Anti-leakage aseptic cold filling system for plant extraction concentrated solution

A plant extraction and concentrate technology, which is applied in liquid bottling, packaging, bottling machines, etc., can solve the problems of filling system pollution and concentrate leakage, and achieve the effect of reducing retention, avoiding leakage and increasing practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

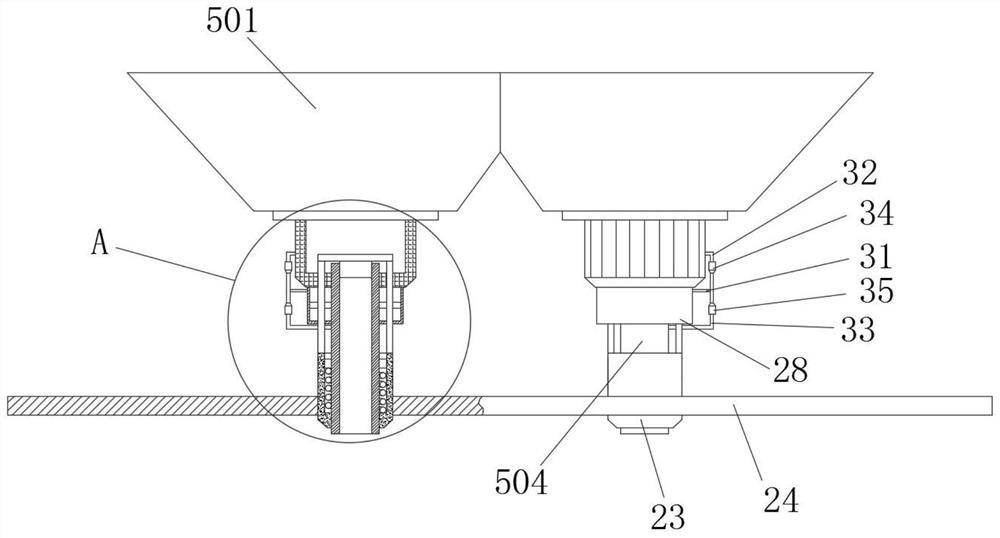

[0038] see Figure 1-3 , the present invention provides a technical solution: a leak-proof plant extract concentrate aseptic cold filling system, comprising a box body 1, a base 2, a feeding cylinder 3 and a casing 4, and the four corners of the bottom end of the box body 1 are fixedly connected There is a base 2, a feeding pipe 3 is fixedly connected to the top of the box body 1, the feeding tube 3 is connected with the box body 1, the left side of the box body 1 is connected with a shell 4, and the lower part of the inner cavity of the box body 1 is installed with a jacking Push rod 21, the upper end of the jacking push rod is fixed with a placement plate 15, and the bottom end of the feeding cylinder 3 is equipped with a filter mechanism 5;

[0039]Filtration mechanism 5 comprises bottom case 501, mesh plate 502, screw 503 and liquid outlet pipe 504; The side is threadedly connected with the feeding cylinder 3 through the screw 503, the bottom of the bottom shell 501 is co...

Embodiment 2

[0041] see Figure 1-8 , the present invention provides a technical solution: a leak-proof plant extract concentrate aseptic cold filling system, comprising a box body 1, a base 2, a feeding cylinder 3 and a casing 4, and the four corners of the bottom end of the box body 1 are fixedly connected There is a base 2, and a feeding pipe 3 is fixedly connected to the top of the box body 1. The feeding tube 3 communicates with the box body 1, and the feeding tube 3 guides the concentrated liquid in the liquid storage tank into the box body 1, and the box body 1 The left side is connected with the shell 4, and the bottom end of the feeding cylinder 3 is equipped with a filter mechanism 5. The filter mechanism 5 includes a bottom shell 501, a mesh plate 502, screws 503 and a liquid outlet pipe 504, and the inside of the bottom shell 501 is sleeved with a mesh plate. 502, the surface of the mesh plate 502 is processed with 1-2mm through holes, the outer wall of the mesh plate 502 is ma...

Embodiment 3

[0043] As an option, see figure 1 , 4 And 8, anti-leakage plant extract concentrate aseptic cold filling system, the left side of the inner cavity of the shell 4 is symmetrically fixed with a slide plate 9, the right side of the inner cavity of the shell 4 is processed with a chute 10, and the inside of the shell 4 is sleeved with a The electric push rod 11, the stroke of the electric push rod 11 is specifically selected according to actual use requirements, the outer wall of the electric push rod 11 is in interference fit with the shell 4, and the right end of the box body 1 is provided with a bracket 12, which is used to place the ultraviolet lamp. The left end of the bracket 12 is fixedly connected to the box body 1, and the middle position on the right side of the box body 1 is provided with a cover plate 13, and the top of the cover plate 13 is hingedly connected with the box body 1, and the cover plate 13 can rotate on the right side of the box body 1 , The inside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com