Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Small bubble diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

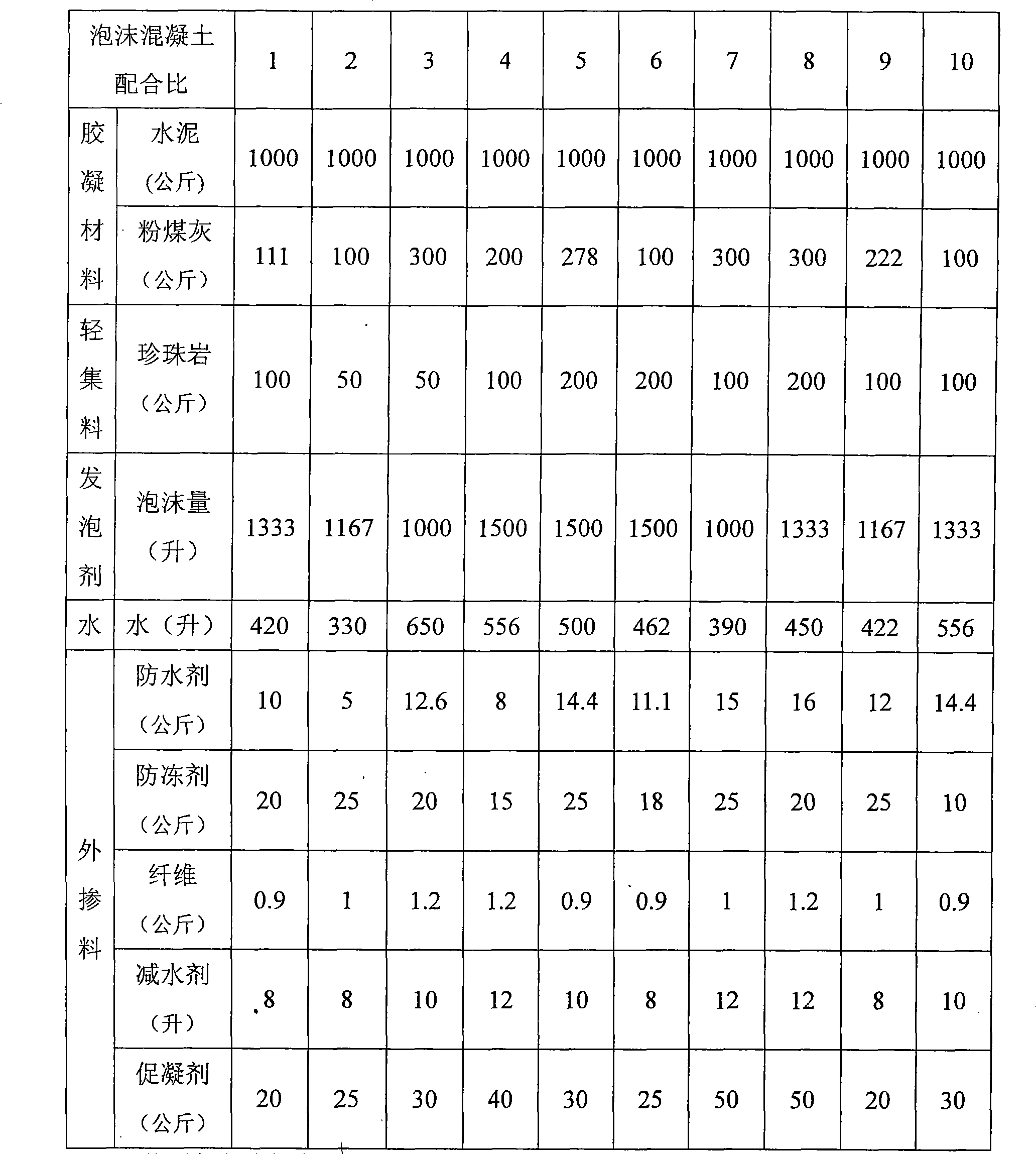

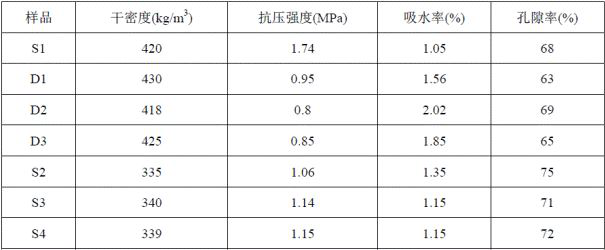

Foam concrete and preparing process thereof

InactiveCN101497533AHigh strengthLight weightCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

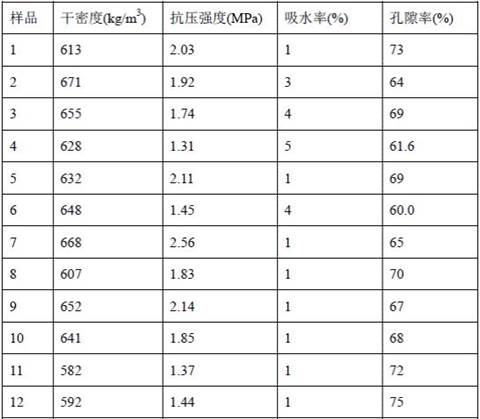

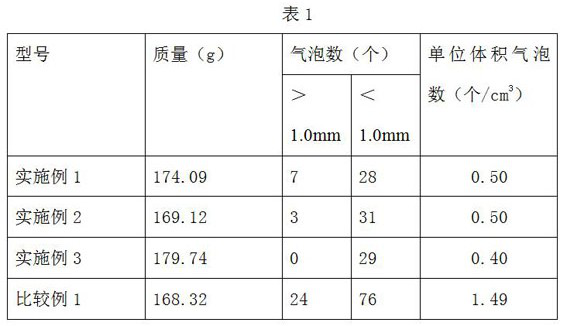

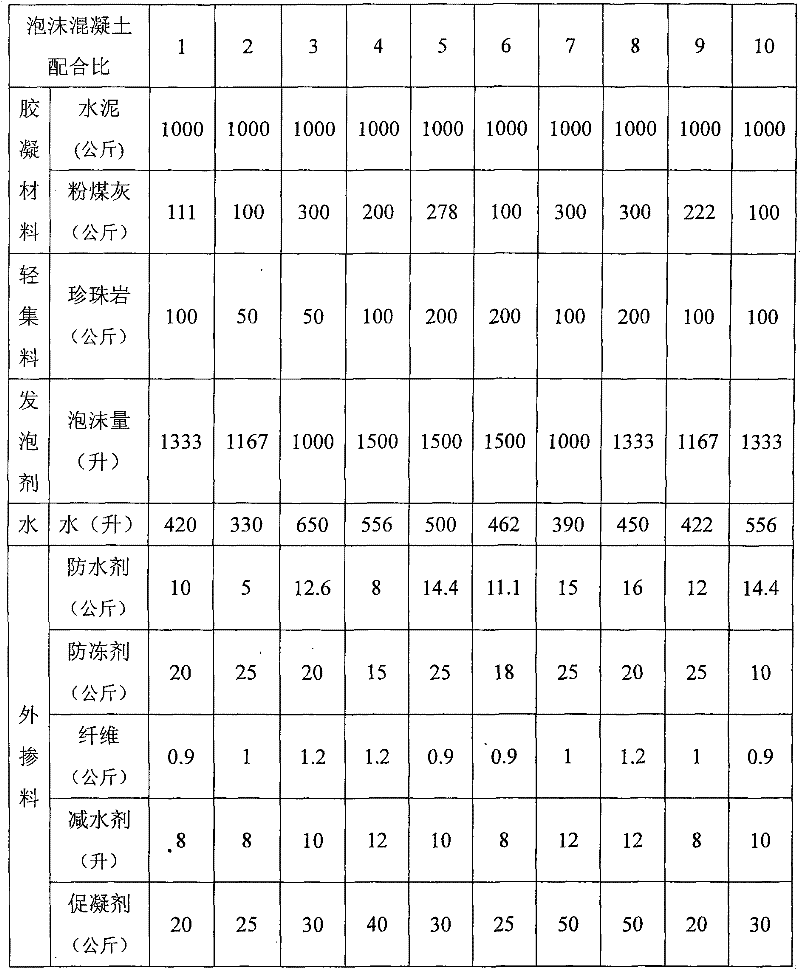

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting and molding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heat insulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

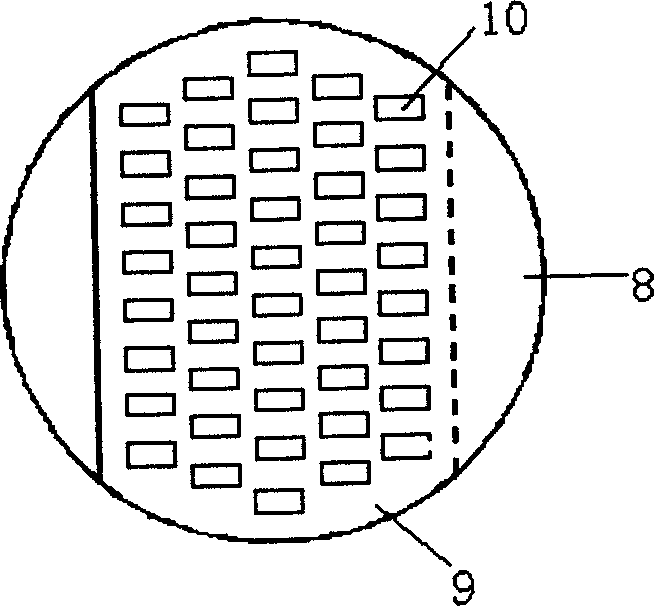

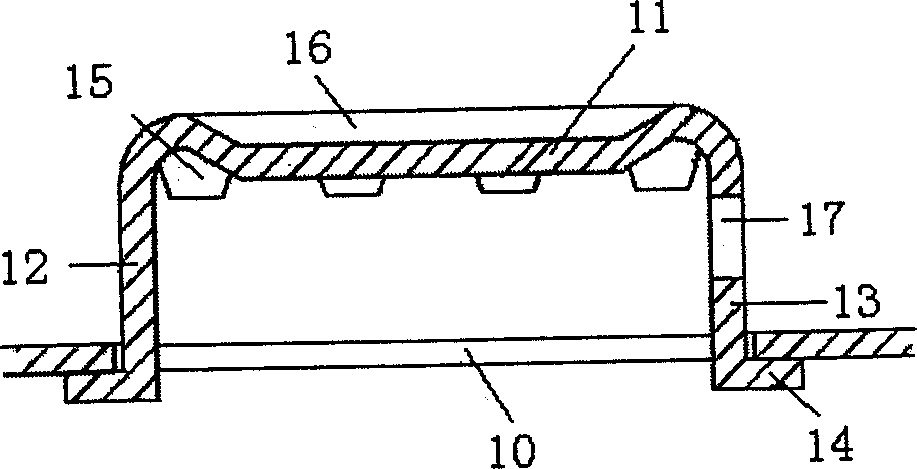

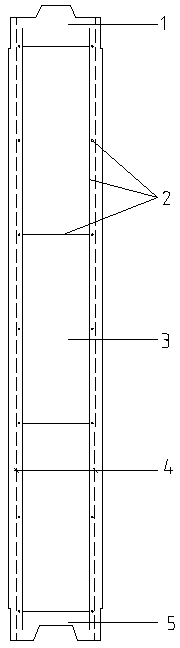

Tooth edge float valve

ActiveCN1683043ASmall bubble diameterIncrease the gas-liquid contact areaDistillation separationAirflowEngineering

The tooth edge float valve includes tabulated valve cover, liquid facing valve leg on one end of the valve cover and in the upstream position, liquid backing valve leg on the other end of the valve cover and in the downstream position, and valve feed fixed separately to the lower ends of the liquid facing valve leg and the liquid backing valve leg. The valve cover has downward bending toothed structures in the sides and the downward bending toothed structures can reduce the bubble diameter, raise the stability of the foam layer and avoid the direct spray of gas and liquid. In addition, the valve cover is provided with wedged slot to avoid the formation of gas flow eddy below the float valve, decrease liquid back mixing and lower the gas resistance of the float valve; and the liquid backing valve leg is provided with liquid guide hole for gas to drive liquid towards the outlet dam so as to reduce the liquid surface fall and decrease liquid back mixing.

Owner:CHINA PETROLEUM & CHEM CORP +1

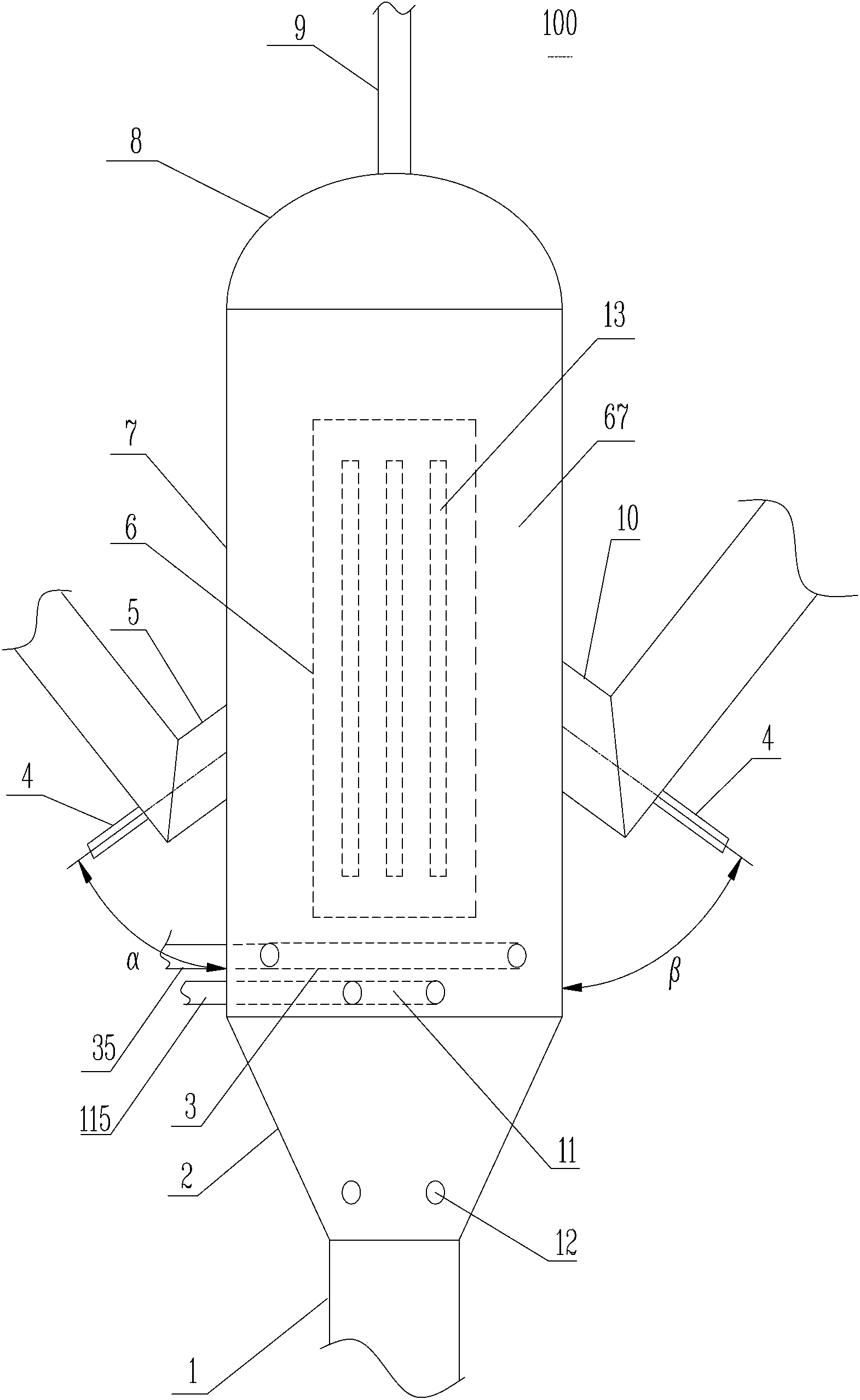

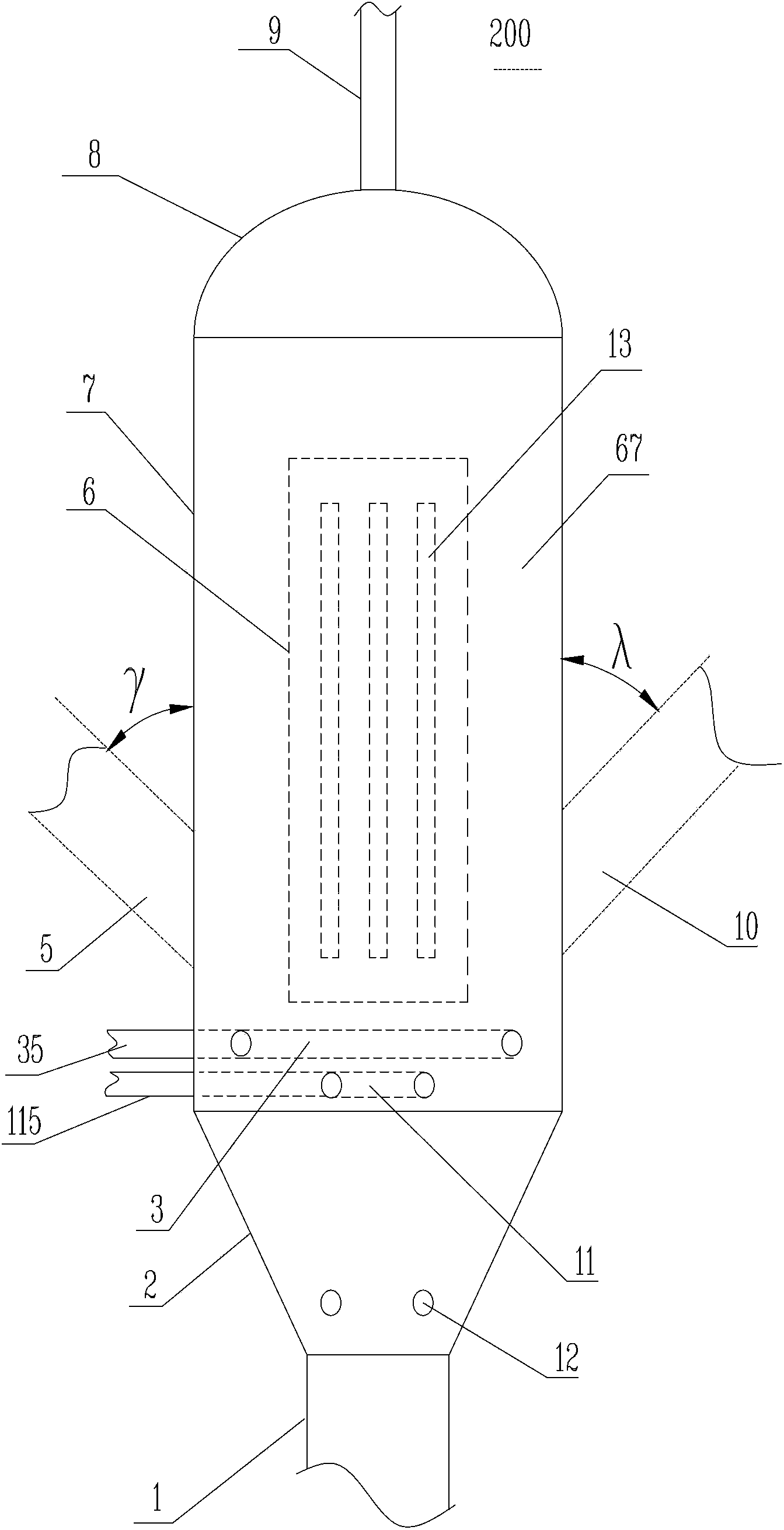

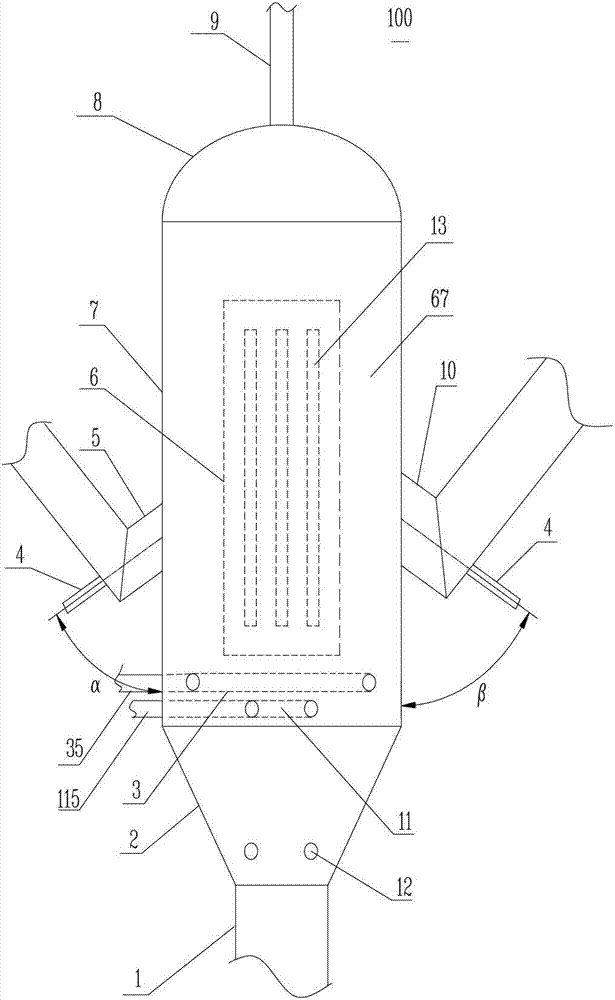

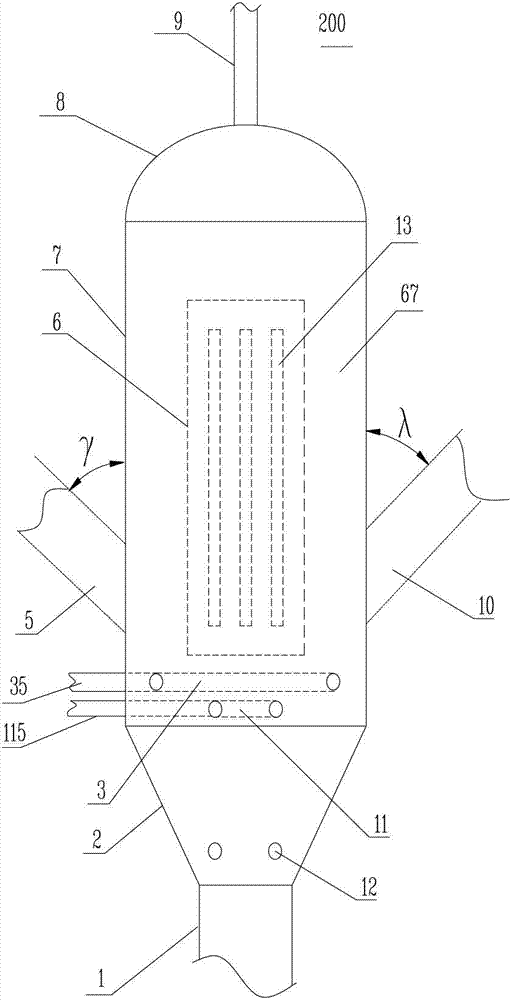

Circulating method for cold regenerated catalyst and catalytic cracking reaction regenerating system

The invention provides a circulating method for a cold regenerated catalyst and a catalytic cracking reaction regenerating system. The catalytic cracking reaction regenerating system comprises a hoisting pipe reactor, a pre-hoisting section, a regenerator, a heater and a gas-solid annular flow mixing stripper, wherein the gas-solid annular flow mixing stripper is used for mixing a first solid grain and a second solid grain at different temperatures during a regenerating form fluid catalytic cracking process and stripping the smoke and air taken by the solid grains after being mixed; the first solid grain is a low-temperature catalyst or low-temperature to-be-generated agent; and the second solid grain is a high-temperature catalyst. The circulating method for the cold regenerated catalyst comprises the following steps of: mixing and exchanging heat of the first solid grain from the heater and the second solid grain from the regenerator in the gas-solid annular flow mixing stripper, and meanwhile, stripping the taken smoke and air, forming the mixed catalyst and then entering into the pre-hoisting section.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

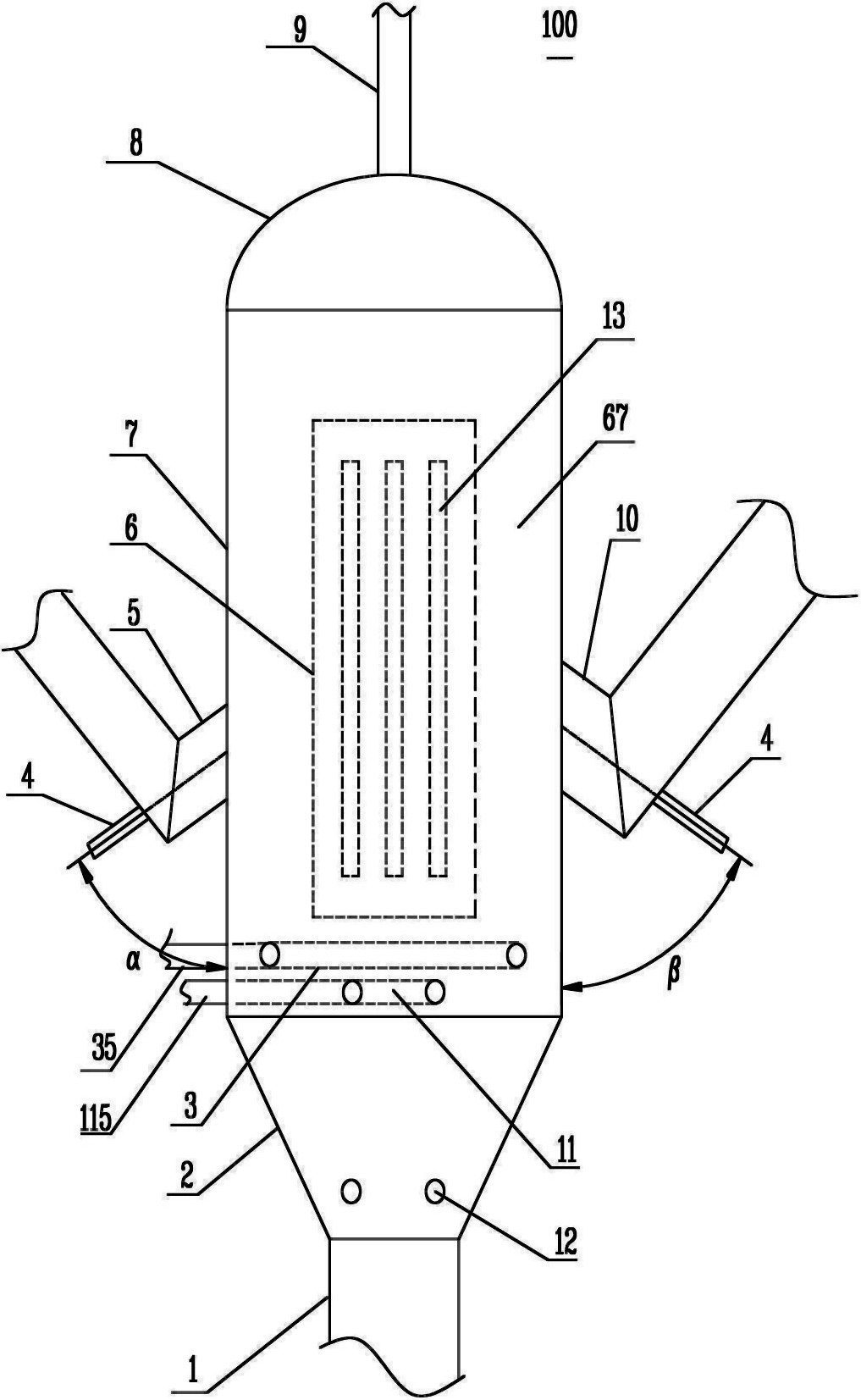

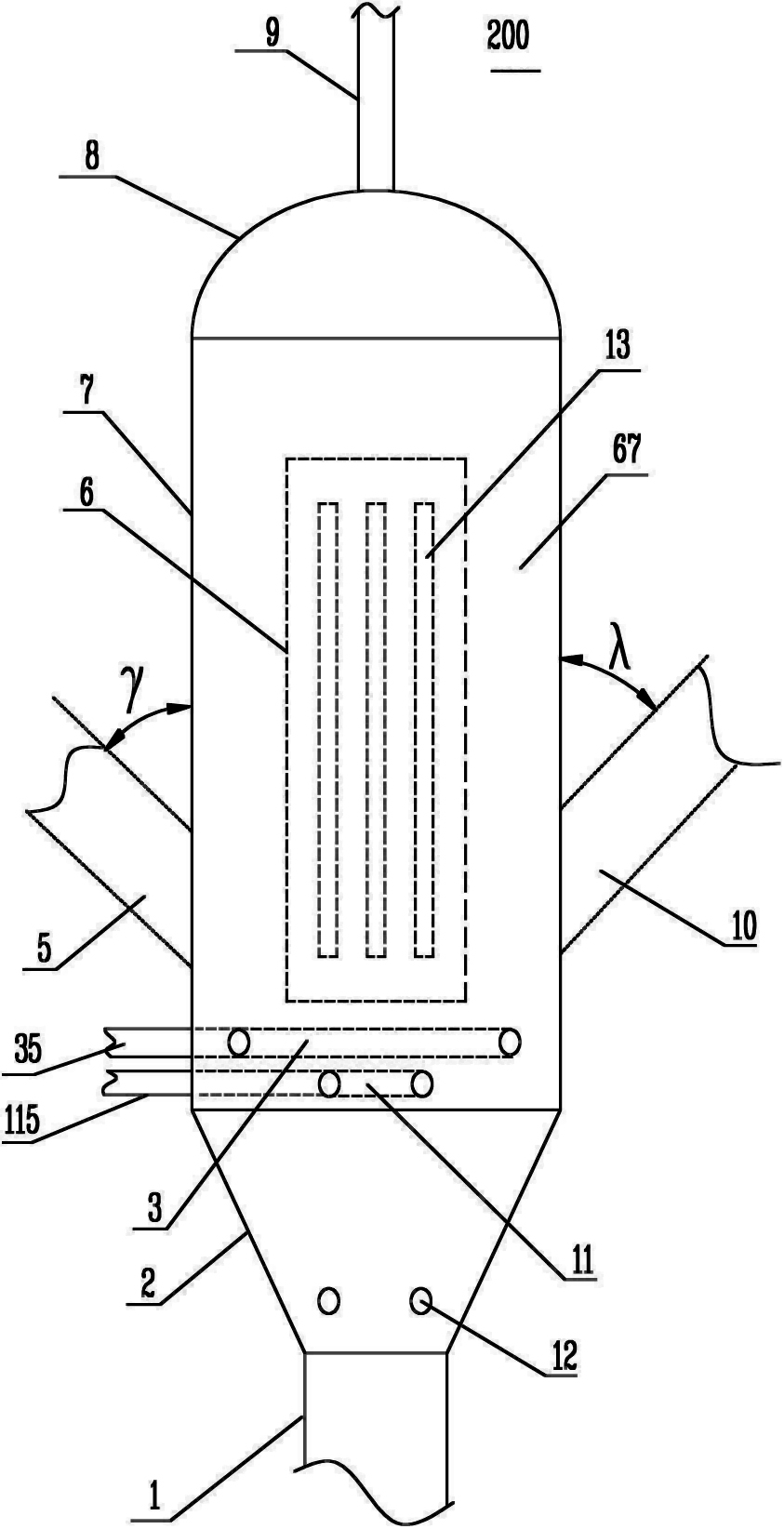

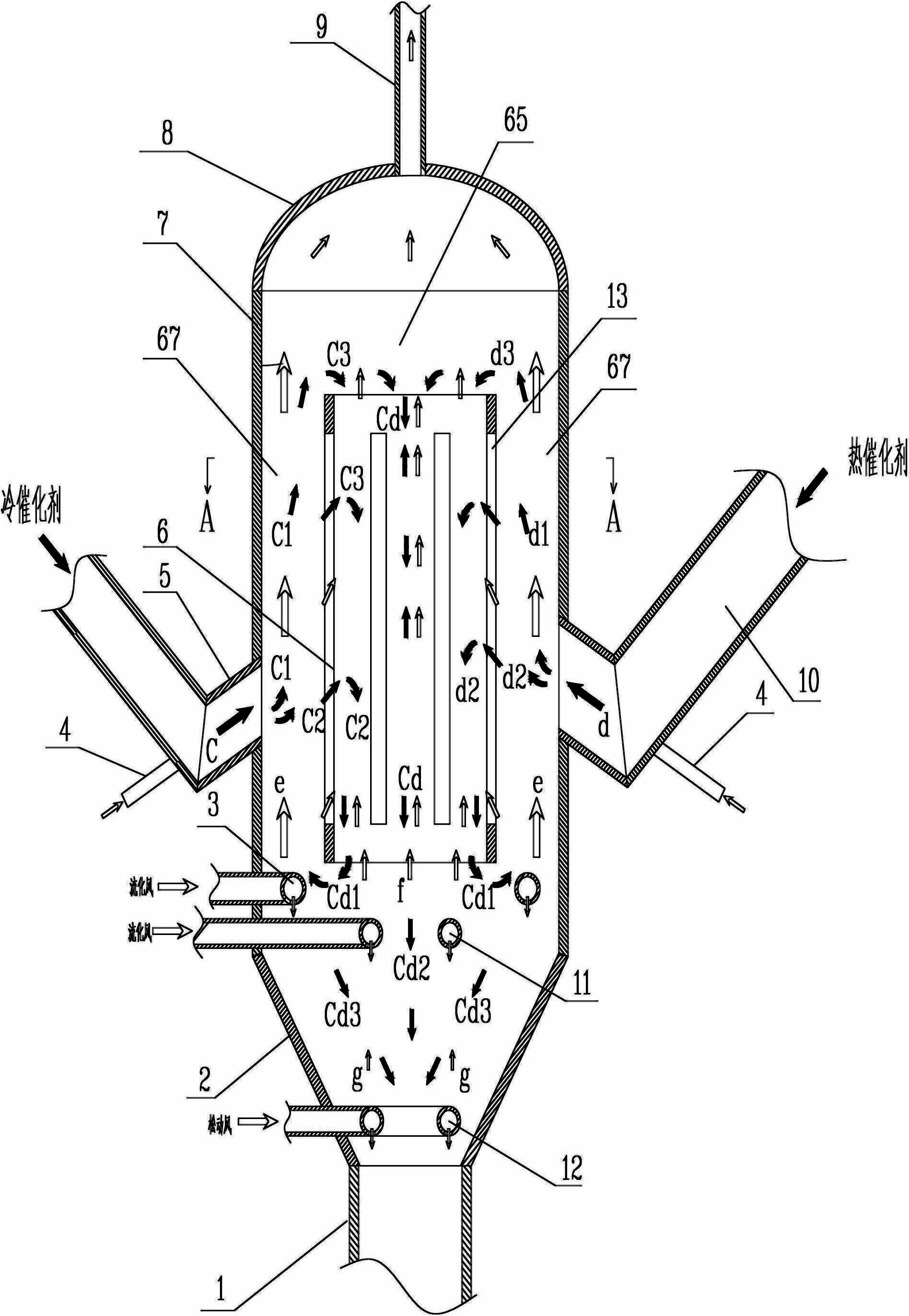

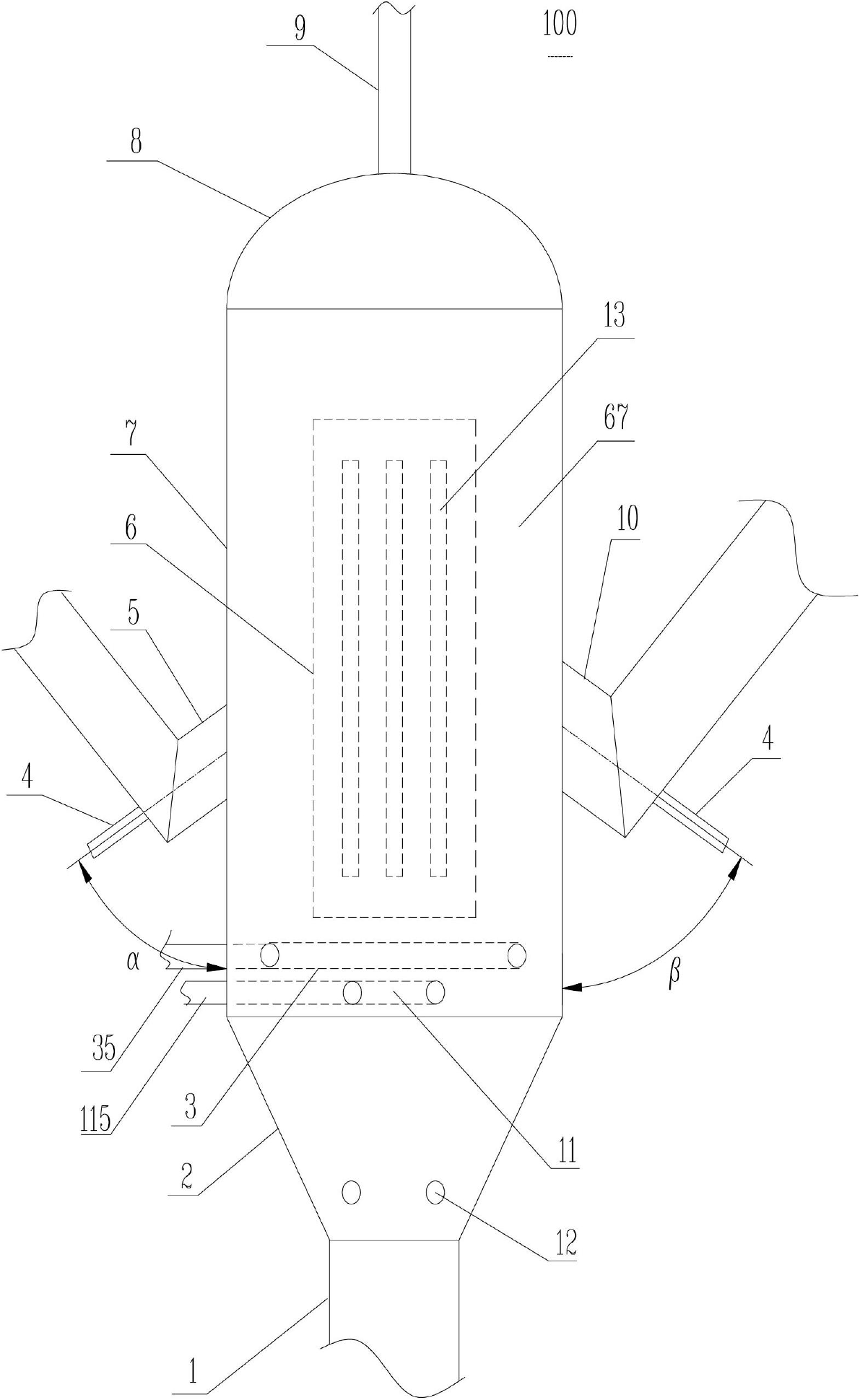

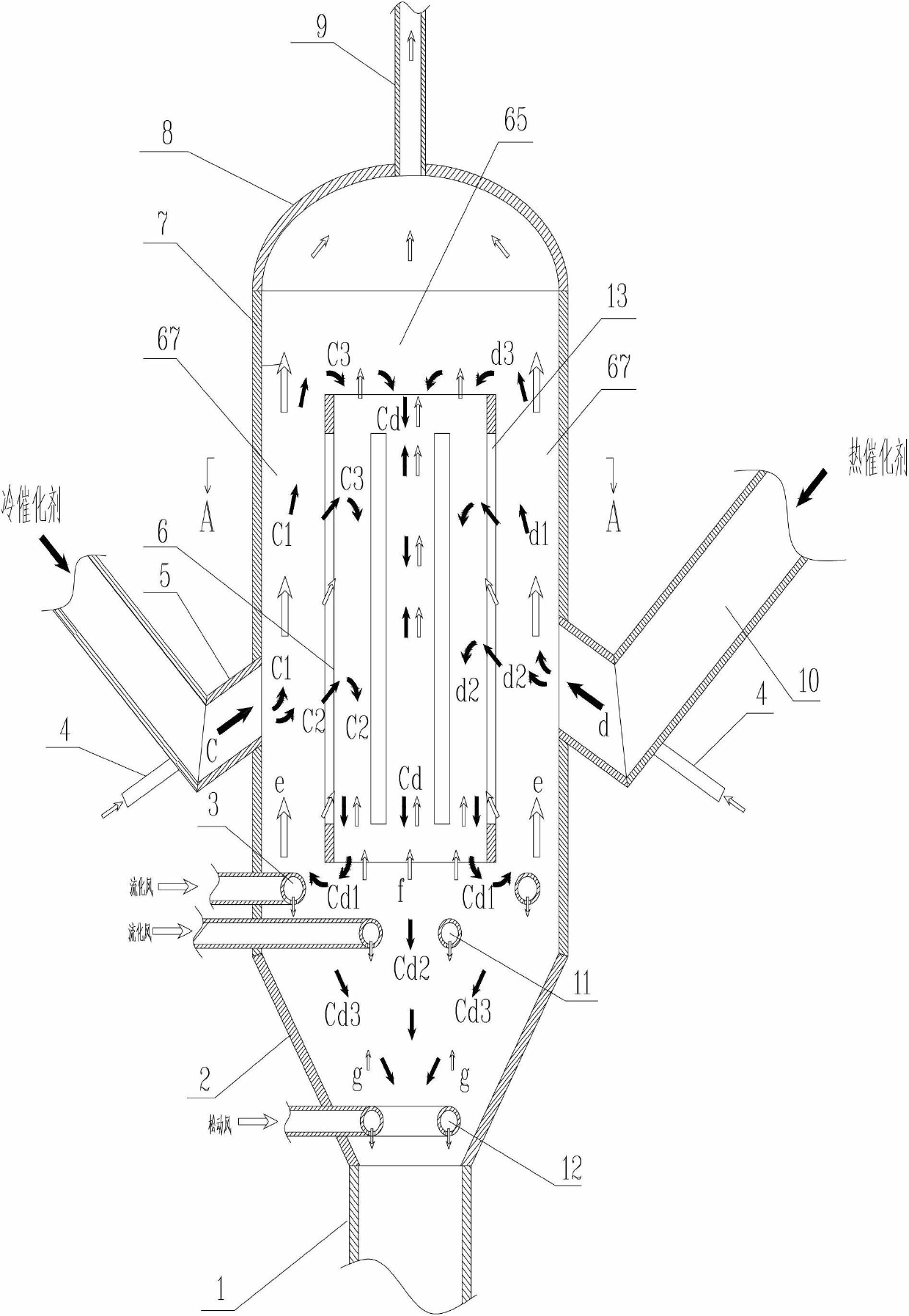

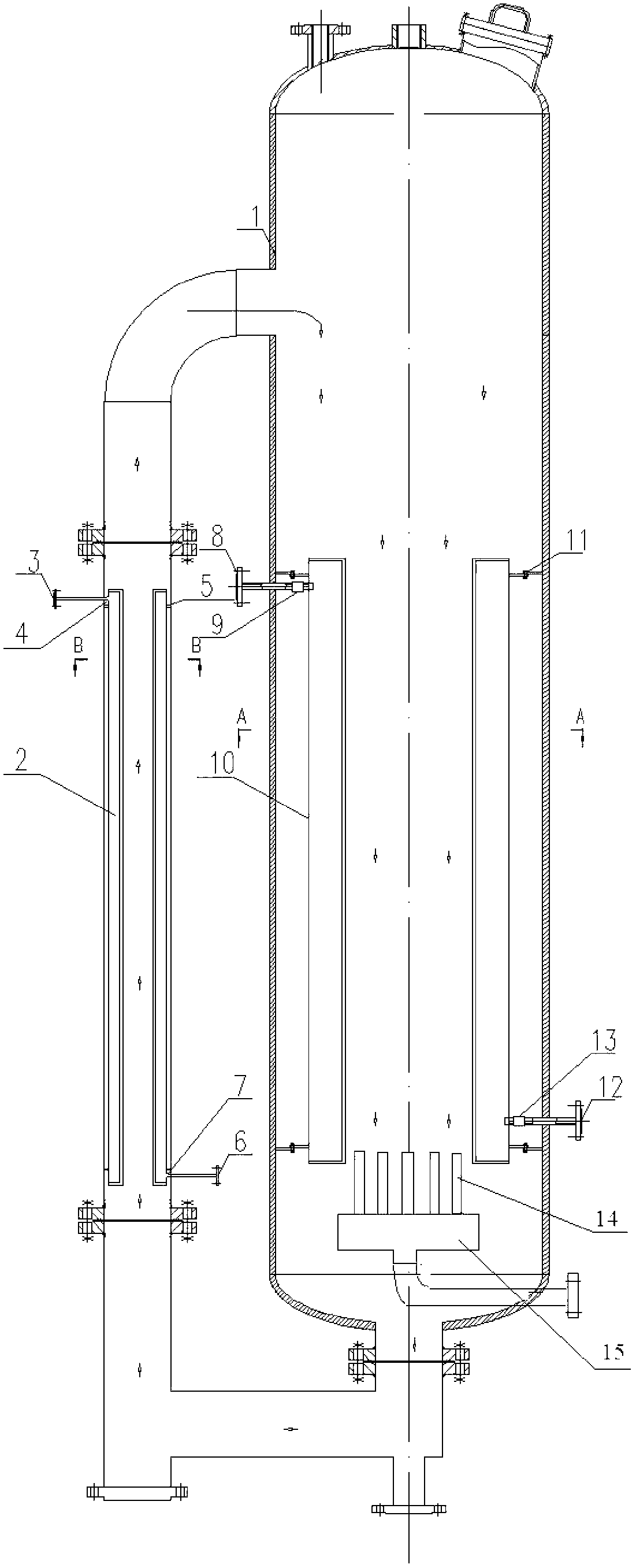

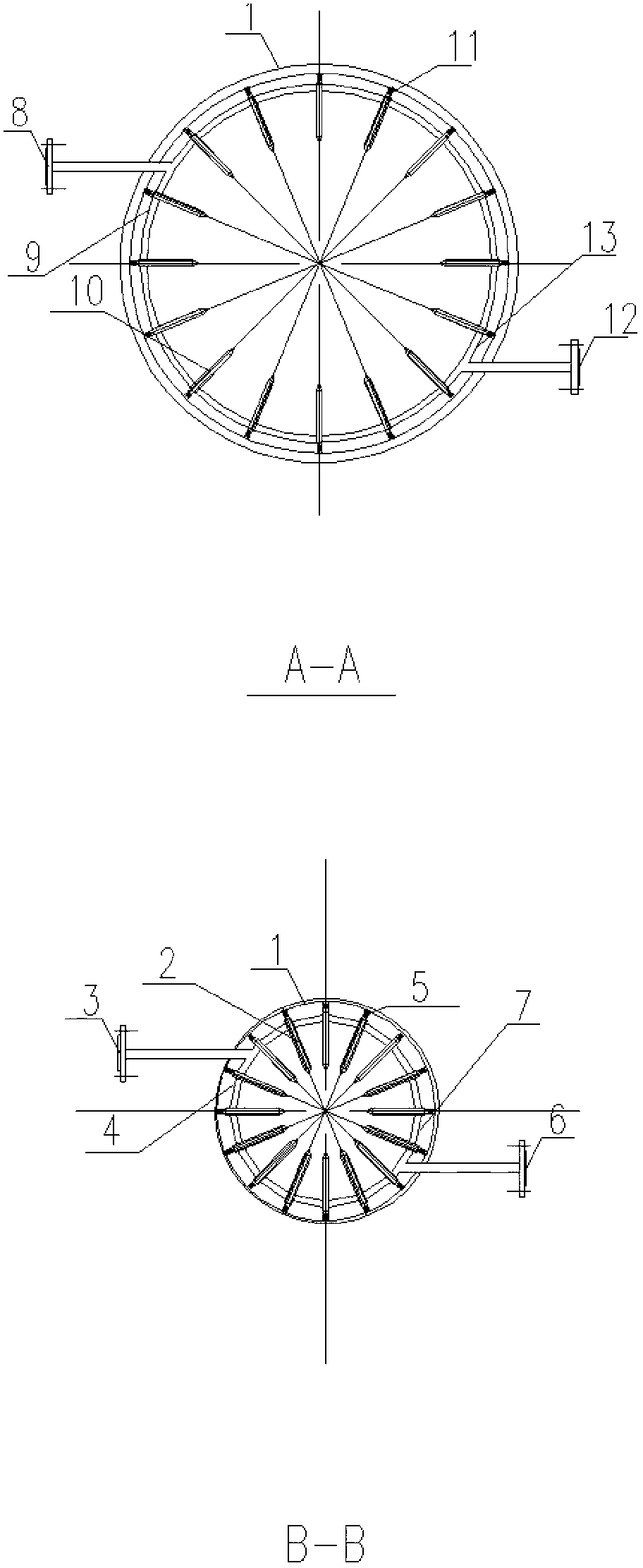

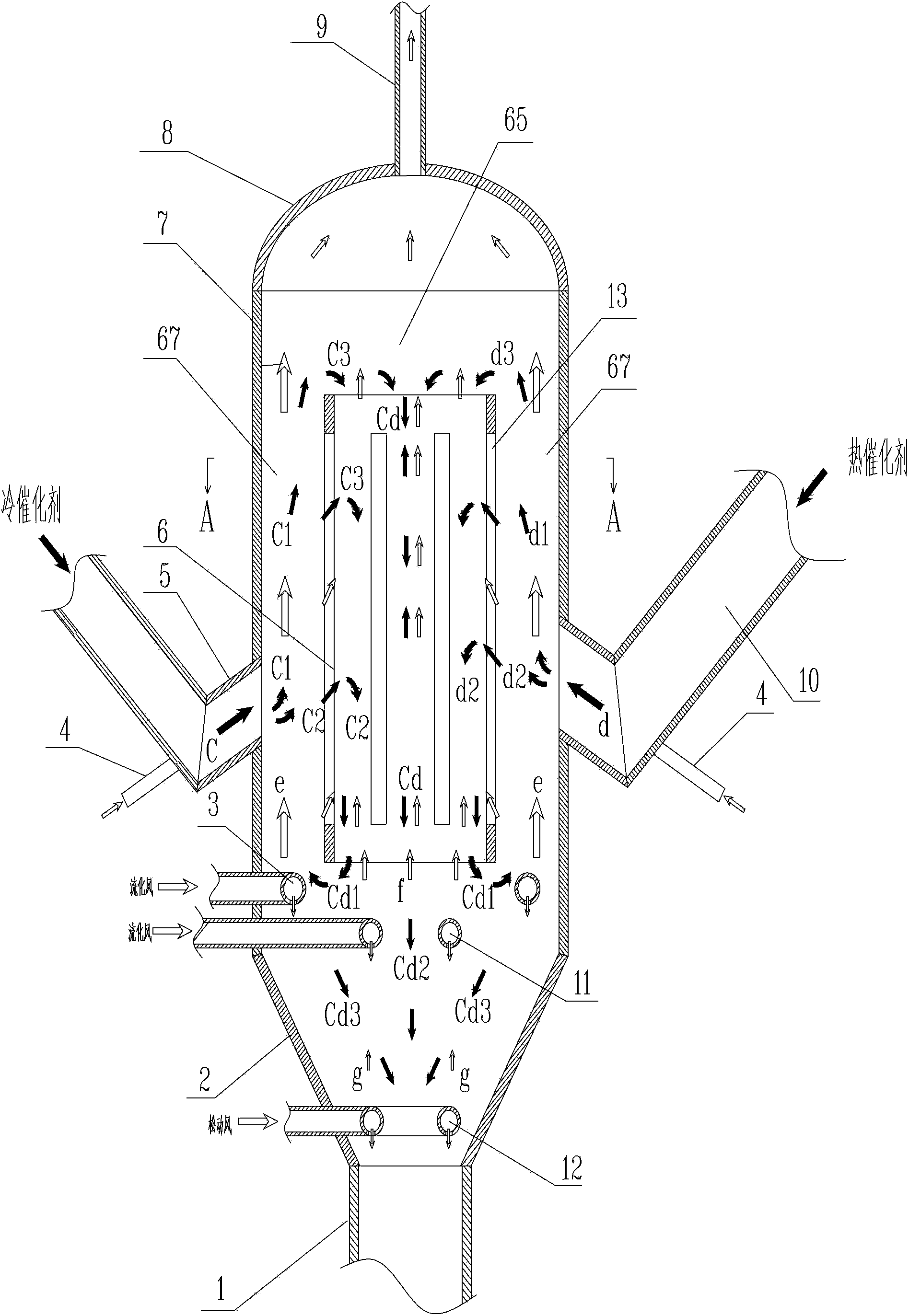

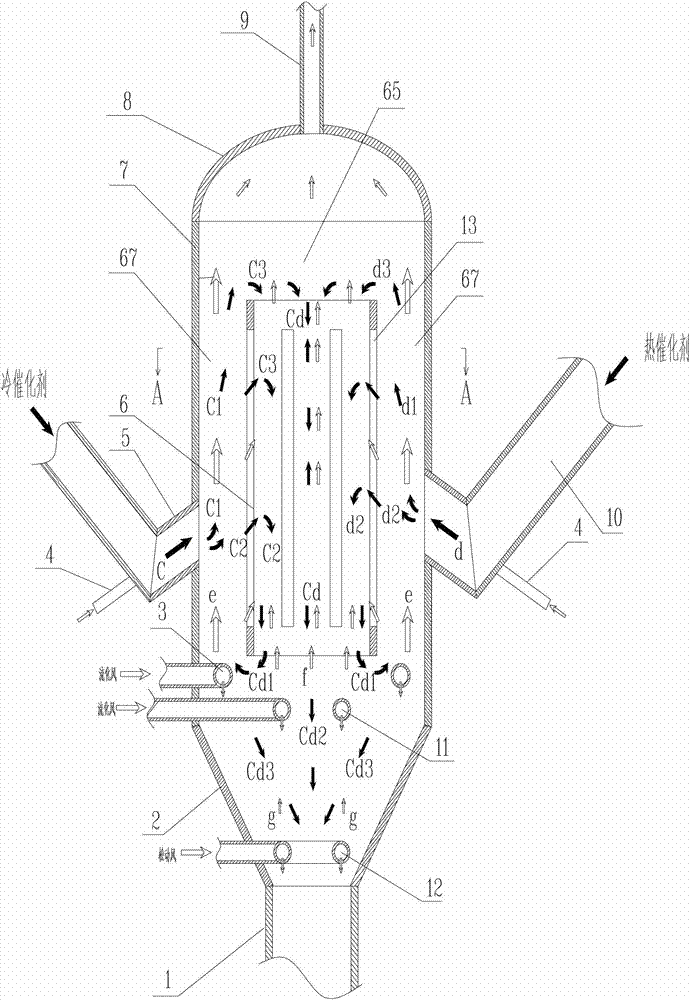

Gas/solid circulation mixing steam stripper and mixing and steam stripping method of solid particles

ActiveCN102676206AStrong shearImprove contact efficiencyCatalytic crackingCatalyst regeneration/reactivationEngineeringProduct gas

The invention provides a gas / solid circulation mixing steam stripper and a mixing and steam stripping method of solid particles. The gas / solid circulation mixing steam stripper comprises a cylinder body (7) with an inner cavity, a flow guide cylinder (6), a ring-gap gas distributor (3), a gas distributor (11) of the flow guide cylinder, a gas outlet extending into the inside of the cylinder body (7), a cone (2) connected with the lower end of the cylinder body (7), a mixed solid particle outlet (1) arranged below the cone (2), a loose steam ring (12) which is positioned at the bottom of the cone (2) and is also positioned above the mixed solid particle outlet (1), a first solid particle inlet passage and a second solid particle inlet passage, wherein the first solid particle inlet passage and the second solid particle inlet passage are respectively connected to the inside of the cylinder body. The gas / solid circulation mixing steam stripper is adopted by the mixing and steam stripping method of the solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

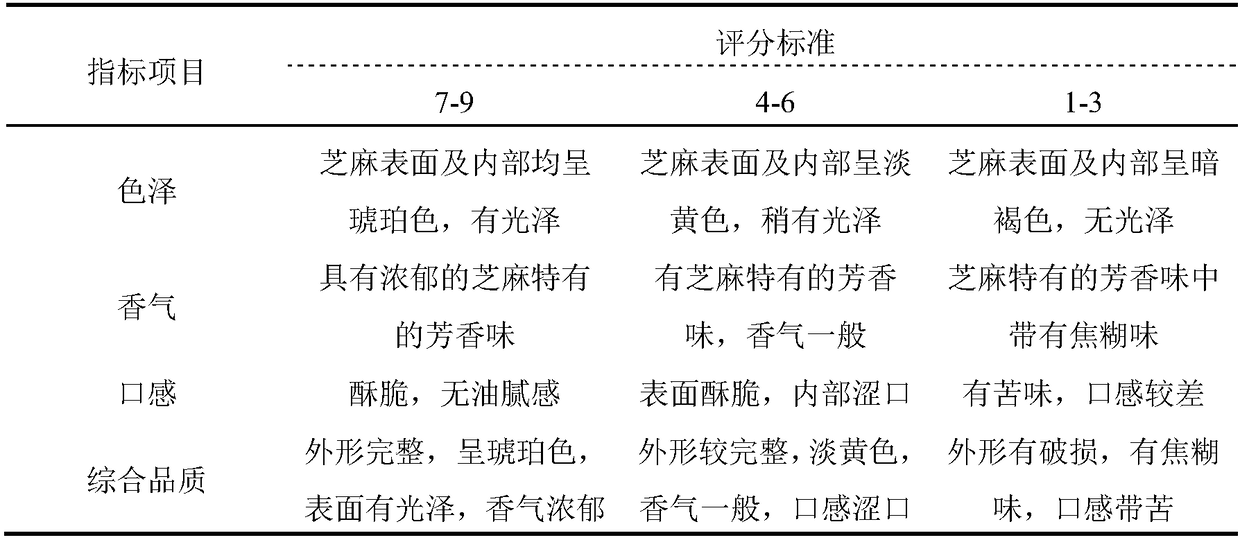

Sesame sauce and processing method thereof

The invention provides sesame sauce and a processing method thereof. The sesame sauce includes the following constituents in parts by weight: sesame 100, oil 6.5-7.5, an emulsifying agent 0.001-0.25,wherein the emulsifying agent includes the following constituents in parts by weight: sucrose esters 0.03-0.18 and monostearin 0.07-0.18. The sesame sauce is prepared by the method including the processes of roasting and grinding the sesame. According to the invention, through adopting a scientific formula and preparation process, the viscosity coefficient of the sesame sauce is increased from 2.3778 to 29.0216 and the stability coefficient of the sesame sauce is increased from 81.60% to 99.31%. Meanwhile, no oil phase is precipitated and yield is increased by about 23%.

Owner:HUAZHONG AGRI UNIV

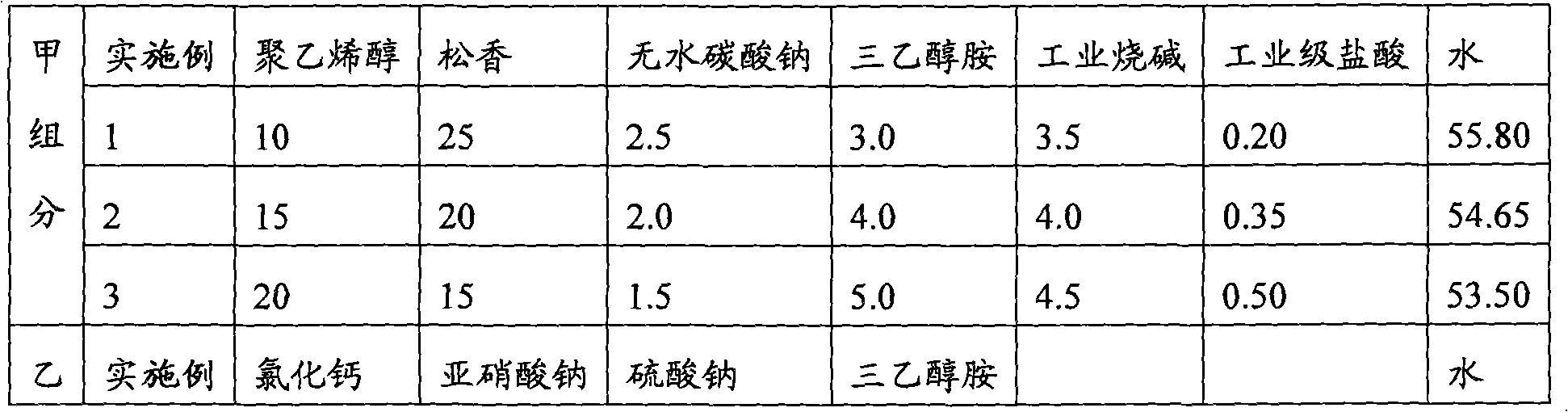

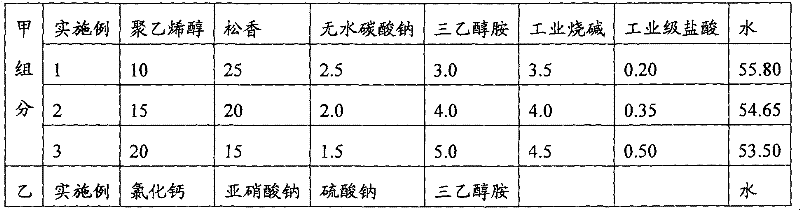

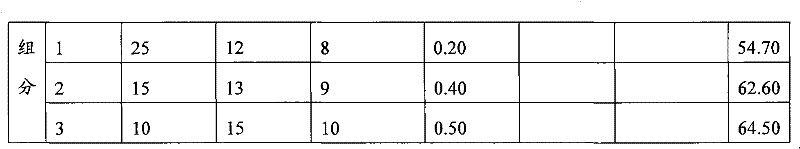

Compound type concrete foaming agent, preparation method and application thereof

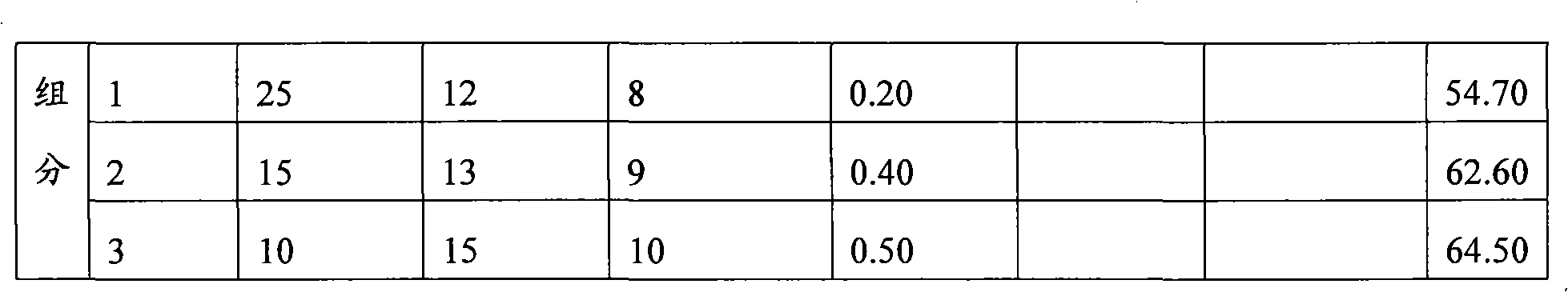

The invention provides a compound type concrete foaming agent, a preparation method and an application thereof. The compound type concrete foaming agent is prepared by compounding a component A and acomponent B, wherein the component A comprises 10-20 parts of polyvinyl alcohol, 15-25 parts of colophony, 1.5-2.5 parts of anhydrous sodium carbonate, 3.5-4.5 parts of industrial sodium hydroxide, 3-5 parts of triethanolamine, 0.2-0.5 parts of industrial grade hydrochloric acid and 53.5-55.8 parts of water; and the component B comprises 0.2-0.5 parts of triethanolamine, 8-10 parts of sodium sulfate, 12-15 parts of sodium nitrite, 10-25 parts of calcium chloride and 54.7-64.5 parts of water. The compound type concrete foaming agent not only can increase the doped quantity of the foaming agentbut also can compensate the concrete strength and the solidification time; the compound type concrete foaming agent can be used for manufacturing foam concrete with super-low capacity, also utilize alarge amount of waste residues, such as industrial and architectural rubbish and the like, to produce light foamed concrete.

Owner:刘兴山

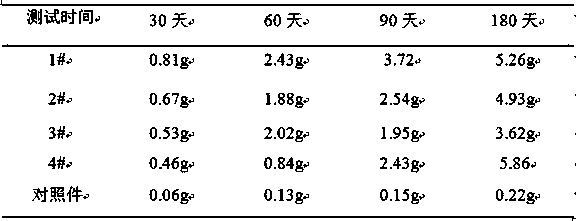

External-circulation airlift type reactor adopting membrane tube aeration

InactiveCN103215180ASmall diameterDissolved Oxygen ControlBioreactor/fermenter combinationsBiological substance pretreatmentsSpray nozzleEngineering

The invention relates to an external-circulation airlift type reactor adopting membrane tube aeration. The external-circulation airlift type reactor comprises an external-circulation airlift type reactor body, wherein a gas distributor is arranged on the bottom of the external-circulation airlift type reactor body; and a membrane tube with a nanoscale pore diameter is connected on the gas distributor. According to the external-circulation airlift type reactor adopting the membrane tube aeration, the membrane tube is applied to the external-circulation airlift type reactor, and the nanoscale pore diameter of the membrane tube is adopted, so air bubbles escaping from the membrane tube are small in diameter and large in quantity, and therefore, the problem that the air bubbles of a spray nozzle type distributor and a plate pore type distributor are larger is overcome; moreover, the mass transfer performance is greatly improved for facilitating the control of dissolved oxygen in fermentation liquor.

Owner:NANJING UNIV OF TECH

Low-density and aerated foaming gypsum block

The invention relates to a low-density and aerated foaming gypsum block. The low-density aerated foaming gypsum block mainly comprises gypsum powder, coal ash, cement, limestone, gas forming agent, calcium carbide, retarders and the like. The low-density aerated foaming gypsum block has the characteristics of low volume density, high strength, light weight, good anti-seismic property, thermal insulation, damp proofing and sound insulation, good workability, fire proofing and flame retardance and the like.

Owner:张家港市创成纺织有限公司

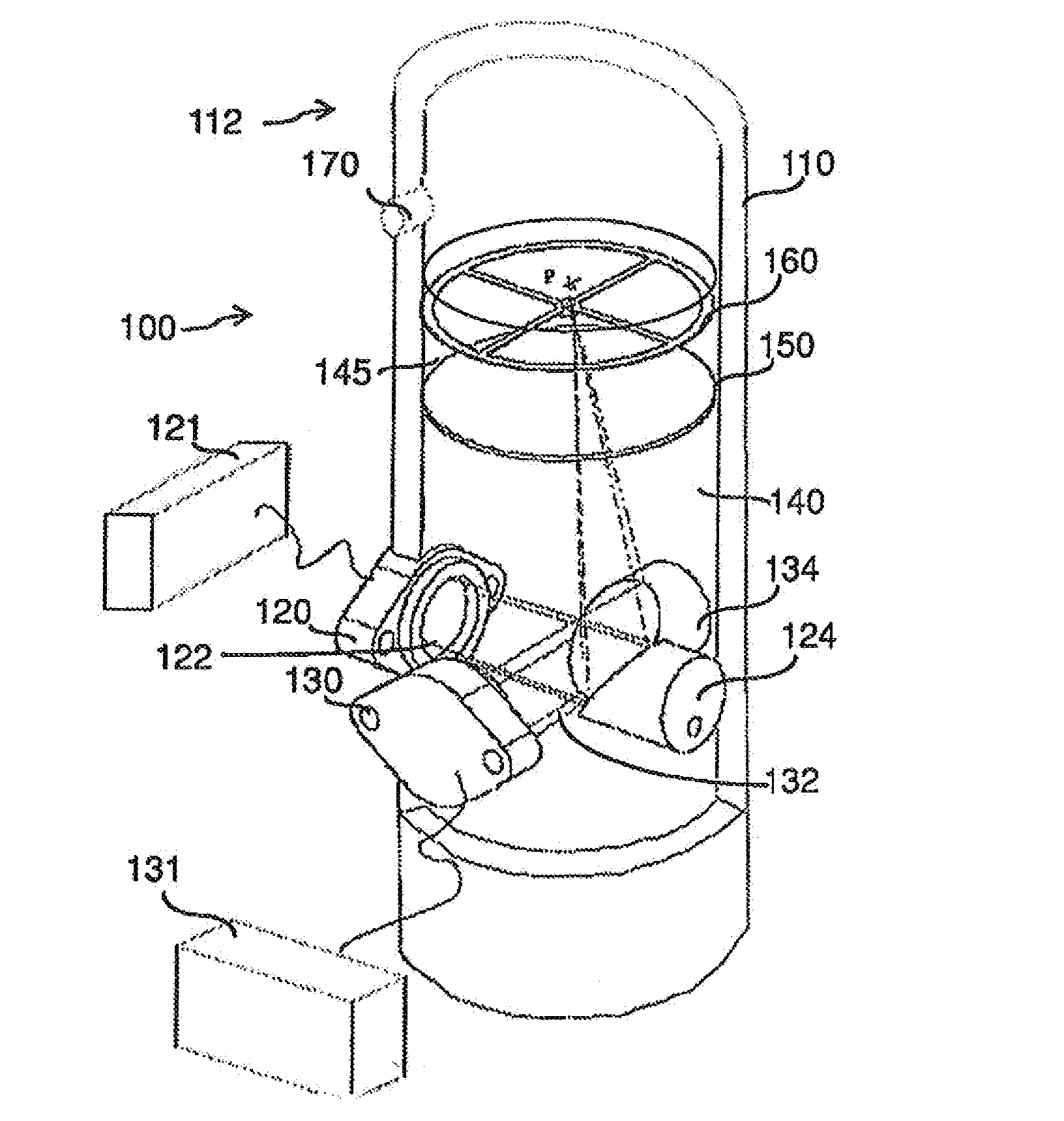

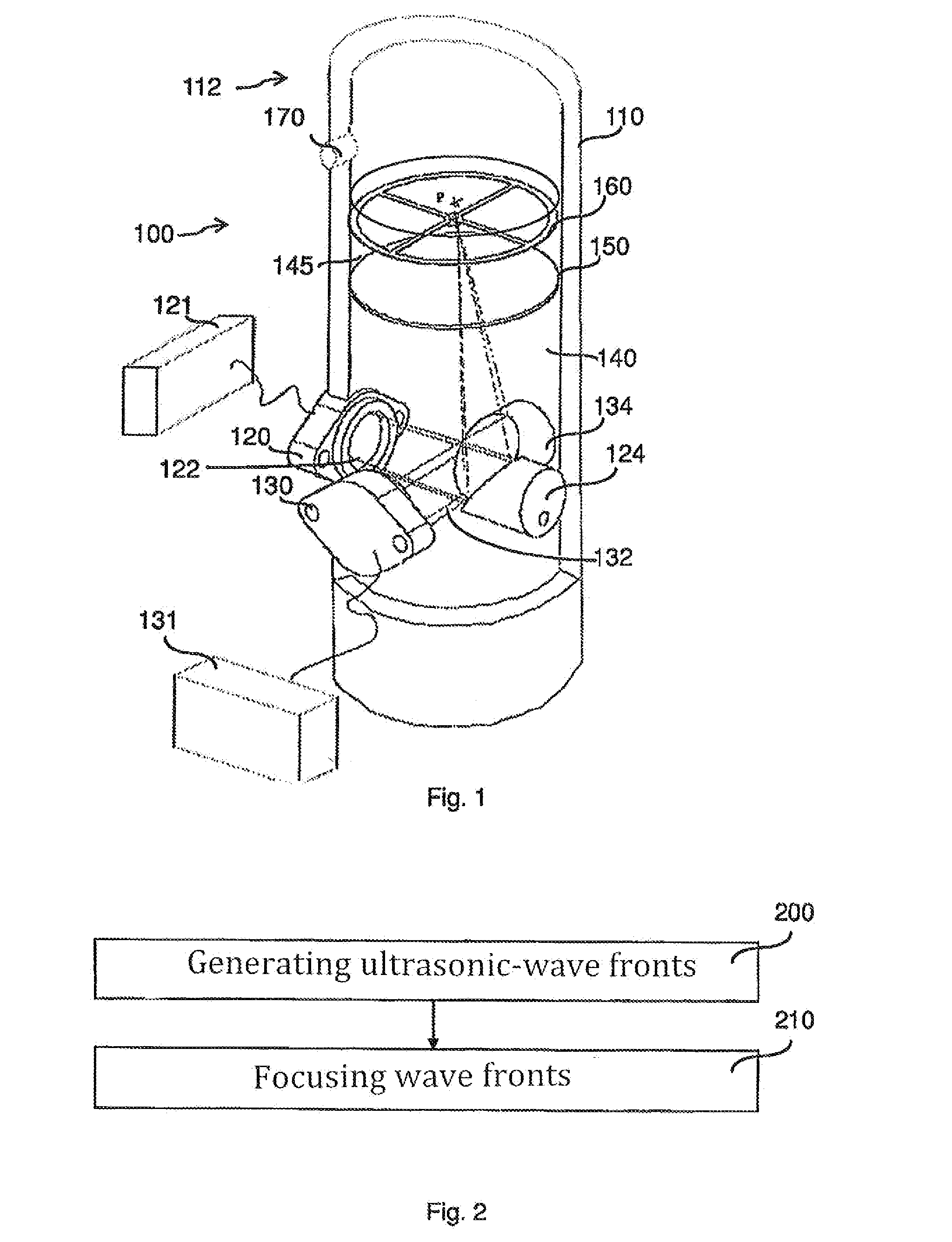

Device for nebulizing a liquid

InactiveUS20150076245A1Frequency spectrum is thereby increasedHigh strengthGeneral water supply conservationLighting and heating apparatusAcousticsMillimeter

The invention relates to a device (100) for nebulizing a liquid, comprising: a vessel (110) that is open at the top portion thereof and configured so as to contain the liquid to be nebulized; at least two ultrasonic-wave generators (120, 130) for emitting at least two ultrasonic-wave fronts (122, 132) into the liquid; and at least two means (134, 124) for focusing the ultrasonic waves, each of which engages with one of said generators (120, 130) in order to concentrate ultrasonic waves at a single point P less than ten millimetres from the free surface of the liquid, wherein the vibration frequencies of the two wave fronts (122, 132) are different.

Owner:ADLYNX

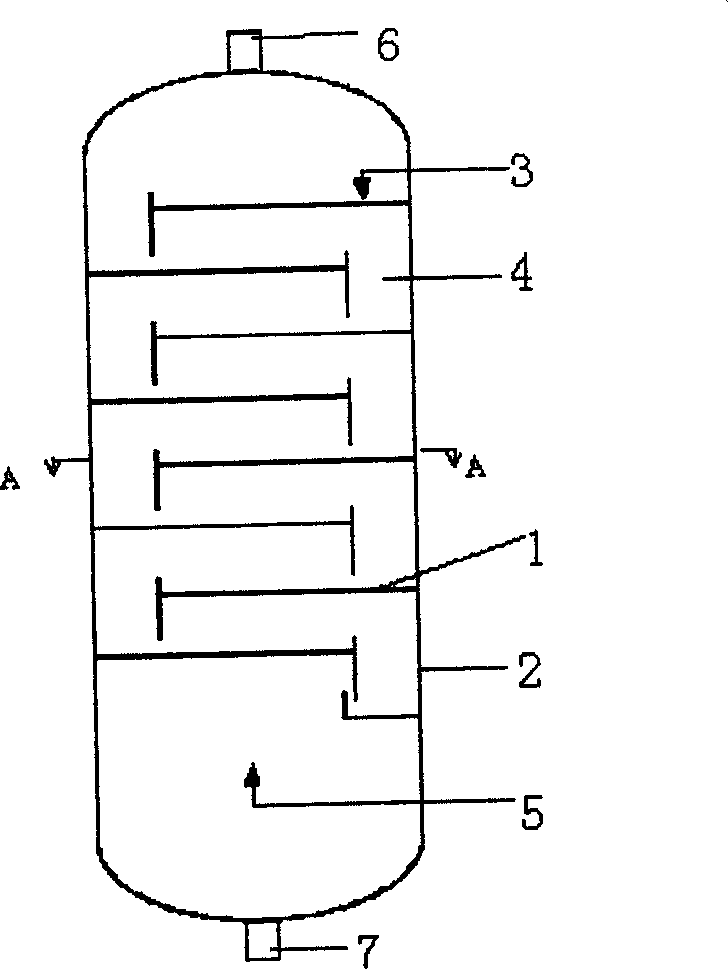

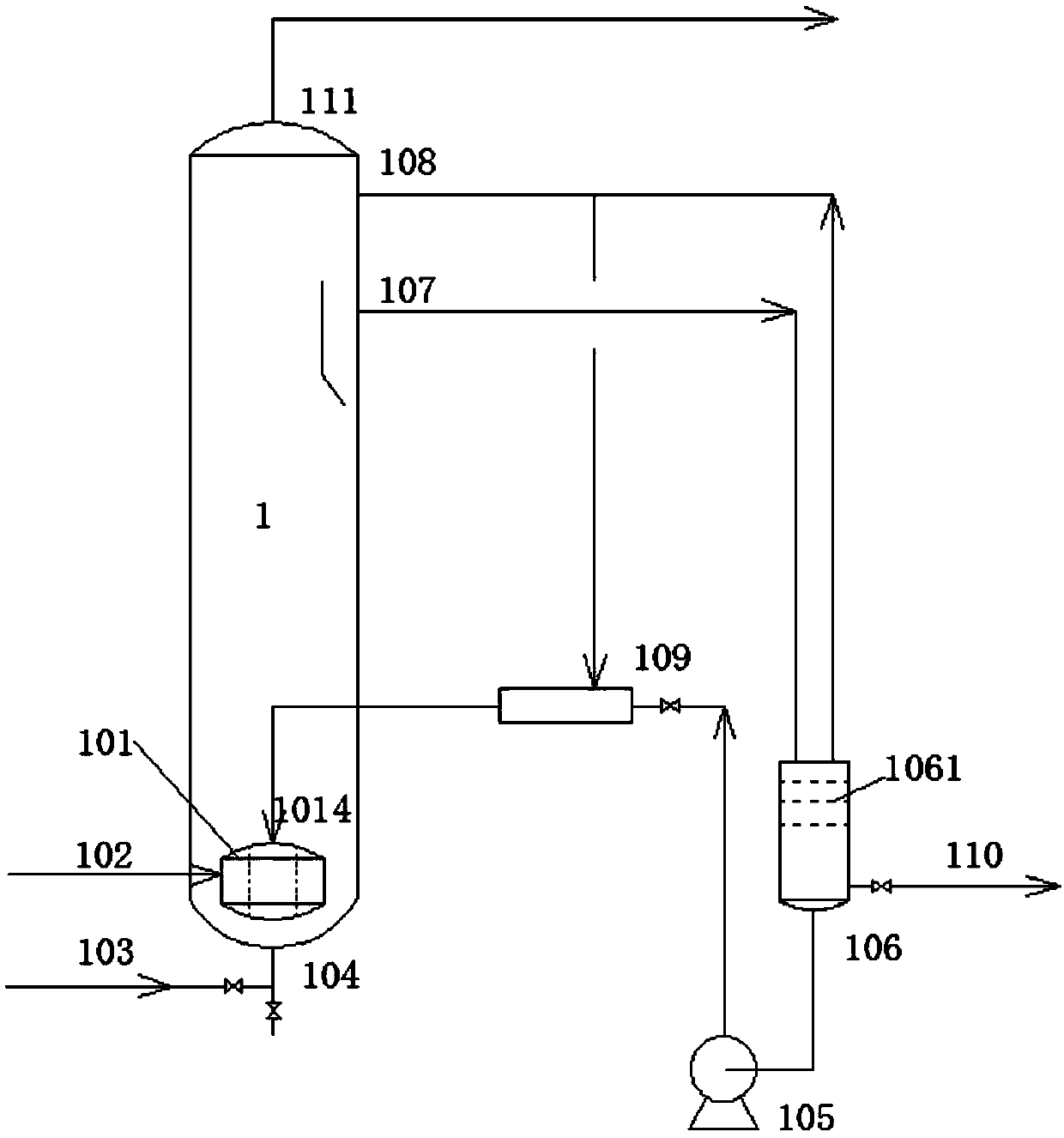

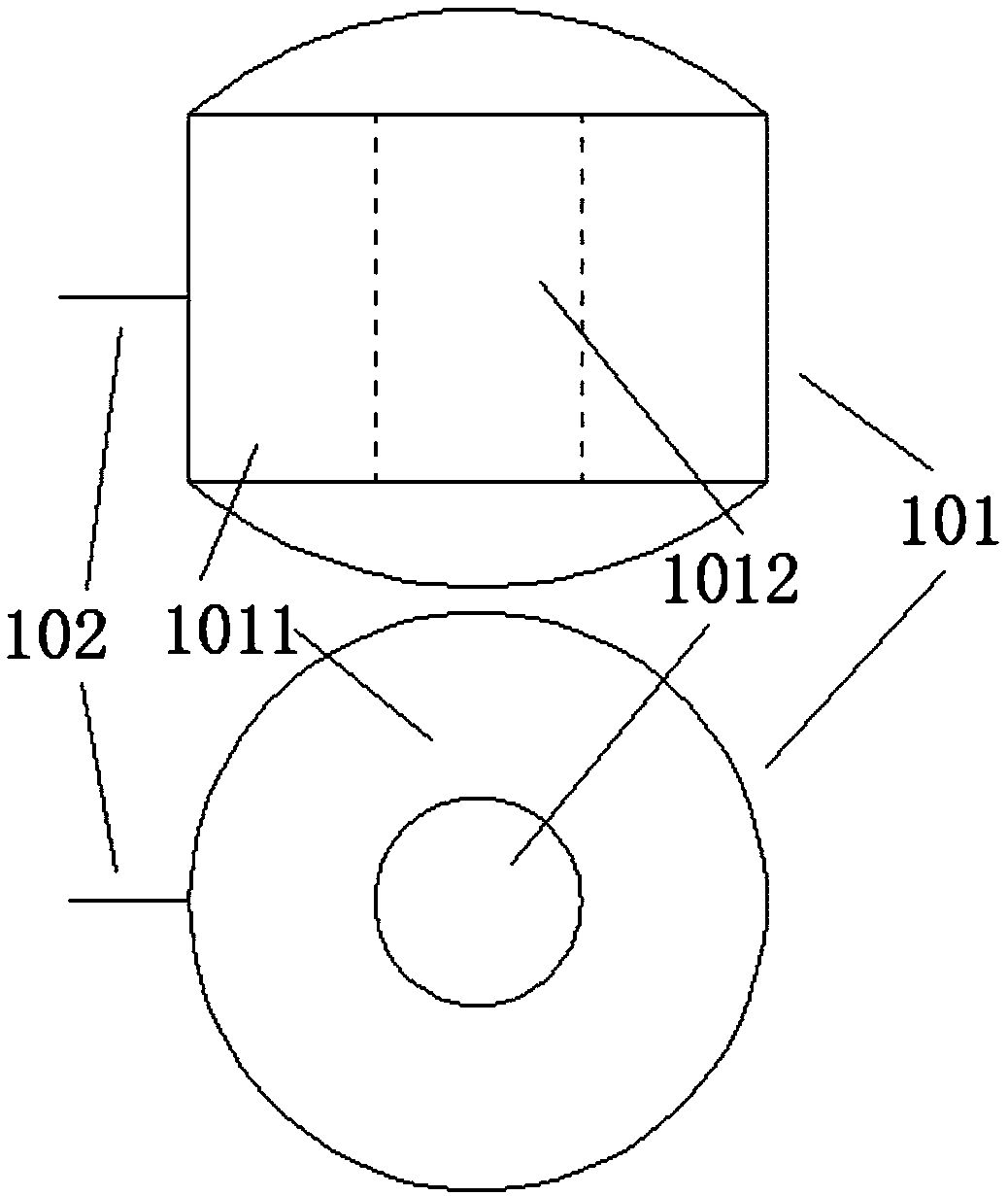

Ozone oxidation reactor and using method thereof

PendingCN111217441ASmall pressure dropIncrease gas-liquid mass transfer areaWater/sewage treatment apparatusWater/sewage treatment by oxidationThermodynamicsPtru catalyst

The invention discloses an ozone oxidation reactor, which comprises a mixer, a gas phase balance pipe, a tower type reactor and an ultrafine bubble distributor at the lower portion in the tower type reactor, wherein the ultrafine bubble distributor comprises a gas cavity communicated with a gas inlet and a gas-liquid channel vertically arranged in the gas cavity, the gas-liquid channel is a pipeline penetrating through the gas cavity, gas holes communicated with the gas cavity are formed in the side wall of the pipeline, the tower type reactor comprises a gas outlet and a circulating liquid outlet at the upper portion, a liquid inlet is communicated with the bottom of the tower type reactor, the circulating liquid outlet penetrates through the wall of the tower type reactor and is communicated with the gas-liquid channel through a liquid circulating pipeline, a circulating pump and a mixer are arranged on the liquid circulating pipeline, and the inlet of the mixer is communicated withthe upper portion of the tower type reactor through the gas phase balance pipe. The ozone oxidation reactor disclosed by the invention has the advantages of good catalyst fluidization performance, small gas pressure drop, large gas-liquid mass transfer reaction area, almost 100% utilization of gas, high reaction speed and the like.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

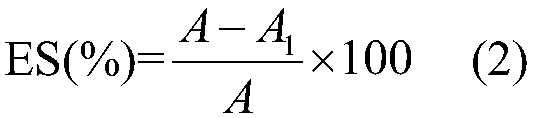

A kind of composite concrete foaming agent and its preparation method and application

The invention provides a compound concrete foaming agent and its preparation method and application. 1.5-2.5 parts of anhydrous sodium carbonate, 3.5-4.5 parts of industrial caustic soda, 3-5 parts of triethanolamine, 0.2-0.5 parts of industrial grade hydrochloric acid, 53.5-55.8 parts of water; the B component is: triethanolamine 0.2- 0.5 parts, 8-10 parts of sodium sulfate, 12-15 parts of sodium nitrite, 10-25 parts of calcium chloride, 54.7-64.5 parts of water. The composite concrete foaming agent of the present invention can not only increase the amount of foaming agent, but also compensate the concrete strength and solidification time; it can not only produce ultra-low-capacity foamed concrete, but also use a large amount of waste residues such as industrial and construction waste , to produce lightweight foamed concrete.

Owner:刘兴山

Light weight foam concrete capable of adsorbing mass decoration pollutants

ActiveCN109437793APromote absorptionImprove decomposition abilityCeramicwareFoam concreteDecomposition

The invention discloses light weight foam concrete capable of adsorbing mass decoration pollutants. The light weight foam concrete is prepared from a polyhydroxy compound, Portland cement, gypsum powder, aramid hollow staple fibers, a cement foaming agent, a peroxide product with a protective film and water. The light weight foam concrete is prepared in the following steps: firstly, adding the polyhydroxy compound into the water for dissolving; secondly, adding the Portland cement, the gypsum powder and the aramid hollow staple fibers into a solution and continuously stirring until gel is formed; preparing the cement foaming agent into foam, adding the peroxide product with the protective film into the foam for uniformly stirring; adding a foam material into the gel for uniformly mixing, pouring a mixture into a die, molding and curing for 15 to 25 days to obtain a finished product of the light weight foam concrete. The light weight foam concrete prepared by the invention greatly improves the absorption and decomposition capabilities of the decoration pollutants such as formaldehyde and harmful organic matters and is more suitable for serving as a geotechnical building material.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

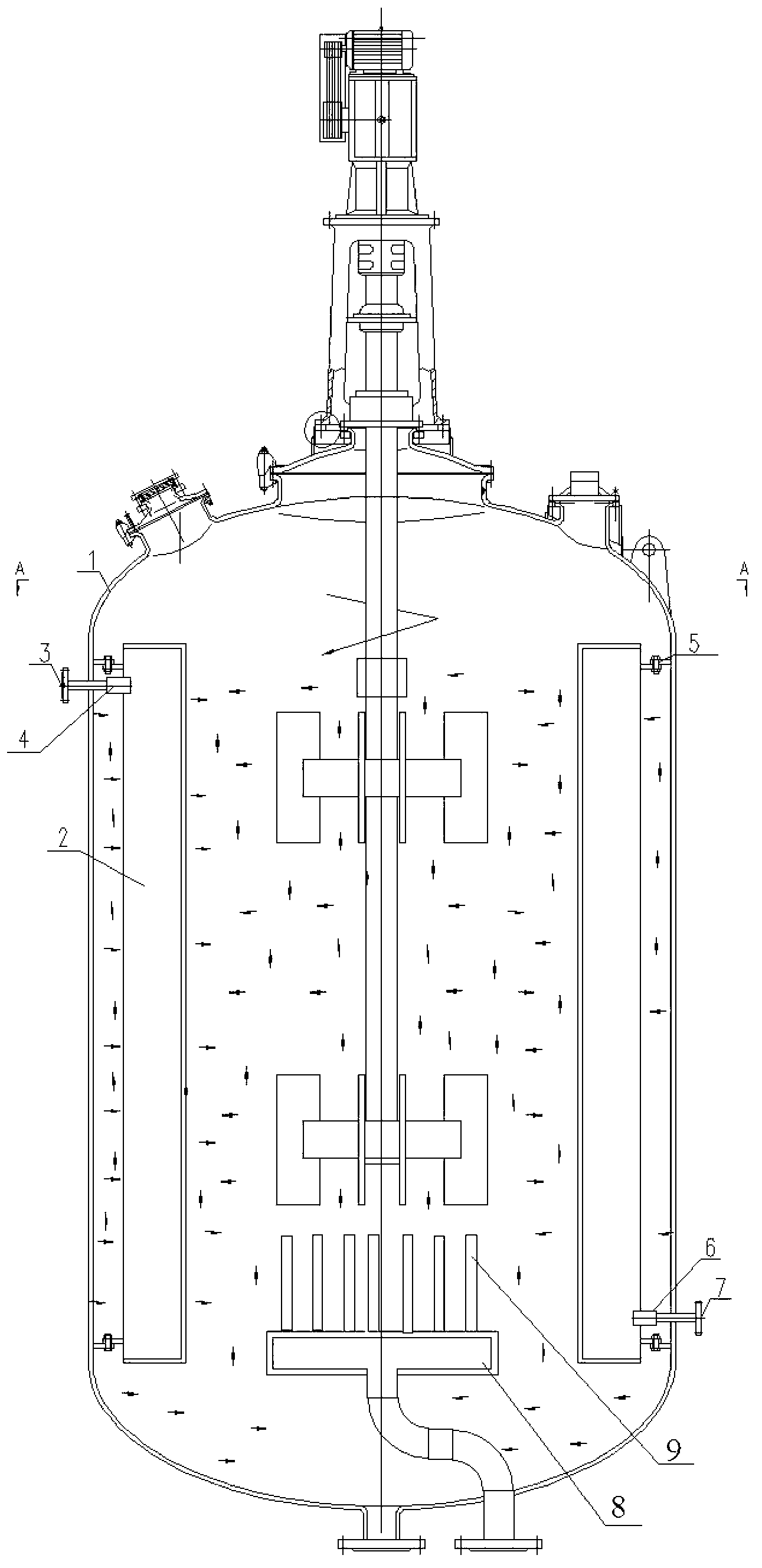

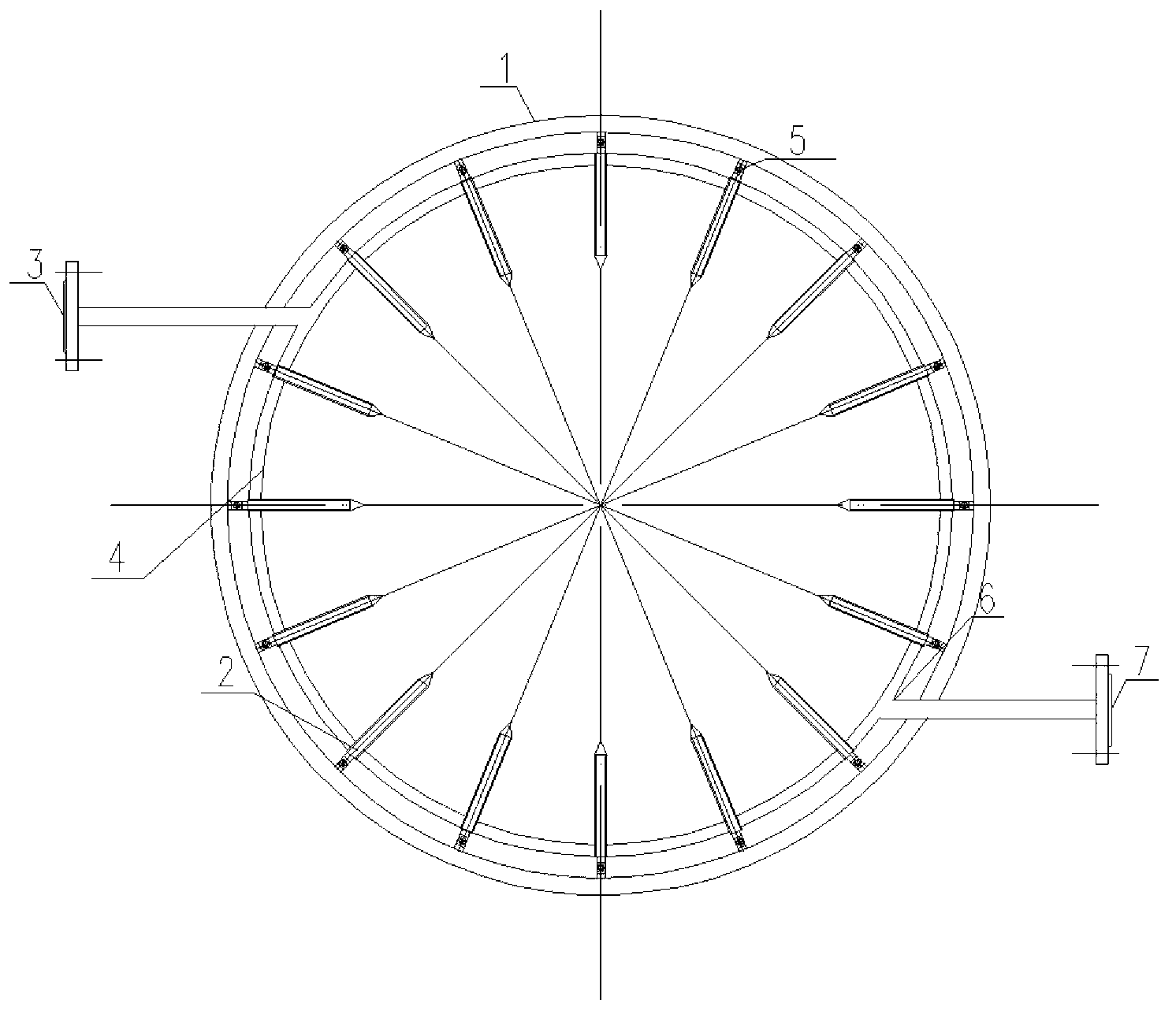

Stirring reactor adopting film tube aeration

InactiveCN103224876ASmall diameterEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOxygen

The invention relates to a stirring reactor adopting film tube aeration. The stirring reactor adopting film tube aeration comprises a stirring reactor, the bottom of the stirring reactor is provided with a gas distributor, and the gas distributor is connected with a film tube having nanometer level apertures. The stirring reactor adopting film tube aeration, which allows the film tube to be applied to the stirring reactor and utilizes the nanometer level apertures of the film tube, makes bubbles escaping from the film tube have small diameters and a large quantity, overcomes the large bubbles of a nozzle distributor and a perforated plate distributor, substantially increases the mass transfer performance, and is in favor of the control of dissolved oxygen in a fermentation liquid.

Owner:NANJING TECH UNIV

Method for preparing novel composite concrete air entraining agent

The invention discloses a method for preparing a novel composite concrete air entraining agent. The novel composite concrete air entraining agent is prepared from 5%-15% of dodecyl dimethylamine, 5%-15% of sodium ethoxylated alkyl sulfate, 5%-10% of sodium abietate, 5%-15% of coconut oil diethanolamide and the balance water. According to the method, the materials with different components for airentraining, bubble stabilizing, plastification and the like are compounded to be used for perfecting the application performance of concrete, the novel composite concrete air entraining agent is liquid, can be dissolved in water, and can be diluted into the liquid with the concentration of 1.5%-2.0% in a stirring station to be automatically metered and added. The novel composite concrete air entraining agent can be used when a finished additive is compounded, the compounding performance of the product and other concrete additives is good, the amount of admixture is small, the compounding effect is superior to that of a deltonin air entraining agent, the surface tension of a solution can be effectively reduced, and sealed and independent bubbles are generated. The advantages of being high in foaming rate, small in bubble diameter and bubble stabilizing time are achieved, and the work performance of the concrete and the concrete flowing slump loss resistant performance can be obviously improved.

Owner:湖南加美乐素新材料股份有限公司

Concrete foaming agent preparation method

The invention discloses a concrete foaming agent preparation method. A foaming agent, laurinol, rosin soap solution, gelatin, acrylic acid emulsion, cement sealant and water are utilized as raw materials, the raw materials are evenly mixed and stirred in a reaction kettle, and the raw materials are matched according to the following matching that the proportion of the foaming agent is 12%, the proportion of the laurinol is 1%, the proportion of rosin soap solution is 13%, the proportion of the gelatin is 2%, the proportion of the acrylic acid emulsion is 5%, the proportion of the cement sealant is 2%, and the proportion of water is 65%. The preparation method comprises the steps of firstly adding water into the reaction kettle to be heated to be not lower than 95 DEG C; then adding the gelatin and the rosin soap solution and evenly stirring after dissolving; adding the foaming agent, the laurinol, the acrylic acid emulsion and the cement sealant to be fully stirred for 3 hours after temperature of solution in the reaction kettle in the last step is cooled to 45 to 50 DEG C, wherein stirring speed is controlled as 180 turns / minute. The foaming agent is an AES foaming agent or an AOS foaming agent. The foaming agent prepared through the preparation method has good stability, is suitable for varieties of cement, has small foam diameter, improves concrete strength and is safe and environmentally friendly.

Owner:ZHANGZHOU WANKETU ENERGY SAVING BUILDING MATERIAL TECH CO LTD

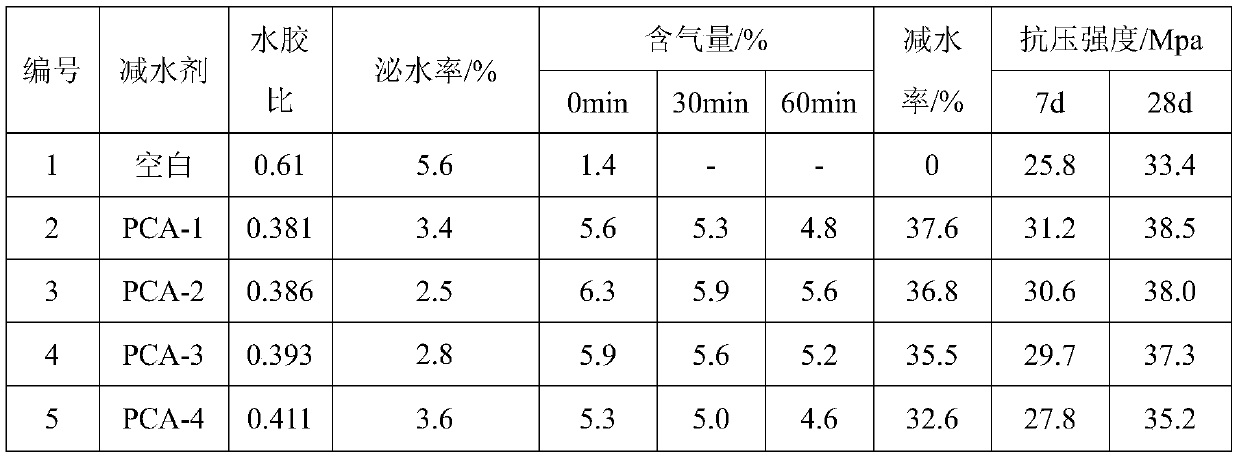

An air-entraining controllable polycarboxylate water reducer for pure machine-made sand concrete and its preparation method

The invention belongs to the field of concrete additives, and concretely relates to an air entrainment-controllable polycarboxylic water reducer used for purely machine-made sand concrete, and a preparation method thereof. The preparation method comprises the following steps: carrying out an esterification reaction on an alkylphenol polyoxyethylene monomer and an unsaturated carboxylic acid to generate an unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, carrying out an aqueous solution copolymerization reaction on the unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, an unsaturated polyether monomer and an unsaturated sulfonic acid monomer through an oxidation-reduction initiation system, and adding a proper amount of a molecular weight control agent to control the molecular weight in order to obtain the air entrainment-controllable polycarboxylic water reducer. The water reducer prepared in the invention has the advantages of high water reduction rate, good adaptability, small bubble diameters, stable sealing property and controllable air entrainment when applied to the purely machine-made sand concrete, and well solves the problems of difficult air entrainment, poor bubble stability and large concrete pumping loss of the purely machine-made sand concrete.

Owner:中建商品混凝土(福建)有限公司 +1

Silica sand grain graduation non-alkali glass batch

InactiveCN108483901AReduce the number of bubblesSmall bubble diameterGlass shaping apparatusSilicon dioxideMaterials science

The invention relates to a silica sand grain graduation non-alkali glass batch which comprises the following ingredients in percentage by mass: 59% of SiO2, 17% of Al2O3, 0.2% of ZrO2, 5% of CaO, 7% of B2O2, 3% of MgO, 6.55% of SrO, 1.8% of P2O5, 0.15% of SnO, 0.15% of MoO3 and 0.15% of WO3. The batch is characterized in that silica sand grains in grain sizes of greater than 0.15 mm, 0.075-0.15 mm, 0.045-0.75 mm and less than 0.045 mm account for 1.0%, 80.0%, 14.0% and 5.0% of the weight of total silica sand respectively. The batch has the benefits that high quality non-alkali glass with a small residual bubble quantity, small bubble diameter and good homogeneity is obtained through silica sand grain graduation and an optimized proportion of the silica sand grain sizes; the cost is effectively reduced through the silica sand grain graduation; a technology is simple.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Gas/solid circulation mixing steam stripper and mixing and steam stripping method of solid particles

ActiveCN102676206BStrong shearImprove contact efficiencyCatalytic crackingCatalyst regeneration/reactivationEngineeringProduct gas

The invention provides a gas / solid circulation mixing steam stripper and a mixing and steam stripping method of solid particles. The gas / solid circulation mixing steam stripper comprises a cylinder body (7) with an inner cavity, a flow guide cylinder (6), a ring-gap gas distributor (3), a gas distributor (11) of the flow guide cylinder, a gas outlet extending into the inside of the cylinder body (7), a cone (2) connected with the lower end of the cylinder body (7), a mixed solid particle outlet (1) arranged below the cone (2), a loose steam ring (12) which is positioned at the bottom of the cone (2) and is also positioned above the mixed solid particle outlet (1), a first solid particle inlet passage and a second solid particle inlet passage, wherein the first solid particle inlet passage and the second solid particle inlet passage are respectively connected to the inside of the cylinder body. The gas / solid circulation mixing steam stripper is adopted by the mixing and steam stripping method of the solid particles.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Power unit of aeration device

InactiveCN103011386ASmall bubble diameterImprove internal energySludge treatmentTreatment using aerobic processesPower unitEngineering

The invention relates to a power unit of an aeration device. The unit provides power for a vapor-liquid equilibrium chamber. The unit is characterized in comprising a motor 14, a transmission gear set 15, and a change gear set 16. Power is transmitted to a transmission shaft 2 through the change gear set. And an equilibrium plate 24 operates under the driving of the transmission shaft 2.

Owner:周靖

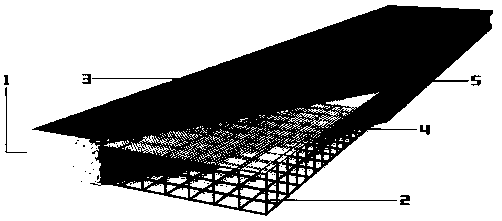

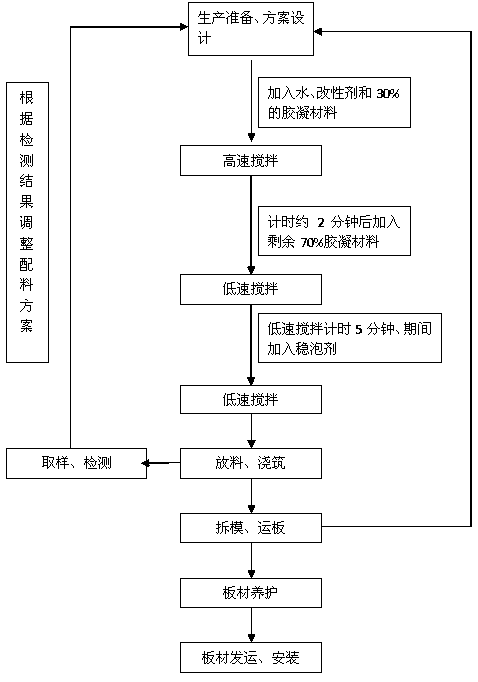

Steel mesh and fiber reinforced integrated foam concrete lightweight wallboard and manufacturing method thereof

ActiveCN105804315BSimple structureGuaranteed integrityWallsHeat proofingFoam concreteCarvacryl acetate

The invention relates to a steel wire mesh and fiber enhanced integrated foam concrete lightweight wall plate and a manufacturing method thereof. The wall plate comprises foam concrete, wherein the foam concrete covers a 3D steel wire mesh; alkali-resisting glass fiber gridding cloth is arranged on each of the upper and lower surfaces of the 3D steel wire mesh; proper amount of alkali-resisting anti-cracking fibers are added into the foam concrete; the 3D steel wire mesh and the alkali-resisting glass fiber gridding cloth are integrally poured and molded to form an integrated structure sheet material through foam concrete paste; a tenon convenient for mounting and a groove matched with the tenon are pre-formed on the two sides of the sheet material respectively. The manufacturing method of the wall plate comprises the following steps: preparing the foam concrete paste and pouring and molding the integrated structure sheet material; and preparing a compound type high molecular modifier containing an ethylene / vinyl acetate copolymer, calcium stearate, lithium carbonate and silicon resin polyether emulsion. The wall plate has the advantages of light weight, high strength, heat preservation and heat insulation, good waterproof performance, good durability, no layering and cracking, simple manufacturing process and capability of greatly improving industrial production efficiency.

Owner:唐山冀东发展集成房屋有限公司

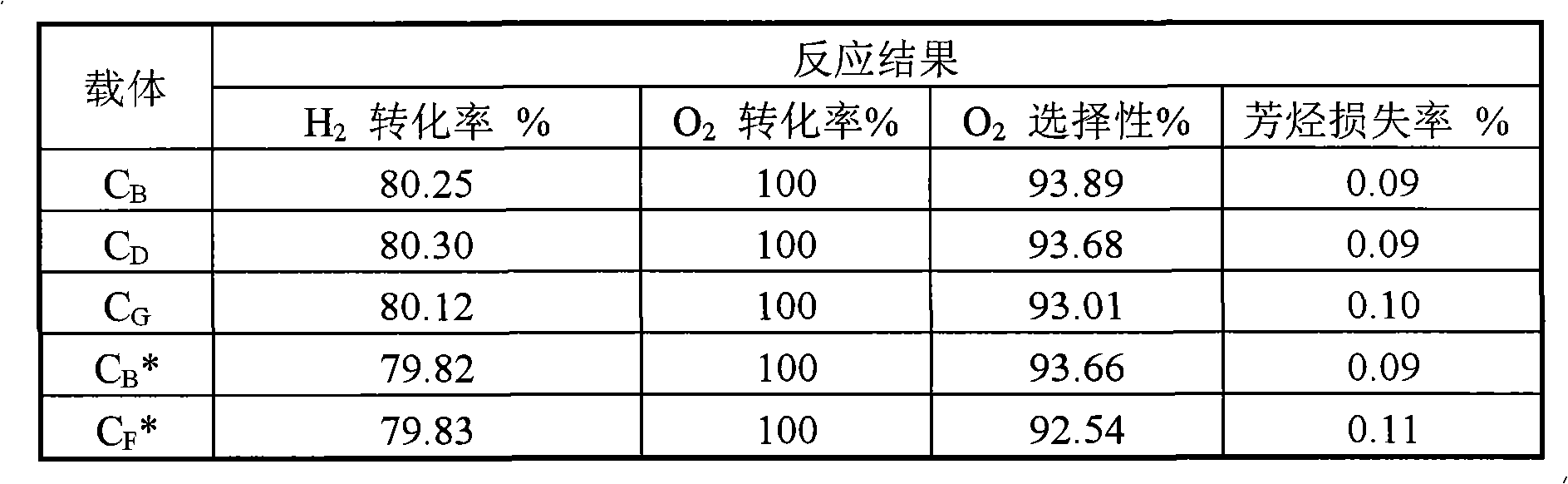

Slurry for hydrogen oxidation catalyst coating and preparation method of slurry

ActiveCN102463145BSimple preparation processReduce production processCatalyst carriersFoaming agentAdjuvant

The invention relates to slurry for a hydrogen oxidation catalyst coating and a preparation method of the slurry, mainly solving the problems that in the prior art, the preparation of the slurry costs a long time and the slurry is large in granularity and low in stability, and thus a catalyst is long in production period and high in cost, the abrasive loss rate of the prepared coating is high, and the performance and the stability of the catalyst are low. The slurry for the hydrogen oxidation catalyst coating comprises the following components of water, aluminium sol, aluminium oxide, a coating adjuvant, a pH regulating agent and a foaming agent. The preparation method of the slurry comprises the following steps of: sequentially adding the water, the aluminium sol, the aluminium oxide and the coating adjuvant into a colloid mill, and circulating the mixture; regulating the slurry by the pH regulating agent to obtain slurry I; foaming a certain amount of the foaming agent and water by using a foaming machine; and adding foams into the slurry I to obtain slurry II. By the technical scheme, the problems are solved well; and the slurry and the preparation method thereof can be applied to the industrial production of the catalyst coating slurry.

Owner:CHINA PETROLEUM & CHEM CORP +1

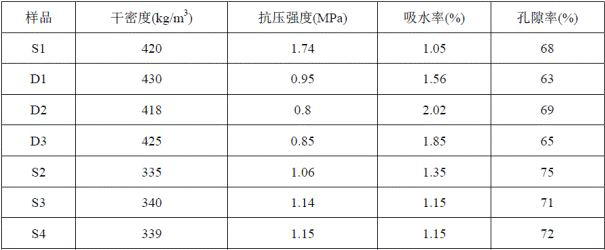

a foam concrete

The invention provides a foam concrete, which is prepared according to the following method: (1) uniformly mixing cement, water reducing agent, waterproofing agent and part of water to obtain cement slurry. (2) Foam the composite foaming agent and the remaining water in a foam machine, add the cement slurry in step (1) and mix evenly to obtain foam cement slurry, then add ceramsite and coagulant, mix evenly to obtain foam concrete pulp. (3) Pour the foamed concrete slurry into the mold, and after molding, steam curing to the specified age, that is to say. Described cement is made up of portland cement and aluminate cement by mass ratio 5-10:1, and described composite blowing agent is made up of fatty alcohol polyoxyethylene ether, sodium dodecylbenzene sulfonate and tapioca starch by mass The ratio is 1‑2:0.5‑2 composition. The foamed concrete material of the invention has good waterproof and anti-seepage properties, high strength and is not easy to crack, and can be widely used in building materials.

Owner:山东威汉新材料有限公司

Circulating method for cold regenerated catalyst and catalytic cracking reaction regenerating system

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for reducing microbubbles of alumina silicate glass

The invention relates to a method for reducing microbubbles of a piece of alumina silicate glass. The optimal founding and homogenization effects are realized by special grain size distribution of glass batch, the alumina silicate glass with fewer bubbles and small diameter bubbles is obtained, and the use requirement of the special glass for electronic information display is met. Specifically, the granular size of the glass batch such as feldspar, silica sand, dolomite, limestone, sodium carbonate and mirabilite is controlled to be in a specific range, due to the optimization and matching of larger granular raw materials and smaller granular raw materials, the reaction homogeneity and completeness of the batch are realized, the optimal founding effect is realized, and the excellent alumina silicate glass with fewer bubbles and small diameter bubbles is obtained.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

A foamed cement insulation material

ActiveCN111943611BImprove surface activityReduce surface tensionPassive housesCeramicwareAluminateThermal insulation

The invention provides a foamed cement insulation material, which comprises the following raw materials in weight percentage: 30-55% of cement, 0.1-1% of admixture, 1-5% of composite foaming agent, and the balance is water. The cement is composed of Portland cement and aluminate cement in a mass ratio of 5-10:1. The composite blowing agent is composed of hydrogen peroxide, fatty alcohol polyoxyethylene ether, sodium dodecylbenzenesulfonate and tapioca starch in a mass ratio of 10:1-2:0.5-1:1-2. The foamed cement insulation material of the invention has good waterproof and anti-seepage properties, high strength and is not easy to crack, and can be widely used in building materials to play the role of heat insulation.

Owner:山东威汉新材料有限公司

A kind of clarification method of alkali-free glass melting under reduced pressure

ActiveCN109775963BAchieve uniformityAchieve completenessGlass furnace apparatusAlkali freeIndustrial engineering

The invention relates to an alkali-free glass decompression founding and clarification method which comprises processes of batching of existing alkali-free glass batches, warming founding, clarification, iron plate casting forming, annealing, cutting and polishing and is characterized in that before warming founding, firstly, a melting furnace is subjected to decompression processing, a vacuum degree in the furnace is controlled within a range of 500Pa to 100,000Pa, and consumed time is 0.5 to 1 hour; and after clarification is ended, air is introduced into the melting furnace, and internal and external air pressures of the furnace are regulated to be balanced. The alkali-free glass decompression founding and clarification method disclosed by the invention has the advantage that the batches are subjected to decompression founding and decompression clarification so as to implement uniformity and completeness of the reaction among the batches, reach the optimal founding, clarifying and homogenizing effects and obtain high-quality alkali-free glass which is small in number of residual bubbles, small in diameter of the bubbles and excellent in homogeneousness.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

A kind of preparation method of concrete foaming agent

The invention discloses a concrete foaming agent preparation method. A foaming agent, laurinol, rosin soap solution, gelatin, acrylic acid emulsion, cement sealant and water are utilized as raw materials, the raw materials are evenly mixed and stirred in a reaction kettle, and the raw materials are matched according to the following matching that the proportion of the foaming agent is 12%, the proportion of the laurinol is 1%, the proportion of rosin soap solution is 13%, the proportion of the gelatin is 2%, the proportion of the acrylic acid emulsion is 5%, the proportion of the cement sealant is 2%, and the proportion of water is 65%. The preparation method comprises the steps of firstly adding water into the reaction kettle to be heated to be not lower than 95 DEG C; then adding the gelatin and the rosin soap solution and evenly stirring after dissolving; adding the foaming agent, the laurinol, the acrylic acid emulsion and the cement sealant to be fully stirred for 3 hours after temperature of solution in the reaction kettle in the last step is cooled to 45 to 50 DEG C, wherein stirring speed is controlled as 180 turns / minute. The foaming agent is an AES foaming agent or an AOS foaming agent. The foaming agent prepared through the preparation method has good stability, is suitable for varieties of cement, has small foam diameter, improves concrete strength and is safe and environmentally friendly.

Owner:ZHANGZHOU WANKETU ENERGY SAVING BUILDING MATERIAL TECH CO LTD

Foam concrete and preparing process thereof

InactiveCN101497533BHigh strengthWith thermal insulationCeramic shaping apparatusCement mixing apparatusFoam concreteFiber

The invention discloses foam concrete and a preparation method thereof. The foam concrete comprises a gelling material, light aggregate, water, admixture and foaming agent. The preparation method comprises the following steps: (1) pre-treating raw materials to prevent hard lumps and hard grains in the raw materials from depositing in foam slurry; (2) weighing each component according to a proportion; (3) preparing and adding foaming solution; (4) loading and stirring, namely, adding water into a stirrer, starting the stirrer, and adding cement, coal ash, perlite, waterproof agent, anti-freezing agent, water reducing agent and fiber into the stirrer in turn; (5) foaming, namely, foaming at the same time of stirring the slurry, sealing a valve firstly and then pressurizing the valve by an air compressor; (6) adding foam, namely, after the gelling slurry is well prepared, adding the foam into the gelling slurry under the state of stirring without stopping the stirrer; and (7) casting andmolding, namely, when the slurry surface has no floating foam, finishing the preparation of the foam slurry. The foam concrete has the functions of light weight, water proofing, fire resistance, heatinsulation, freezing resistance, cracking resistance, shock resistance and the like, and is particularly suitable for engineering insulating layers in cold areas and water-blocking and shock-resistant layers of underground engineering.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Foam concrete

The invention provides foam concrete. The foam concrete is prepared by the following method: (1) uniformly mixing cement, a water reducing agent, a waterproof agent and part of water to obtain cementpaste, (2) foaming a composite foaming agent and the balance of water in a foaming machine, adding the cement paste in the step (1), uniformly mixing to obtain foamed cement paste, adding ceramsite and a coagulant, and uniformly mixing to obtain the foam concrete paste, and (3) pouring the foam concrete slurry into a mold, molding, and carrying out steam curing to a specified age, wherein the cement is composed of Portland cement and aluminate cement according to a mass ratio of (5-10): 1, and the composite foaming agent is composed of fatty alcohol-polyoxyethylene ether, sodium dodecyl benzene sulfonate and cassava starch according to a mass ratio of (1-2): (0.5-2). The foam concrete disclosed by the invention has the characteristics of good waterproof and anti-seepage performance, high strength and difficulty in cracking, and can be widely applied to building materials.

Owner:山东威汉新材料有限公司

Aluminum oxide slurry for spray coating and preparation method thereof

ActiveCN102463146BImprove dispersion efficiencyReduce lossesCatalyst carriersFoaming agentGranularity

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com