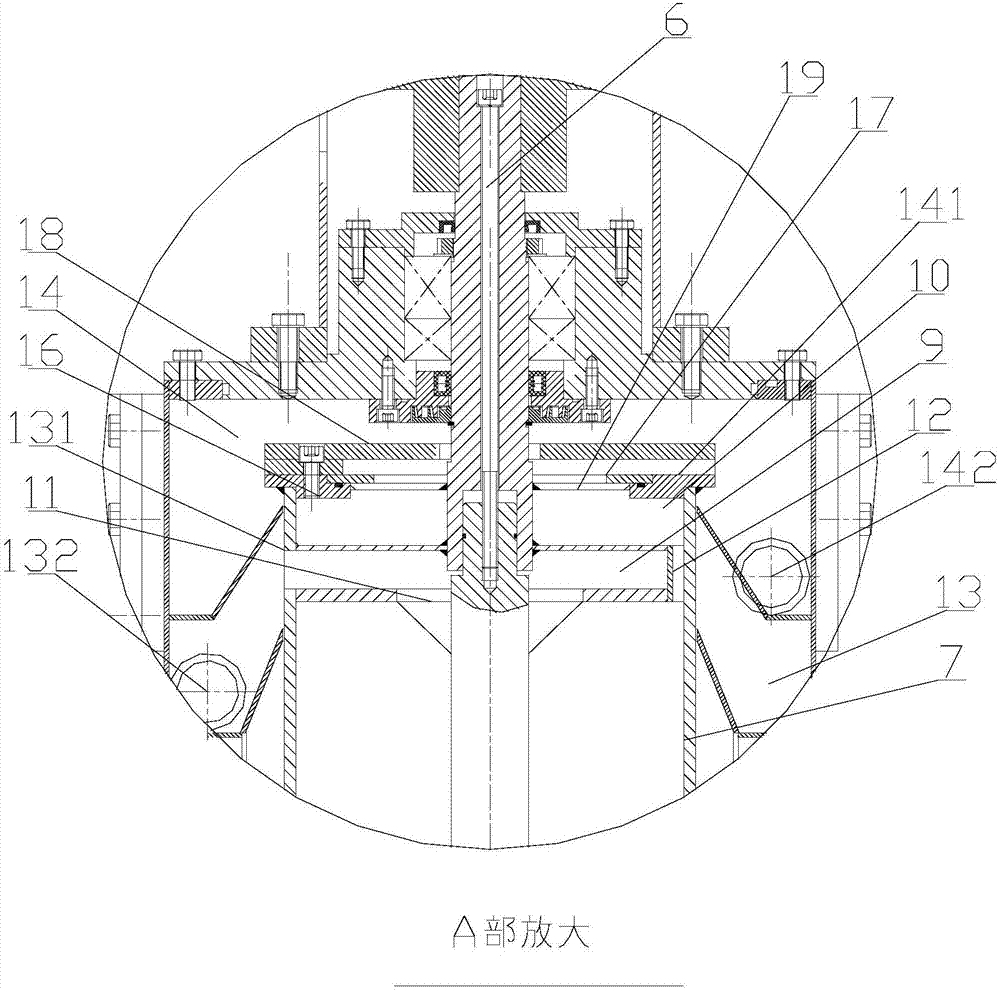

Cylinder type centrifugal extractor

ActiveCN103830933ALarge adjustment rangeSmall sizeLiquid solutions solvent extractionImpellerEngineering

The invention discloses a cylinder type centrifugal extractor. The centrifugal extractor comprises a motor, a transmission system, a rotating shaft, an auxiliary support, a mixing chamber, a light-phase outlet, a light-phase inlet, a heavy-phase outlet, a heavy-phase inlet, a sandwich layer, an annular impeller, a feeding impeller, a rack, a light-phase weir plate, a heavy-phase weir plate, a light-phase collecting chamber and a heavy-phase collecting chamber, wherein one end of the transmission system is connected with the motor, and the other end of the transmission system is connected with the top of the rotating shaft of a rotor drum; the bottom of the rotating shaft of the rotor drum is provided with the auxiliary support; the bottom of the rotor drum is provided with a baffle plate; the feeding impeller is arranged under the central position of the bottom of the rotor drum; the mixing chamber is arranged below the rotor drum; both the periphery and the bottom of the mixing chamber are provided with mixing baffle plates; the heavy-phase inlet and the light-phase inlet are respectively formed in the two ends of the bottom of the mixing chamber; the exterior of the rotor drum is provided with the sandwich layer, the light-phase collecting chamber and the heavy-phase collecting chamber from the inside out. The cylinder type centrifugal extractor has the advantages that entrainment is reduced, the extraction flux is increased, an extraction separation effect is good, the production efficiency is high, and the like.

Owner:广州富一液体分离技术有限公司

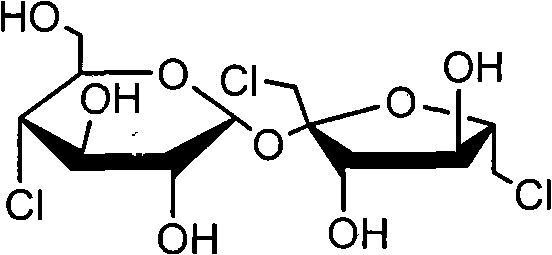

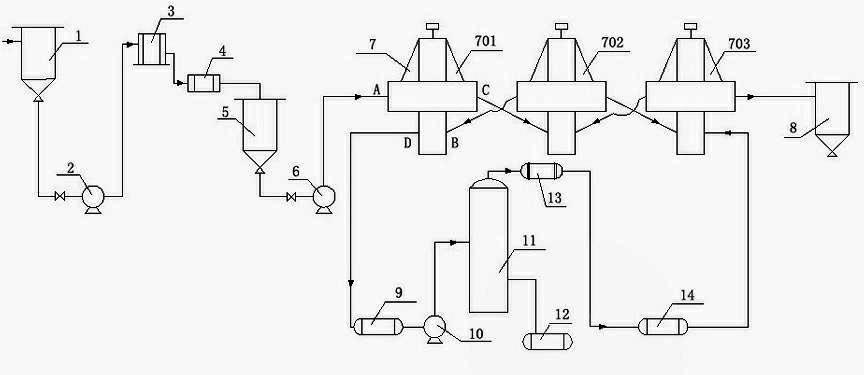

Novel method for separating and purifying sucralose-6-ethyl ester

InactiveCN101709069ALarge amount of solutionSolve the problem of energy consumptionEsterified saccharide compoundsSugar derivativesSucroseEthyl acetate

The invention discloses a novel method for separating and purifying sucralose-6-ethyl ester, which is realized in a way that: preparing a water solution from crude sucralose-6-ethyl ester obtained by chlorinating sucrose-6-ester; constituting a serial counter-current extraction process by utilizing a plurality of annular space type centrifugal extractors, and separating and extracting by using ethyl acetate or butyl acetate as the extraction solvent; condensing the extract to be dry; and crystallizing and recrystallizing to obtain the sucralose-6-ethyl ester crystal. The invention carries out the continuous extraction by using the annular space type centrifugal extractors, thereby greatly reducing the use amount of the organic solvent for extraction and also reducing the loss of the organic solvent and the environmental pollution. The extraction rate of the product is enhanced from 90% to 98%, thereby obviously reducing the product loss in the separation process. Meanwhile, the technique can obviously reduce the labor intensity of the operational workers and improve the working environment of the workers.

Owner:ZHEJIANG UNIV OF TECH +1

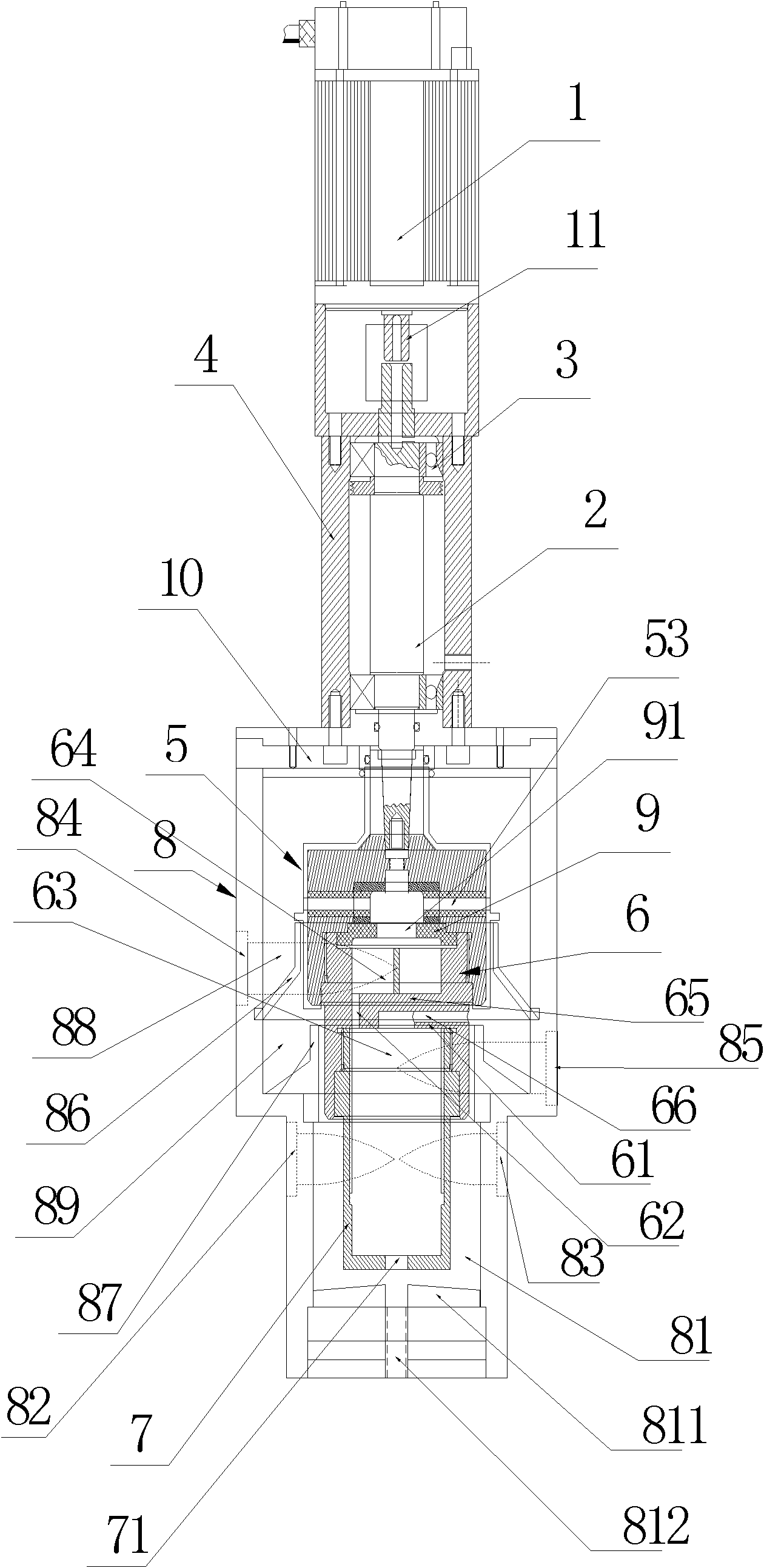

Centrifugal extractor

ActiveCN102078704AGood extraction and separationLiquid solutions solvent extractionEngineeringDensity difference

The invention discloses a centrifugal extractor. The centrifugal extractor comprises a motor (1), a spindle (2), a flow guide part (56), a rotating drum (7) and a shell (8), wherein one end of the spindle (2) is connected with an output shaft (11) of the motor (1), and the other end of the spindle (2) is fixedly connected with the flow guide part (56); and the flow guide part (56) is fixedly connected with the rotating drum (7) and is positioned in the shell (8). Through the technical scheme, the rotating drum is indirectly connected to the spindle through the flow guide part and is indirectly driven to rotate by the spindle, so that when the spindle drives the rotating drum to rotate through the flow guide part, the extractor is not obviously vibrated even if rotating speed is high; therefore, ideal extraction and separation effects also can be achieved under the condition that the ratio difference of two-phase flow is large or the density difference of two phases is small.

Owner:北京萃取应用技术研究所

Washing and separation method of nitrobenzene

InactiveCN102675118ASmall footprintLow in phenatesOrganic chemistryOrganic compound preparationNitrobenzeneNitration

The invention relates to a washing and separation method of nitrobenzene. The washing and separation method of nitrobenzene includes allowing nitration product and waste acid to enter a nitrifying separator for separation when nitration is over, allowing organic phase to enter a coalescing separator after separation to further remove the waste acid in the organic phase, subjecting the organic phase to alkaline cleaning and water washing in two centrifugal extractors respectively, and subjecting the obtained organic phase to post-treatment. The coalescing separator can be static separators such as a fiber-cartridge separator, a plate separator or a combined separator. Organic phase and inorganic phase are reversely mixed in the centrifugal extractors. The waste acid in the crude nitrobenzene can be further removed by water washing and separation by the method, and alkaline consumption in neutralization is lowered. The centrifugal extractors are used in neutralization and washing, and accordingly no additional neutralization and washing separator is needed, and floor area of equipment is reduced. Mixing effect is fine, washing is sufficient, content of phenoxide in the washed crude nitrobenzene is lower, and safety of a production system is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Plutonium purification and concentration method

ActiveCN104004928AHigh yieldIncrease the concentration factorProcess efficiency improvementFuel reprocessingAfter treatment

The invention belongs to the technical field of fuel-short after-treatment and discloses a plutonium purification and concentration method. The method comprises the following steps: extracting tetravalent plutonium in a nitric acid solution into a 30% TBP (tributyl phosphate)-kerosene solution with relatively small volume for purification and concentration in a centrifugal extractor, reducing tetravalent plutonium into trivalent plutonium by using a dimethylhydroxylamine-containing nitric acid solution with relatively small volume, performing back extraction on trivalent plutonium, and further purifying and concentrating plutonium in a water phase. In the whole concentration process, a plutonium replenishment and extraction link is removed. The method is simple in step, short in time and small in solvent radiation effect; the plutonium back-extraction yield reaches up to 99.98% while the plutonium concentration is increased by more than 10 times.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

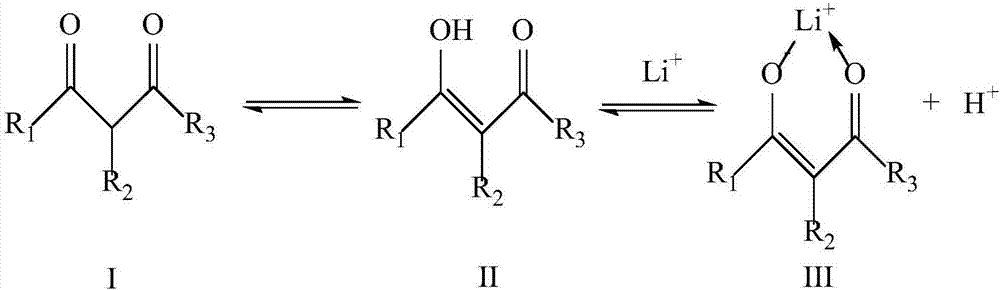

Technology for extracting lithium from lithium-containing alkaline brine based on centrifugal extractor

ActiveCN108004420AReduce usageAvoid densityLithium halidesProcess efficiency improvementLithium chlorideLithium carbonate

The invention discloses a technology for extracting lithium from lithium-containing alkaline brine based on a centrifugal extractor. The technology comprises the following steps including extraction water phase providing, extraction organic phase providing, the extraction step, the washing step, the reverse extraction step and the regeneration step. The brand new extraction system is adopted in the technology, the lithium is extracted from the lithium-containing alkaline brine system, and the extraction-washing-reverse-extraction-regeneration total process technology based on the centrifugal extractor is determined for the first time instead of staying on the basic study on the extraction workshop section, the series, the flow rate, reagent concentration and other technology parameters ofevery workshop section to which the extraction system is adaptive are determined finally, and the industrial production technology path based on the centrifugal extractor is provided. The technology for extracting lithium from lithium-containing alkaline brine is particularly suitable for a filter liquor system generated in the lithium carbonate product preparing process through a lithium chloridesolution, accordingly, the lithium is further extracted from the lithium chloride solution, real comprehensive cyclic utilization of salt lake brine is achieved, and practical significance is achieved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

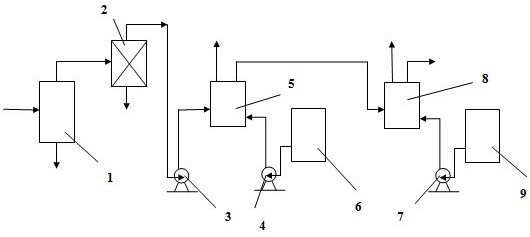

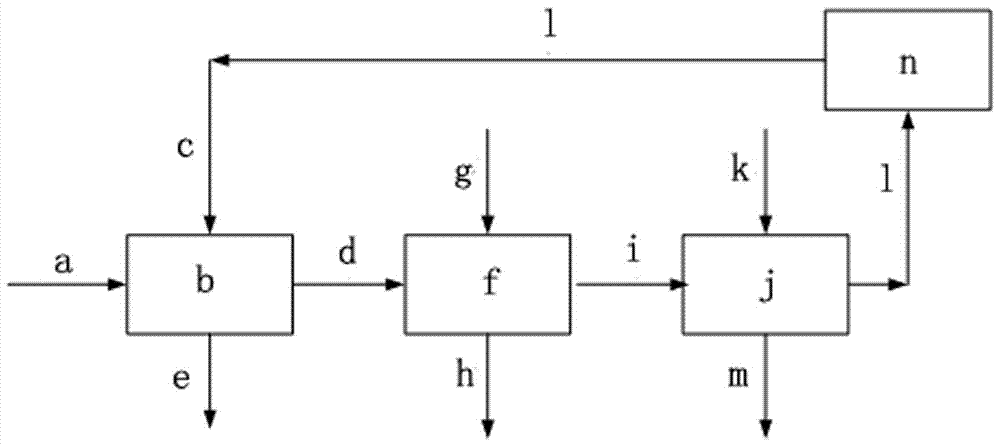

Method and device for recovering caprolactam in benzene distillation residue

InactiveCN103539738AAvoid churnIncrease productionLactams separation/purificationLiquid solutions solvent extractionBenzeneDistillation

The invention relates to a method and device for recovering caprolactam in benzene distillation residue, and provides a method for recovering caprolactam in the benzene distillation residue. The method comprises the following steps: (a) respectively feeding the benzene distillation residue and water obtained by distilling in a benzene distillation column into a centrifugal extractor; (b) enabling the benzene distillation residue and water to fully mix and be subjected to mass transfer in the centrifugal extractor, in order to extract caprolactam in benzene distillation residue into the water; (c) performing liquid-liquid separation on the mixed solution of the benzene distillation residue and water through the centrifugal extractor in order to separate out an aqueous solution rich in caprolactam and the benzene distillation residue in which the caprolactam is removed; and (d) recycling the aqueous solution rich in caprolactam, separated out in step (c), and treating the benzene distillation residue in which the caprolactam is removed, by incineration. The invention also provides the device for recovering the caprolactam in the benzene distillation residue.

Owner:EAST CHINA UNIV OF SCI & TECH

Sinomenine hydrochloride and preparation method thereof

The invention discloses sinomenine hydrochloride and a preparation method thereof. According to the technical scheme, sinomenine hydrochloride is prepared with a single-stage extraction or multi-stageextraction method. The single-stage extraction is based on a single centrifugal extractor for extraction, a centrifugal extractor drum motor is started, a liquid medicine is pumped into the centrifugal extractor from a light phase inlet at a speed of 10000 L / h, an extraction agent chloroform is pumped into the centrifugal extractor from a heavy phase inlet at a speed of 7500 L / h, and extract liquor is collected; the multi-stage extraction is based on two or more centrifugal extractors for extraction in a series-connection manner.

Owner:HUNAN ZHENGQING PHARM GRP CO LTD

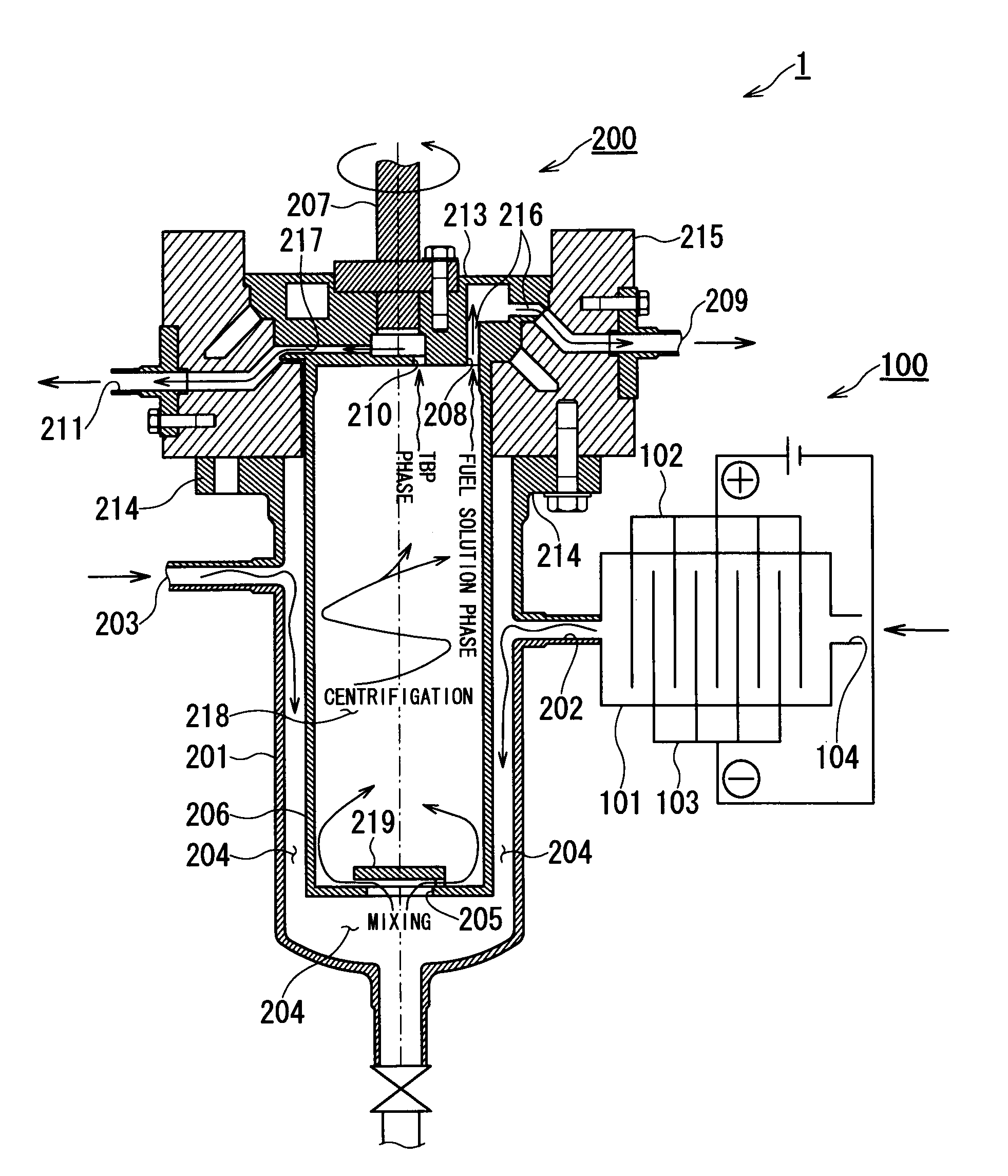

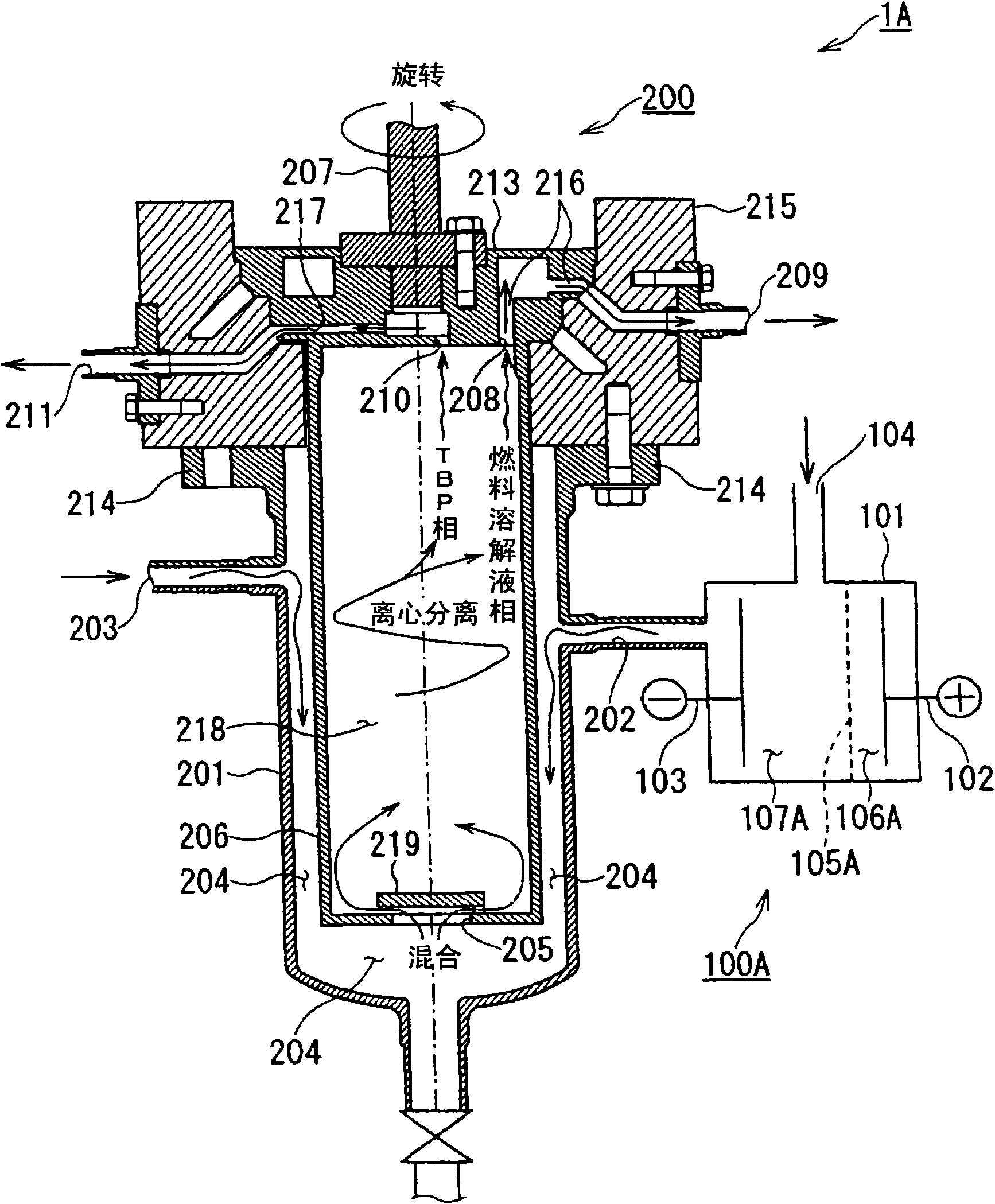

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

ActiveUS20100038249A1Isolation difficultRecovery difficultPhotography auxillary processesElectrolysis componentsElectrolysisEngineering

A spent nuclear fuel is reprocessed by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction. A spent nuclear fuel reprocessing method includes: an electrolytic valence adjustment step in which nuclides contained in the fuel solution is electrolytically reduced without removing fission products or minor actinides until valence of plutonium is at a level at which solvent extraction efficiency is low by using the valence of plutonium contained in the fuel solution as a parameter; and a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

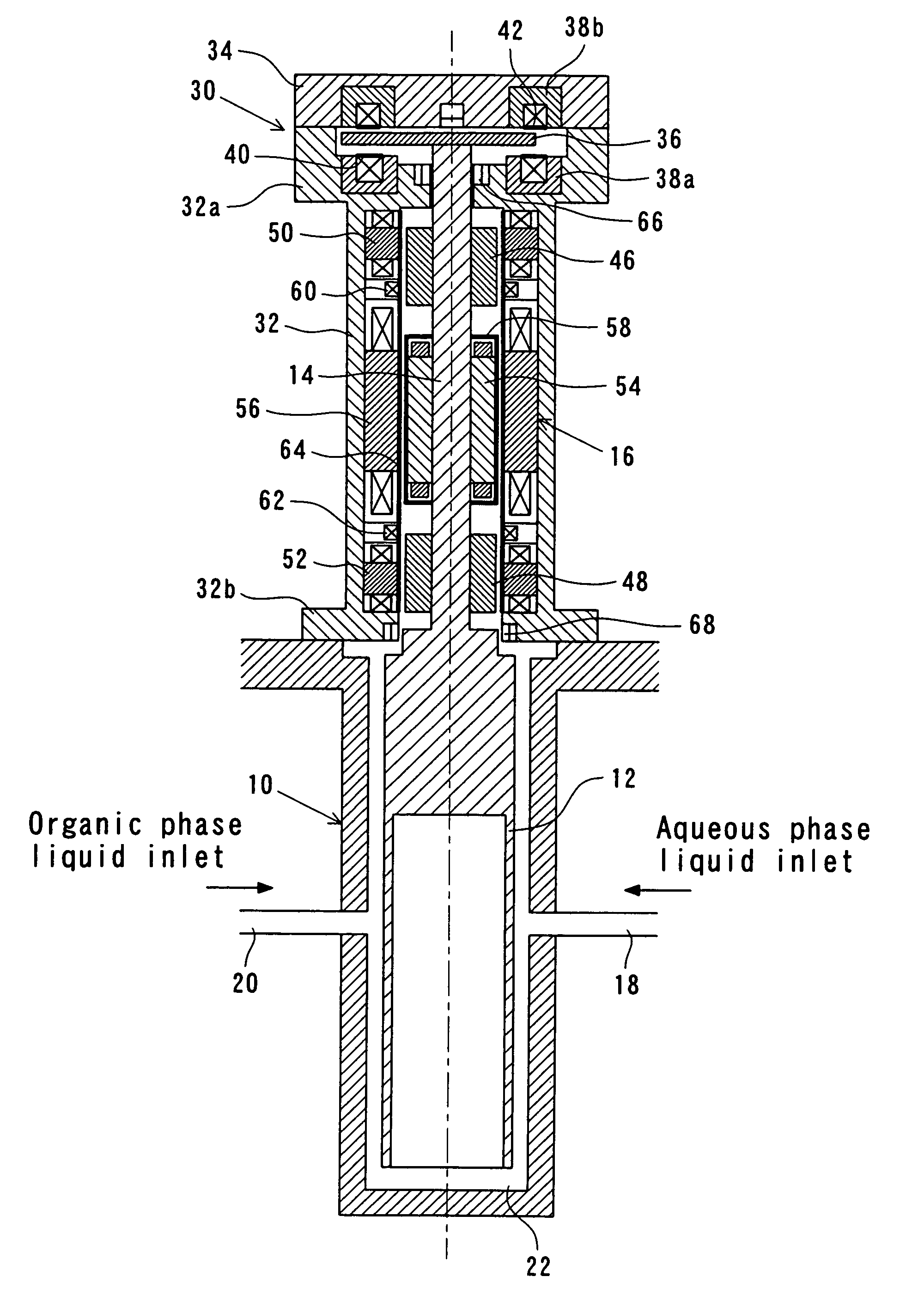

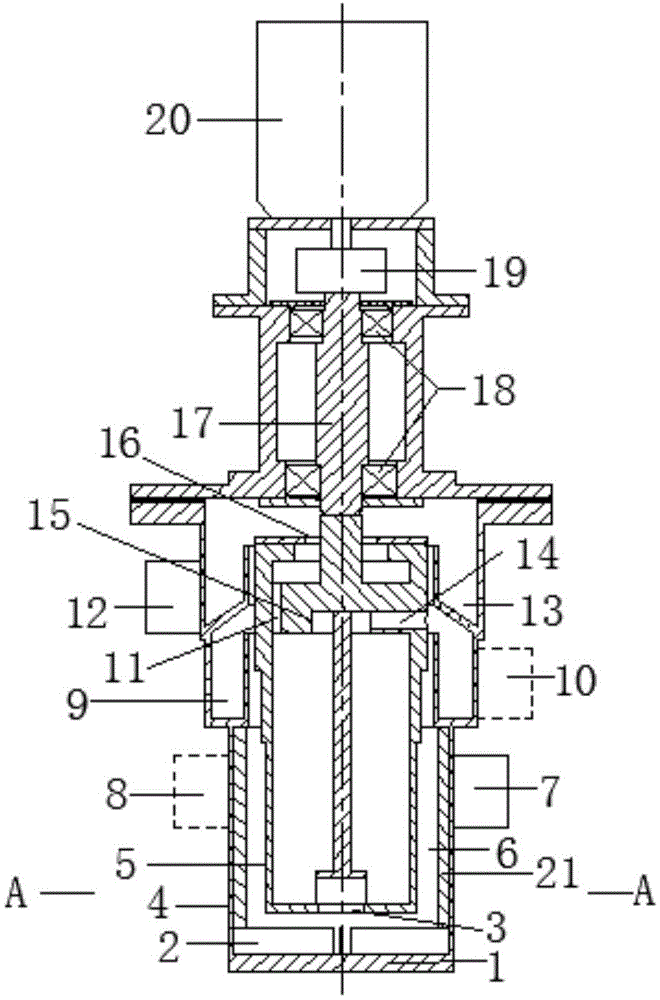

Centrifugal extractor of non-contact journaled construction

InactiveUS6976947B2Improve reliabilityEasy to useLiquid solutions solvent extractionMagnetic bearingsThrust bearingNon magnetic

A centrifugal extractor of non-contact journaled construction is provided in which, even under the environments of corrosive gase and mist-like liquid such as nitric acid mist generated in the reprocessing of a spent nuclear fuel, no problem in corrosion or deterioration of parts occurs and high reliability is obtained, and operation is enabled for a long period of time free from maintenance. A rotor 12 housed in a rotor housing 10 is journaled by a main shaft 14 and rotated and driven by a motor 16. The main shaft is surrounded by a drive-portion housing 30, and has a thrust magnetic disk 36 on the upper end and radial magnetic disks 46, 48 and a motor-rotor portion 54 in the circumference thereof. Thrust bearing electromagnets 38a, 38b, radial bearing electromagnets 50, 52 and a motor stator portion 56 are incorporated into the drive-portion housing, and covered by non-magnetic anticorrosive protective plates 40, 42, and a protective pipe 64, the motor-rotor portion being also covered by a protective can 58. Slide bearings 66, 68 for touch down made of fluorocarbon resin are disposed on the upper end of the main shaft and on the inner wall of the drive-portion housing in the vicinity of the upper end of the rotor.

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

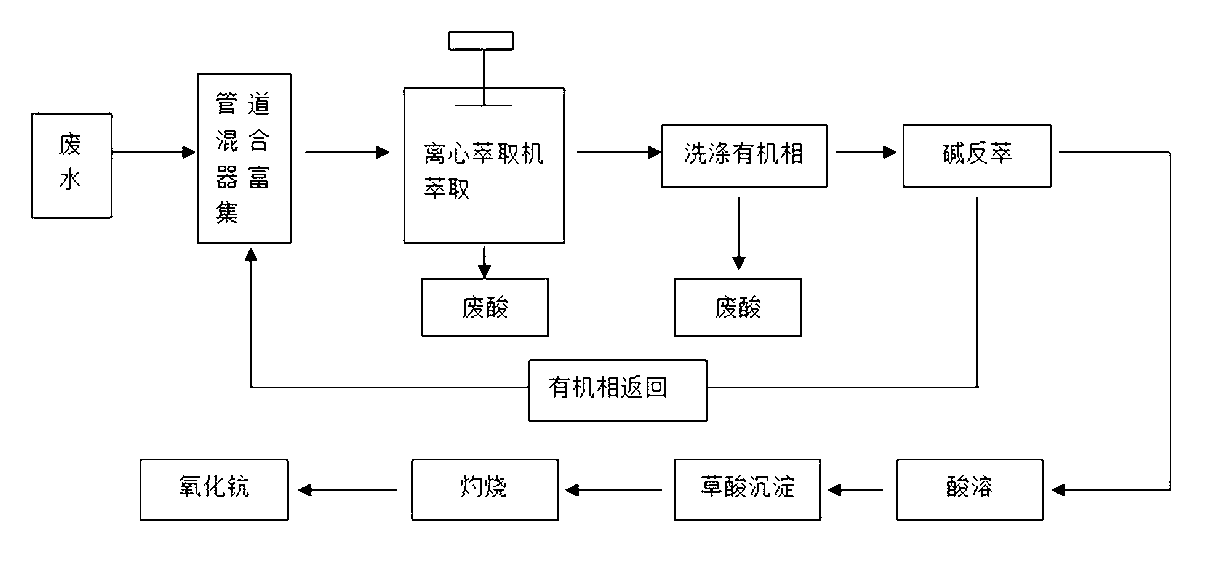

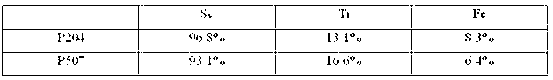

Method for recovering scandium from titanium dioxide wastewater on large scale

ActiveCN102701262ARapid separation and clarificationReduce contentRare earth metal compoundsAcid dissolutionPhysical chemistry

The invention discloses a method for recovering scandium from titanium dioxide wastewater on a large scale. According to the method, a centrifugal extractor is matched with a pipeline mixer for use; and P507 is used as an extracting agent. The method has the advantages of short time, high treatment amount, small occupied area and realization of oil-water separation. An organic phase is washed by using a H2O2 and sulfuric acid mixed solution, so that the amount of an alkali reaction substance is greatly reduced, and further acid is dissolved, most impurities are removed and the treatment amount of subsequent-stage work procedures is reduced. According to the method, scandium oxide with the purity of 98 percent can be obtained from the wastewater on a large scale.

Owner:河南荣佳钪钒科技有限公司

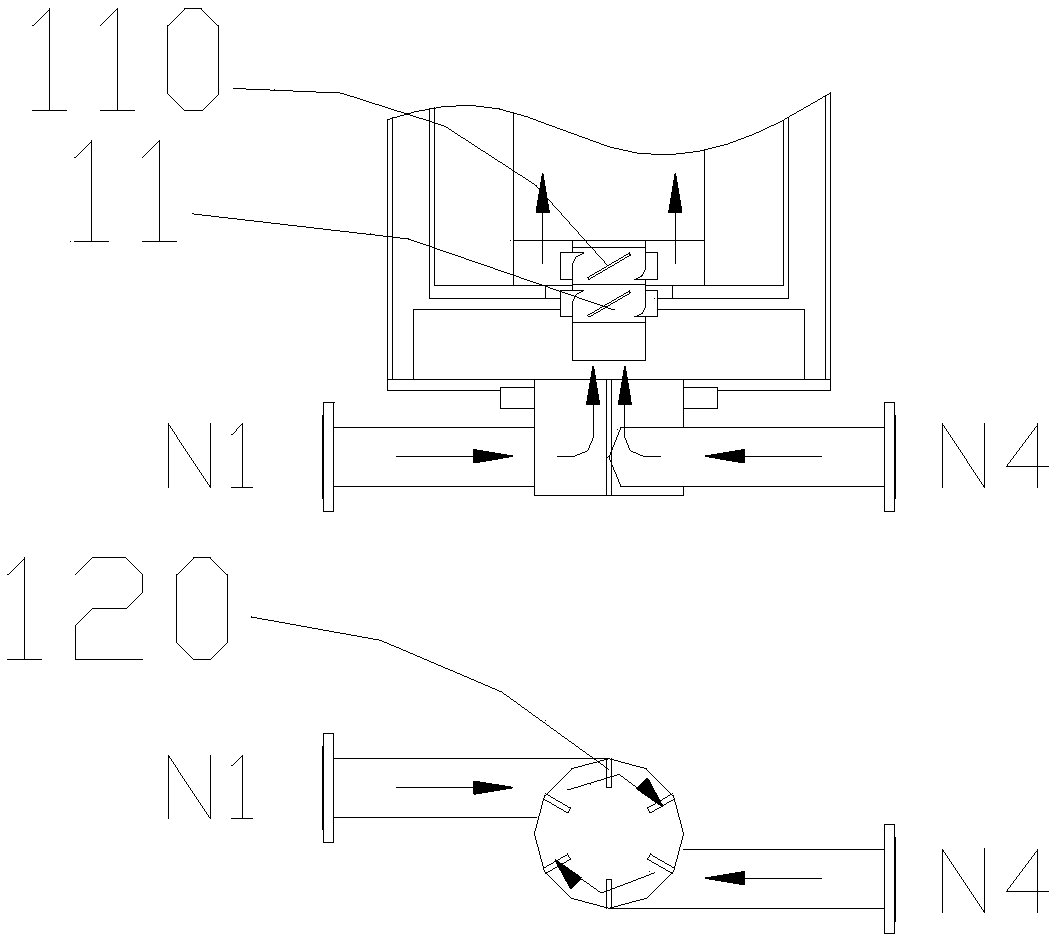

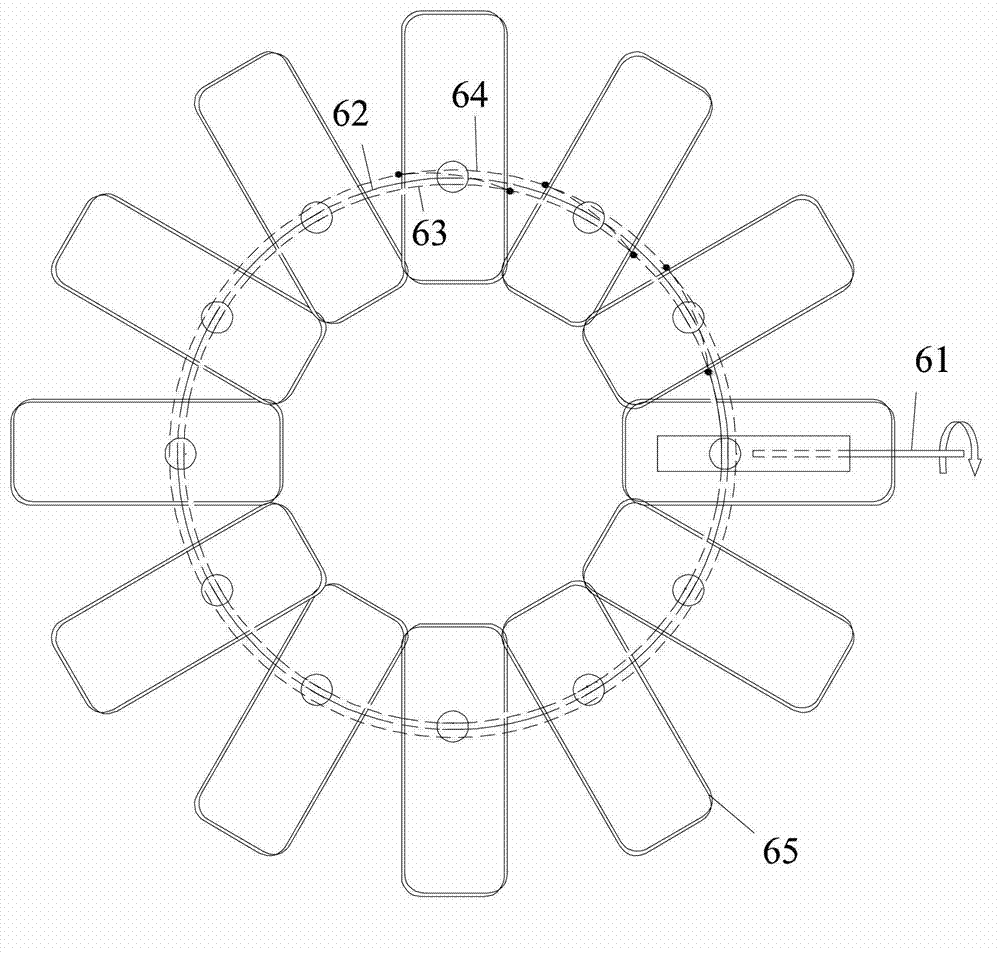

Combined centrifugal extractor

InactiveCN104874201AClosely connectedReduce resistanceLiquid solutions solvent extractionCentrifugesEngineeringCentrifugal extractor

The present invention relates to the technical field of liquid-liquid separation, and specifically discloses a combined centrifugal extractor, which comprises a driving device, a synchronous transmission mechanism, and a plurality of centrifugal extractors connected in series, wherein the driving device is connected with the plurality of the centrifugal extractors through the synchronous transmission mechanism so that the plurality of the centrifugal extractors can perform synchronized operation. According to the present invention, the plurality of the centrifugal extractors are combined to form the integration, and the synchronized operation of the plurality of the centrifugal extractors is achieved by the synchronous transmission mechanism so as to achieve the simultaneous control on the plurality of the centrifugal extractors and effectively improve the extraction effect and the extraction efficiency; and the assembled, modular and skid-mounted design is used and the extractors are compactly connected so as to provide the strong integrity, reduce the occupation area, shorten the length of the connection pipeline, simplify the pipeline structure, reduce the pipeline resistance, reduce the flow loss inside the pipeline, reduce the energy consumption, save the production cost, substantially reduce the on-site construction amount, and rapidly and conveniently install and disassemble.

Owner:THUNIP CORP LTD

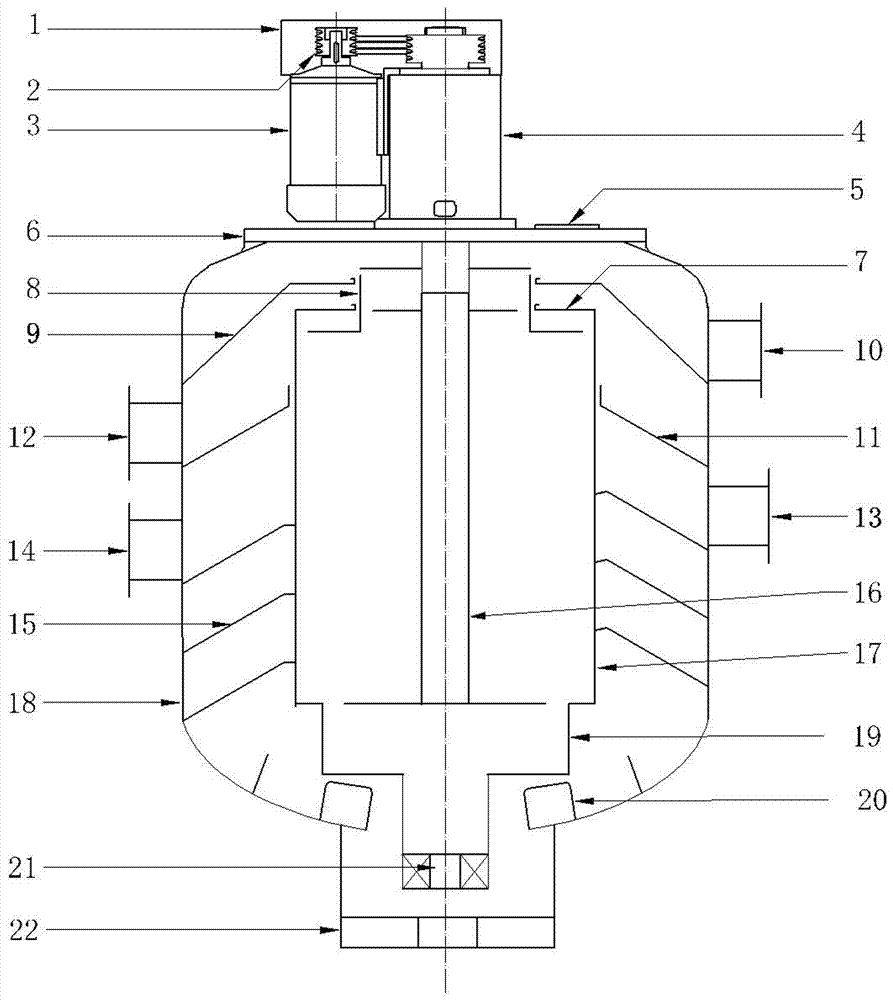

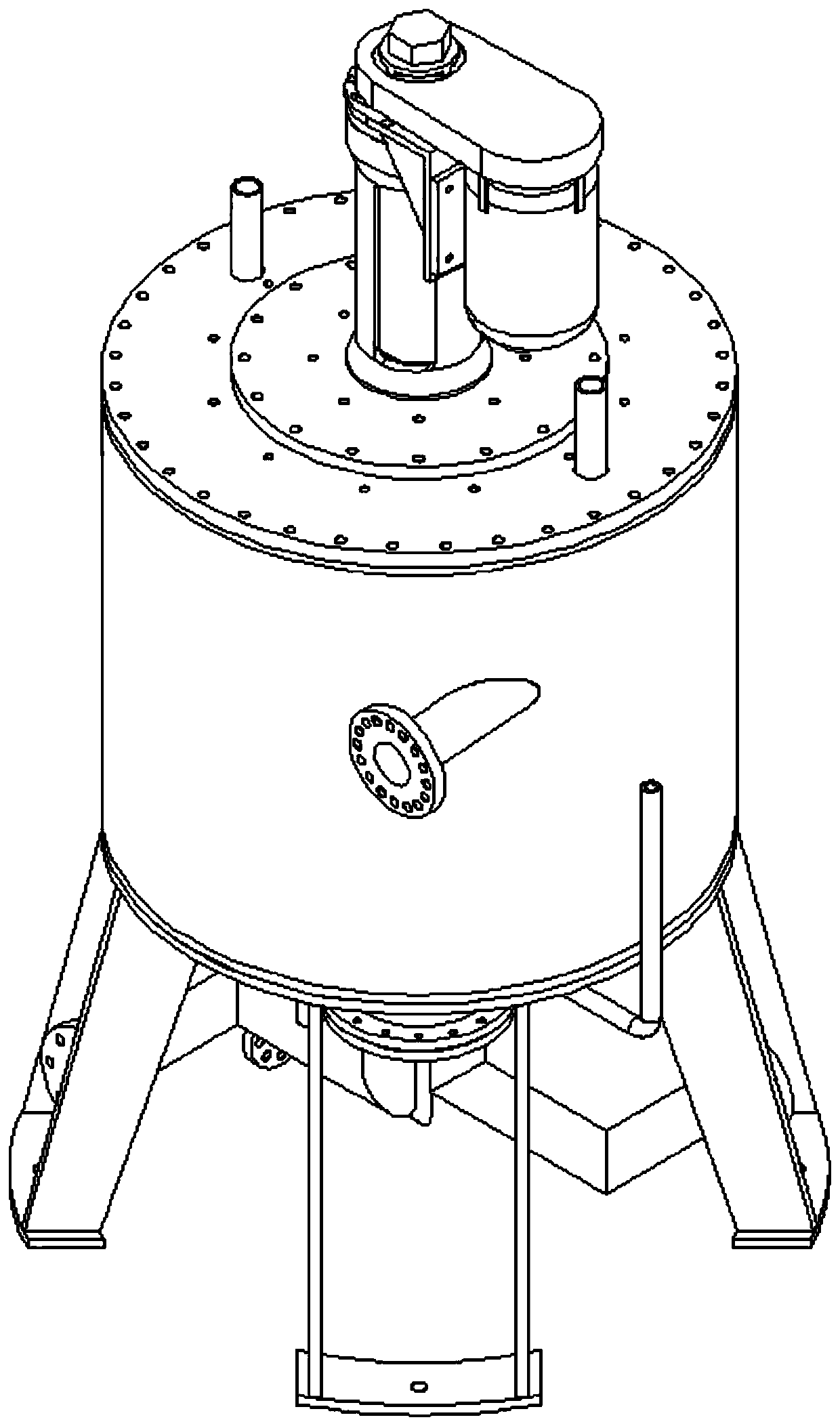

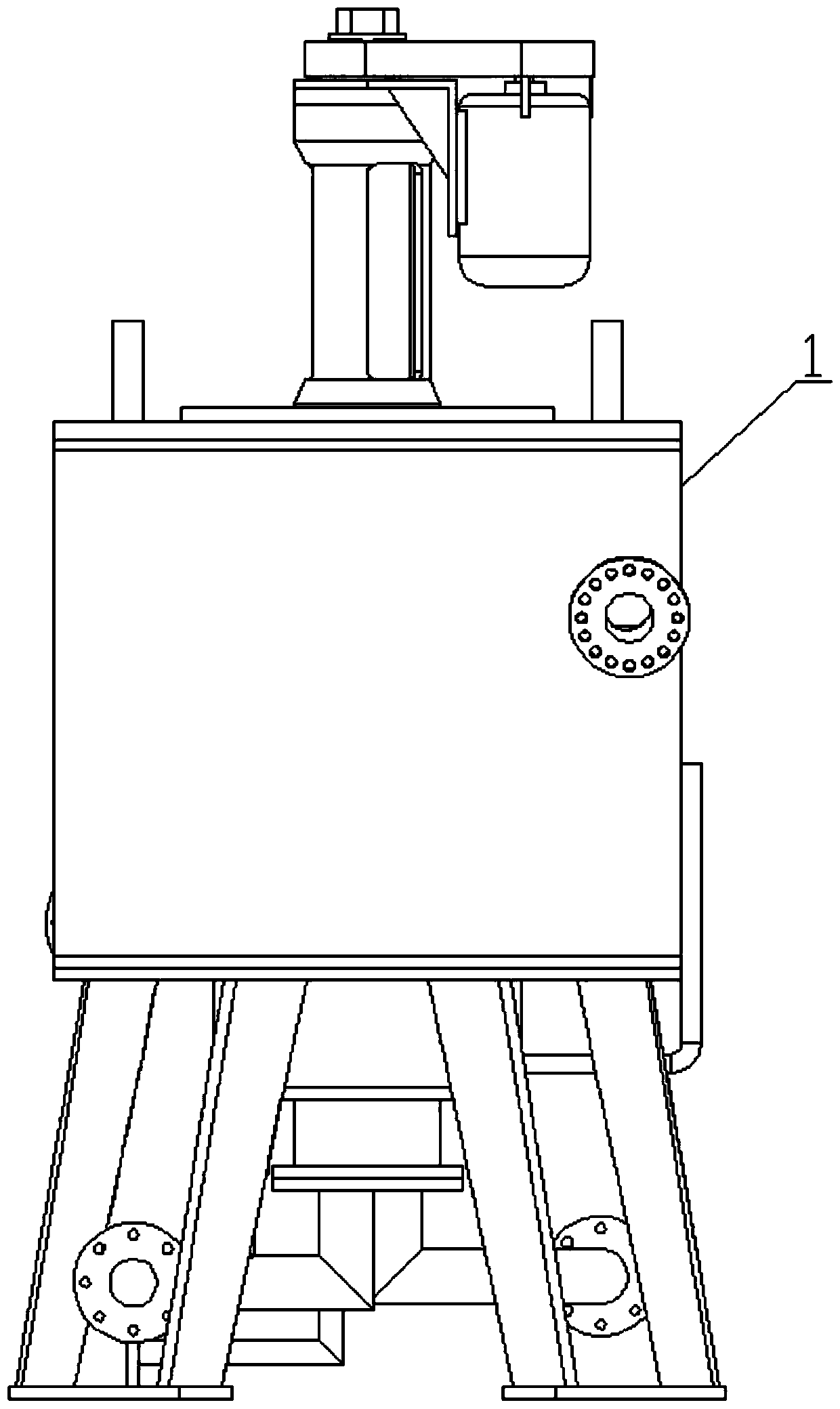

Top-suspended low-power consumption and weak-shearing type liquid-liquid centrifugal extractor

ActiveCN109011691AWell mixedLarge contact surfaceLiquid solutions solvent extractionImpellerMotor drive

The invention relates to a top-suspended low-power consumption and weak-shearing type liquid-liquid centrifugal extractor. The liquid-liquid centrifugal extractor includes a shell and a rotating drumwhich are coaxially arranged, the upper shaft end of the rotating drum is connected with a motor driving shaft by a shaft coupling, the lower shaft end of the rotating drum is suspended in the shell,the outer bottom surface of the shell is provided with a material mixing cylinder communicated with the internal of the shell and arranged coaxial with the rotating drum, a material-to-be-extracted inlet and an extractant inlet which are arranged along the tangential direction of the mixing cylinder are arranged in the outer side surface of the mixing cylinder, material dispersing blades are arranged on the inner side surface of the mixing cylinder, and a centripetal impeller structure arranged coaxial with the rotating drum is arranged on the inner bottom surface of the shell. The liquid-liquid centrifugal extractor realizes non-contact of the outer side surface of the rotating drum and the material, so the problems of power consumed by material stirring generated turbulent flow, power consumed by the contact friction with the material, wearing of the outer surface of the rotating drum by the material scouring and heat are solved, and the problem of material emulsification caused by the shearing effect of the side surface of the rotating drum on the material is also solved.

Owner:HEFEI GENERAL MACHINERY RES INST

Method for extracting and separating L-lactic acid from ammonium lactate fermentation material liquid

ActiveCN104557515ASpecific adsorptionAchieve purificationPreparation from carboxylic acid saltsCarboxylic compound separation/purificationSpecific adsorptionCoupling

The invention discloses a method for extracting and separating L-lactic acid from an ammonium lactate fermentation material liquid. The method comprises the following steps: (1) pre-treating the ammonium lactate fermentation material liquid; (2) carrying out sulphuric acidolysis on ammonium lactate; (3) adding an acidolysis material liquid and a coupling adsorbent in a centrifugal extractor respectively, and extracting L-lactic acid through coupling adsorption at 15-25 DEG C; (4) separating an organic phase from a water phase; and (5) adding the organic phase and hot water at 55-65 DEG C in the centrifugal extractor respectively, and extracting L-lactic acid through backcoupling adsorption. The method disclosed by the invention is capable of rapidly extracting and separating L-lactic acid from the lactic acid acidolysis liquid, changing the process route of separating various impurities from L-lactic acid one by one, and directly separating L-lactic acid through coupling adsorption by virtue of a coupling adsorption agent so as to leave the various impurities in a raffinate; because the coupling adsorption agent in the method disclosed by the invention has a specific adsorption property on L-lactic acid, the purpose of further purifying L-lactic acid is achieved, and a decolouring process and most of hybridization processes in the existing processes are removed.

Owner:河南金丹乳酸科技股份有限公司

Down-transmission type centrifugal extractor for the chemical industry operation

InactiveCN101036841AEasy to adjustGuaranteed uptimeSolvent extractionChemical industryCentrifugal extractor

The invention relates to a drive-type centrifugal extractor for use in chemical industrial operation, which belongs to the chemical processing equipment field, comprising a mixing tank, a rotary drum, and a motor. The mixing tank and the rotary drum are coaxially mounted on the machine base, the mixing tank covers the rotary drum in reverse to make the rotary drum in the mixing tank, and the rotary drum is linked with the motor via a rotating shaft. Between the outer shell of the mixing tank and the outer shell of the rotary drum are arranged a heavy-phase collection ring and a light-phase collection ring, a heavy phase outlet is arranged on the mixing tank outer shell between the heavy-phase collection ring and the upper cover of the mixing tank, and a light phase outlet is arranged on the mixing tank outer shell between the heavy-phase collection ring and the light-phase collection ring, and on the mixing tank outer shell between the light-phase collection ring and the bottom of the mixing tank are arranged two inlets. In the invention, the motor and the transmission parts are provided on the bottom of the main machine, which makes the weight of the machine shift downwards to the bottom. The centrifugal extractor is provided with compact structure, stable operation, and more convenient utilization and maintenance, and the rotary drum may not be disassembled when replacing phase barrage, thereby the centrifugal extractor is suitable for use in large-scale equipment.

Owner:THUNIP HLDG

Method for preparing high pure scandium oxide from hydrochloric acid mother liquid for producing zirconium oxychloride

InactiveCN104232945ASolve the difficulty of phase separationSolve the technical problems of extraction with severe emulsificationProcess efficiency improvementSeparation technologyFiltration

The invention belongs to the field of wet metallurgy, and particularly relates to a method for preparing high pure scandium oxide from a hydrochloric acid mother liquid for producing zirconium oxychloride. The method comprises the following steps of (1) extracting the hydrochloric acid mother liquid, separating by centrifugation to remove water phase from an organic phase and for demulsification and washing with acid; (2) subjecting an organic phase loaded in the acid solution to reverse extraction and filtration, discharging the filtrate, dissolving filter residues with acid and extracting; (3) subjecting the organic phase to reverse extraction and filtration, discharging the filtrate, and dissolving the filter residues with acid; (4) regulating a pH value of the acid solution, adding oxalic acid to precipitate scandium, filtering, roasting the filter residues, then dissolving the roasted residues with acid and filtering; (5) regulating a pH value of the filtrate, adding oxalic acid to precipitate scandium again, filtering, roasting the filter residues again, boiling the roasted residues in an acid water, regulating the pH, filtering, washing with water, roasting and drying to obtain a product. The method is used for preparing the high pure scandium oxide from an acid liquid solution with complex components, and changes wastes into valuables. A separation technology employing a baffle-free type self-flow extraction tank, a variable frequency technique and a centrifugal extractor is used to solve technical problems of difficult phase separation and serious emulsification in the extraction technology, and conditions for recovering valuable metals from the complex material liquid are provided.

Owner:ZIBO GUANGTONG CHEM

Method for reprocessing spent nuclear fuel and centrifugal extractor therefor

InactiveCN101650980AEnhanced inhibitory effectLiquid separation by electricityNuclear energy generationEngineeringSolvent

The invention provides a method for reprocessing a spent nuclear fuel which can reprocess highly purified uranium without arranged with a step of separating Pu from solely from a spent nuclear fuel, and solely separated reprocessing of the reprocessed Pu is more difficult and has an excellent repression effect to nuclear proliferation. In a method for reprocessing a spent nuclear fuel by dissolving a spent nuclear fuel in an aqueous nitric acid solution and separating and recovering nuclides contained in the resulting fuel solution by solvent extraction comprising an electrolytic valence adjustment step by using the valence of plutonium contained in the fuel solution as a parameter until the valence of plutonium becomes 3 in which nuclides contained in the fuel solution is electrolyticallyreduced without removing fission products or minor actinides; a nuclide separation step in which, by using an extraction solvent which extracts uranium contained in the fuel solution, uranium is distributed from the fuel solution subjected to the electrolytic valence adjustment step to the extraction solvent.

Owner:KK TOSHIBA

Mixed feeder for centrifugal extractor

InactiveCN105013209ASimple structureImprove the mixing effectMixer accessoriesLiquid solutions solvent extractionEmulsionEngineering

The invention provides a mixed feeder for a centrifugal extractor. The mixed feeder for the centrifugal extractor is mainly used for mixing and feeding of the centrifugal extractor. The mixed feeder for the centrifugal extractor overcomes the defect that the mixing power consumption and the mixing strength of an existing centrifugal extractor are large, and according emulsion of mixed liquid is cause easily, and has wide applicability.

Owner:ZHENGZHOU TIANYI EXTRACTION TECH

Conical barrate centrifugal extractor

InactiveCN101549215AExtended stayWell mixedReversed direction vortexLiquid solutions solvent extractionCentrifugal extractor

A conical barrate centrifugal extractor is provided with a barrate with blades in a cylindrical casing, each charging tube and discharging tube is arranged on a lateral part of the cylindrical casing separately, is characterized in that the barrate is a round bench body with conicity, and the round bench body has a small lower bottom and a large upper bottom. By means of using the conical barrate, it is capable of increasing the material detention period in the barrate without alteration of the barrate height, so that the material may be mixed and transferred with mass perfectly. The barrate is capable of generating different centrifugal forces in the height direction, and further meets the requirement of an extraction process.

Owner:合肥天工科技开发有限公司

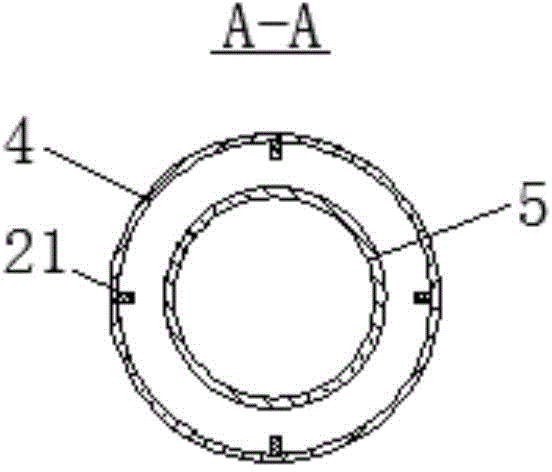

Annular gap-type centrifugal extractor with vertical mixed baffle

ActiveCN104587704AImprove application levelIncrease mixing intensityLiquid solutions solvent extractionEngineeringCentrifugal extractor

The invention discloses an annular gap-type centrifugal extractor with a vertical mixed baffle and belongs to the field of chemical machinery equipment. On the basis of existing annular gap-type centrifugal extractor structure, the annular gap-type centrifugal extractor is characterized in that at least two vertical mixed baffles are uniformly arranged on the inner wall of the lower section of the shell, wherein the lower ends of the vertical mixed baffles are connected with bottom of the shell while the upper ends are connected with the lower part of a light phase colleting ring. According to the invention, the bigger the drum diameter is, the larger the sizes and amounts of the vertical mixed baffles are. According to the invention, the mixing strength of two-phase liquids in the annular gap is strengthened to effectively improve mass transfer efficiency. The annular gap-type centrifugal extractor is characterized by being simple in structure, low in cost, easy in processing and manufacturing and wide in application range. The application level of existing annular gap-type centrifugal extractors is greatly increased, so as to promote the application of the annular gap-type centrifugal extractors in various industrial fields.

Owner:TSINGHUA UNIV

Method for extracting citric acidby employingcentrifugal extractor

ActiveCN107050924AImprove the mixing effectHigh extraction rateCounter-current extractionLiquid solutions solvent extractionEmulsionSmall footprint

The invention discloses a method for extracting citric acidby employinga centrifugal extractor. The centrifugal extractor comprises an extraction section, a washing section and a re-extraction section. After the efficient centrifugal extractor is applied to the extraction method of citric acid, the two-phase separation efficiency is obviously improved, and meanwhile emulsion phenomenon in the traditional technology is obviously improved; in addition, in the technical condition, wastes are hardly produced in the re-extraction section; the equipment is small in floor space, and the stage efficiency is further obviously improved; as the novel and efficient centrifugal extractor adopts totally sealed equipment, the sharp flavor of an extraction agenthardly exists in an operation site, the operating environment is greatly improved, and the health hazard of operating personnel during production is eliminated.

Owner:ZHENGZHOU TIANYI EXTRACTION TECH

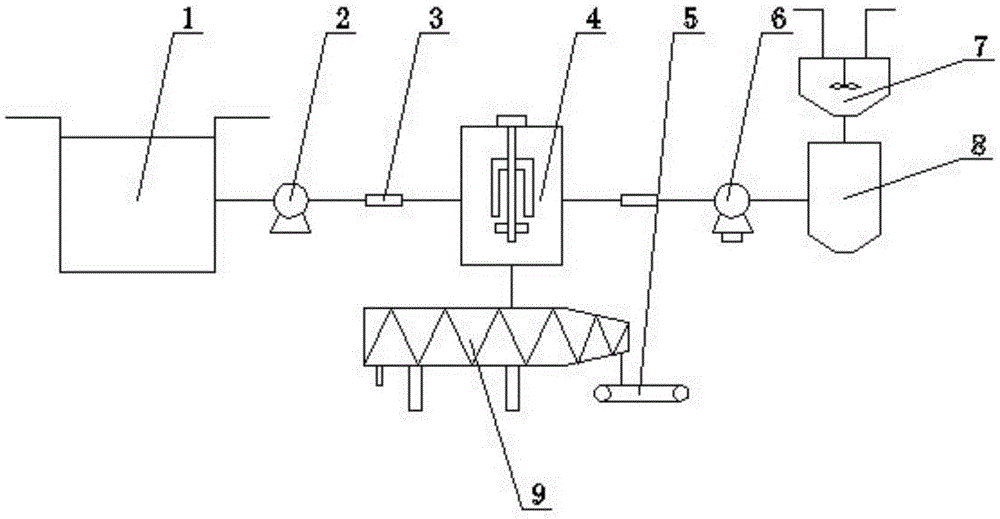

Centrifugal sludge dewatering type small-sized innocent sludge treatment system

InactiveCN105481223AAchieve a fast dehydration processScientific and reasonable structure designSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesChemical storageCentrifugal extractor

The invention relates to a centrifugal sludge dewatering type small-sized innocent sludge treatment system. The centrifugal sludge dewatering type small-sized innocent sludge treatment system comprises a sludge storage pool, a sludge intake pump, a flowmeter, a mixing reactor, a chemical manufacturing tank, a chemical storage tank, a chemical intake pump and a sludge centrifugal extractor, wherein the sludge storage pool is connected with an inlet of the mixing reactor by the sludge intake pump and the flowmeter; the chemical manufacturing tank is connected with another inlet of the mixing reactor by the chemical storage tank, the chemical intake tank and the flowmeter; the outlet of the mixing reactor is connected with the sludge centrifugal extractor. The centrifugal sludge dewatering type small-sized innocent sludge treatment system is scientific and reasonable in design, high in processing effect, convenient to manage and strong in operability, and effectively reduces the sludge dehydration cost.

Owner:TIANZI ENVIRONMENTAL PROTECTION EQUIP MFG TIANJIN

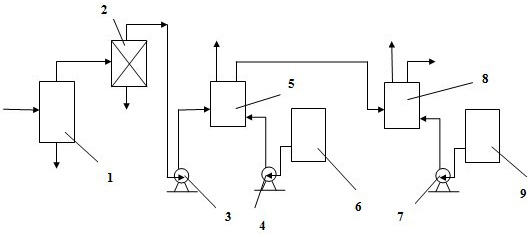

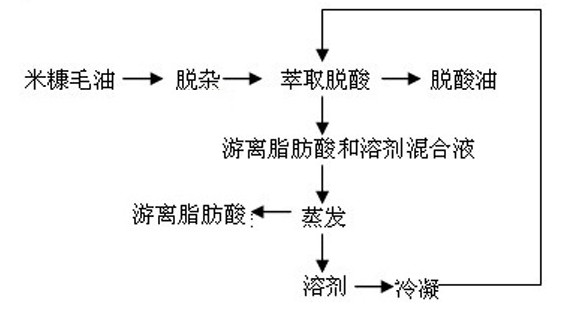

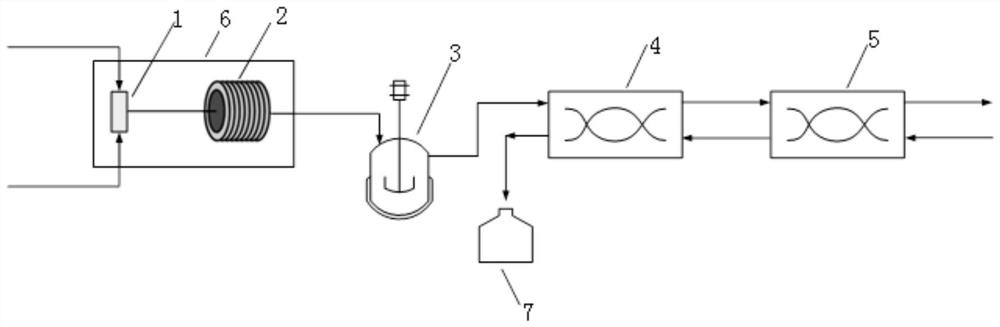

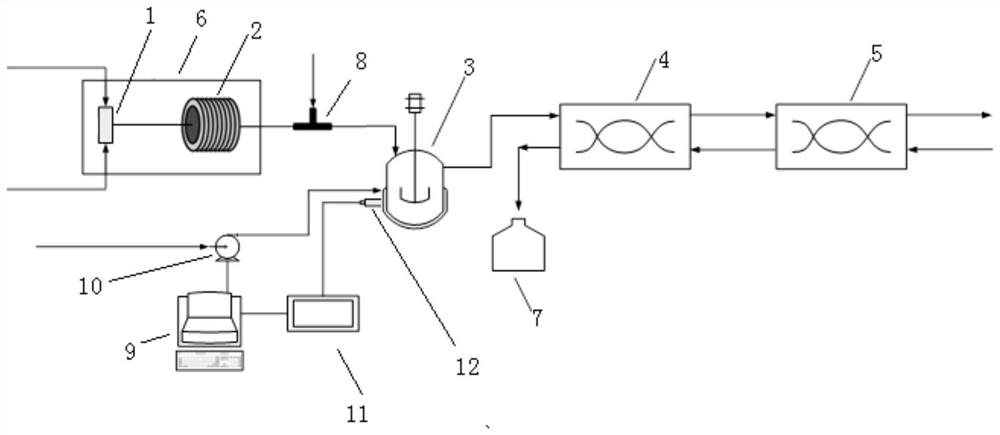

Production method and system of deacidification rice bran oil

ActiveCN102618383AHas a decolorizing effectEfficient removalFatty acids production/refiningFatty-oils/fats refiningRice Bran ExtractFatty acid

The invention relates to a production method and a system of deacidification rice bran oil. The production method comprises the following steps of: feeding rice bran oil into a heat exchanger, warming, and filtering through a frame filter; feeding the filtered rice bran oil into a cylinder centrifugal extractor, extracting, and separating the rice bran oil from fatty acid to obtain the deacidification rice bran oil and mixed liquor of the fatty acid and ethanol; and feeding the mixed liquor of the fatty acid and the ethanol into an evaporator, separating, feeding ethanol steam into a condenser, condensing the ethanol steam to be liquid, and recycling the ethanol steam as an extracting agent. The system comprises a crude oil storage tank, a pump I, the heat exchanger, the frame filter, a filtered oil storage tank, a pump II, the cylinder centrifugal extractor, a deacidification oil storage tank, a fatty acid and ethanol mixing liquor storage tank, a pump III, the evaporator, a free fatty acid storage tank, the condenser and an ethanol recovery tank. The whole production process is non-toxic and environmental-friendly, the extracting agent ethanol can be recovered and recycled, the production cost is low, the operation process is continuous, the equipment is simple to operate, the operation cost is low, and scale production can be realized.

Owner:辽宁五峰农业科技股份有限公司

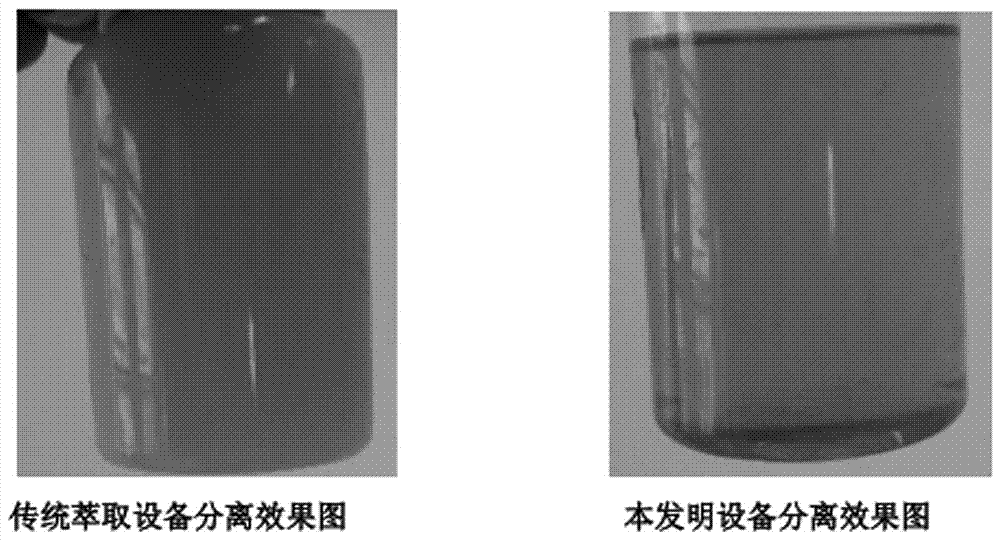

Annular-space type centrifugal extractor, and application of same in oil phase-water phase separation technique of 4-amino diphenylamine reducing solution

ActiveCN102824755AEasy to adjustEasy to operateAmino compound purification/separationLiquid solutions solvent extractionEngineeringOil phase

Owner:JIANGSU SINORGCHEM TECH CO LTD

Method for separating phenylsuccinic acid enantiomer by extraction from multi-stage centrifugal inclusion reaction

InactiveCN102701946AReactive extraction completeEnhanced mass transferChemical recyclingCarboxylic compound separation/purificationPhysical chemistryCyclodextrin

The invention discloses a method for separating phenylsuccinic acid enantiomer by extraction, specifically a method for separating phenylsuccinic acid enantiomer by extraction from reflux inclusion reaction in a multi-stage centrifugal extractor. Through selective inclusion of water-soluble beta-cyclodextrin and the phenylsuccinic acid enantiomer and centrifugal force of the centrifugal extractor, the water phase and the organic phase have strengthened mass transfer efficiency under the action of centrifugal force so as to speed up the inclusion reaction and mass transfer efficiency of the phenylsuccinic acid enantiomer in the water phase and the organic phase. By the technology, the problems of low mass transfer efficiency and low purification of single-stage extraction in the common extraction technology are solved. According to this method, fast and high-selectivity separation of phenylsuccinic acid can be implemented by multi-stage balance extraction. Moreover, the device is simple and the operation is easy and simple to handle.

Owner:唐课文 +2

Centrifugal extractor with stirring, mixing and feeding functions

PendingCN110876858AImprove mixing uniformityAvoid stockpilingTransportation and packagingMixing methodsMechanical engineeringCentrifugal extractor

The invention relates to a centrifugal extractor with stirring, mixing and feeding functions. The centrifugal extractor comprises a shell, a rotary drum extraction unit and a stirring and mixing unit.The rotary drum extraction unit comprises a power shaft and a rotary drum. The stirring and mixing unit is arranged just below the rotary drum extraction unit and comprises a stirring and mixing chamber, a first stirring blade assembly and a second stirring blade assembly with a certain lead angle. The stirring and mixing chamber is directly communicated with the inner cavity of the rotary drum.The power shaft extends into the inner cavity of the stirring and mixing chamber. The first stirring blade assembly and the second stirring blade assembly are both arranged in the stirring and mixingchamber and are driven by the power shaft at the same time. A light phase and a heavy phase are fully mixed in the stirring and mixing chamber, and a liquid-liquid mixed liquid is lifted under the action of the second stirring blade assembly to enter the inner cavity of the rotary drum in time, so that the mixing uniformity of the light phase and the heavy phase is ensured, the accumulation of theliquid-liquid mixed liquid in the stirring and mixing chamber is avoided, and the overflow phenomenon is avoided.

Owner:苏州增华新能源科技有限公司

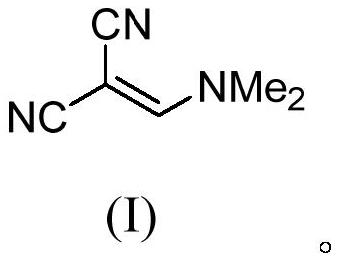

Method for continuously preparing (dimethylamine methylene)malononitrile by using micro-reaction system

ActiveCN112028791AHigh yieldShort reaction timeOrganic compound preparationChemical/physical/physico-chemical microreactorsPtru catalystMethyl palmoxirate

The invention discloses a method for continuously preparing (dimethylamine methylene)malononitrile by using a micro-reaction system. The method comprises the steps of respectively and simultaneously pumping a solution obtained by mixing cyanoacetamide, N,N-dimethylformamide and a catalyst and phosphorus oxychloride into a micro-reaction system comprising a first micro-mixer and a micro-channel reactor which are communicated with each other, and carrying out continuous catalytic dehydration condensation reaction; after the pH value of the crude product mixed solution is adjusted, carrying out continuous liquid-liquid extraction separation on the crude product mixed solution in a centrifugal extraction unit composed of a plurality of annular space type centrifugal extractors connected in series by using an organic solvent, collecting an extraction phase to obtain the target product (dimethylamine methylene)malononitrile. Compared with the prior art, the method has the advantages that thereaction can be safely carried out at normal temperature, the reaction time is short, the product yield is greater than 95%, the efficiency of the technological process is high, the energy consumption is low, and the method has a good industrial application prospect.

Owner:FUDAN UNIV

Centrifugal extractor

InactiveCN107243168AReduce vibrationIncrease speedLiquid solutions solvent extractionImpellerEngineering

The invention discloses a centrifugal extractor low in vibration and excellent in separation effect. The centrifugal extractor comprises a machine frame; a feed inlet barrel is arranged on the machine frame; the feed inlet barrel is provided with a light phase liquid inlet and a heavy phase liquid inlet; a driving motor is arranged on the upper part of the machine frame; a power output shaft of the driving motor is connected with a rotating shaft; the other end of the rotating shaft is inserted into the feed inlet barrel, and is connected with the lower end of the feed inlet barrel; the part of the rotating shaft in the feed inlet barrel is sleeved with a rotary drum; the lower part of the rotary drum is provided with a mixed material inlet; the rotating shaft is provided with a feed inlet blade wheel; the rotary drum is provided with a light phase separation chamber and a heavy phase separation chamber; the lower part of the light phase separation chamber is provided with a light phase inlet; a heavy phase inlet is arranged between the light phase separation chamber and the wall of the rotary drum; an annular light phase collecting chamber and an annular heavy phase collecting chamber are arranged on the machine frame above the feed inlet barrel successively; the light phase separation chamber is provided with a light phase outlet; the light phase collecting chamber is provided with a light phase discharge port; the heavy phase separation chamber is provided with a heavy phase outlet communicated with the heavy phase collecting chamber; and the heavy phase collecting chamber is provided with a heavy phase discharge port.

Owner:ZHANGJIAGANG ZHONGNAN CHEM MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com